Patents

Literature

98results about How to "Protection material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

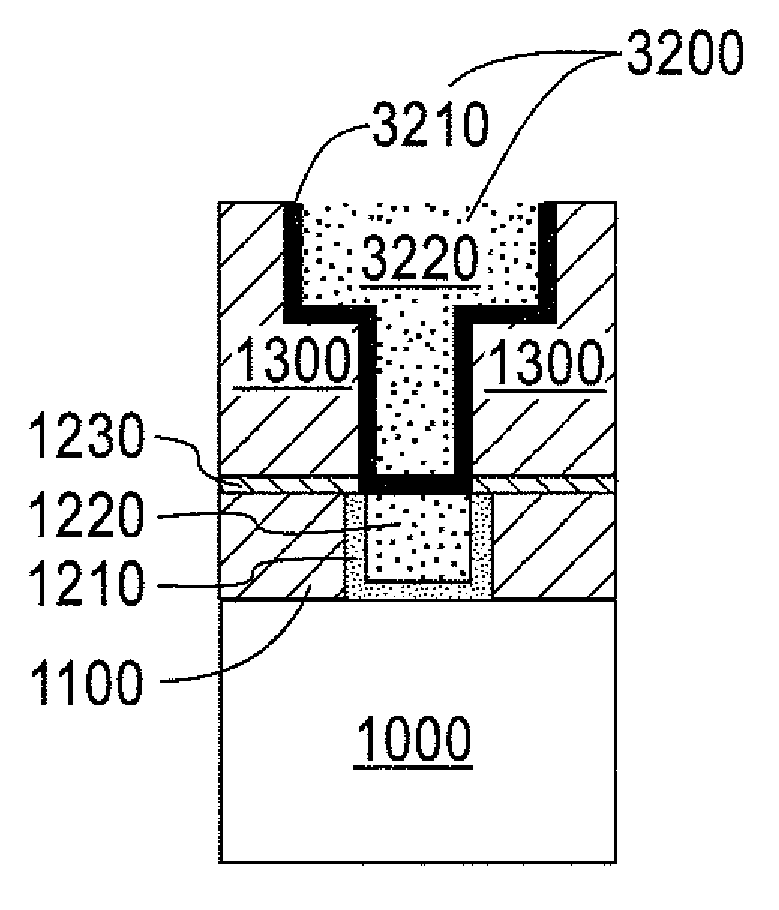

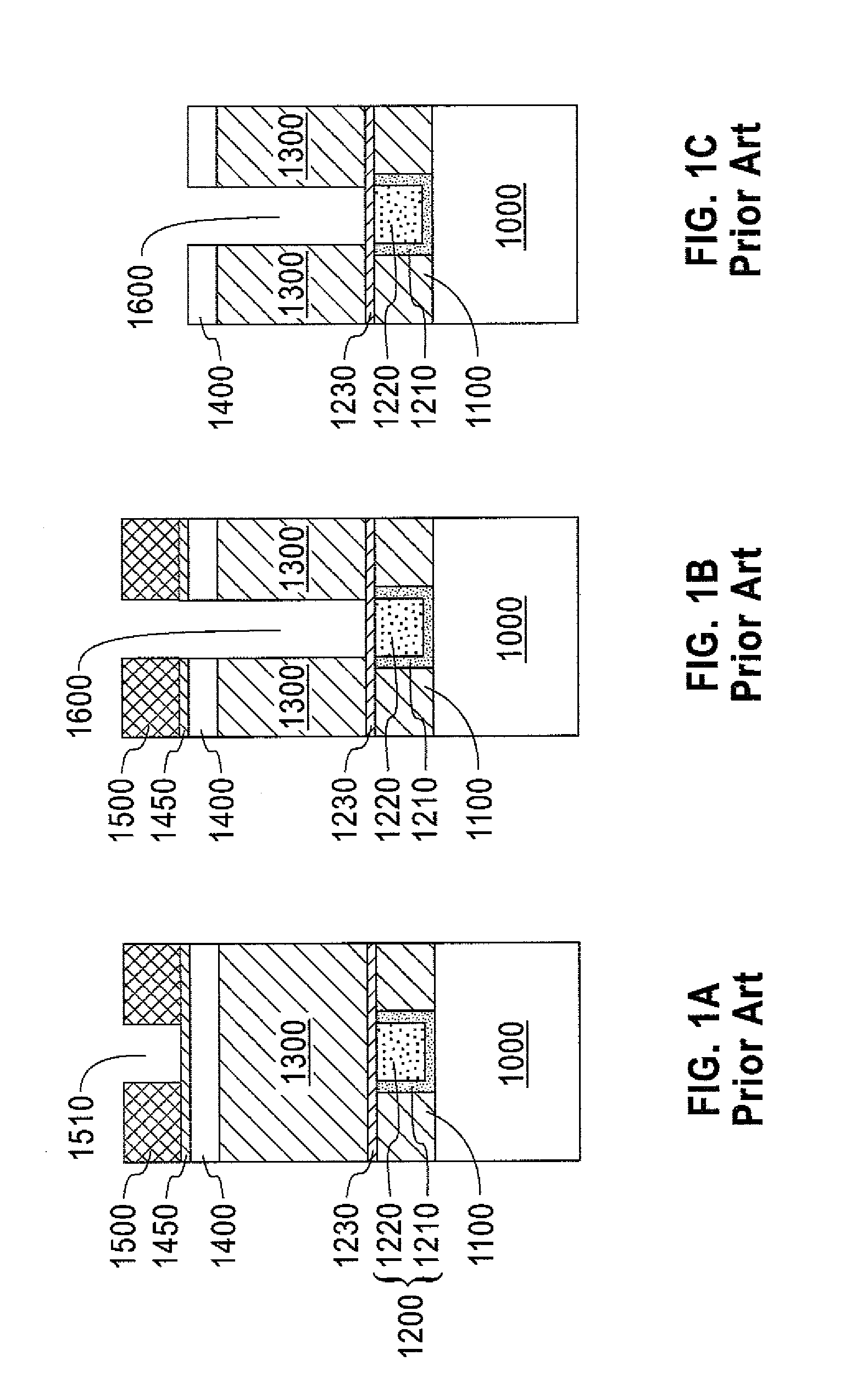

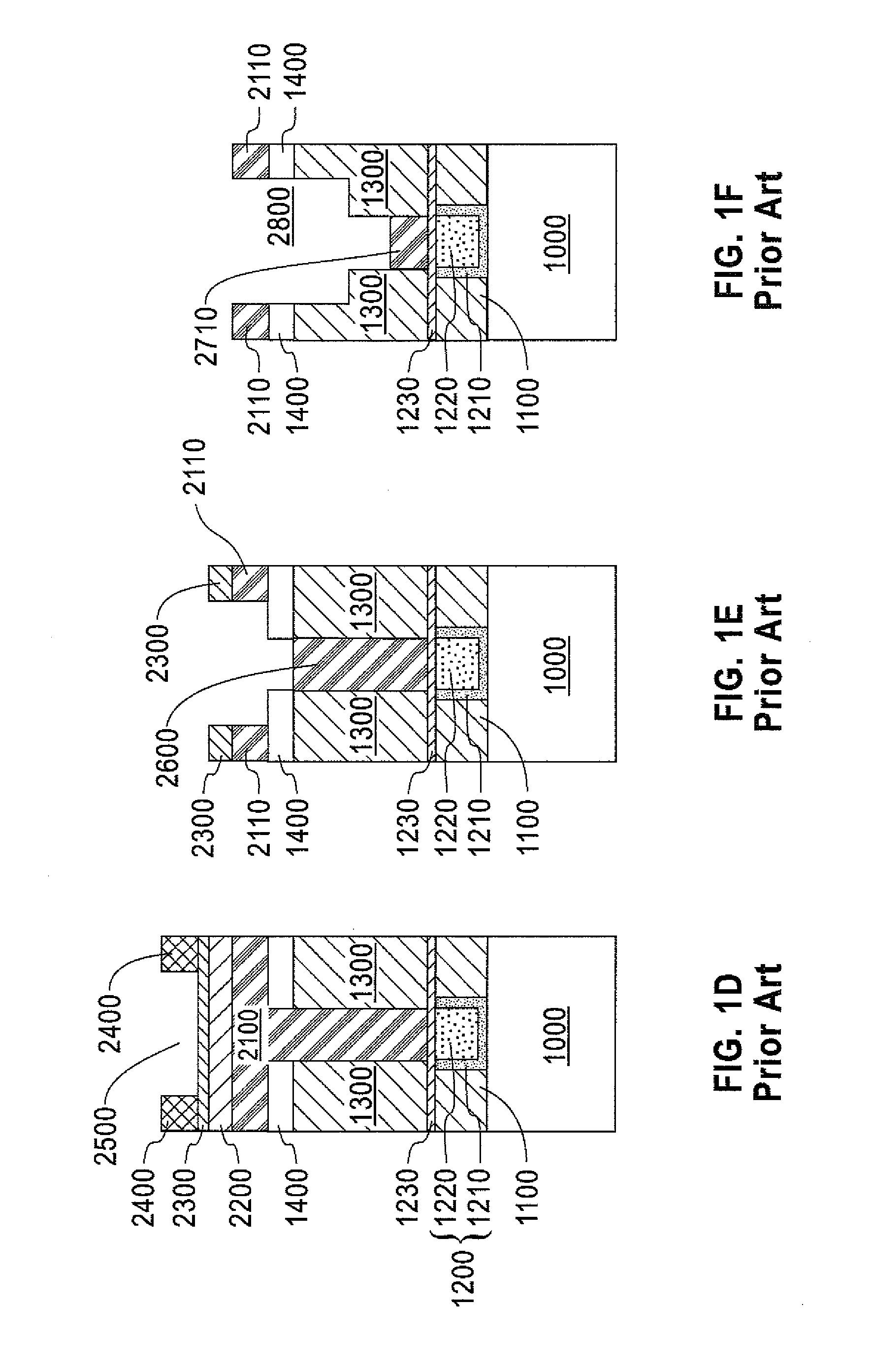

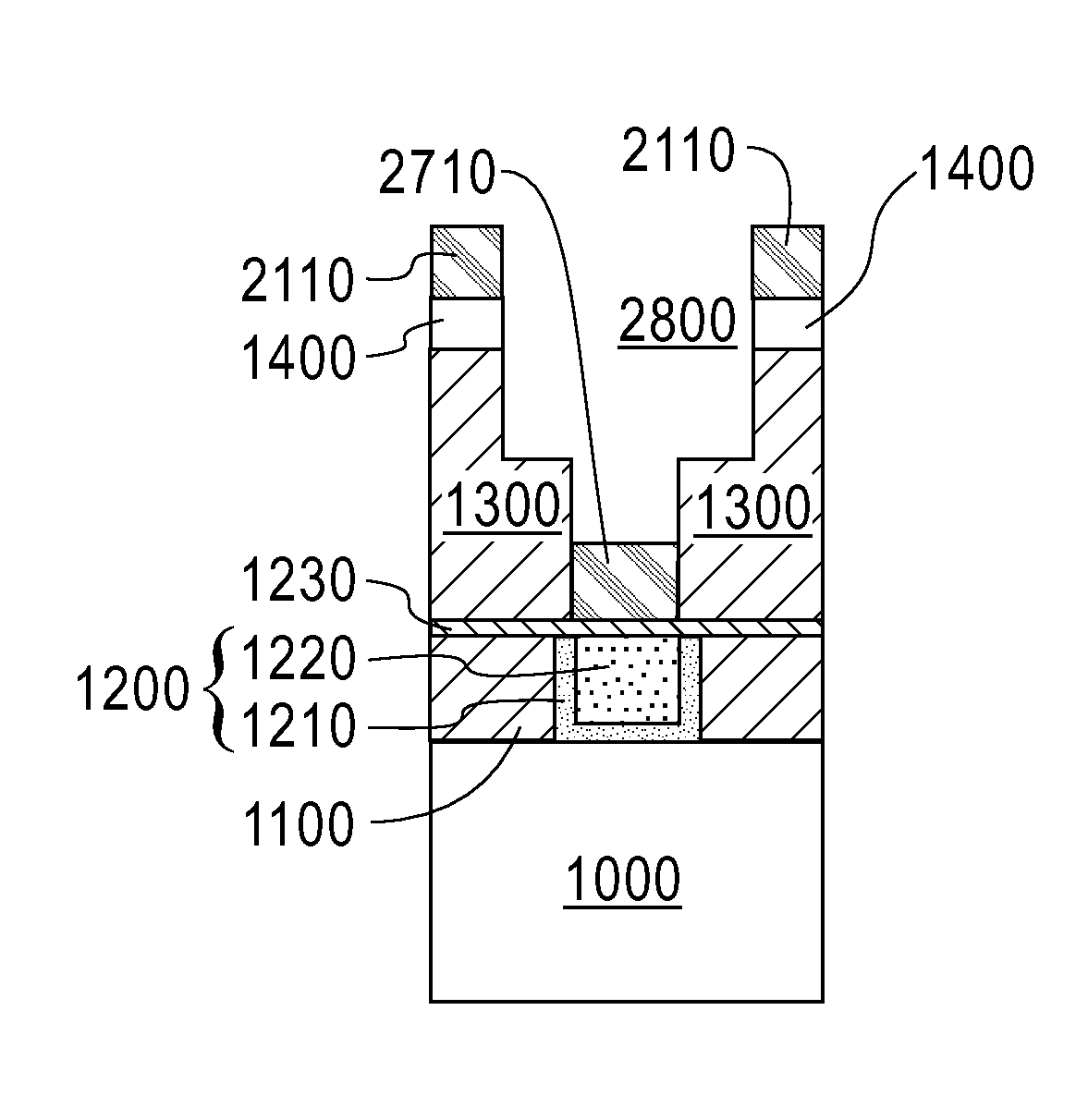

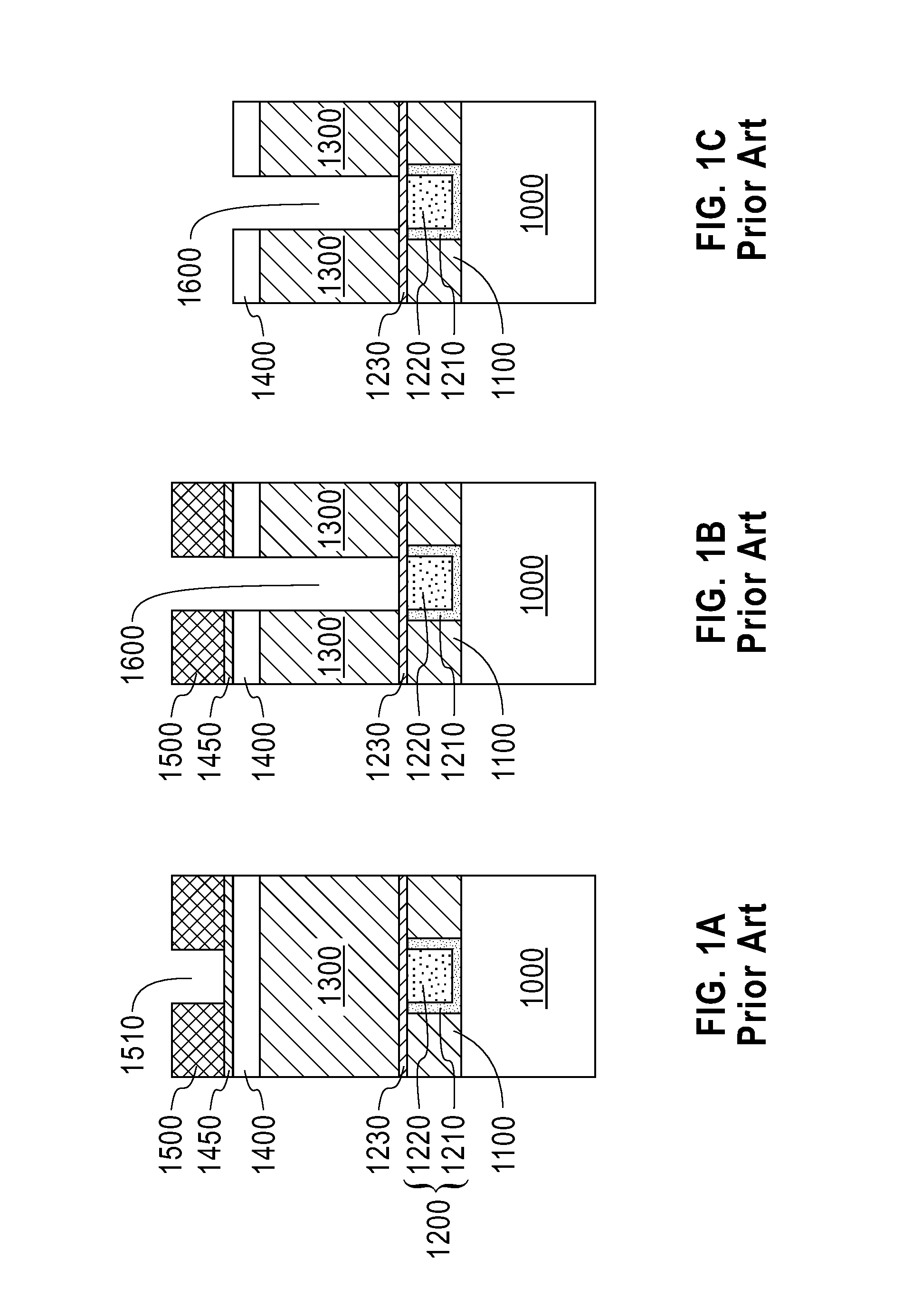

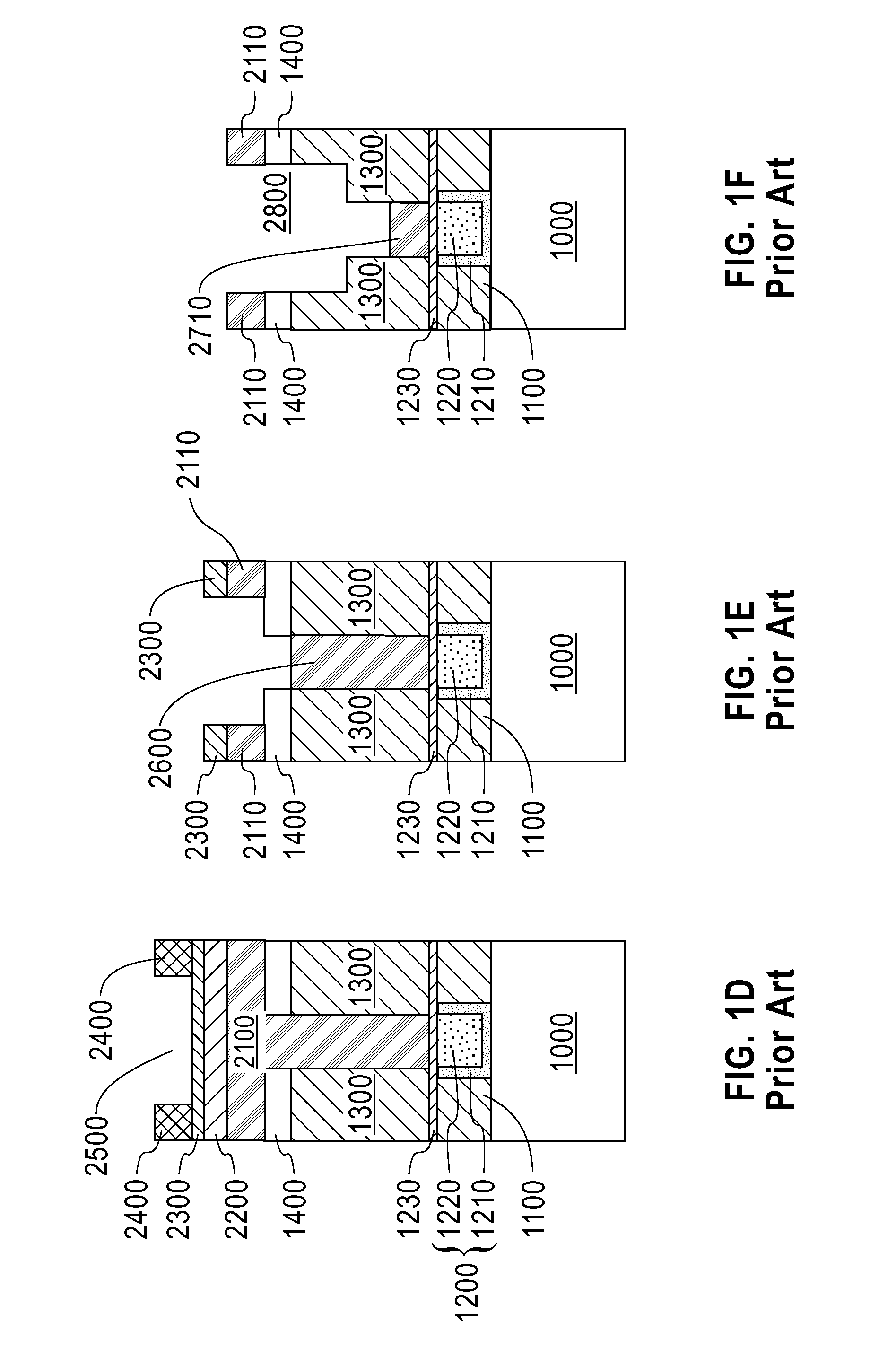

Methods to mitigate plasma damage in organosilicate dielectrics

InactiveUS20090075472A1High yieldMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingMetal interconnectLine width

Methods of minimizing or eliminating plasma damage to low k and ultra low k organosilicate intermetal dielectric layers are provided. The reduction of the plasma damage is effected by interrupting the etch and strip process flow at a suitable point to add an inventive treatment which protects the intermetal dielectric layer from plasma damage during the plasma strip process. Reduction or elimination of a plasma damaged region in this manner also enables reduction of the line bias between a line pattern in a photoresist and a metal line formed therefrom, and changes in the line width of the line trench due to a wet clean after the reactive ion etch employed for formation of the line trench and a via cavity. The reduced line bias has a beneficial effect on electrical yields of a metal interconnect structure.

Owner:ADVANCED MICRO DEVICES INC +1

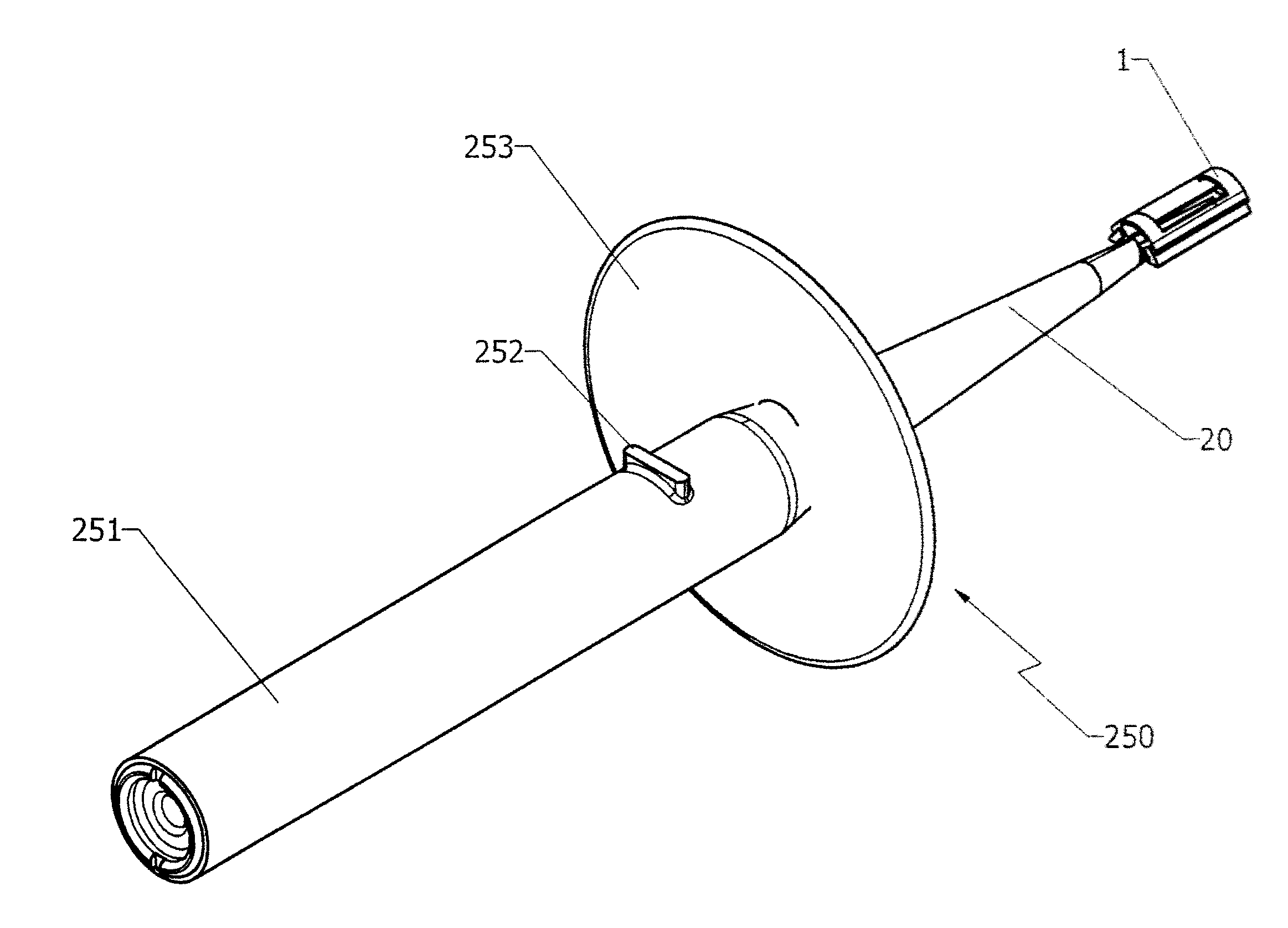

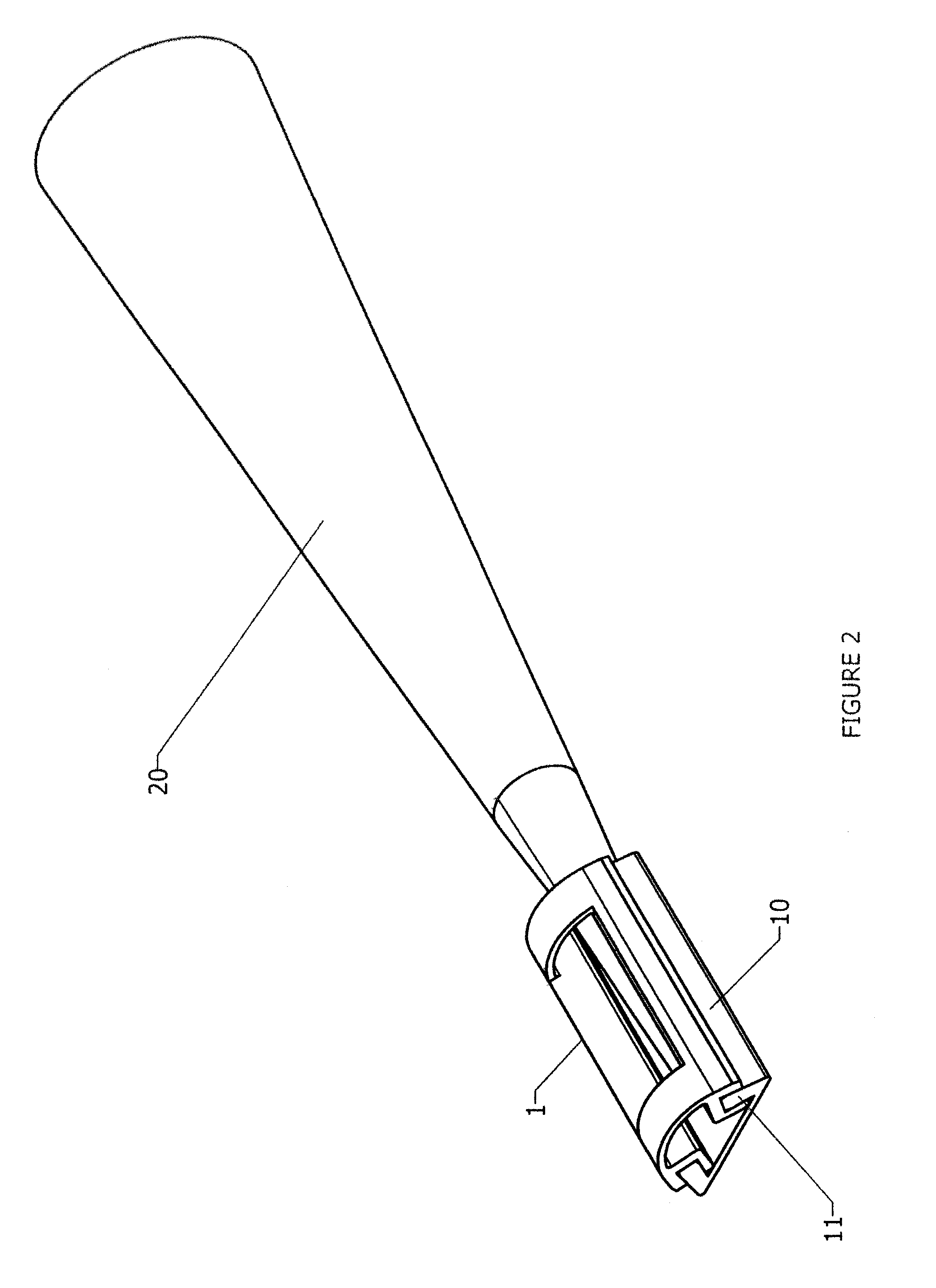

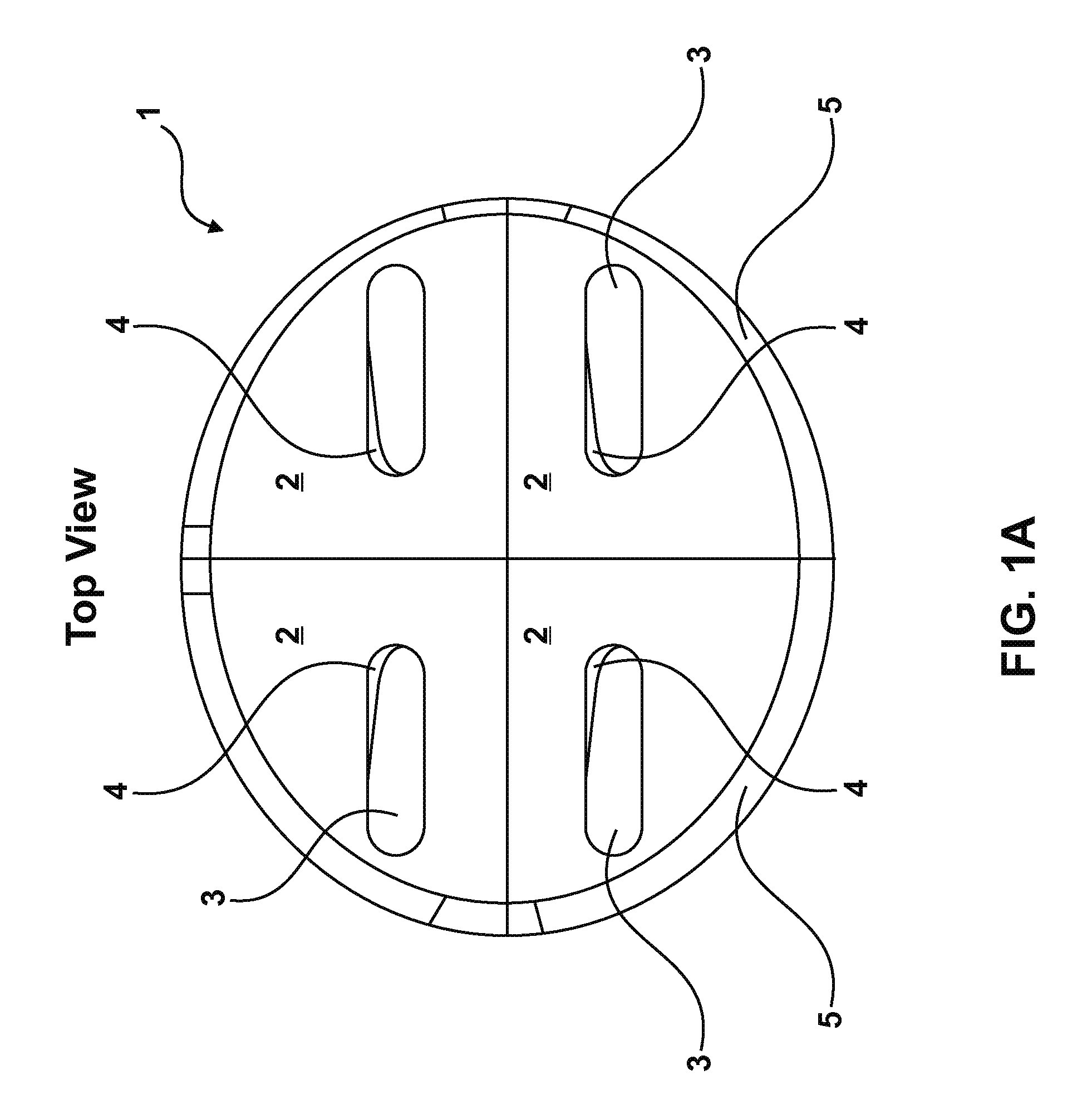

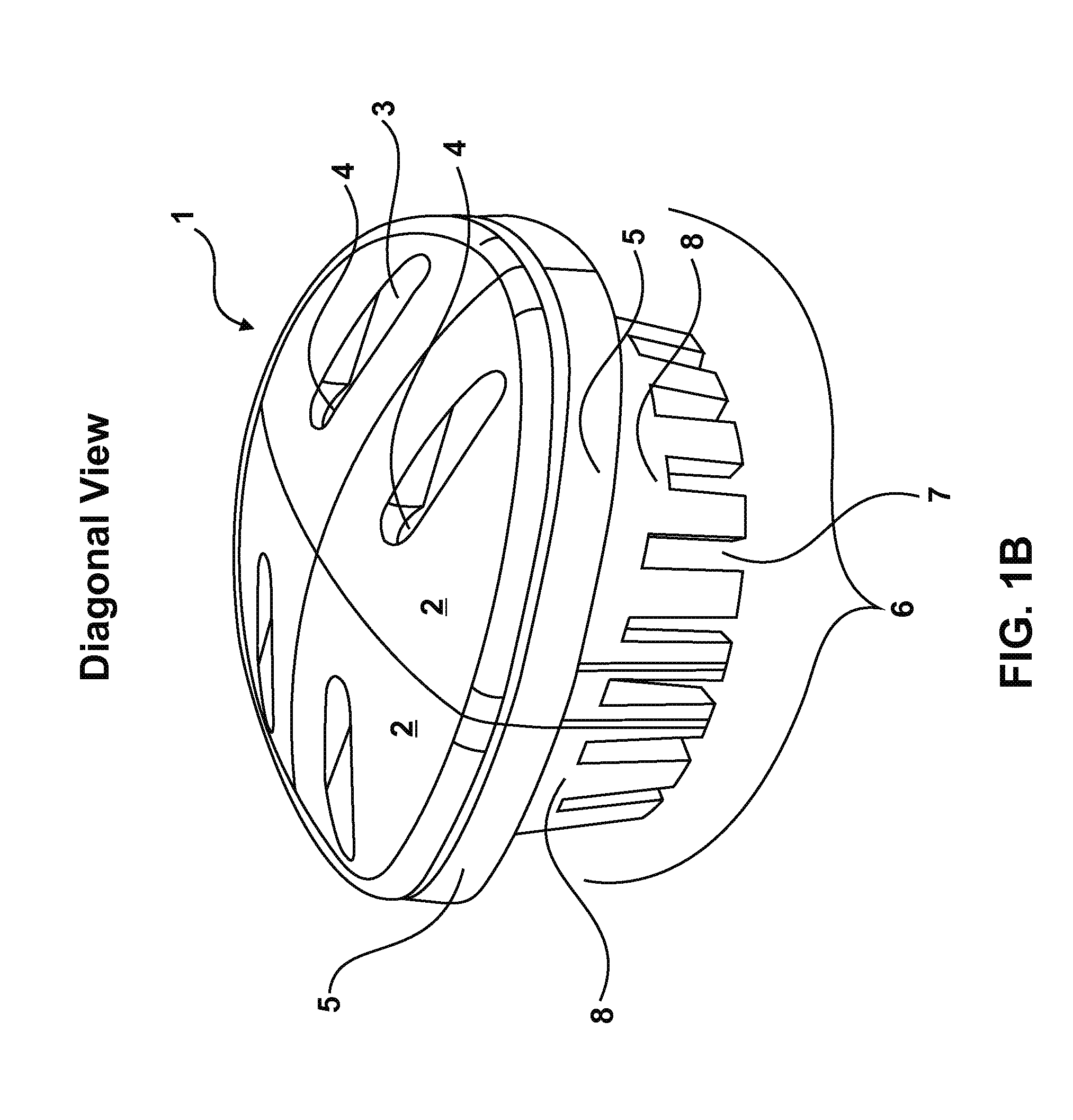

Biological sample collection device

InactiveUS20070249961A1Raise transfer toAvoid pollutionSamplingSurgical furnitureBiotechnologyMedicine

A swab device for collecting a biological sample from an individual is disclosed, the swab device comprising a head having a swab material for trapping a biological sample thereon and a body comprising means for moving the head relative to the body. Also disclosed is method of obtaining a biological sample from an individual which method comprises contacting at least a portion of the head of a swab device with a surface of the individual, the head of the swab device being moved relative to the body of the swab device whilst the head of the device is in contact with the surface.

