Patents

Literature

70results about How to "Reduce heat fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

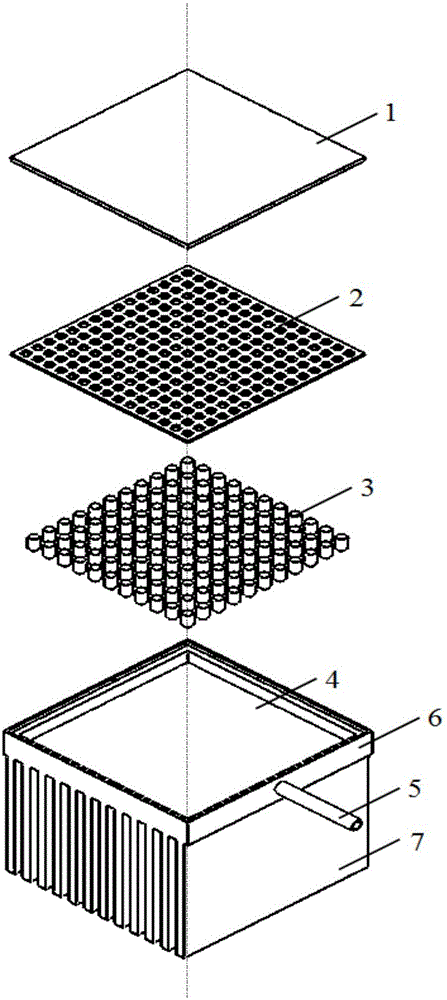

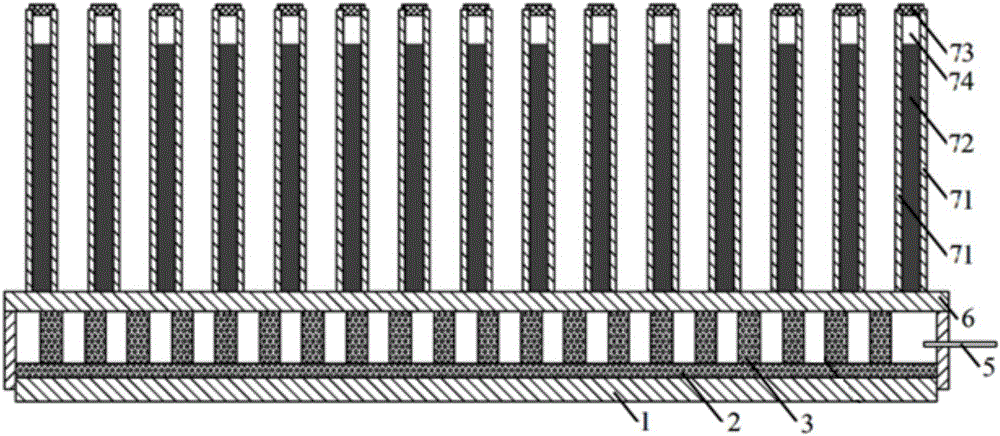

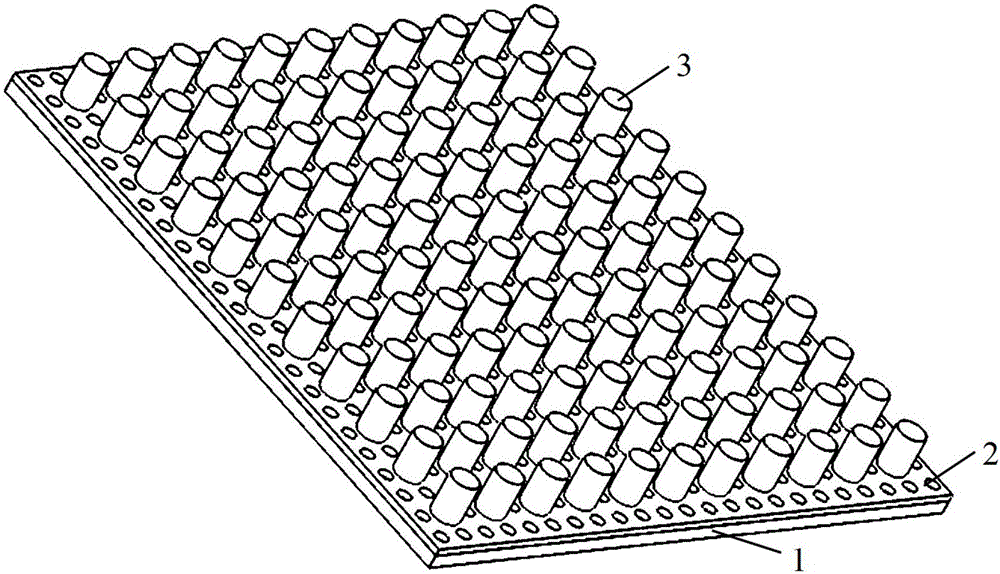

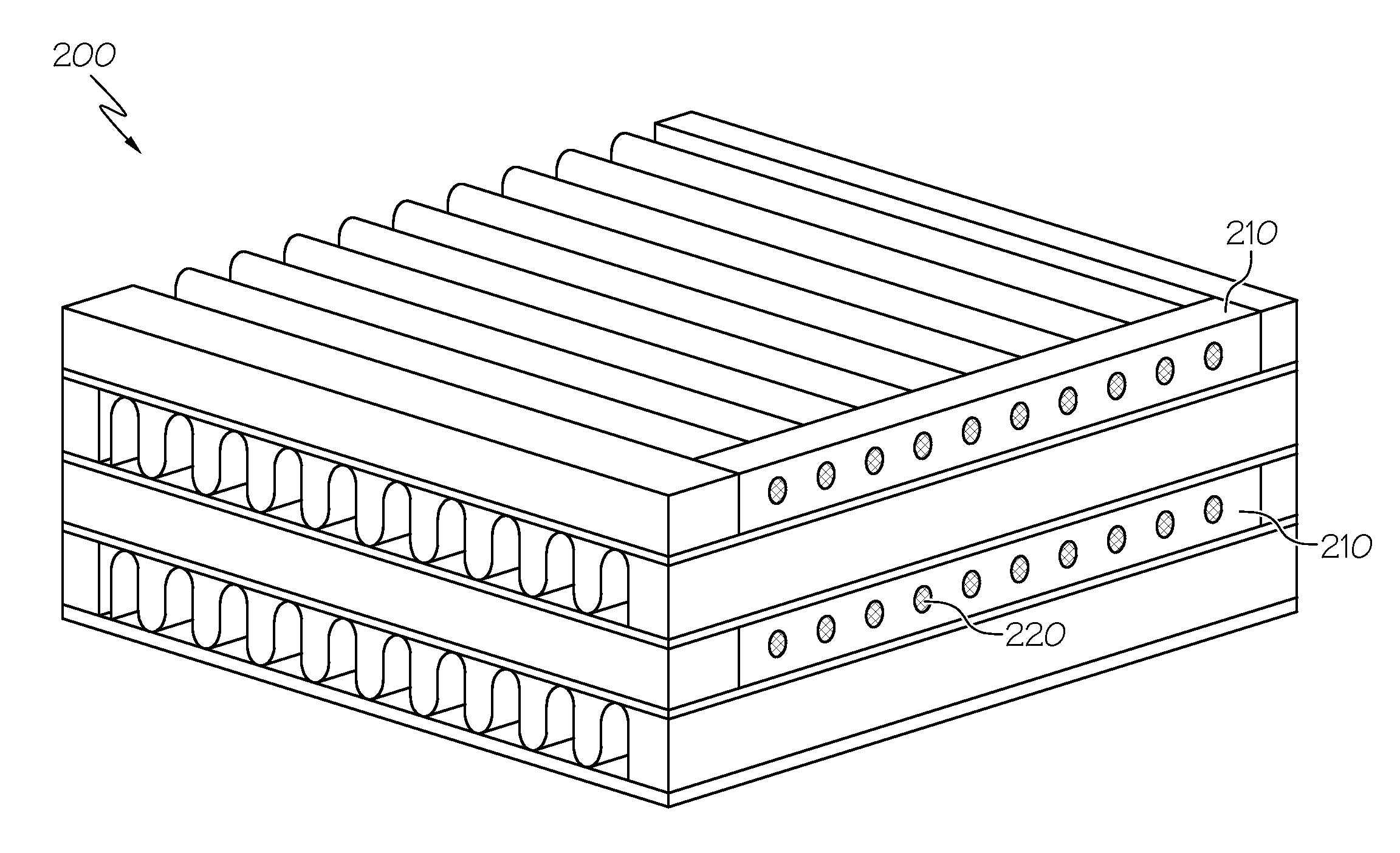

Composite heat dissipation device

InactiveCN106793685AImprove performancePromote escapeHeat storage plantsMachines using electric/magnetic effectsEvaporationIntegrated design

The invention discloses a composite heat dissipation device. The device comprises a flat plate heat tube and multiple sandwiched phase transition material composite boards. The evaporation end of the flat plate heat tube is used for taking heat from a heating element. The condensation end of the flat plate heat tube is connected with base parts of the sandwiched phase transition material composite boards. A multi-hole capillary liquid adsorbing core layer is arranged on the inner wall of the evaporation end. A bionic capillary liquid adsorbing core is arranged on the multi-hole capillary liquid adsorbing core layer. Each sandwiched phase transition material composite board comprises an enclosed inner cavity. Phase transition materials are arranged in each inner cavity. The side wall of each inner cavity is a metal plate. According to the invention, the flat plate heat tube with the capillary liquid adsorbing core has good temperature averaging ability; through the phase transition materials, temperature peaks are inhibited, so normal work of the whole electronic device is ensured; and through the integrated design of the flat plate heat tube and the sandwiched phase transition material composite boards, contact thermal resistance between a traditional flat plate heat tube and a heat sink is eliminated. In one word, the heat dissipation device is better in temperature averaging ability, stronger in heat dissipation ability, high in safety and simple to process.

Owner:淳铭散热科技股份有限公司 +1

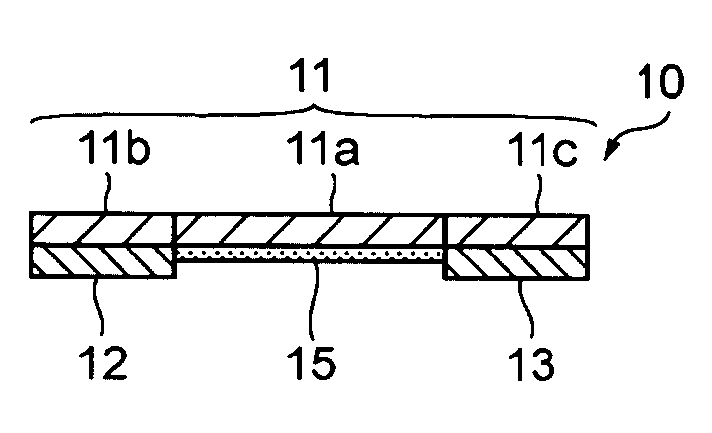

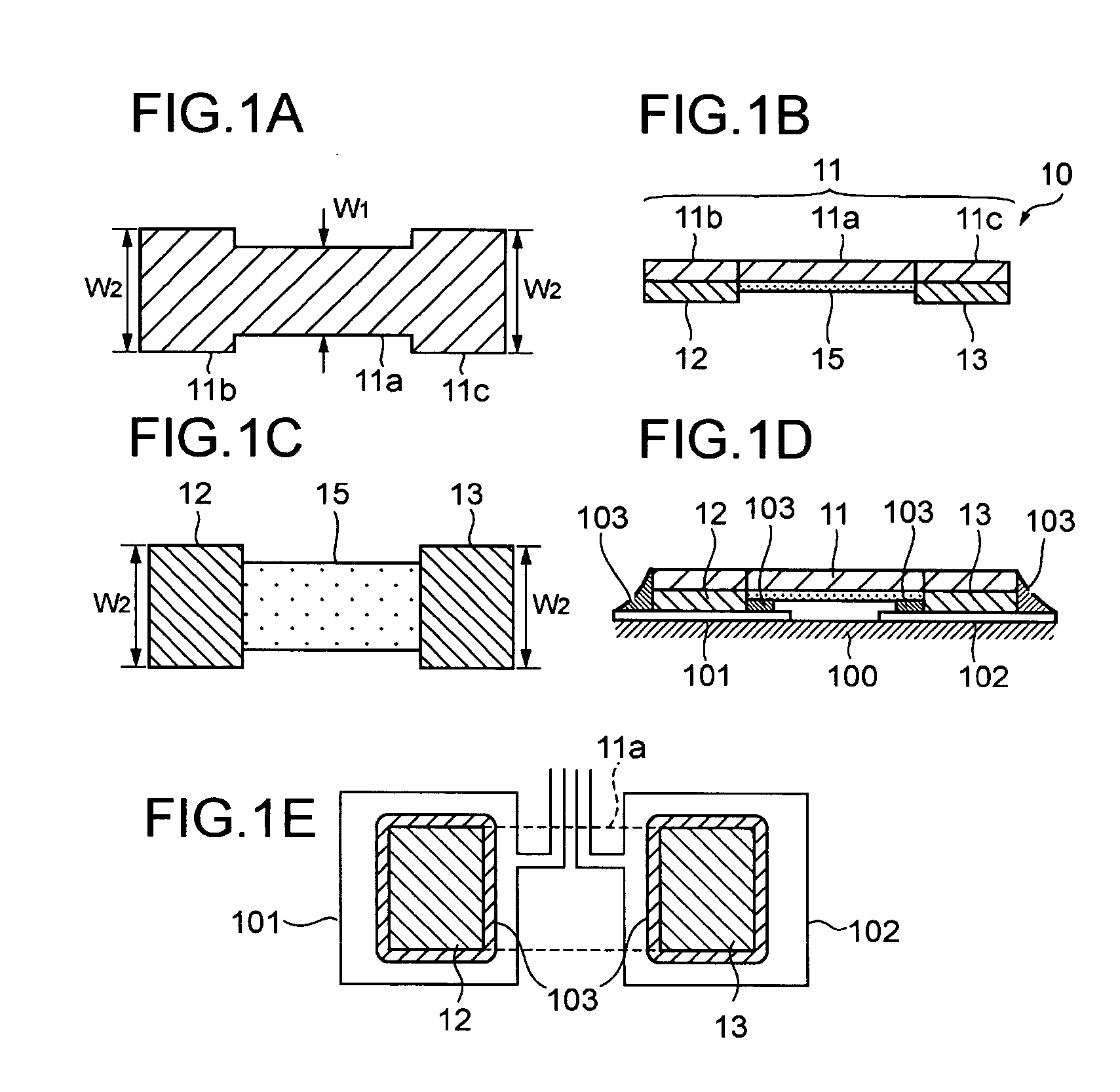

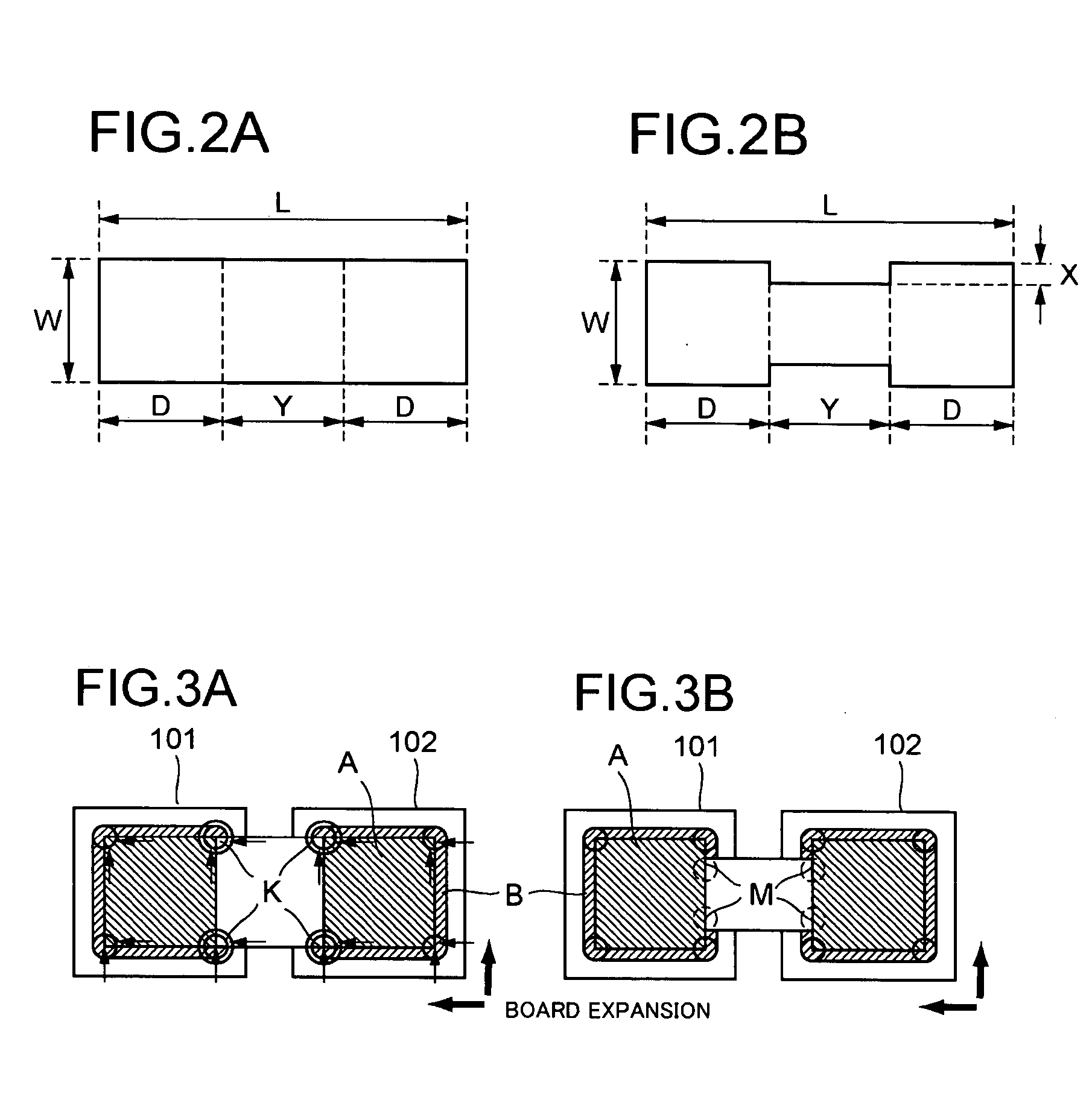

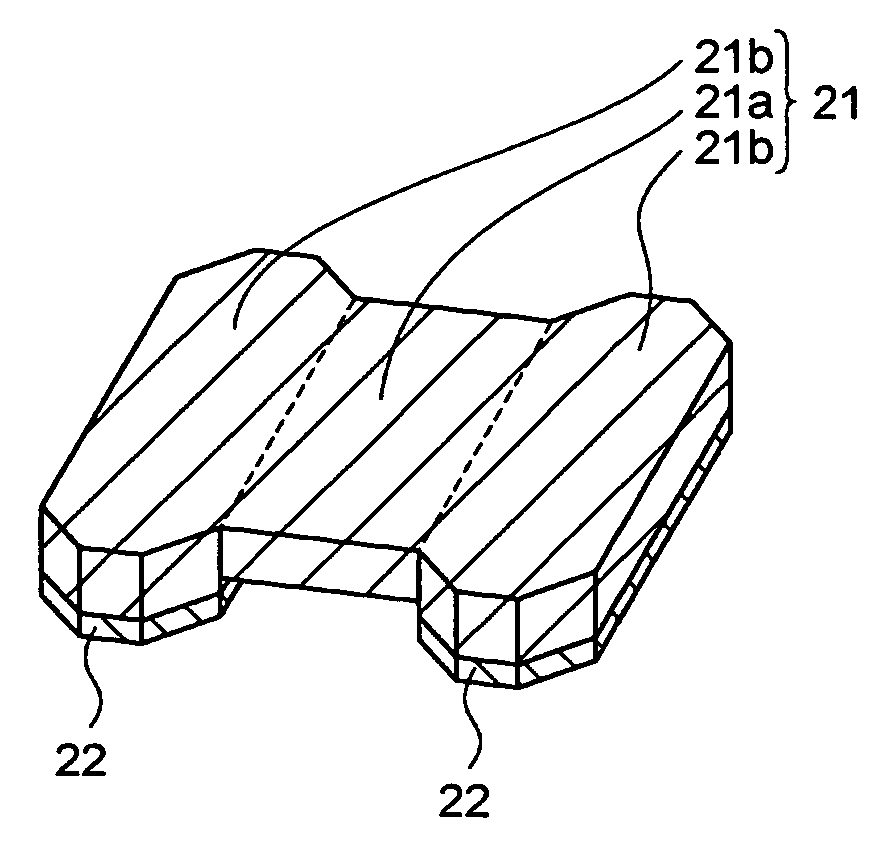

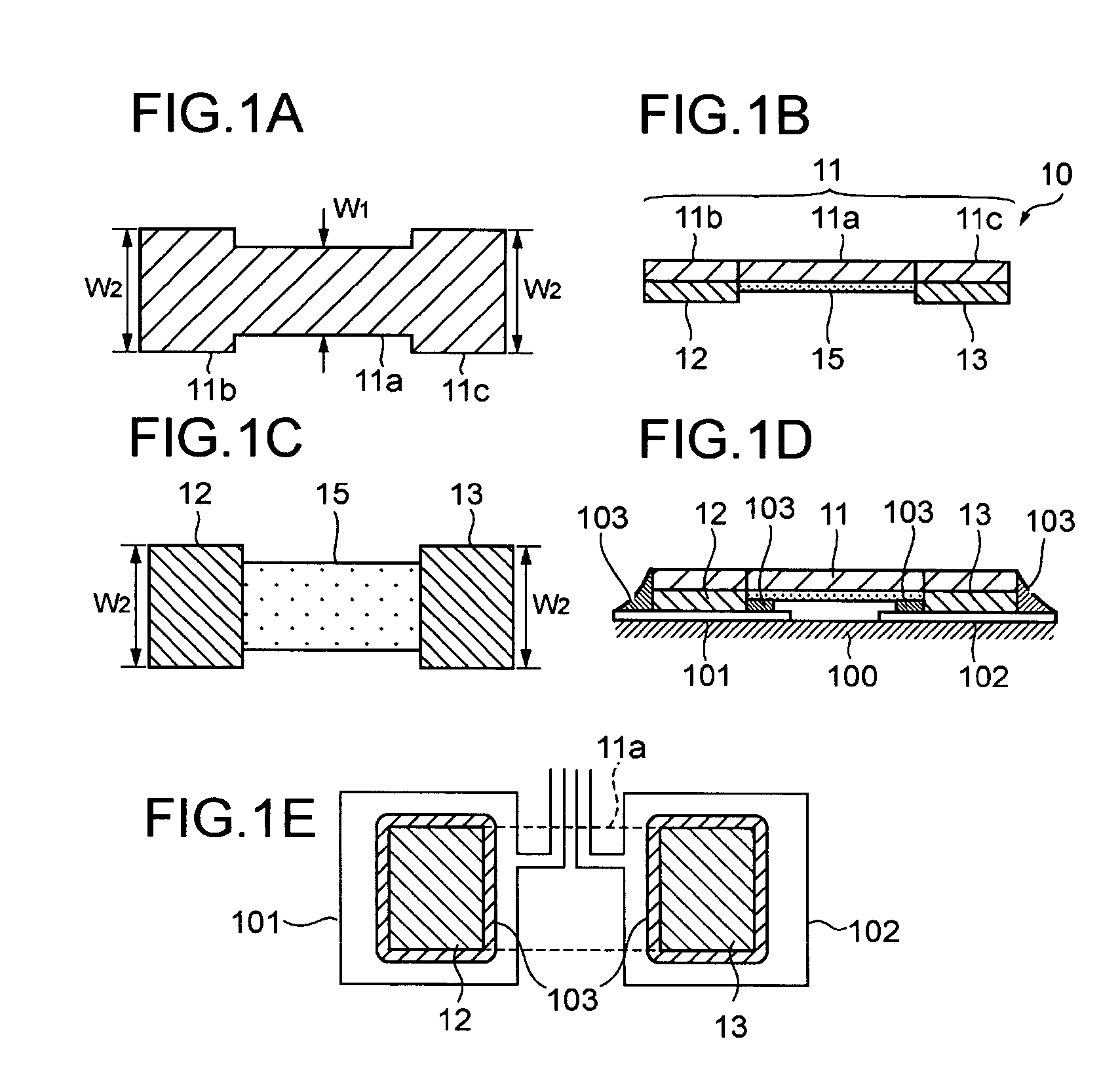

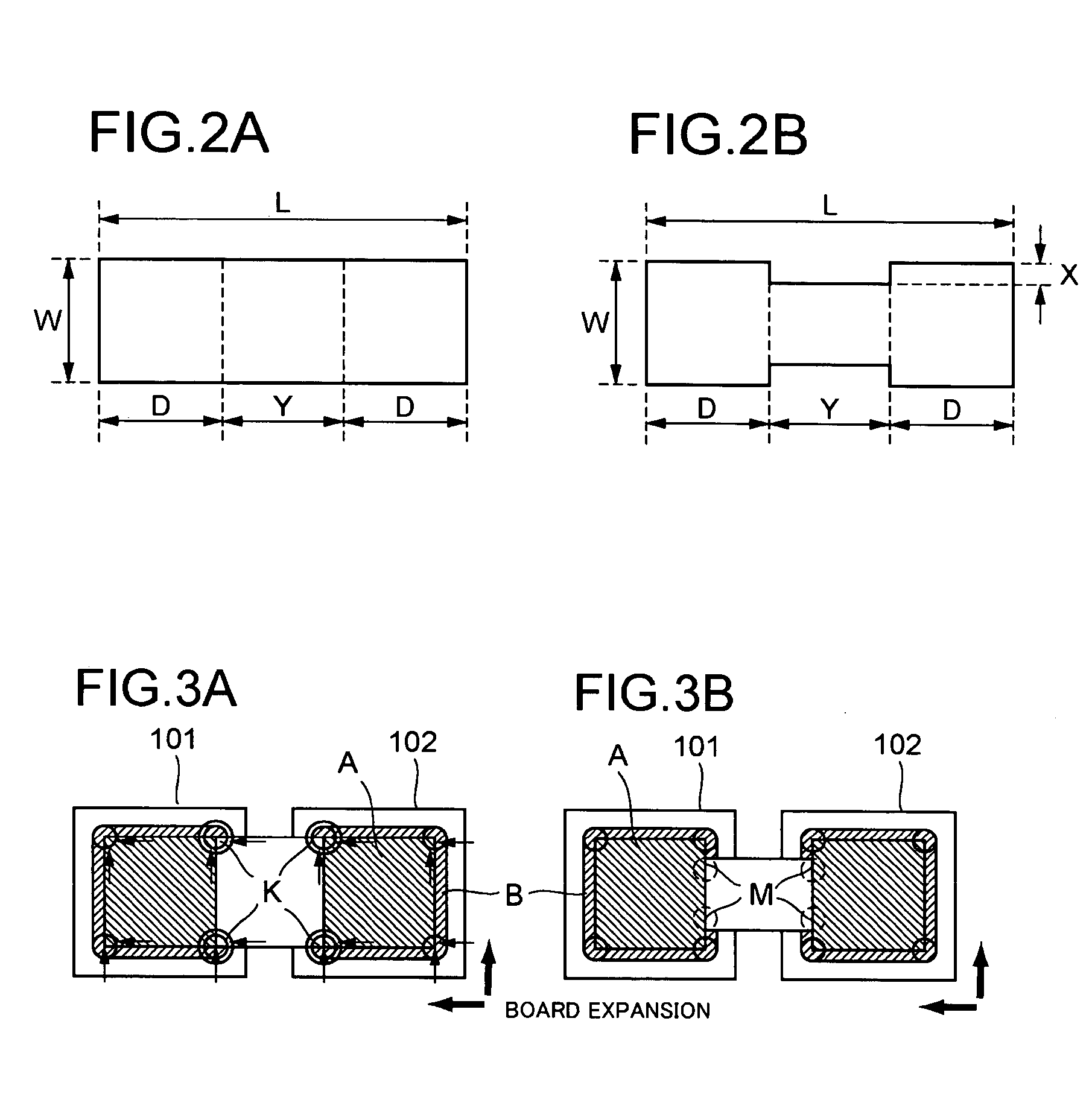

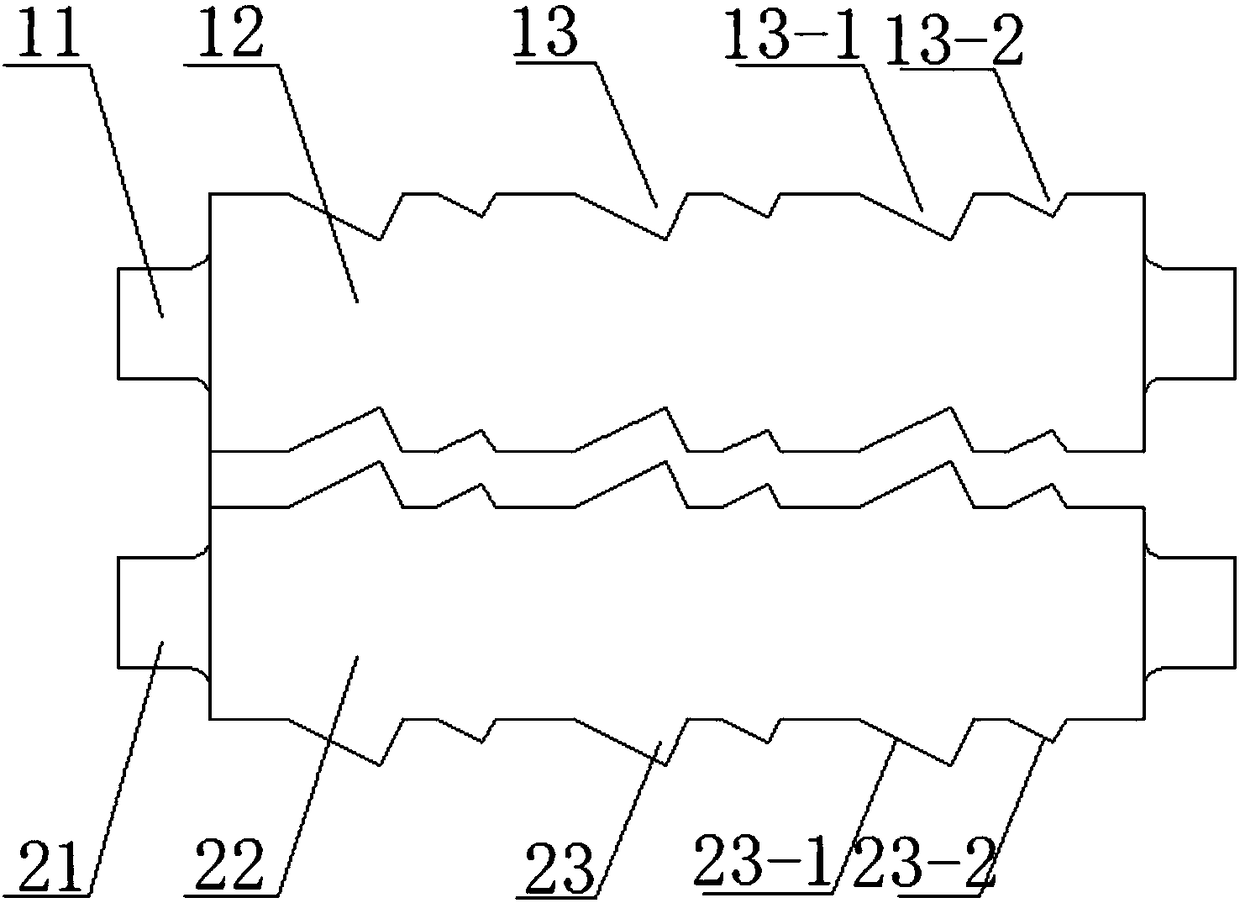

Metal plate resistor

ActiveUS20050258930A1Highly stable against agingImprove stabilityResistor terminals/electrodesAdjustable resistorsElectrical conductorBiomedical engineering

A metal plate resistor includes a resistive body comprising a metal plate, and at least a pair of electrodes joined respectively to opposite ends of the resistive body, the electrodes being made of a highly conductive metal conductor. The resistive body has a main section positioned between the electrodes and a pair of electrode sections progressively wider than the main section in directions away from the main section. The electrodes are disposed respectively beneath the electrode sections and identical in shape to the electrode sections.

