Full-premixing burner, heat exchanger and wall hanging stove

A burner, full premix technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of low heat exchange efficiency, disordered flame direction, long distance, etc., to improve heat exchange efficiency and reduce heat. Fatigue, heat loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment relates to a wall-hung boiler, and the wall-hung boiler is installed with a fully premixed heat exchanger.

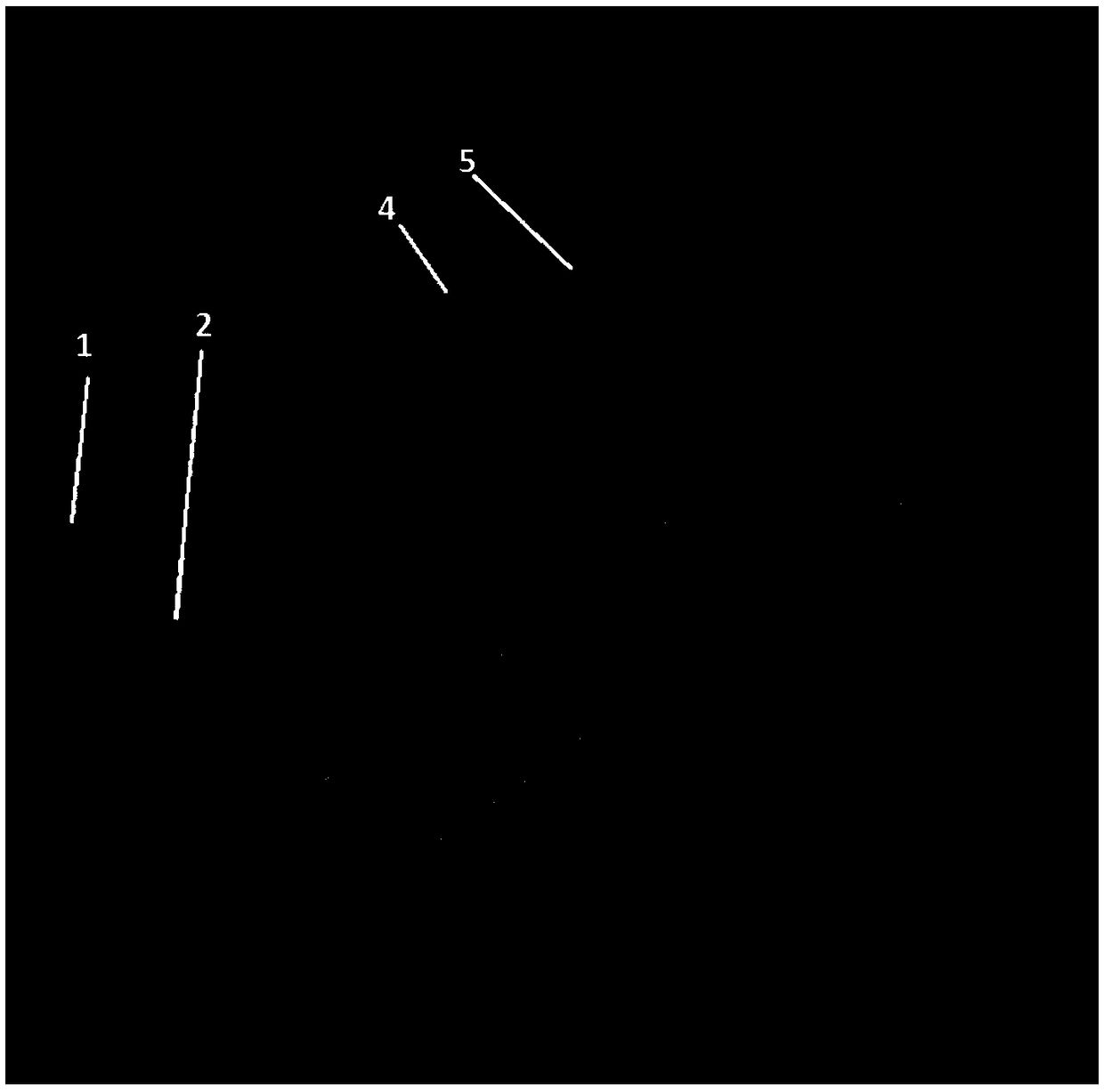

[0048] The full premix heat exchanger includes a full premix burner 6, a heat exchanger 7 and a casing 8, the heat exchanger 7 is arranged around the combustion wall 4 of the burner 6, and the casing 8 connects the burner 6 1. The heat exchanger 7 is covered and forms an air intake component. The air intake component includes a pancake-shaped air intake chamber 9 at the front end of the air intake plate 1 of the burner 6 and an air intake duct 10 communicating with the edge of the air intake chamber 9 . The combustion wall 4 of the burner 6 is fixedly connected with the air intake chamber 9 by screws.