Owner:BIZPAC (AUSTRALIA) PTY LTD

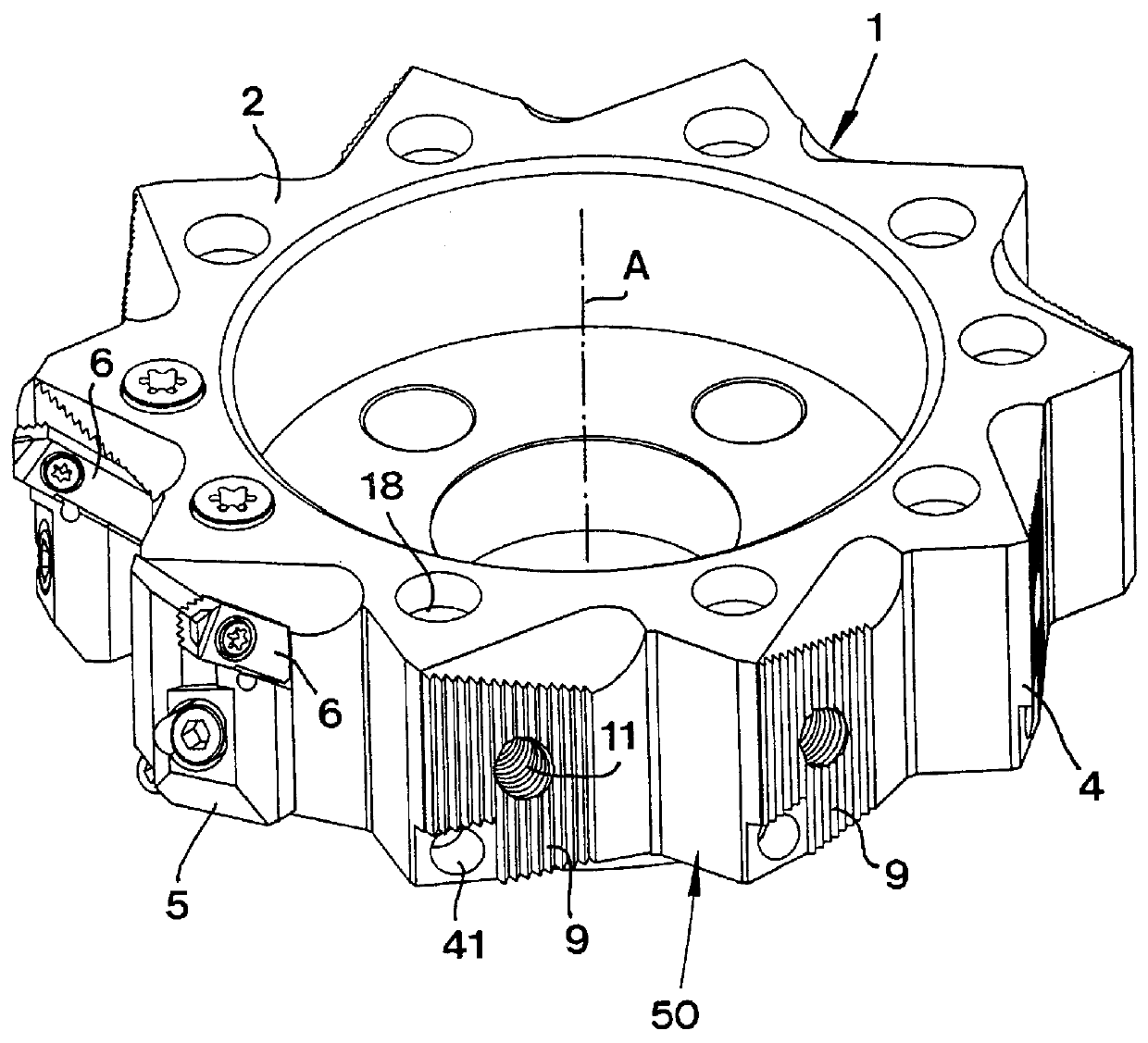

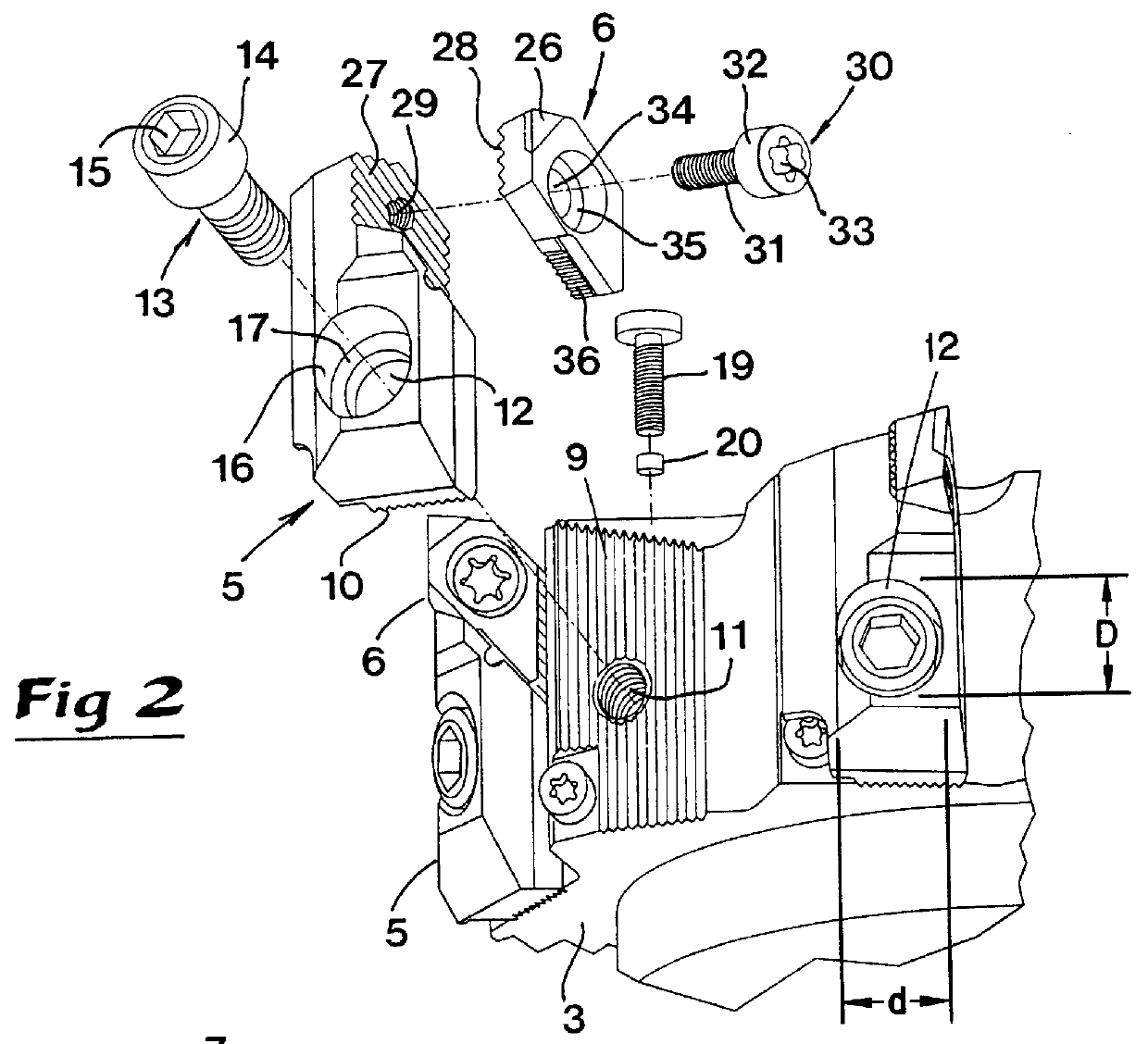

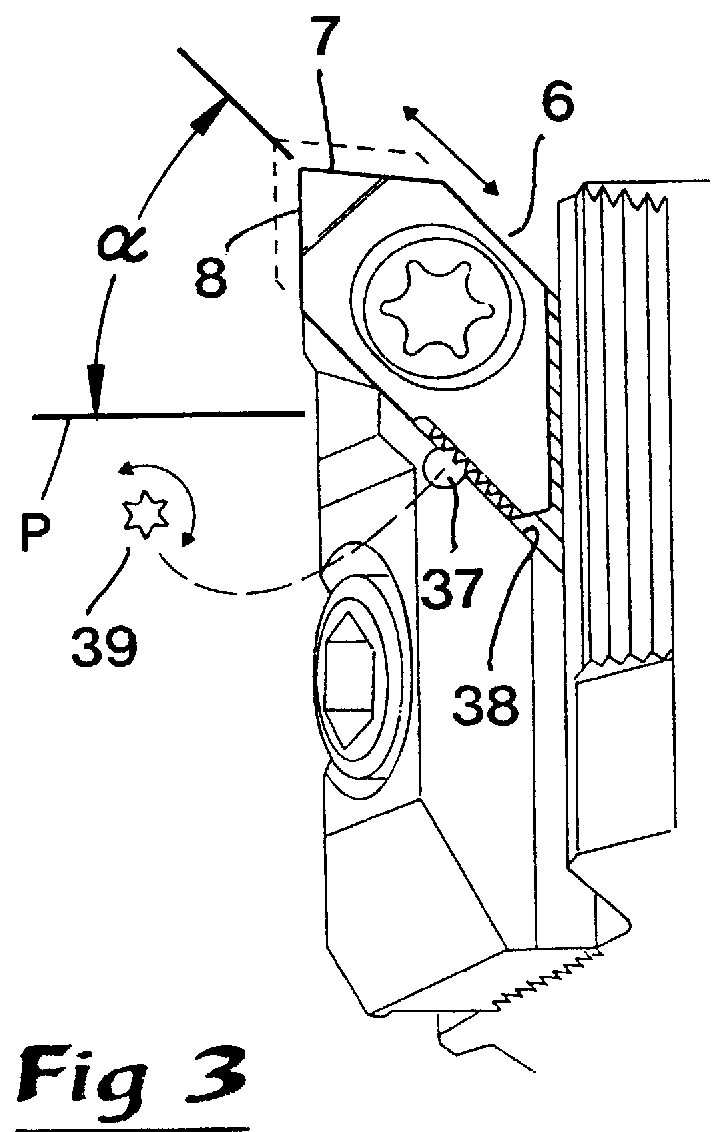

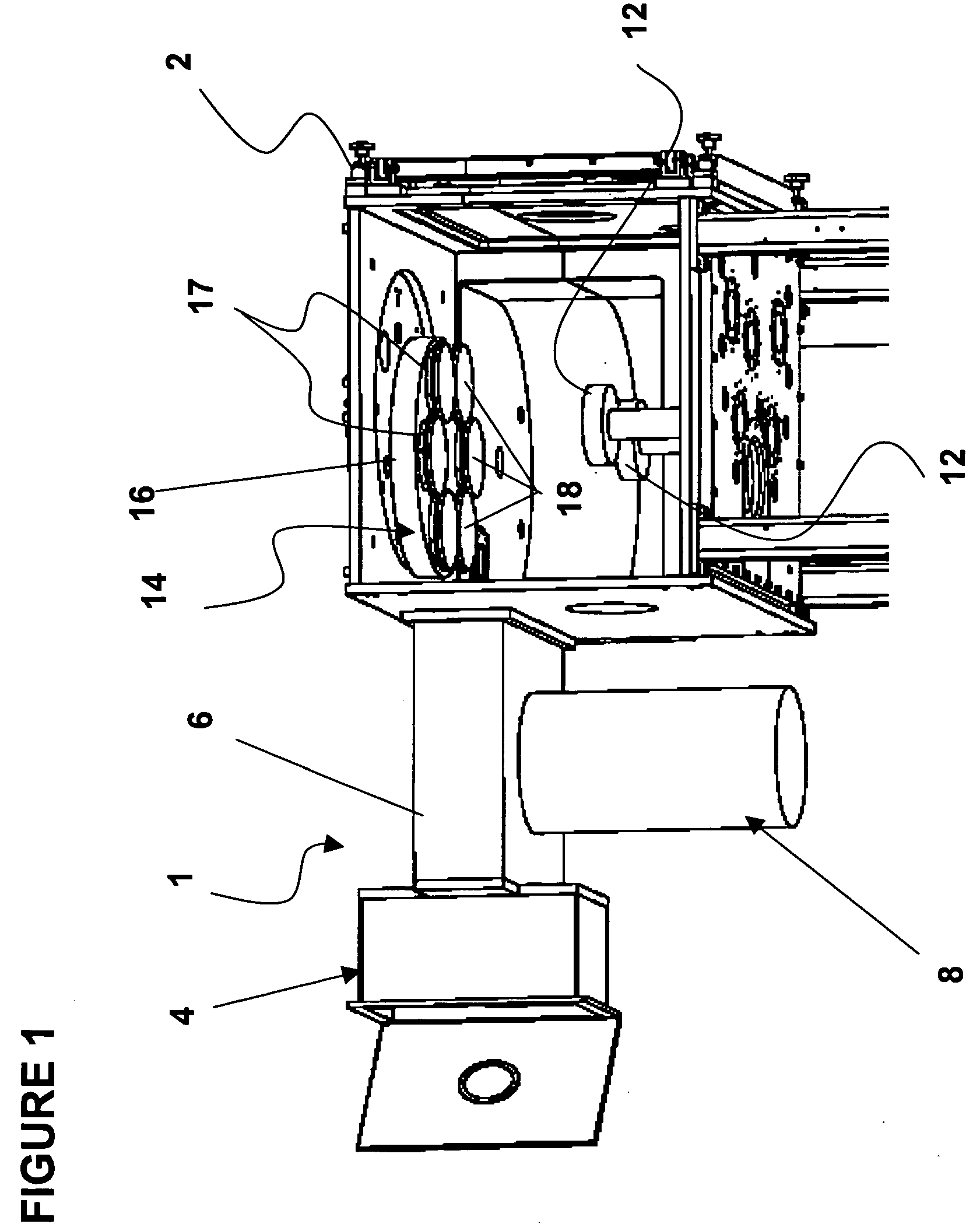

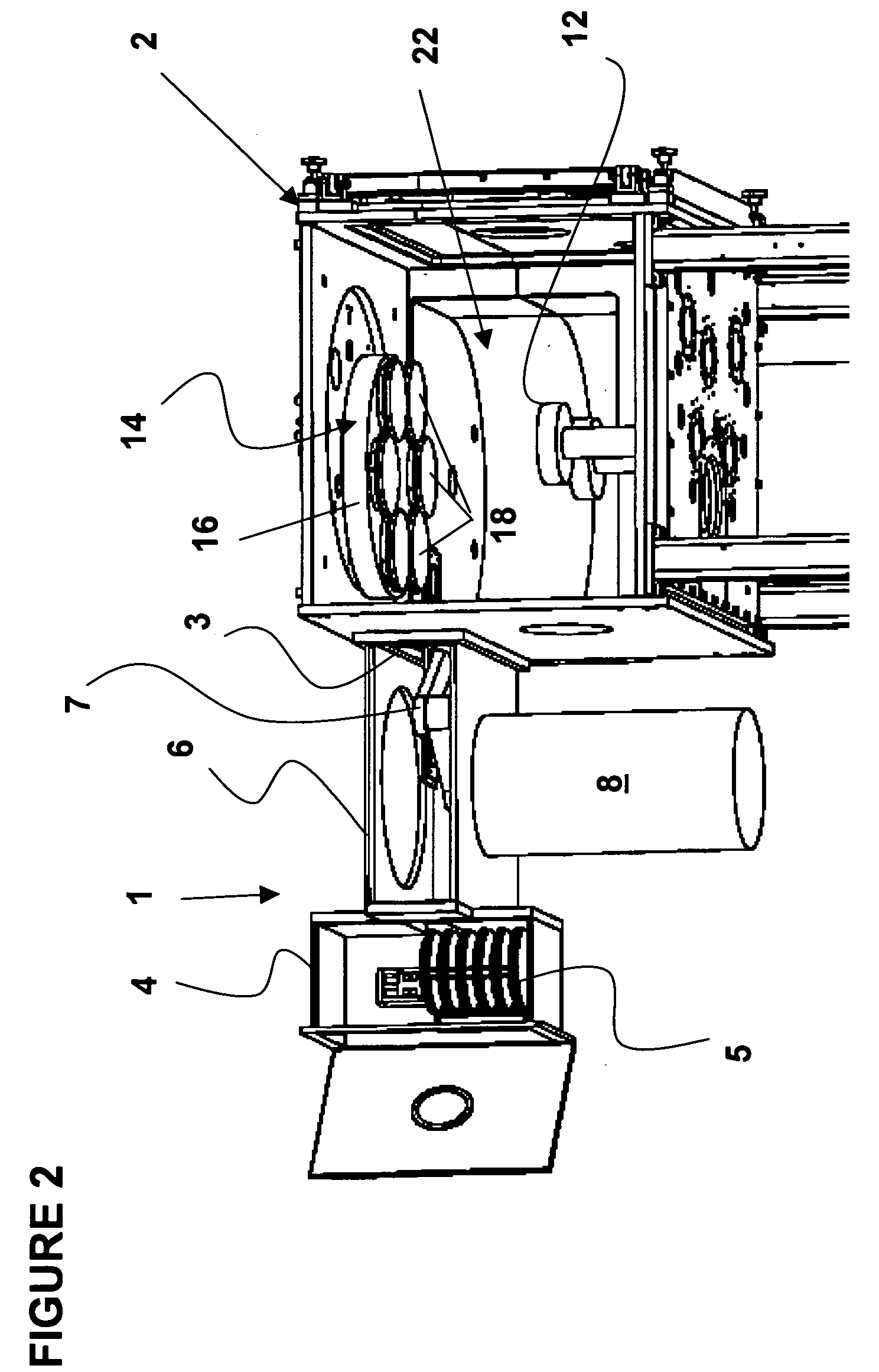

Milling tool having cassette-mounted inserts attached to a rotary supporting body

InactiveUS6086290AIncrease machine speedReduce supportMilling cuttersShaping cuttersEngineeringMechanical engineering

A milling tool includes a rotatable supporting body having detachable cassettes upon which cutting inserts are mounted. The cutting inserts are provided with cutting edges. Two serrated surfaces are provided in order to connect the individual cassette with the supporting body. A first of the two serrated surfaces is located upon the periphery of the supporting body and faces outwards from the supporting body, while the other serrated surface is formed at an inner side of the cassette.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

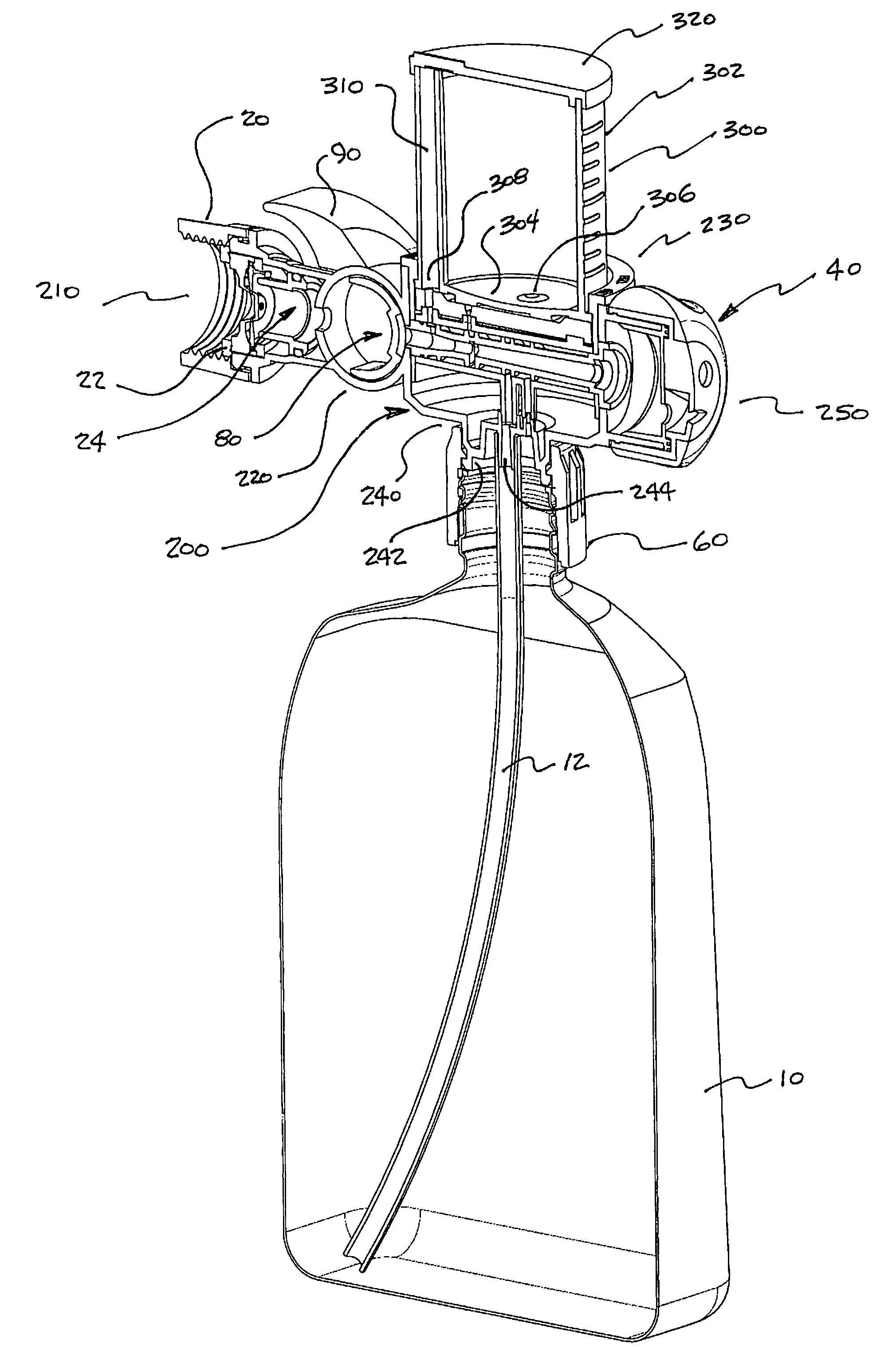

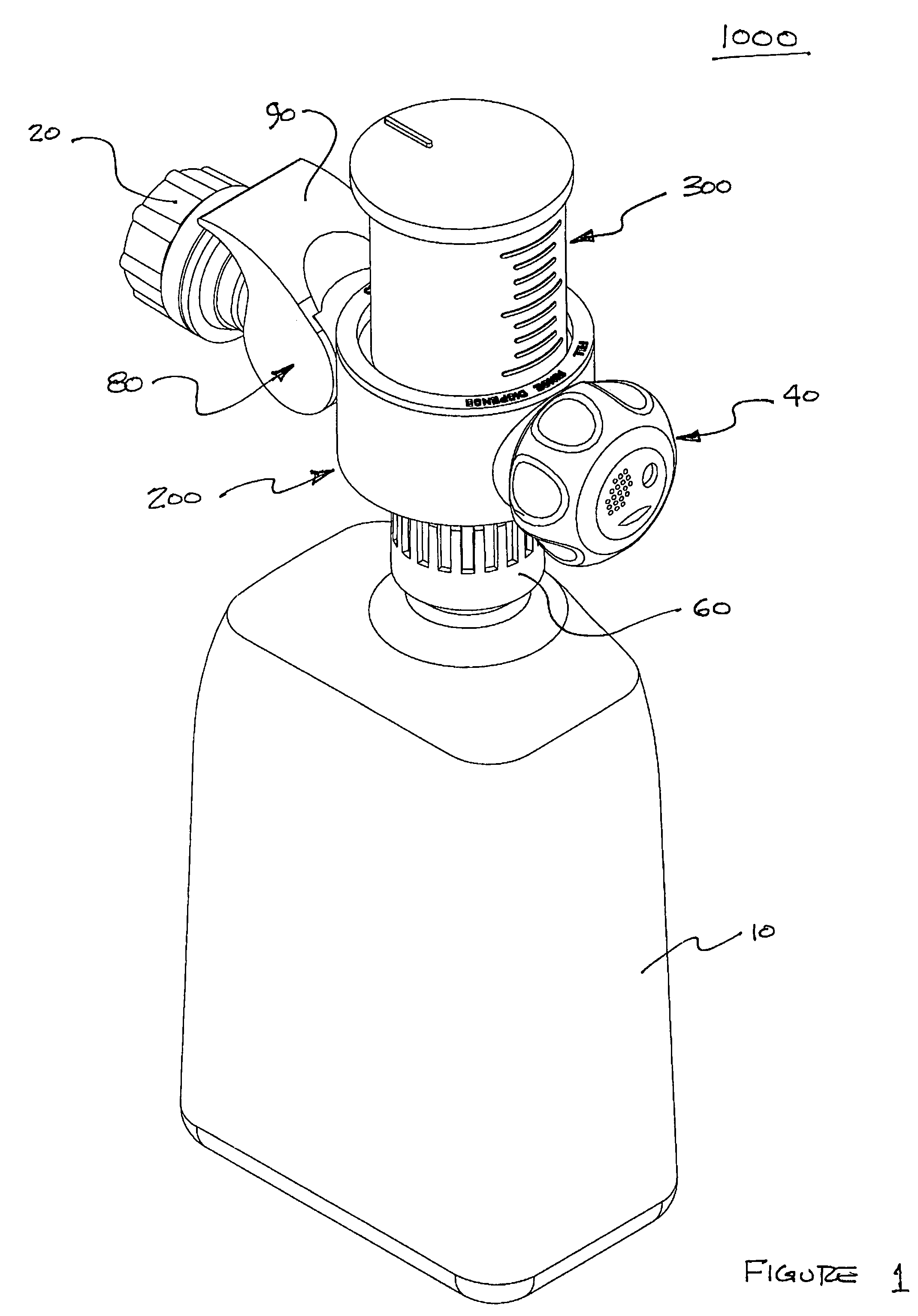

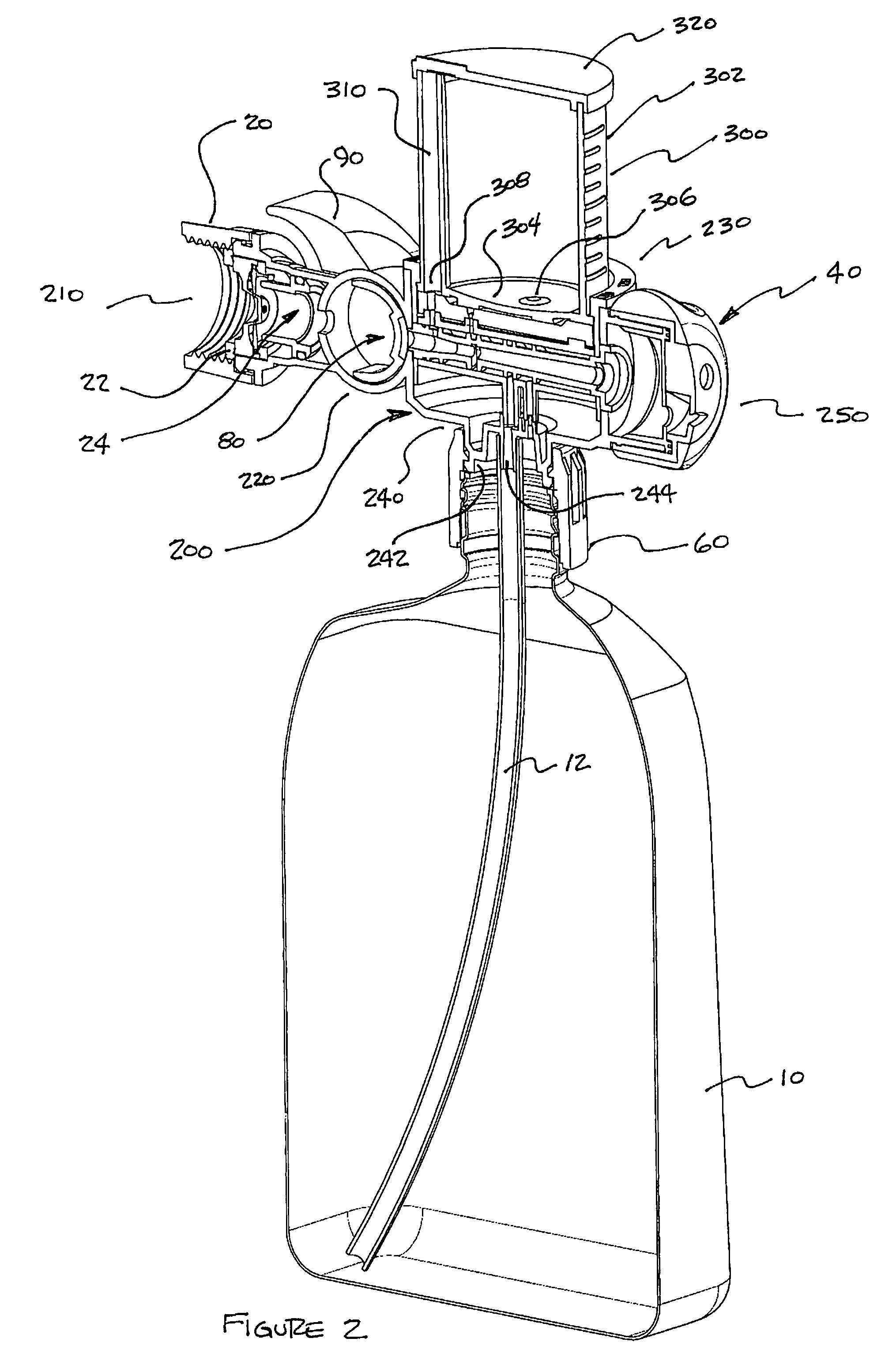

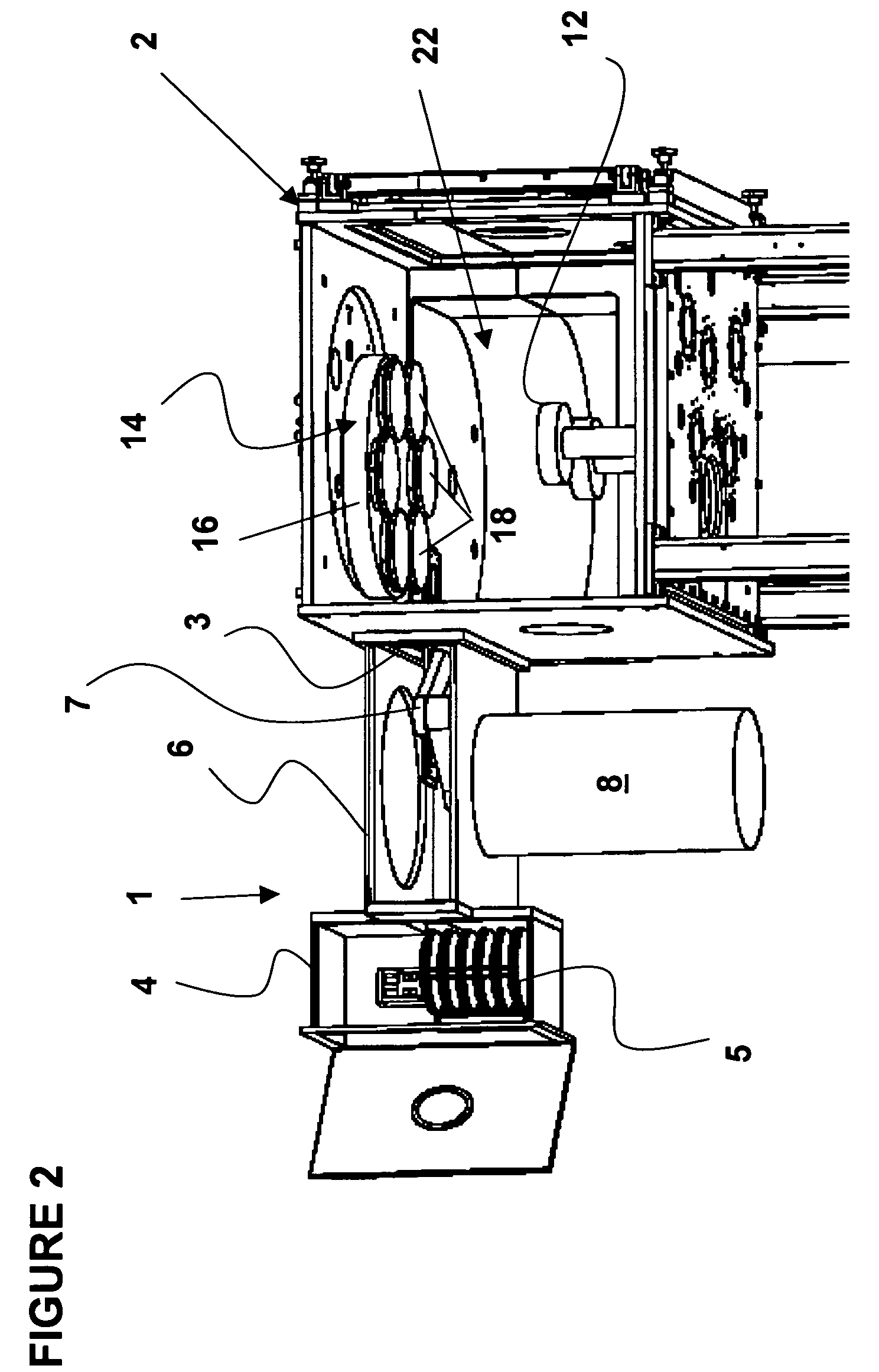

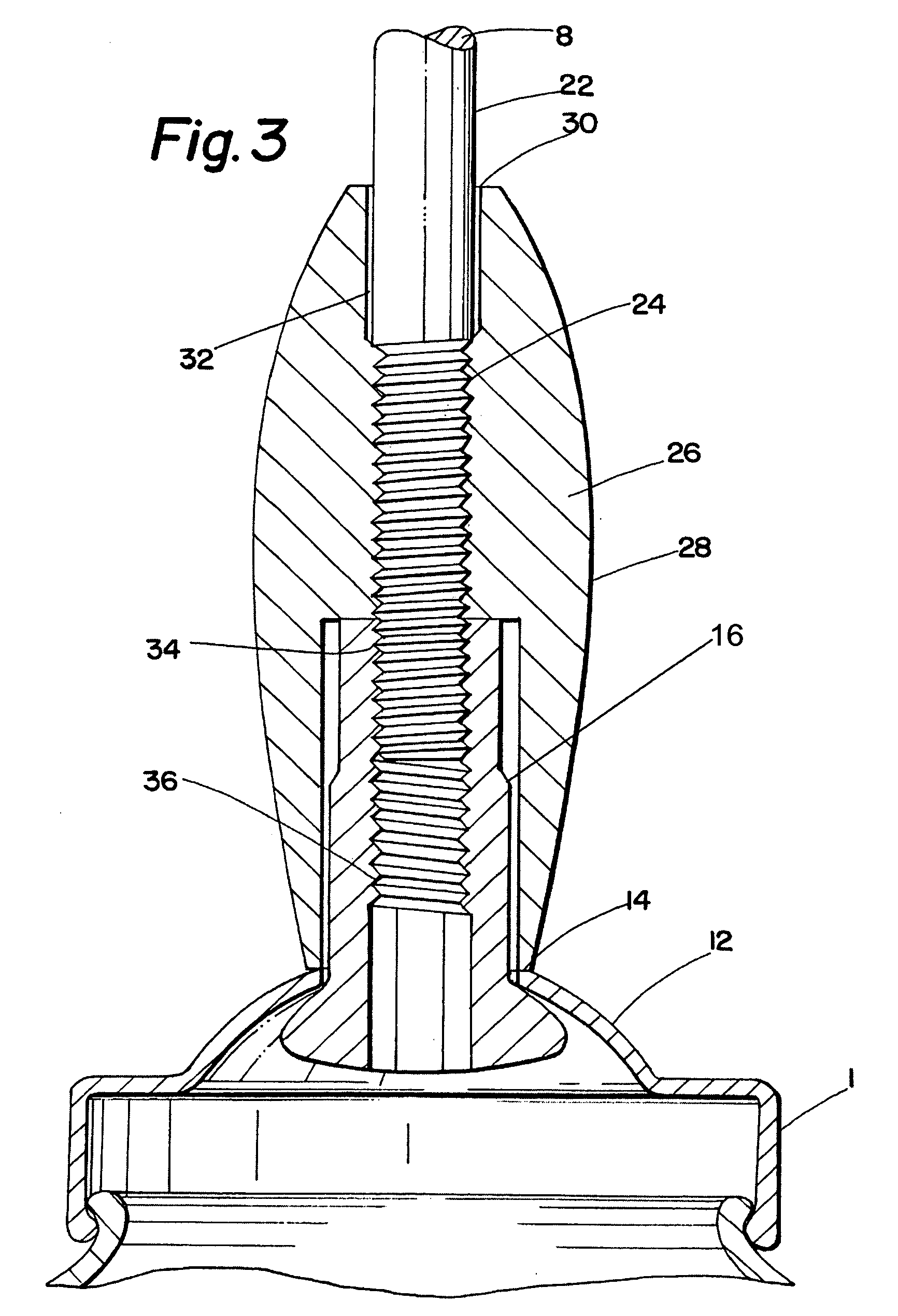

System and method for controlled dosing and dispensing of liquid material

InactiveUS7661604B1Accurate ratingSimple featuresSelf-acting watering devicesSpray nozzlesSight glass

A system and method are provided for selectively dosing and dispensing a predetermined liquid material in and from a pre-dispensing measuring sight glass container vessel, wherein a housing is disposed to receive a pressurized fluid stream, to provide an intermediate measurement and storage vessel for the liquid material and to provide a selectively operable valve assembly that is disposed in a flow path defined in the housing. The housing includes an inlet, an outlet, and an intermediate portion extending therebetween, which is formed with an admission port for admitting the predetermined liquid material. The valve assembly is disposed between the housing's inlet and outlet, and may be selectively operated to fill the sight glass container from the source container; or, to dispense the liquid material from the sight glass container; or, to clean the sight glass container; or, to just provide a flow of the pressurized fluid without any liquid material. At no selection or operating condition can liquid material from the source container be dispensed without first being measured into the sight glass container.