Owner:KOA CORP

Metal plate resistor

ActiveUS7053749B2Improve stabilityReduce heat fatigueResistor terminals/electrodesAdjustable resistorsElectrical conductorBiomedical engineering

A metal plate resistor includes a resistive body comprising a metal plate, and at least a pair of electrodes joined respectively to opposite ends of the resistive body, the electrodes being made of a highly conductive metal conductor. The resistive body has a main section positioned between the electrodes and a pair of electrode sections progressively wider than the main section in directions away from the main section. The electrodes are disposed respectively beneath the electrode sections and identical in shape to the electrode sections.

Owner:KOA CORP

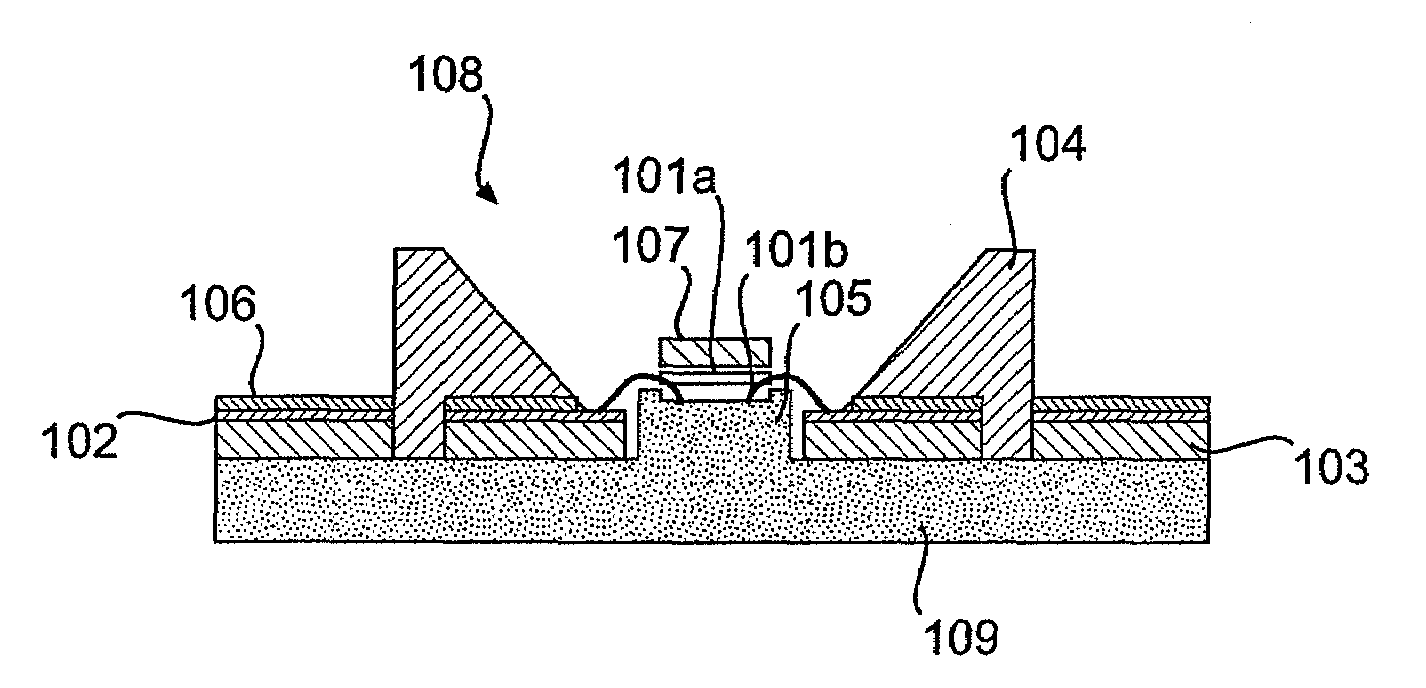

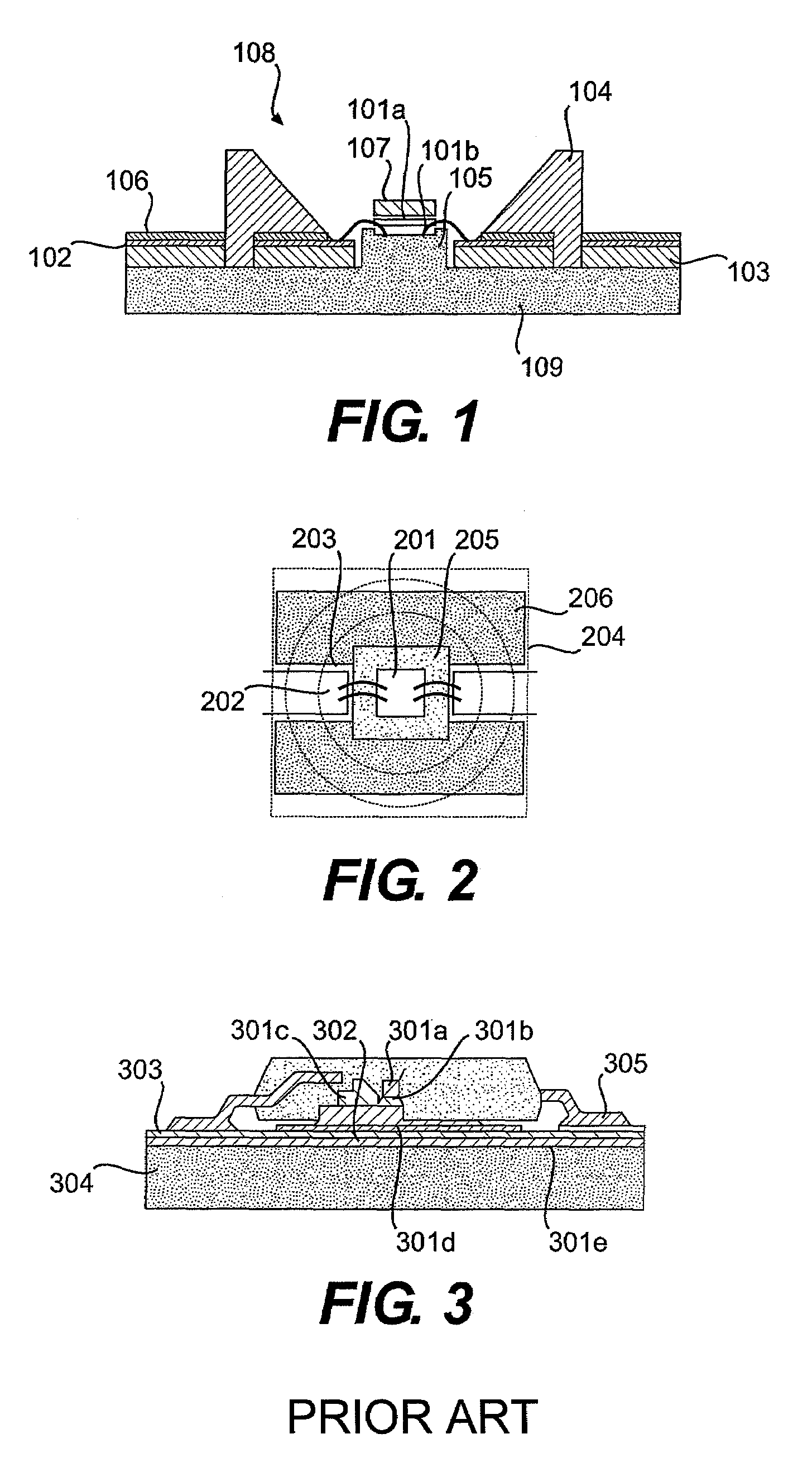

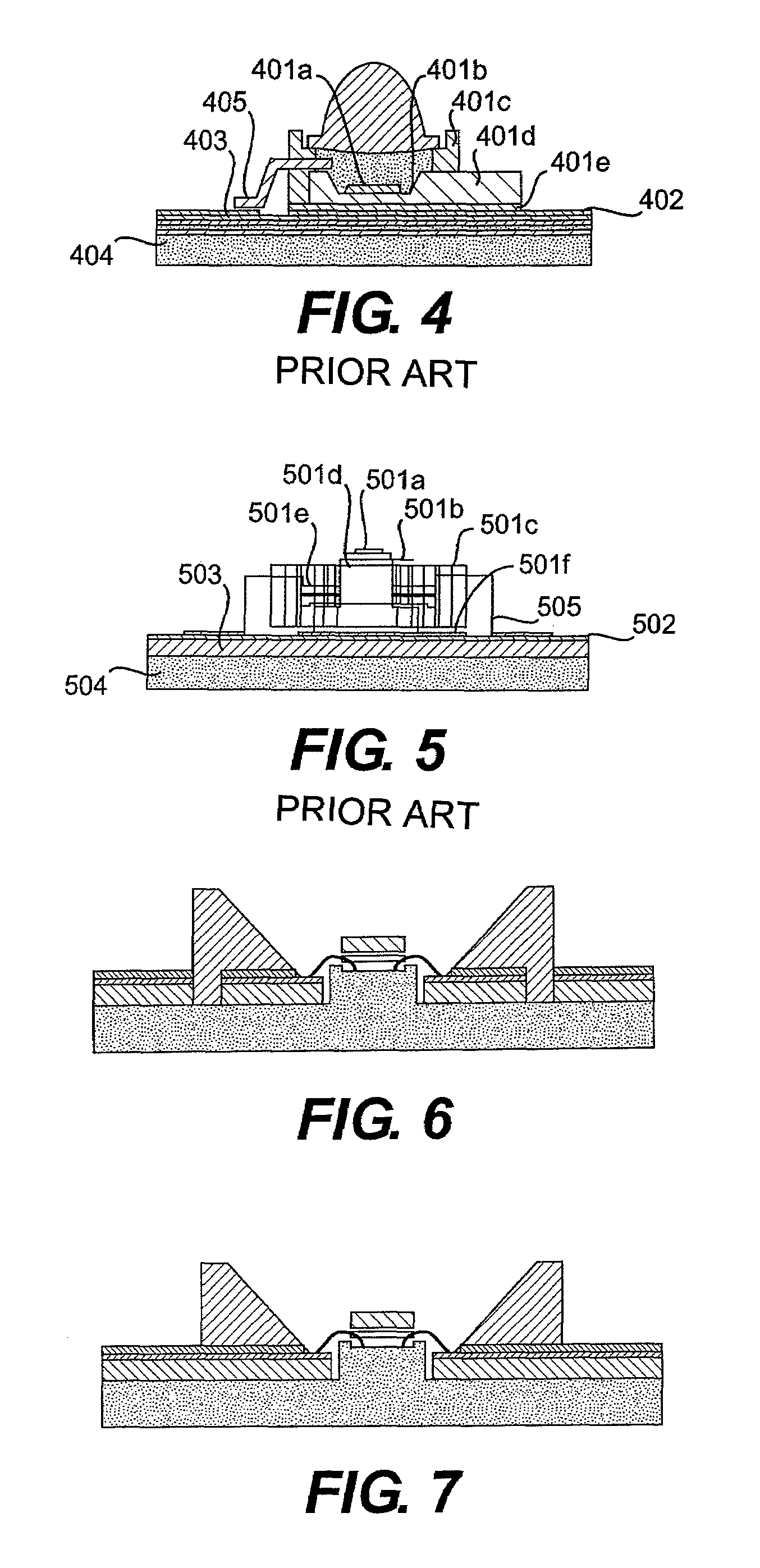

High power light-emitting diode package comprising substrate having beacon

InactiveUS7612385B2Reduce resistanceReduce the temperatureSemiconductor/solid-state device detailsSolid-state devicesCo-fired ceramicPrinted circuit board

Disclosed herein is a package structure including at least one high power light-emitting diode to exhibit excellent heat release properties. In the package structure, a light-emitting diode chip which generates heat is directly attached to a beacon processed to protrude from part of a heat spreader having high heat conductivity, whereby an electrical wiring portion is separated from a heat release portion, thus maximizing heat release properties and realizing high luminance and reliability. The package structure is composed of a beacon formed on a metal or non-metal substrate having high heat conductivity to mount a high power light-emitting diode chip, to increase heat release properties; a wiring portion provided on the same line as the diode to input and output power and signals; and a reflection cup having a cavity, which may be inserted into or attached to the heat spreader or the wiring substrate, including a low temperature co-fired ceramic substrate, a high temperature co-fired ceramic substrate, or a printed circuit board.

Owner:KOREA PHOTONICS TECH INST

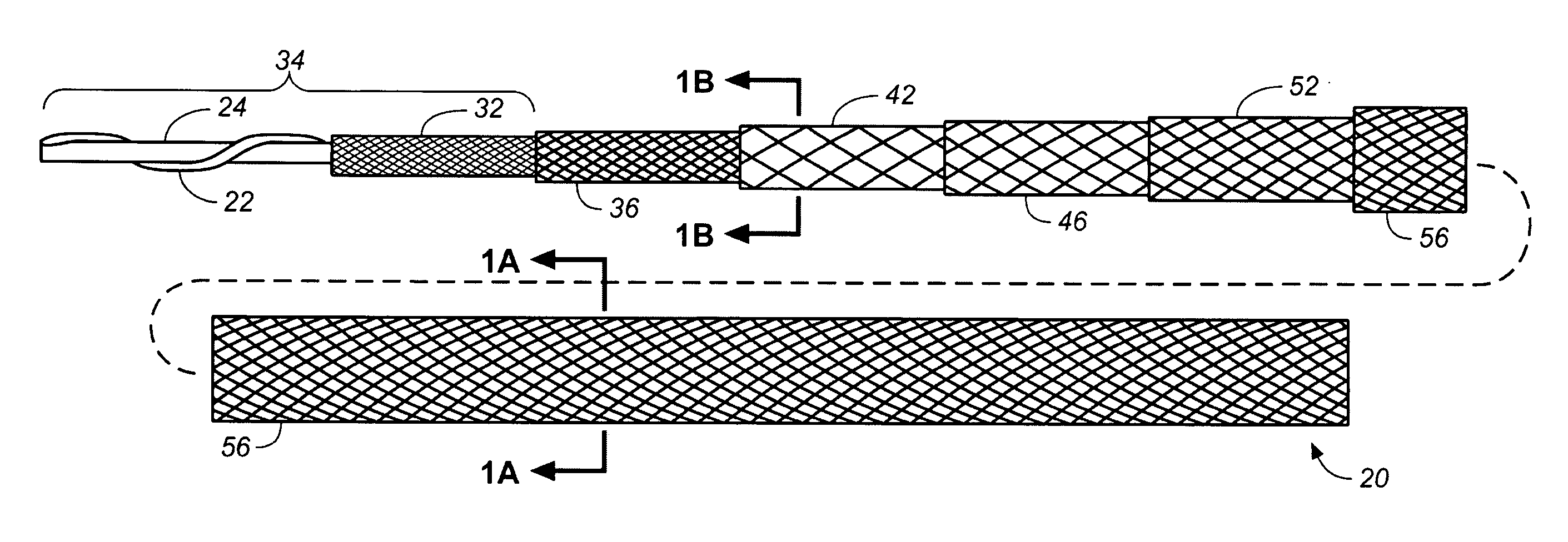

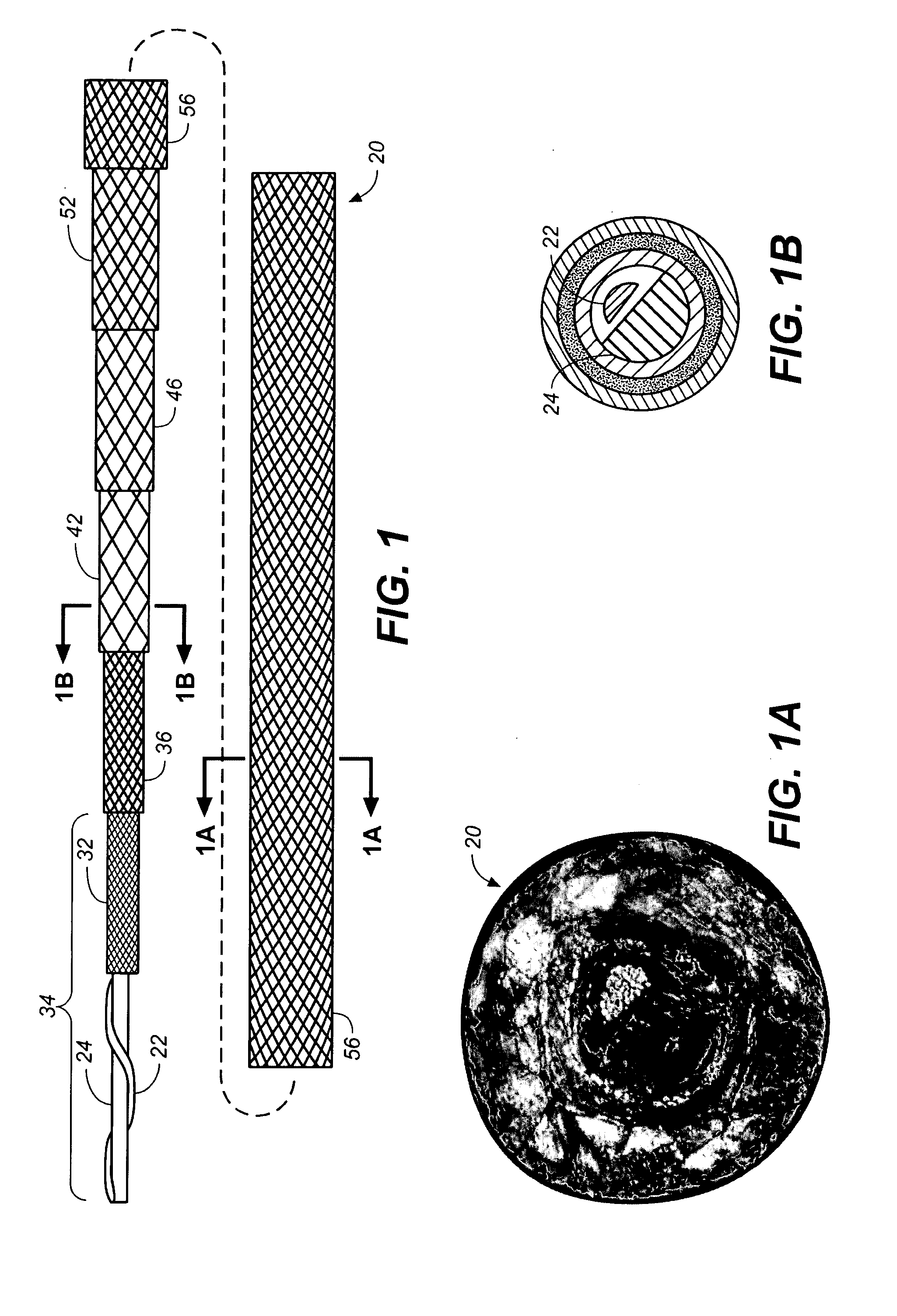

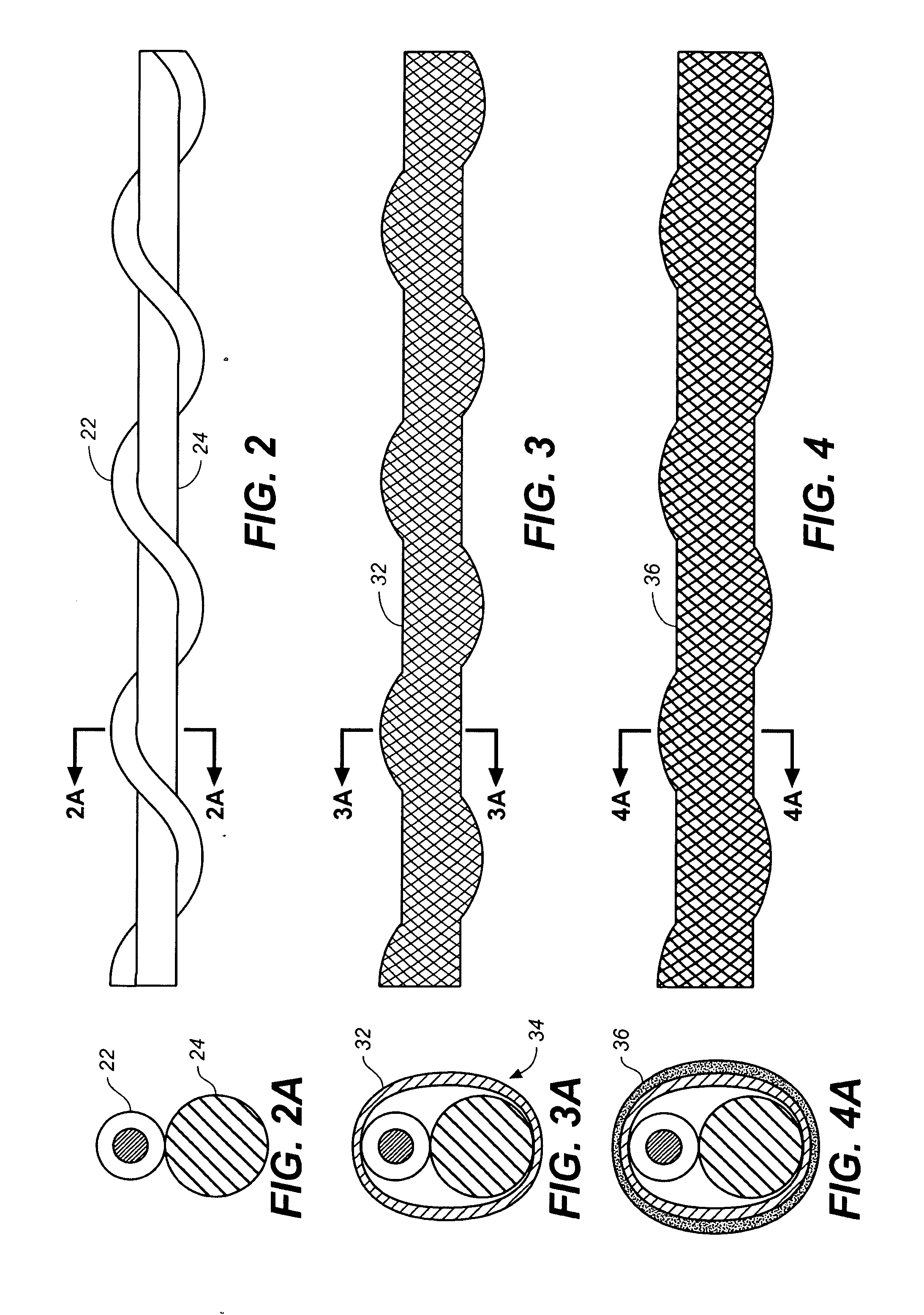

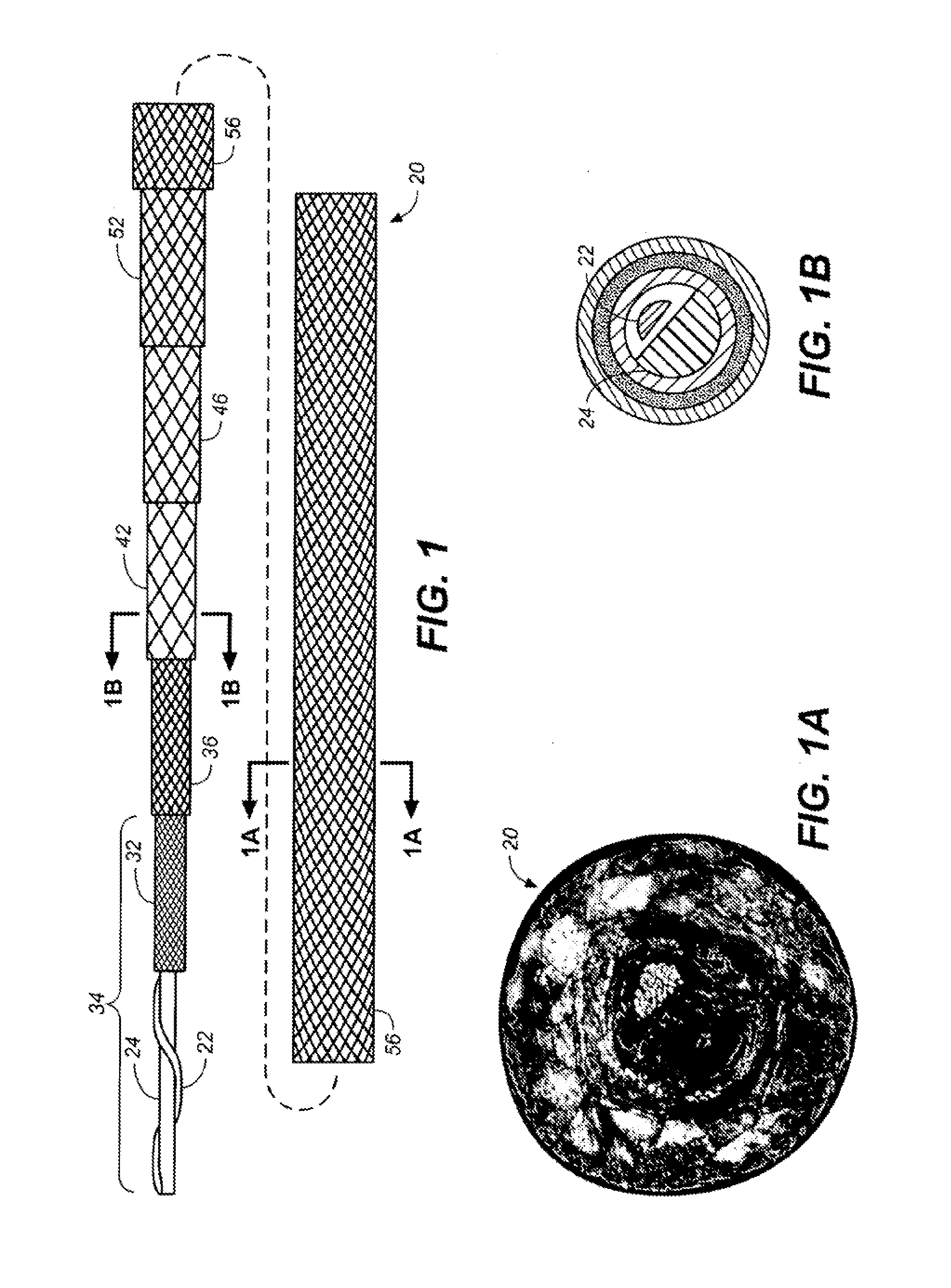

Headline sonar cable

A production method for a headline sonar cable (20, 120) that exhibits a high breaking-strength and lighter weight than a conventional steel headline sonar cable. Producing the headline sonar cable (20, 120) is characterized by the steps of: a. providing an elongatable internally-located conductive structure (34, 134) that is adapted for data signal transmission; and b. braiding a strength-member jacket layer (52) of polymeric material around the structure (34, 134) while ensuring that the structure (34, 134) is slack when surrounded by the jacket layer (52).

Owner:HAMPIDJAN

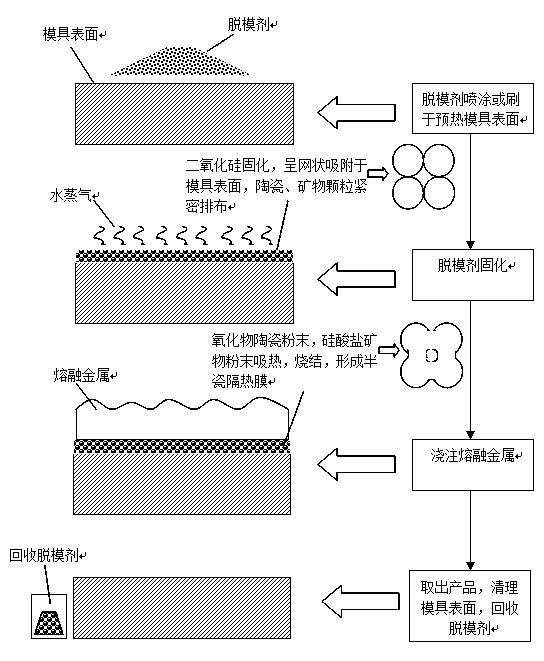

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

ActiveCN103537613AIncrease contact interfaceReduce porosityFoundry mouldsFoundry coresThermal fatiguePhysical chemistry

The invention provides a mold-releasing type complexing agent with effects of resisting a high temperature of more than 1450 DEG C, insulating heat and demolding and a preparation method thereof. The mold-releasing type complexing agent comprises the following raw materials in percentage by weight: 20-60% of nano colloidal silicon dioxide solution; 5-30% of composite oxide ultramicro (0.1-1.0 microns) powder including Na, Mg, Ca, Fe, Li, Al, Si, B, Zr and other elements; 0.2-2% of water-based dispersing agent;0.02-0.5% of water-based thickening agent and the balance of water; and the sum of the weight of the components is 100%. According to the mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding, the nano colloidal silicon dioxide solution is cooperated with the ultramicro (0.1-1.0 microns) multielement composite oxide powder, so that the excellent performances of high temperature resistance, heat insulation, demolding, environment protection and the like are achieved, the thermal fatigue resistance of the mold surface is effectively improved, and the service life of the mold is prolonged. The mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding is particularly applicable to using at the part of a mold directly contacting molten steel in fired mold casting and other high temperature forming technologies of metal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

