Patents

Literature

140results about How to "Increase machine speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

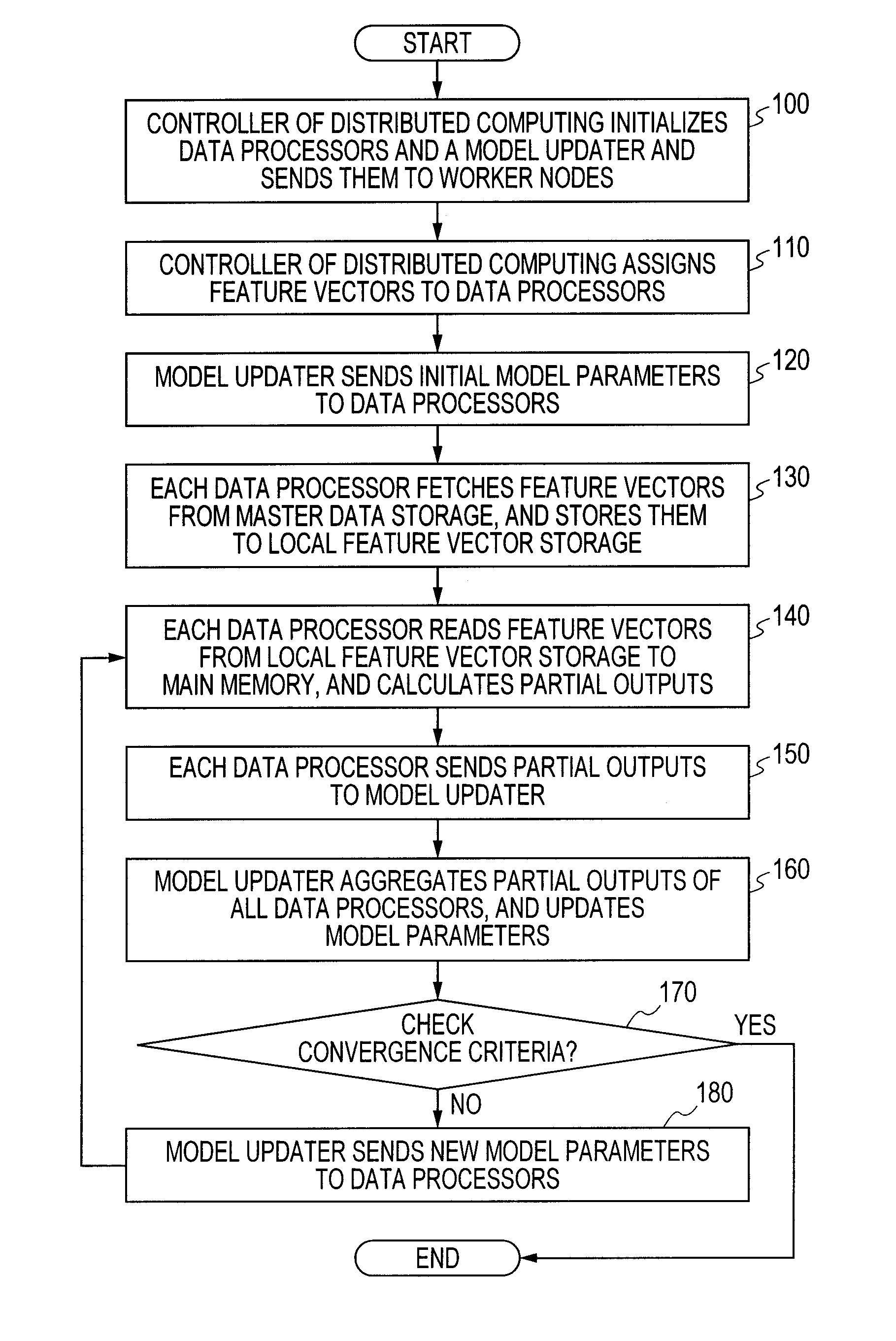

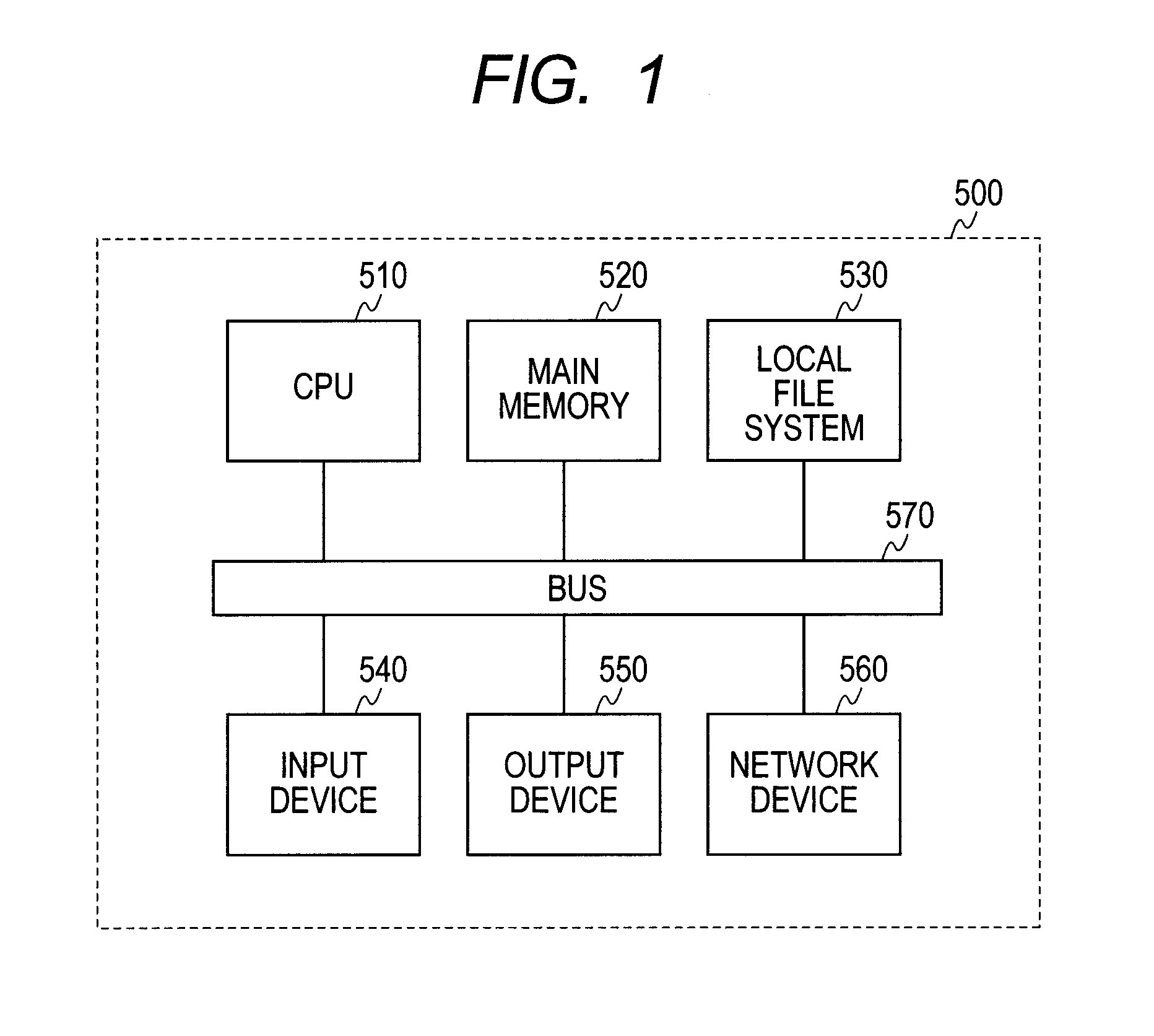

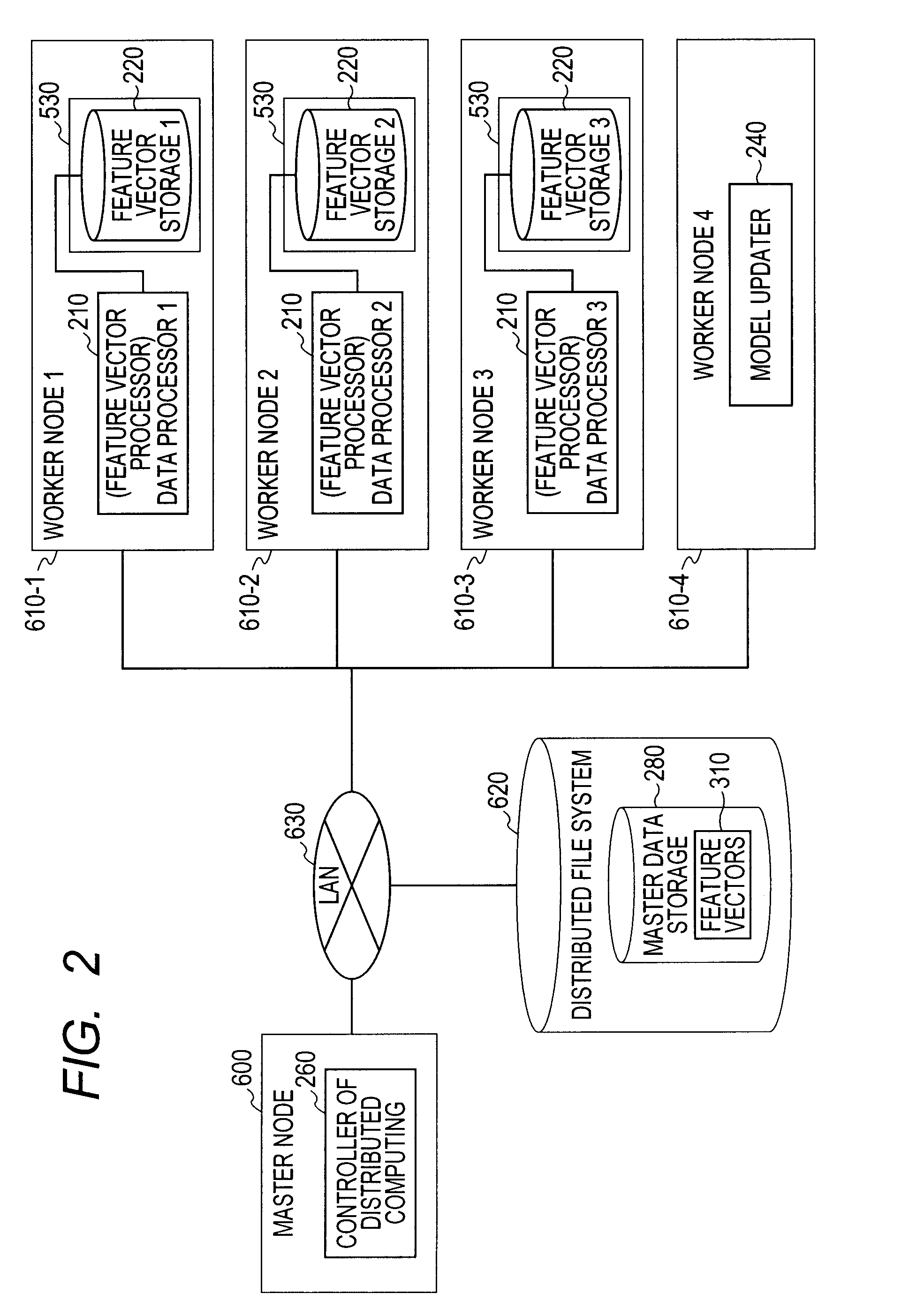

Distributed computing system for parallel machine learning

InactiveUS20120016816A1Efficient executionEasy to handleEnsemble learningDigital computer detailsFeature vectorModel parameters

A controller of a distributed computing system assigns feature vectors, and assigns data processors and a model updater to first computers. The data processors have charge of iteration calculation of machine learning algorithms, acquire the feature vectors over a network when starting learning, and store the feature vectors in a local storage. In iteration of second and subsequent learning processes, the data processors load the feature vectors from the local storage, and conduct the learning process. The feature vectors are retained in the local storage till completion of learning. The data processors send only the learning results to the model updater, and waits for a next input from the model updater. The model updater conducts the initialization, integration, and convergence check of the model parameters, completes the processing if the model parameters are converged, and transmits new model parameters to the data processor if the model parameters are not converged.