Owner:MACLEAN BLEVINS MARK T

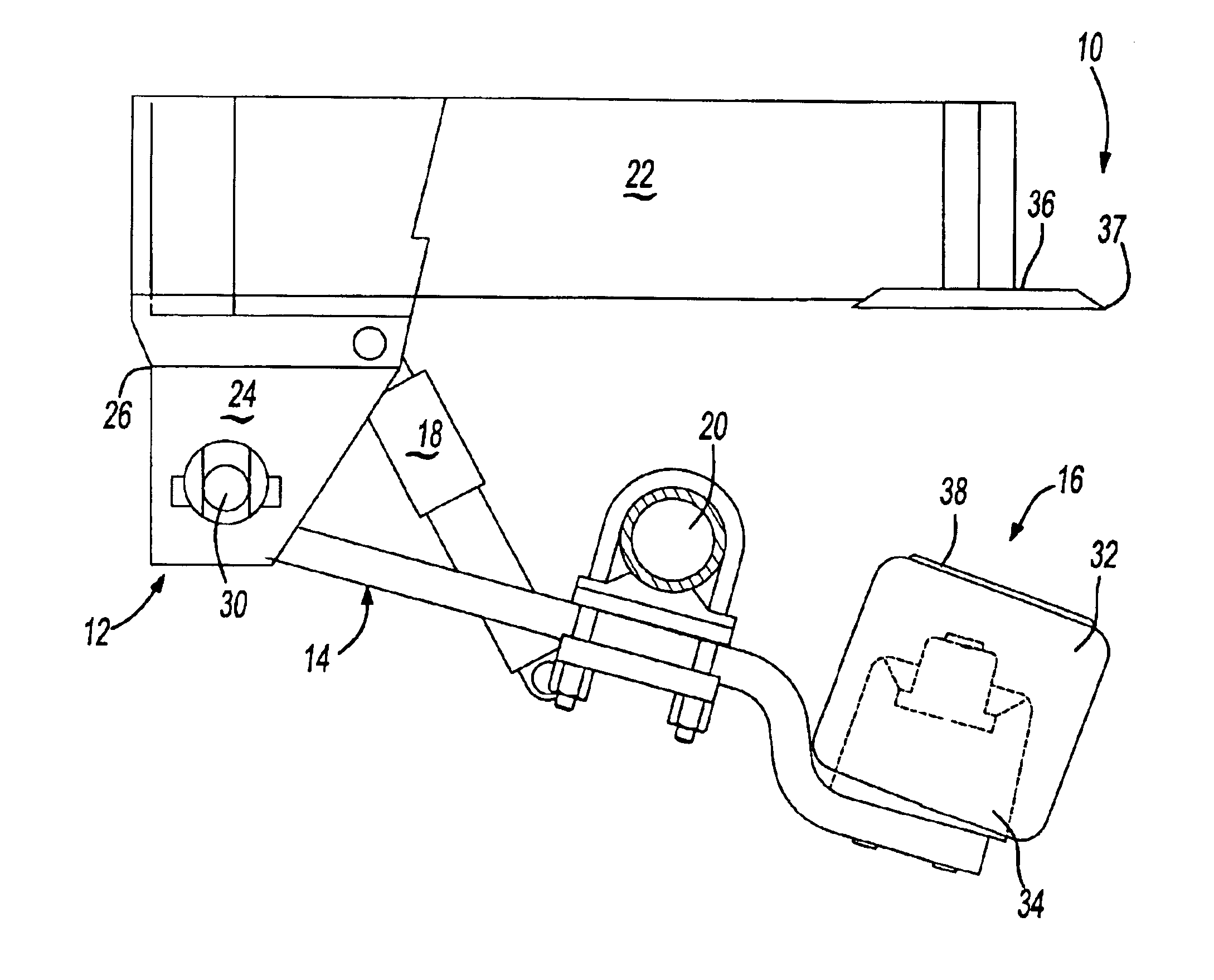

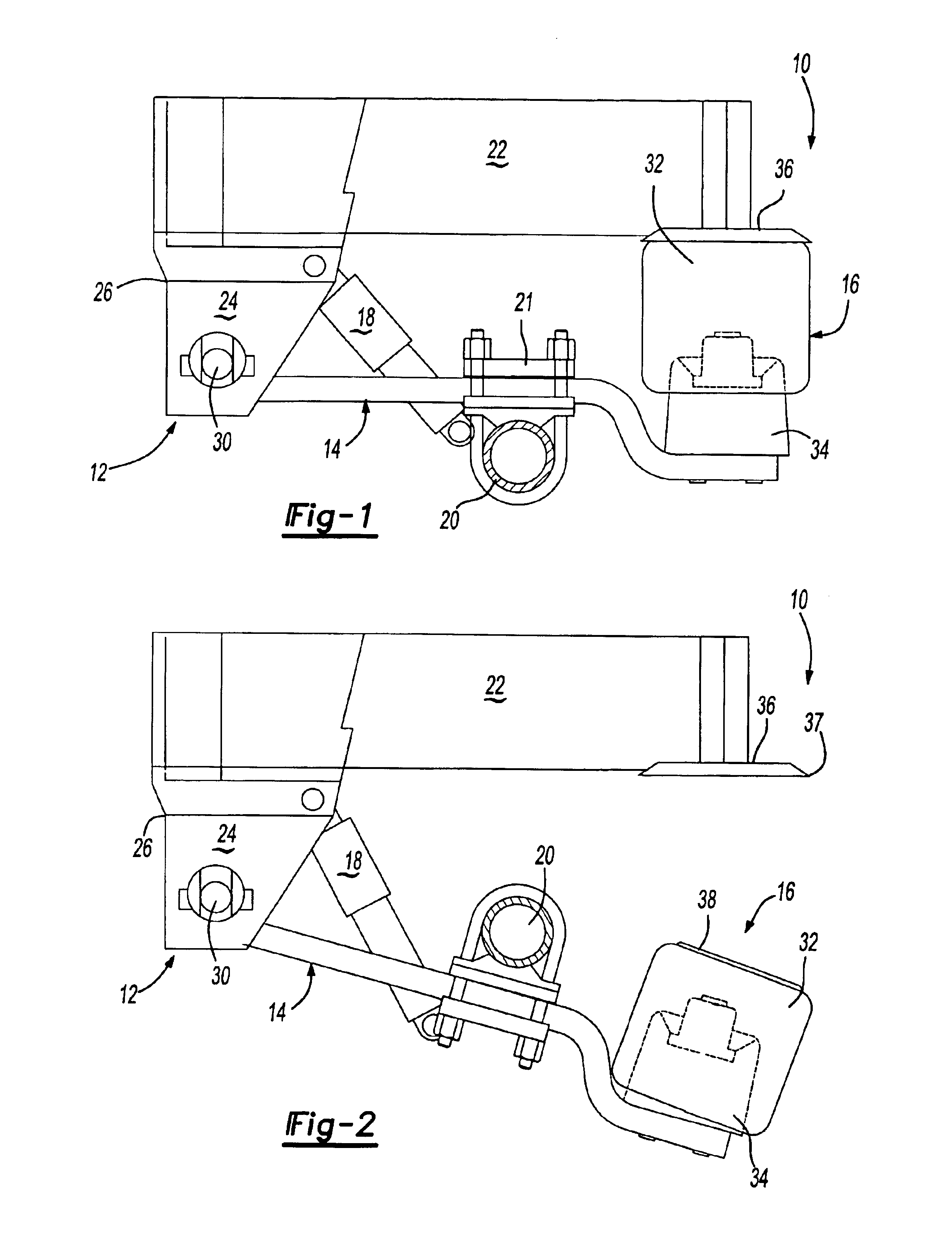

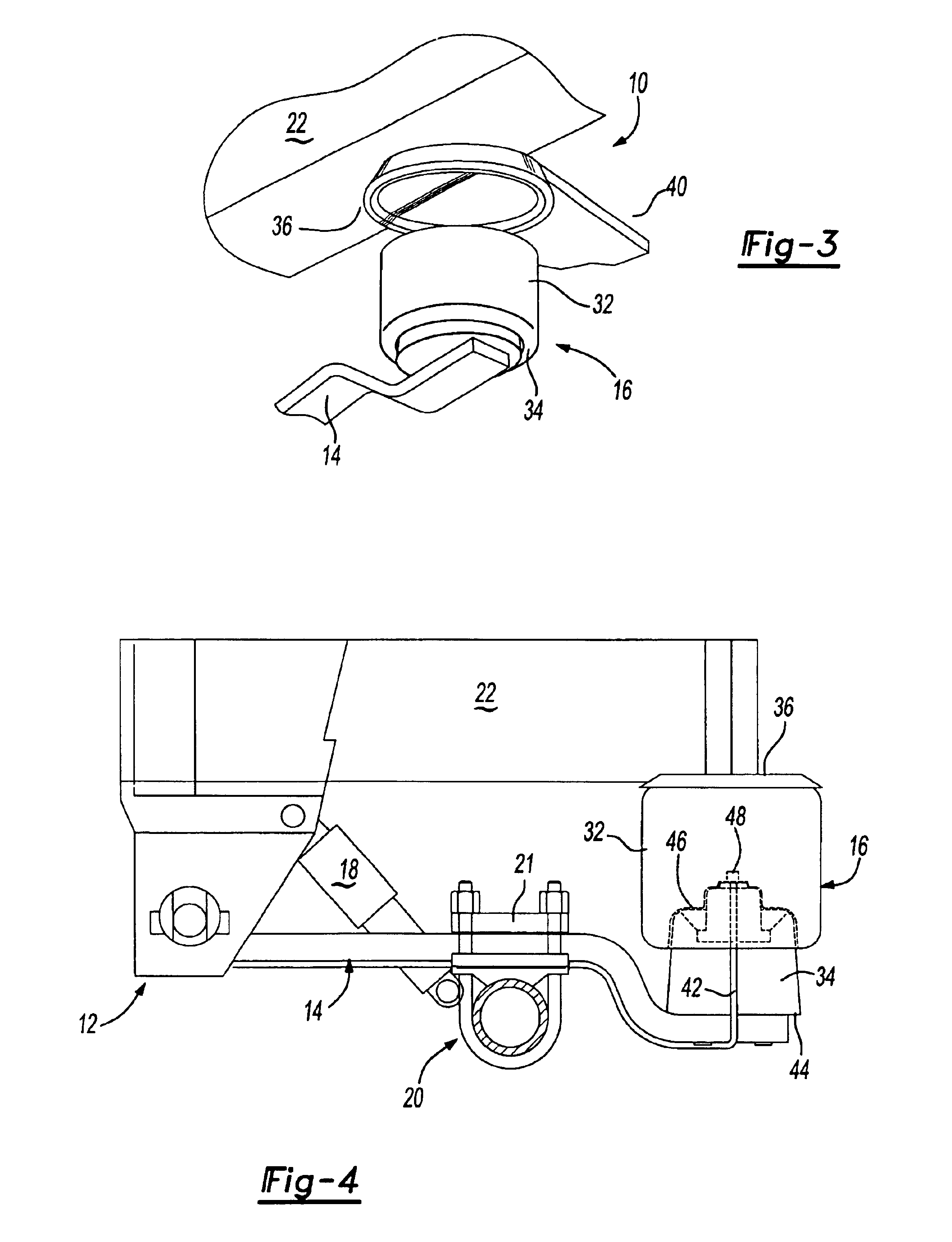

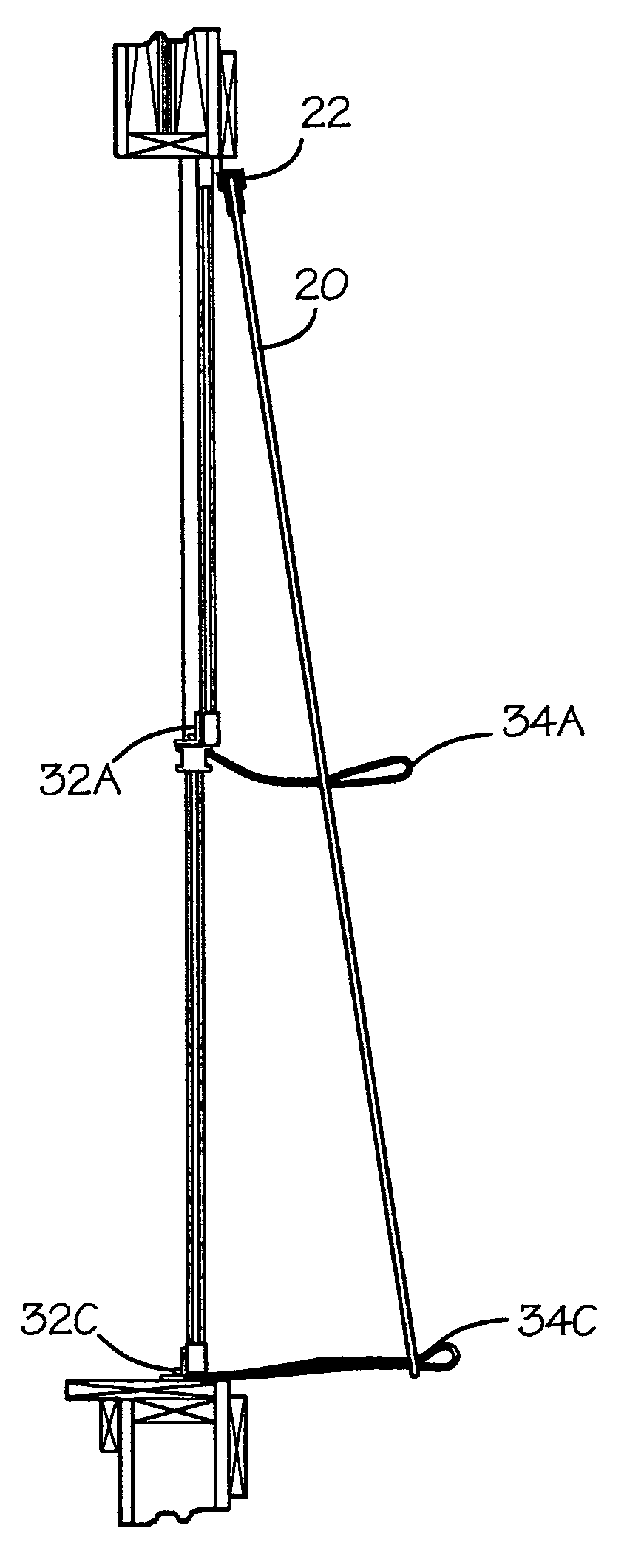

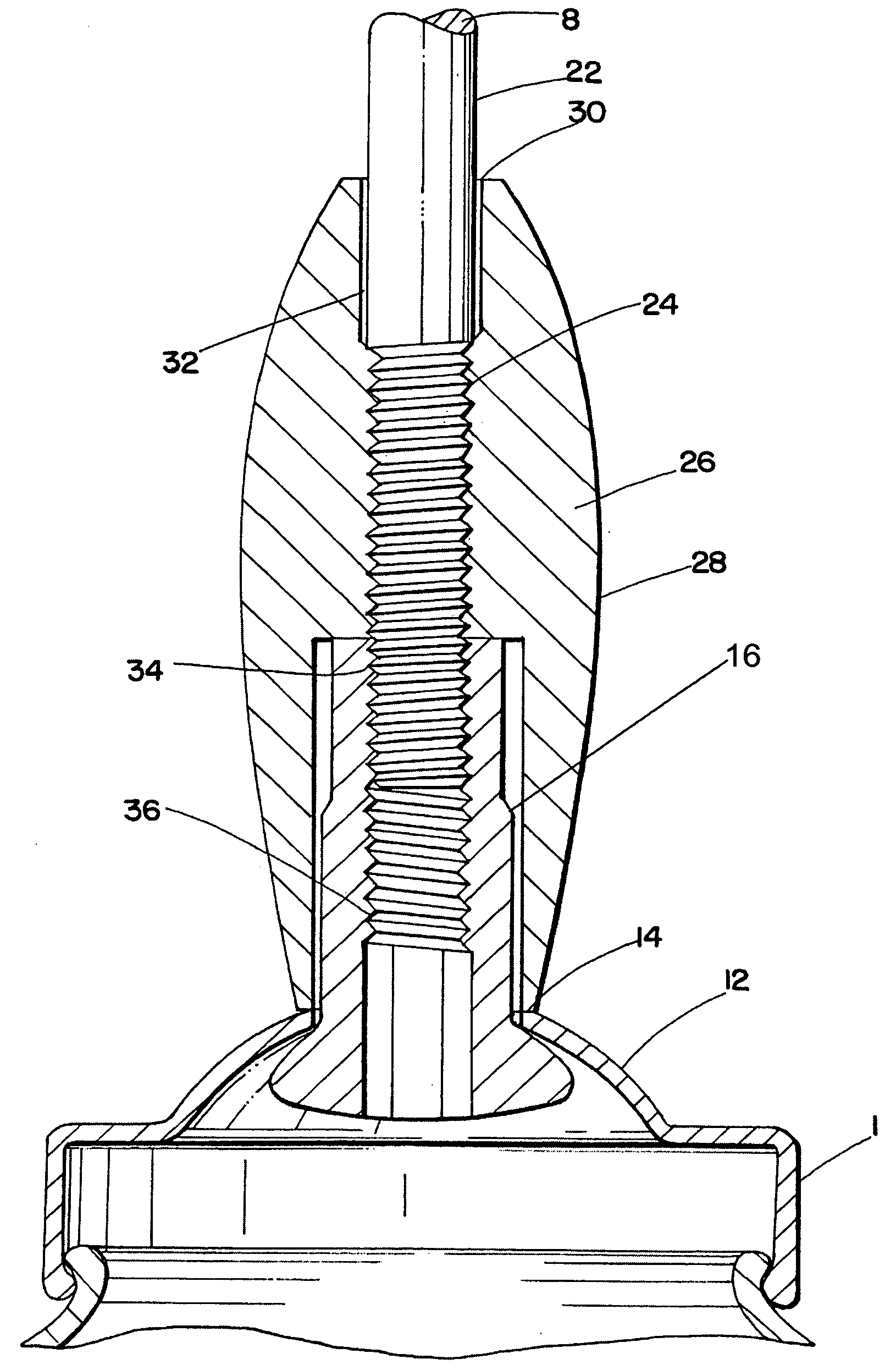

Air spring and pedestal

InactiveUS6840525B1Avoid trappingPrecise positioningSpringsResilient suspensionsAir springEngineering

A suspension system includes a longitudinal member, an air spring, a damper and an axle assembly. The air spring is not directly attached to the chassis but is mounted to contact a locating plate attached to the chassis. The locating plate includes a lip such that the locating plate is of a frustum configuration that laterally locates and self aligns the air spring upon pivotal movement and re-alignment of the air spring with the chassis. Preferably, the suspension system includes a protective skirt which aids in bringing the air cell into a correct position with the locating plate. In addition the axle assembly extends away from the chassis at a speed restricted by the damper such that the anti-vacuum system can equalize the pressure within the air cell.

Owner:MERITOR HEAVY VEHICLE SYST

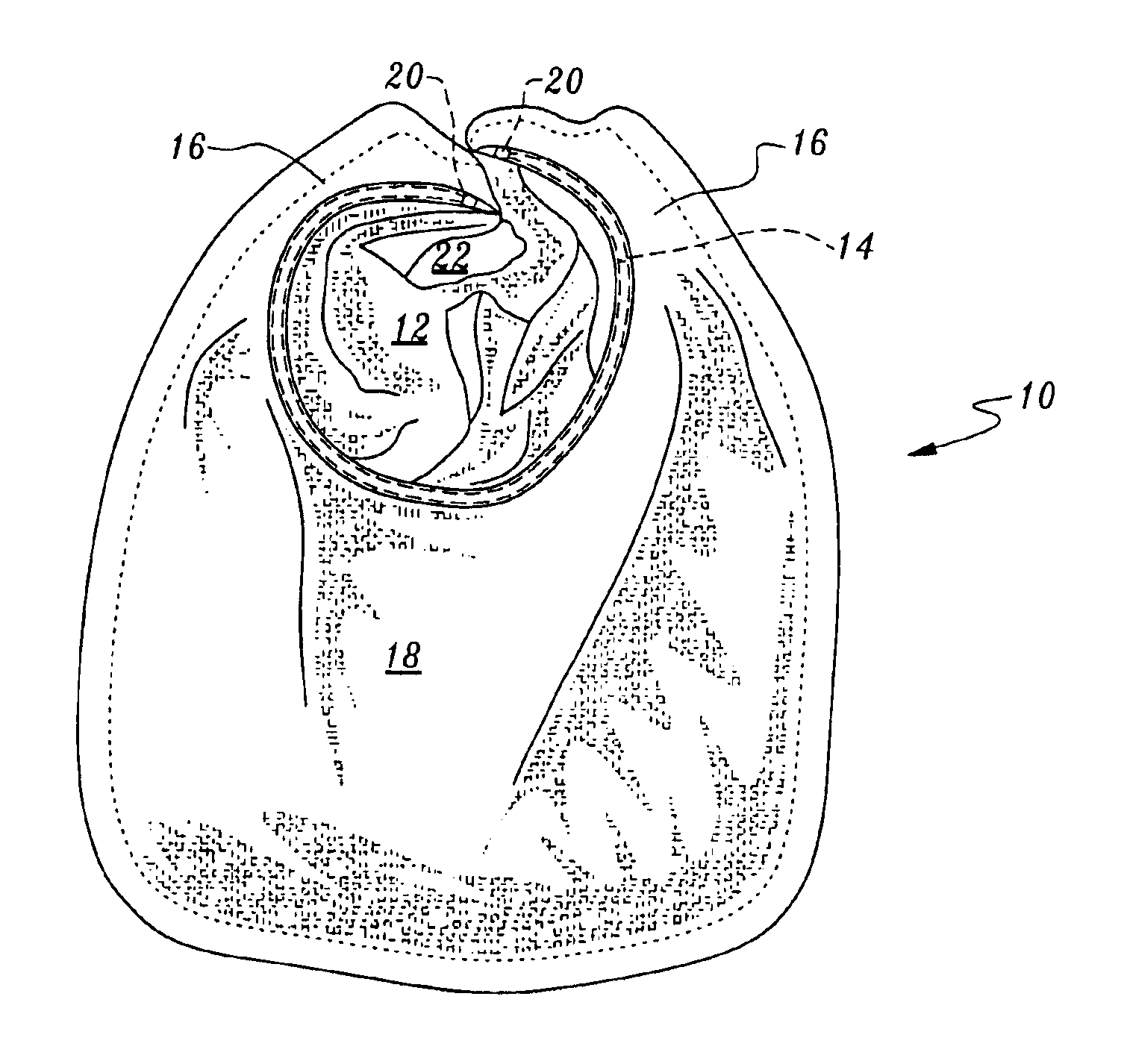

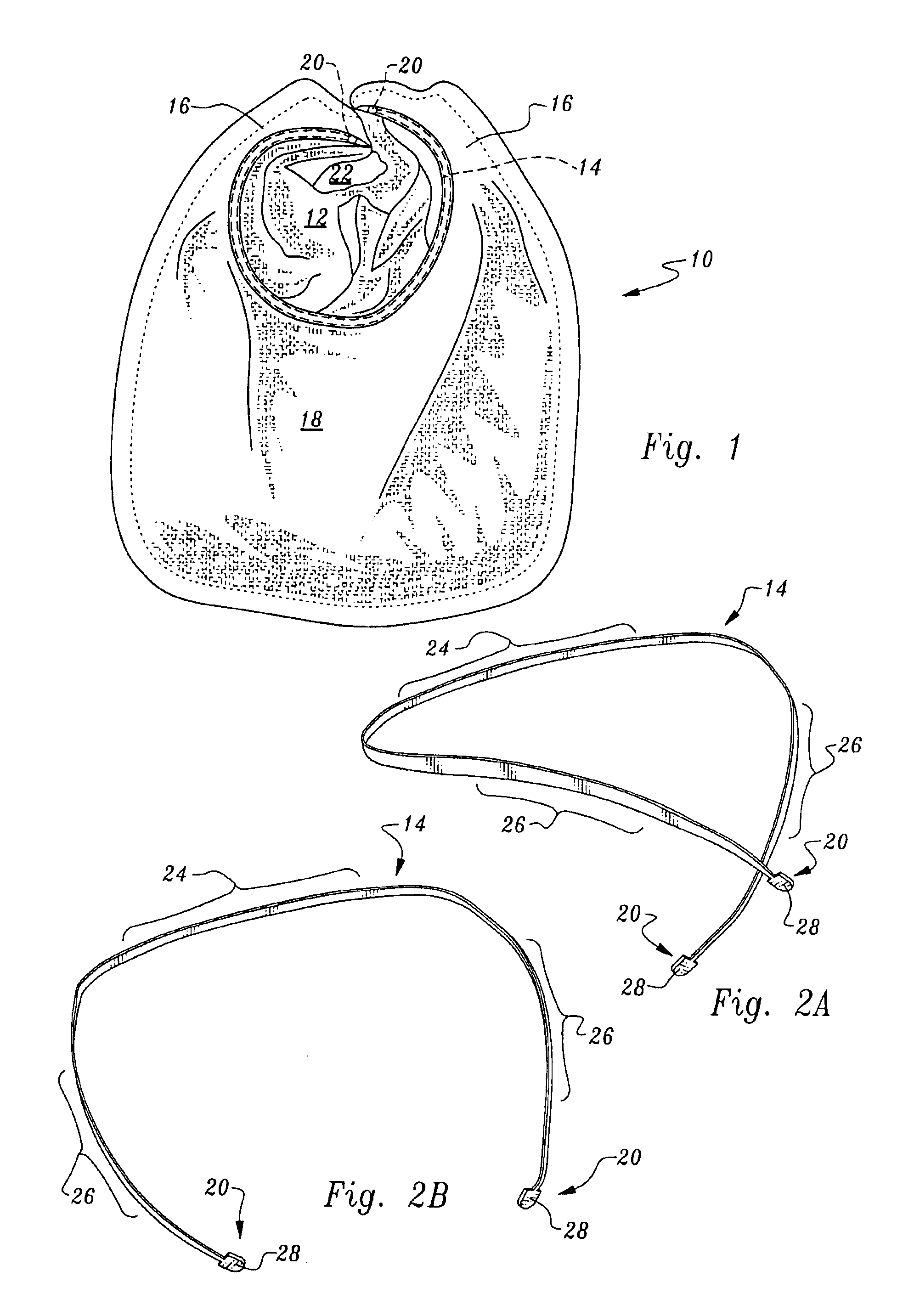

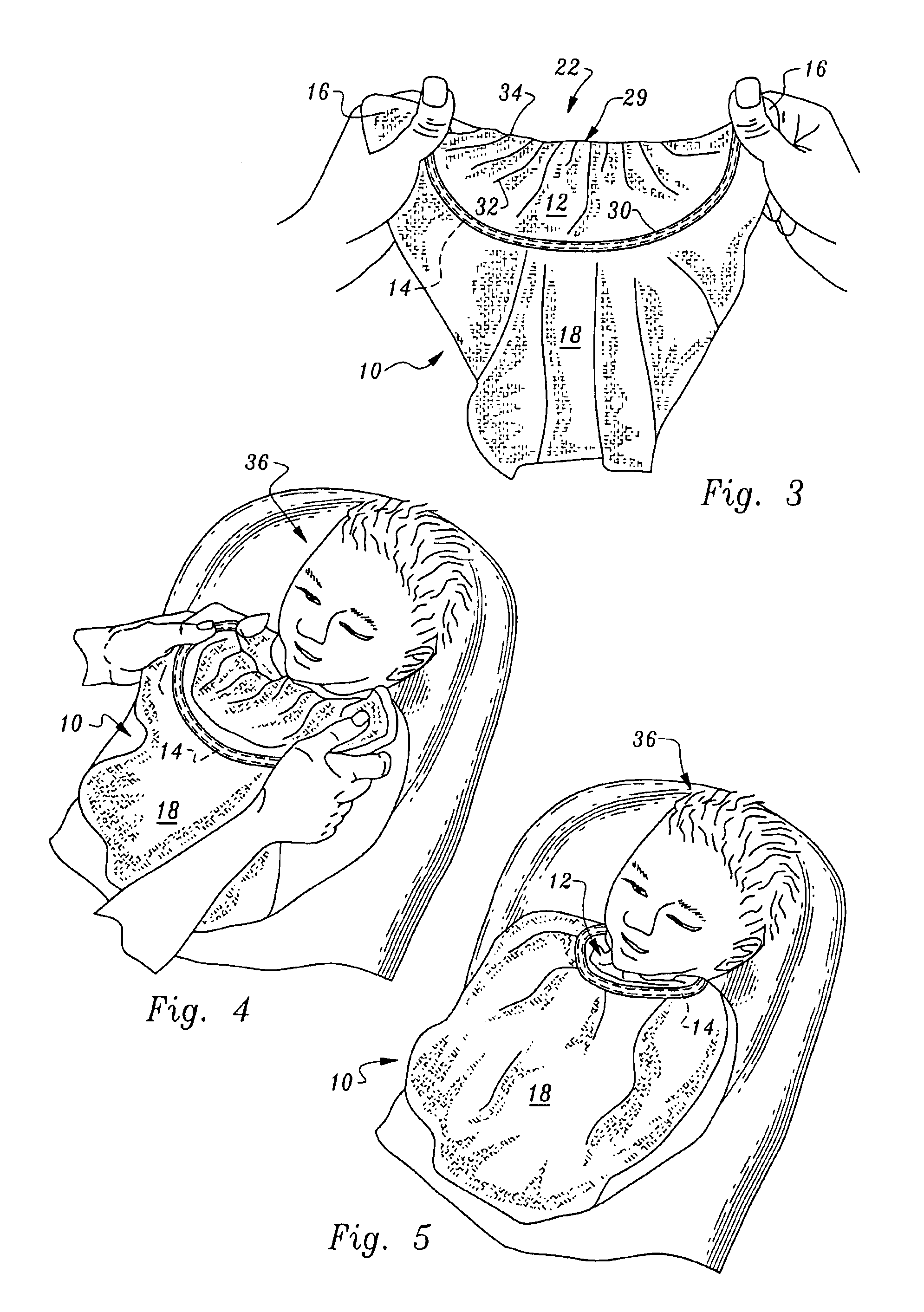

Protective bib with snug fitting feature

InactiveUS6859938B1Snugly and easily placed onto wearerAvoid problemsBaby linensProtective garmentEngineering