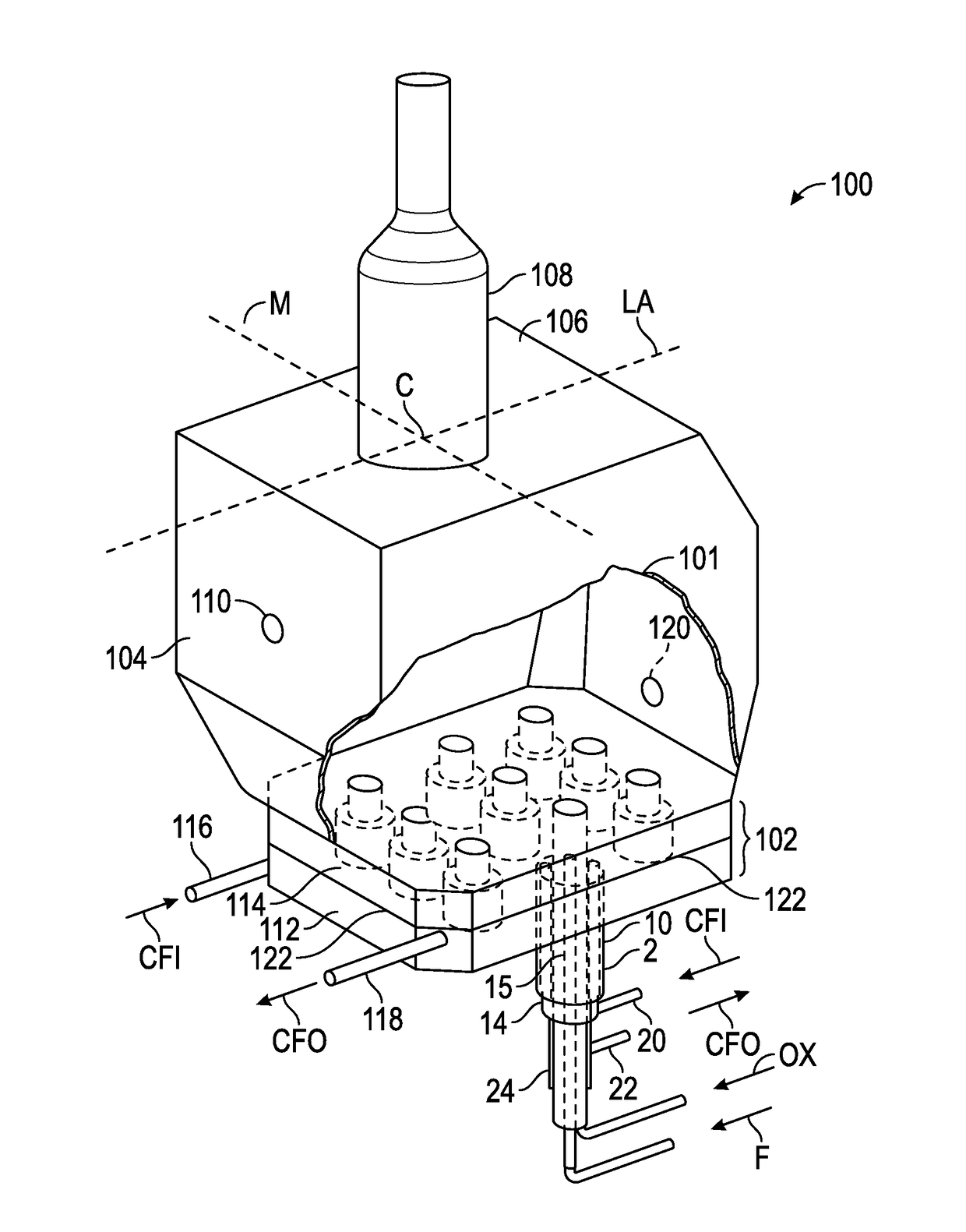

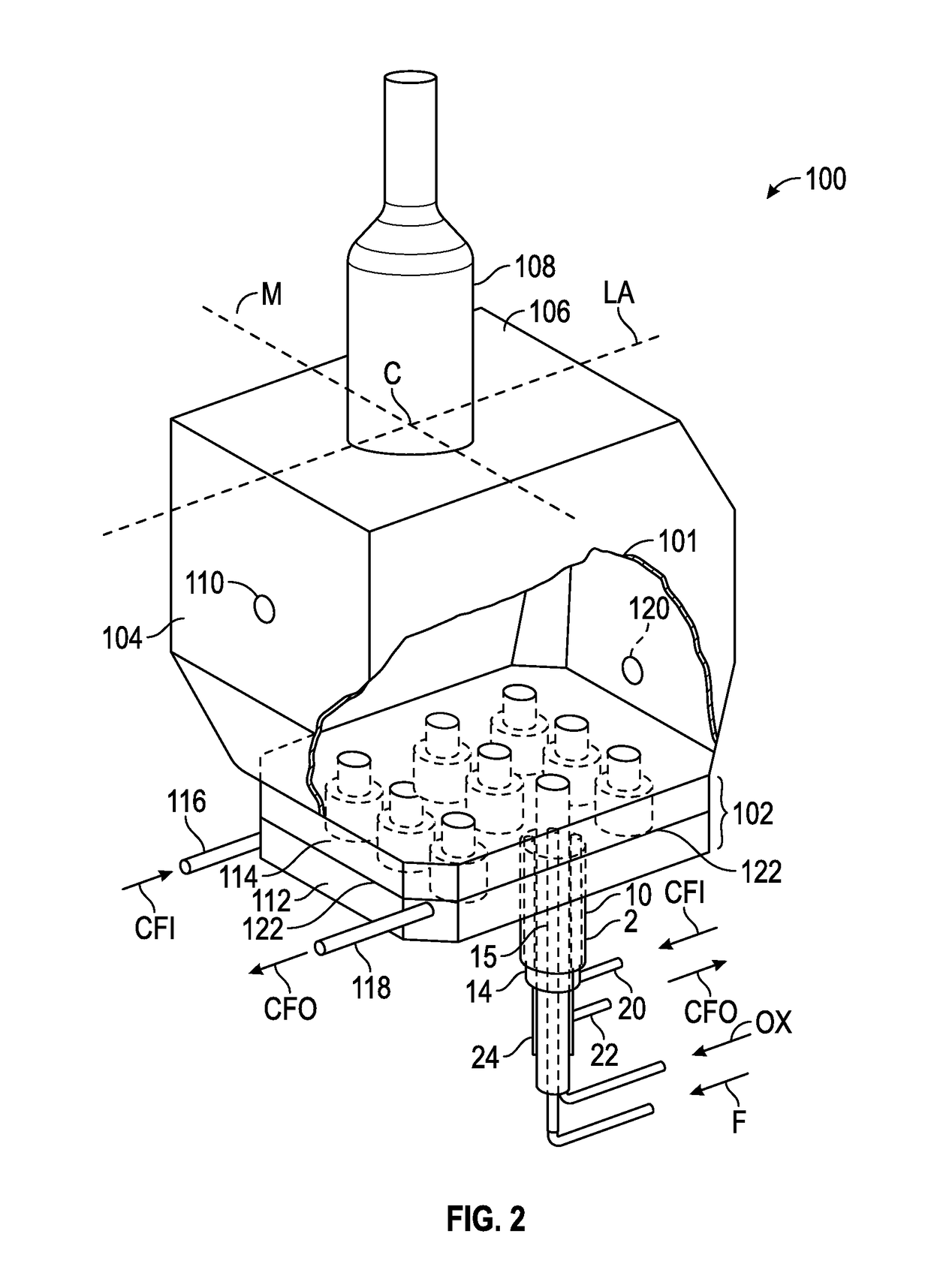

Submerged combustion melters, wall structures or panels of same, and methods of using same

ActiveUS20180065877A1Reduce heat fatigueProtection materialGlass furnace apparatusGlass melting apparatusCombustorEngineering

Submerged combustion burner panels, submerged combustion melters including one or more of the panels, and methods of using the same. The burner panel includes a panel body including a fluid-cooled portion and a protective non-fluid cooled portion. An exterior surface defined by the fluid-cooled portion, and an interior surface defined by the protective non-fluid cooled portion, exterior and interior referring to an SCM in which the panel is installed. The fluid-cooled portion has at least one burner support passage of diameter (d1) extending from the exterior surface to a seam where the fluid-cooled and protective non-fluid cooled portions meet supporting at least one fluid-cooled SC burner having a fluid-cooled burner tip attached to a burner body protruding away from the seam. The protective non-fluid-cooled portion has a combustion products flow passage of diameter (d2)<(d1). The burner panels promote burner life and melter campaign length.

Owner:JOHNS MANVILLE CORP

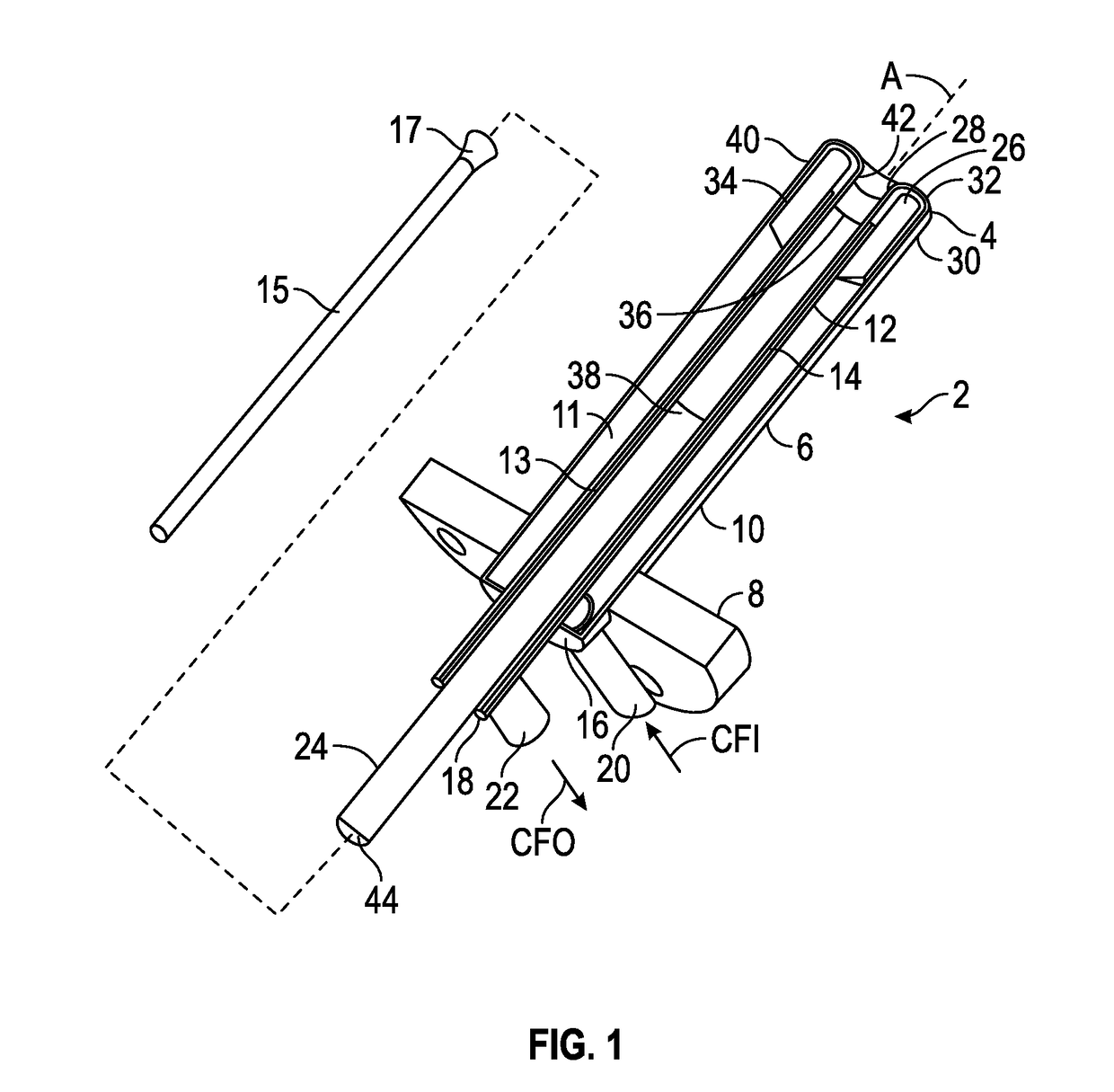

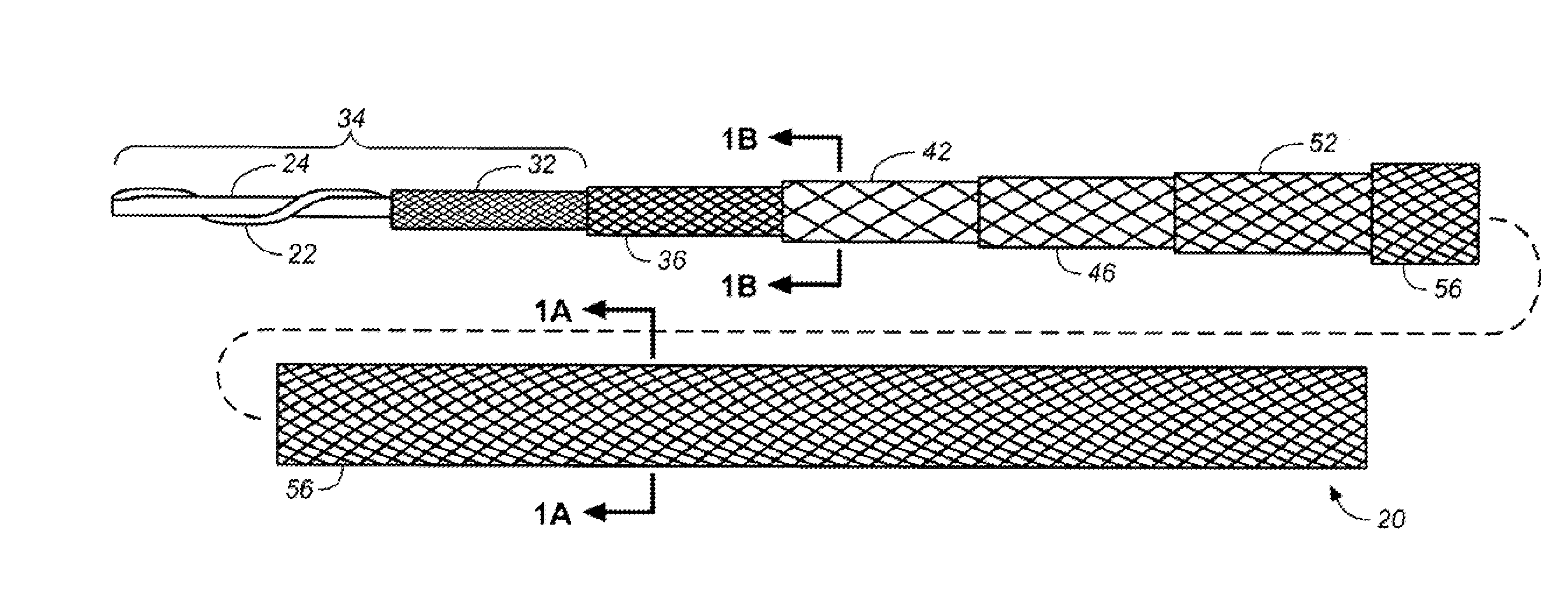

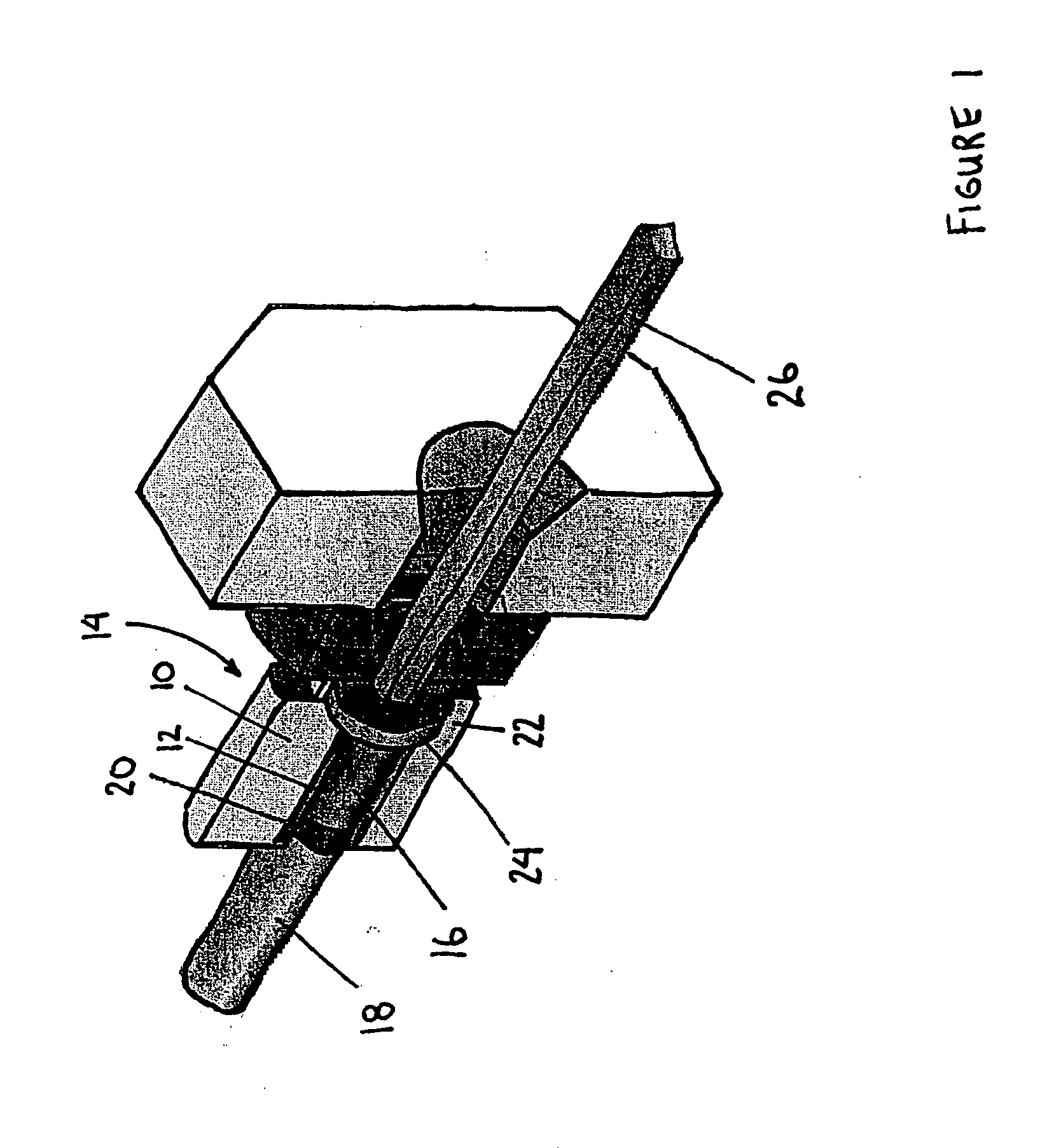

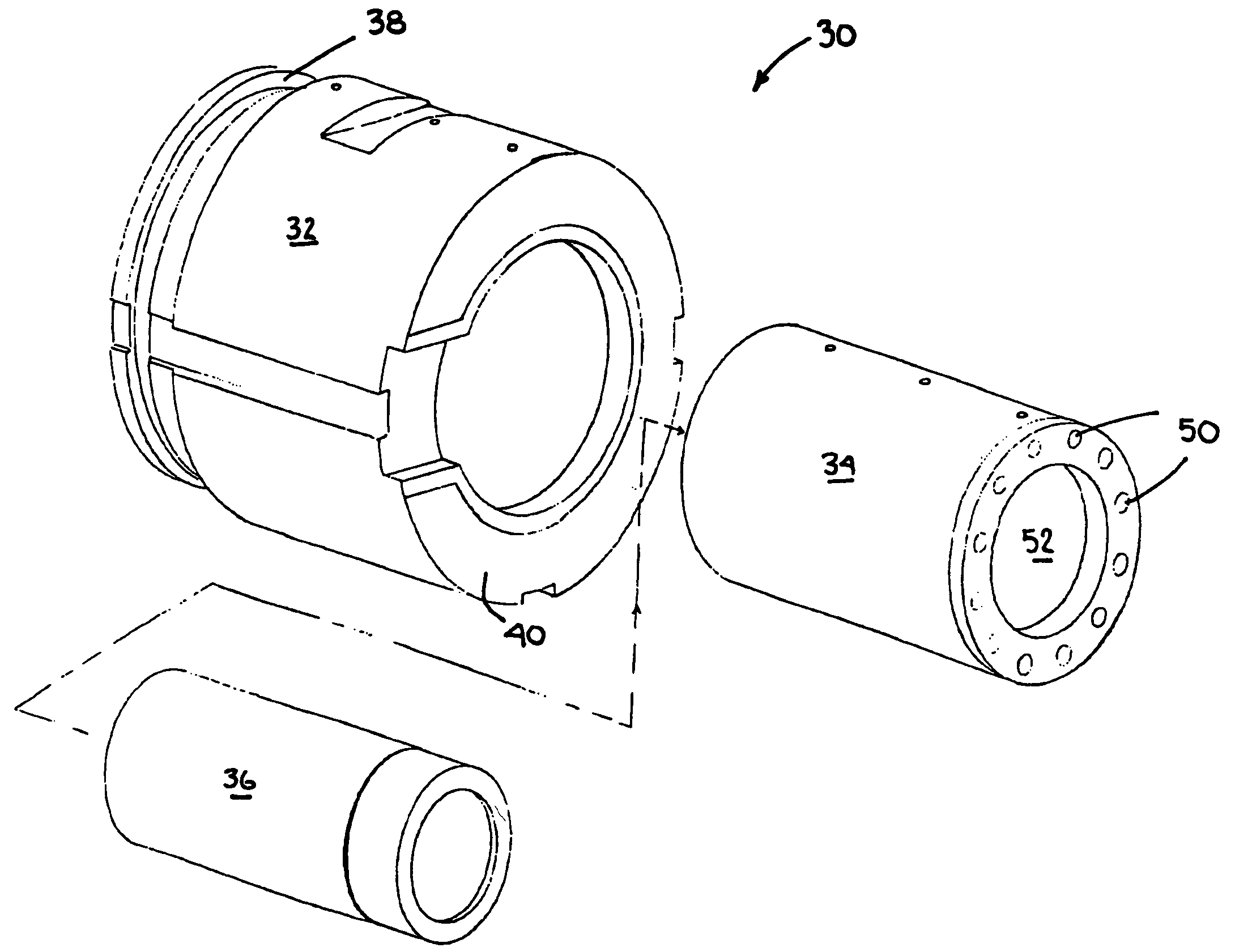

Headline sonar cable

ActiveUS20140216782A1Reduced Power RequirementsReduce heat fatigueLine/current collector detailsPlastic/resin/waxes insulatorsSonarBreaking strength

A production method for a headline sonar cable (20, 120) that exhibits a high breaking-strength and lighter weight than a conventional steel headline sonar cable. Producing the headline sonar cable (20, 120) is characterized by the steps of:a. providing an elongatable internally-located conductive structure (34, 134) that is adapted for data signal transmission; andb. braiding a strength-member jacket layer (52) of polymeric material around the structure (34, 134) while ensuring that the structure (34, 134) is slack when surrounded by the jacket layer (52).The structure (34, 134) of the cable (20, 120) retains conductivity upon stretching of the jacket layer (52) surrounding the structure (34, 134) that lengthens the cable (20, 120). For one embodiment of the method a conductor (20) wrapped around a rod (24) and enclosed within a sheath layer (32) forms the structure (34, 134). For another embodiment of the method a braided conductor (122) enclosed within a braided sheath (124) and a polymeric layer (132) forms the structure (34, 134).

Owner:HAMPIDJAN

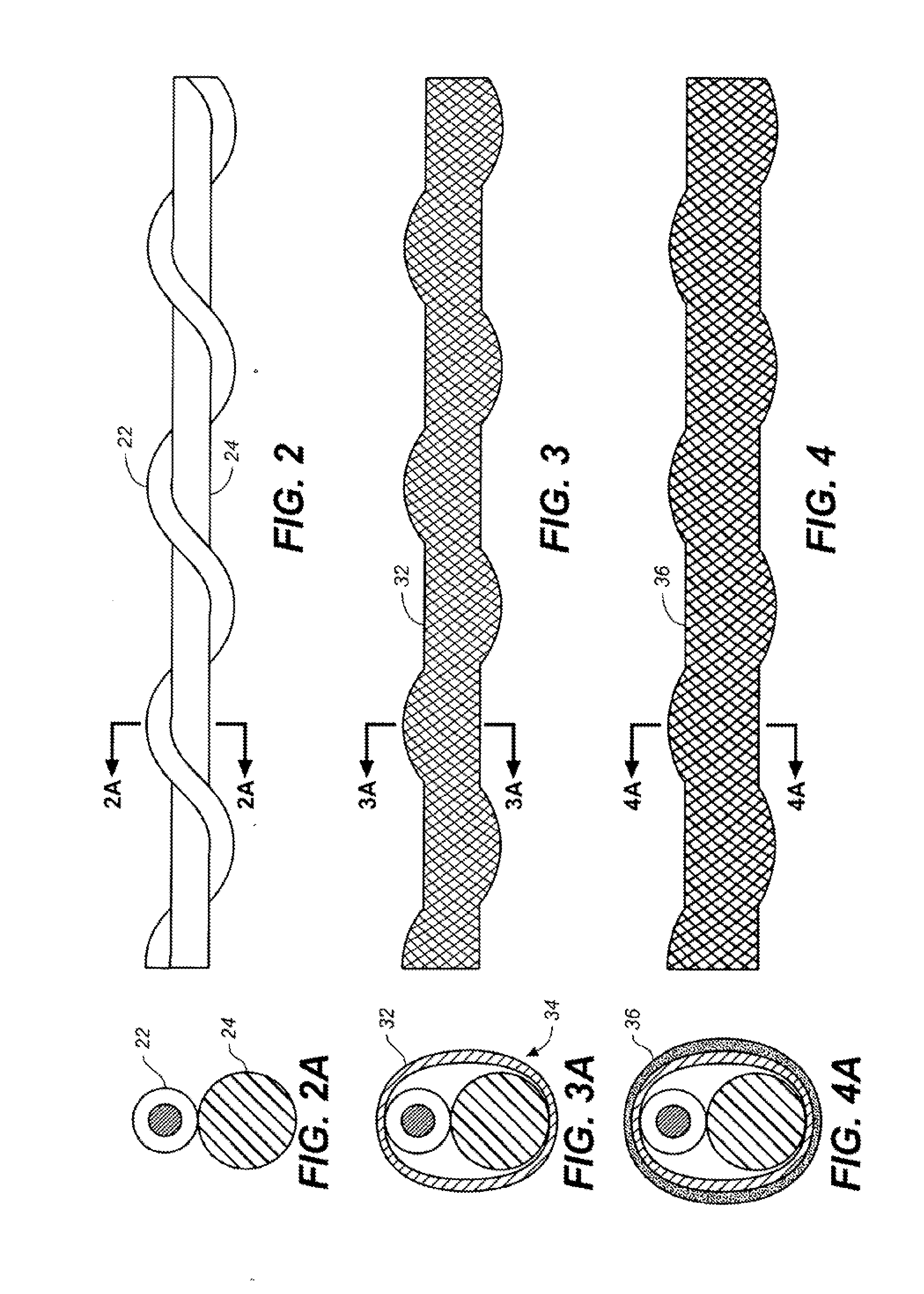

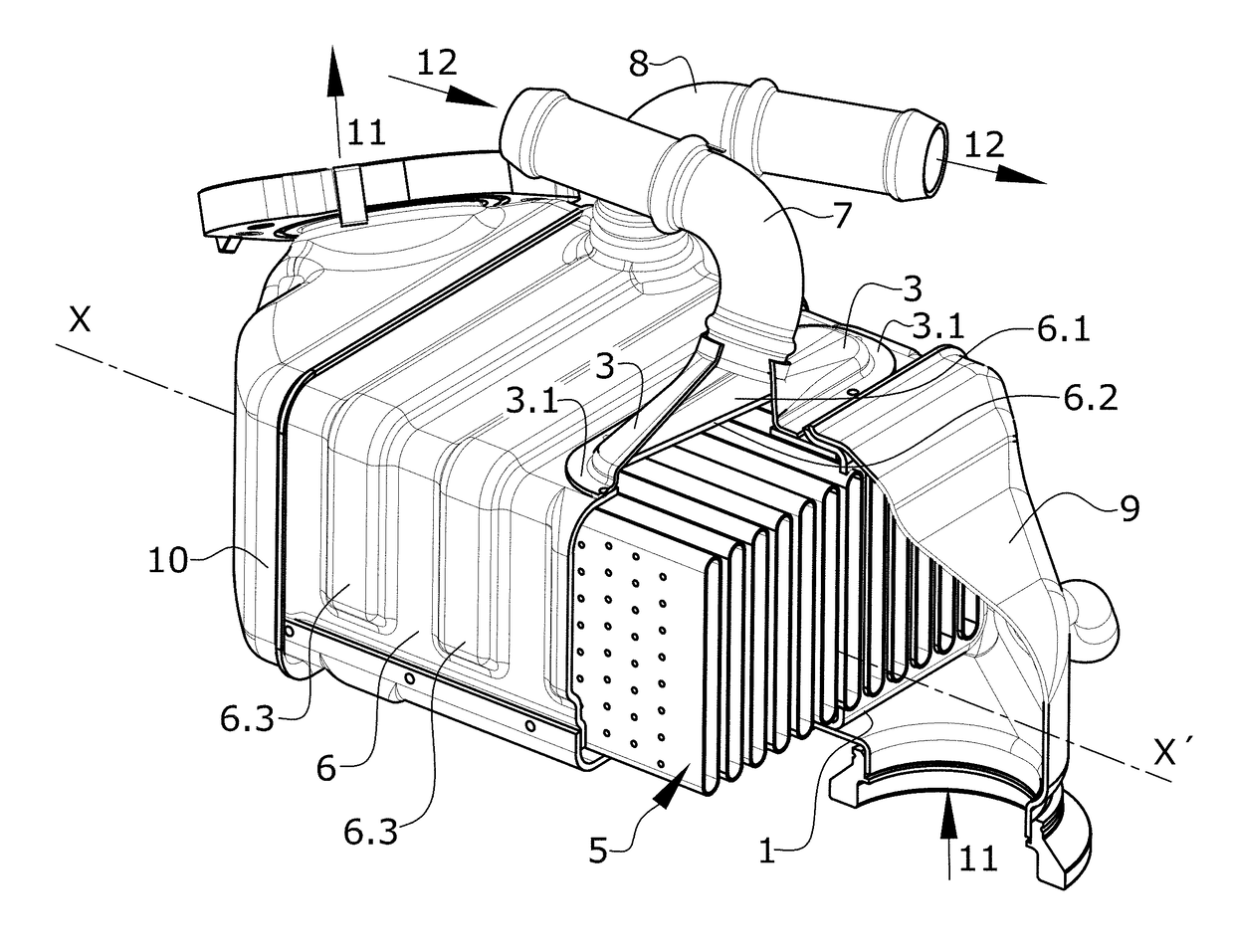

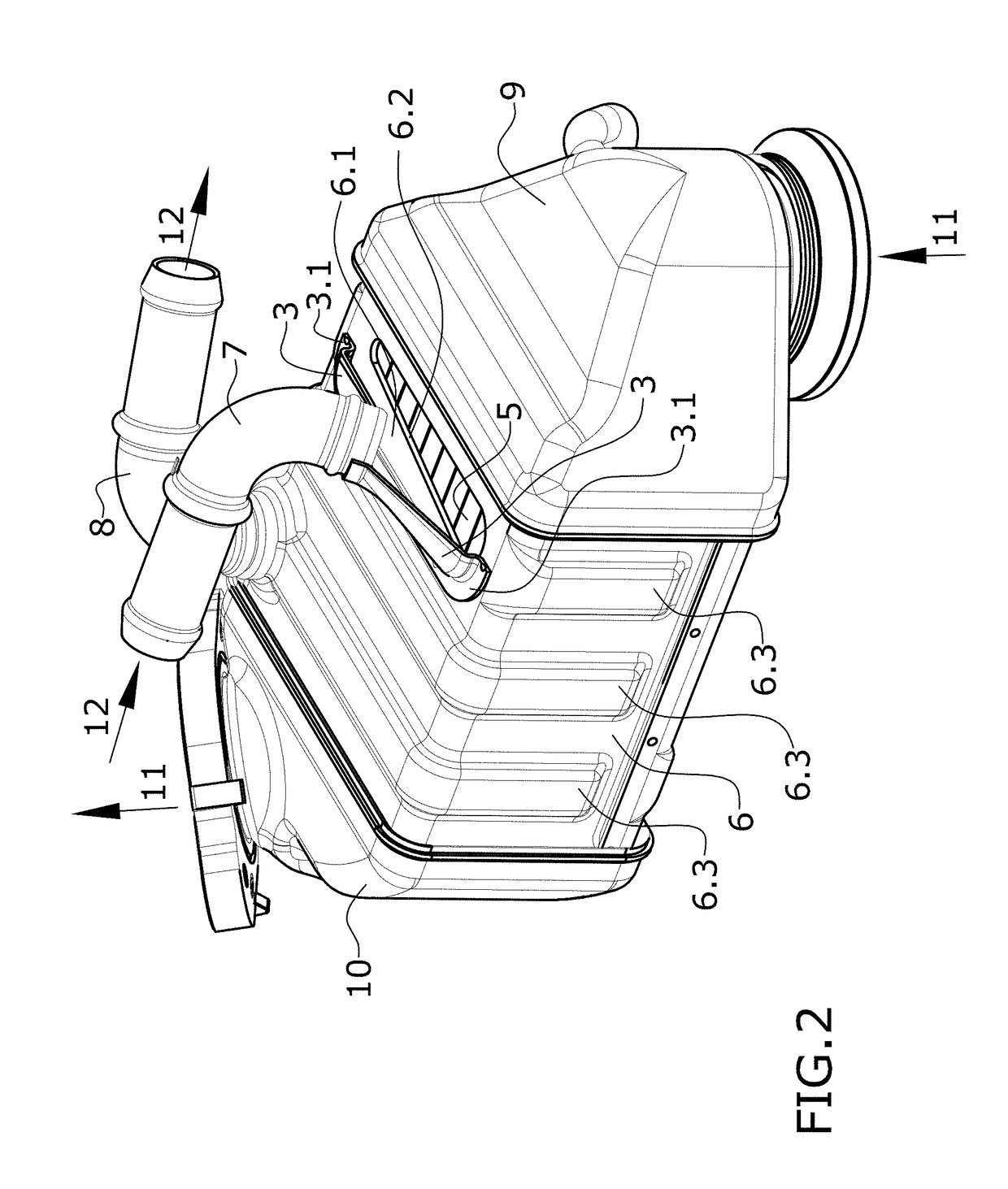

Heat exchange device

InactiveUS20170336147A1Area maximizationReduce usageRecuperative heat exchangersExhaust gas recirculationConvective heat transferMechanical engineering

The invention relates to a heat exchange device characterized by a particular configuration of the liquid inlet or outlet manifold in which it incorporates a baffle formed from the shell itself. This configuration allows not only suitably orient the inflow into regions of the tube bundle of the exchanger where convection must be more intense, but also allows generating a flow suitable for reaching all the regions having a higher convective heat transfer requirement. Configuring a baffle from the shell prevents incorporating and manufacturing specific additional parts, as well as the additional operations required for their configuration and attachment to the heat exchanger.