Owner:HITACHI LTD

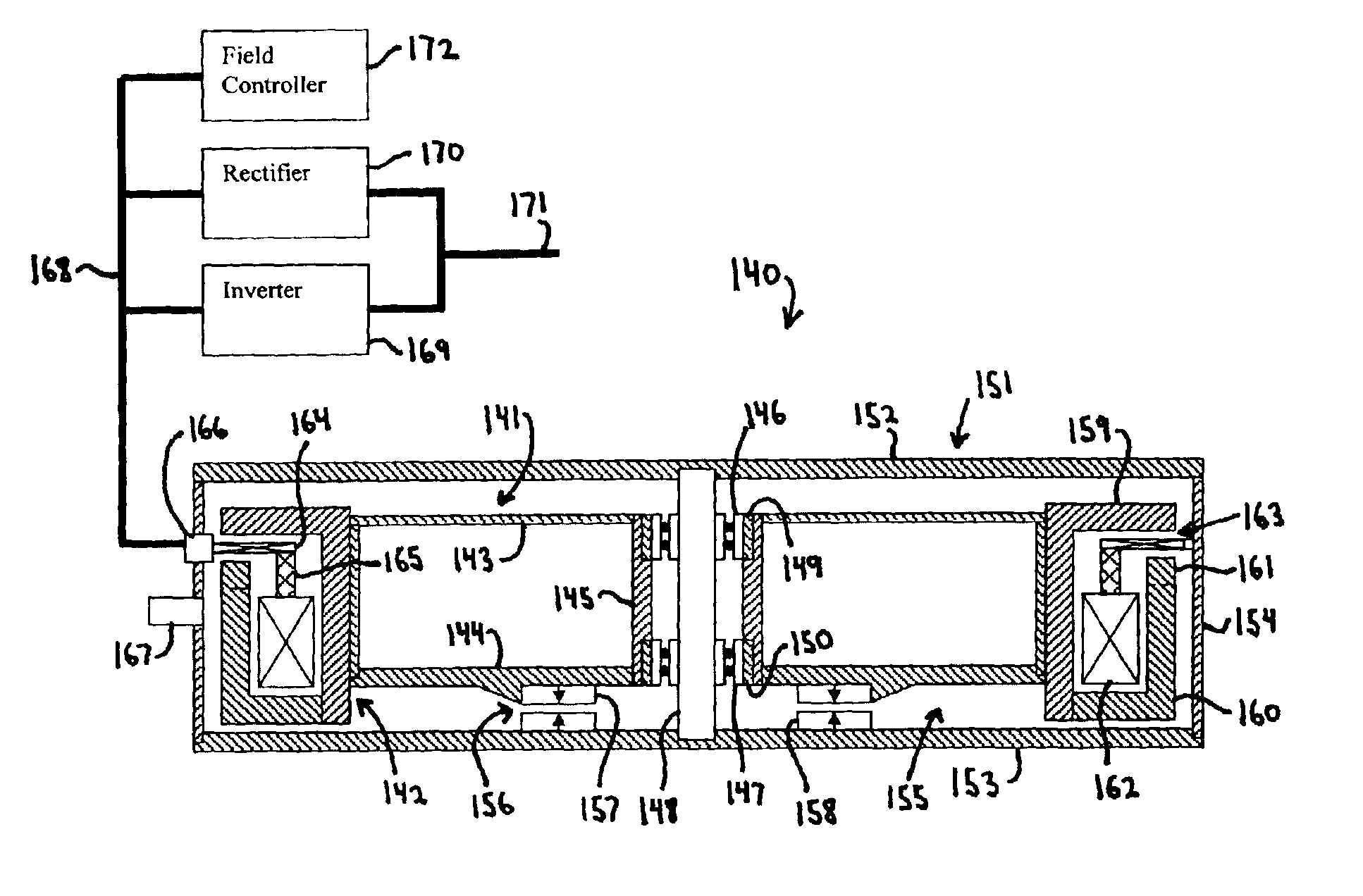

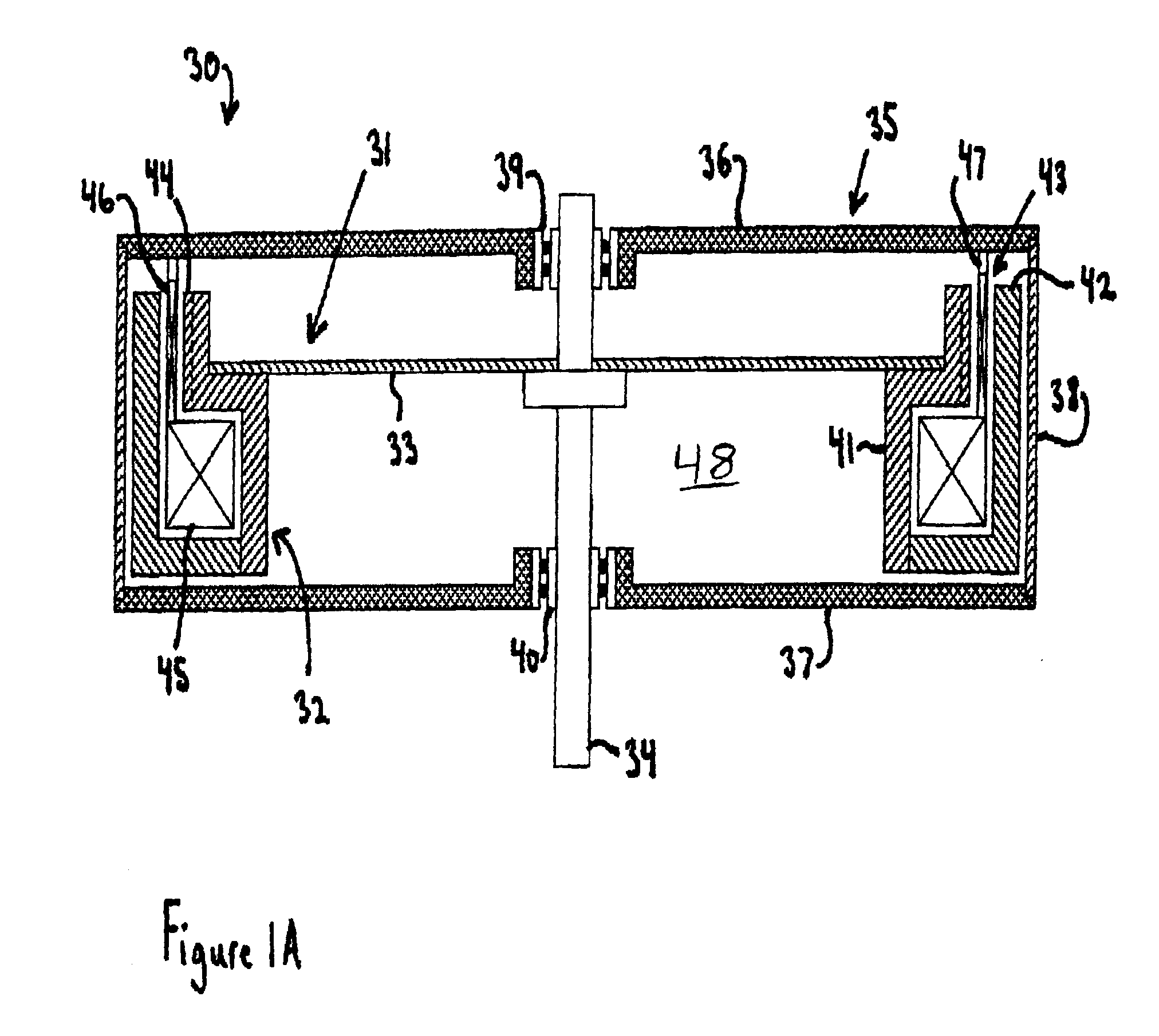

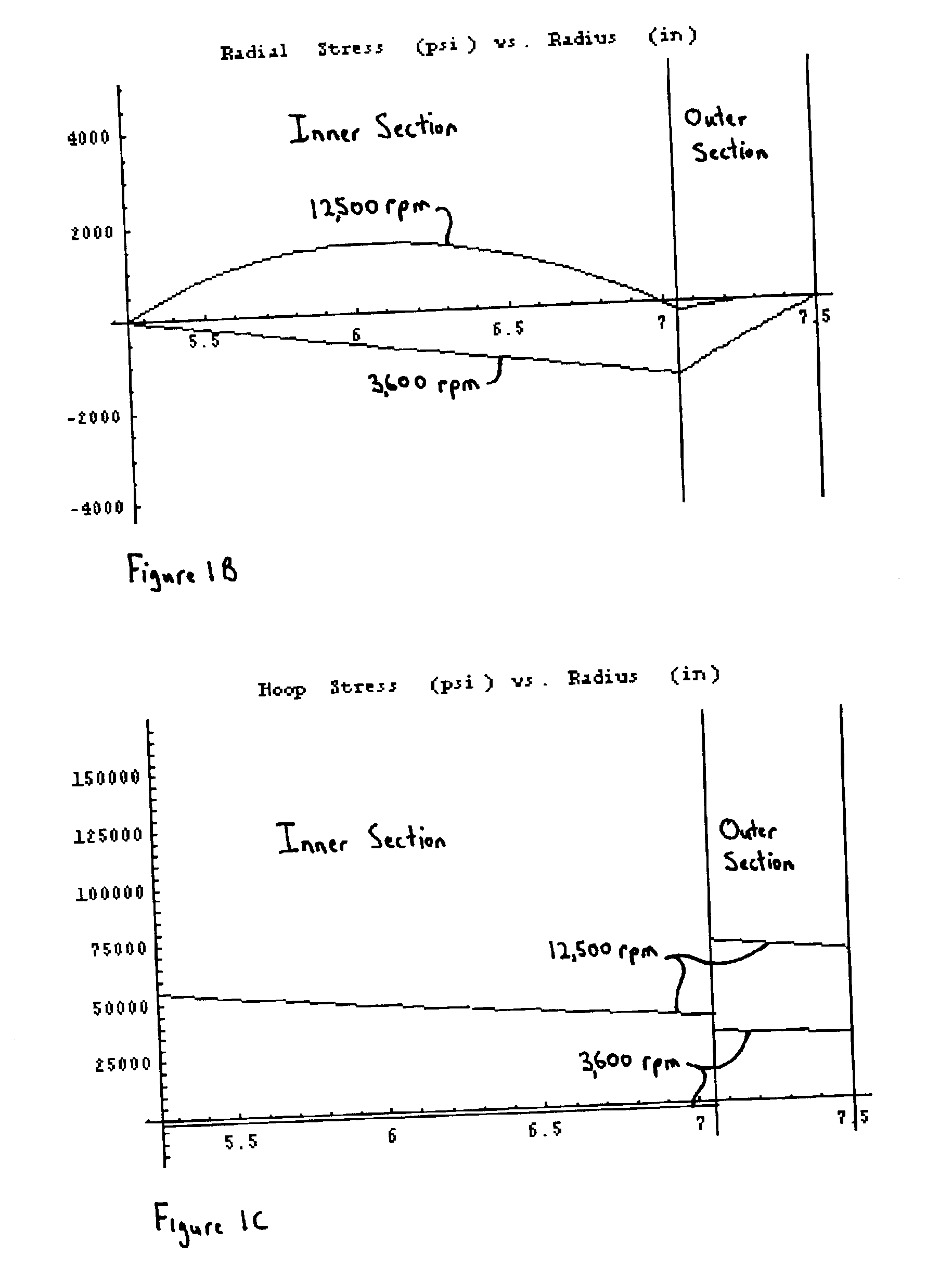

Light-weight high-power electrical machine

InactiveUS6891302B1High energyMotor/generator magnetic lossHybrid vehiclesWindingsAlternatorElectrical polarity

A brushless electrical machine, usable as a motor, generator, or alternator, has a rotor that is comprised of a rim portion and a substantially open center portion. The rim portion has a partially hollow core in which a stationary field coil is supported. Current to the field coil generates magnetic flux that circulates in a poloidal flux path in the rim, crossing a single magnetic air gap formed by the rim. Protrusions in the rim located around the circumference form poles all having the same polarity. As the rotor rotates, the flux exiting the poles passes through multiple stationary armature windings around the circumference that are located in the single air gap. An AC voltage is induced in the armature windings from rotation.