Owner:NISKI BRIAN W +1

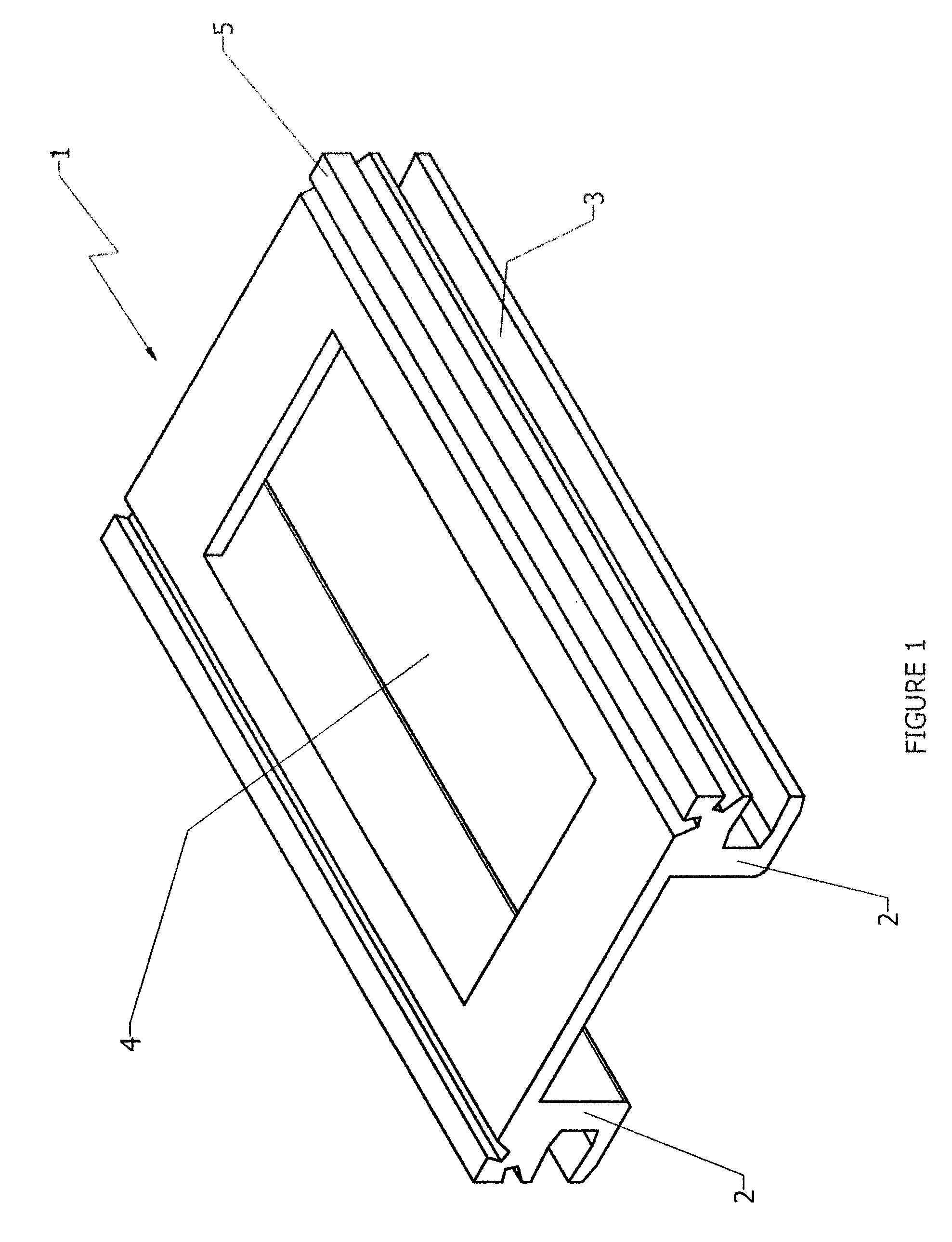

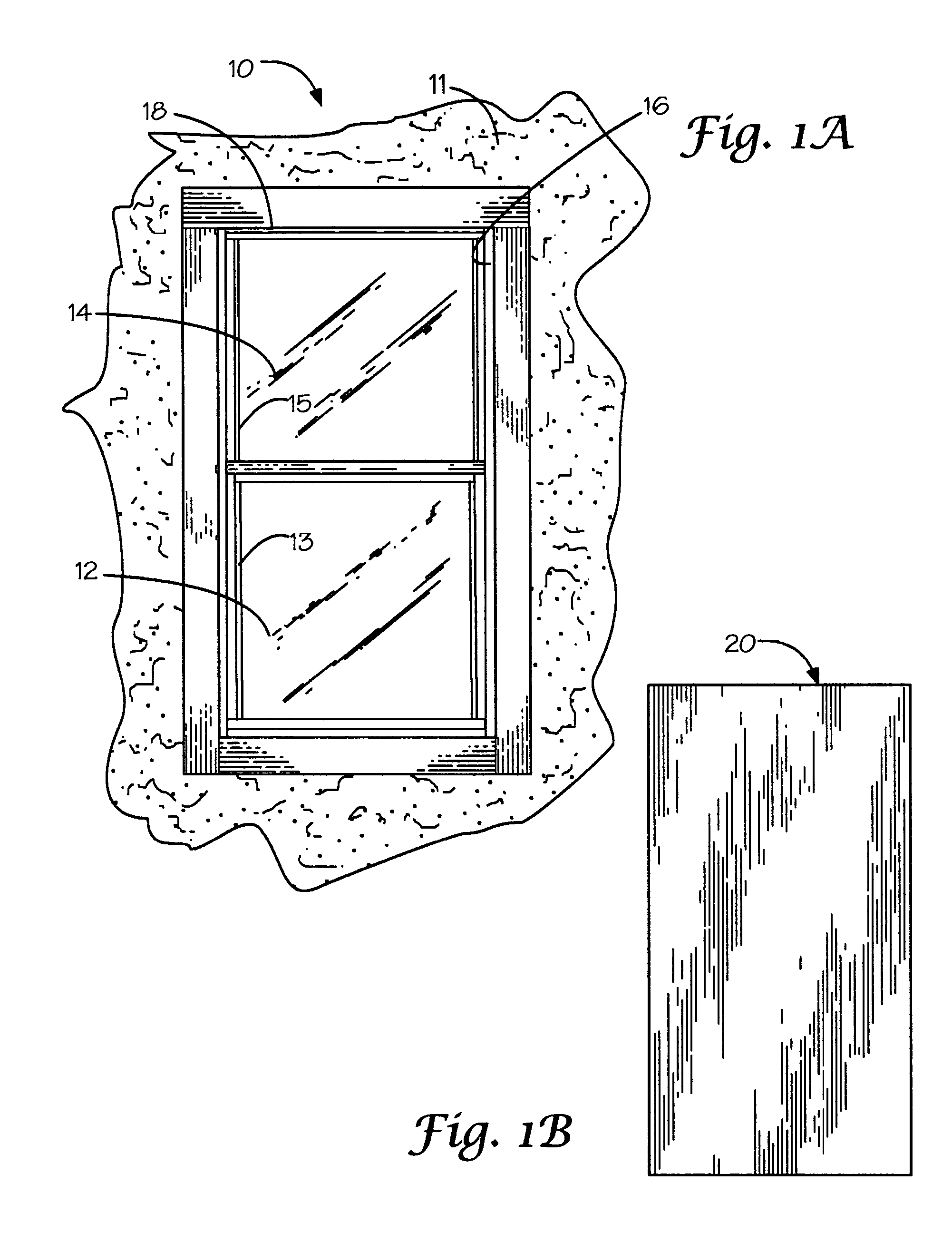

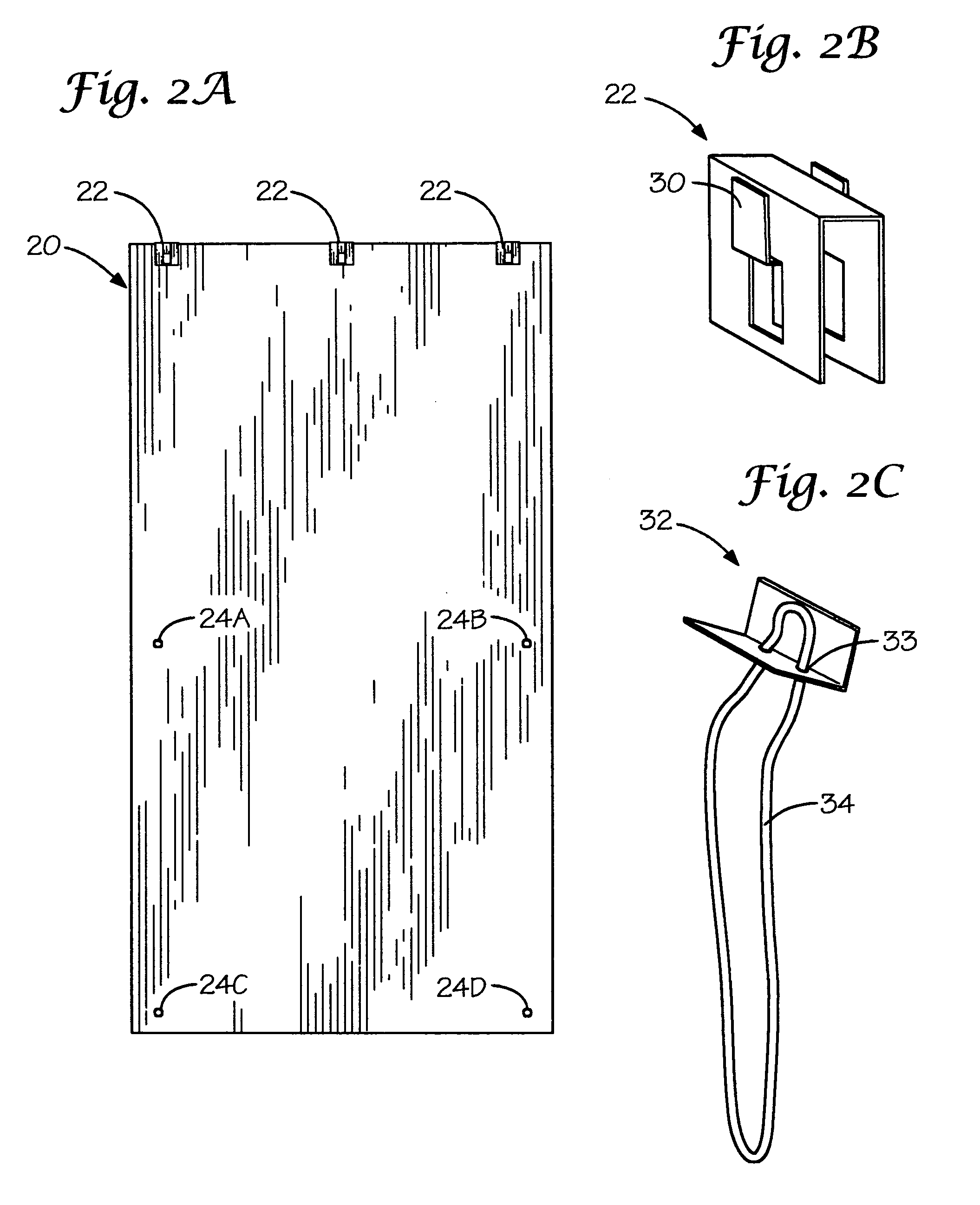

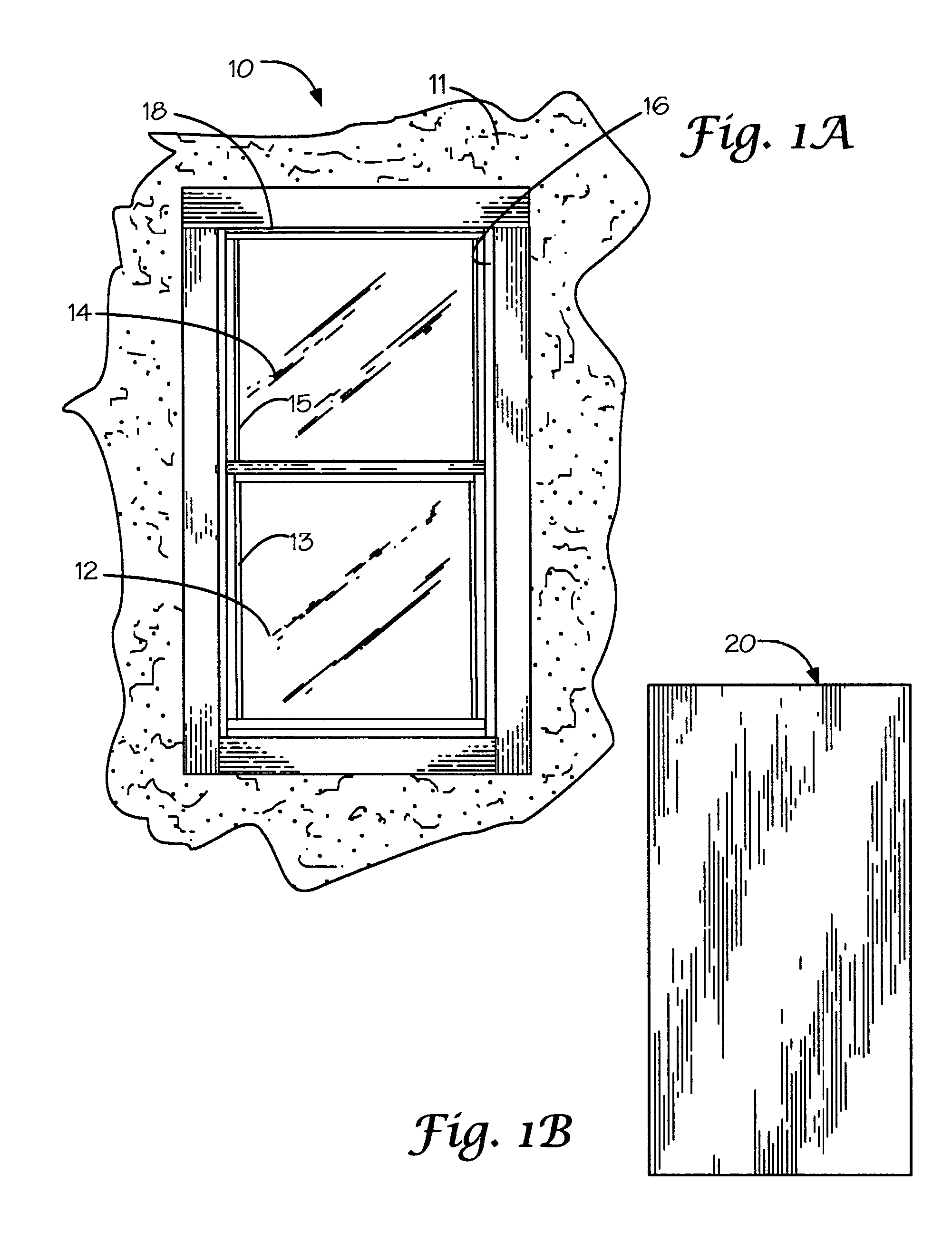

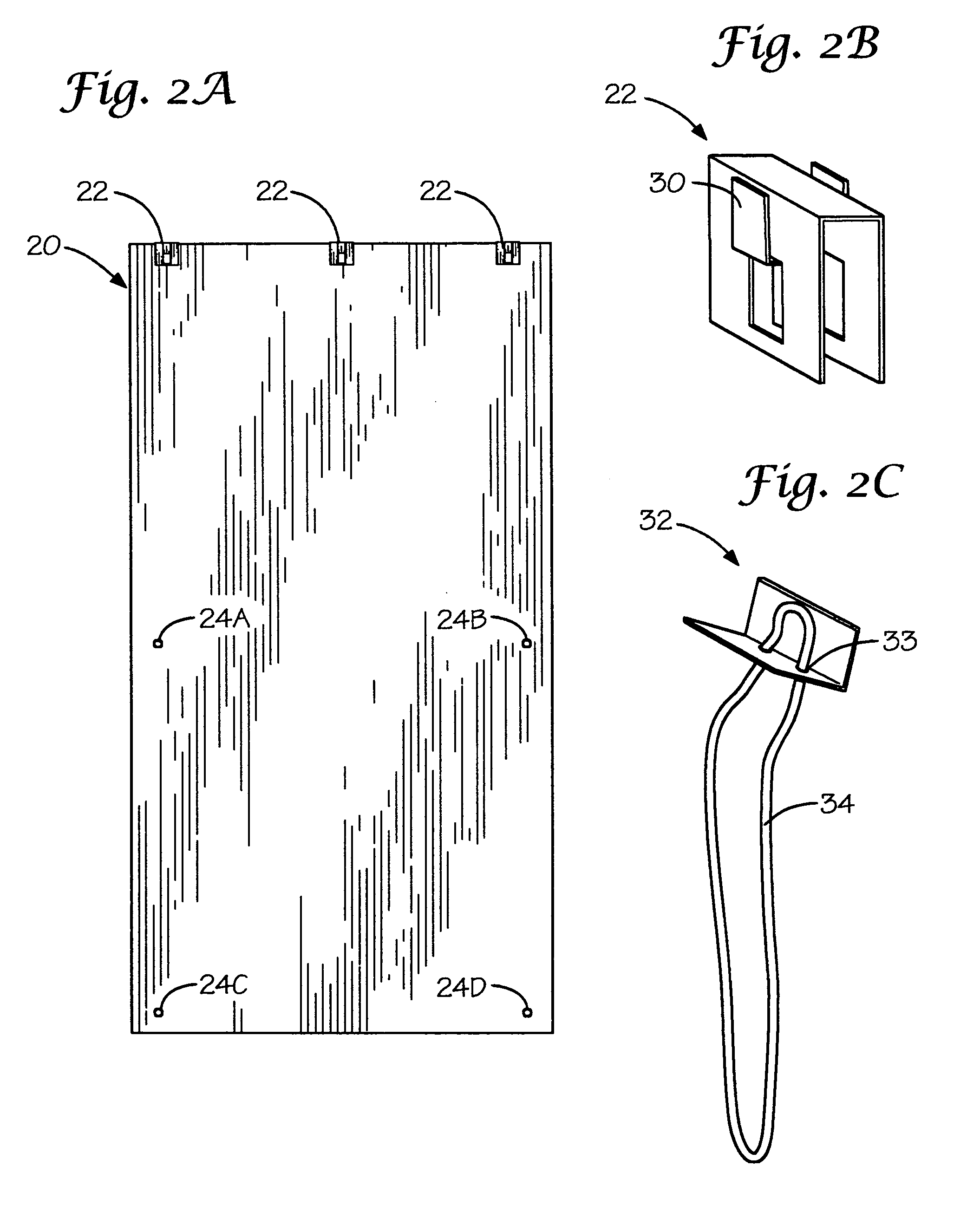

Window protection structure

InactiveUS7325365B2Simple and rapid methodEasy to installShutters/ movable grillesFixed grillesWindow openingEngineering

A window protection structure for a building including novel structure for affixing a sheet of protection material over the window opening. The sheet material is cut to the size of the window opening in the building, and holes are formed therein. U-shaped clips are slid onto an upper edge of the sheet material, and a plurality of brackets are provided with a pair of holes formed therein. Cords loops are secured through the holes in the brackets. The brackets are adapted for receipt by the interior of the window and the cords are threaded to the exterior of the window. The cord loops are threaded through the holes in the sheet material. A bungee cord is then used for securing the ends of the cord loops, whereby the sheet material is held firmly against the window.

Owner:WARNER JERALD R

Methods to mitigate plasma damage in organosilicate dielectrics

InactiveUS20120329269A1High yieldMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingMetal interconnectLine width

Methods of minimizing or eliminating plasma damage to low k and ultra low k organosilicate intermetal dielectric layers are provided. The reduction of the plasma damage is effected by interrupting the etch and strip process flow at a suitable point to add an inventive treatment which protects the intermetal dielectric layer from plasma damage during the plasma strip process. Reduction or elimination of a plasma damaged region in this manner also enables reduction of the line bias between a line pattern in a photoresist and a metal line formed therefrom, and changes in the line width of the line trench due to a wet clean after the reactive ion etch employed for formation of the line trench and a via cavity. The reduced line bias has a beneficial effect on electrical yields of a metal interconnect structure.

Owner:GLOBALFOUNDRIES INC

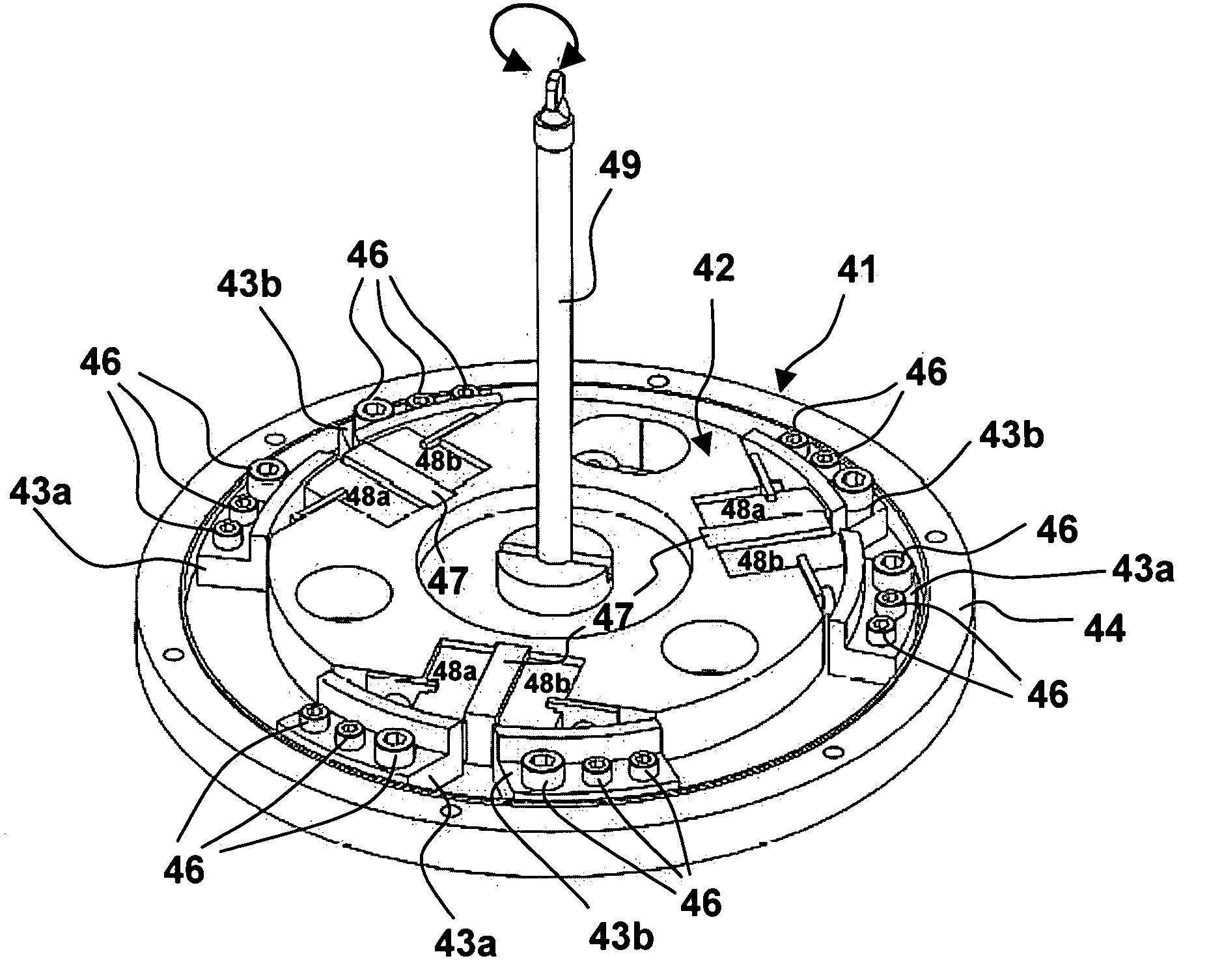

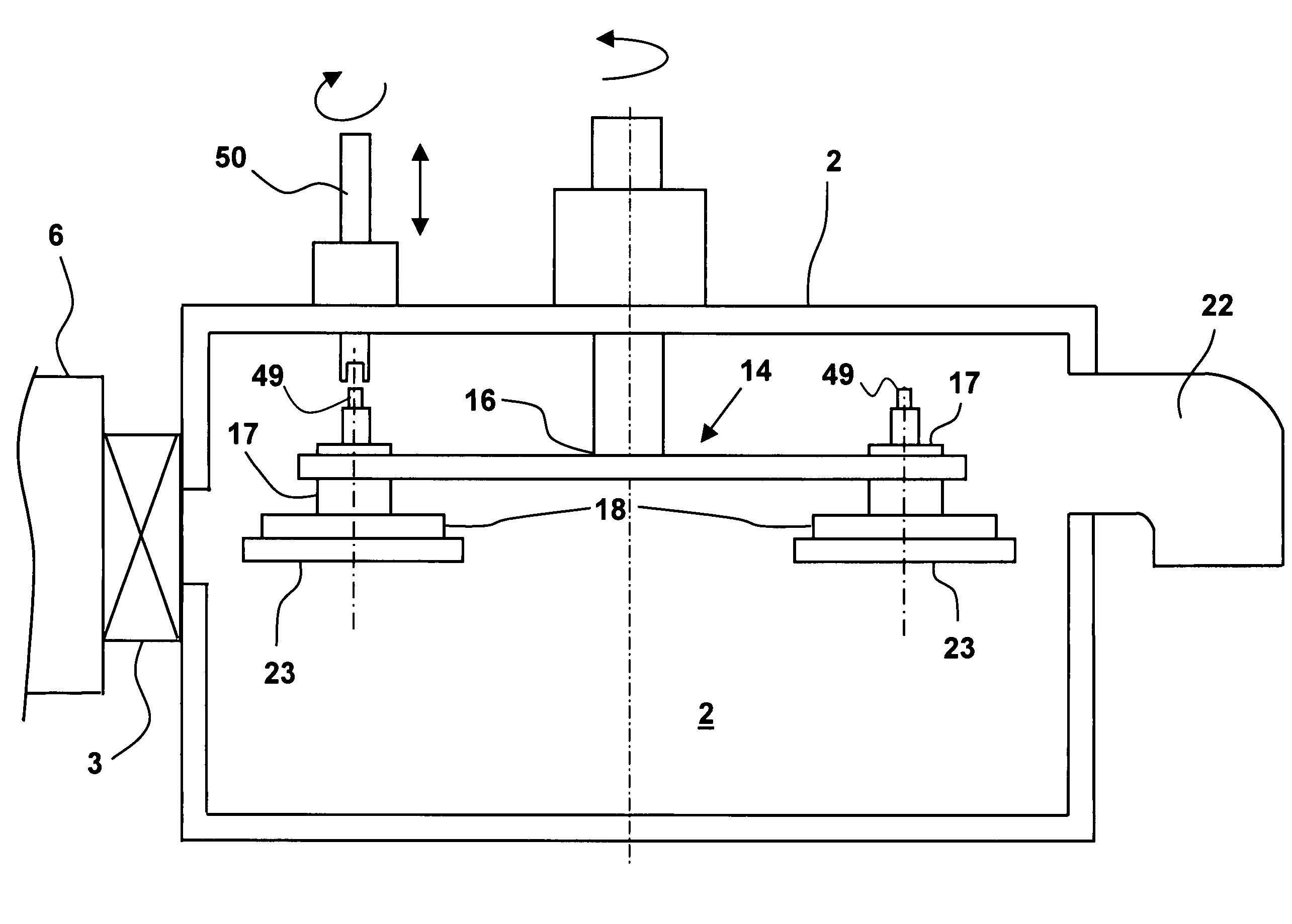

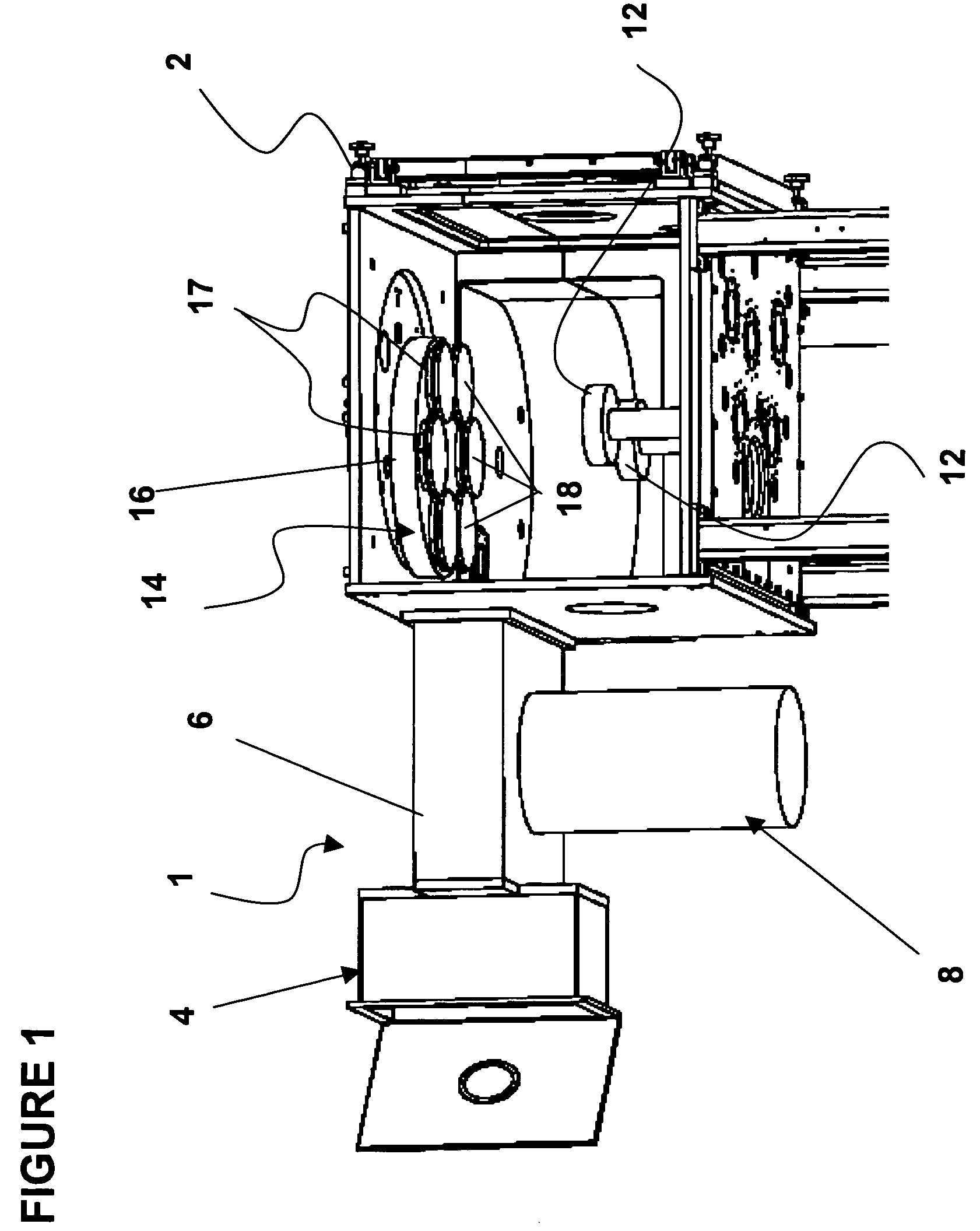

Substrate holder for a vapour deposition system

The invention relates to a partially disposable substrate holder used in magnetic latches for securing substrates on a planetary rotating platform suspended above a coating source in a vacuum chamber of a vapor deposition system, e.g. a chemical vapor deposition (CVD) system or a physical vapor deposition (PVD) system. The substrate holder includes a reusable base formed, at least partially, from a ferro-magnetic material, which is attracted to the magnetic latch, and a disposable cover formed from a relatively inexpensive, ferromagnetic, easily formable material, which encourages adherence of coating material and has a low vapor pressure at coating temperatures.

Owner:VIAVI SOLUTIONS INC

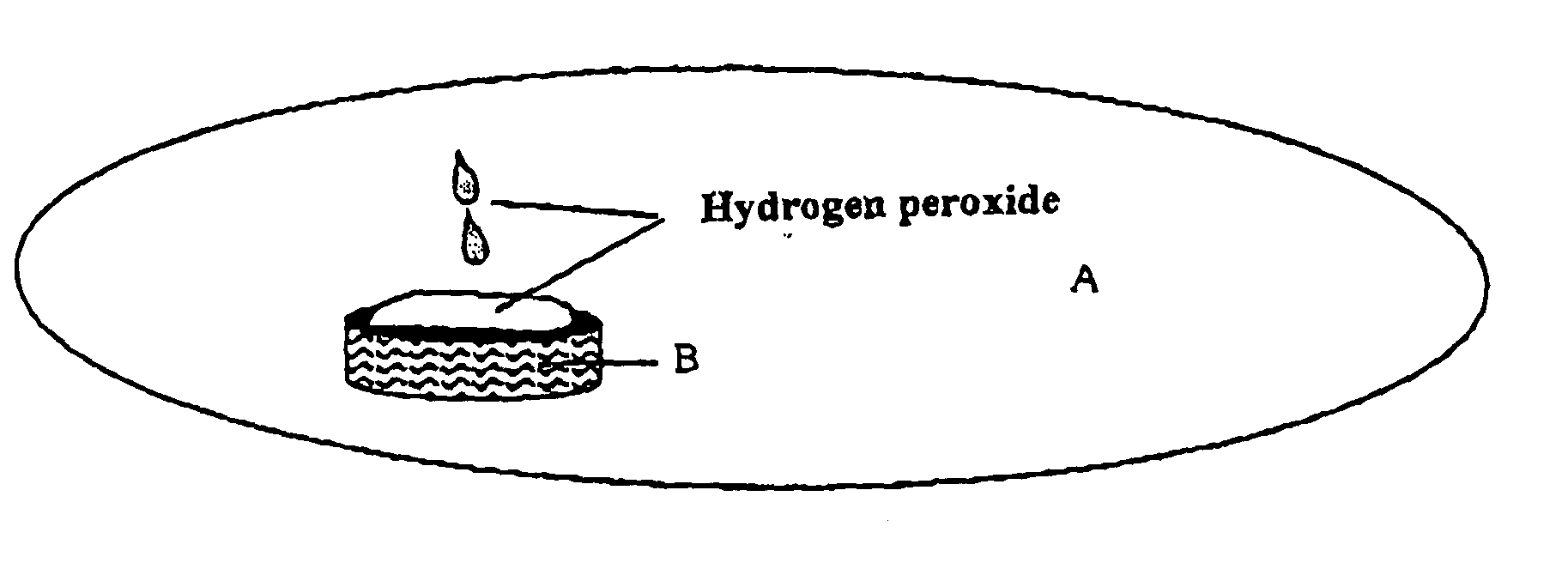

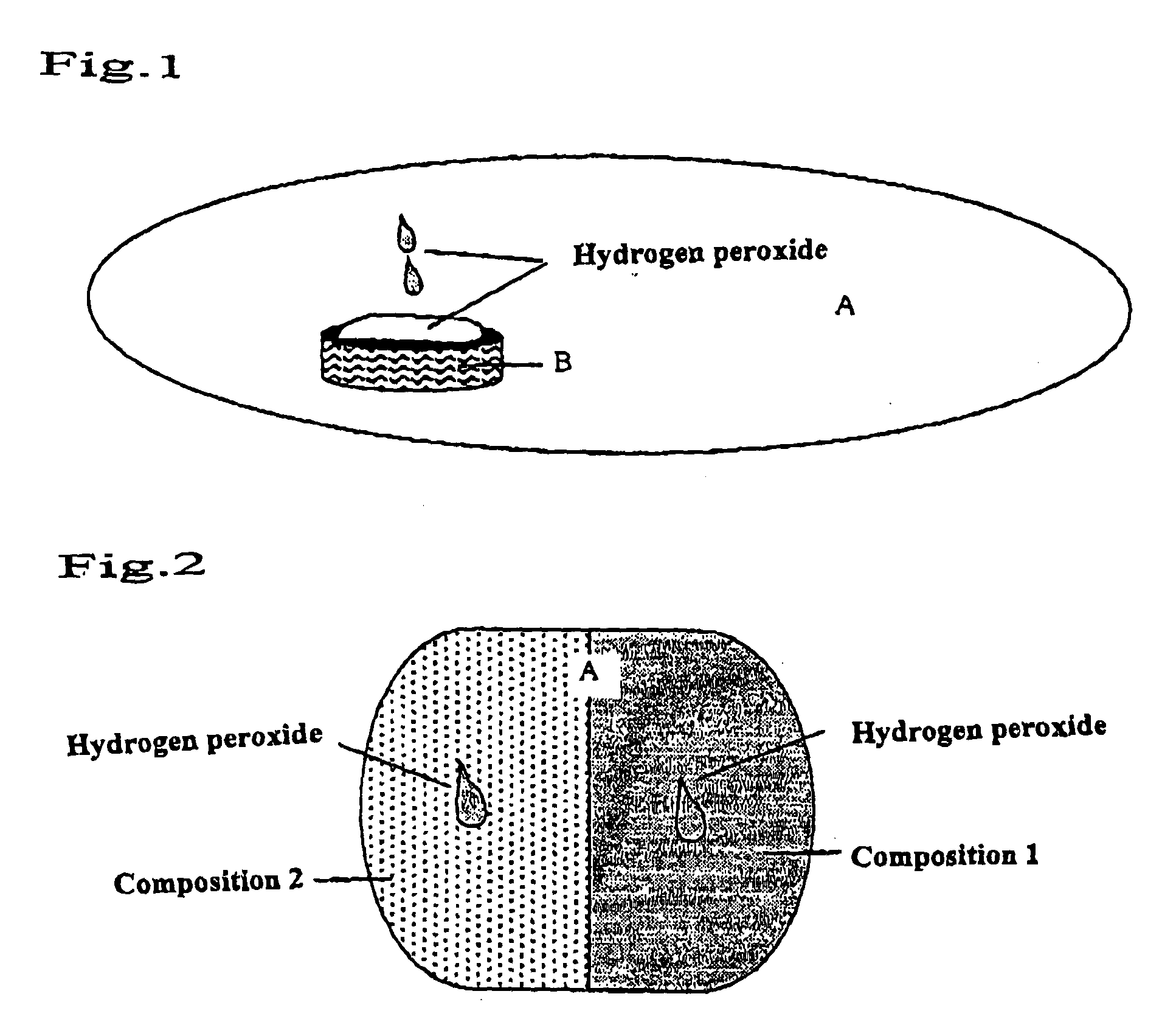

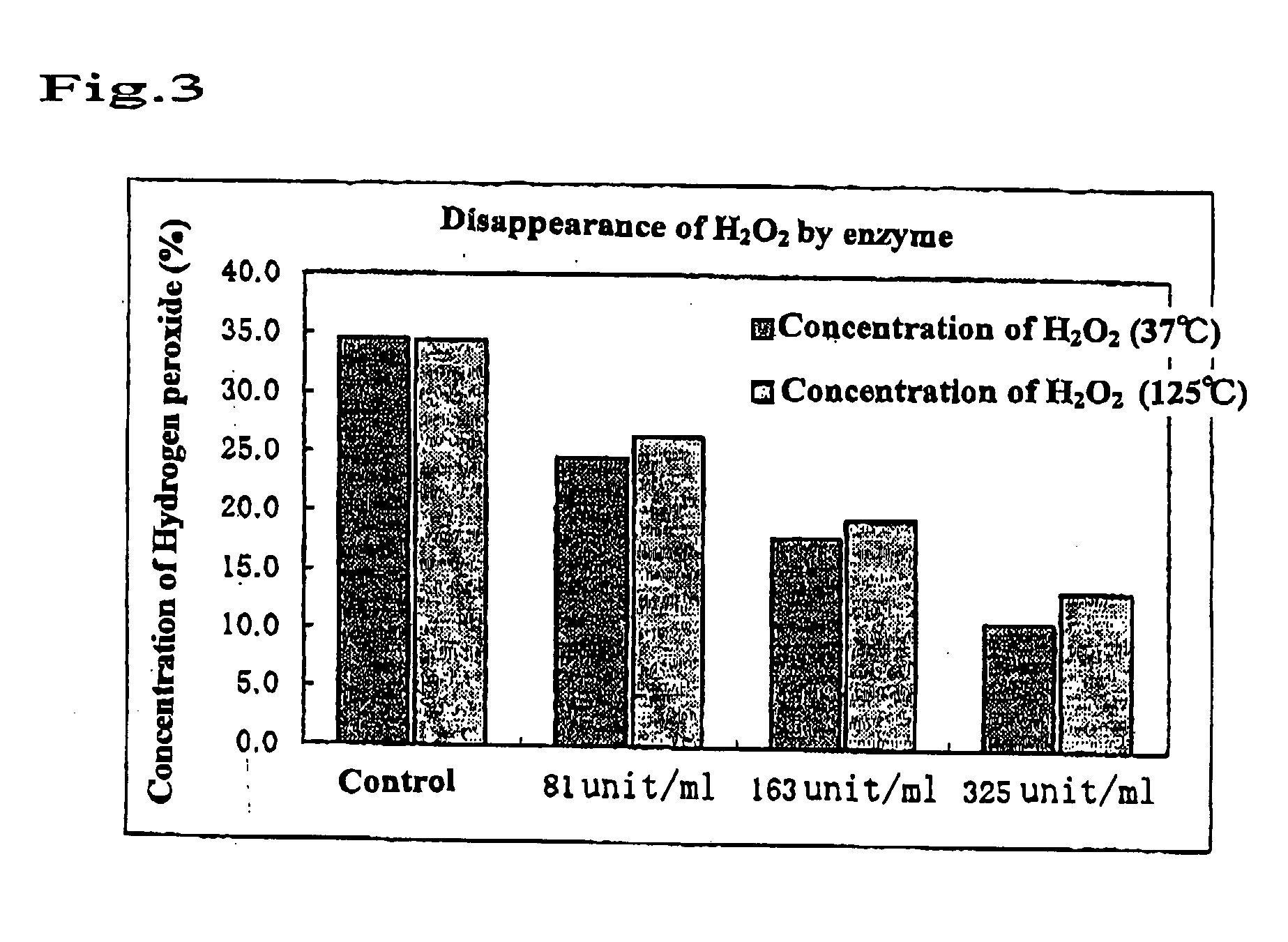

Composition for oral cavity

InactiveUS20050100514A1Prevent leakageProtection materialCosmetic preparationsTeeth fillingFree radicals scavengerDentistry

An object of the present invention is to provide a composition for the oral cavity which protects gingiva and oral mucosas against a bleaching treatment with a tooth bleaching agent. The present invention provides a composition for the oral cavity containing a free radical scavenger.

Owner:SHOWA YAKUHIN KAKO

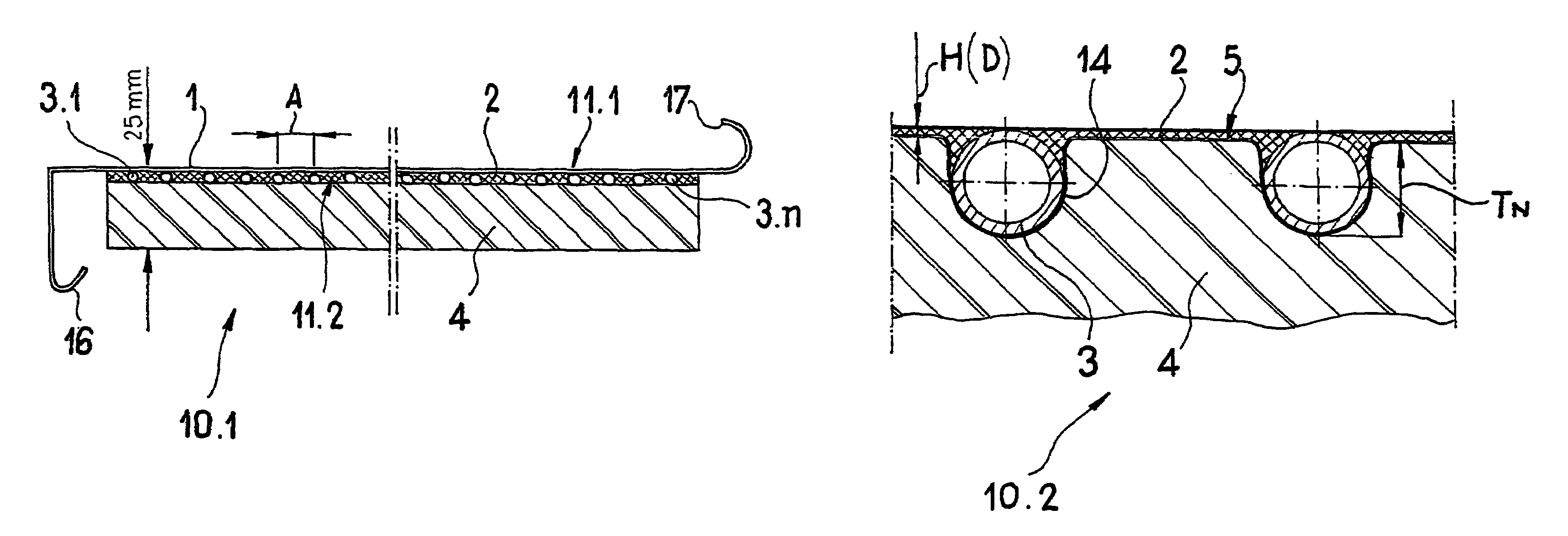

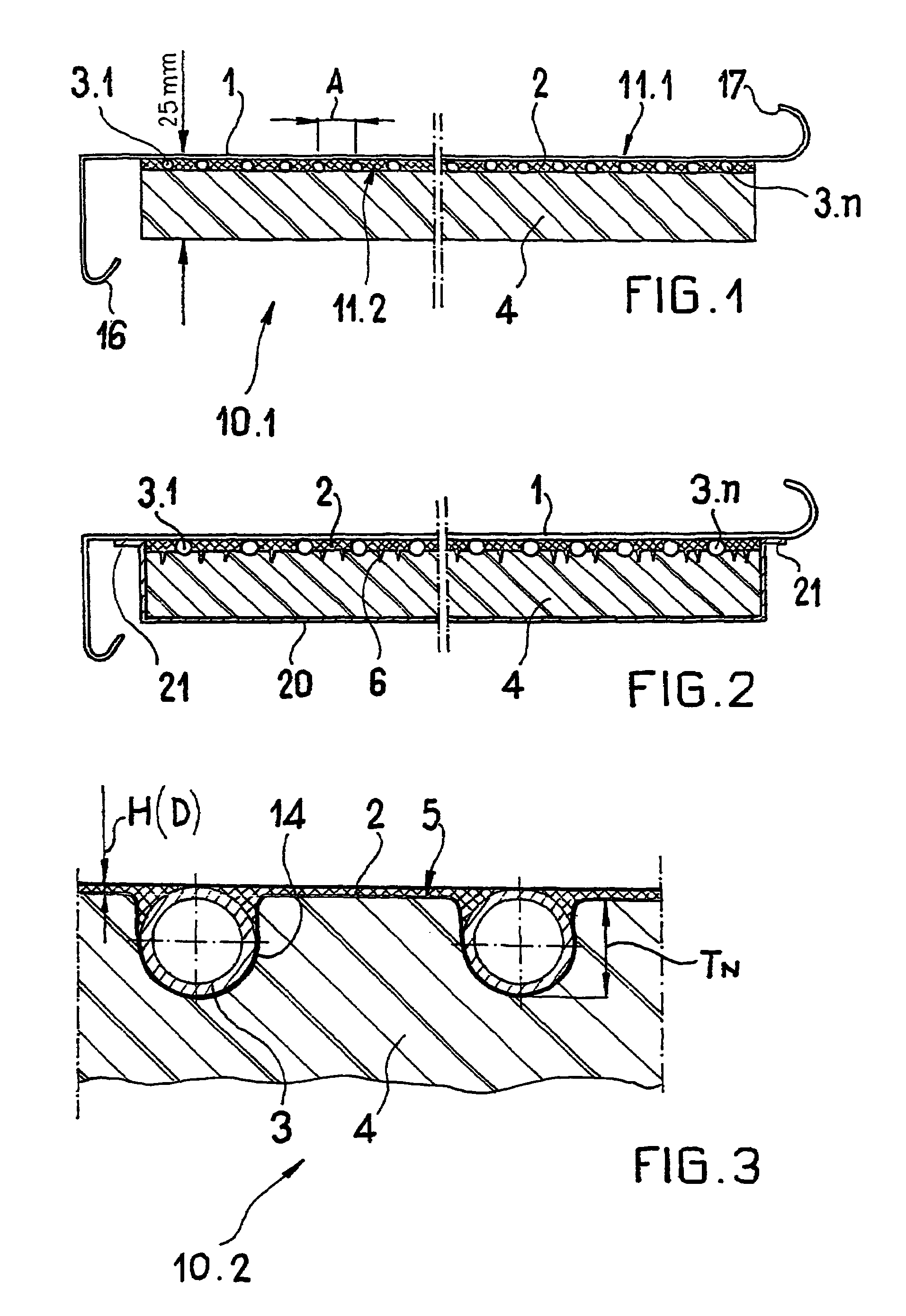

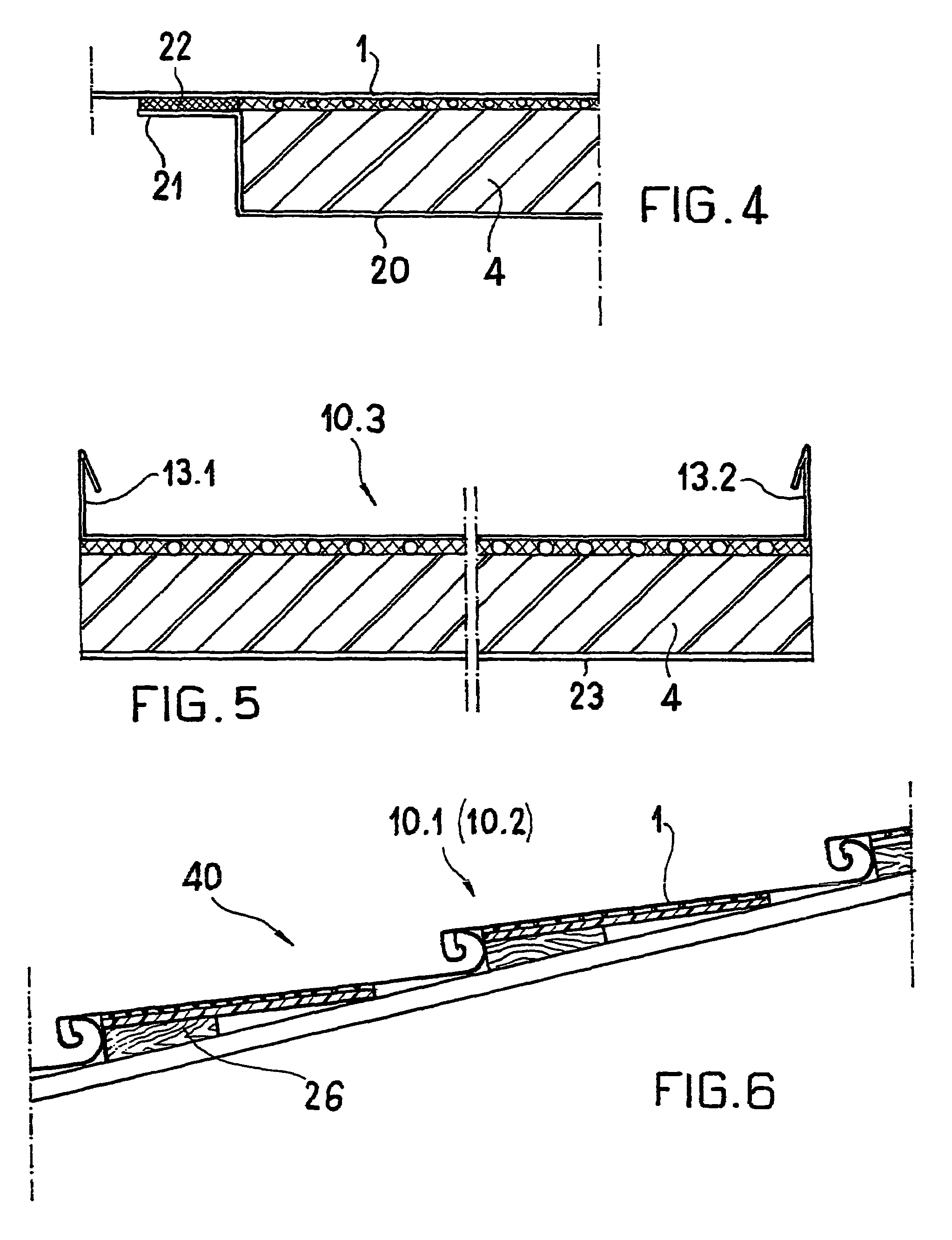

Heliothermal flat collector module having a sandwich structure

InactiveUS7610911B2Degree of resistanceResistance to stabilityRoof covering using slabs/sheetsSolar heating energyEngineeringELASTIC ADHESIVE

A self-supporting heliothermal flat collector module includes a sheet metal panel; a register-type arrangement of capillary tubes separated from one another for the flow of a fluid medium that lies on the rear side of the sheet metal panel opposite that to be irradiated; and a thermally-insulating insulation core also positioned on the rear side. According to the invention, the capillary tubes of the register-type arrangement are placed into contact with the surface of the thermally-insulating insulation core, and the thermally-insulating insulation core is attached to the sheet metal panel by means of an elastic adhesive layer, whereby the capillary tubes are at least partially embedded into the adhesive layer between the sheet metal panel and the insulation core.