Owner:BORGWARNER EMISSIONS SYST SPAIN S L U

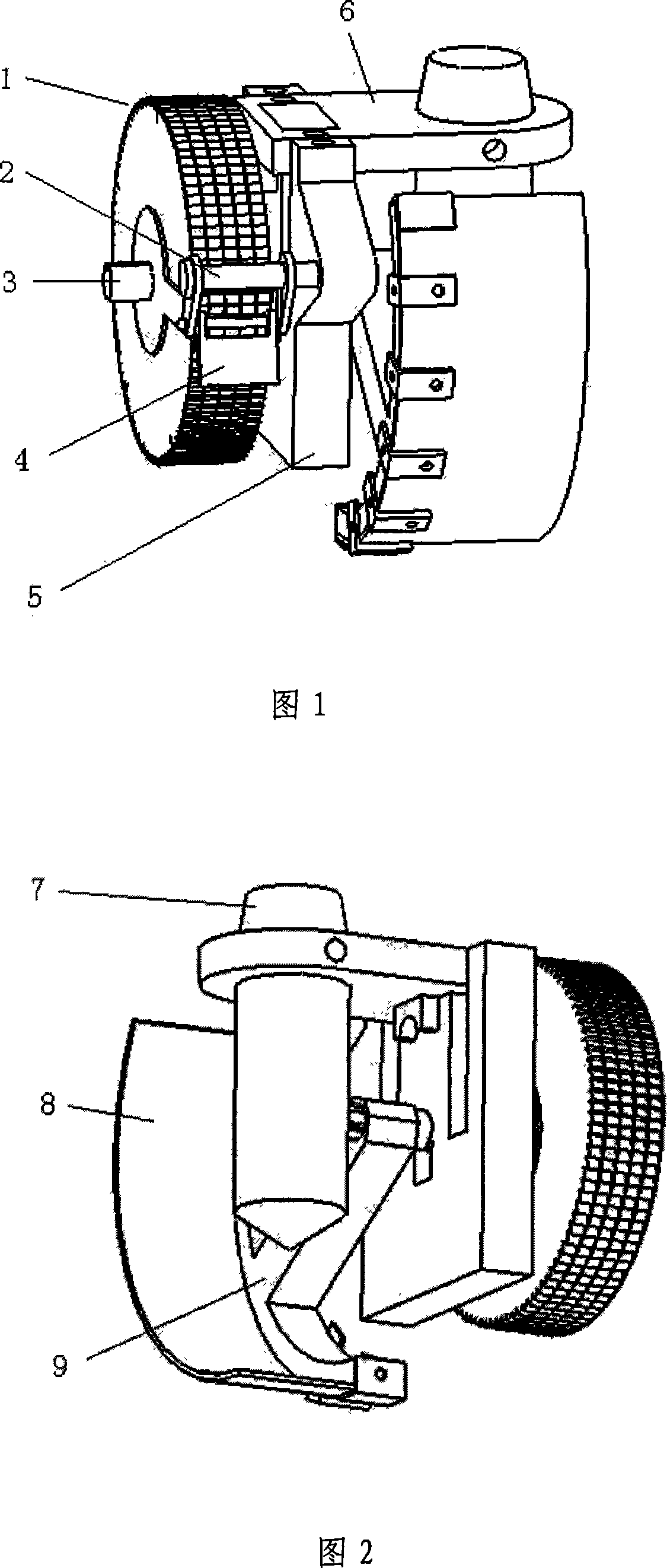

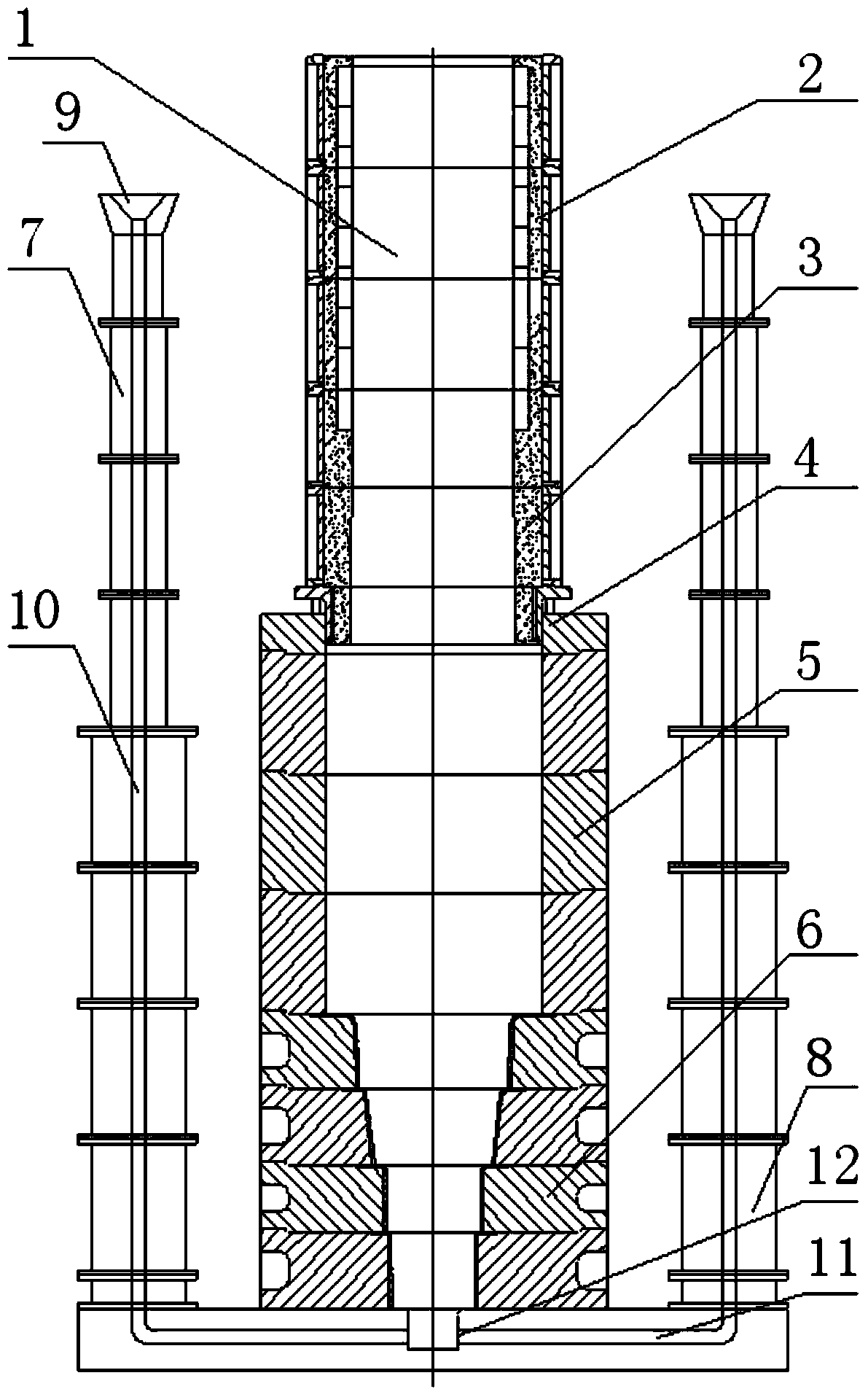

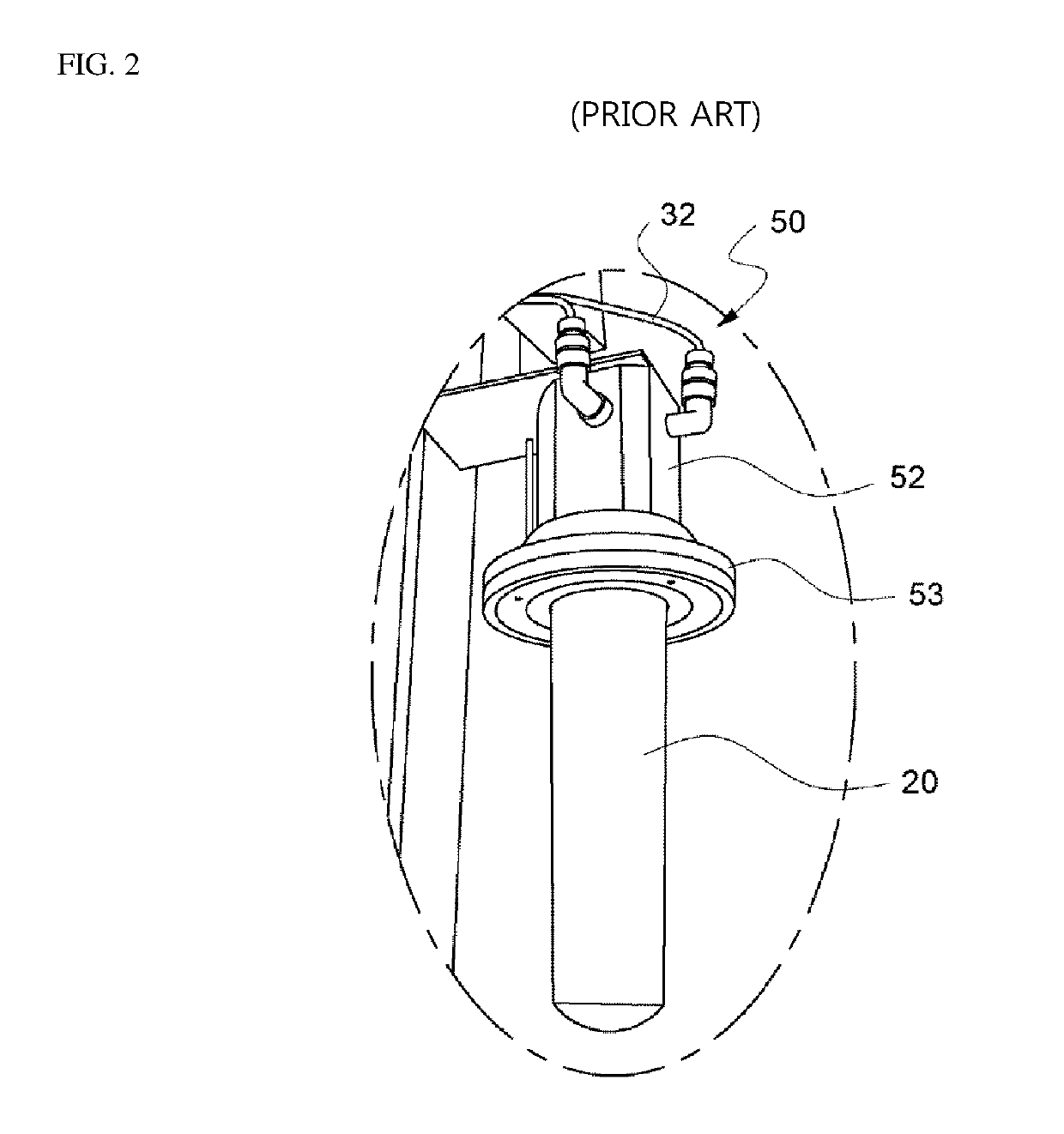

Device for prolonging the lifetime of resistance spot welding electrode

InactiveCN101081456AExtend your lifeReduce alloyingResistance electrode holdersElectrical resistance and conductanceFlywheel

The present invention relates to one kind of life increasing device for resistance spot welding electrode, and belongs to the field of resistance spot welding technology. The device includes one upper movable rack, one upper rack connected movably to the upper movable rack, one lower movable rack, one lower rack connected movably to the lower movable rack, one upper main shaft, one lower main shaft, springs separately between one main shaft and one rack, one arced upper flywheel, one arced lower flywheel, one upper ratchet wheel mechanism, one lower ratchet wheel mechanism, copper tabs on the flywheels, one upper link rod mechanism, one lower link rod mechanism, one upper hook mechanism and one lower hook mechanism. It has the advantages of reduced alloying, less wear, less pitting corrosion, less heat fatigue and long electrode life.

Owner:TIANJIN UNIV

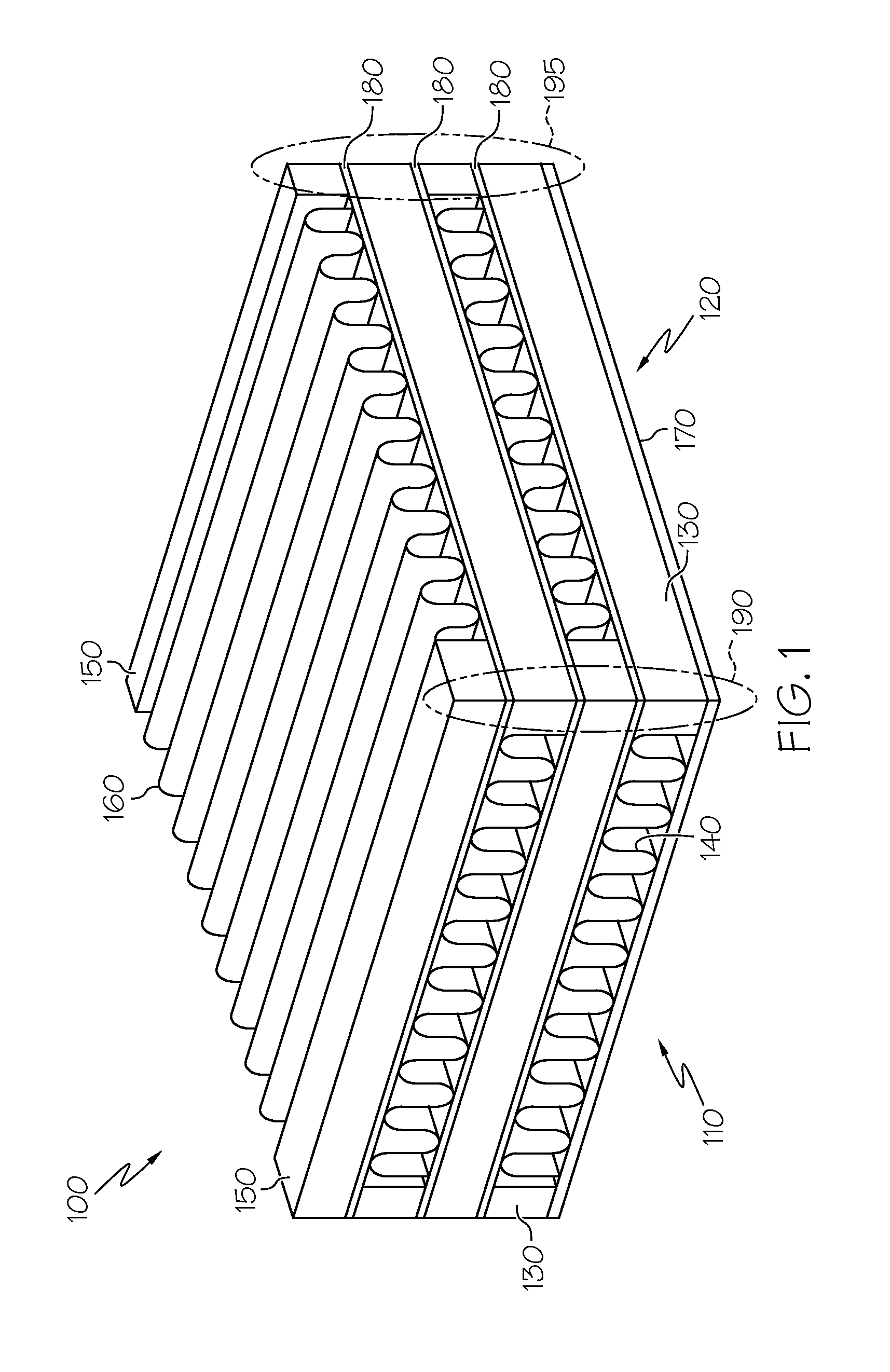

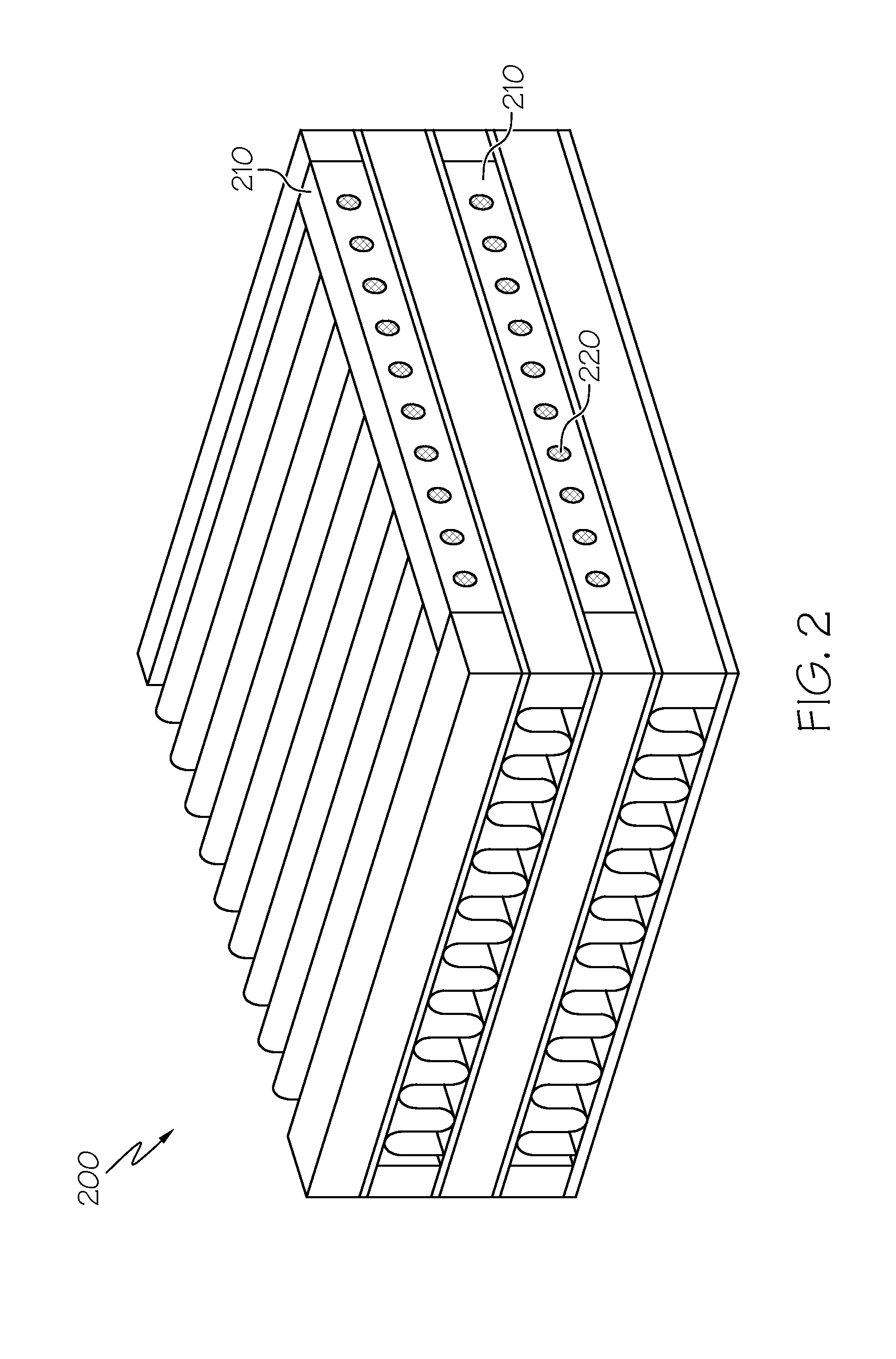

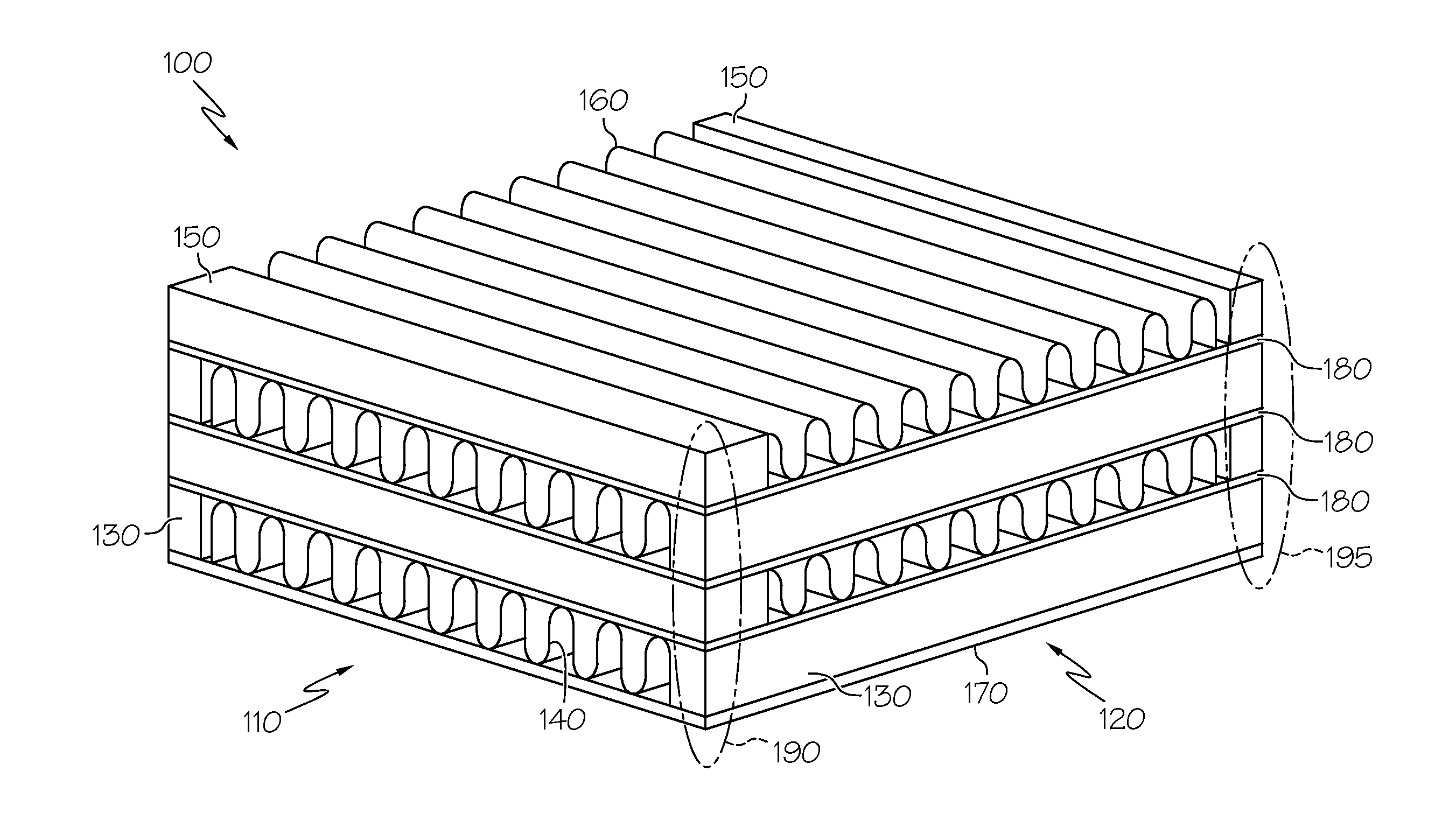

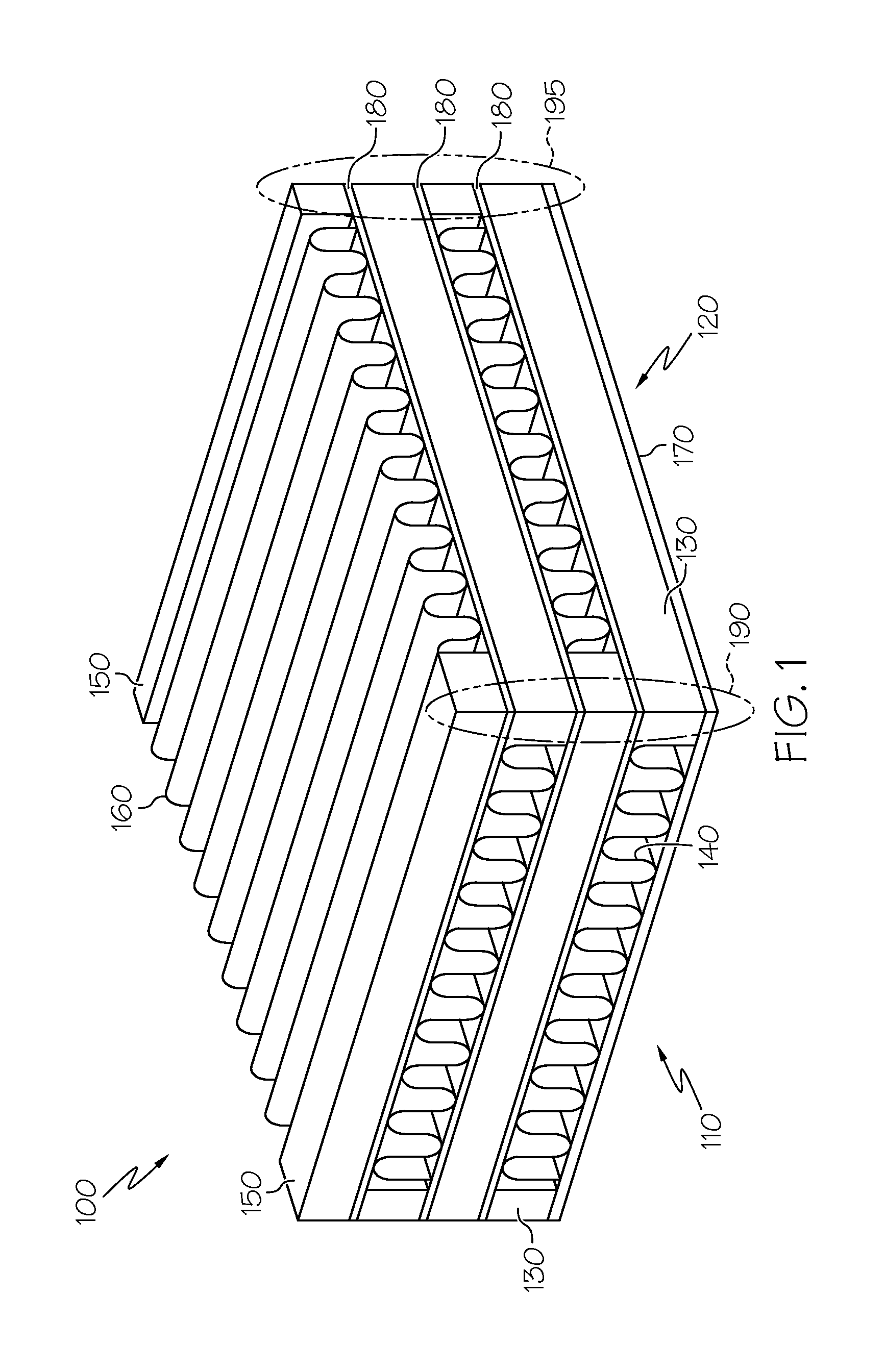

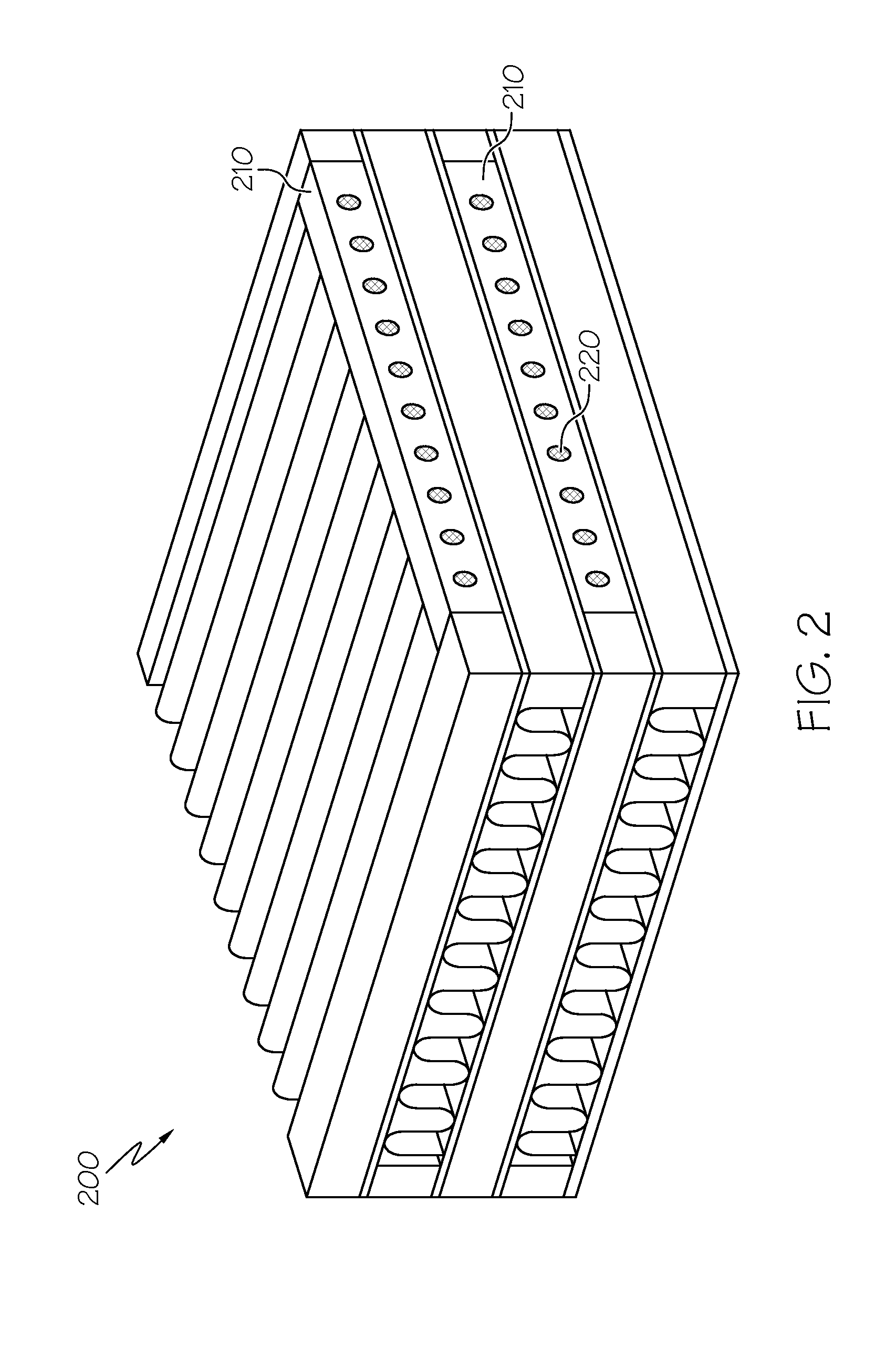

Plate-fin heat exchanger with a porous blocker bar

ActiveUS9279626B2Improve the immunityReduce heat fatigueHeat exchanger casingsStationary tubular conduit assembliesEngineeringPlate fin heat exchanger

The plate-fin heat exchanger includes a first fluid pathway running along a first axis, a second fluid pathway running along a second axis perpendicular to the first axis, and a blocker bar having an inlet face and an outlet face. The blocker bar inlet face coincides with a heat exchanger face. The blocker bar is at an inlet of the second fluid pathway and receives a second fluid. The outlet face of the blocker bar is at the inlet of the second fluid pathway. The blocker bar includes a set of spaced apart pores that extend from the inlet face to the outlet face.