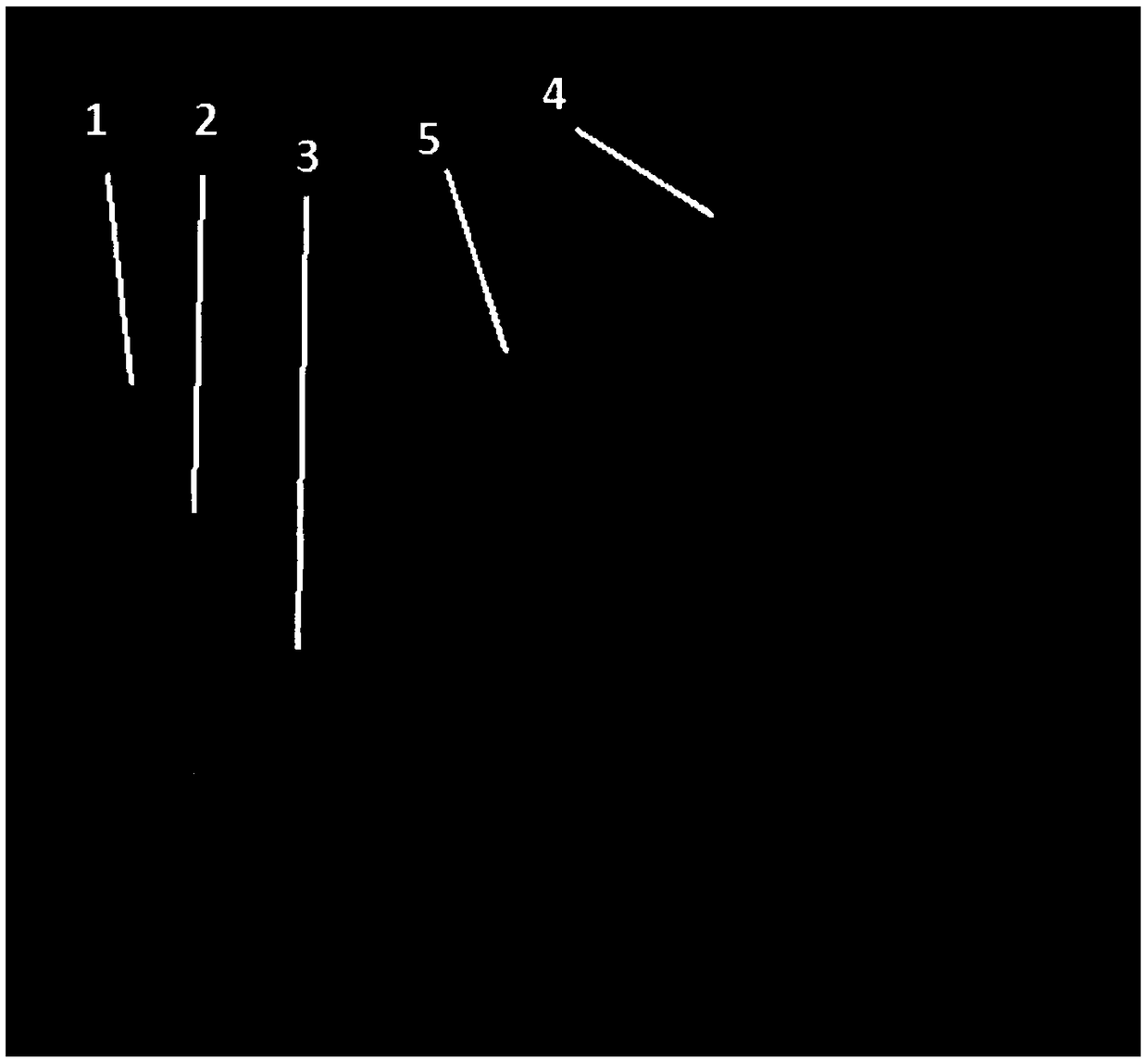

[0049] The full premix burner includes an air intake plate 1 and a combustion wall 4 . The air intake plate 1 is uniformly provided with a plurality of air intake holes 2 in the circumferential direction, and the air intake holes 2 face the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com