Owner:RHEINZINK

Packaging device for disc-shaped items and related materials and method for packaging such discs and material

InactiveUS20050051442A1Avoid contactEliminate needApparatus modification to store record carriersClosure with auxillary devicesAdhesiveEngineering

Owner:AVECMEDIA

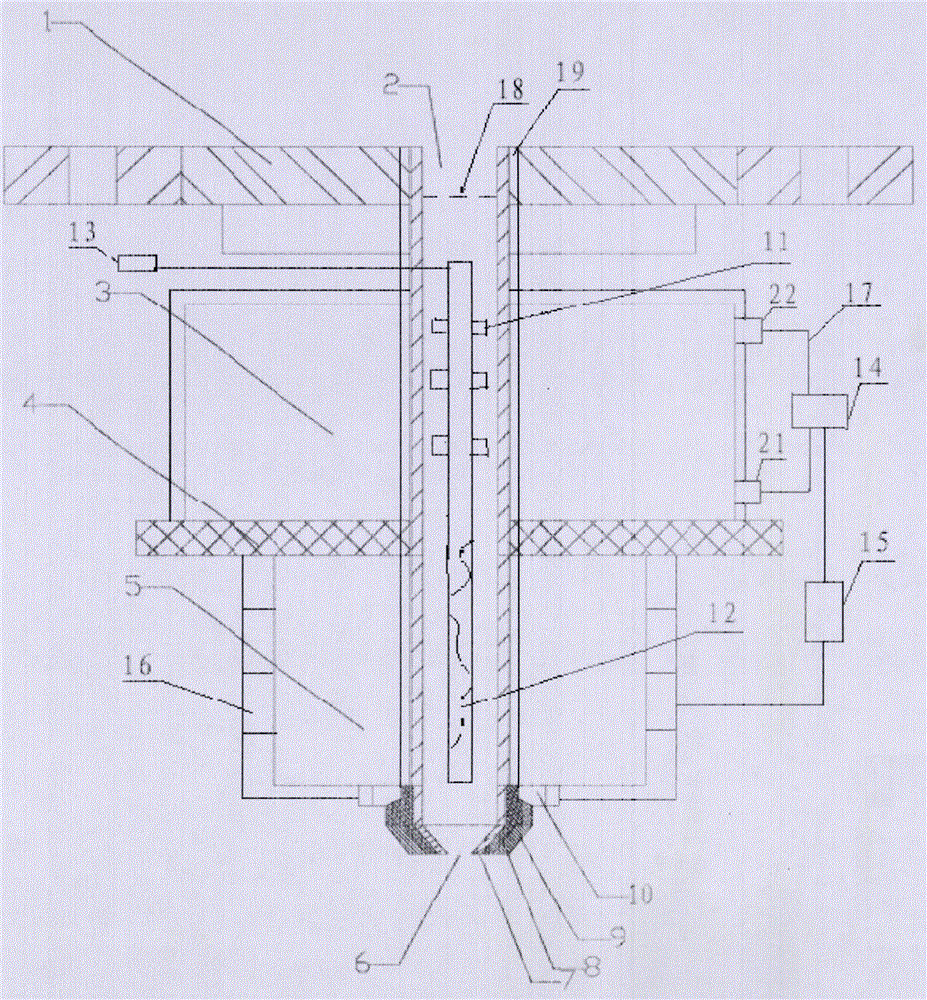

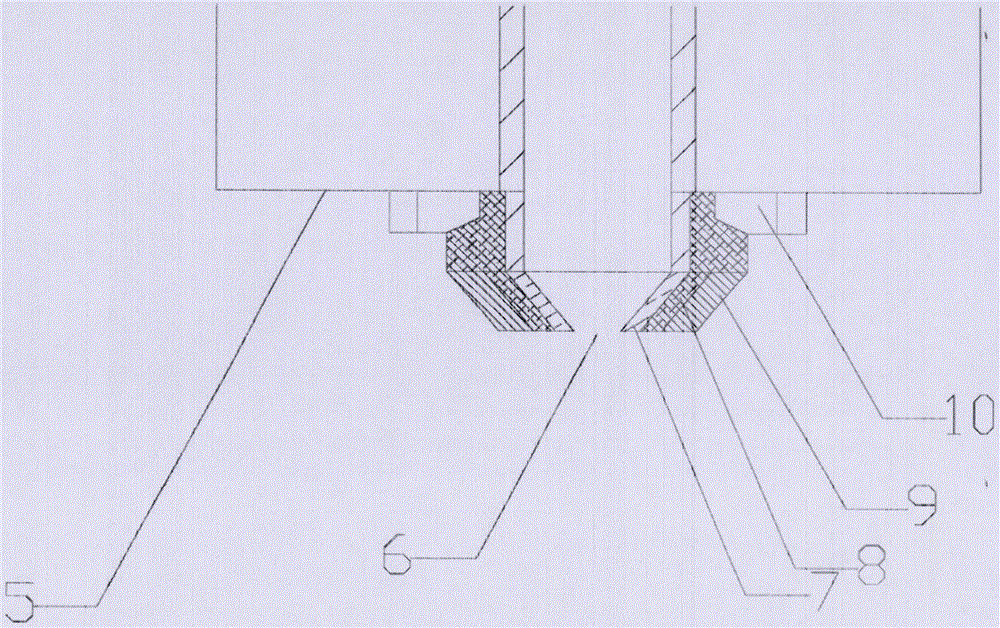

Cyclic heating high efficiency 3D printer nozzle device

InactiveCN106426912ANot easy to cureSolve obstaclesManufacturing heating elements3D object support structuresHeat conductingThermal insulation

The invention relates to a cyclic heating high efficiency 3D printer nozzle device, including a base plate, the middle of the base plate is provided with a feeding tube, the main body of the feeding tube is located below the base plate, the lowermost of the feeding tube is a nozzle, the upper outer side of the feeding tube is provided with a heat dissemination component, the outside of the lower part of the feeding tube is a heating component, the outer wall of the nozzle is constructed from multiple layered structures, the inner layer is a main heat conducting layer, which is touched and fixed with an elastic thermal preservation layer outside the main heat conducting layer, the outer side of the elastic thermal insulation layer is an outer wall, the top of the elastic thermal preservation layer is provided with a compression rod, the inside of the feeding tube is provided with a rotating shaft, the rotation of which is driven by a motor, the heat dissemination component includes a heat dissemination tube and a liquid heat dissemination device connected with the heat dissemination tube, the liquid heat dissemination device is connected with a control device, the control device through controlling a temperature sensor provided on the heat dissemination tube performs a heat disseminating control to the materials in the feeding tube. The device has good performance on heating and disseminating heat, and has obvious effect on anti clogging.

Owner:HUNAN RUIDU TECH

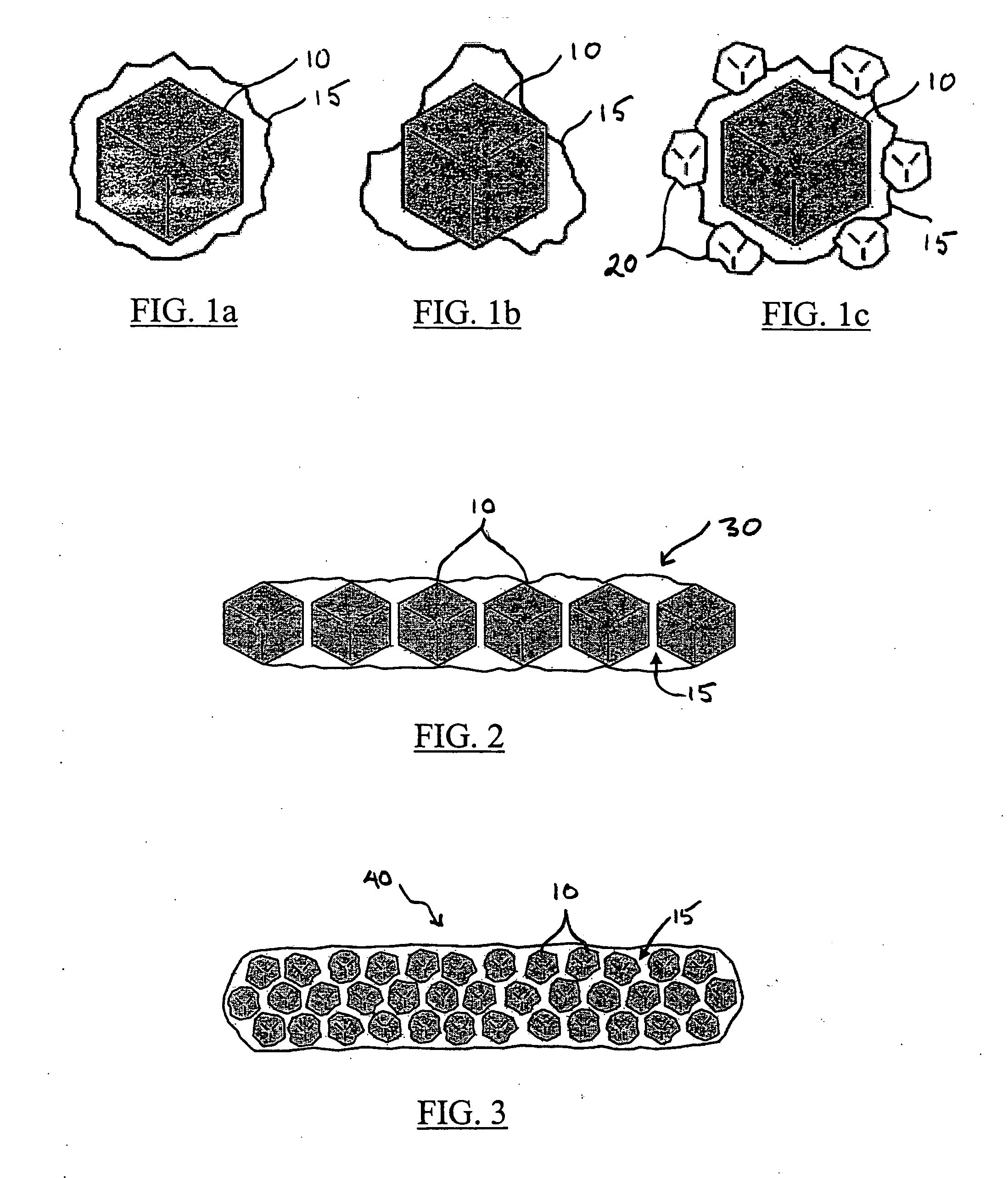

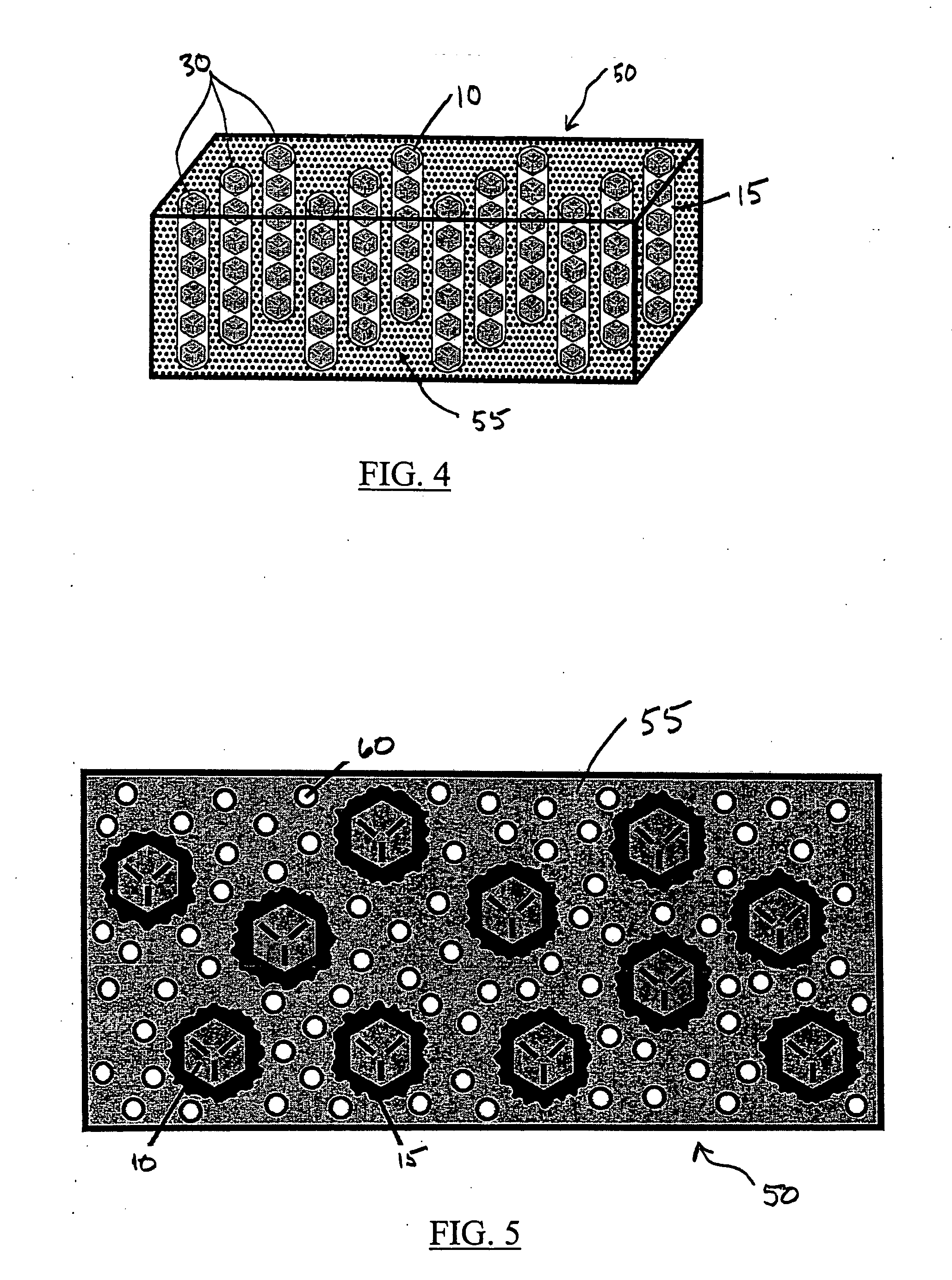

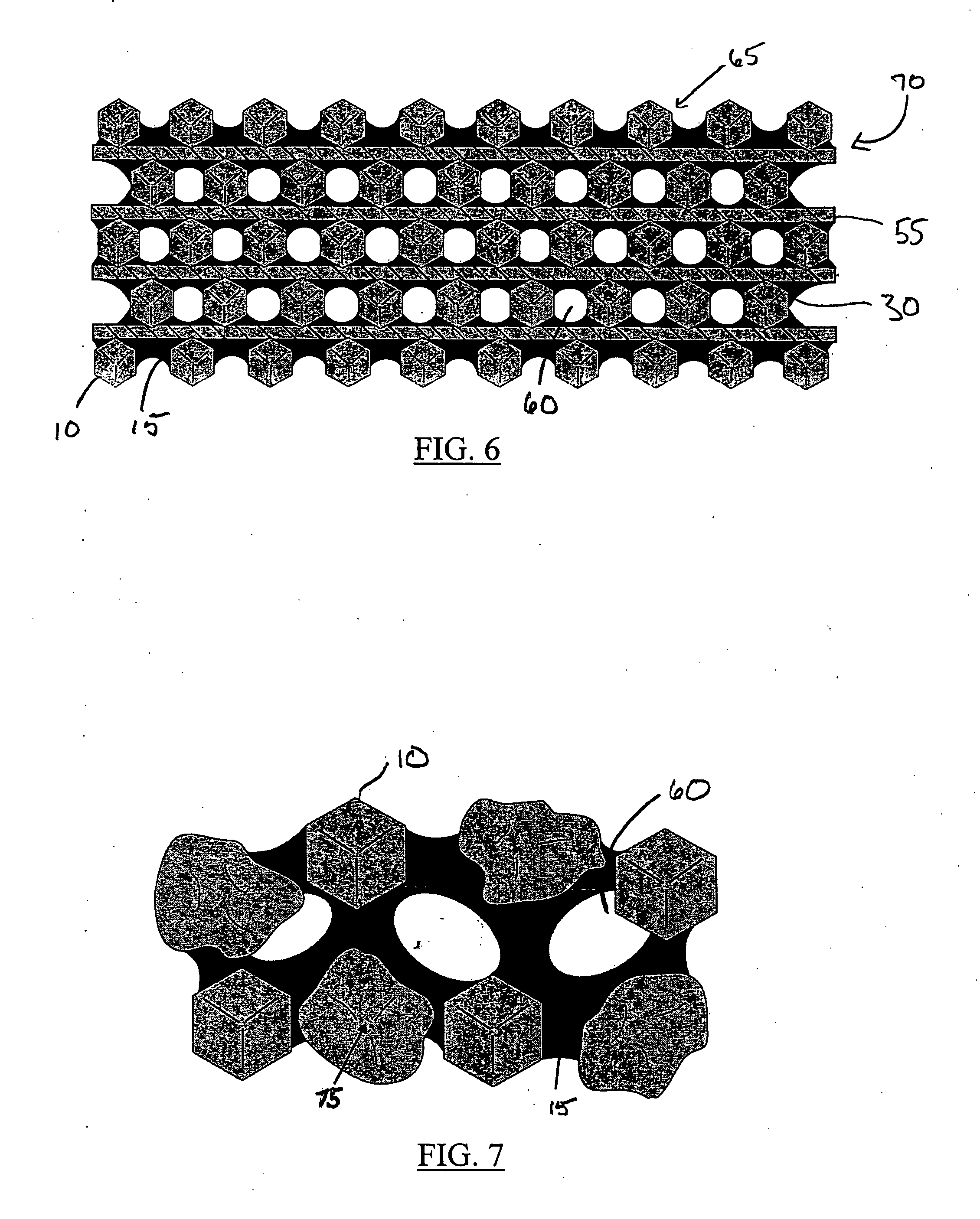

Molten braze-coated superabrasive particles and associated methods

InactiveUS20050108948A1Improved superabrasive particle retentionPreserve strengthPigmenting treatmentDrill bitsAlloyBraze alloy

A superabrasive particle coated with a solidified coating of a molten braze alloy that is chemically bonded to the superabrasive particle, where the molten braze alloy includes a substantially less-reactive protective material, is disclosed and described. In one aspect, the molten braze alloy may coat at least about 80% of an outer surface of the superabrasive particle. Various methods for making and using such a coated superabrasive particle are additionally disclosed and described.

Owner:SUNG CHIEN MIN

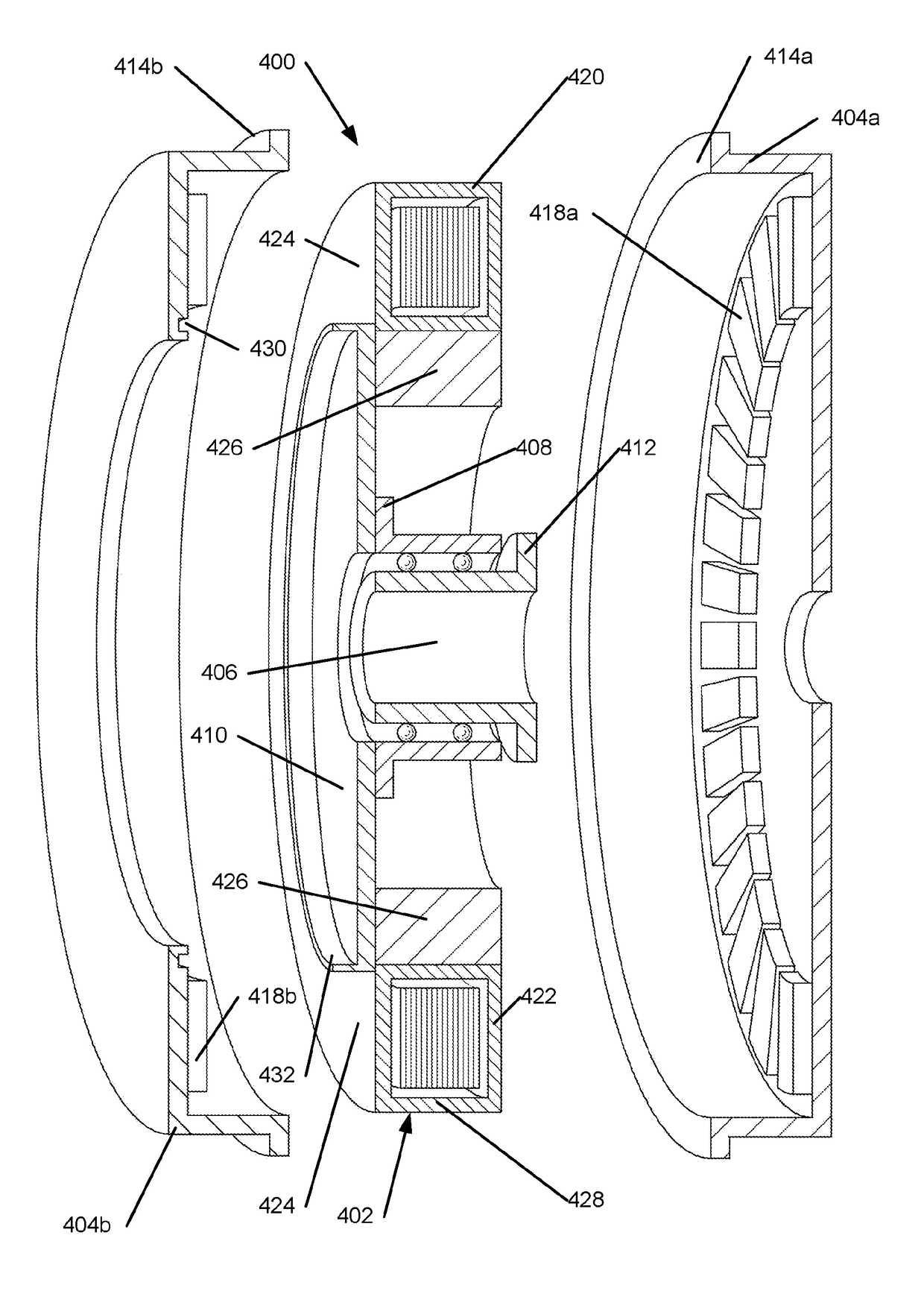

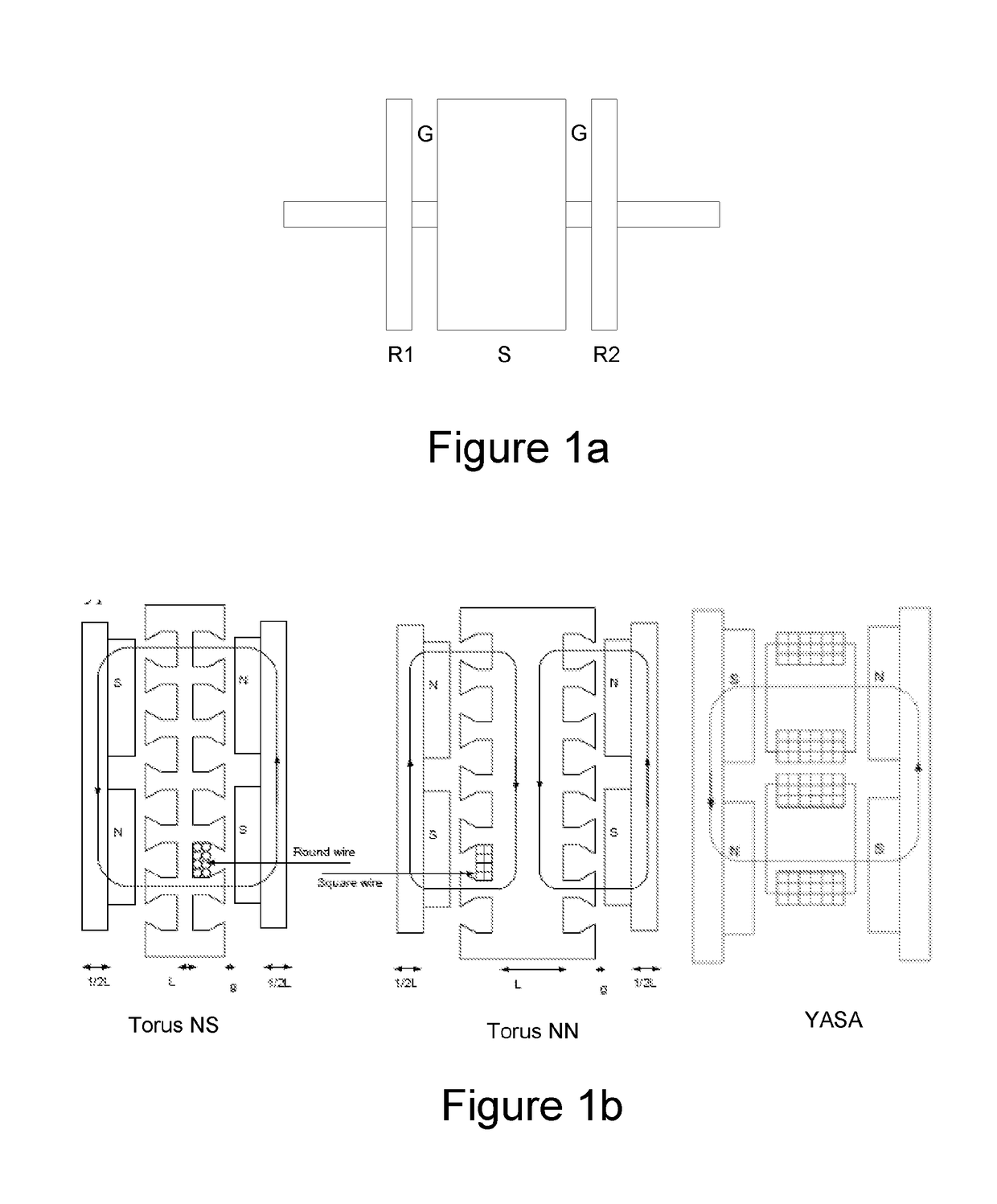

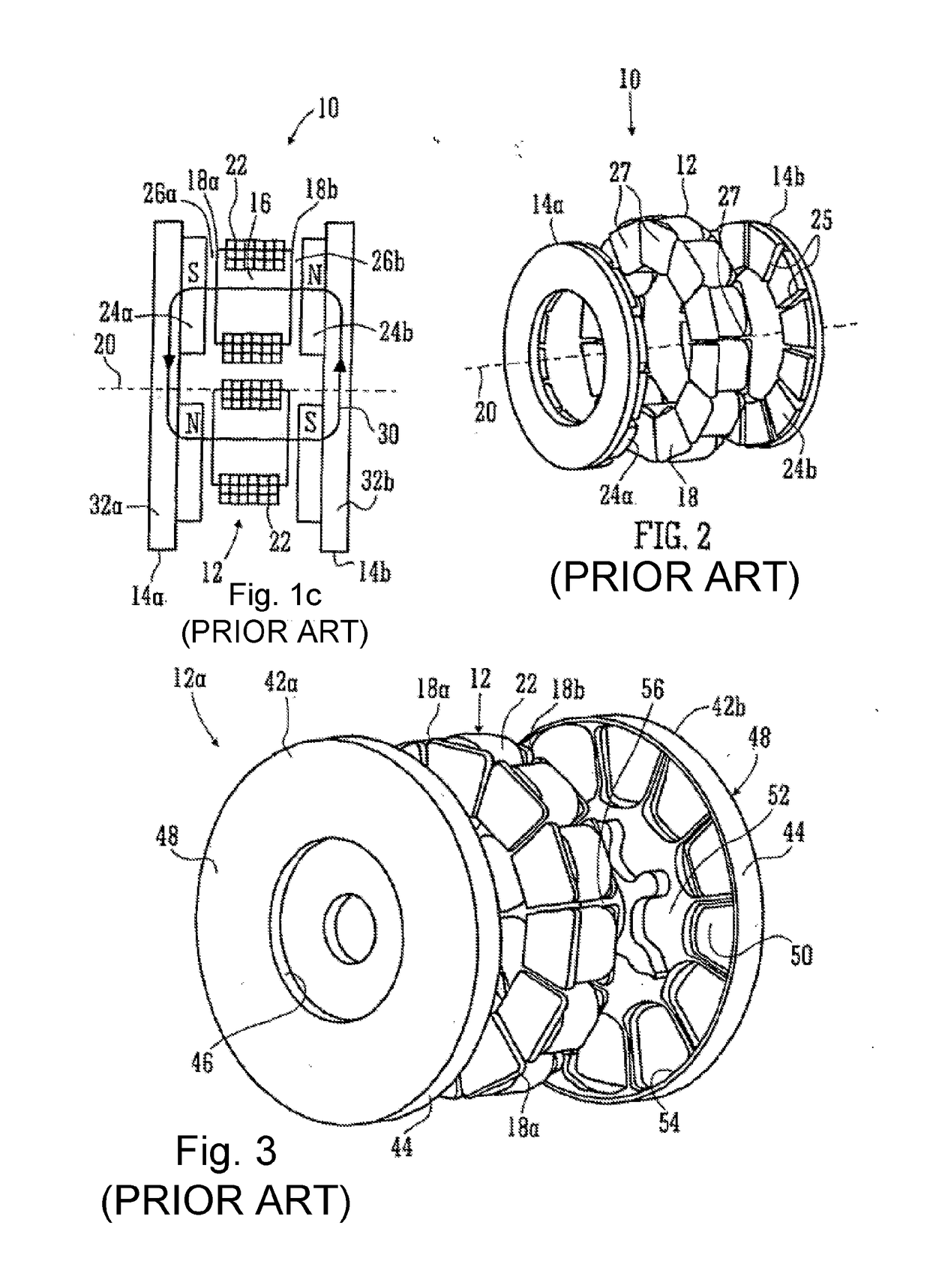

Axial Flux Machine

ActiveUS20180013323A1Increase stiffnessRigid enoughMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringMagnetic flux

An axial flux machine is described. The machine has a stator comprising a stator housing enclosing a plurality of stator bars disposed circumferentially at intervals around an axis of the machine, and a rotor comprising a set of permanent magnets and mounted for rotation about the axis of the machine. The rotor is spaced apart from the stator along the axis of the machine to define a gap between the stator and rotor and in which magnetic flux in the machine is generally in an axial direction. The machine also comprises a hub assembly comprising a rotating hub and a mount separated by a bearing to permit the hub to rotate relative to the mount, the rotating hub comprising a hub flange and the mount comprising a mount flange, each of the flanges being spaced axially apart from one another. The machine further comprises a bulkhead for mounting the hub assembly and stator, wherein the bulkhead is mounted to the mount flange of the hub assembly and the stator housing is mounted to the bulkhead. The rotor comprises first and second rotors disposed either side of the stator, the first rotor being mounted to the hub flange and the second rotor being mounted only to the first rotor, the first and second rotors together forming a U-shaped rotor extending across and either side of the stator and being rotatable relative to the stator about the axis of the machine.