Owner:HONEYWELL INT INC

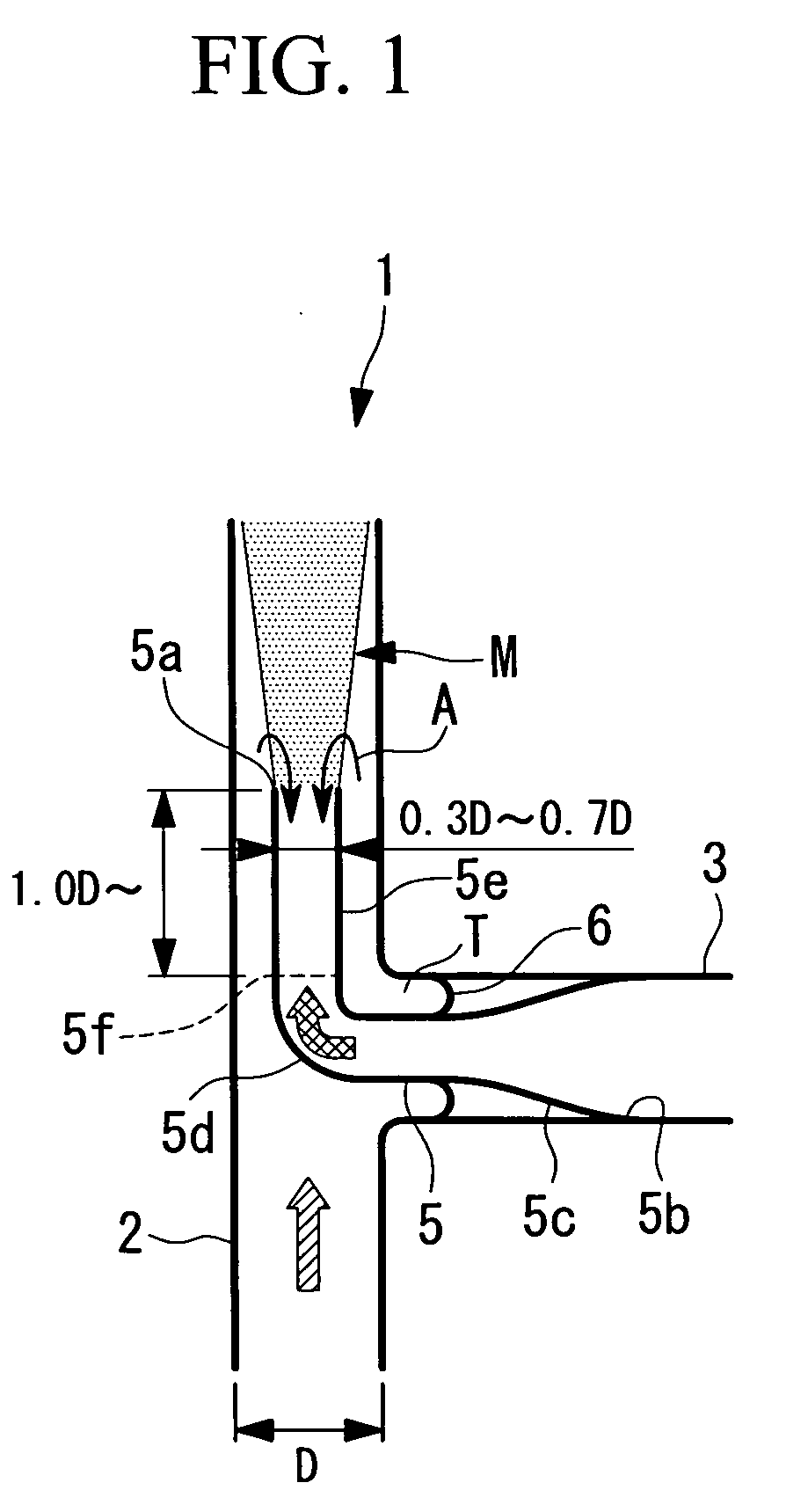

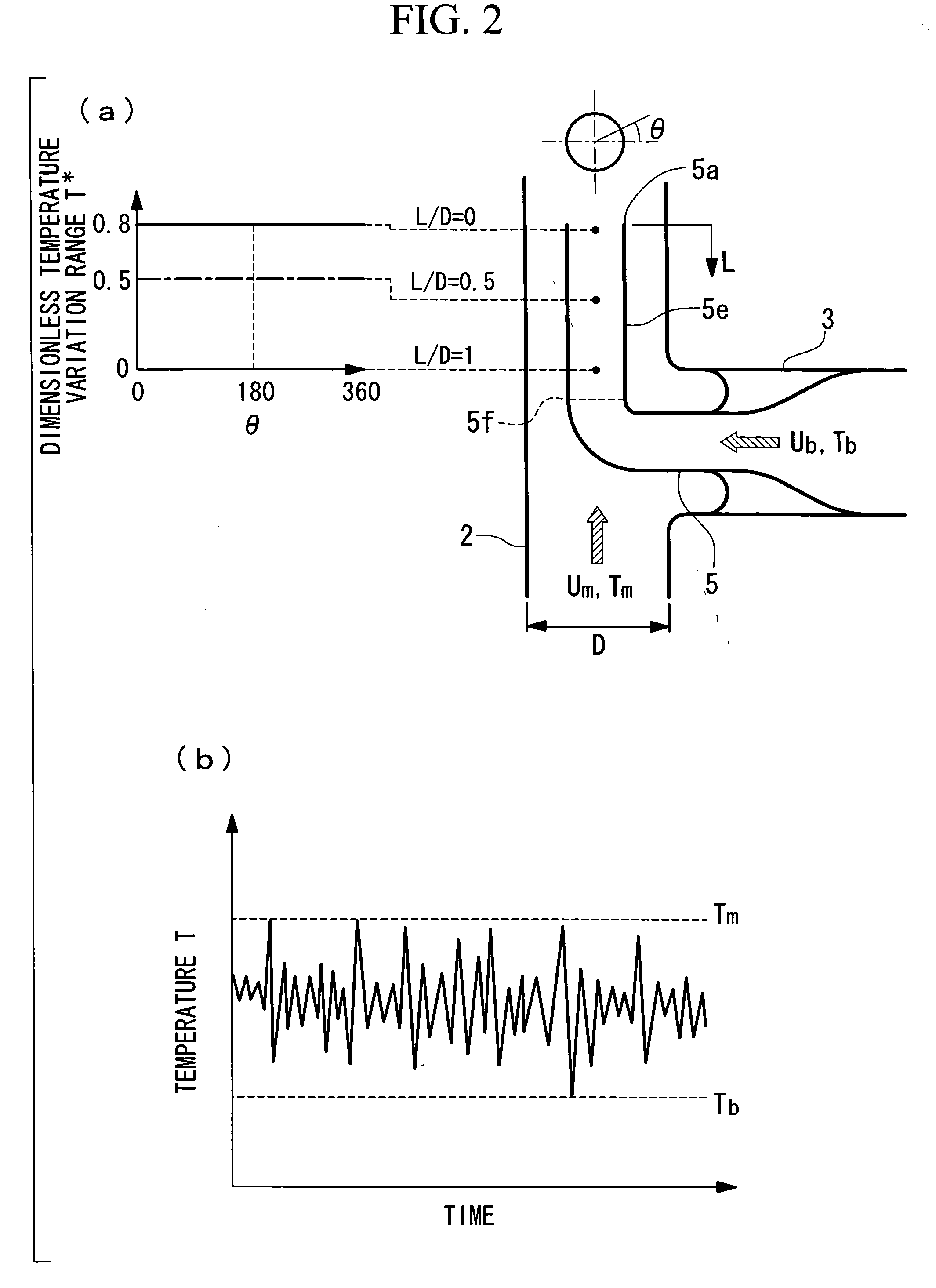

Piping having fluid-mixing region

ActiveUS20090090424A1Facilitates fluid mixingReduce temperature changesFlow mixersNuclear energy generationThermal fatigueWater flow

An object is to prevent thermal fatigue, resulting from variations in temperature interfaces, of piping having a fluid-mixing region where fluids of different temperatures are mixed. Piping 1 having a fluid-mixing region M includes a reducer 5 including an end portion 5e disposed substantially on a central axis of a main pipe 2. Low-temperature water flows through the reducer 5 at a lower velocity than high-temperature water flowing outside the end portion 5e. The low-temperature water and the high-temperature water have different temperatures. The low-temperature water and the high-temperature water are mixed in the fluid-mixing region M downstream of the reducer 5. The reducer 5 has a weld line 5f formed to connect the end portion 5e and an elbow portion 5d together. The distance between the weld line 5f and a downstream end 5a is equal to or larger than the inner diameter D of the main pipe 2.

Owner:MITSUBISHI HEAVY IND LTD

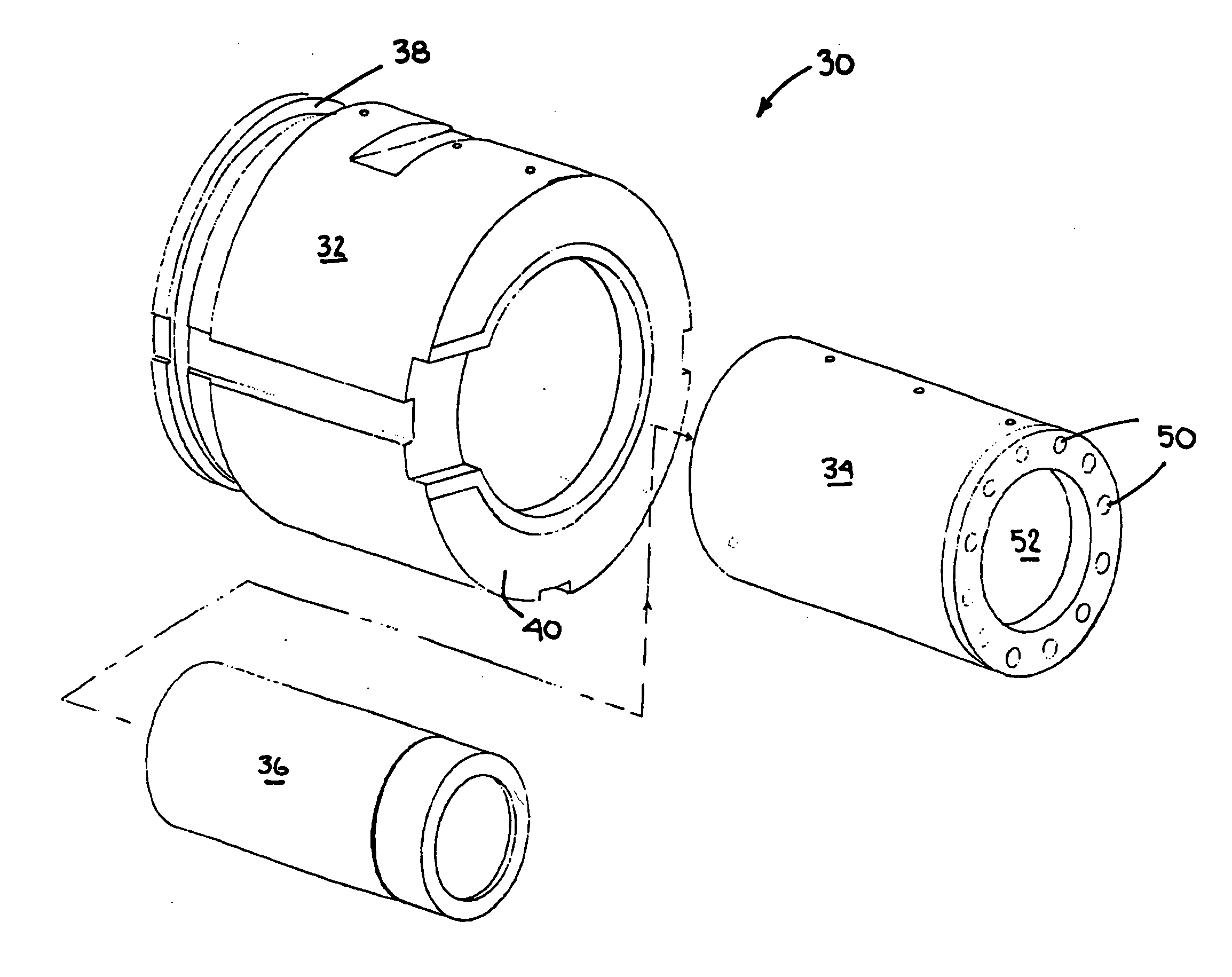

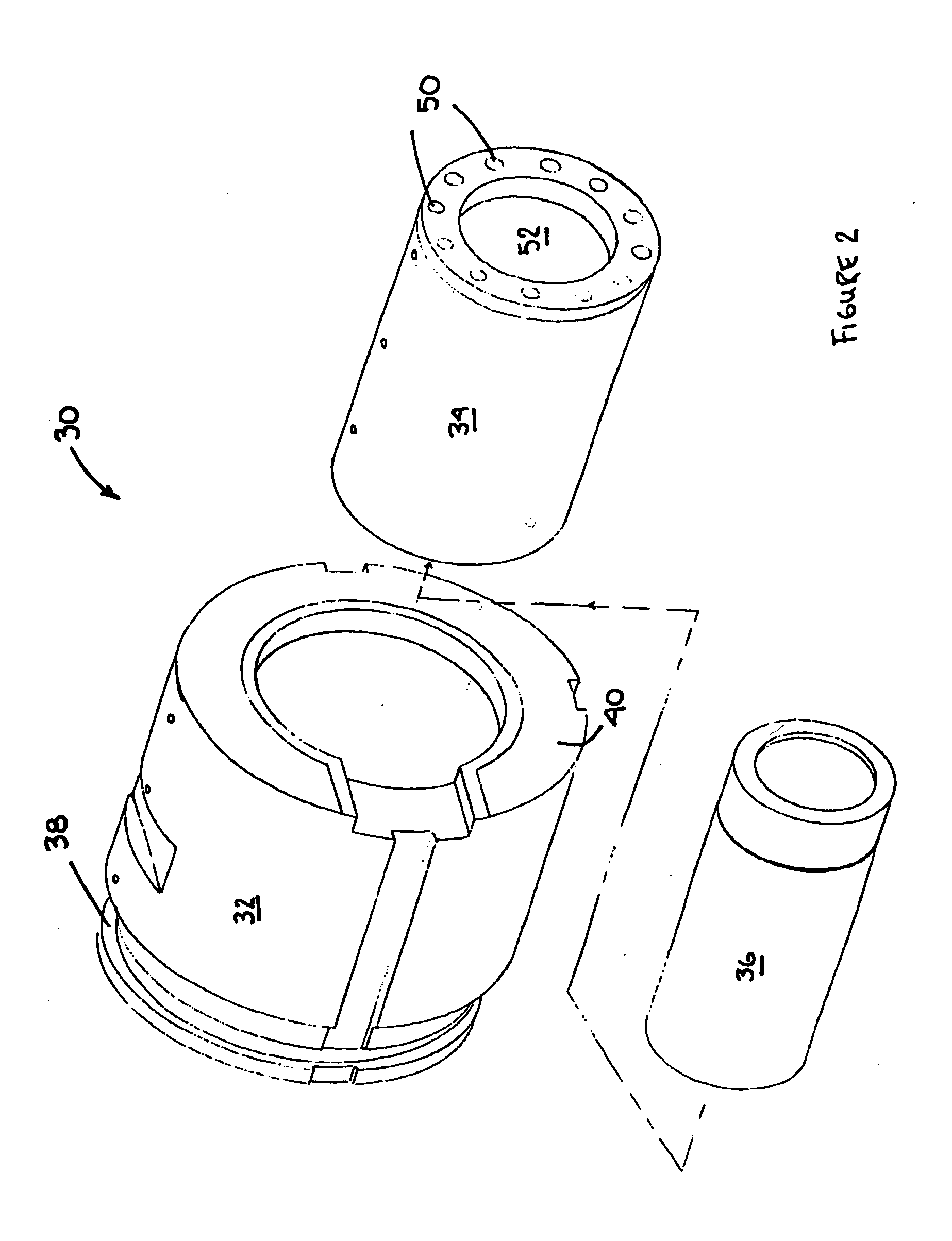

Thermal control extrusion press container

ActiveUS20050262913A1Easy to controlReduce the possibilityShaping toolsExtrusion containersEngineeringBiomedical engineering

A subliner for use in a metal extrusion press, the subliner comprising an elongate annular body having an outer surface dimensioned for placement within an outer mantle, and an inner surface dimensioned to receive an inner liner. The subliner further comprises at least one heating element positioned longitudinally between the outer and inner surfaces of the elongate annular body for providing heat in at least one selected region of the subliner, in close proximity to the inner liner.

Owner:ROBBINS PAUL

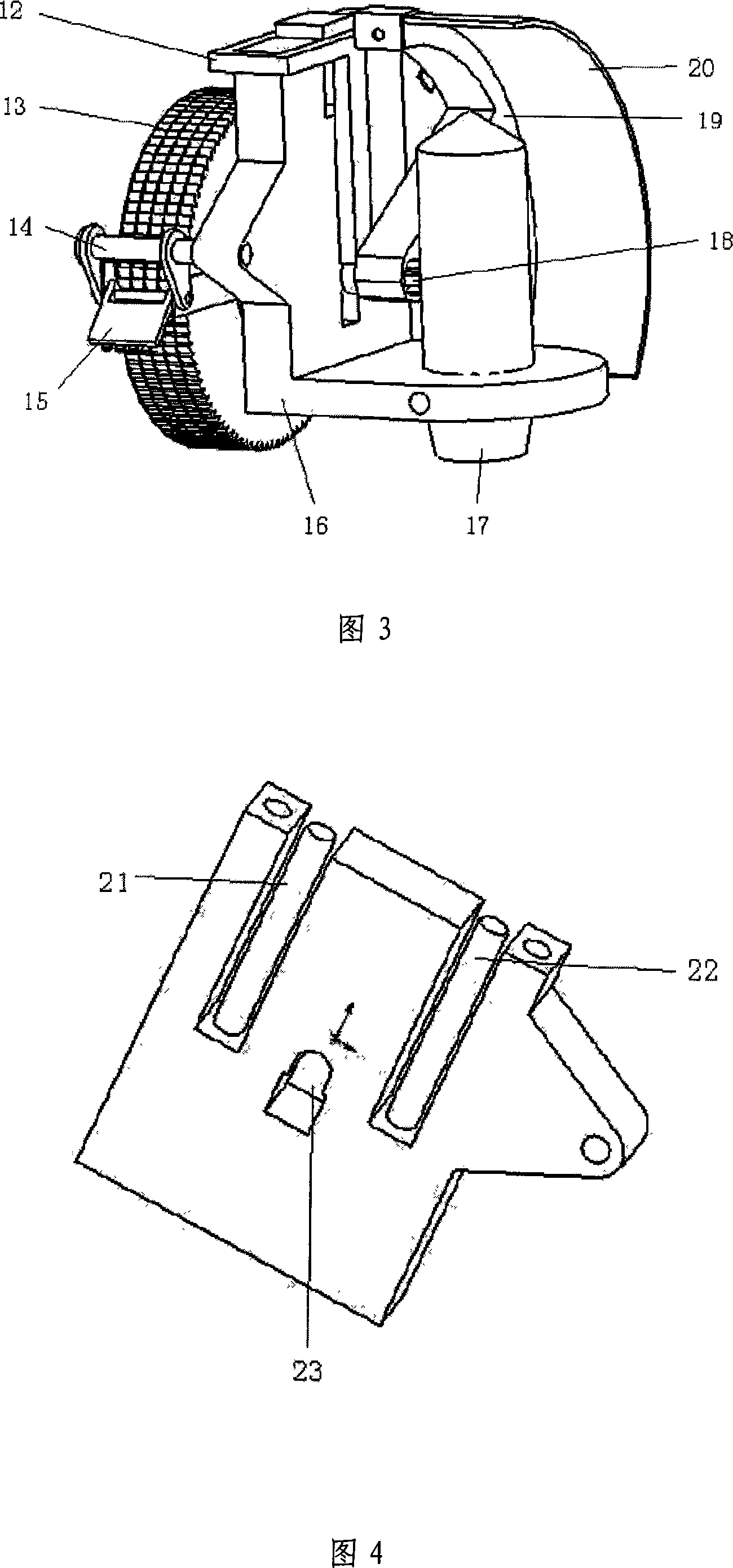

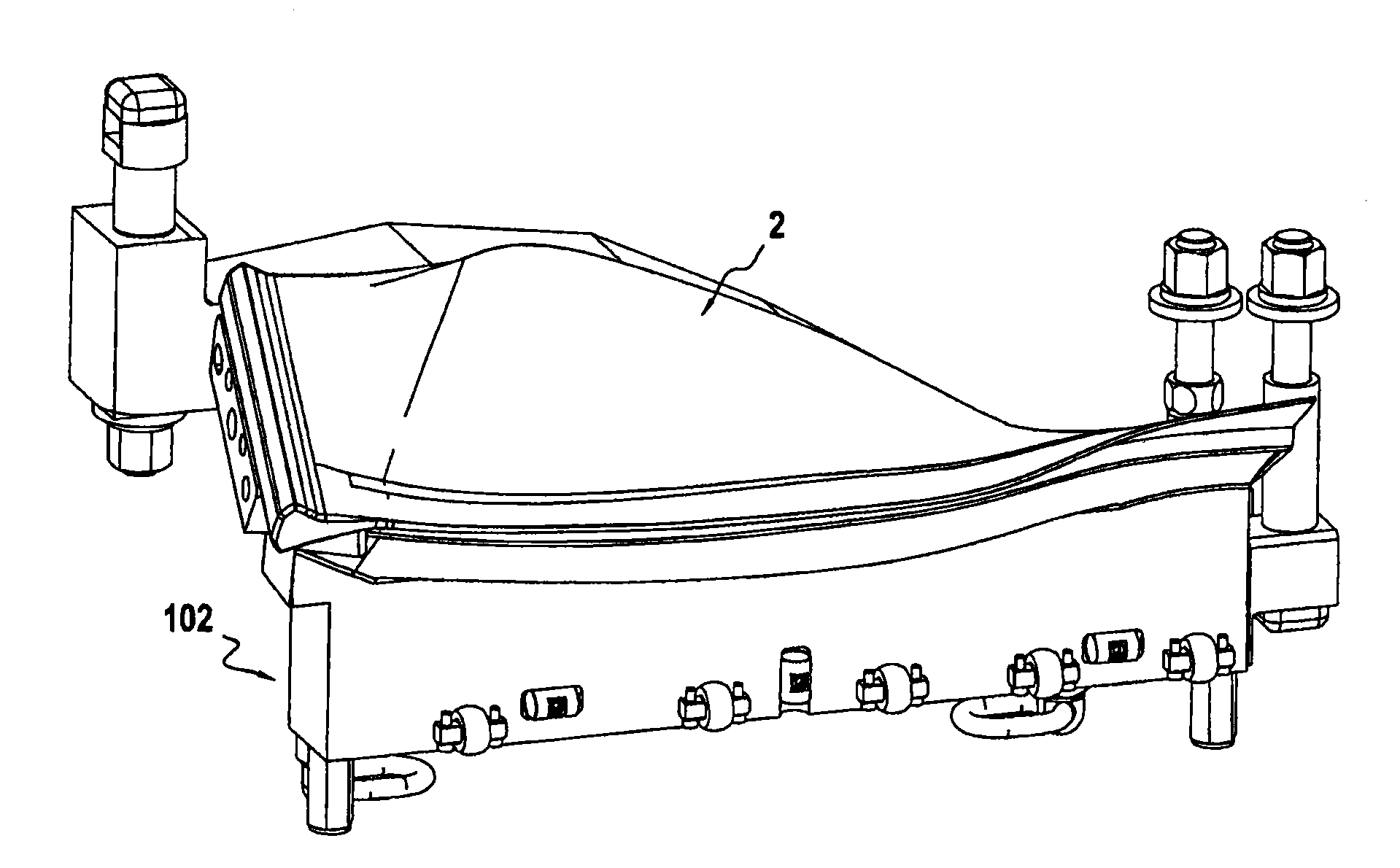

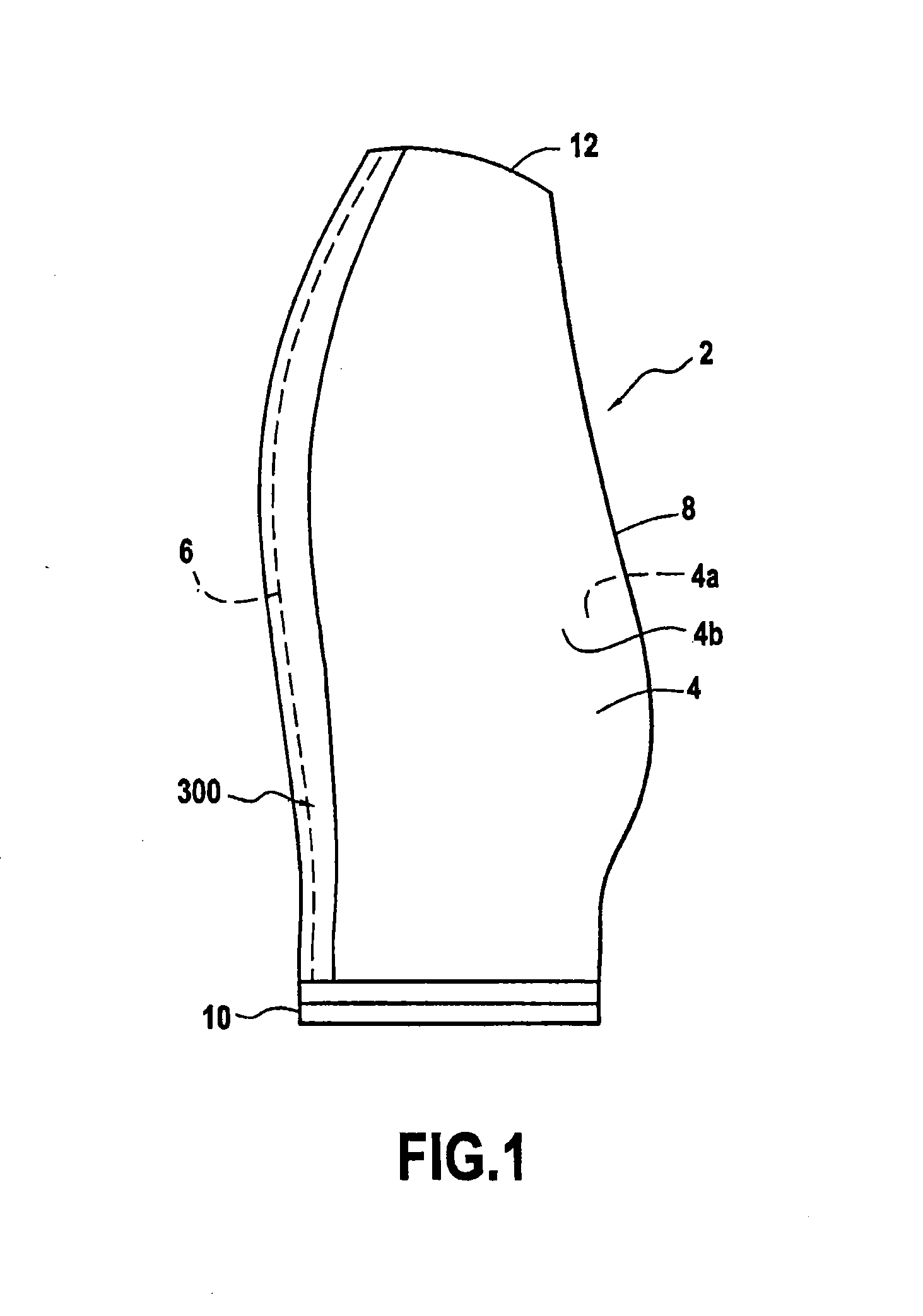

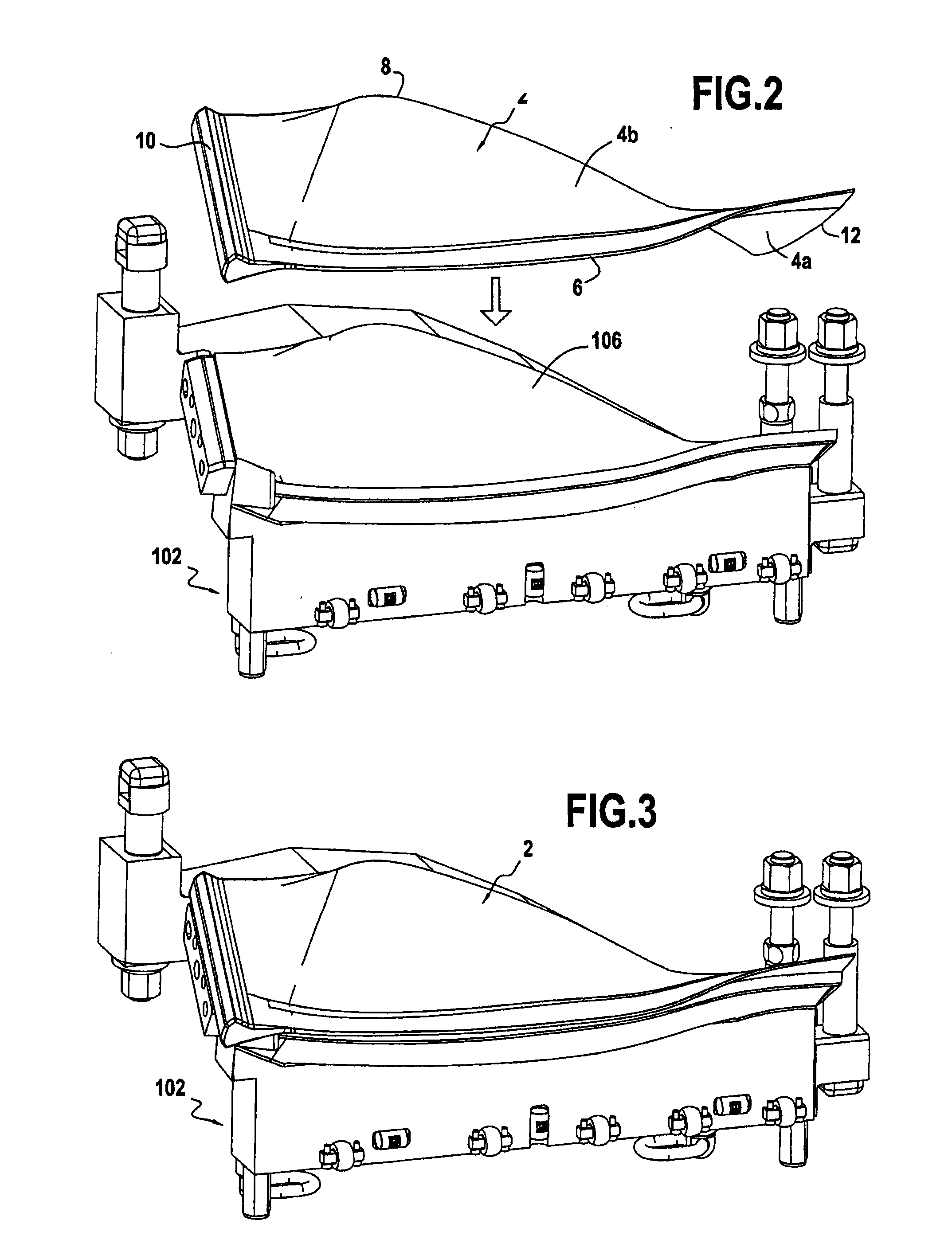

Tooling for fastening metal reinforcement on the leading edge of a turbine engine blade, and a method using such tooling

ActiveUS20160076387A1Avoid defectsReduce heat fatiguePump componentsBlade accessoriesLeading edgeTurbine

A tooling for fastening metal reinforcement on the leading edge of a turbine engine blade, the tooling including a blade support for receiving a blade while leaving surfaces of the leading edge of the blade disengaged; and a leading edge reinforcement support on which the blade support is designed to be mounted, and including two lateral wedges between which the metal reinforcement for the leading edge of the blade is positioned, the wedges being suitable for being capable of moving towards each other and apart from each other and each of them being provided with a suction grid for gripping the metal reinforcement, the leading edge reinforcement support further including heater elements for polymerizing an adhesive film applied on the leading edge surfaces of the blade.