Owner:REVOLUTION ELECTRIC MOTOR

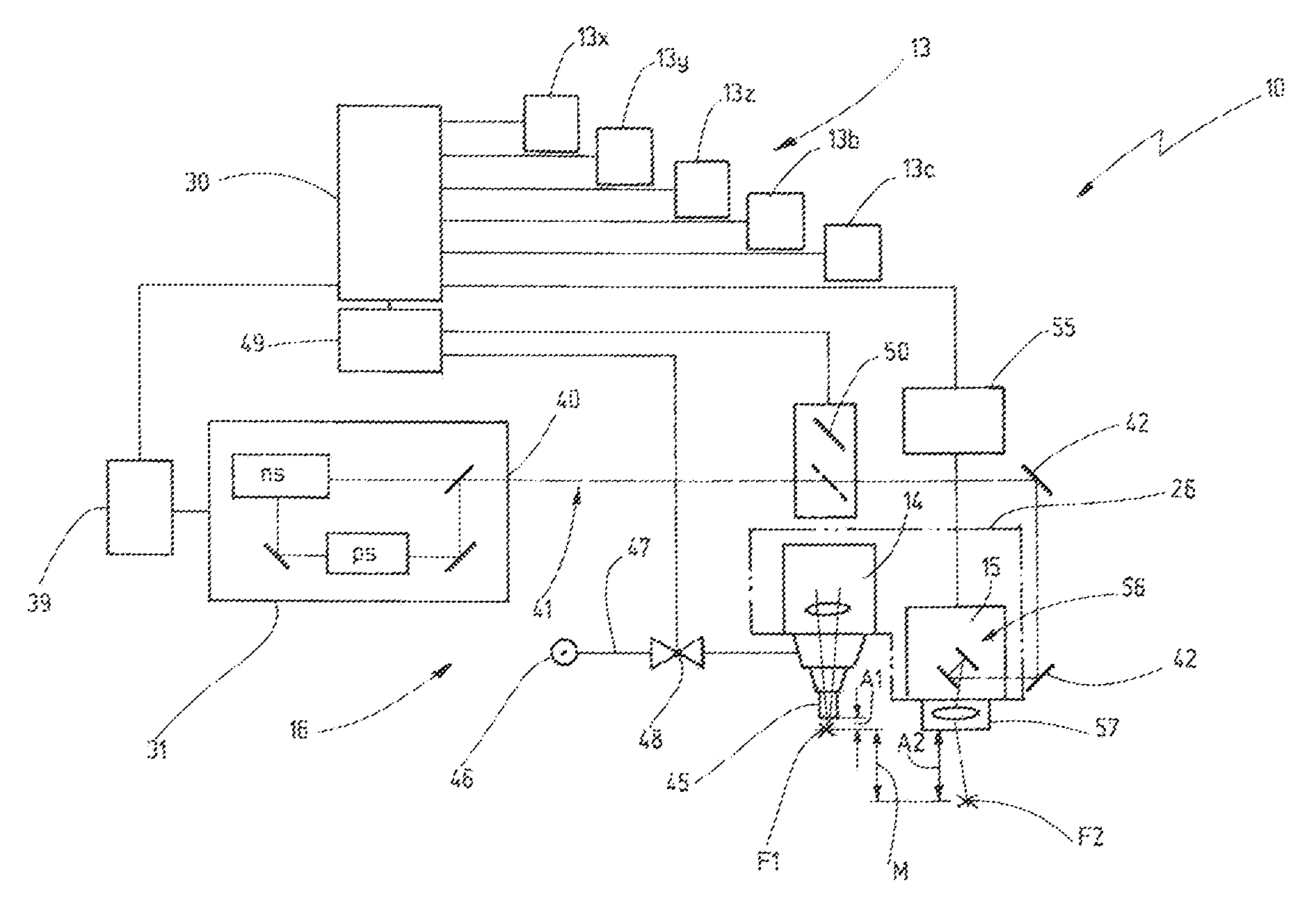

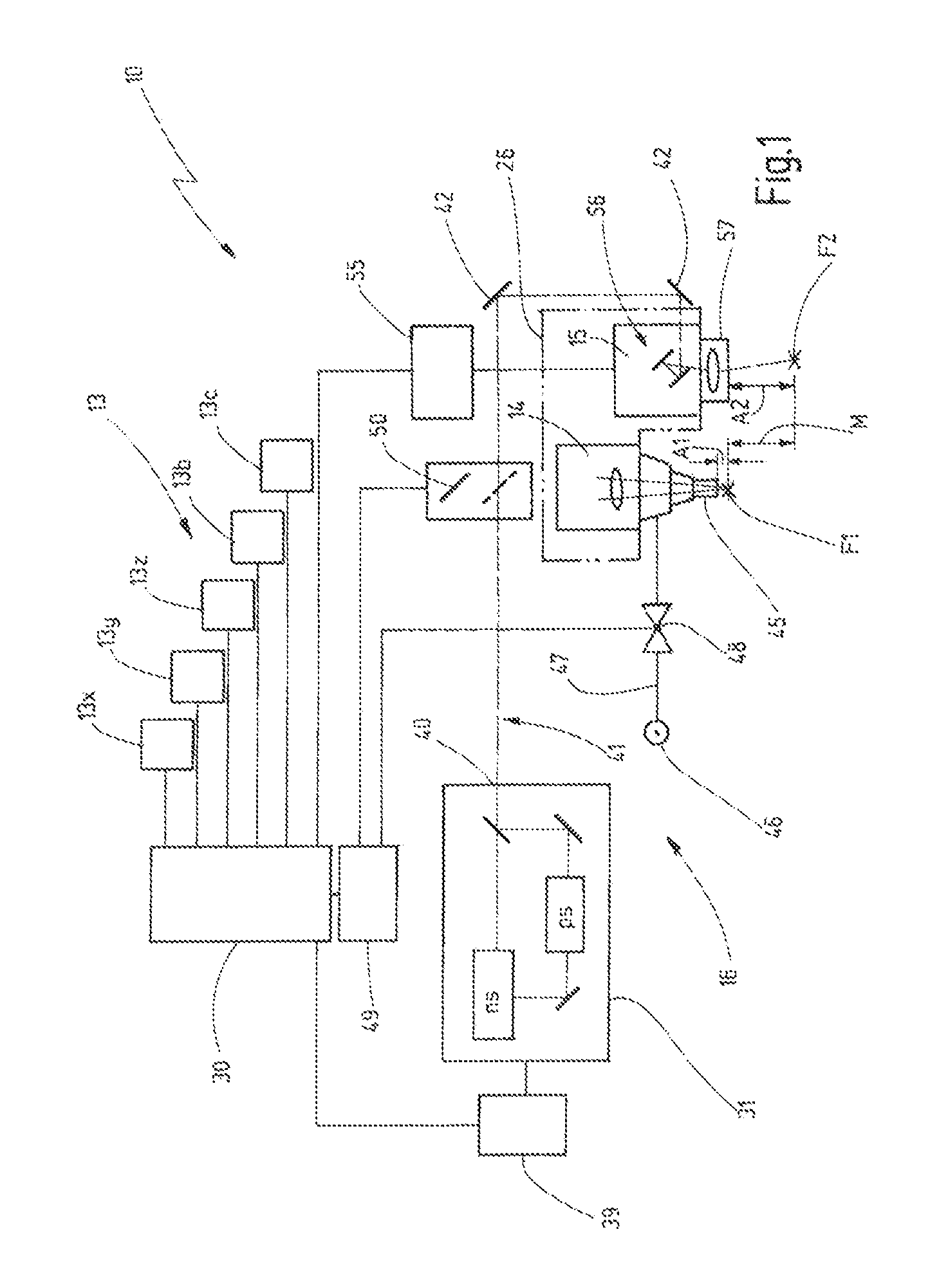

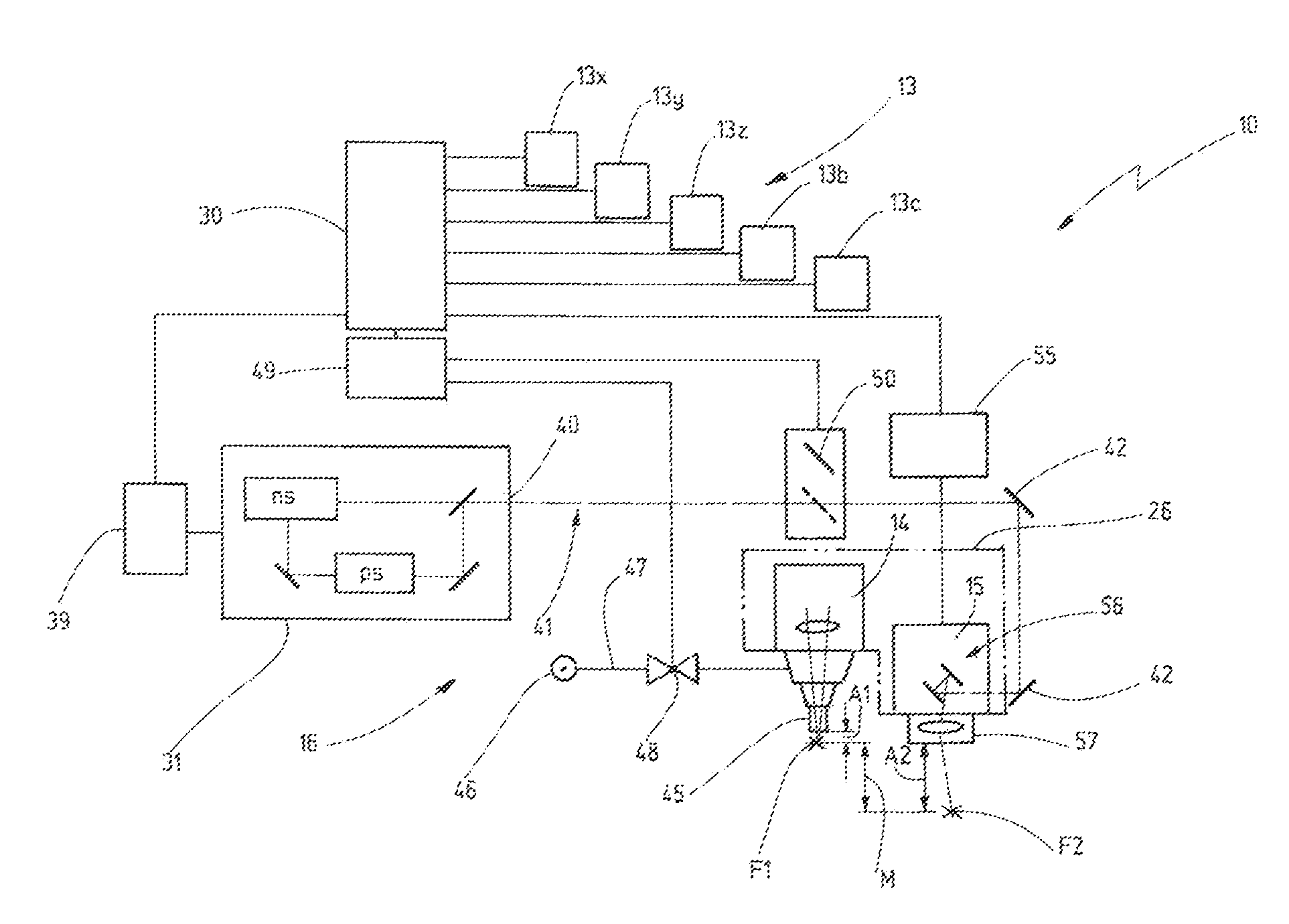

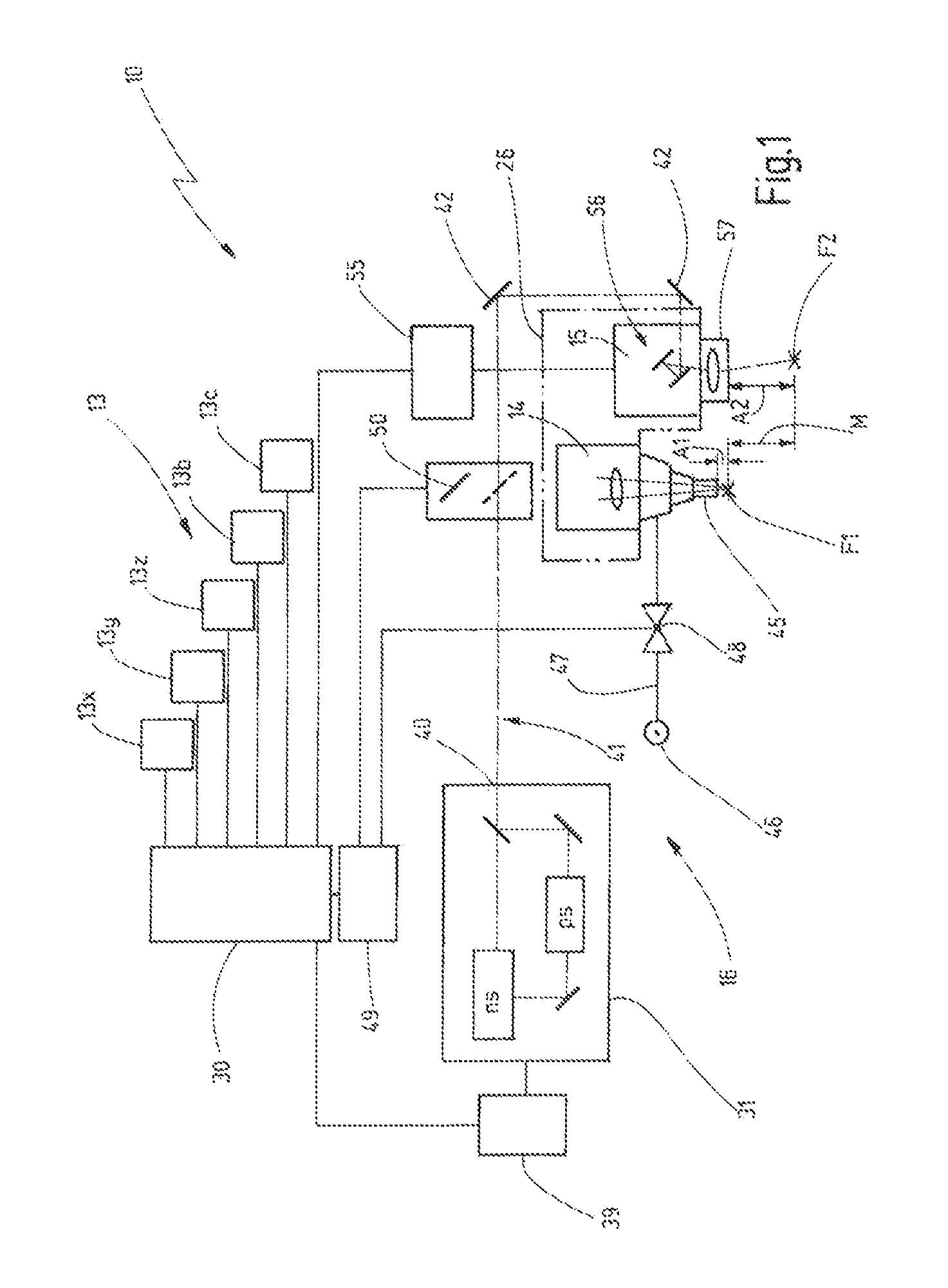

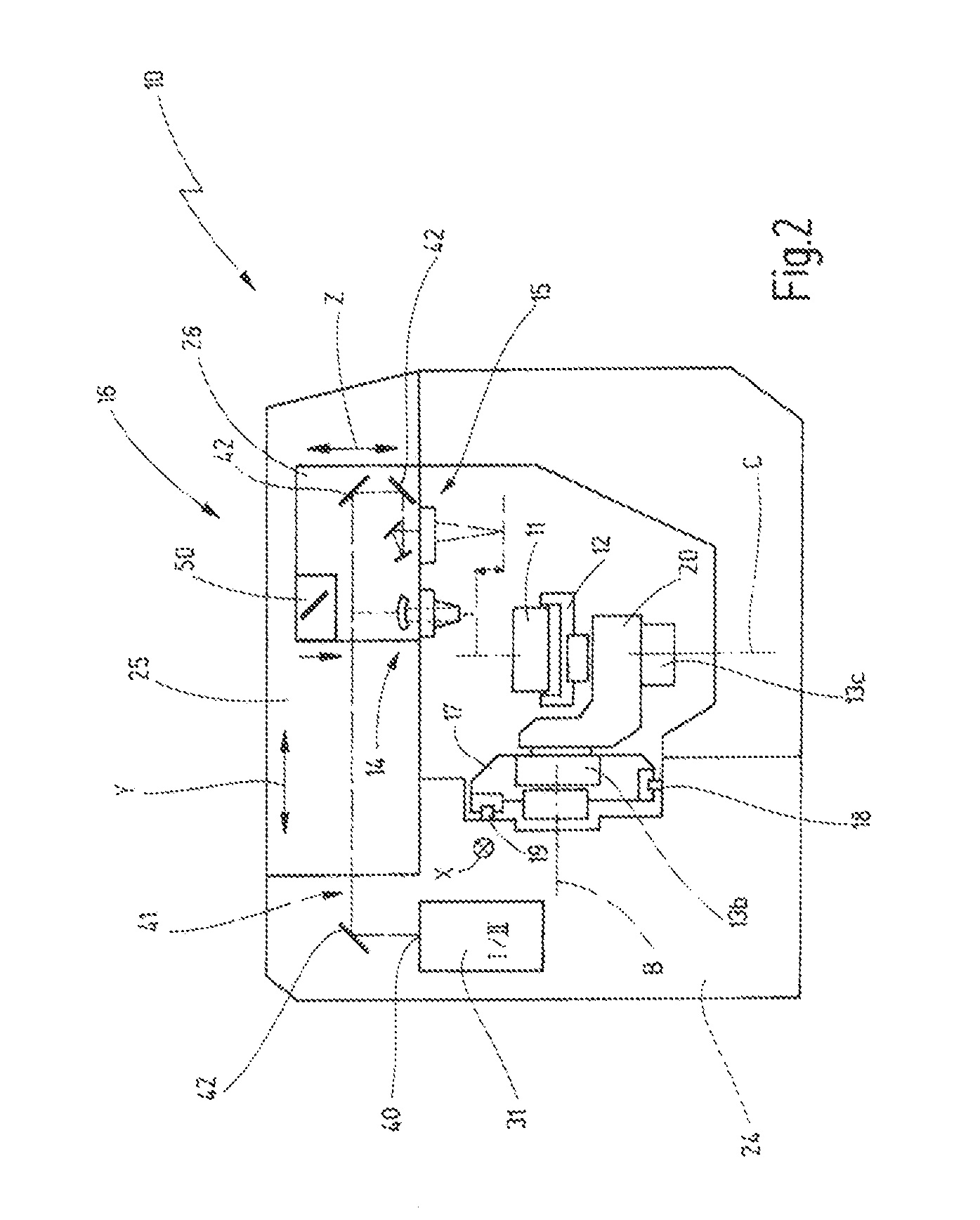

Laser machining apparatus with switchable laser system and laser machining method

ActiveUS8916798B2Quality improvementIncrease machine speedMetal working apparatusLaser beam welding apparatusNanosecondLaser processing

A laser machining apparatus and method for producing from a workpiece a rotating cutting tool having a cutting edge and a flank. The laser machining apparatus works in two different operating modes. In the first operating mode, a first laser head is used for machining the workpiece at high advance speeds of the workpiece relative to the first laser head to form a rough desired contour with pulses having a duration in the nanosecond range resulting in laser melt cutting. Subsequently, the laser machining apparatus is operated in the second operating mode generating laser pulses with having a pulse duration in the picosecond range. In the second operating mode, a second laser head is activated by means of an optical scanner system and directs the laser pulses onto a two-dimensional pulse area on the surface of the workpiece, the material removal is accomplished by laser ablation.