Owner:YASA LIMITED

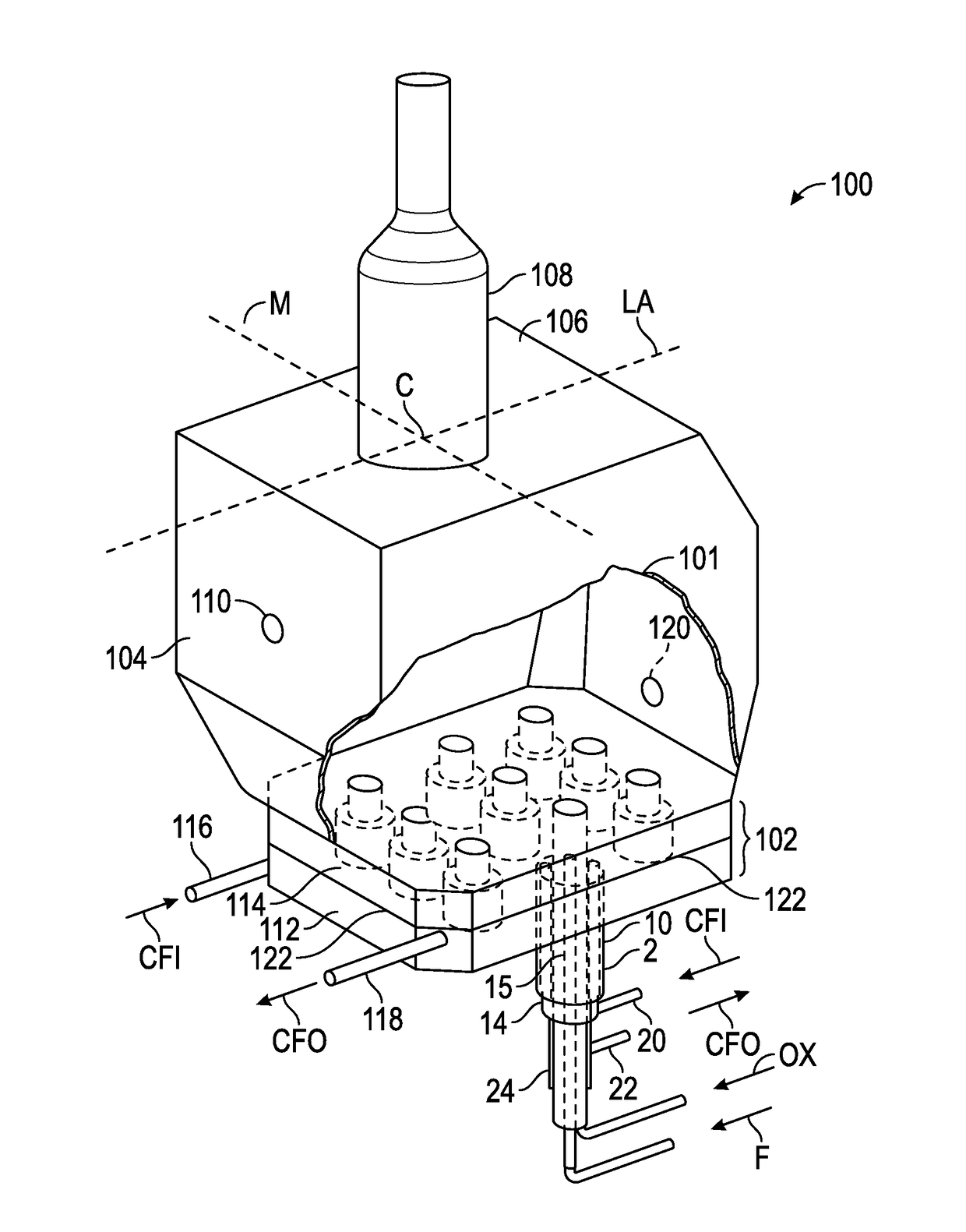

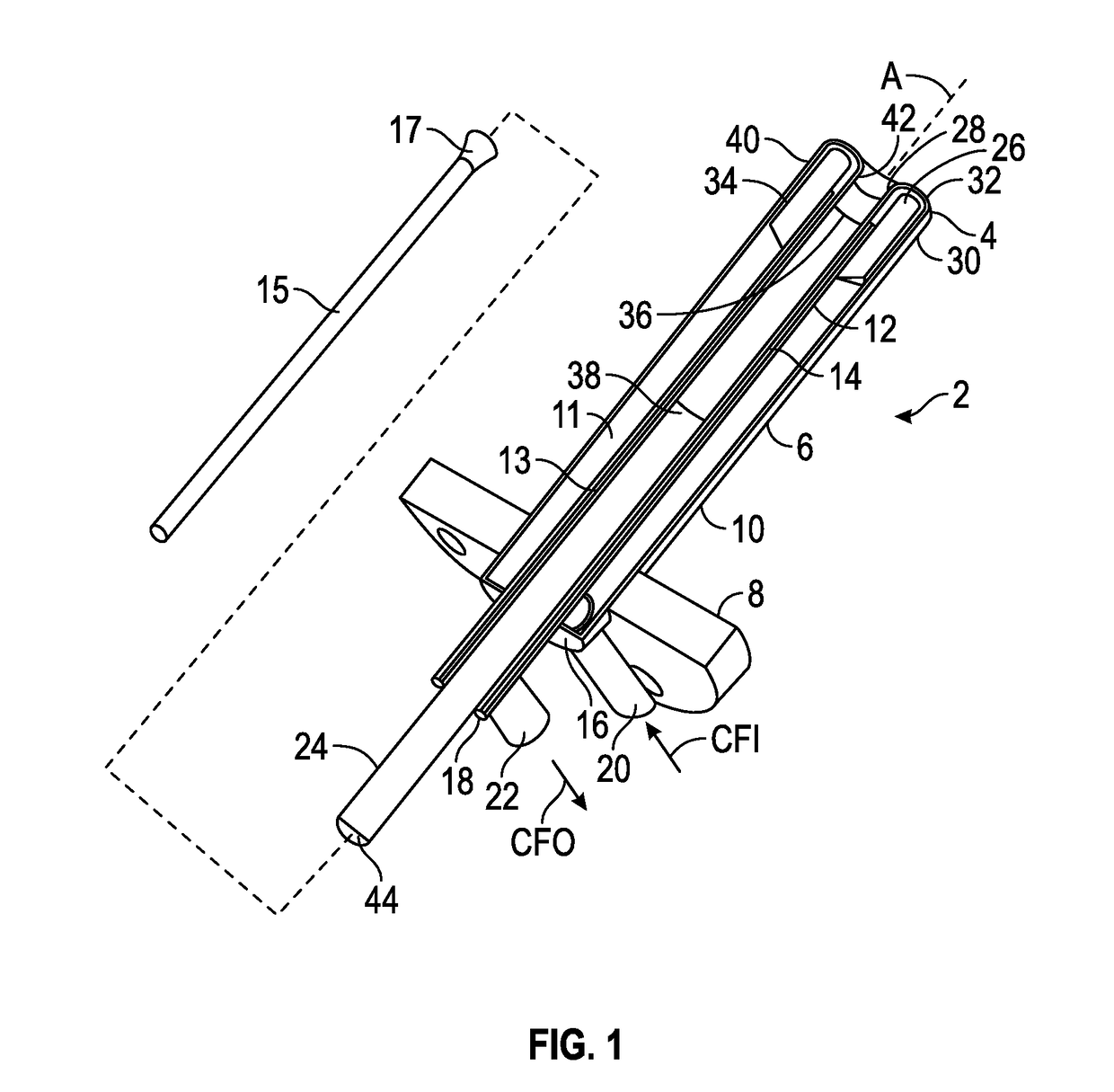

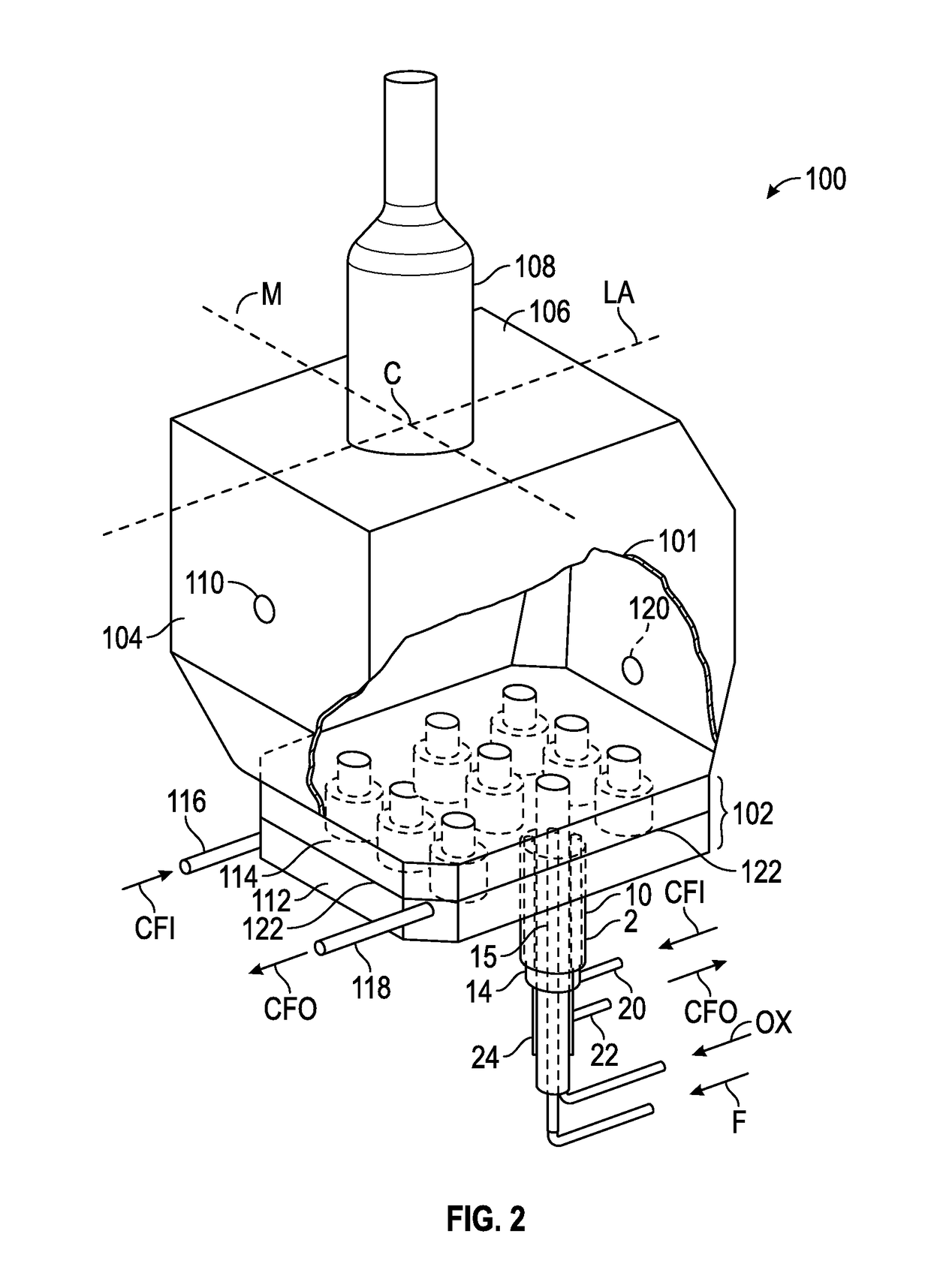

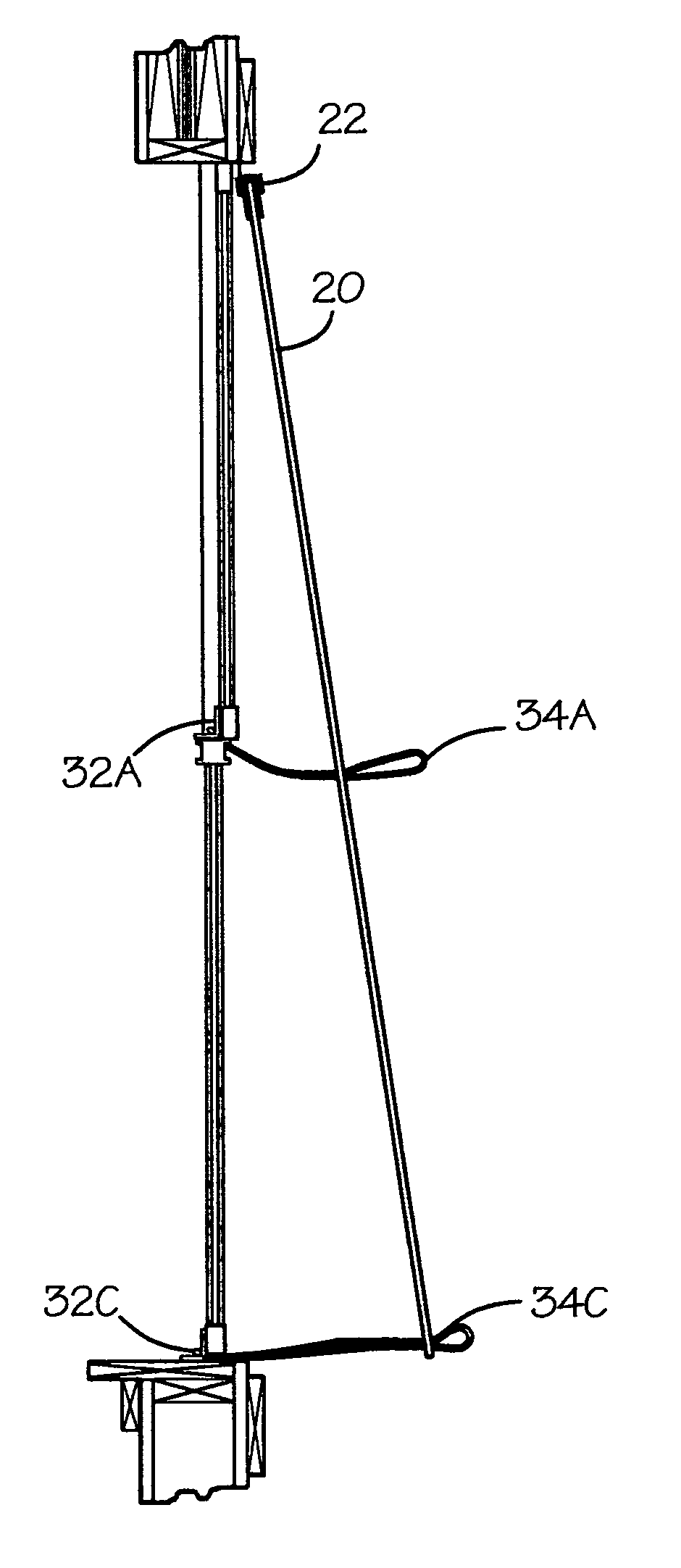

Submerged combustion melters, wall structures or panels of same, and methods of using same

ActiveUS20180065877A1Reduce heat fatigueProtection materialGlass furnace apparatusGlass melting apparatusCombustorEngineering

Submerged combustion burner panels, submerged combustion melters including one or more of the panels, and methods of using the same. The burner panel includes a panel body including a fluid-cooled portion and a protective non-fluid cooled portion. An exterior surface defined by the fluid-cooled portion, and an interior surface defined by the protective non-fluid cooled portion, exterior and interior referring to an SCM in which the panel is installed. The fluid-cooled portion has at least one burner support passage of diameter (d1) extending from the exterior surface to a seam where the fluid-cooled and protective non-fluid cooled portions meet supporting at least one fluid-cooled SC burner having a fluid-cooled burner tip attached to a burner body protruding away from the seam. The protective non-fluid-cooled portion has a combustion products flow passage of diameter (d2)<(d1). The burner panels promote burner life and melter campaign length.

Owner:JOHNS MANVILLE CORP

Window protection structure

InactiveUS20070107327A1Simple and rapid methodEasy to installShutters/ movable grillesFixed grillesEngineeringBungee cord

A window protection structure for a building including novel structure for affixing a sheet of protection material over the window opening. The sheet material is cut to the size of the window opening in the building, and holes are formed therein. U-shaped clips are slid onto an upper edge of the sheet material, and a plurality of brackets are provided with a pair of holes formed therein. Cords loops are secured through the holes in the brackets. The brackets are adapted for receipt by the interior of the window and the cords are threaded to the exterior of the window. The cord loops are threaded through the holes in the sheet material. A bungee cord is then used for securing the ends of the cord loops, whereby the sheet material is held firmly against the window.

Owner:WARNER JERALD R

Substrate holder for a vapour deposition system

The invention relates to a partially disposable substrate holder used in magnetic latches for securing substrates on a planetary rotating platform suspended above a coating source in a vacuum chamber of a vapor deposition system, e.g. a chemical vapor deposition (CVD) system or a physical vapor deposition (PVD) system. The substrate holder includes a reusable base formed, at least partially, from a ferro-magnetic material, which is attracted to the magnetic latch, and a disposable cover formed from a relatively inexpensive, ferromagnetic, easily formable material, which encourages adherence of coating material and has a low vapor pressure at coating temperatures.

Owner:VIAVI SOLUTIONS INC

Copper composite conductive powder with grapheme structure and wrapped by carbon layer and preparation method thereof

ActiveCN104036875AImprove conductivityImprove antioxidant capacityMetal/alloy conductorsCable/conductor manufactureCarbon layerOligomer

The invention discloses copper composite conductive powder with a grapheme structure and wrapped by a carbon layer and a preparation method thereof. The preparation method comprises the steps of (A) stirring an LPAN solution at the temperature of 80-300 DEG C for 8-72 hours to form a micro-cyclized LPAN solution; (B) performing heat treatment on the micro-cyclized LPAN solution at the temperature of 200-300 DEG C for 1-10 hours to form a thermally oxidized polyacrylonitrile oligomer with a trapezoid structure; (C) adding the thermally oxidized polyacrylonitrile oligomer and a copper compound into a solvent and performing even mixing to obtain an LPAN wrapped copper compound; (D) drying the evenly-dried LPAN wrapped copper compound at the temperature of 180-250 DEG C for 1-10 hours till the solvent is completely evaporated to obtain a low-temperature carbonization precursor wrapped copper compound; (E) calcining the low-temperature carbonization precursor wrapped copper compound under the inert atmosphere protection and conditions of 10-500ml / mi gas flow and 300-1800 DEG C temperature for 6-24 hours, and accordingly obtaining the copper composite conductive powder with the grapheme structure and wrapped by the carbon layer.

Owner:SHENZHEN EIGEN EQUATION GRAPHENE TECH CO LTD

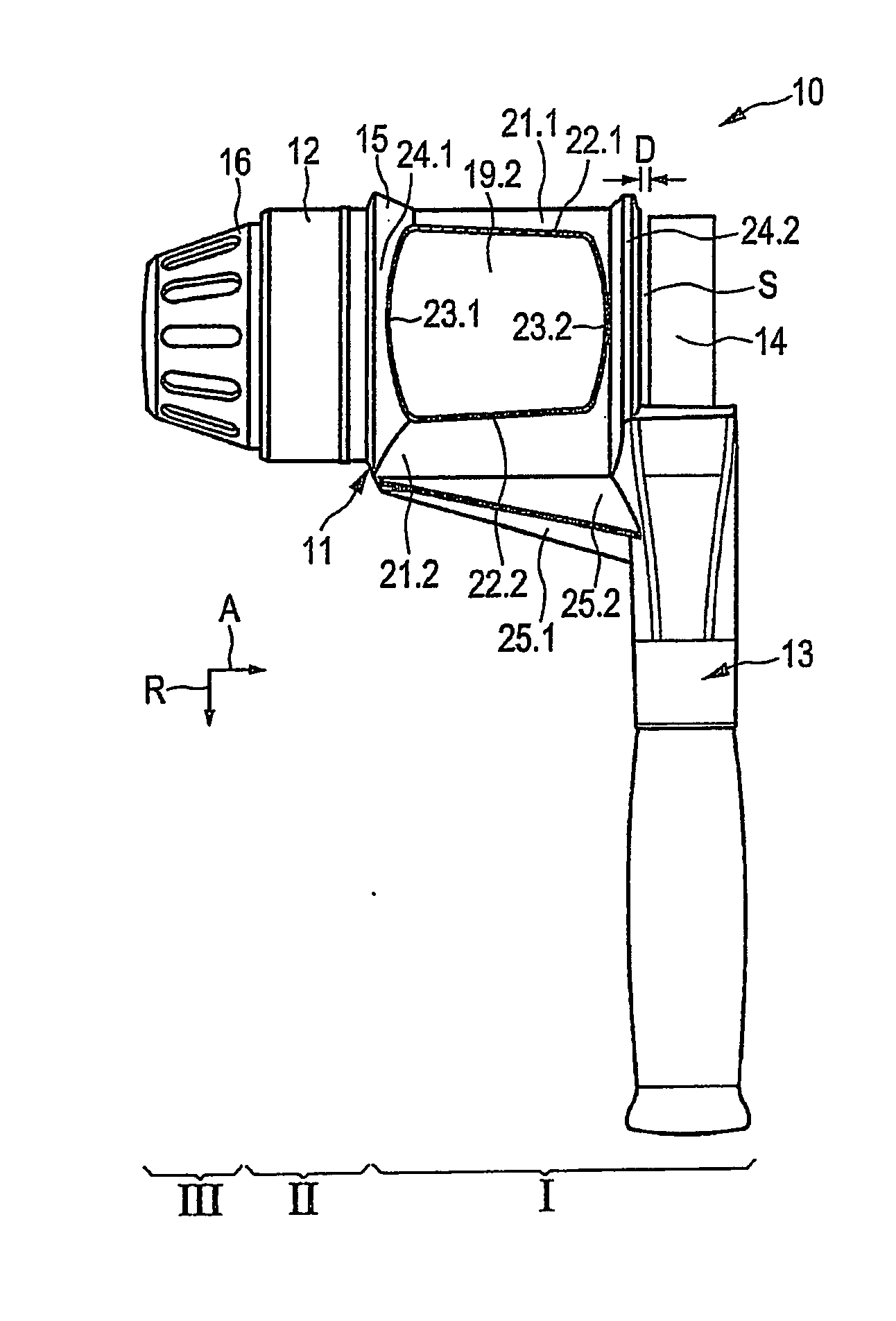

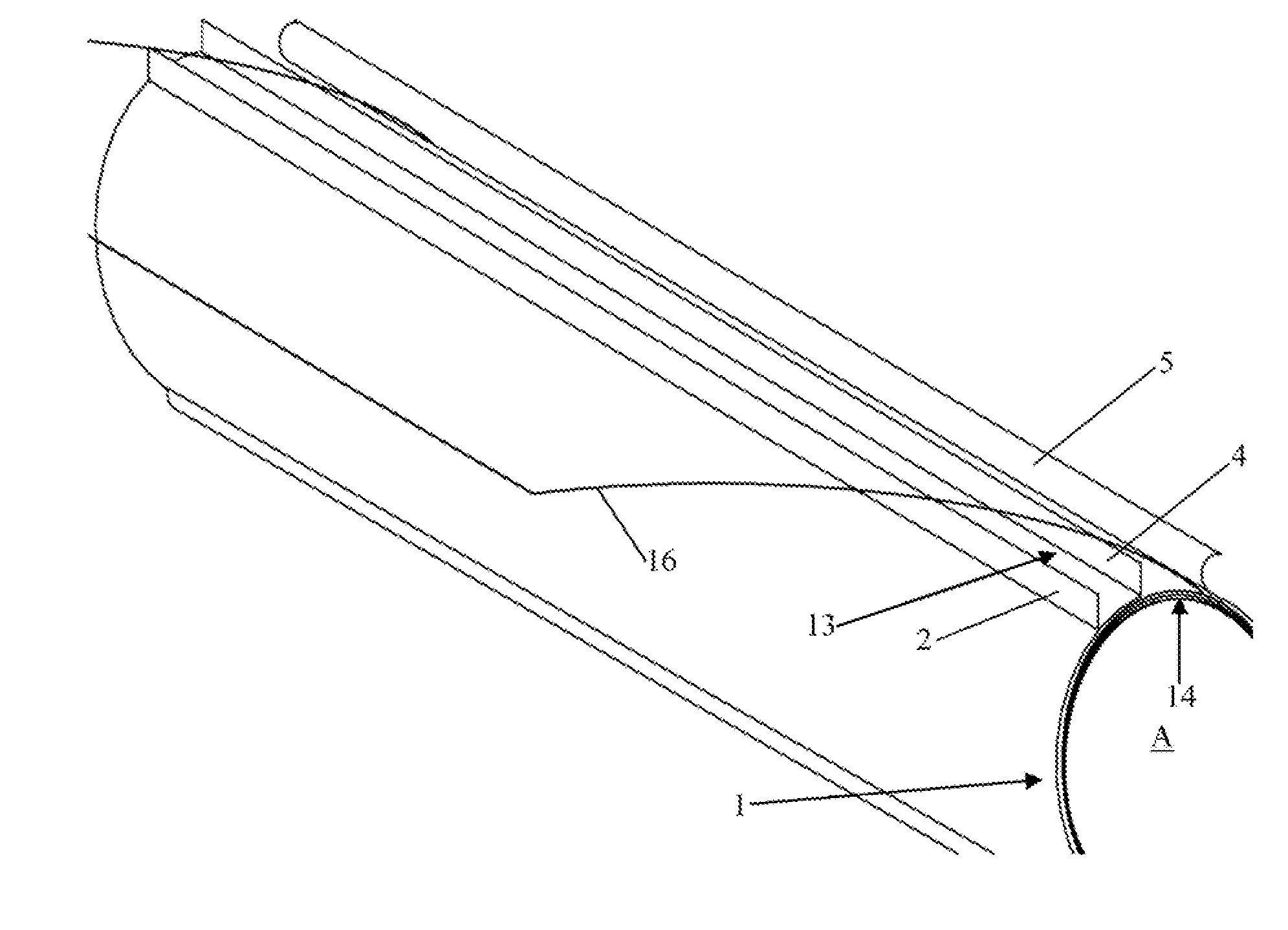

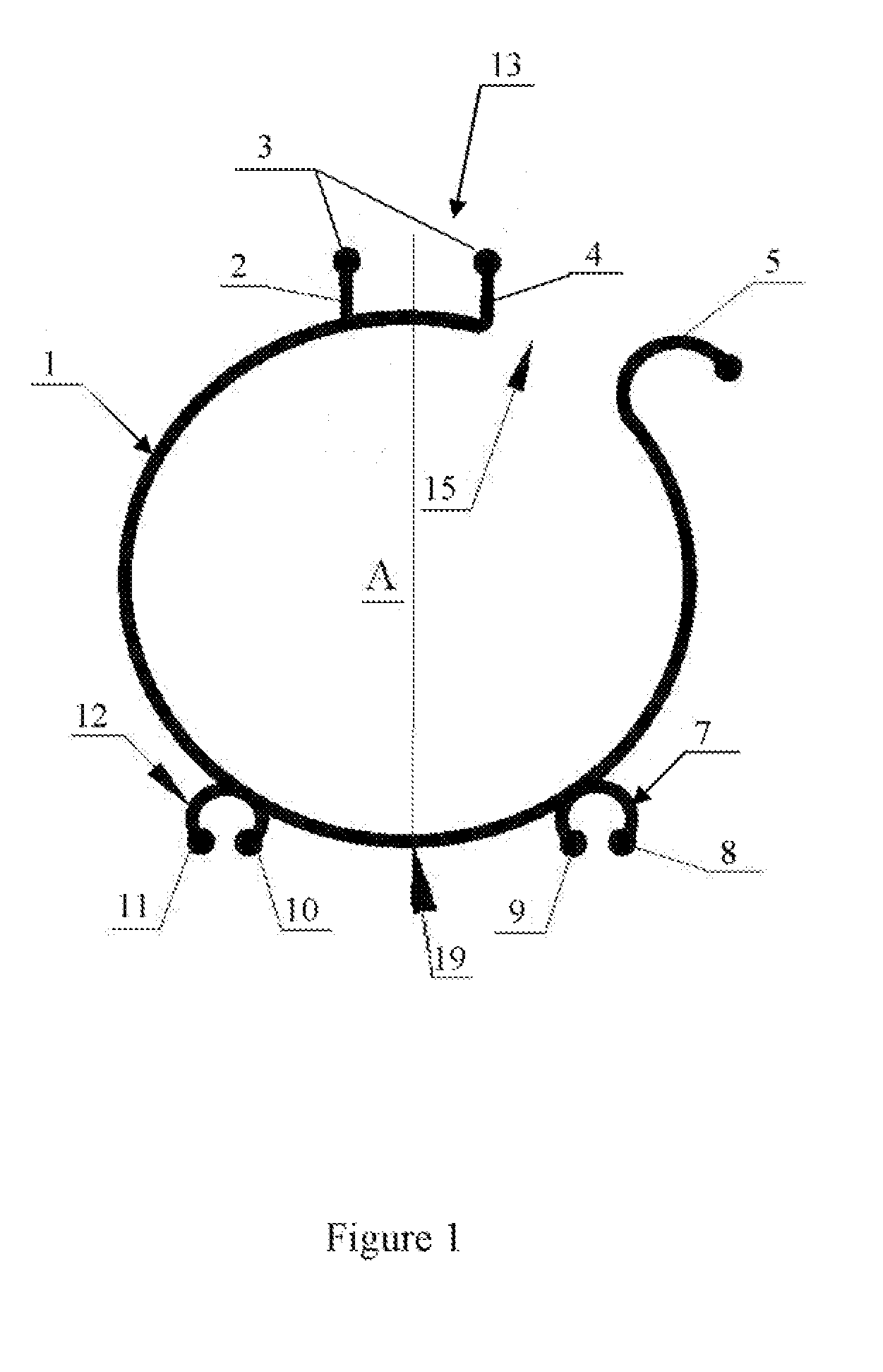

Process for preparing turbine blades or vanes for a subsequent treatment, and associated turbine blade or vane

InactiveUS20100254818A1Protection materialReduce riskMolten spray coatingPump componentsTurbine bladeCoating

Process for preparing turbine blades or vanes for a subsequent treatment, for example the application of a coating and / or a material-removing operation, wherein the turbine blade or vane has an airfoil, which is delimited at at least one end by an endplate with peripheral surfaces, wherein at least one of the peripheral surfaces is at least partially covered prior to the treatment of the turbine blade or vane. In the process a covering strip is fitted onto at least one peripheral surface to form a plug connection.