Owner:SAFRAN +1

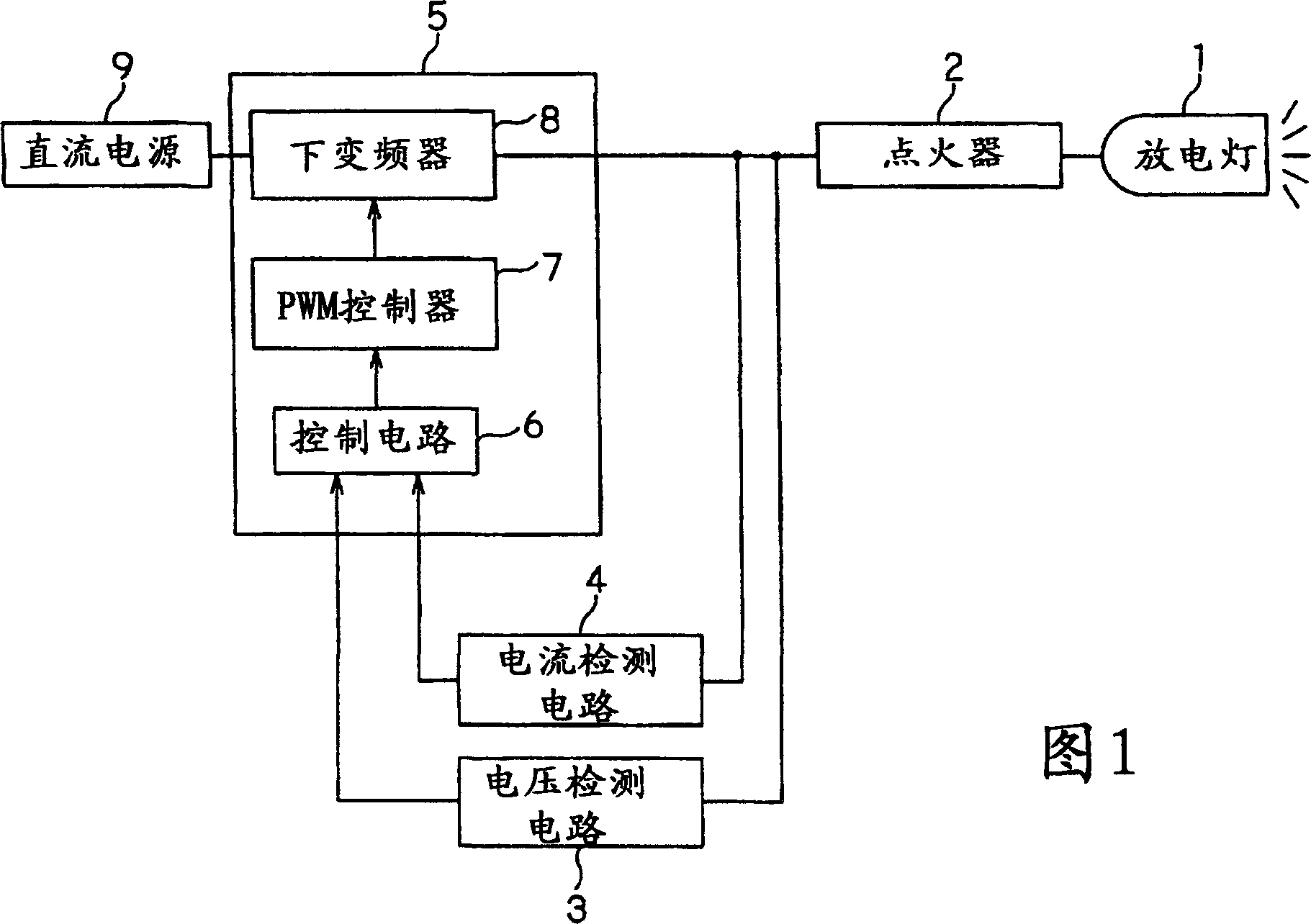

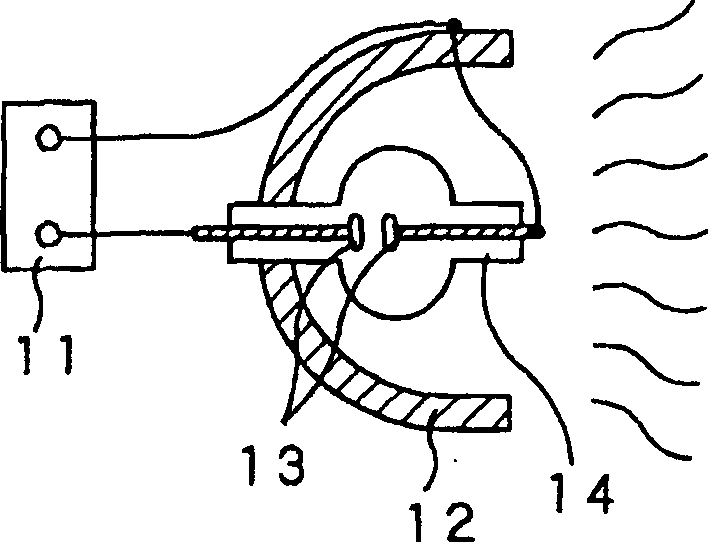

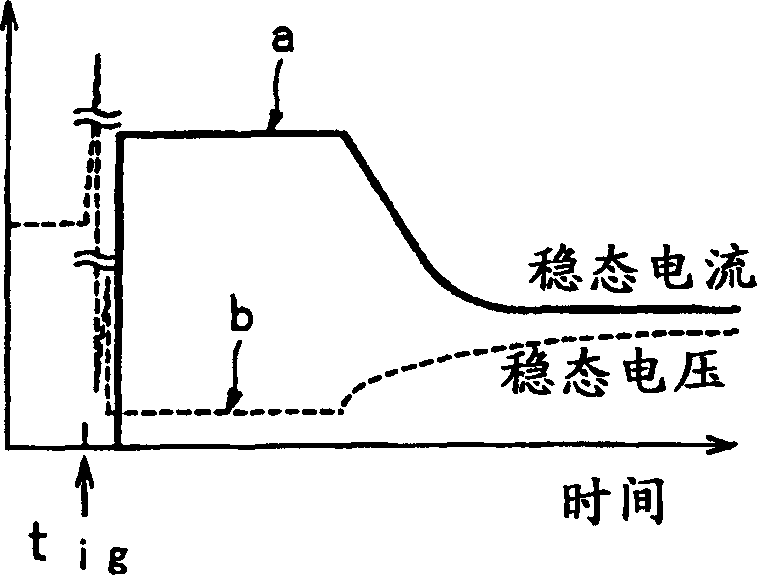

Discharge lamp igniter device and projector device

InactiveCN1465210AReduce heat loadReduce heat fatigueElectrical apparatusProjectorsGas-discharge lampControl circuit

A discharge lamp igniter for igniting a discharge lamp (1) comprises an igniter (2) serving as a starting means for igniting the discharge lamp (1) by applying a starting voltage to the discharge lamp (1) at starting the discharge lamp (1), a voltage determining circuit (3) for determining the voltage of the discharge lamp (1), and a current control circuit part (5) for controlling the current supplied to the discharge lamp (1) according to the result of the determination of the voltage determining circuit (3). After the ignition, the current control circuit part (5) starts the control of the current supplied to the discharge lamp (1) according to the result of the determination by the voltage determining circuit (3) and continuously varies the current supplied to the discharge lamp (1) at a predetermined rate of increase. In such a way, an inexpensive discharge lamp igniting device excellent in reliability and leading to a prolonged life of the discharge lamp (1) is provided.

Owner:SONY CORP

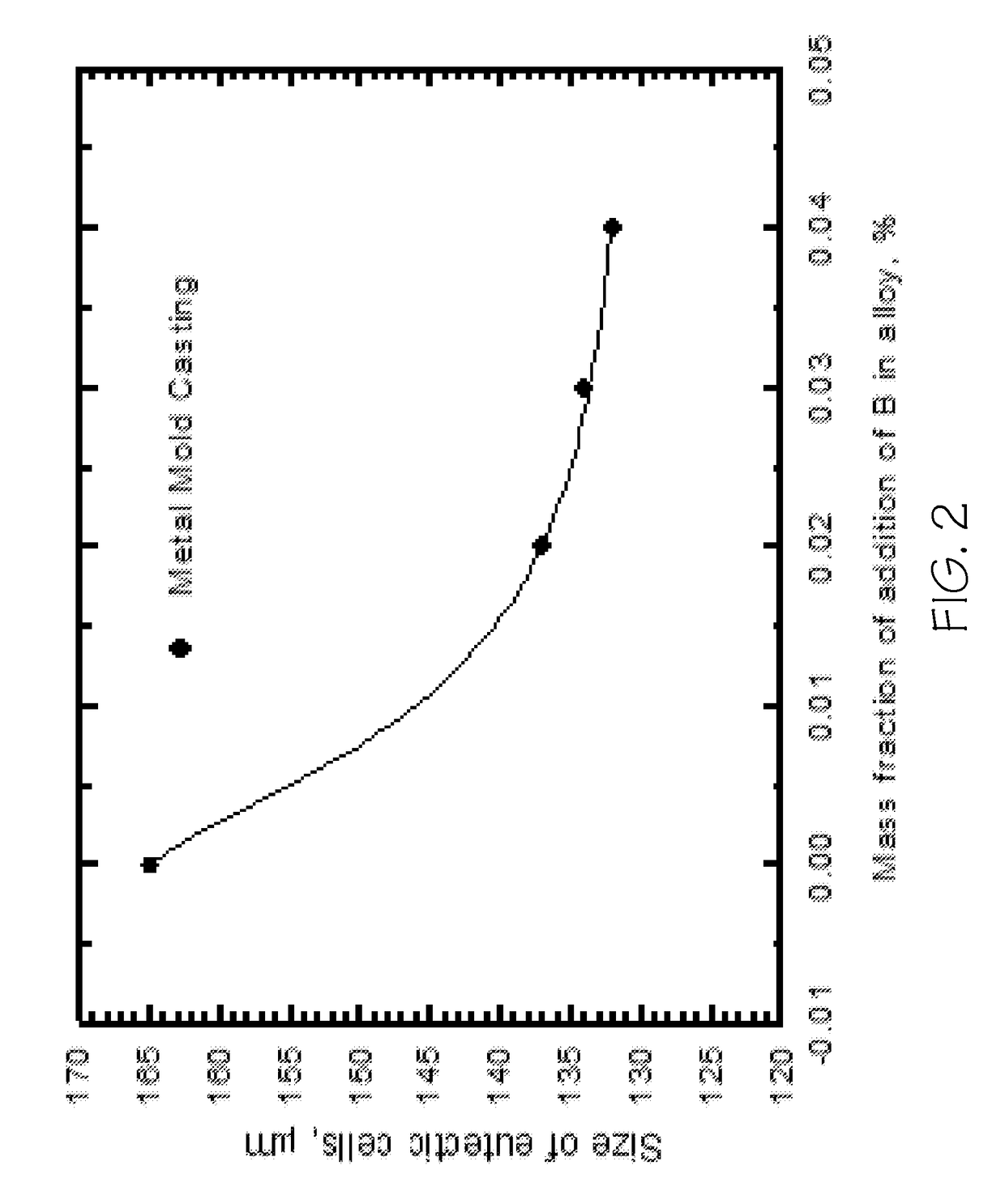

Special chilled cast iron roller for wire rod bar finishing mill rack and production process thereof

The invention relates to a roller and a production process thereof, in particular to the special chilled cast iron roller for a wire rod bar finishing mill rack and the production process thereof. Theroller is prepared from chemical components of an outer layer and a core part. The outer layer is prepared from the chemical components: 3.0 to 3.2 percent of C, 0.4 to 0.60 percent of Si, 0.3 to 0.5percent of Mn, less than or equal to 0.05 percent of P, less than or equal to 0.03 percent of S, 1.25 to 1.45 percent of Cr, 0.3 to 0.5 percent of Mo, 3.0 to 3.5 percent of Ni, 0.1 to 0.3 percent ofV, 0.06 to 0.15 percent of Re, and 0.2 to 0.4 percent of Nb; and the core part is prepared from the chemical components: 3.0 to 3.5 percent of C, 2.2 to 2.60 percent of Si, 0.40 to 0.60 percent of Mn,less than or equal to 0.05 percent of P, less than or equal to 0.03 percent of S, 0.8 to 1.2 percent of Cu, larger than or equal to 0.05 percent of Mg, and the balance Fe and a small amount of residual elements. According to the special chilled cast iron roller for a wire rod bar finishing mill rack and the production process thereof provided by the invention, a traditional advantage of the chilled cast iron roller is fully played, and a carbide morphology and a roller microstructure are improved through optimized component preparation and improvement of a heat treatment process, so that a precious alloy resource is saved, a comprehensive performance of the roller is improved, and a production requirement of a steel rolling enterprise is met with a reasonable cost performance; and the on-machine rolling quantity of the roller is improved by 1.7 times compared with bainite made of a traditional material, and the roller price is only half of the price of high-speed steel.

Owner:湖州中杭轧辊有限公司

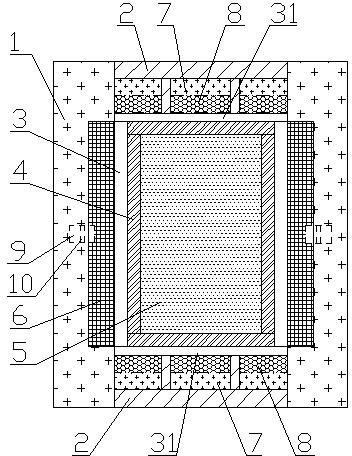

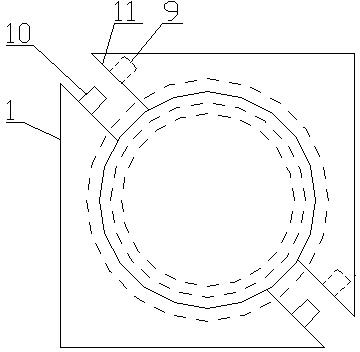

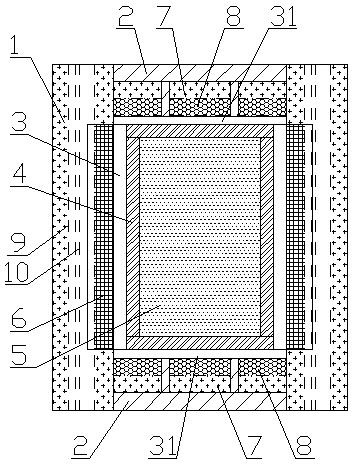

Sloping diamond synthesis block

InactiveCN102166498ACompression volume is smallReduce heat fatigueUltra-high pressure processesThermal fatiguePyrophyllite

The invention discloses a sloping diamond synthesis block, which comprises a graphite column, conductive steel rings at the two ends of the graphite column, and pyrophyllite blocks in the periphery of the graphite column and the conductive steel rings; the conductive steel rings are filled with pyrophyllite rings and dolomite rings; the periphery of the graphite column is provided with a heating element; an insulating element is arranged between the heating element and the graphite column; the pyrophyllite block consists of two half blocks buckled with each other; and a graphite column cavity is formed in the middle of the two buckled half blocks, and each half block is in a triangular prism shape. The sloping pyrophyllite blocks are formed, and a joint seam of the sloping pyrophyllite blocks is at the corner of the pyrophyllite blocks, and is staggered from the middle part of a non-heating top hammer; hot gas cannot rush to the non-heating top hammer, so that thermal fatigue of the non-heating top hammer can be obviously mitigated, and the top hammer is effectively protected; and the number of the broken non-heating top hammers is greatly reduced, the broken hammer accidents are reduced, the consumption of the hard alloy top hammer is greatly reduced, and the production cost is lowered.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

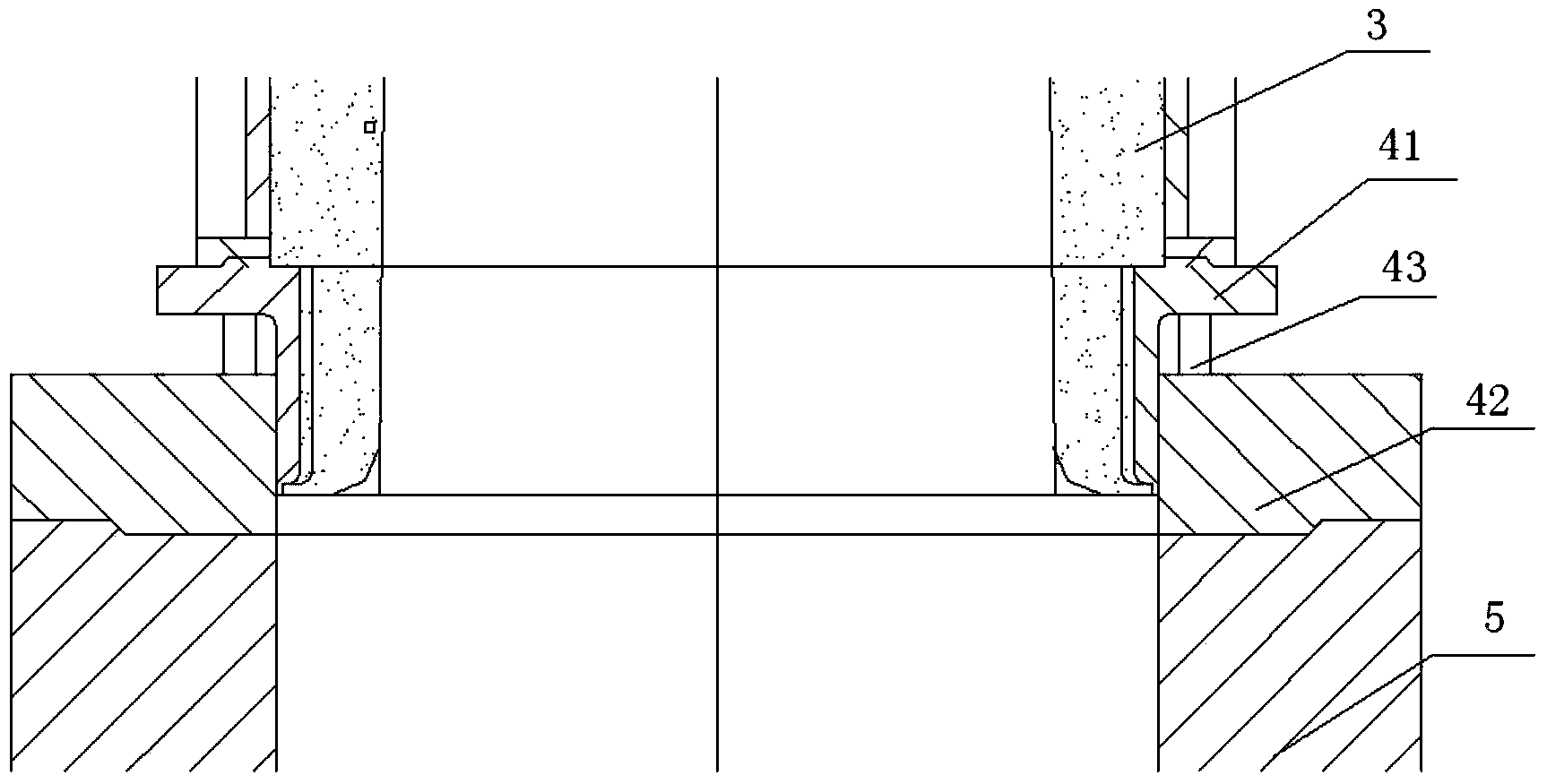

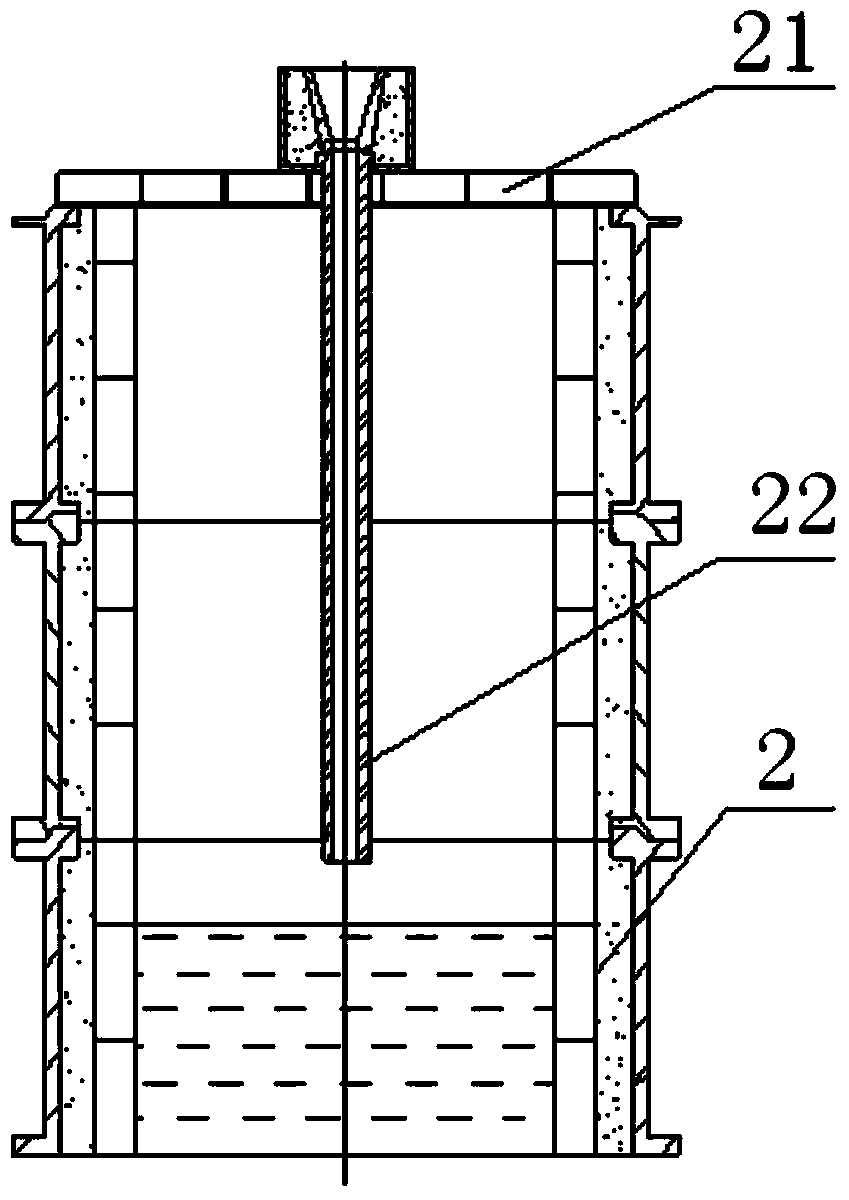

Mono-block casting mould system for large-scale cast steel supporting roller and casting method thereof

ActiveCN103658552ASolve the problem of large quantity and difficult formingPrevent shrinkage crackingFoundry mouldsCounter-pressure devicesMechanical propertyCasting

The invention relates to a mono-block casting mould system for a large-scale cast steel supporting roller and a casting method thereof. The system and the method are suitable for mono-block casting of cast steel supporting roller with a weight of 200 tons or more. The system and the method are different from the conventional technology, adopt a bottom-pouring and double-pouring system, a simple and practicable heat-insulation riser technology and a long nozzle after-teeming technology on the basis of a slide roller mould so as to produce a roller which has the advantages of no crack, capability of relieving element segregation, strong ultrasonic detection penetration ability, and excellent mechanical property of the work layer in the roller body; and especially adopts the long nozzle after-teeming technology so as to successfully solve the problems of segregation and cracks in the large-scale cast steel supporting roller neck.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

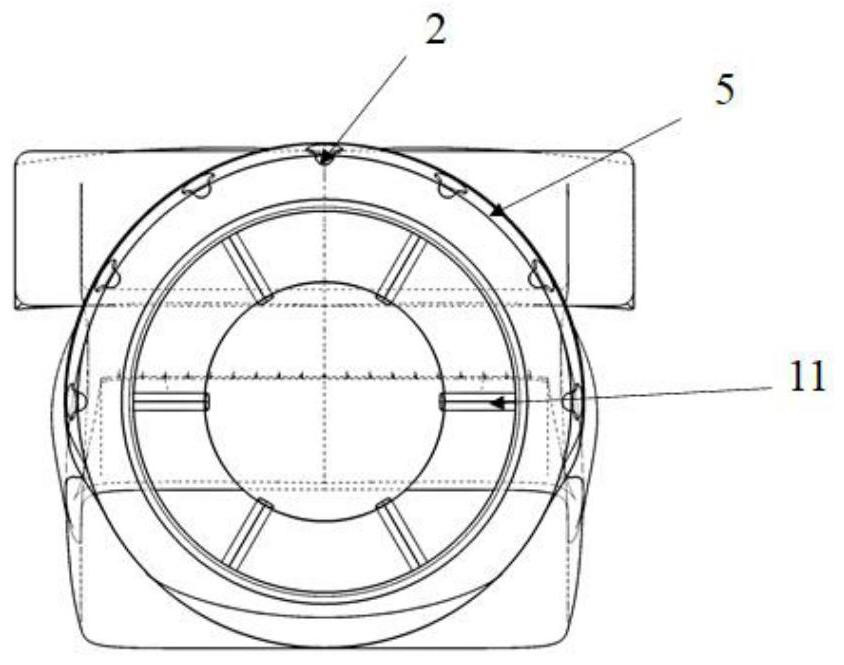

Heat absorber phase-change material heat-preservation method and device for tower type solar thermal power plant

ActiveCN105758020ALow costSmall temperature fluctuationsSolar heating energySolar heat devicesLiquid stateMolten salt

The invention discloses a heat absorber phase-change material heat-preservation method and device for a tower type solar thermal power plant. In case of cloud shielding, direct solar radiation is lower than a certain threshold, a liquid phase-change material can be released from the top of an outer wall surface of a heat absorber, the liquid phase-change material is adhered to the outer wall surface of the heat absorber, and as the liquid phase-change material is small in heat conduction coefficient, heat can be released to keep stable temperature when the liquid phase-change material is converted into a solid state, heat loss of the heat absorber is reduced, the wall temperature fluctuation of the heat absorber is reduced, the service life of the heat absorber can be prolonged, and a molten salt medium inside the heat absorber can be prevented from solidifying, and the system security is improved; when cloud shielding disappears, under the action of solar radiation, the solid phase-change material is liquefied and drops down, and the phase-change material is collected, fed back to the top of the heat absorber through a phase-change material conveying system, and thus can be repeatedly used.

Owner:ZHEJIANG UNIV

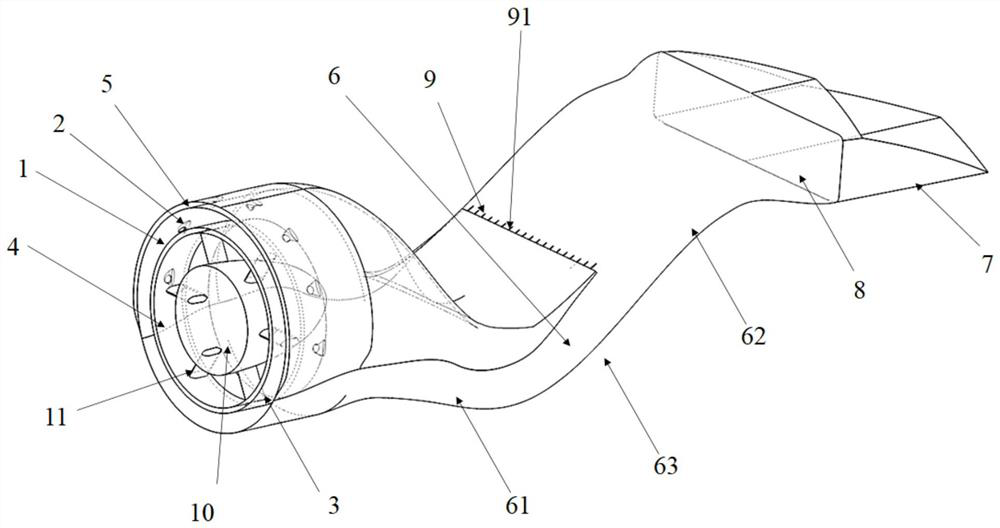

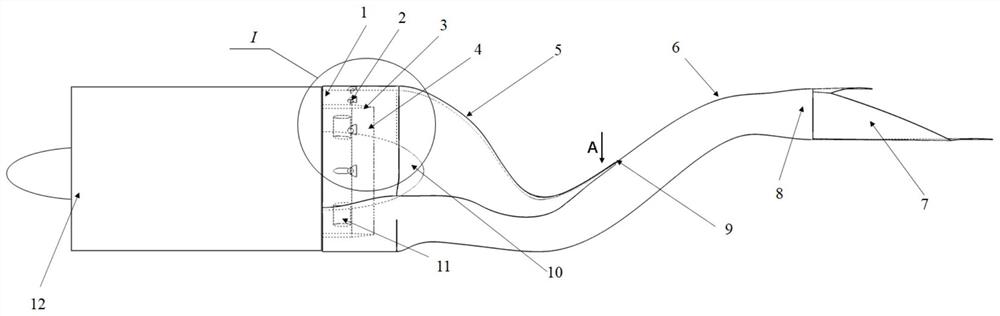

Double-S-bend convergent-divergent spray pipe with infrared suppression measure

ActiveCN113107705AReduce wall temperatureReduced intensity of mid-wave infrared radiationJet propulsion plantsEngineeringMechanical engineering

The invention discloses a double-S-bend convergent-divergent spray pipe with an infrared suppression measure, and belongs to the field of aero-engines. The double-S-bend convergent-divergent spray pipe comprises an engine outer duct, an engine mixer, an engine inner duct, a cooling channel, a spray pipe contraction section, a spray pipe expansion section and a spray pipe throat part, wherein the cooling channel is located on the periphery of a leeward area of the S-bend spray pipe and is composed of a cooling channel wall covering the leeward area of the S-bend spray pipe and an S-bend spray pipe wall; an opening is formed in the starting end of the cooling channel, and the other sides are connected with the S-bend spray pipe wall through the edge of the cooling channel wall to form a closed structure and communicate with the interior of the S-bend spray pipe through bypass air inlet holes and cooling outlets; and the plurality of bypass air inlet holes are evenly distributed in the starting end of the cooling channel in the circumferential direction, and the cooling outlets are located in the tail end of the cooling channel and communicate with the S-bend spray pipe through a plurality of cooling air outlet holes. The temperature of the wall surface of the spray pipe is reduced by airflow in the cooling channel, so that the infrared radiation characteristic of the spray pipe is reduced; and flow separation of the leeward area of the double-S-bend spray pipe is improved through airflow exhausted by cooling holes, so that the thrust of the spray pipe is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

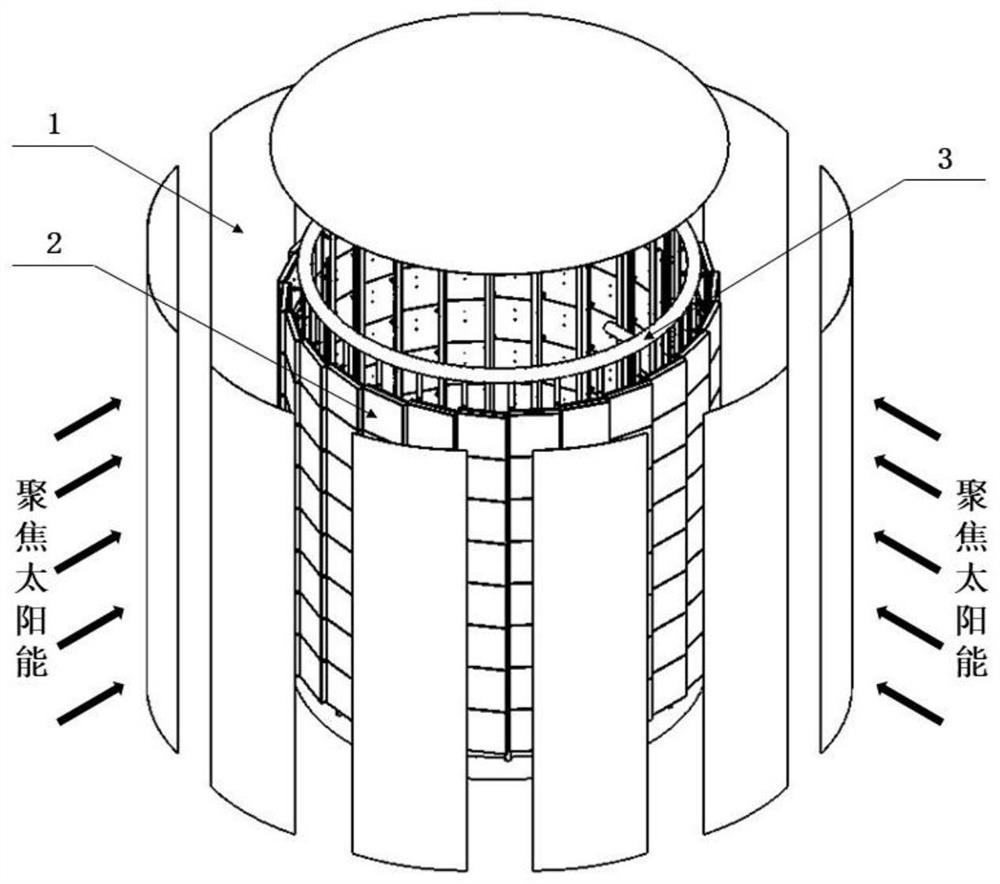

Novel flat plate type heat absorber for solar tower type power generation and system using novel flat plate type heat absorber

ActiveCN112856832AAvoid direct heat exchangeReduce thermal stressSolar heating energyCollector working fluidsHeat flowHeat losses

The invention discloses a novel flat plate type heat absorber for solar tower type power generation and a system using the novel flat plate type heat absorber. The system comprises a windshield, a flat plate type heat absorber and a circulation pipeline, wherein the flat plate type heat absorber is a main element for photo-thermal conversion and heat energy transmission, the windshield avoids heat loss of the heat absorber, and the circulation pipeline guarantees circulation of a working fluid. In the working process, a heat transfer fluid in the flat plate type heat absorber absorbs heat and evaporates from the evaporation face and releases heat and condenses on the condensation face, the condensed heat transfer fluid flows back to the evaporation face to enter the next cycle of work, and heat is transferred to the working fluid through the gas-liquid phase change process. According to the flat plate type heat absorber, through arrangement of the grids and innovation of the structure, the height of the heat absorber is reduced by more than half compared with a traditional heat pipe type heat absorber, the windward area is reduced, the gravity center is lowered, and the stability of the flat plate type heat absorber is improved. Meanwhile, a heat pipe principle indirect heat transfer mode is adopted, so that the flat plate type heat absorber can resist high heat flow density and heat shock, and the service life is prolonged.