Owner:SIEMENS AG

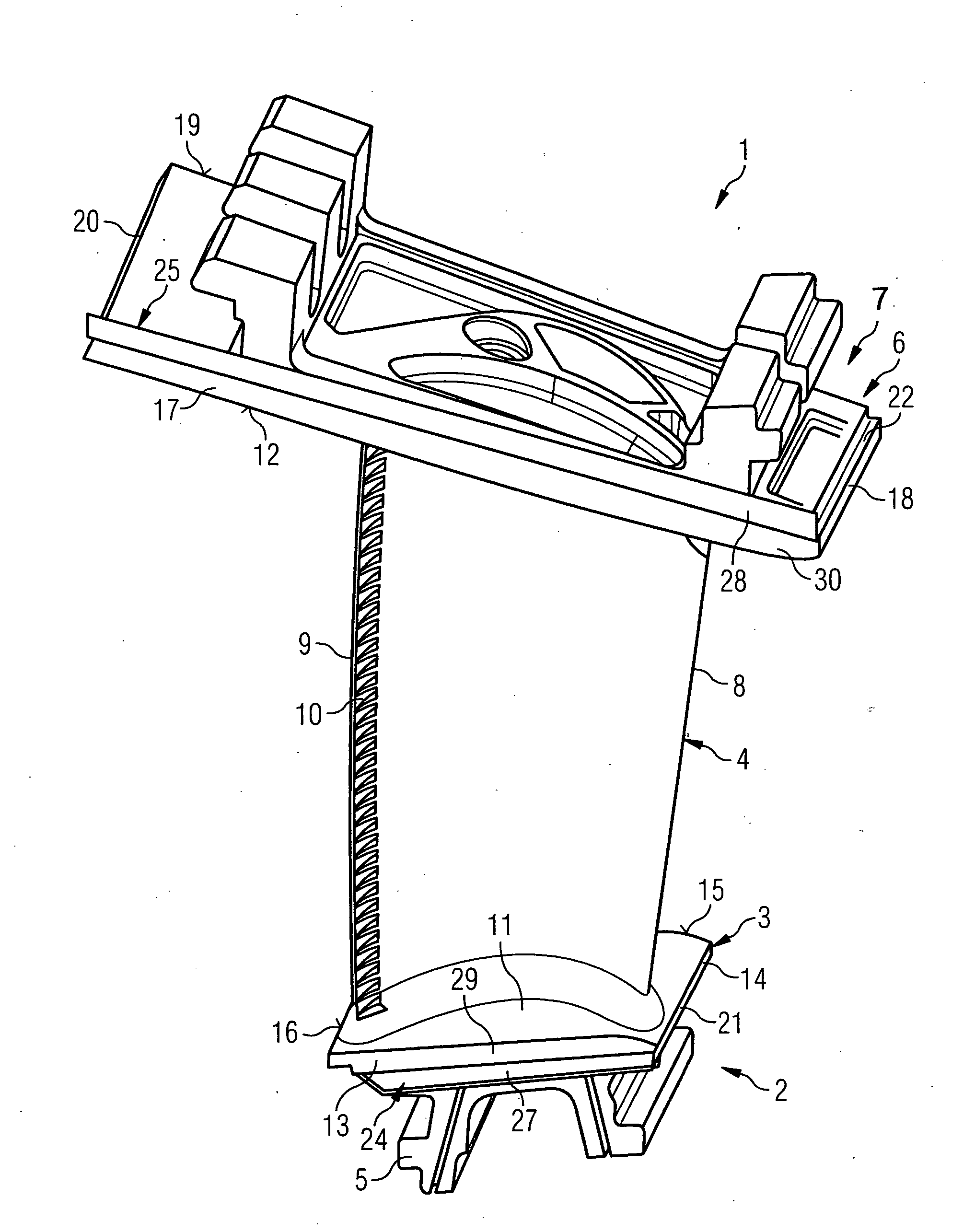

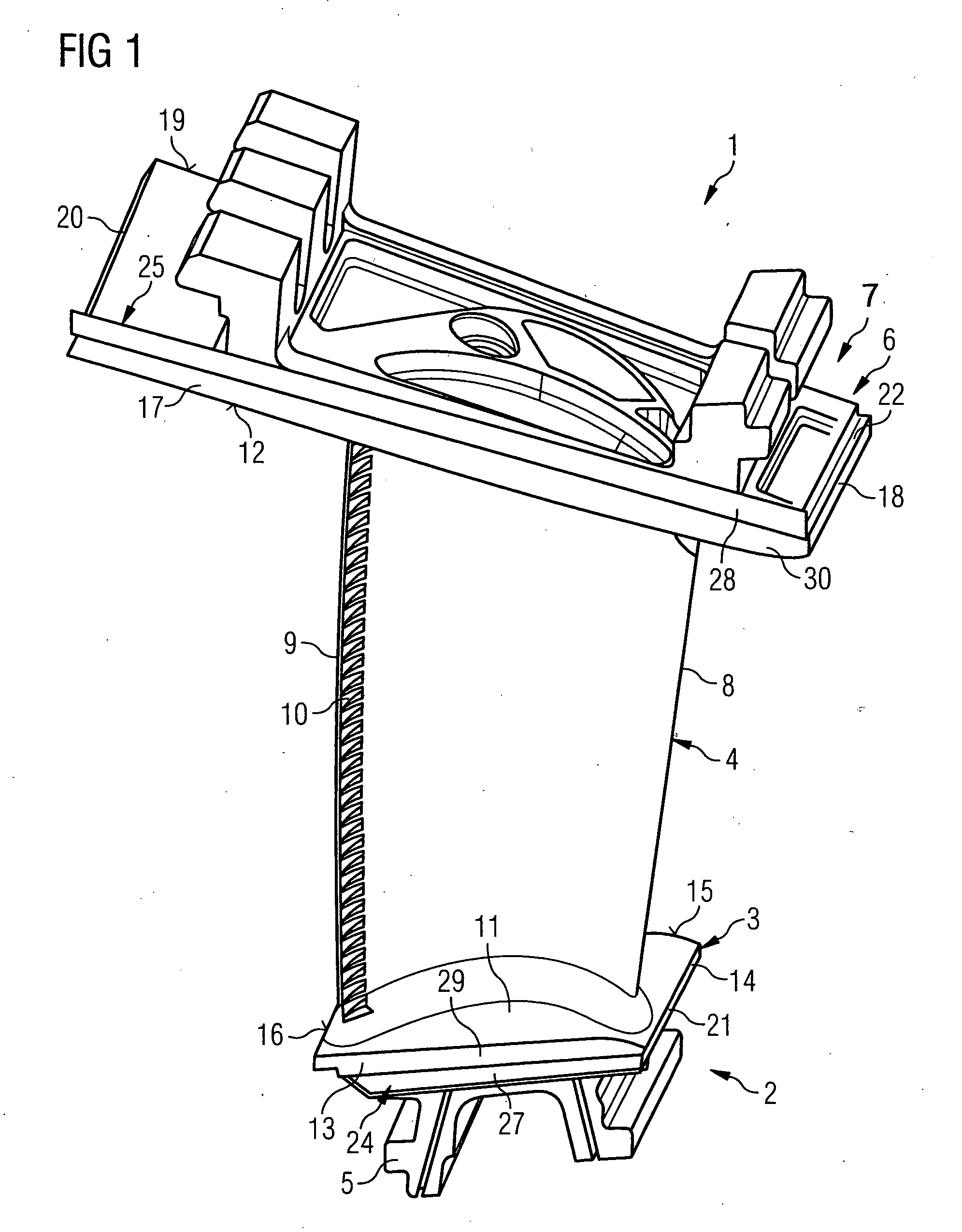

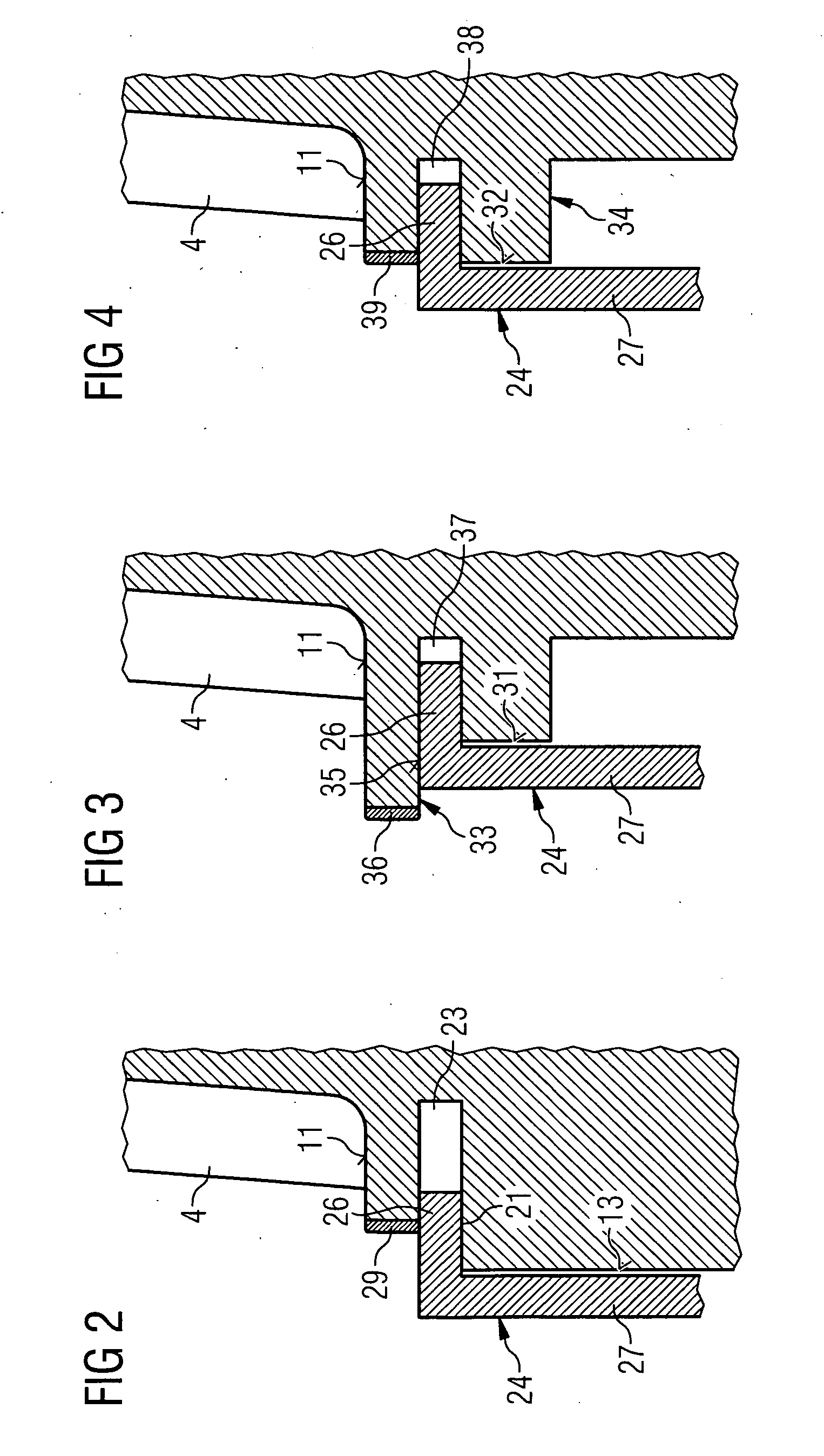

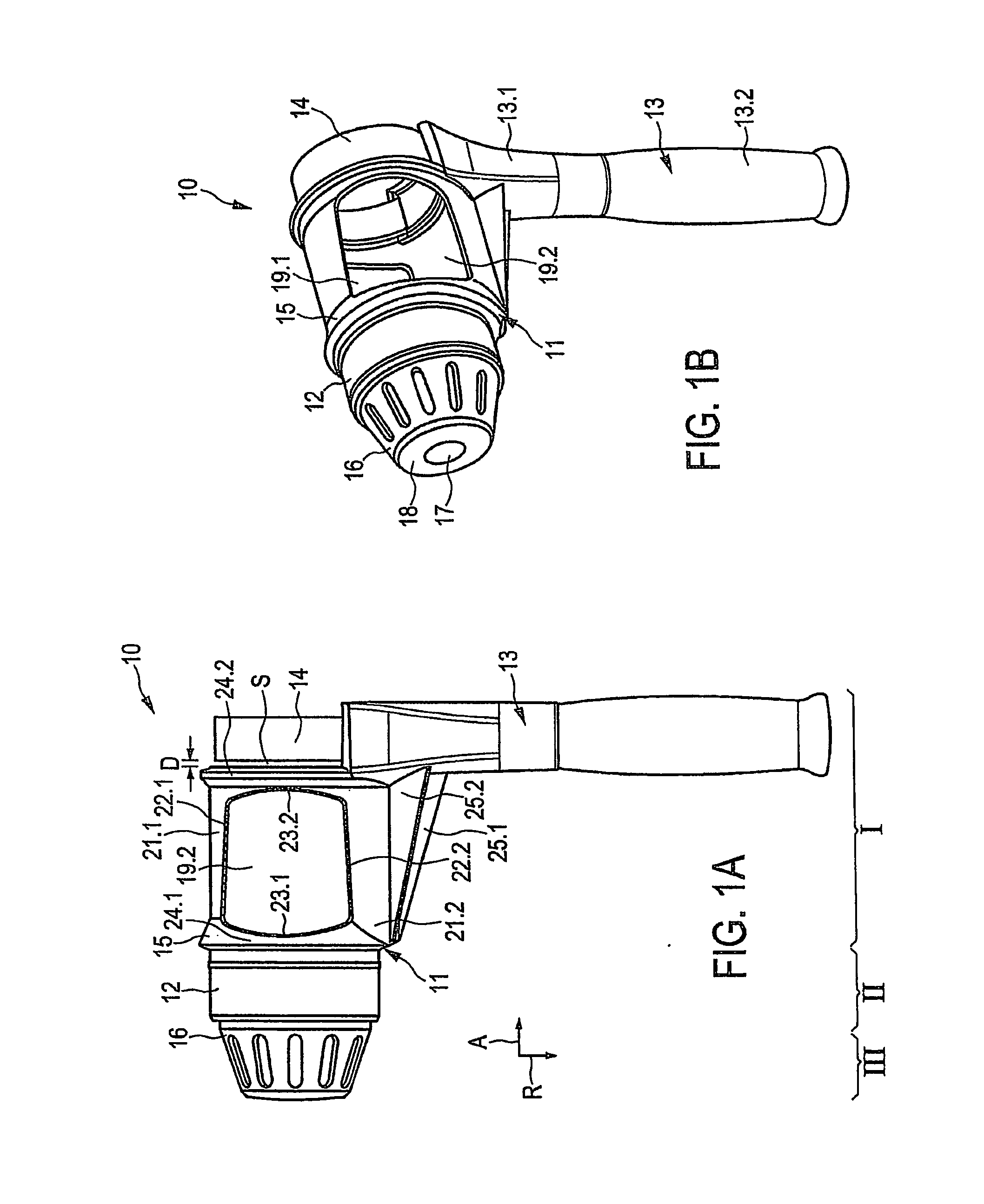

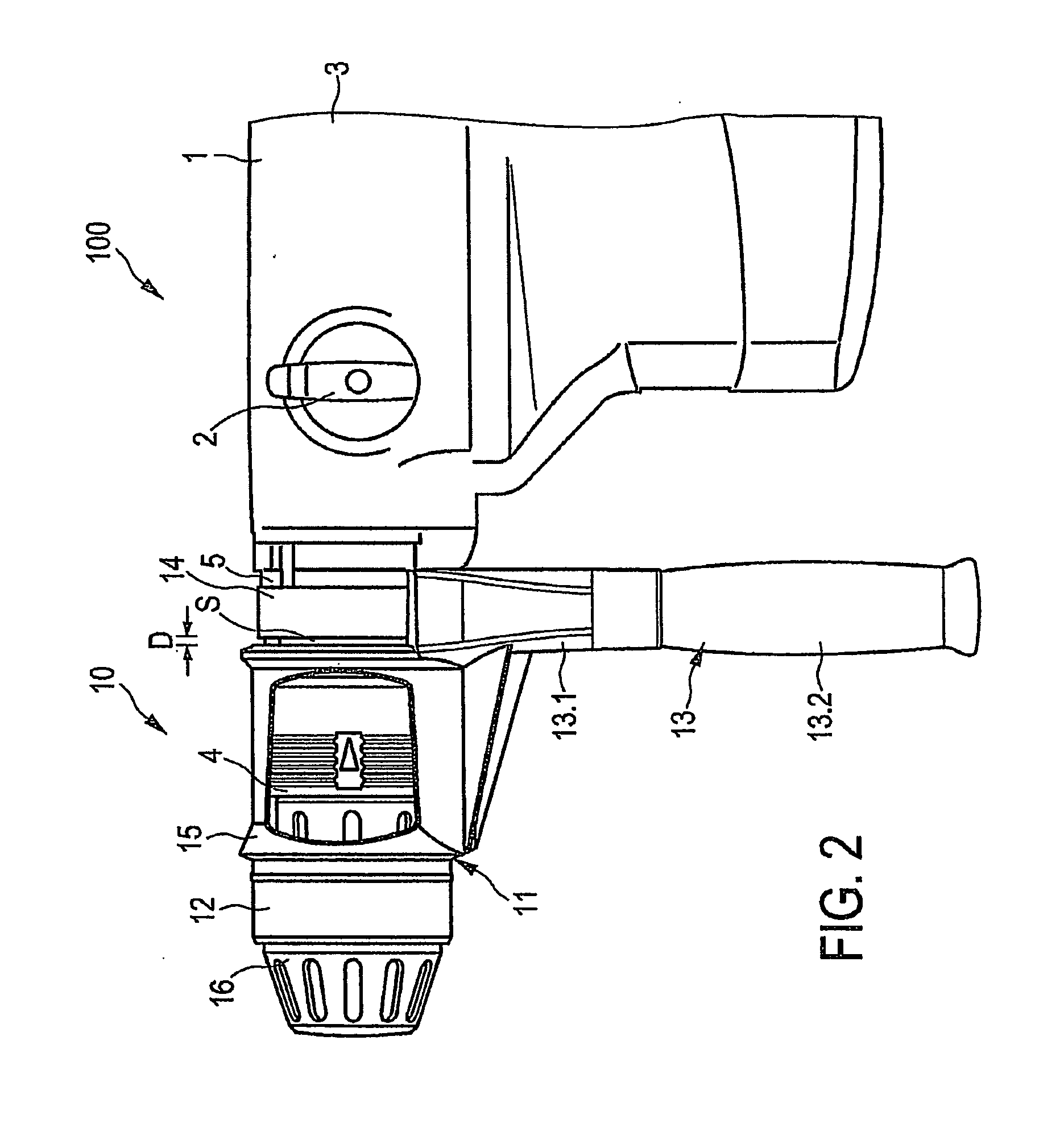

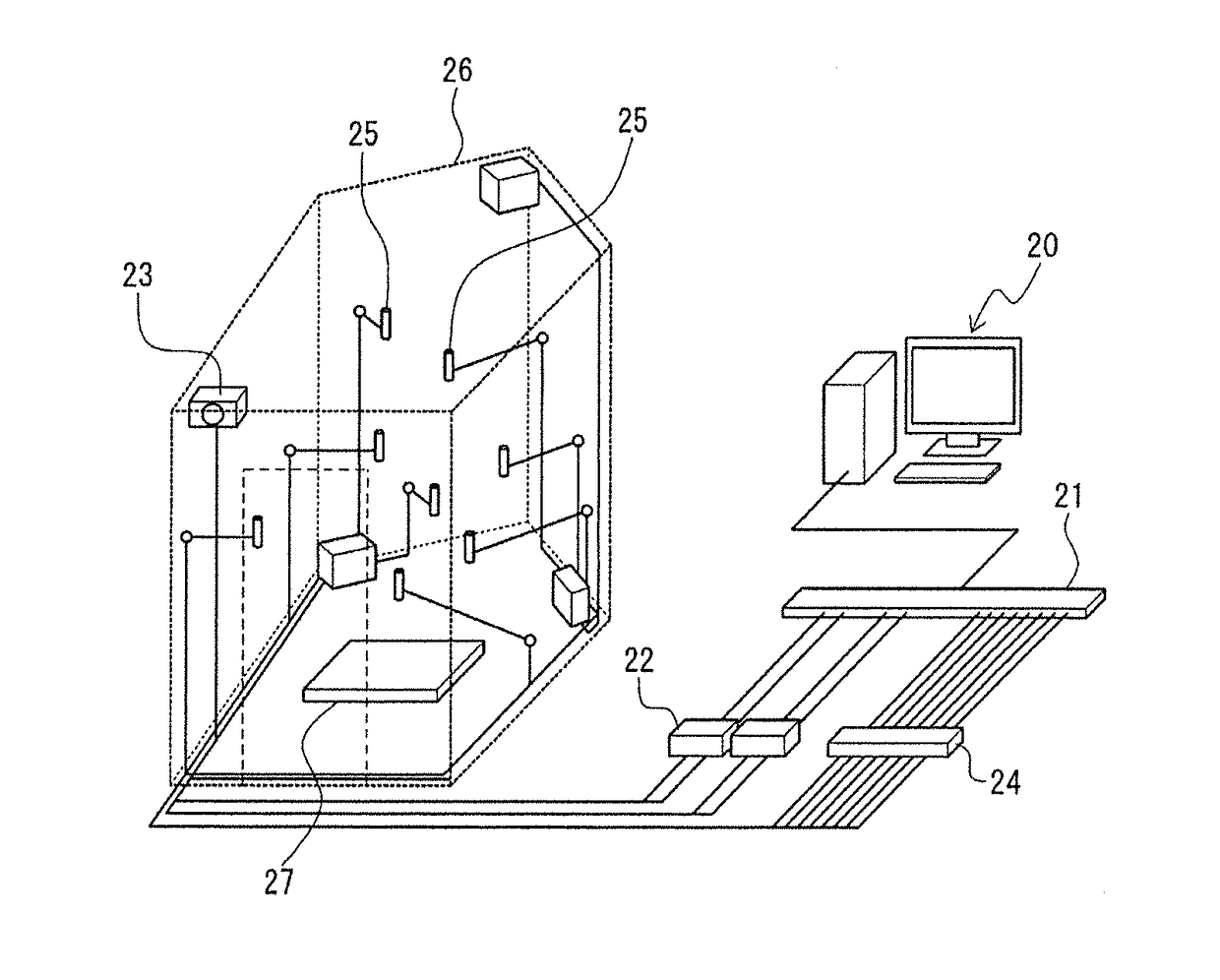

Auxiliary Device and A System Composed Of An Electrical Work Machine Comprising An Auxiliary Device

ActiveUS20110266016A1Flexible designEffective decouplingTravelling carriersHoldersEngineeringElectrical and Electronics engineering

An auxiliary device for an electrical work machine is provided. The auxiliary device can be attached to the electrical work machine, and the electrical work machine can be equipped with a tool in a tool holder. The auxiliary device comprises a housing comprising a handle and an attaching device. The housing can be attached to the electrical work machine with the attaching device. The housing comprises a handling section, which is disposed next to the attaching device, and which comprises an opening, which allows at least the tool holder to be freely accessible from the sides. The handle is permanently connected to the handling section.

Owner:HILTI AG

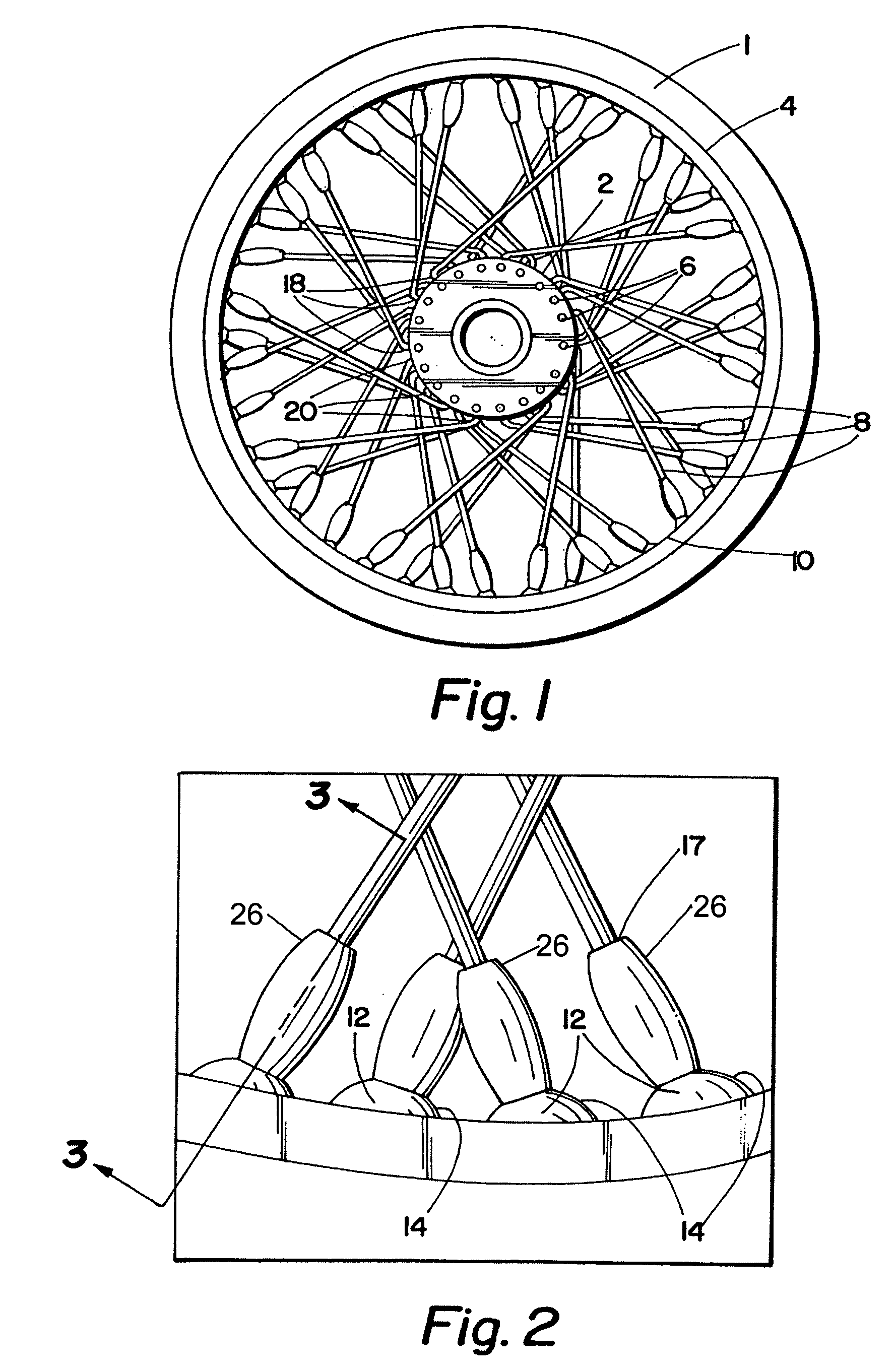

Wheel spoke adjuster guard

InactiveUS7140694B2Prevent intrusionProtection materialRimsNon-metallic wheel bodyEngineeringSealant

Owner:MASON STEVEN

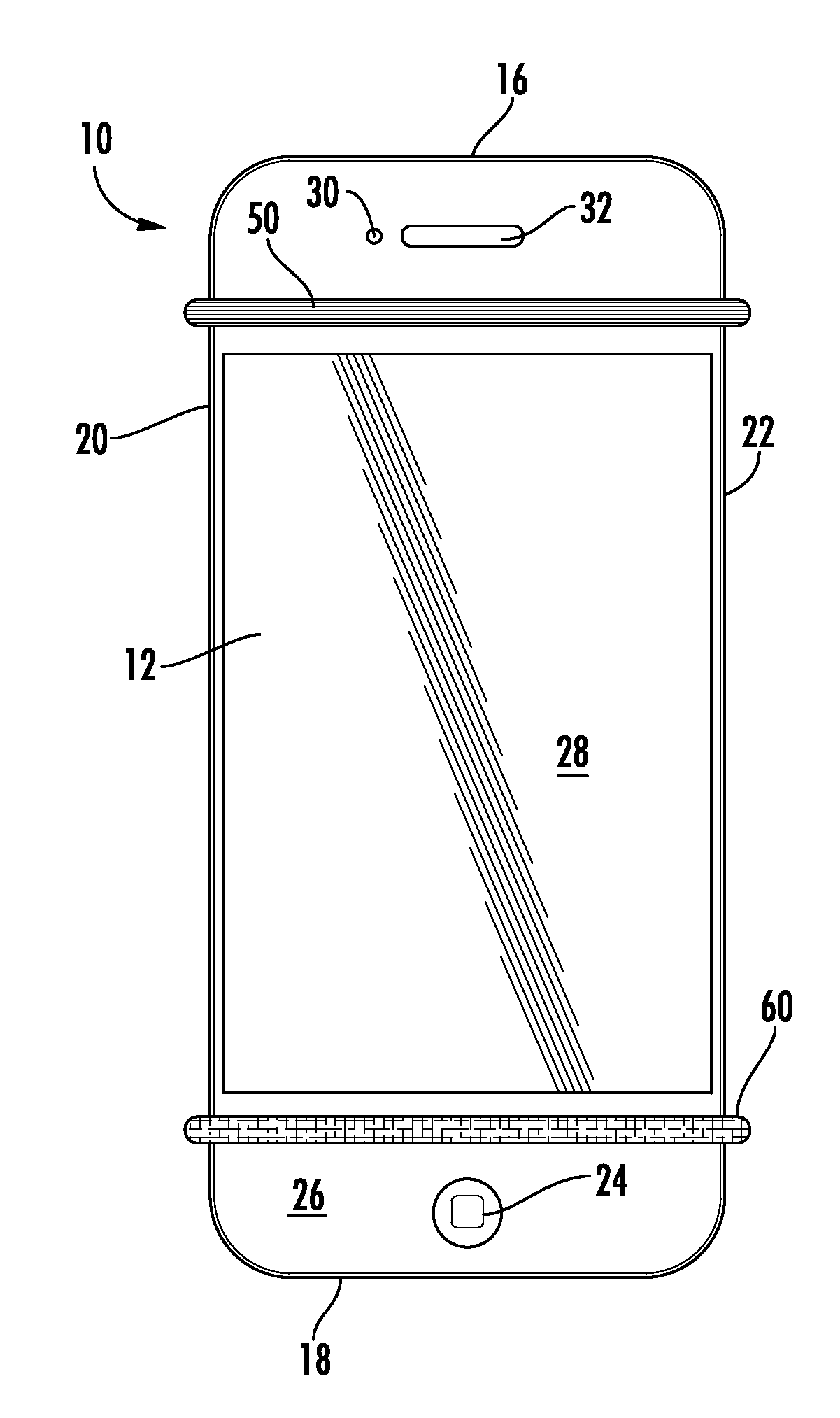

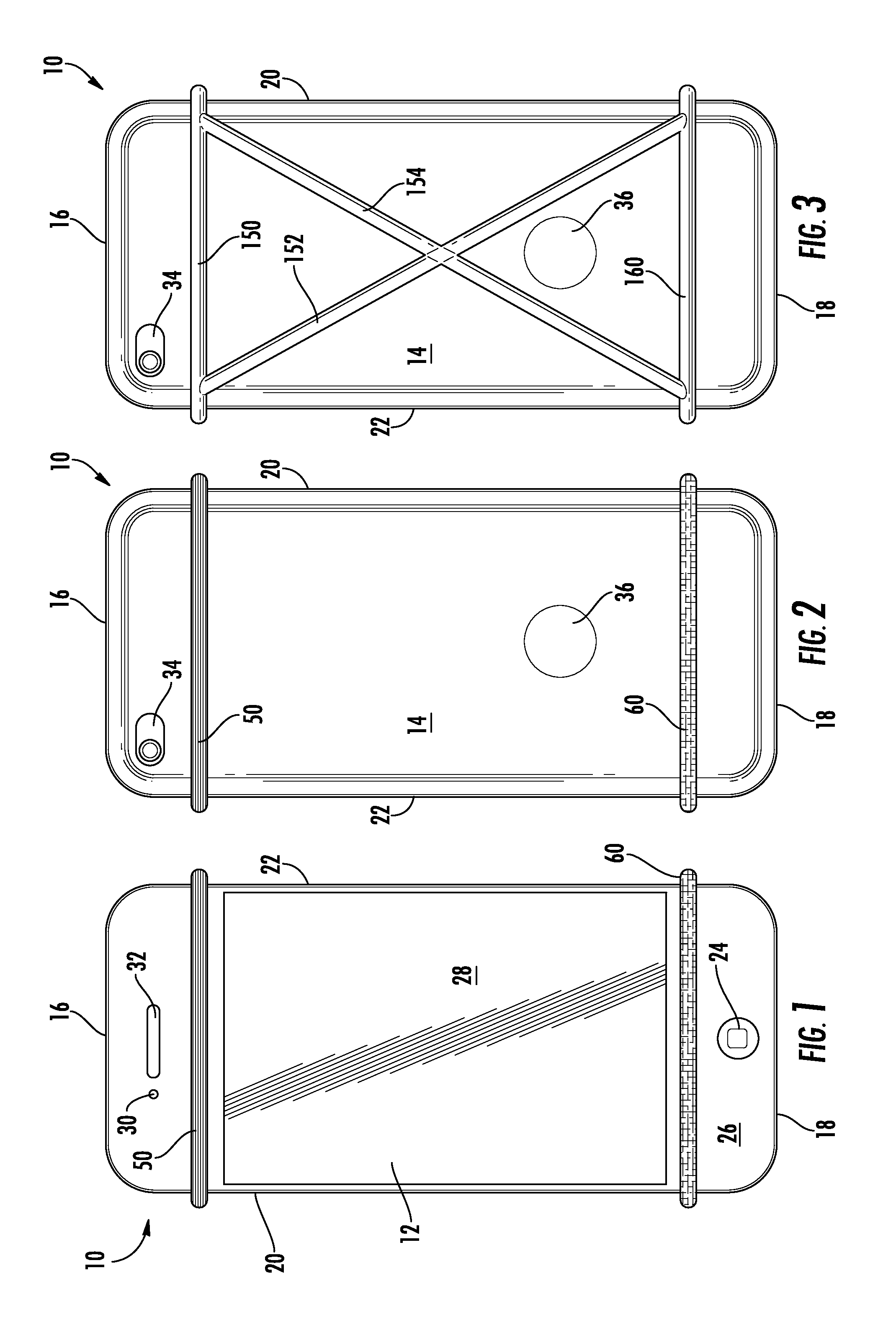

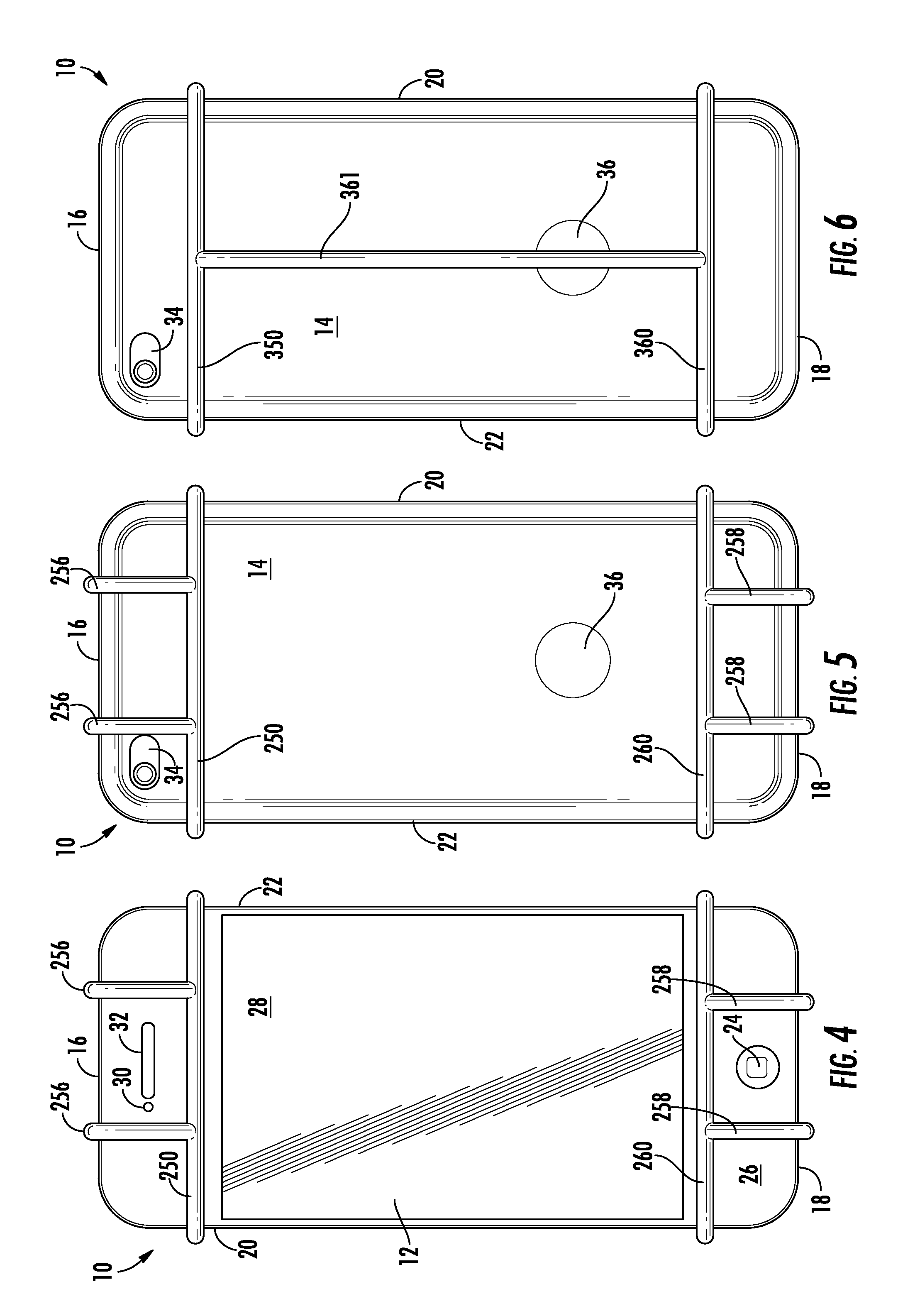

Apparatus and method for securing or protecting electronic devices

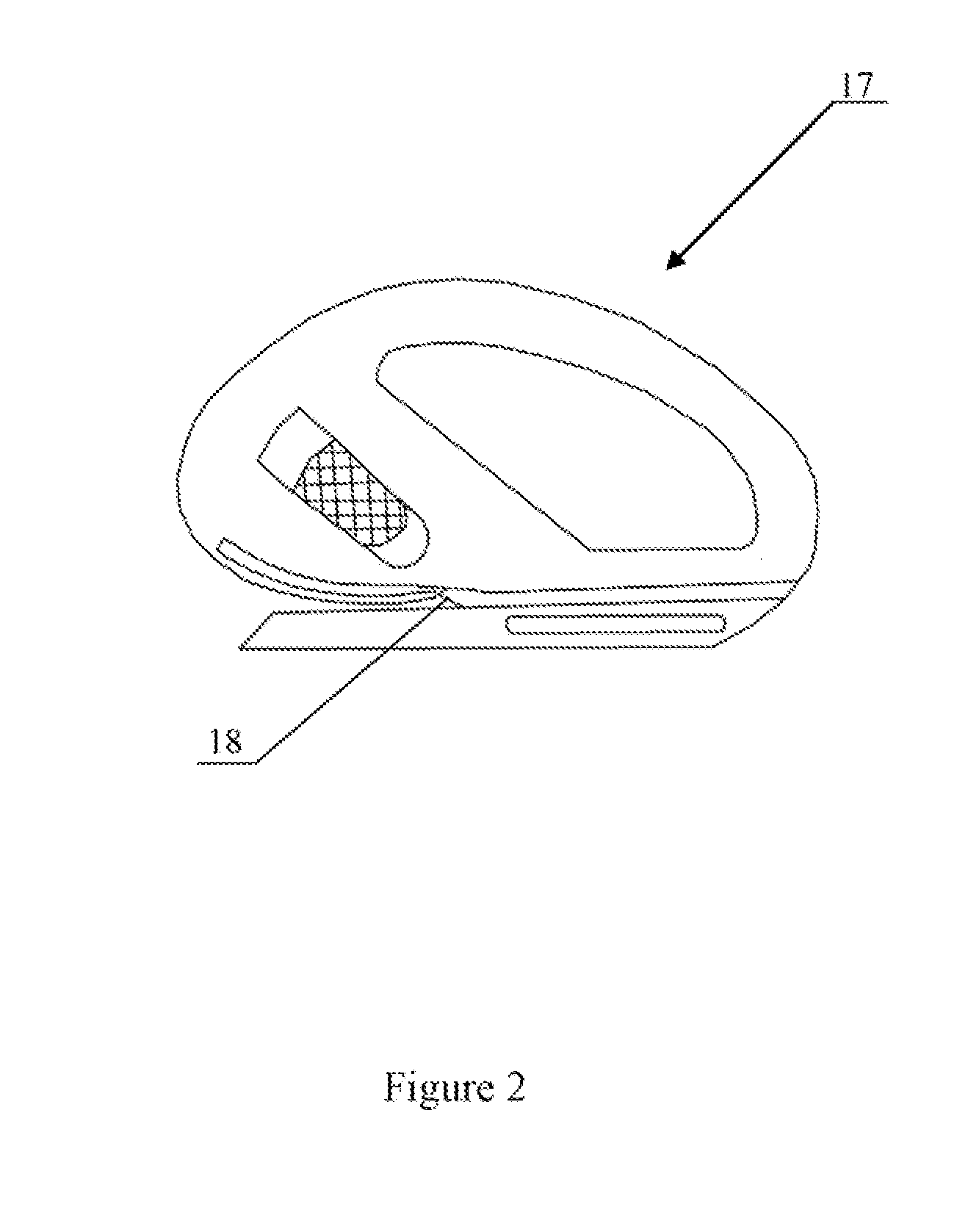

InactiveUS20160105209A1Minimize limitationSufficient protectionSubstation equipmentTransmissionEngineeringCellular telephone

An apparatus for providing impact protection to a cell phone comprises a flexible elongated member configured to loop around an upper end of the phone, and a flexible elongated member configured to loop around a lower end of the phone, each elongated member sized to elastically stretch over and about opposing side edges of the phone. A plurality of different connecting pieces may join these two flexible members over a portion of the rear face of the phone. A method of use is also disclosed.

Owner:DUNN ROBERT T +6

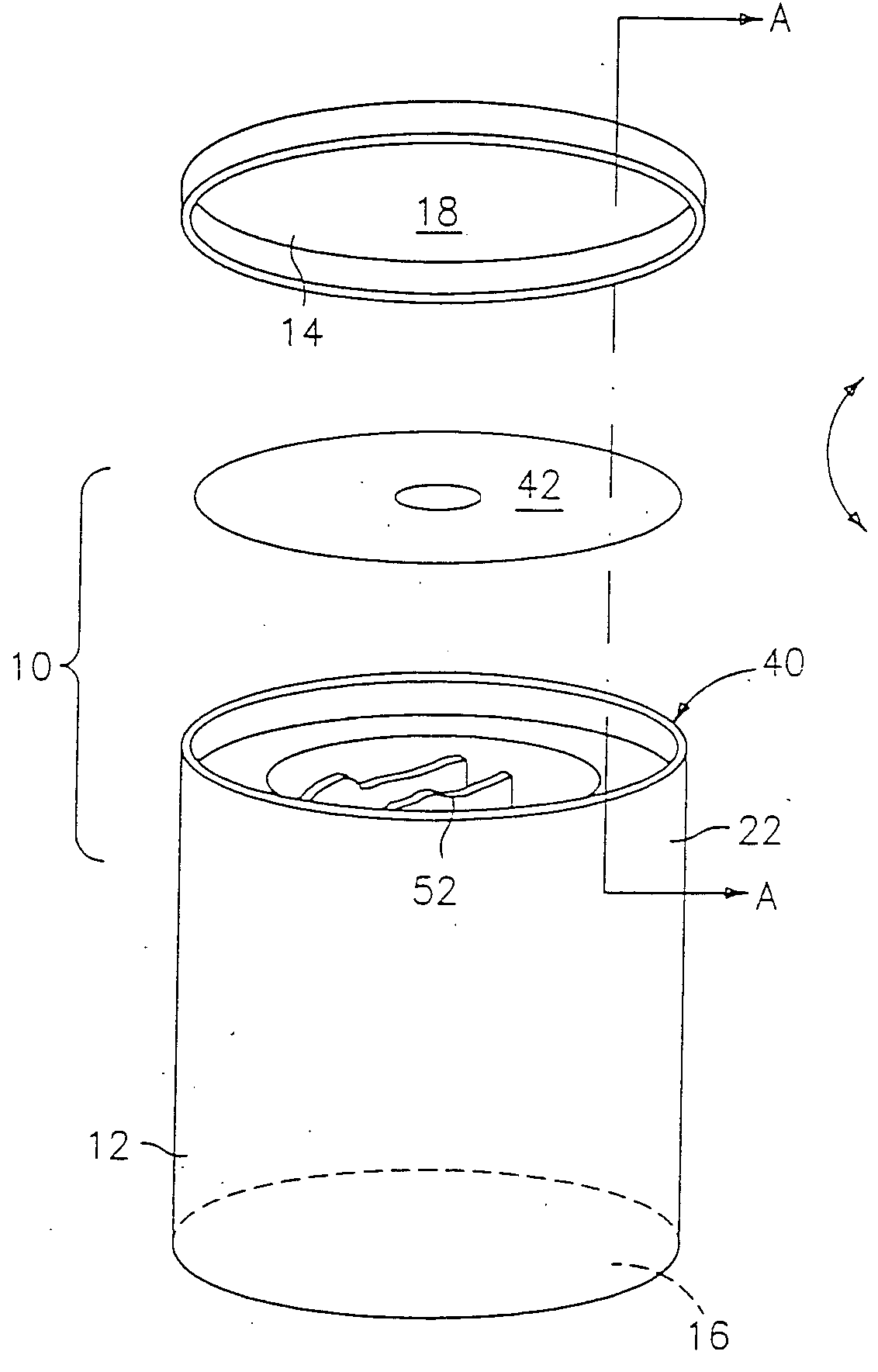

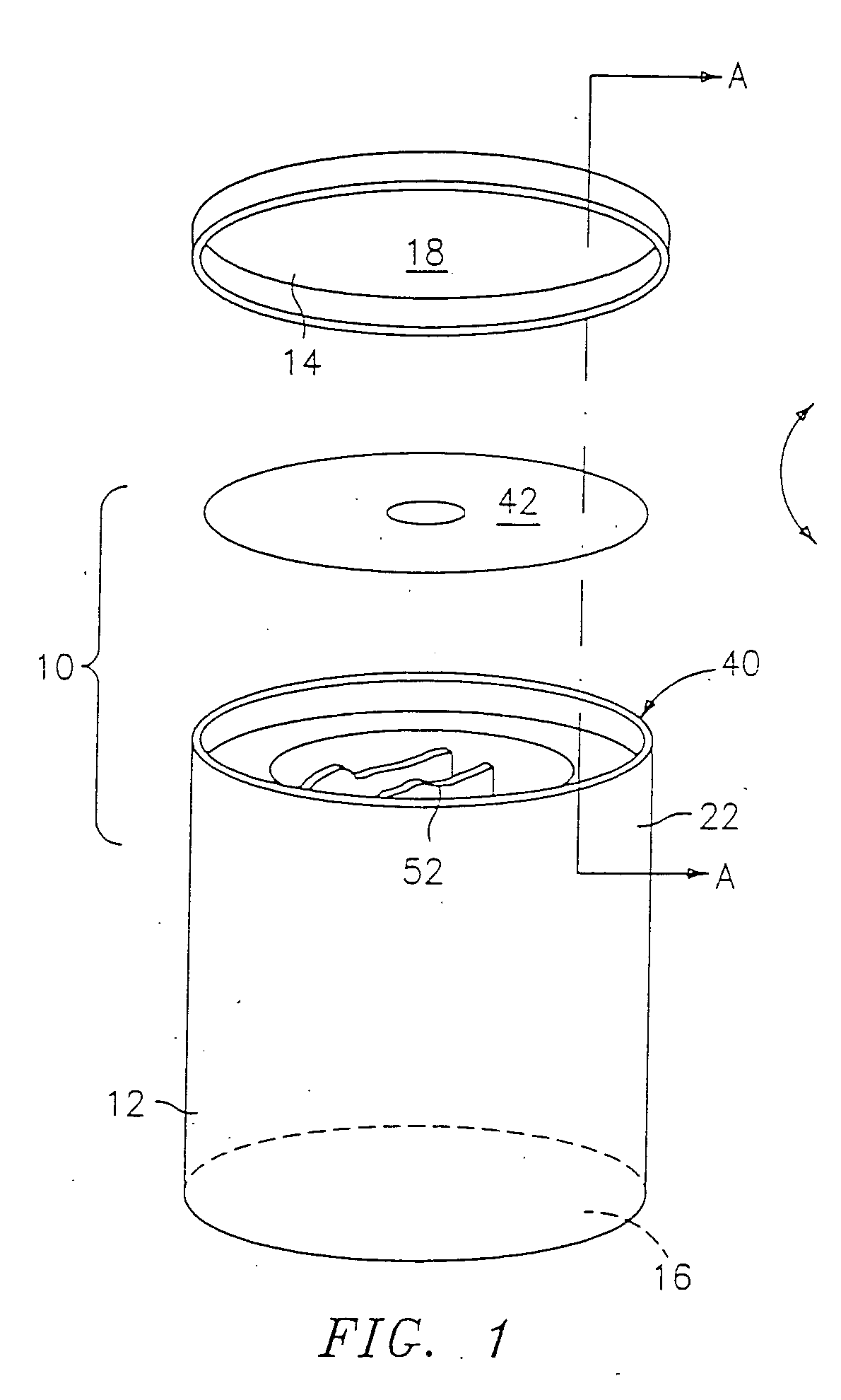

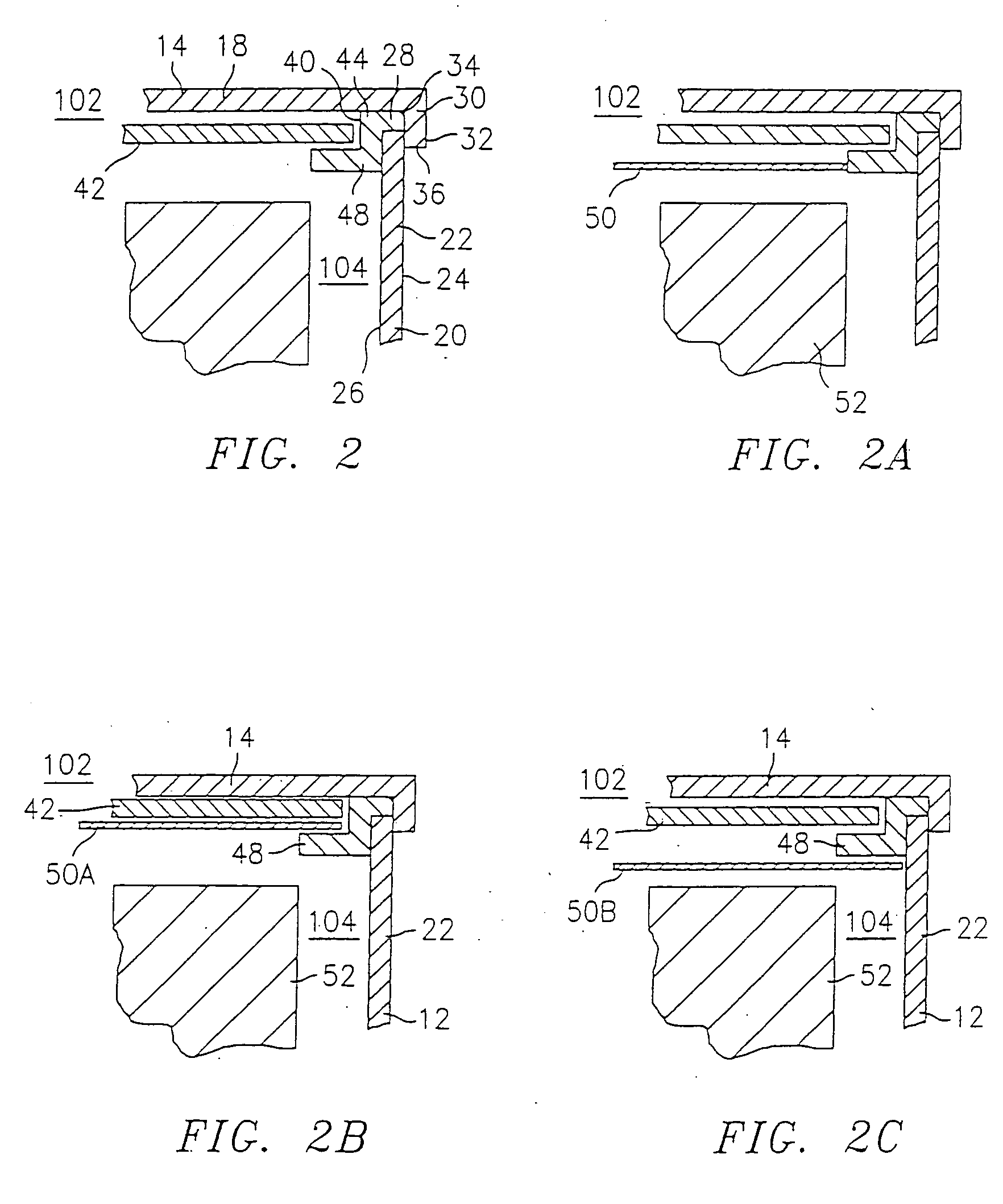

Gift Wrap Material Container and Method of Dispensing

InactiveUS20100072243A1Efficient and economicalProtection materialContainers for annular articlesFilament handlingPack materialEngineering

A new and useful gift wrap material container and method of dispensing gift wrap material from the container in selected lengths is provided. The gift wrap material container and method of the present invention are designed to provide an inexpensive way to store and protect gift wrap material (particularly gift wrap material) until the gift wrap material is needed again. In addition, the container and method of the invention provides a means of dispensing and cutting the gift wrap material in an efficient and economical way. According to the present invention, a gift wrap material container (i) is configured to receive a roll of gift wrap material, (ii) is configured with an opening through which gift wrap material can be directed out of the cavity when the gift wrap material is being dispensed, and (iii) having a cutter guide integrally formed with the container and disposed on the outside of the container, the cutter guide configured guide a cutter along a predetermined path on the outside of the container, and to support gift wrap material in a position that enables the gift wrap material that is being dispensed to be cut to a selected length as the cutter moves along the predetermined path on the outside of the container.