Owner:NANJING UNIV OF TECH

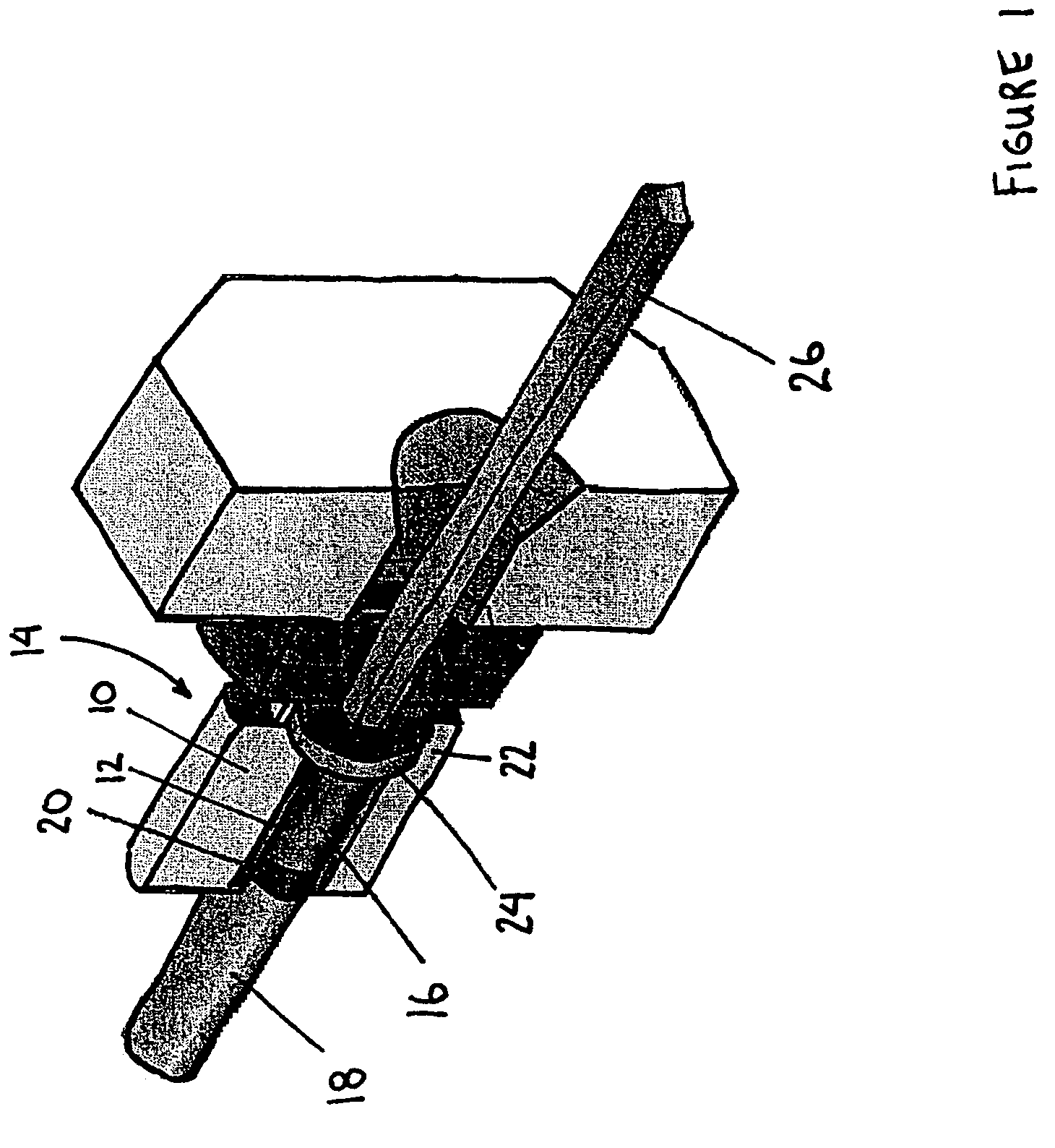

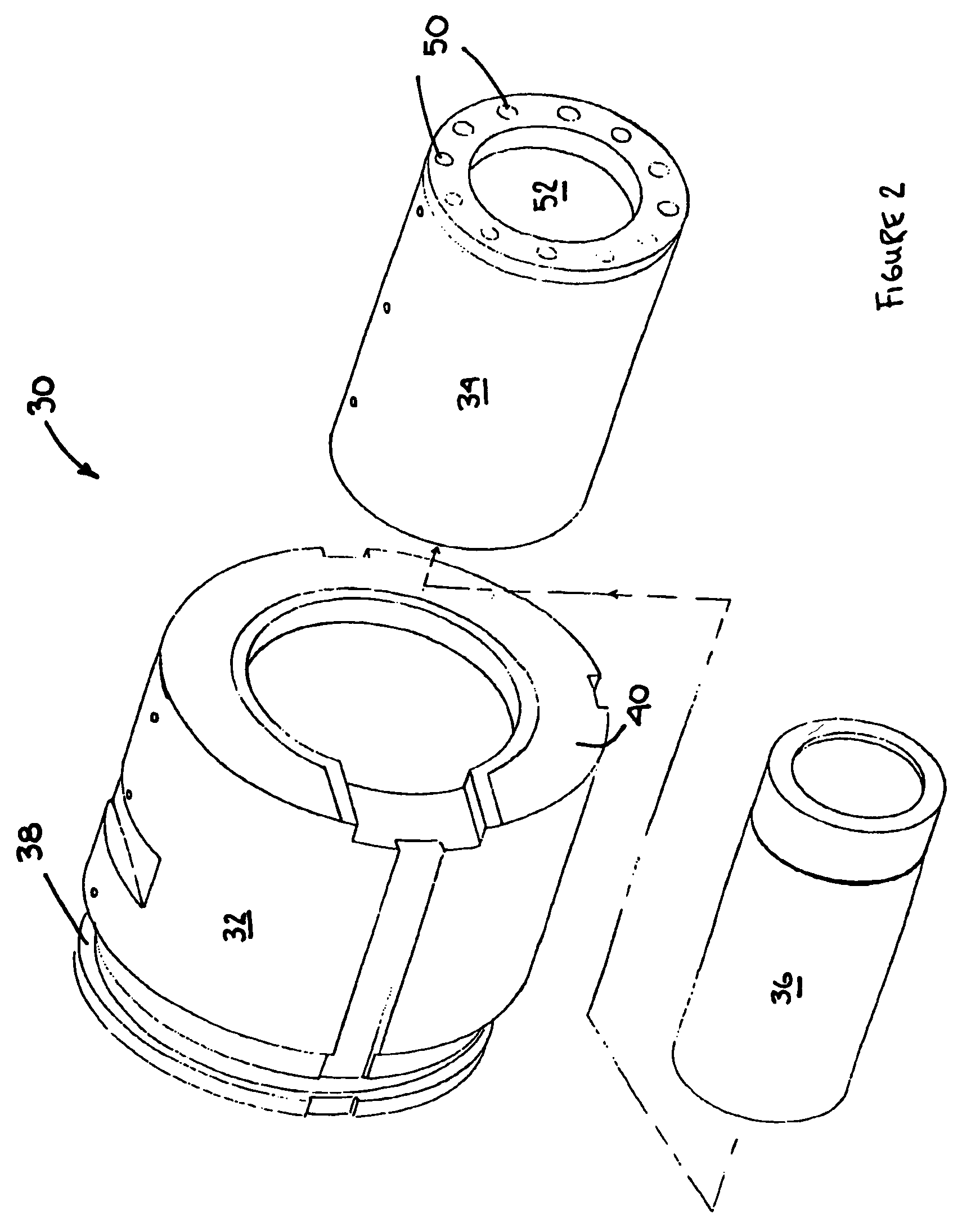

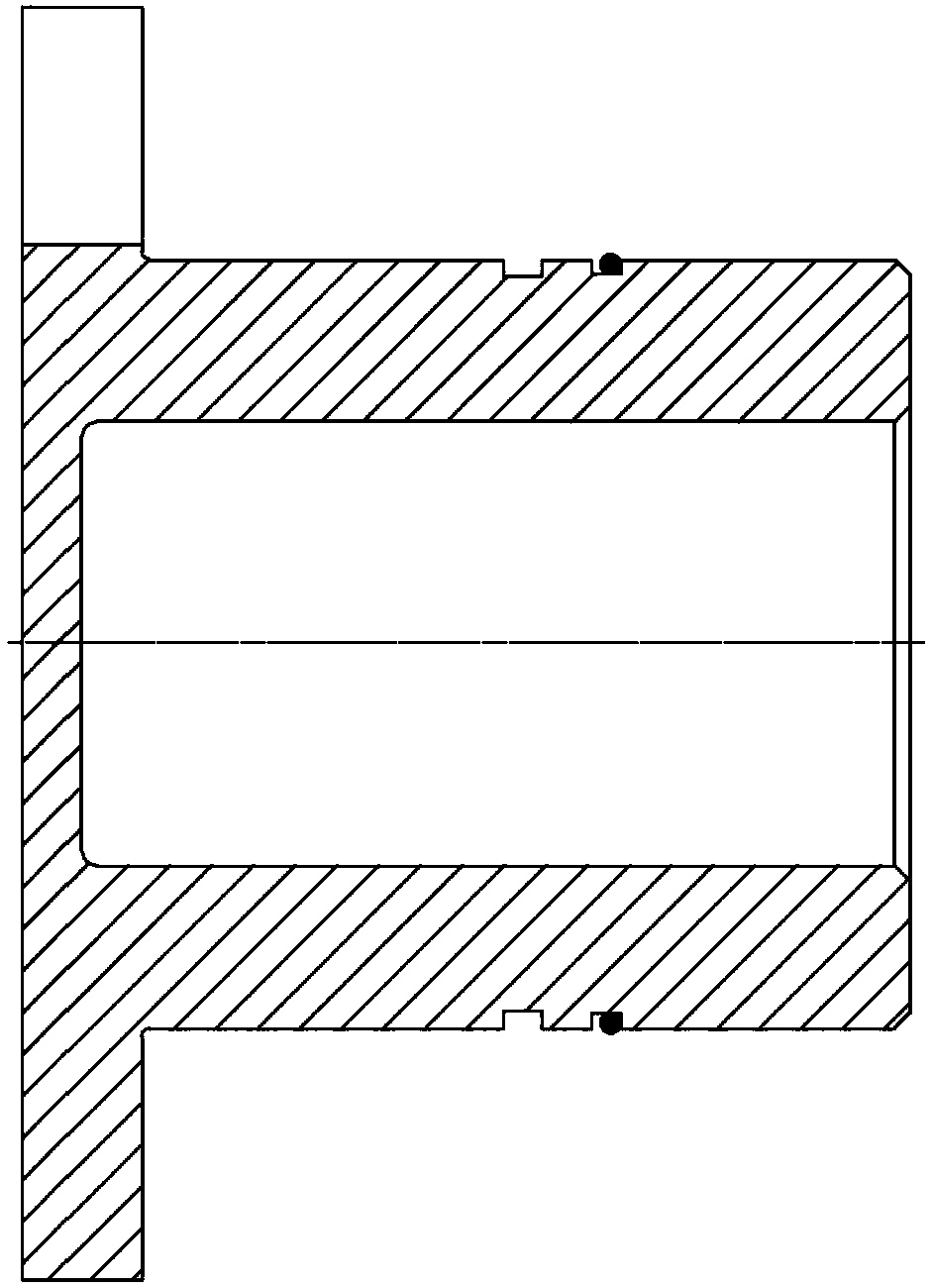

Thermal control extrusion press container

ActiveUS7272967B2Easy to controlReduce the possibilityShaping toolsExtrusion containersEngineeringThermal control

A subliner for use in a metal extrusion press, the subliner comprising an elongate annular body having an outer surface dimensioned for placement within an outer mantle, and an inner surface dimensioned to receive an inner liner. The subliner further comprises at least one heating element positioned longitudinally between the outer and inner surfaces of the elongate annular body for providing heat in at least one selected region of the subliner, in close proximity to the inner liner.

Owner:ROBBINS PAUL

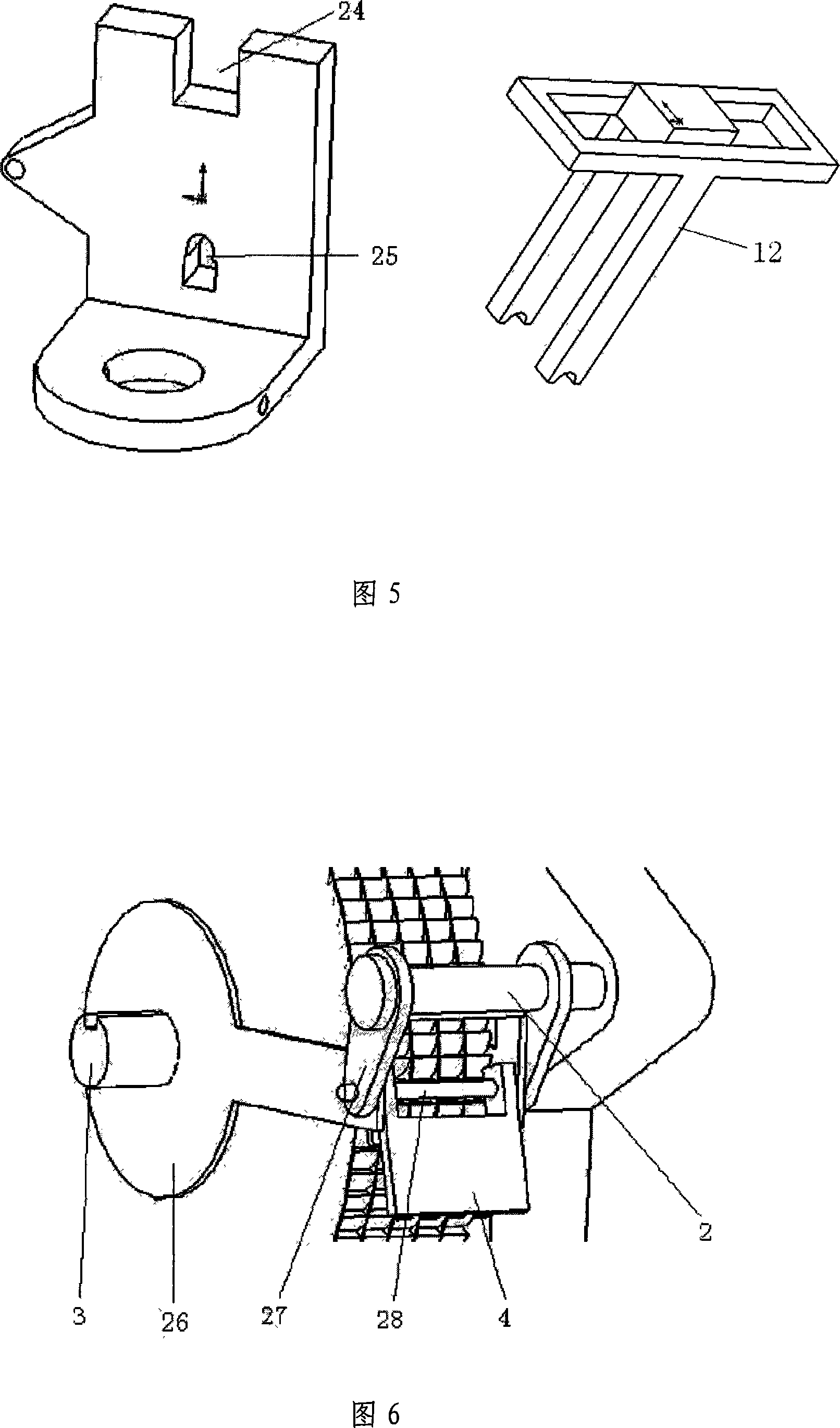

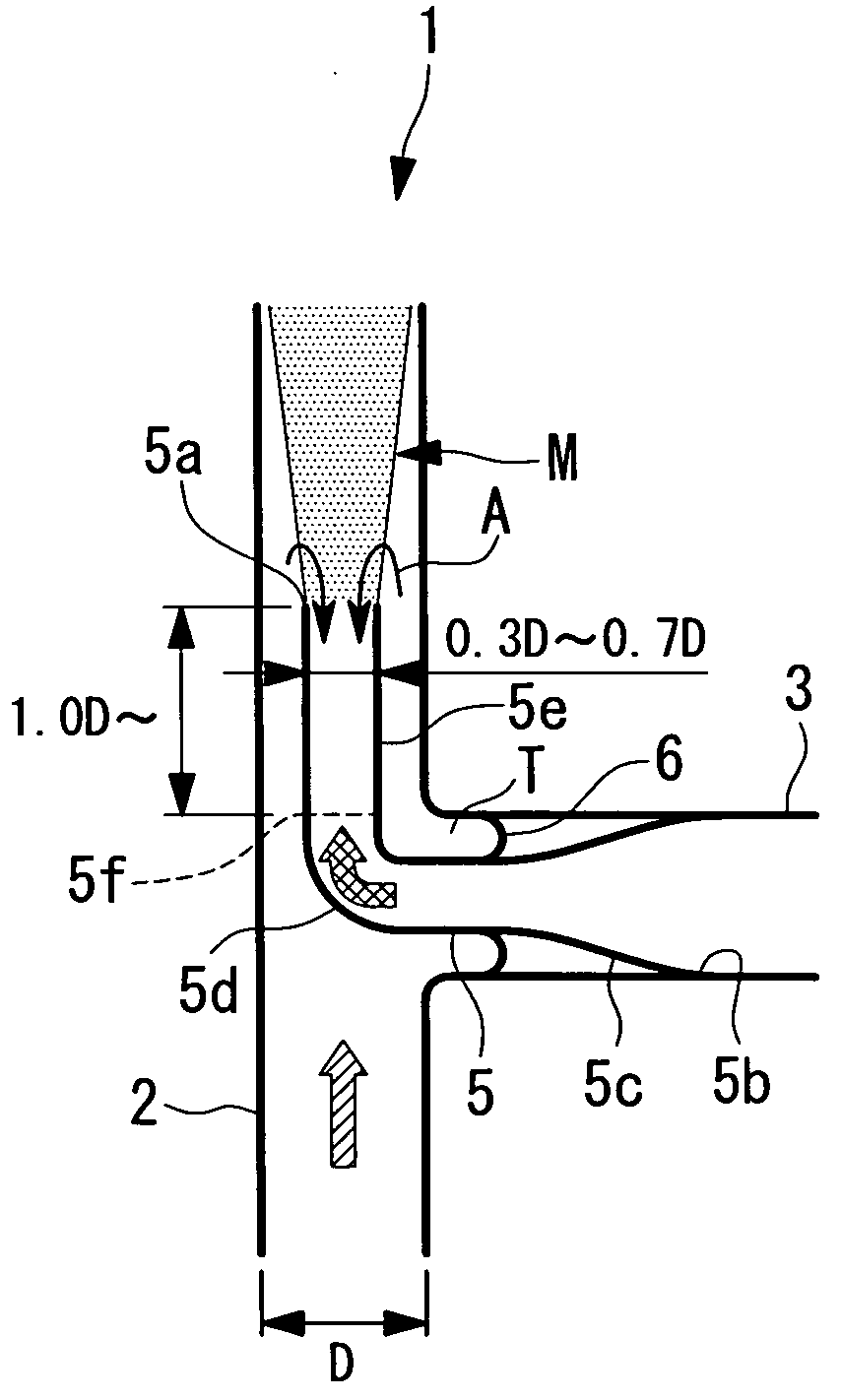

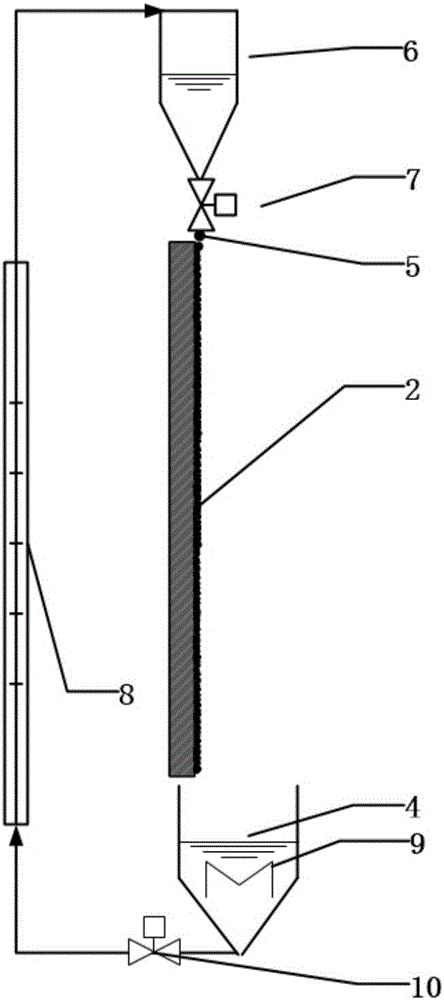

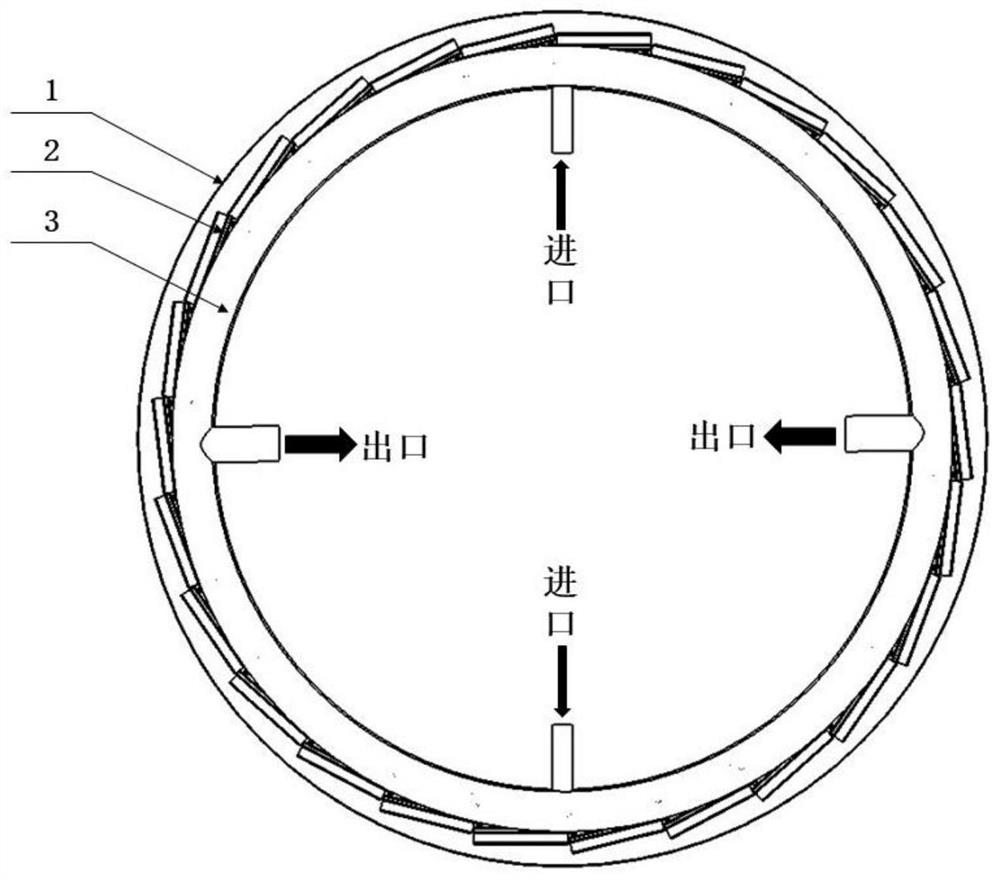

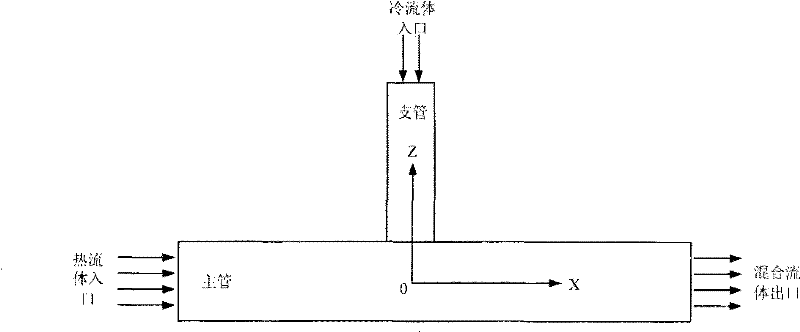

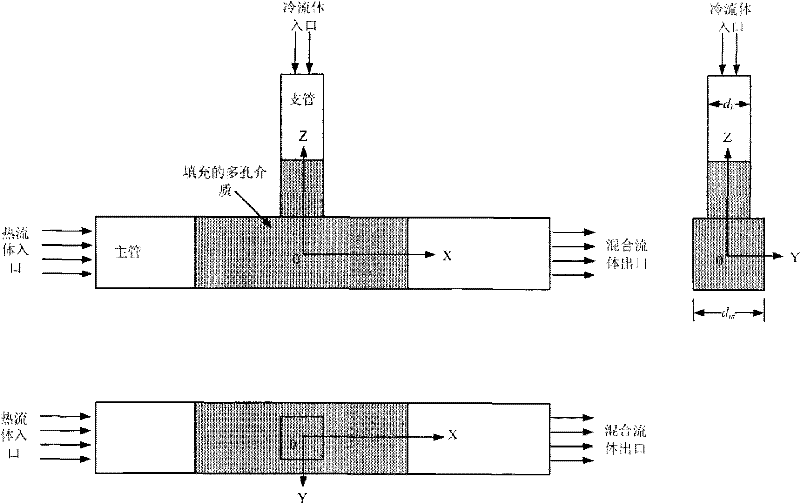

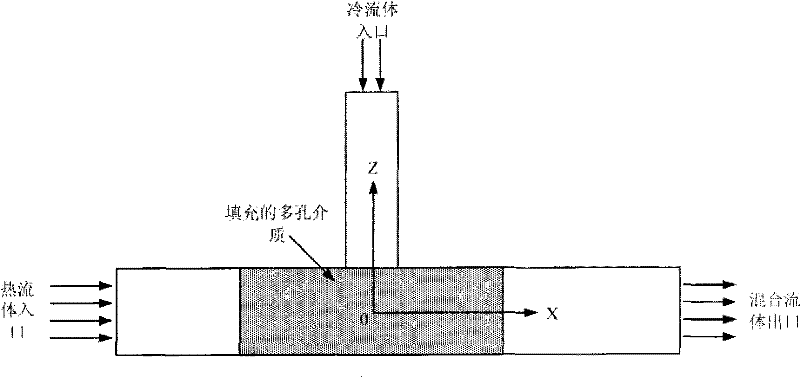

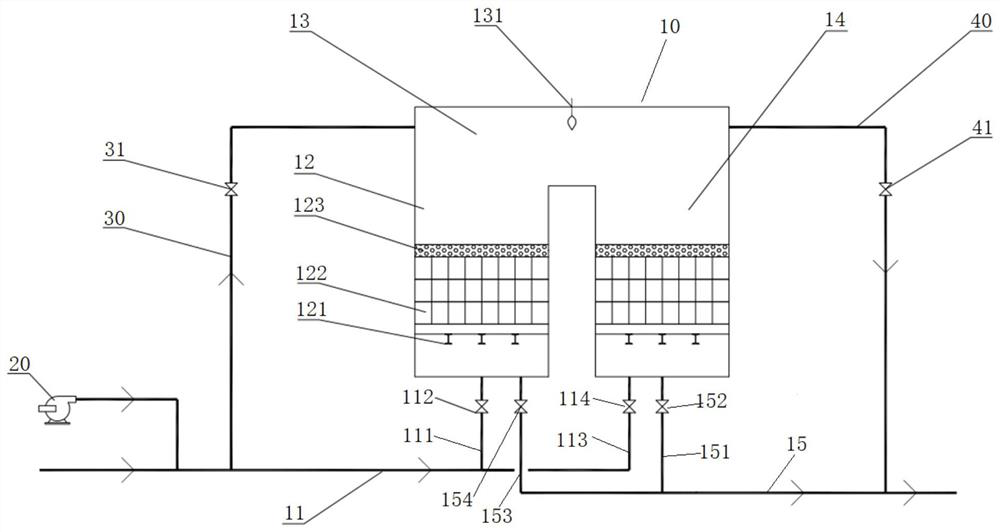

Device and method for reducing thermal fatigue in cold and thermal fluid mixing process in T-shaped pipe

ActiveCN101598258BReduce heat fatigueWeaken thermal shockPipe protection against damage/wearThermal fatiguePorous medium

The invention discloses a device for reducing thermal fatigue in the cold and thermal fluid mixing process in a T-shaped pipe, and the device is composed of porous media which is installed in the cold and thermal fluid mixing zone of the T-shaped pipe; the invention further discloses a method for reducing thermal fatigue in the cold and thermal fluid mixing process in the T-shaped pipe. In the invention, the fluid mixing zone of the T-shaped pipe is filled with porous media, and speed fluctuation and temperature fluctuation in the cold and thermal fluid mixing process can be restrained, thus weakening the thermal shock of the cold and thermal fluid on the pipe wall, effectively reducing transient temperature and time average temperature and temperature fluctuation range, improving energy spectrum characteristics of transient temperature fluctuation and reducing the thermal fatigue of the T-shaped pipe.

Owner:TSINGHUA UNIV +1

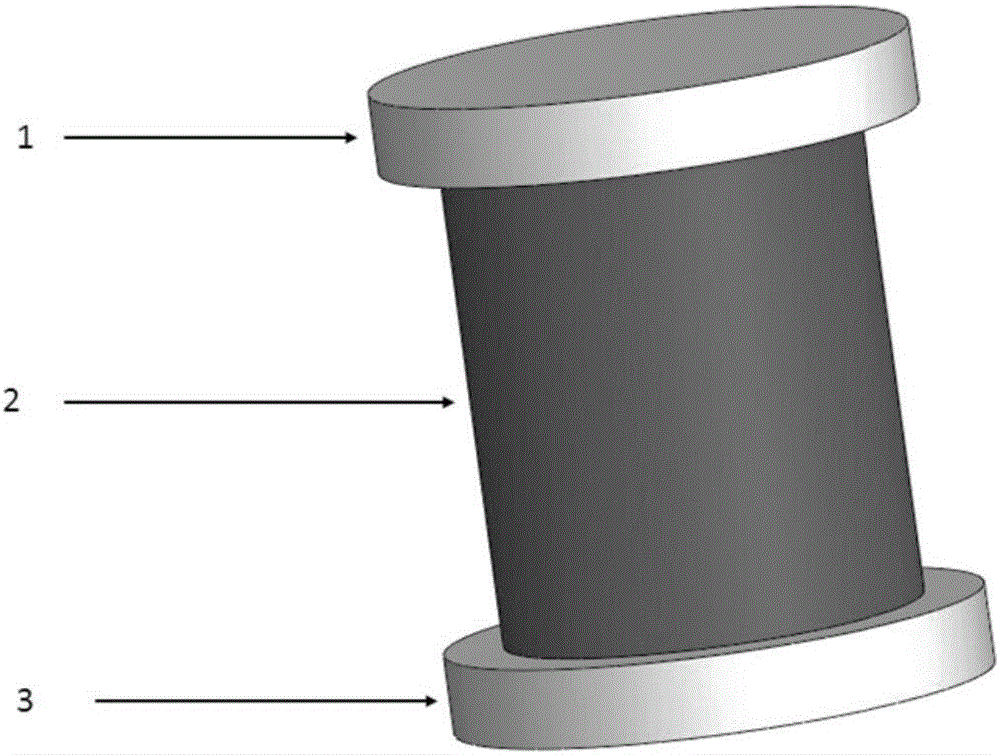

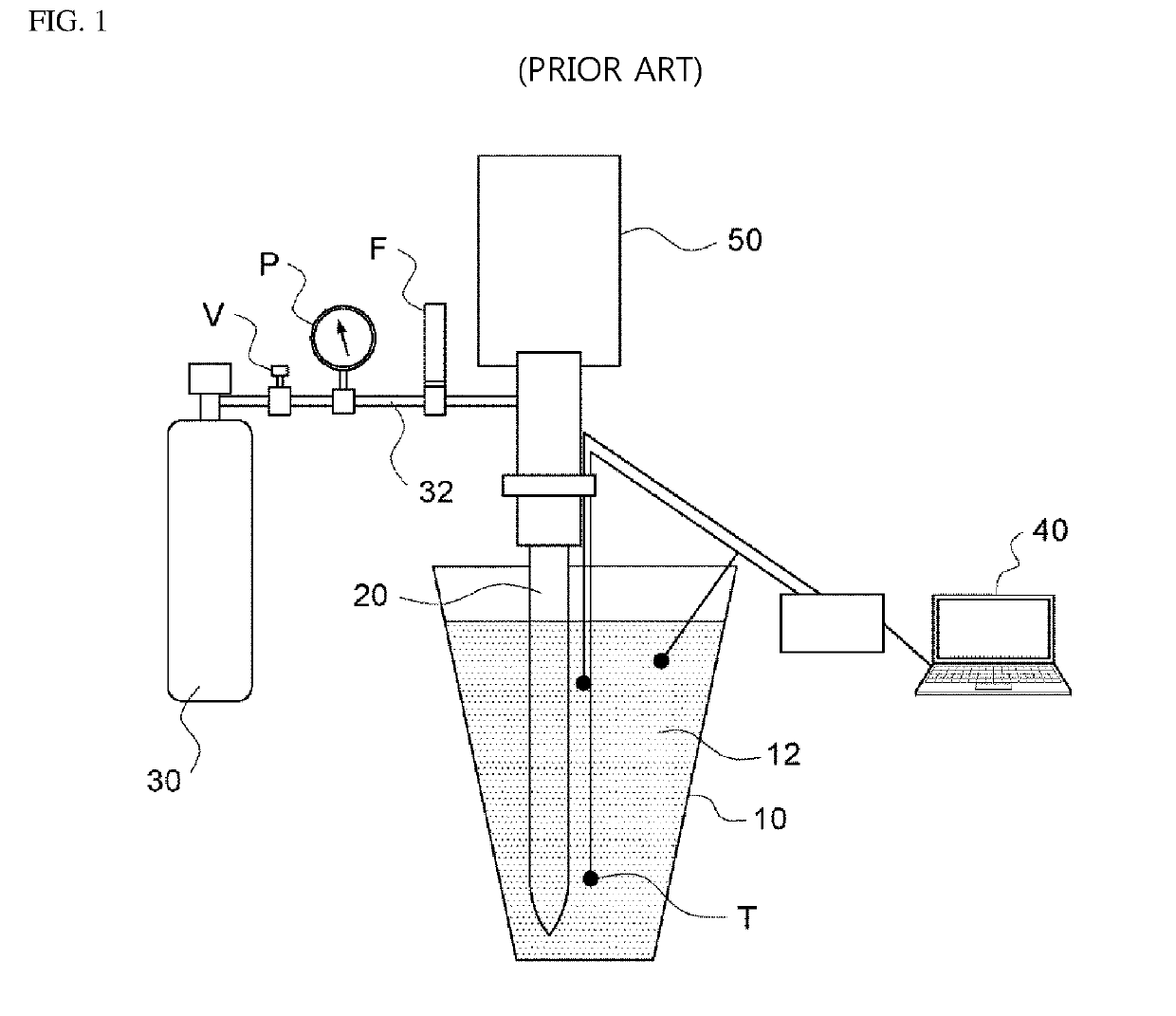

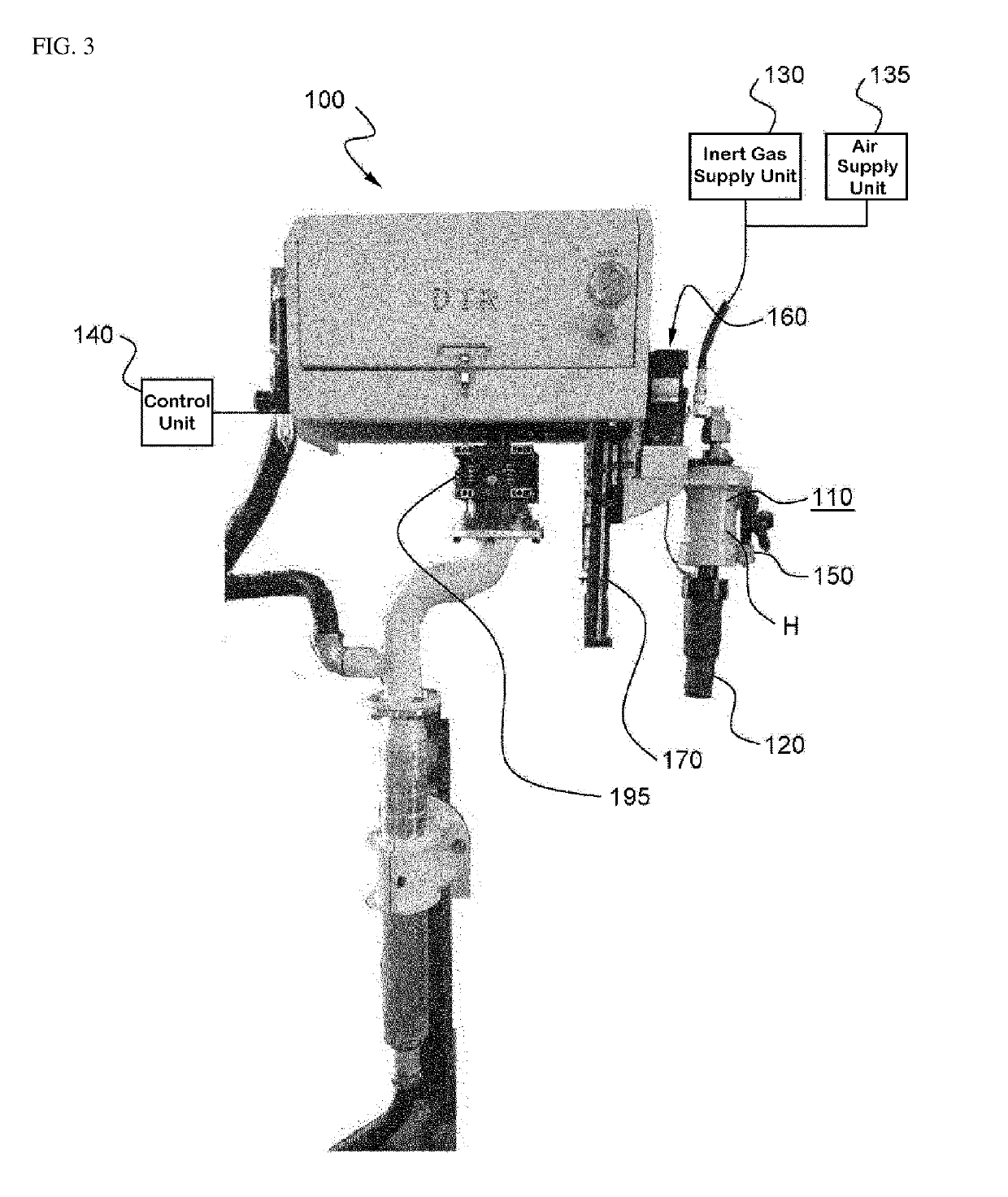

Semi-solid slurry generator and high pressure die casting method

Disclosed are a semi-solid slurry generator and a die casting method which can obtain a dense structure in the entire cross section of a molded product by uniformly dispersing and stirring an inert gas in a slurry compared to a conventional one. The die casting method comprises: a step of immersing a rotating diffuser in a molten metal contained in a ladle to rotate and stir the molten metal while being supplied with an inert gas, or rotating and stirring the molten metal and the inert gas, which are sucked into a pumping impeller, while being ejected through a hole provided on a side surface of the impeller by stirring the same, such that the molten metal is cooled while gas bubbles caused by the inert gas are uniformly dispersed in the molten metal, thereby forming a semi-solid slurry; and a step of pressurizing and injecting the semi-solid slurry into a mold of a molding machine.

Owner:DTR

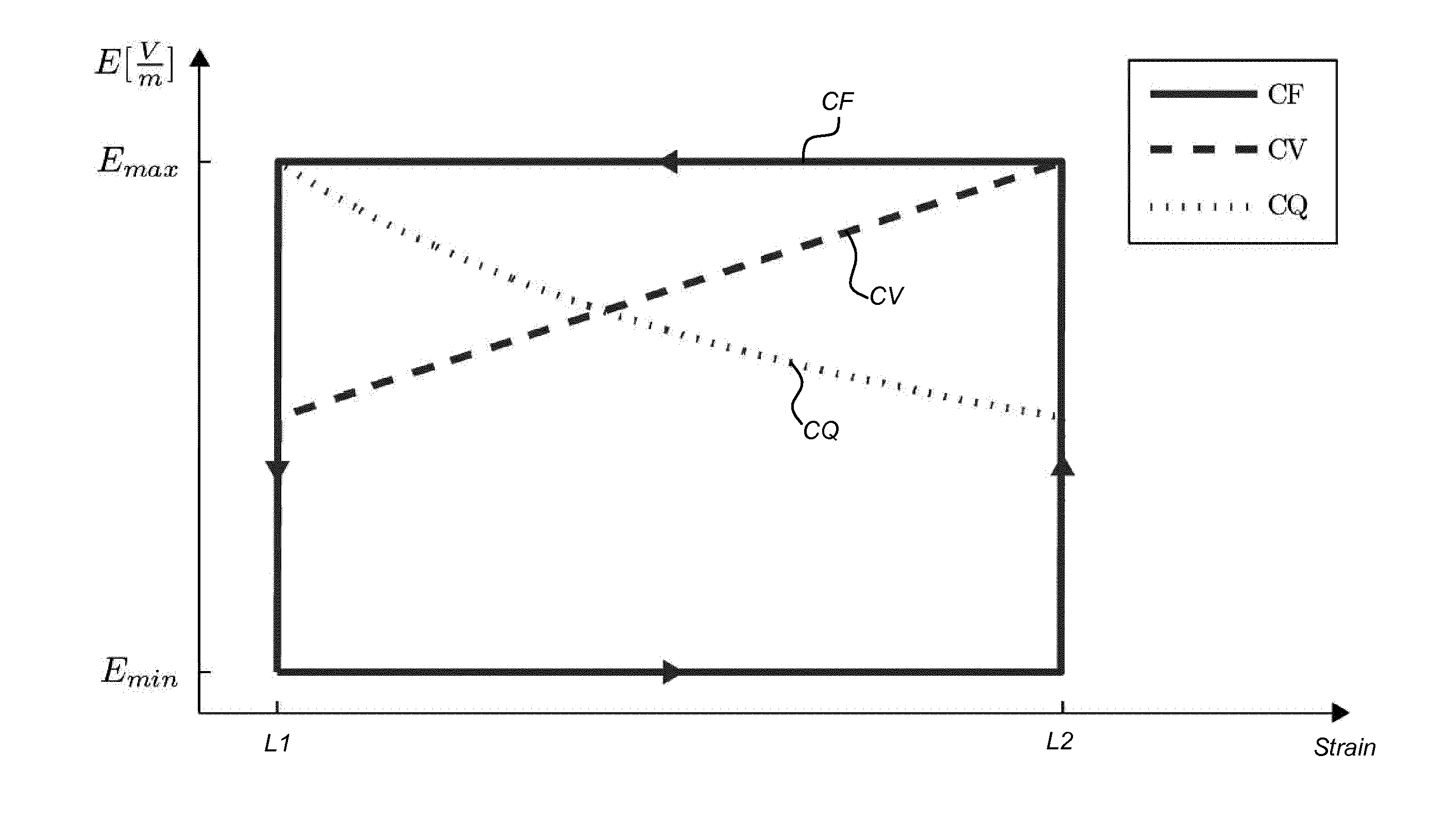

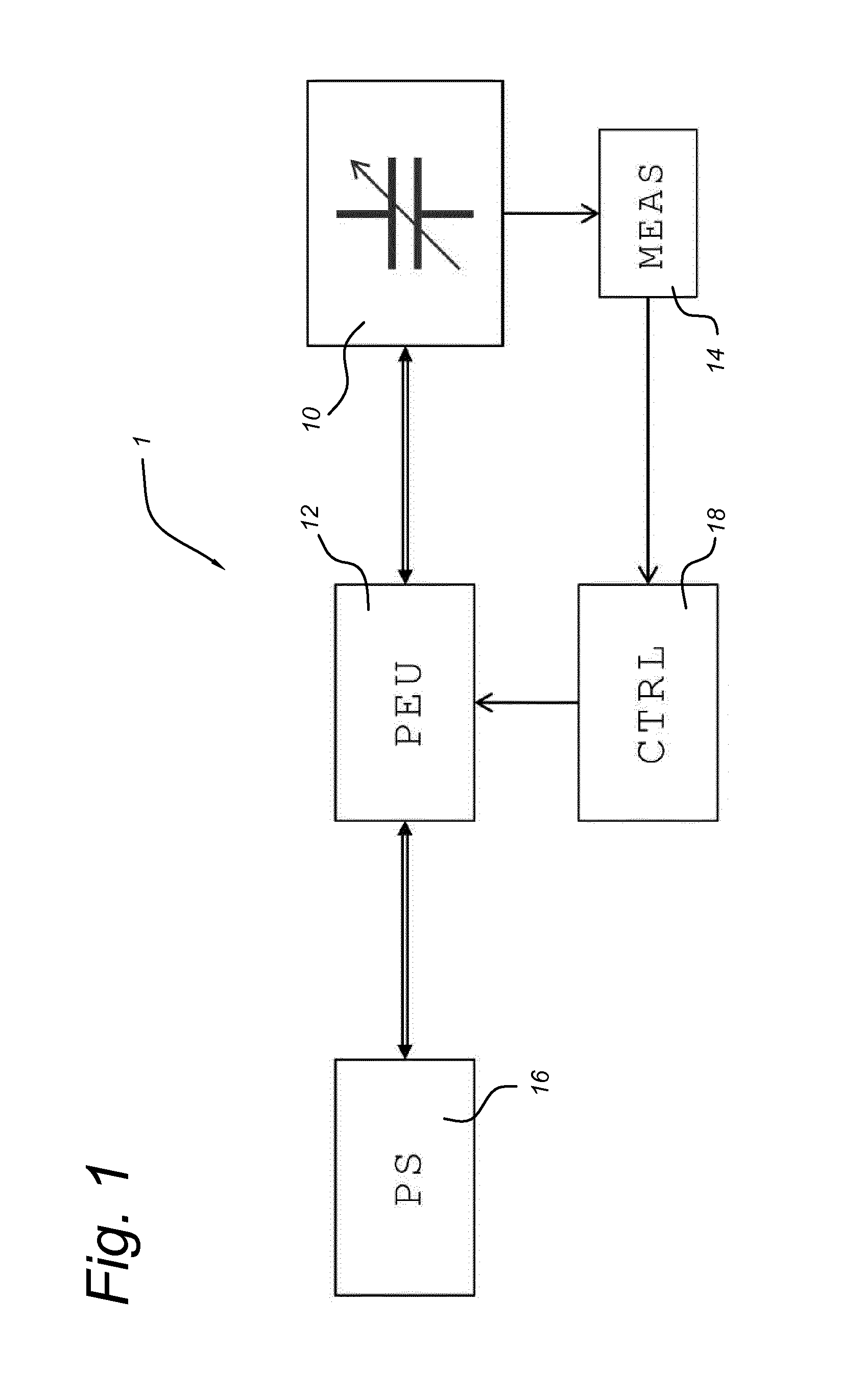

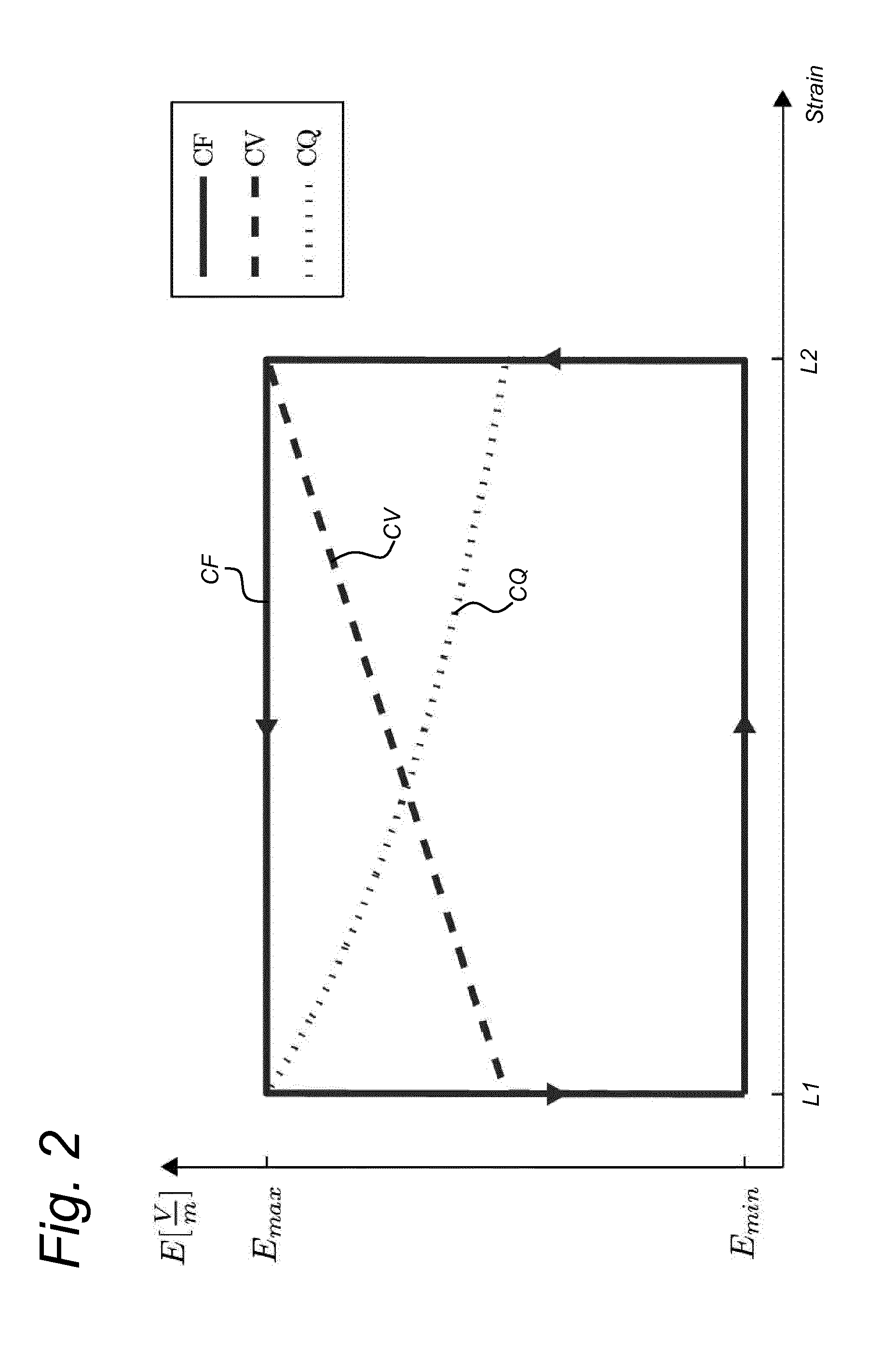

Method and system for harvesting energy using an eap based deformable body

ActiveUS20150076962A1Allow to operateExtended durationPiezoelectric/electrostriction/magnetostriction machinesInfluence generatorsCapacitanceSynthetic materials

Method for harvesting energy using an EAP based deformable body. The EAP based deformable body is an elastically deformable body including an arrangement of stretchable synthetic material and electrodes being arranged as a variable capacitor with a capacitance that varies as the deformable body stretches and relaxes. The method includes: looping through an energy harvesting cycle with a) stretching the deformable body from a minimal relaxed size L1 to a maximal stretched size L2; b) at the maximal stretched size electrically charging of the variable capacitor to create an electric field over the capacitor with an upper electric field level value; and subsequently c) a relaxation step from maximal stretched size to the minimal relaxed size; d) at the minimal relaxed size of the deformable body, electrically discharging the capacitor to a minimal charge level and a minimal electric field level value.

Owner:SINGLE BUOY MOORINGS INC

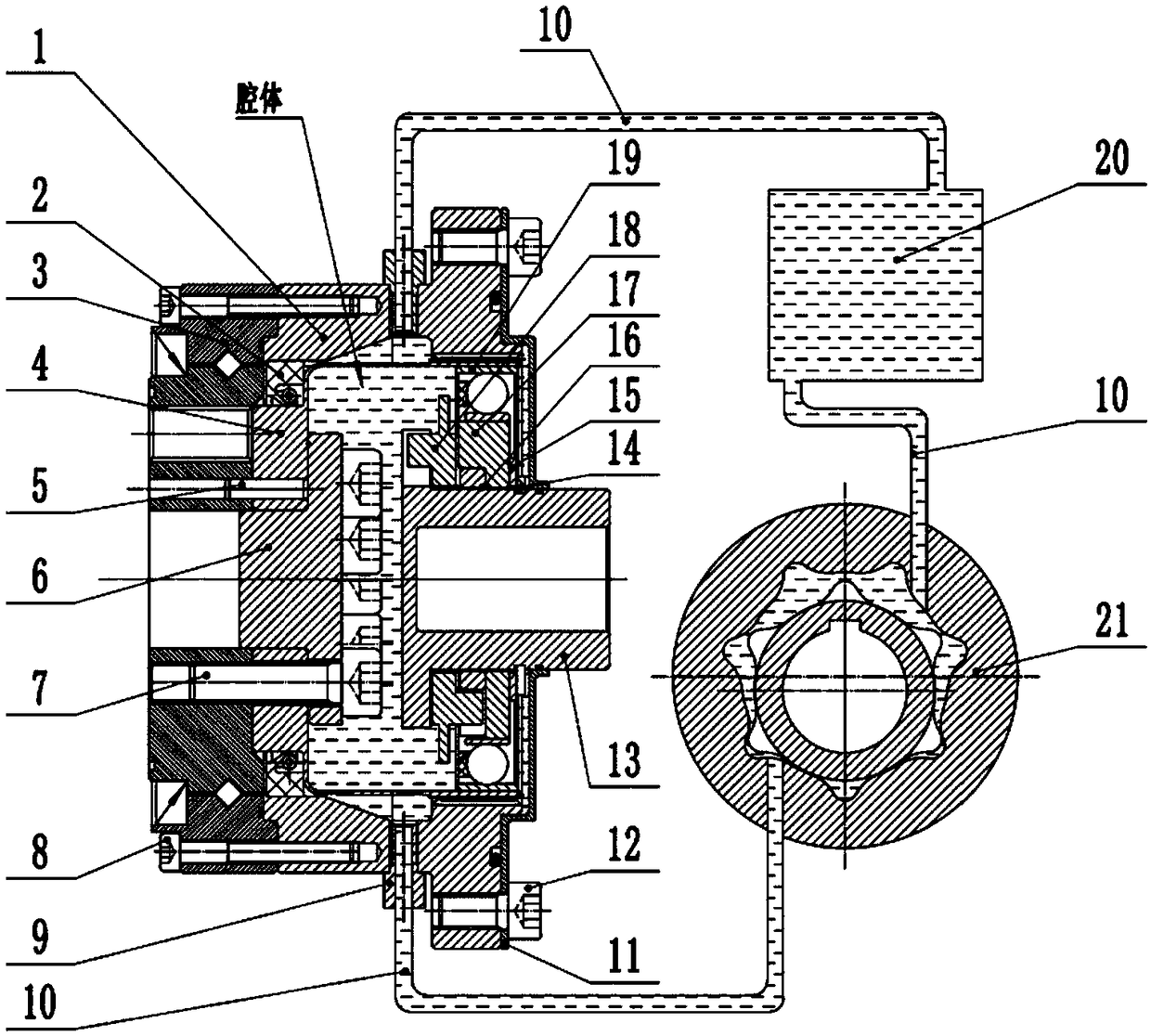

Forced oil lubrication harmonic reducer and method thereof

ActiveCN109505945AExtended service lifeReduce friction and wearGearingGear lubrication/coolingHarmonicThreaded pipe

The invention discloses a forced oil lubrication harmonic reducer and a method thereof. The forced oil lubrication harmonic reducer structurally comprises a harmonic reducer body, a threaded pipe joint, an oil conveying hose, an oil tank and an oil pump, the harmonic reducer body comprises a rigid wheel, a soft wheel and a wave generator, the outer ring of the rigid wheel is provided with two symmetrical threaded holes for being connected with the oil conveying hose, lubricating oil in the oil tank enters a sealing cavity formed by the rigid wheel and the soft wheel and the overall cavity is filled with the lubricating oil during running of the oil pump, continuous lubrication between inner teeth of the rigid wheel and outer teeth of the soft wheel is realized, frictional wear of the innerteeth of the rigid wheel and the outer teeth of the soft wheel can be reduced, temperature rise of the harmonic reducer is reduced, and the service life of the harmonic reducer is prolonged.

Owner:浙江环动机器人关节科技有限公司

Porous blocker bar for plate-fin heat exchanger

ActiveUS20130191079A1Improve the immunityReduce heat fatigueHeat exchanger casingsStationary tubular conduit assembliesThermal fatigueEngineering

A plate-fin heat exchanger adapted to reduce thermal fatigue is described. The plate-fin heat exchanger includes a cold fluid pathway running along a first axis, a hot fluid pathway running along a second axis perpendicular to the first axis, and at least one porous blocker bar running along the first axis. The porous blocker bar includes a set of pores adapted to control the flow along the hot fluid pathway and coupled to an inlet of the hot fluid pathway.

Owner:HONEYWELL INT INC

Regenerative thermal oxidation device and process for processing electroplating sludge sintering waste gas

PendingCN111750367ASolve the problem of heat recovery efficiency dropAchieve self-sustained combustionHeat storage plantsIncinerator apparatusCombustion chamberThermodynamics

The invention relates to a regenerative thermal oxidation device and process for processing electroplating sludge sintering waste gas. The temperature of the inlet waste gas entering an RTO heat storage bed and the flow rate of the waste gas flowing through the heat storage bed are flexibly adjusted by arranging an inlet fresh air fan. An RTO cold bypass regulating pipeline and heat bypass regulating pipeline are arranged to flexibly adjust the heat load distribution, so as to adjust the temperature of an RTO regenerator and combustion chamber and improve the heat recovery efficiency. Throughthe fresh air fan and the cold and heat bypass adjustment, the organic silicon burned in the middle of the heat storage body can be avoided, and at the same time, a replacement layer is arranged on the top of the heat storage bed to solve the problem that the bed is blocked and difficult to clean. Through targeted improvement of the RTO device and process, the regenerative thermal oxidation deviceand process can adapt to the characteristics of electroplating sludge sintering waste gas, solve existing practical problems, realize long-term safe and efficient operation, meet the requirements ofemission standards, remove more than 99% volatile organic compounds, and have good economic and environmental benefits.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

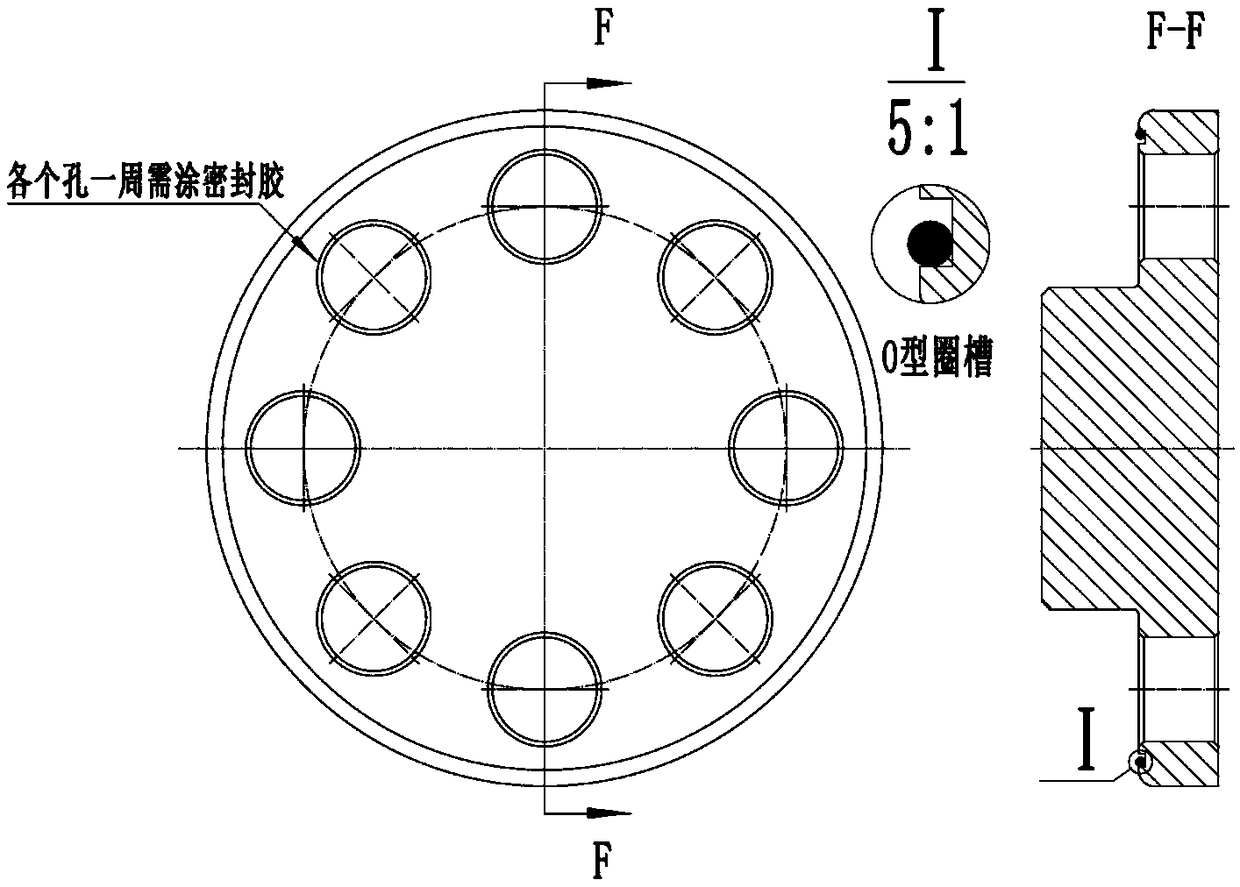

Full-premixing burner, heat exchanger and wall hanging stove

PendingCN109323257APlay a guiding roleAvoid clutterFluid heatersGaseous fuel burnerPlate heat exchangerCombustor

The invention belongs to the technical field of burners, and discloses a full-premixing burner, a heat exchanger and a wall hanging stove. The burner comprises an air inlet plate and a burning wall, aplurality of air inlet holes are uniformly formed in the air inlet plate in the circumferential direction, the air inlet holes face the burning wall, and are connected with the air inlet plate in thedirection opposite to the burning wall; the burning wall is in a circular barrel shape with a closed end, one opened end of the burning wall is fixedly connected with the air inlet plate; and burningholes are uniformly distributed in the circular barrel wall of the burning wall. The full-premixing heat exchanger comprises the burner above, the heat exchanger and a shell, wherein the heat exchanger is arranged around the burning wall of the burner, and the shell is used for covering the burner and the heat exchanger to form an air inlet component. According to the full-premixing burner, the heat exchanger and the wall hanging stove, the burner can guide gas flow, so that mixed gas is directly sprayed to the burning wall and is sprayed out from the burning holes in the burning wall, flamecan burn above the burner due to the fact the gas flow is strong, so that the burner can be prevented from bearing high temperature, and loss and fatigue of burner materials can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com