Owner:WRAP SAVER

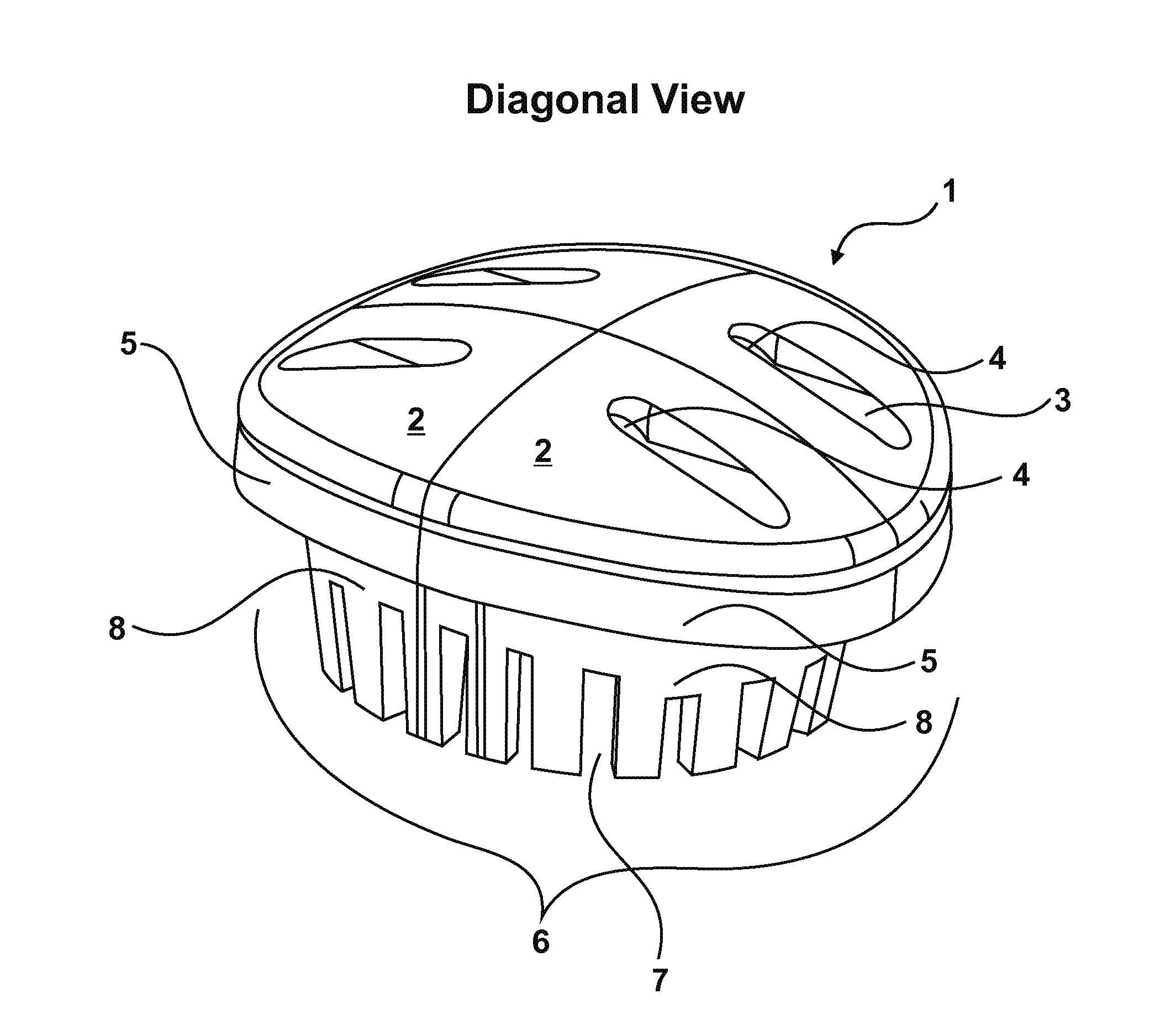

Dental devices for extraction site reconstruction

InactiveUS20150157424A1Maintain integrityEnhance general healingDental implantsBone implantExtraction siteDental Equipment

The extraction socket devices are designed to protect the extraction socket immediately after tooth extraction. These devices protect the socket from oral bacteria and food, support a space to prevent collapse of the alveolar ridge during healing, contain any bone graft material inside of the socket, and provide comfort to patient during the healing process. Procedures are also disclosed for placing the devices in an extraction site to obtain the benefits of the disclosed devices.

Owner:ZADEH HOMAYOUN H

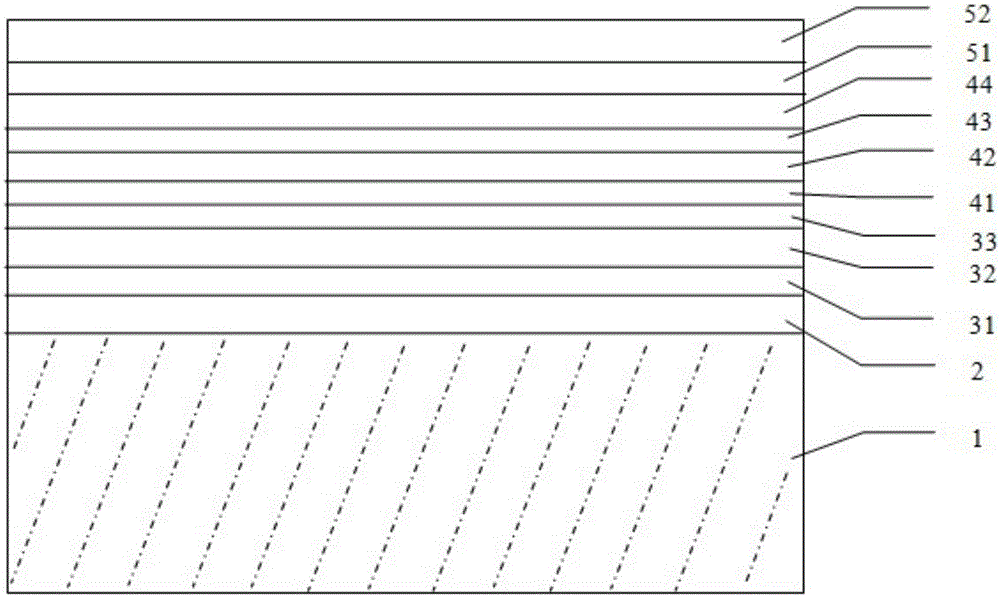

Color adjustable anti-icing anti-fog electric heating film for civil aircraft port glass and preparation method thereof

ActiveCN106082701AStable chemical propertiesGood electric heating performanceCoatingsEngineeringSilicon oxide

The invention discloses a color adjustable anti-icing anti-fog electric heating film for civil aircraft port glass and a preparation method thereof. The color adjustable anti-icing anti-fog electric heating film for civil aircraft port glass comprises a glass substrate, an isolation layer, an electric heating layer, a color adjustable layer and a protective layer. The glass substrate sequentially comprises the isolation layer, the electric heating layer, the color adjustable layer and the protective layer from interior to exterior. The glass substrate is the aircraft port glass substrate. The isolation layer is a first silicon oxide layer (2), and the thickness of the first silicon oxide layer is 25-35 nm. The color adjustable anti-icing anti-fog electric heating film can achieve the low-resistance electric heating performance, can achieve defrosting and demisting rapidly, has the excellent weather resistance and corrosion resistance, and is applicable to flying under the humid salt and humid hot environment, the visible light transmittance of the film layer is high, and the film is soft and adjustable in color, dense, uniform and high in film layer binding force.

Owner:GEMCH MATERIAL TECH SUZHOU

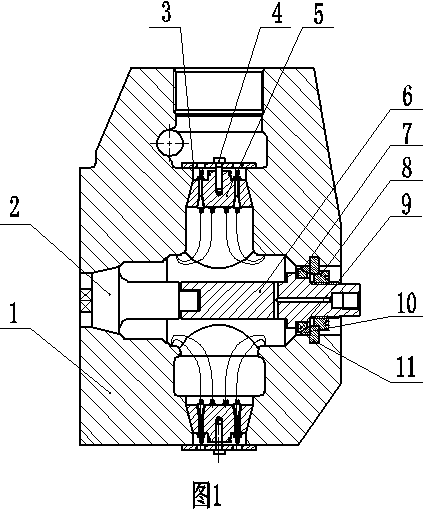

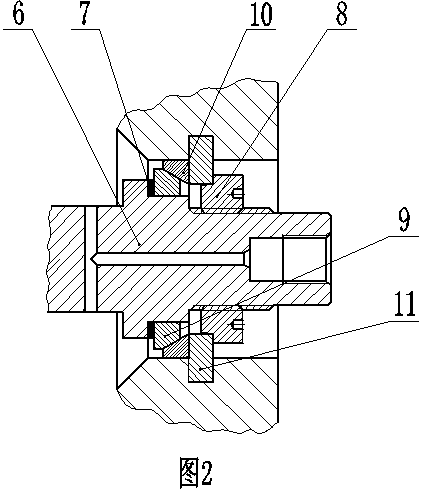

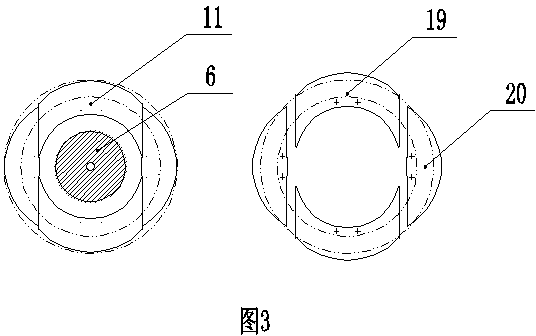

Self-tightening sealing and stress testing device for self-enhancing of ultrahigh-pressure pump head body

ActiveCN103711688AGuaranteed sealing reliabilityReduce local stressPump testingPositive displacement pump componentsCombined usePump head

The invention relates to a self-tightening sealing and stress testing device for self-enhancing of an ultrahigh-pressure pump head body, belonging to the technical field of self-enhancing of a pump head body of an ultrahigh-pressure container. The self-tightening sealing and stress testing device comprises an ultrahigh-pressure pump head body, a horizontal sealed taper rod, a signal lead-out seal taper, a horizontally sealed adjusting rod, an O-shaped seal ring, a signal lead-out rod, an organic glass sealed taper ring, quick-plugging joints, high-strength enameled wires, a strain gauge and a wiring transition plate. All sealing surfaces of the device adopt taper surface hard sealing, the higher the hydraulic pressure in the inner cavity of the pump head body is, the larger the pressure on the sealing surfaces is, and the reliability of sealing under ultrahigh pressure can be guaranteed; in assembling, the sealing of the sealing surfaces in low-pressure or non-pressure state can be controlled by thread pretightening force. The self-tightening sealing and stress testing device has the characteristics of being convenient to install, and convenient and fast to wire. According to the device, the difficulty in testing the stress of the container wall by leading out a wire from the ultrahigh-pressure sealed container can be solved by adopting the combined use of the organic glass sealed taper ring, the O-shaped seal ring and the wire lead-out rod.

Owner:YANGTZE UNIVERSITY +1

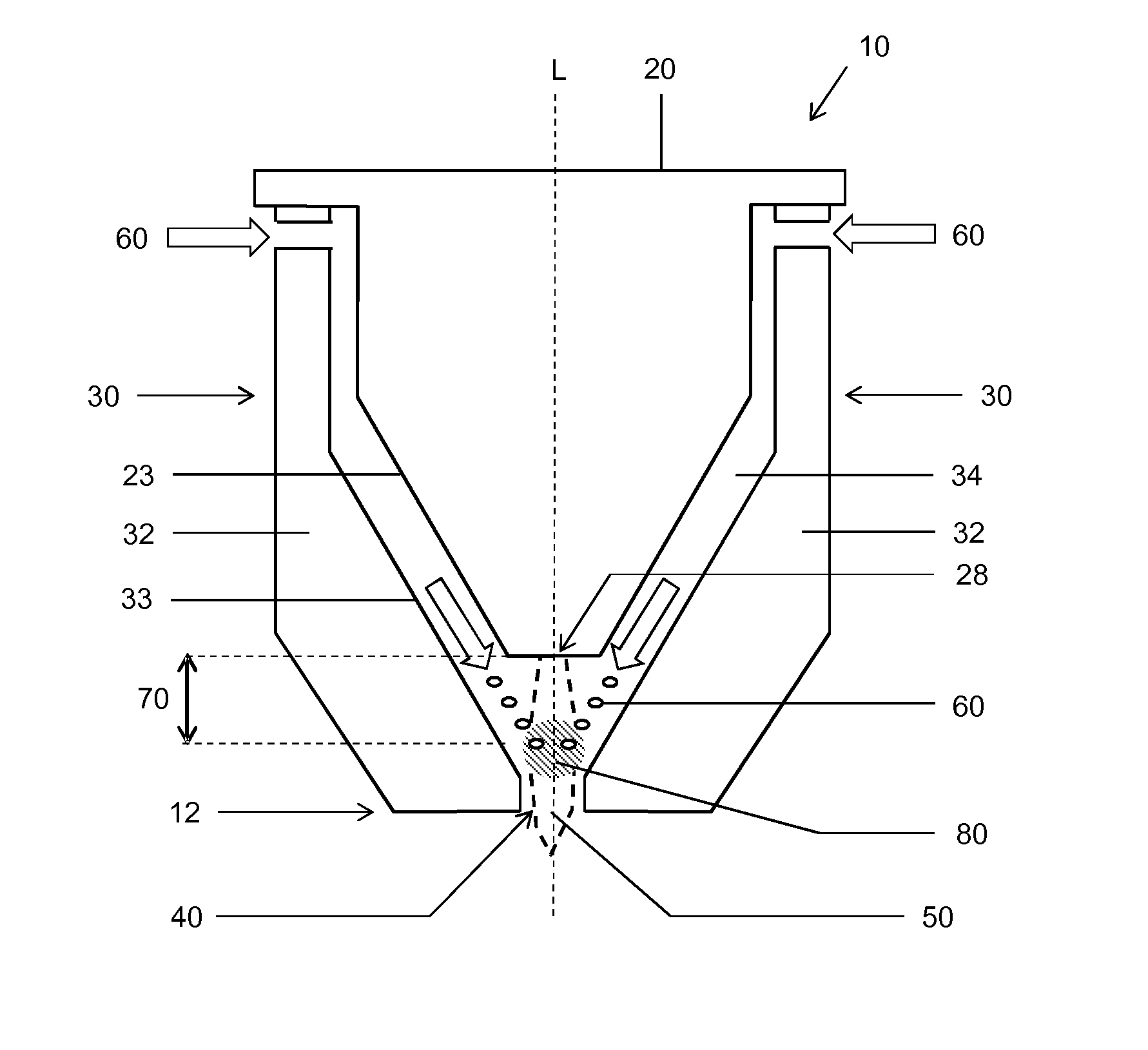

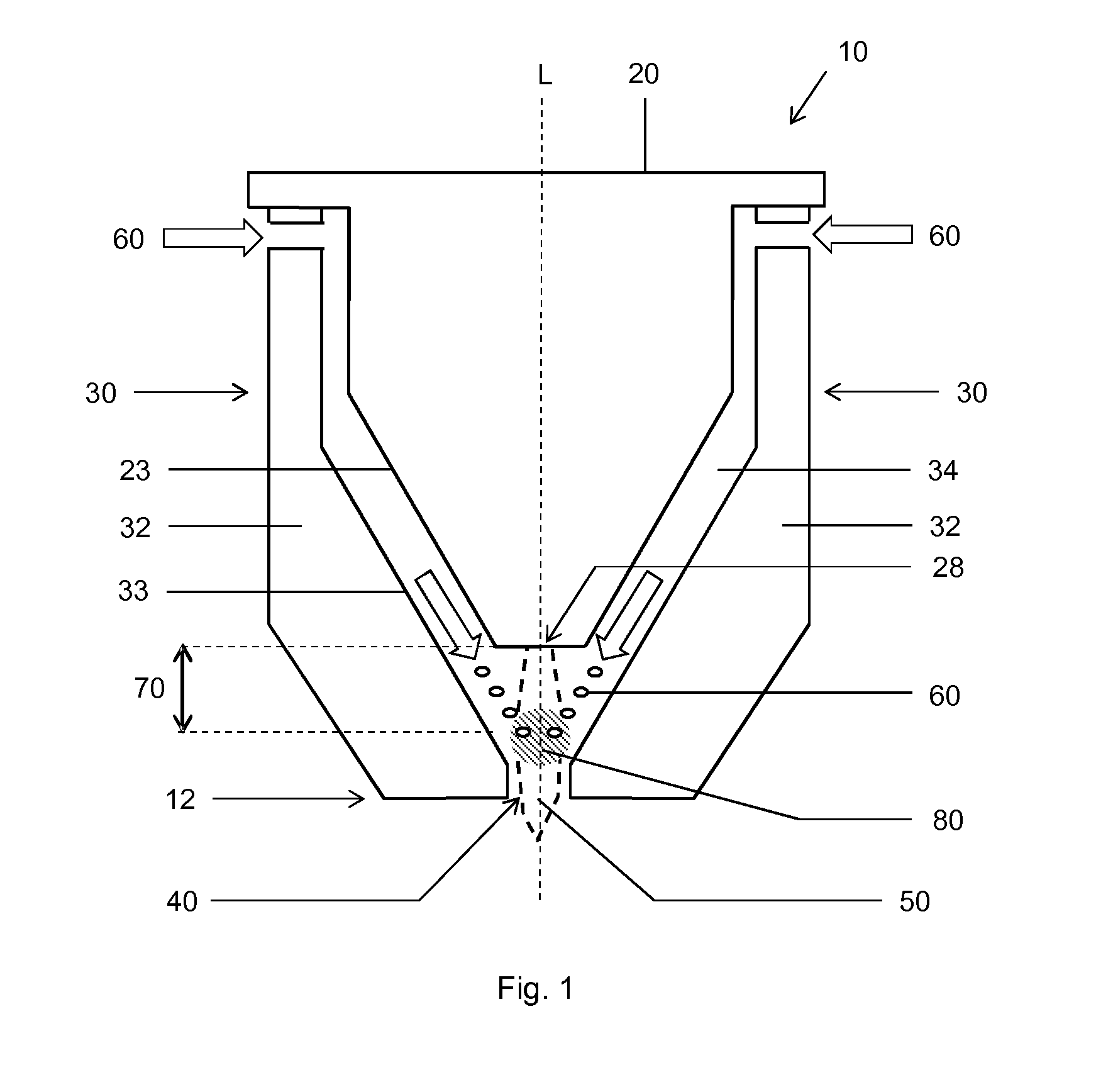

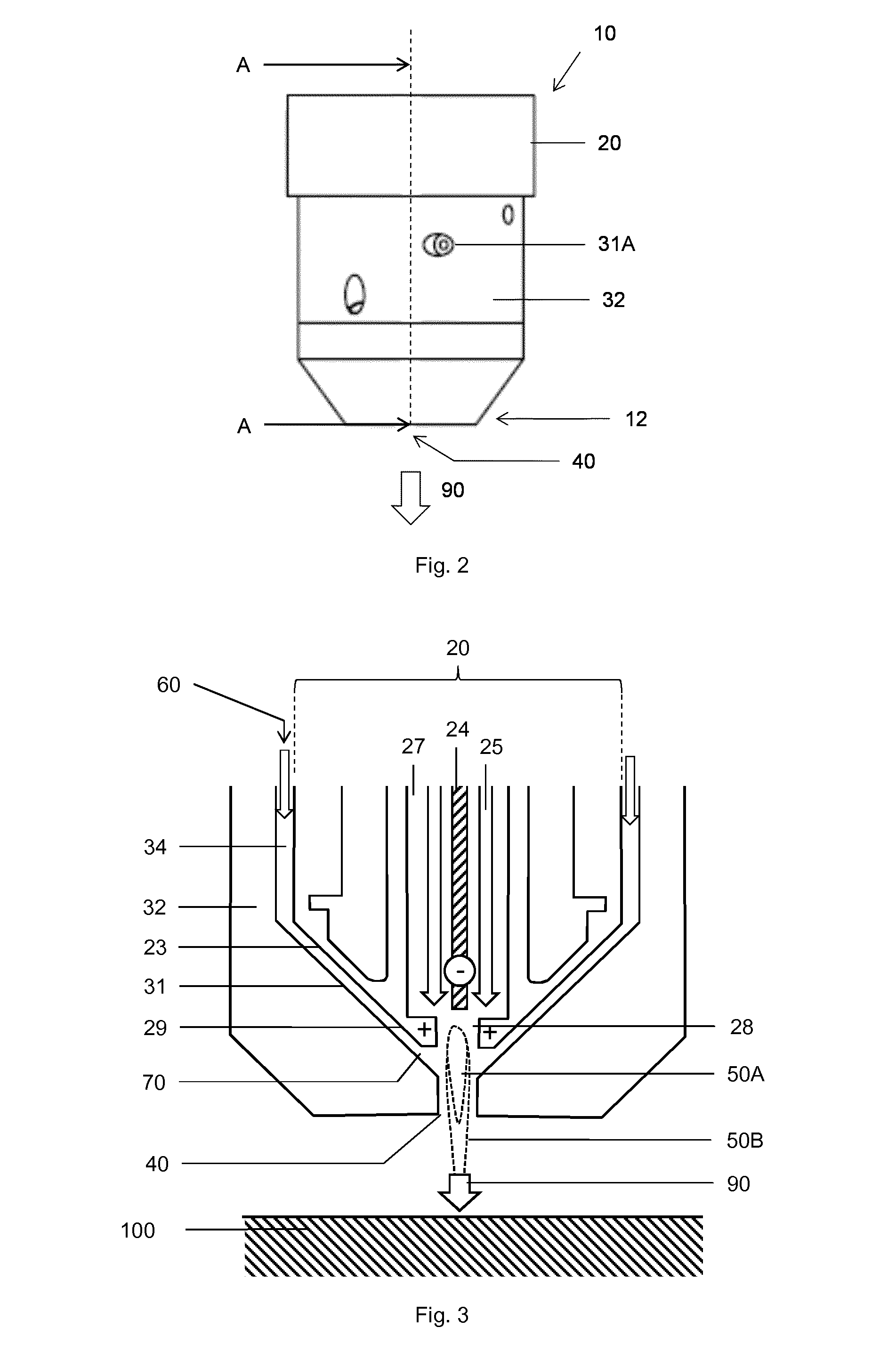

Thermal spray assembly and method for using it

ActiveUS20170021372A1Not easy to layerProtection materialLiquid spraying apparatusPlasma techniqueThermal sprayingEngineering

A thermal spray assembly (10) for transforming precursor material (60) into a layer of deposited material joined to a substrate body. A plasma torch (20) produces a plasma jet from a plasma nozzle (28). A feeder mechanism (30) guides the precursor material (60) into the plasma jet in use and provides a feeder orifice (70) when in an open condition. The feeder mechanism comprises a guide chamber (34) and a moveable guide mechanism (32), and the guide chamber is capable of guiding the precursor material to the feeder orifice, through which the precursor material can move from the guide chamber and enter the plasma jet at a variable mean distance from the plasma nozzle (28) in response to movement of the guide mechanism (32).

Owner:ELEMENT SIX GMBH

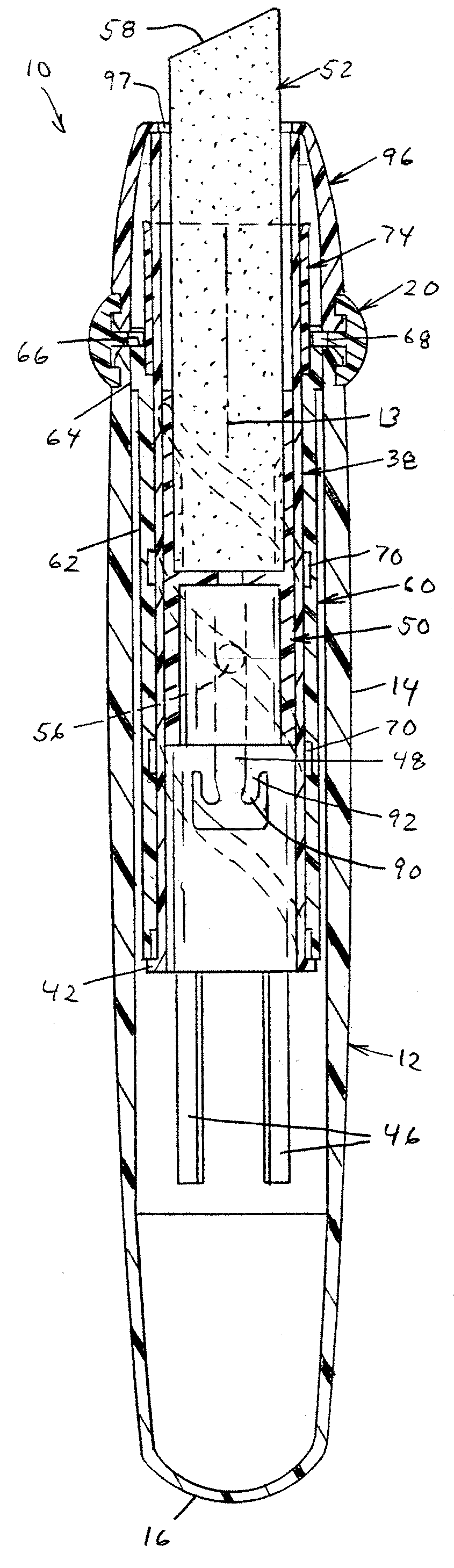

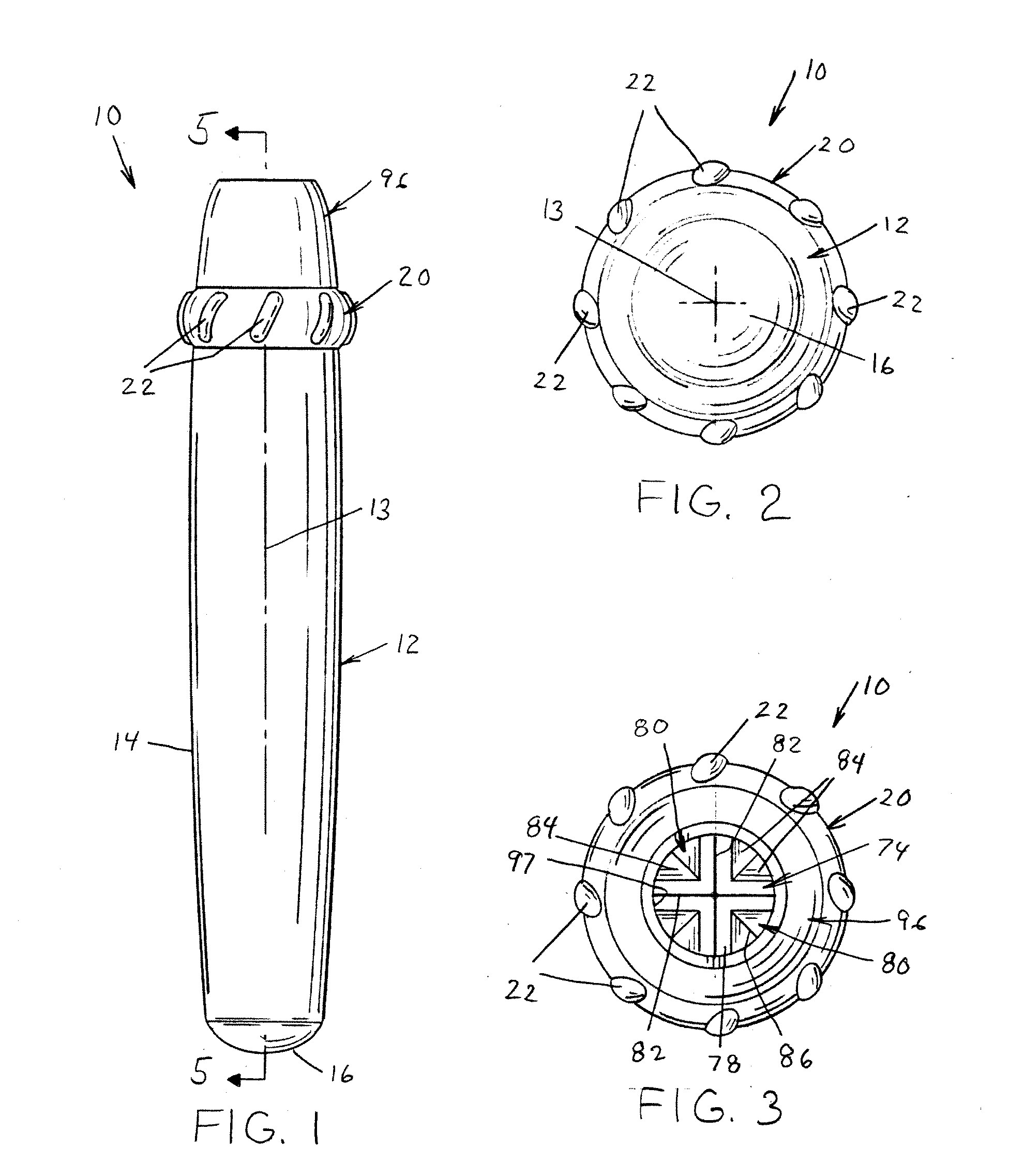

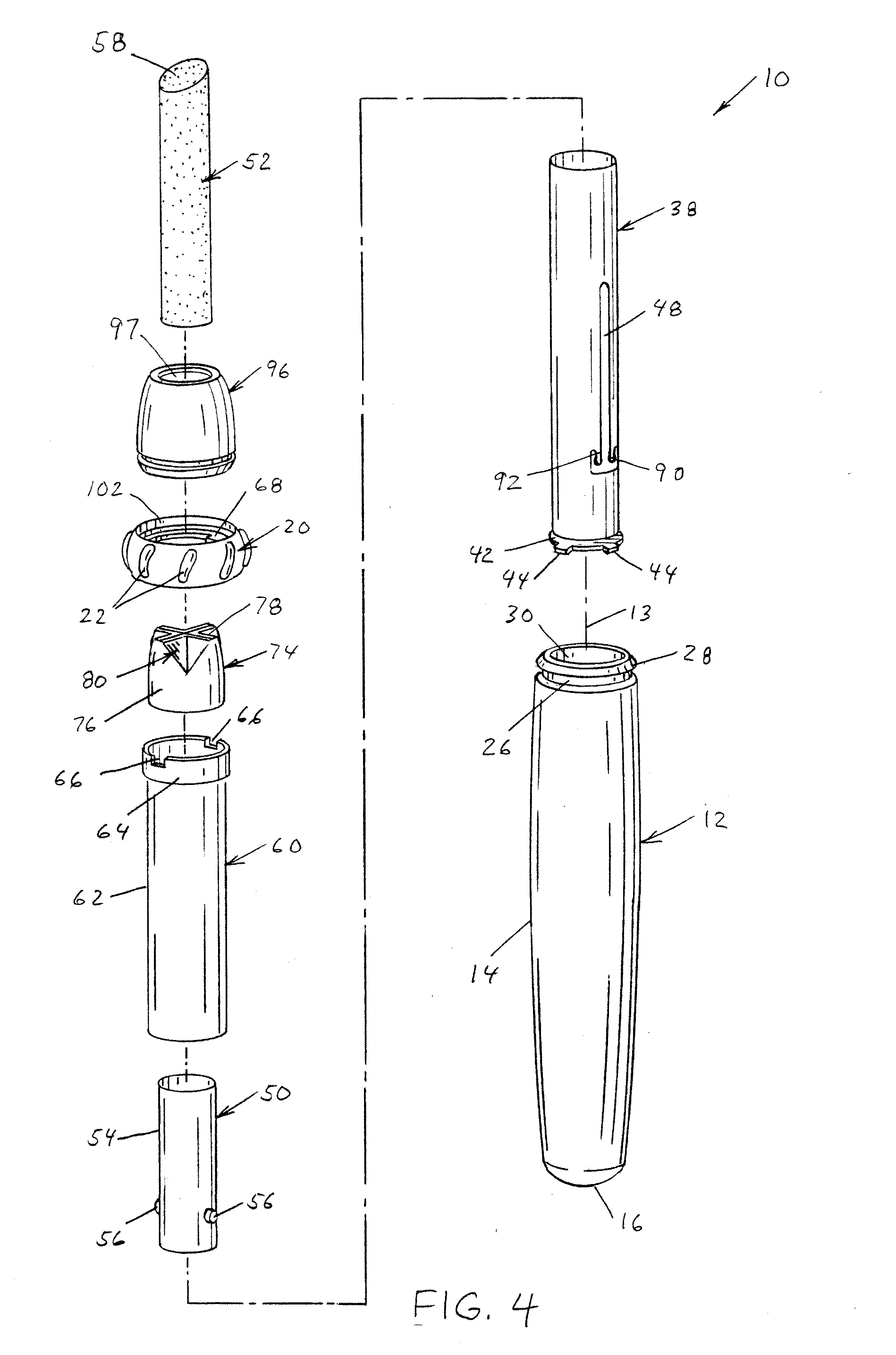

Cosmetic applicator

InactiveUS20080163881A1Simple and intuitive operationGuaranteed uptimePropelling pencilsCurling devicesElastomerEngineering

A cosmetic applicator having an actuator near its top which can be easily used with one hand having an elastomeric top seal is described. The cosmetic applicator is provided with a seal opening sleeve which protects the body of cosmetic from the elastomeric seal during opening operations and closing operations.

Owner:NOTTINGHAM SPIRK DESIGN ASSOCS

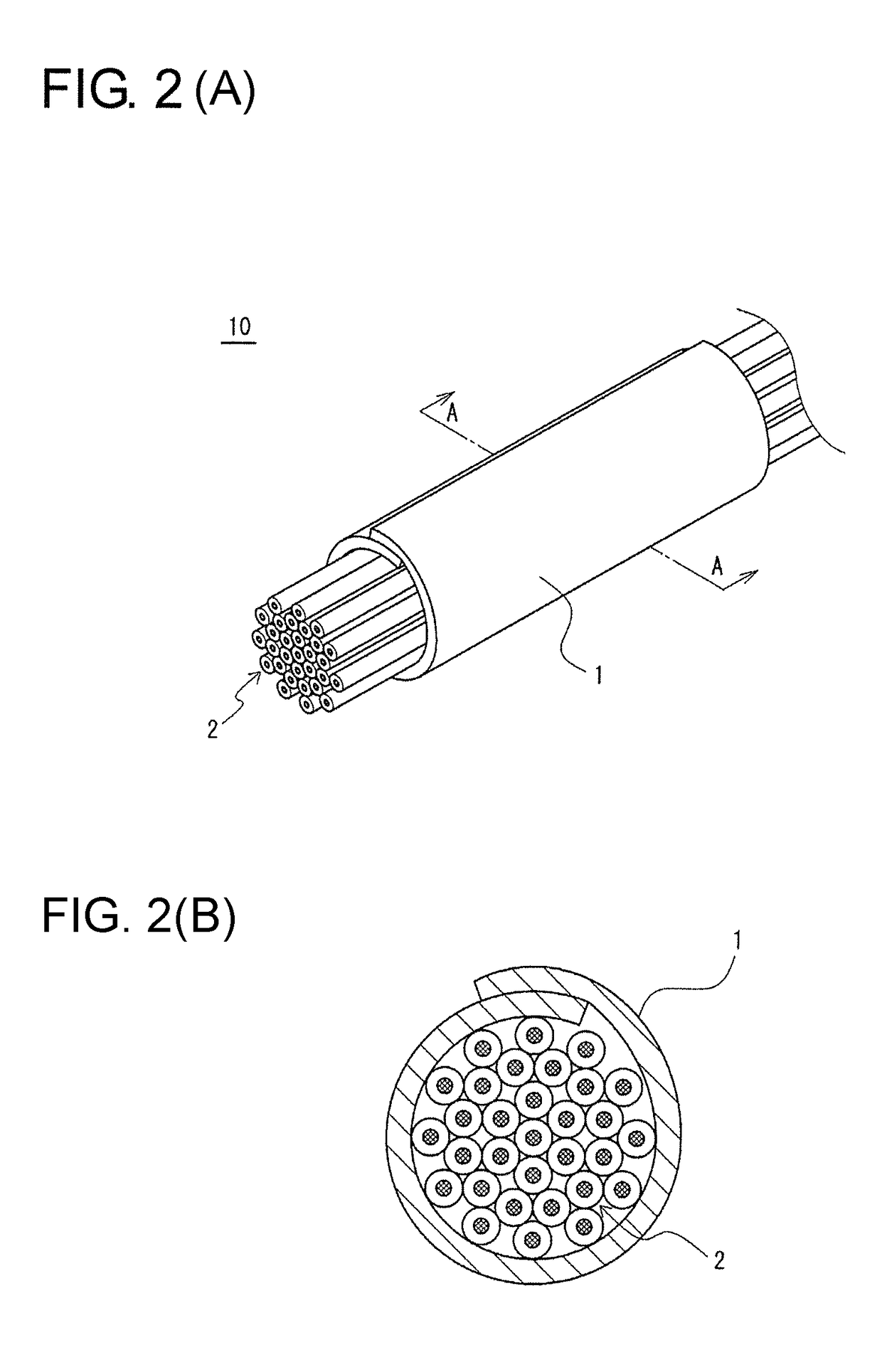

Sound absorber and wiring harness with sound absorber

ActiveUS20170169809A1Improve sound absorptionReducing fiber diameterElectrical apparatusNon-woven fabricsEngineeringSound Absorber

If a thickness of a sound absorber arranged in a vehicle and clearances in the vehicle do not match and gaps are formed between the sound absorber and the respective members in the vehicle, abnormal noise due to the mutual contact of the members and noise outside the vehicle enter the vehicle interior to impair vehicle interior quietness. This is solved by a sound absorber which includes a nonwoven fabric containing 5 to 50 mass % of second fibers having a lower melting point than that of first fibers and can cause the first and second fibers to be more loosely interfaced and increase a volume of the nonwoven fabric by heating the nonwoven fabric to about the melting point of the second fibers and softening or melting the second fibers even after production.

Owner:AUTONETWORKS TECH LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com