Owner:FRITZ STUDER AG

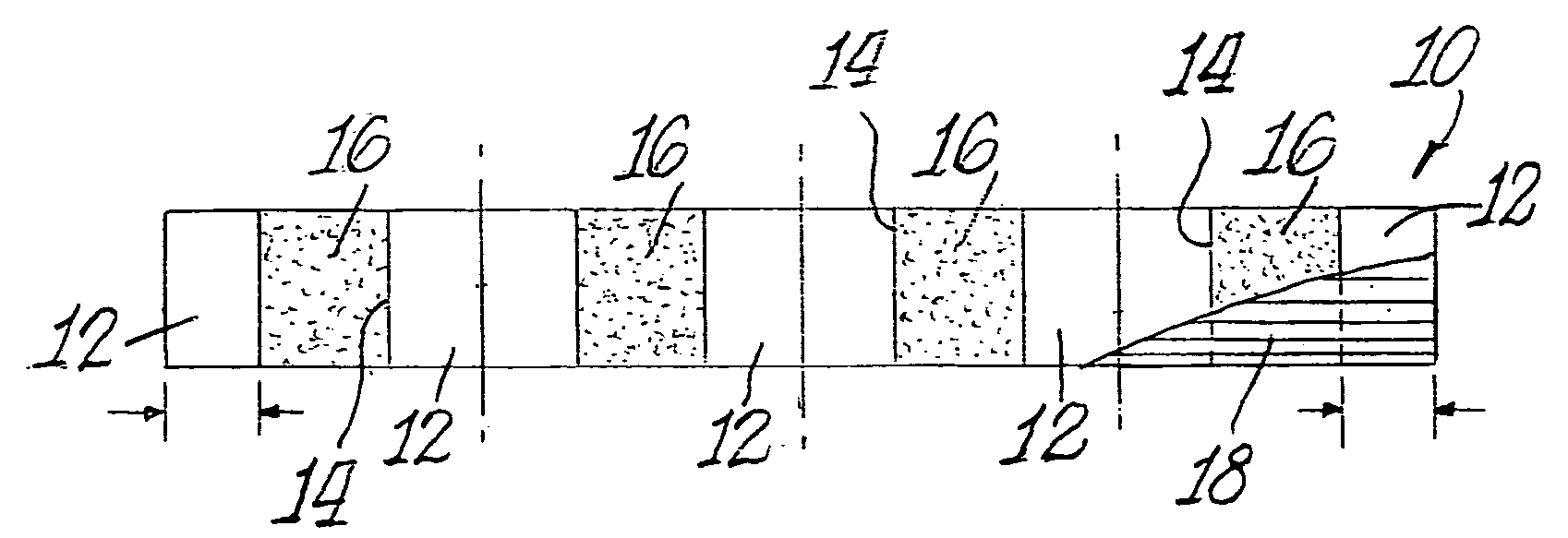

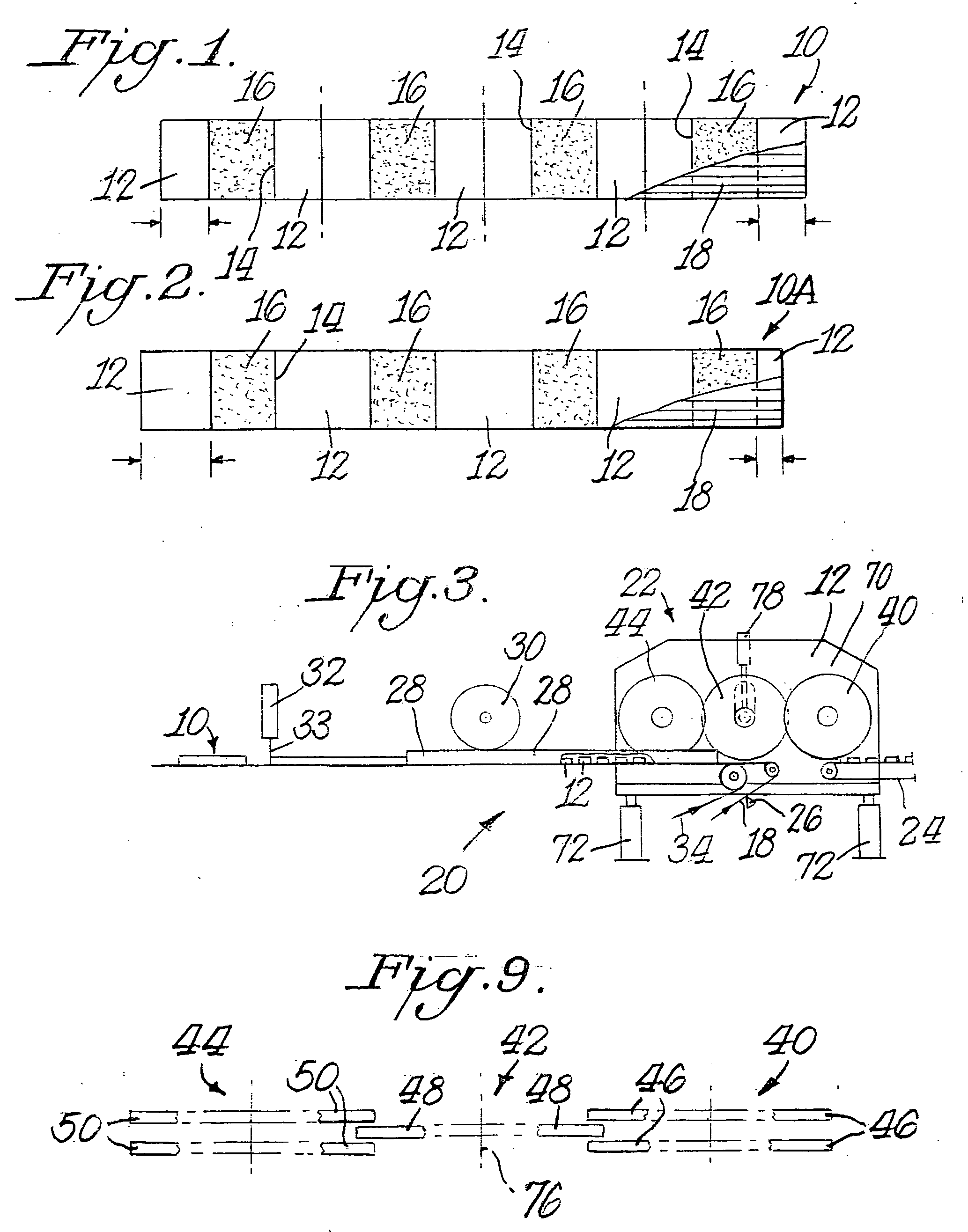

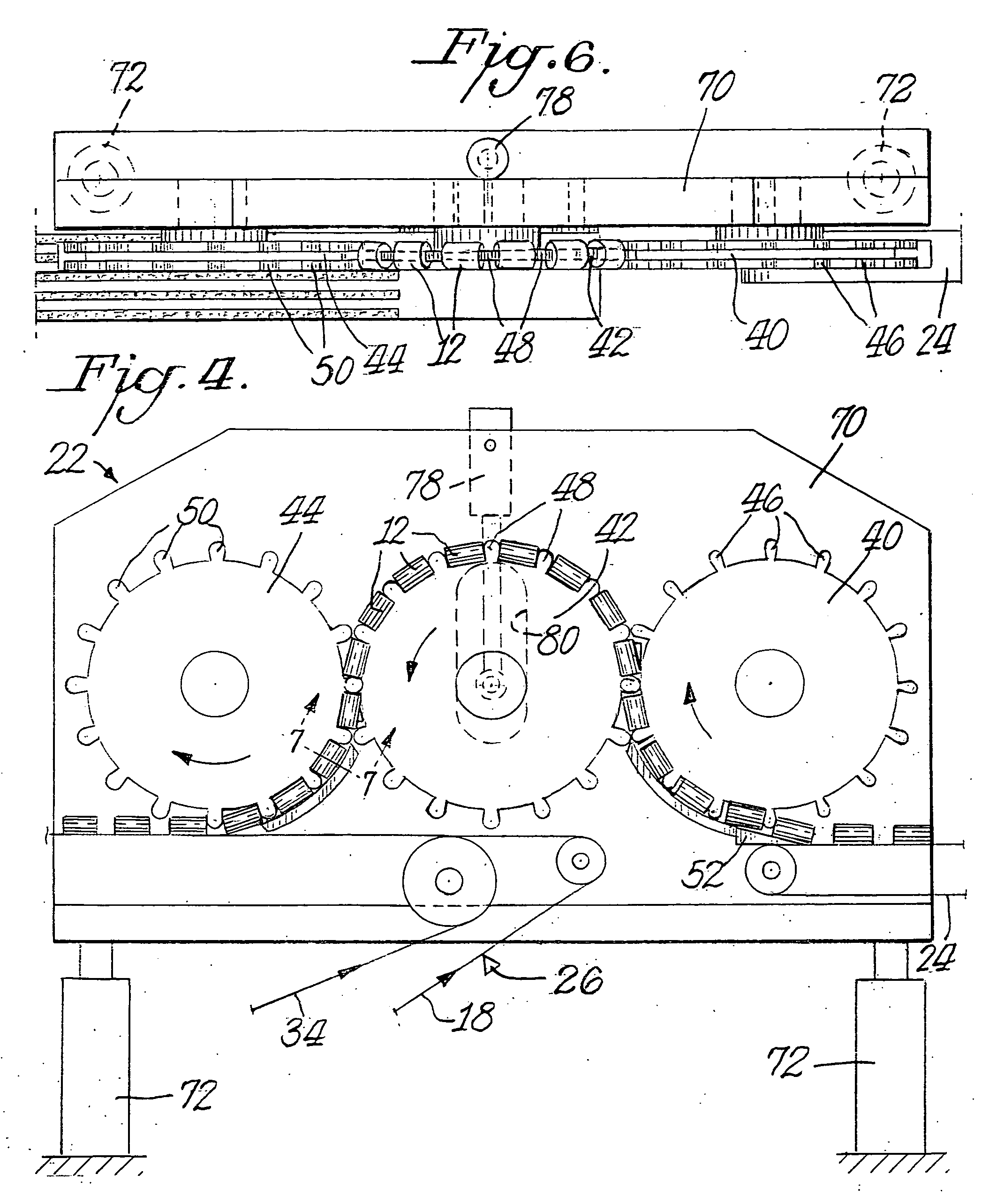

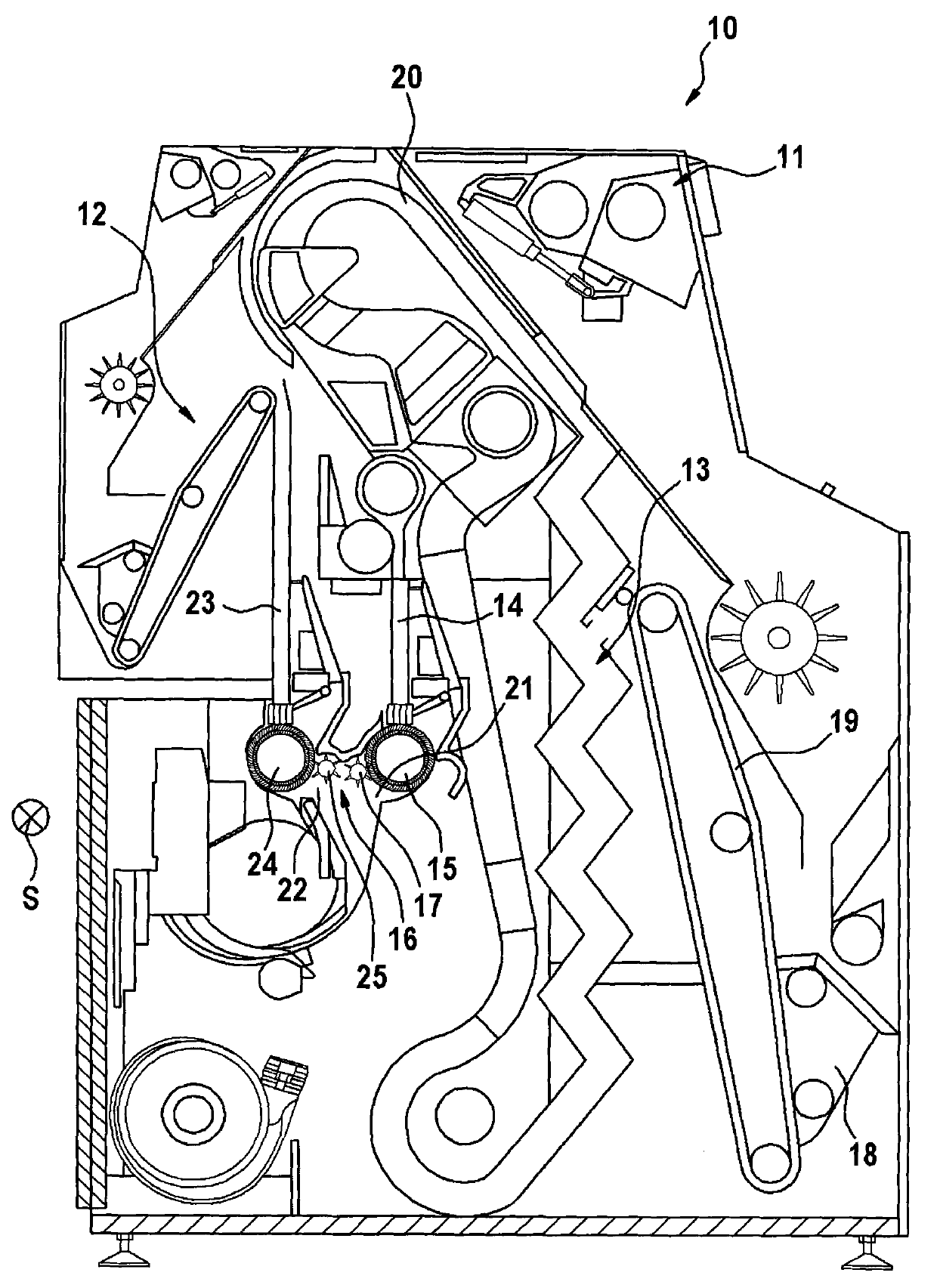

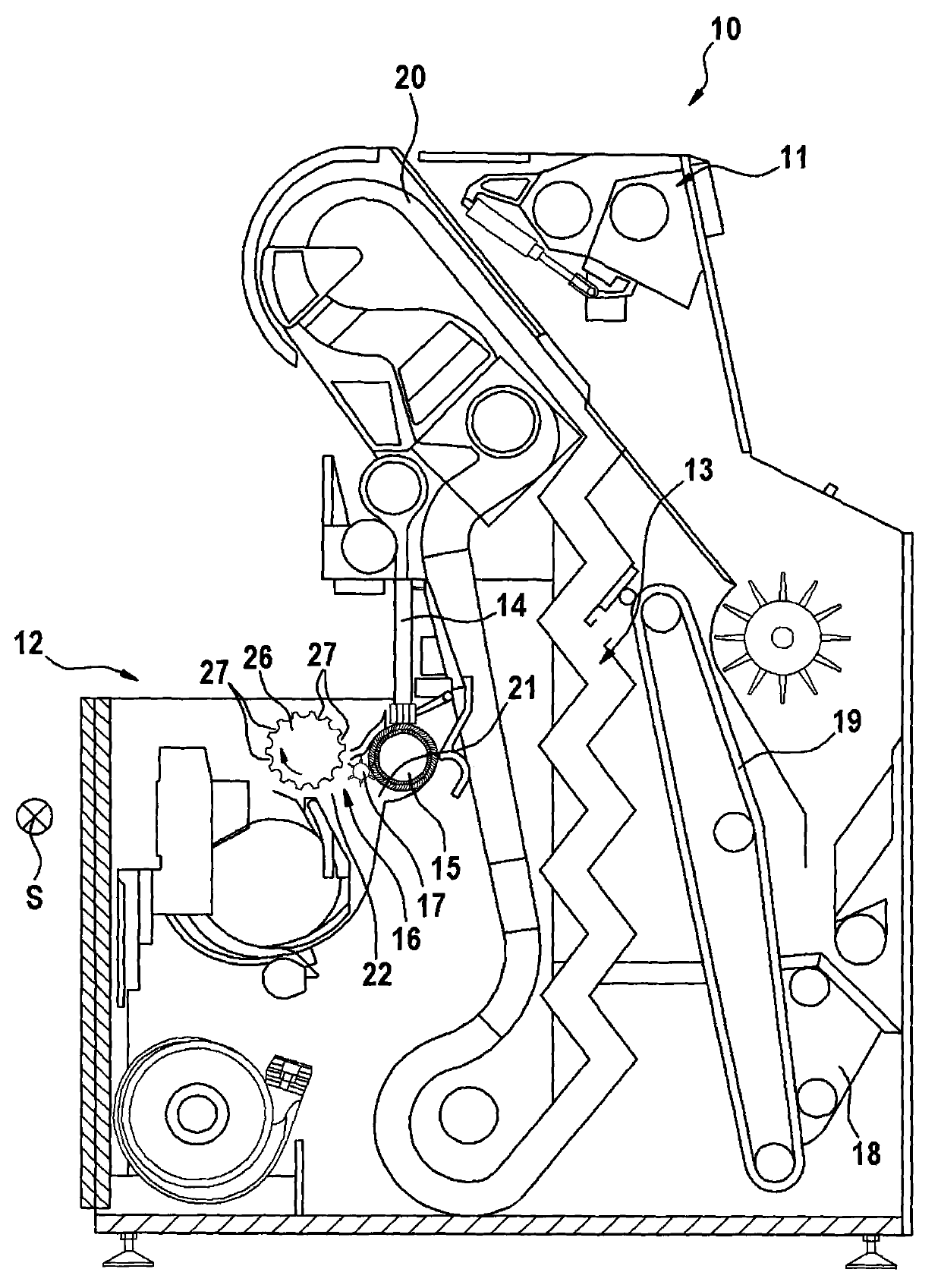

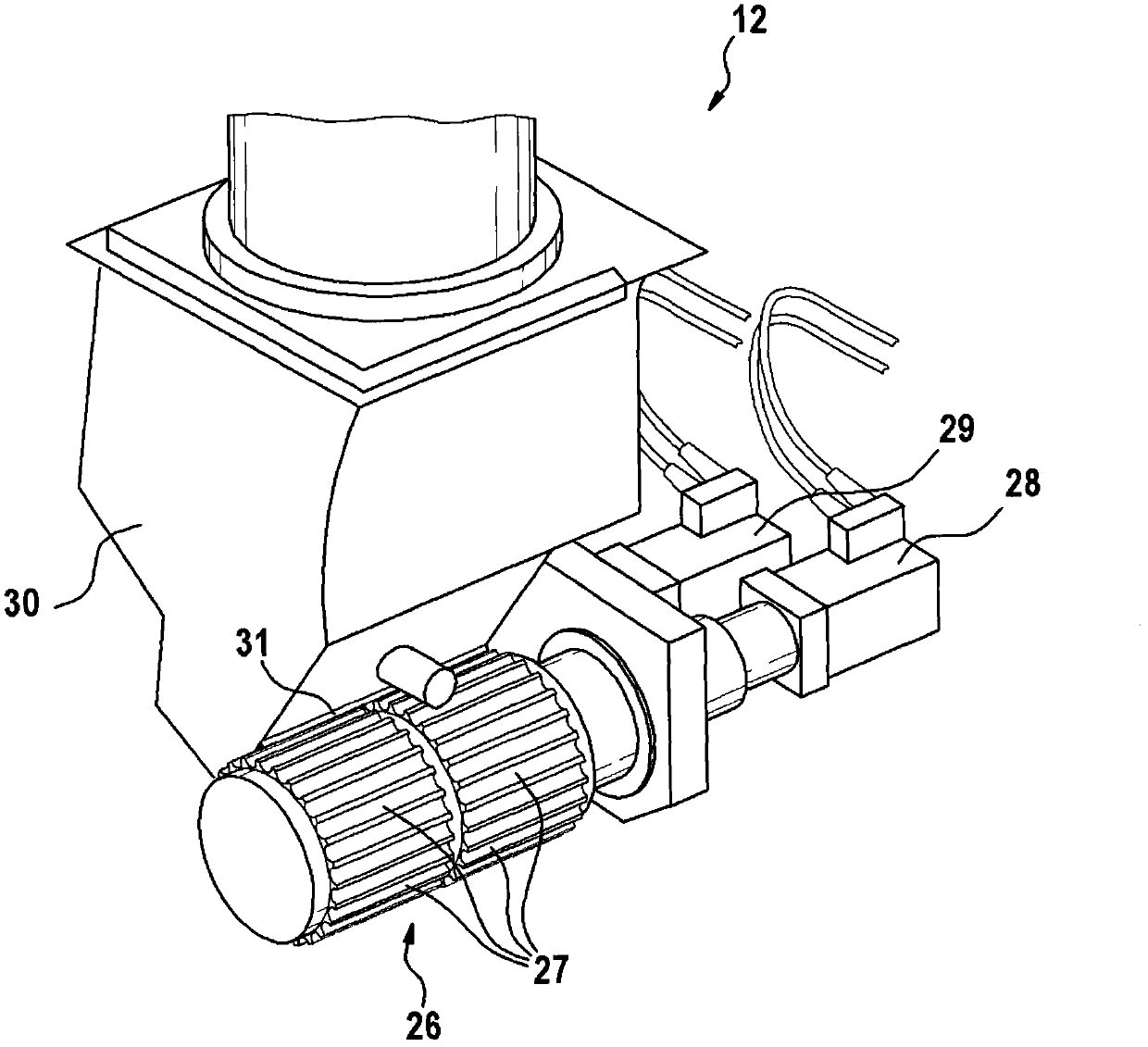

Method and apparatus for producing composite cigarette filters

ActiveUS20050282693A1High precisionIncrease machine speedPackaging cigarettePaper/cardboard wound articlesCigarette filterWrap around

Method and apparatus for producing discrete filter rods includes a first conveyor for transporting filter segments of given length in a downstream direction. Three counter rotating transfer wheels receive the filter segments between spaced apart cleats on the circumference of the wheels. The first wheel receives the filter segments from the first conveyor and transfers the segments to the second wheel which in turn transfers the segments to the third wheel. Filter segments between the cleats on the third wheel are deposited upon a second conveyor with plug wrap thereon in precisely spaced apart relationship. Granular adsorbent material is filled into cavities between the filter segments, and a garniture folds the plug wrap around the filter segments and the filled cavities therebetween.

Owner:PHILIP MORRIS USA INC

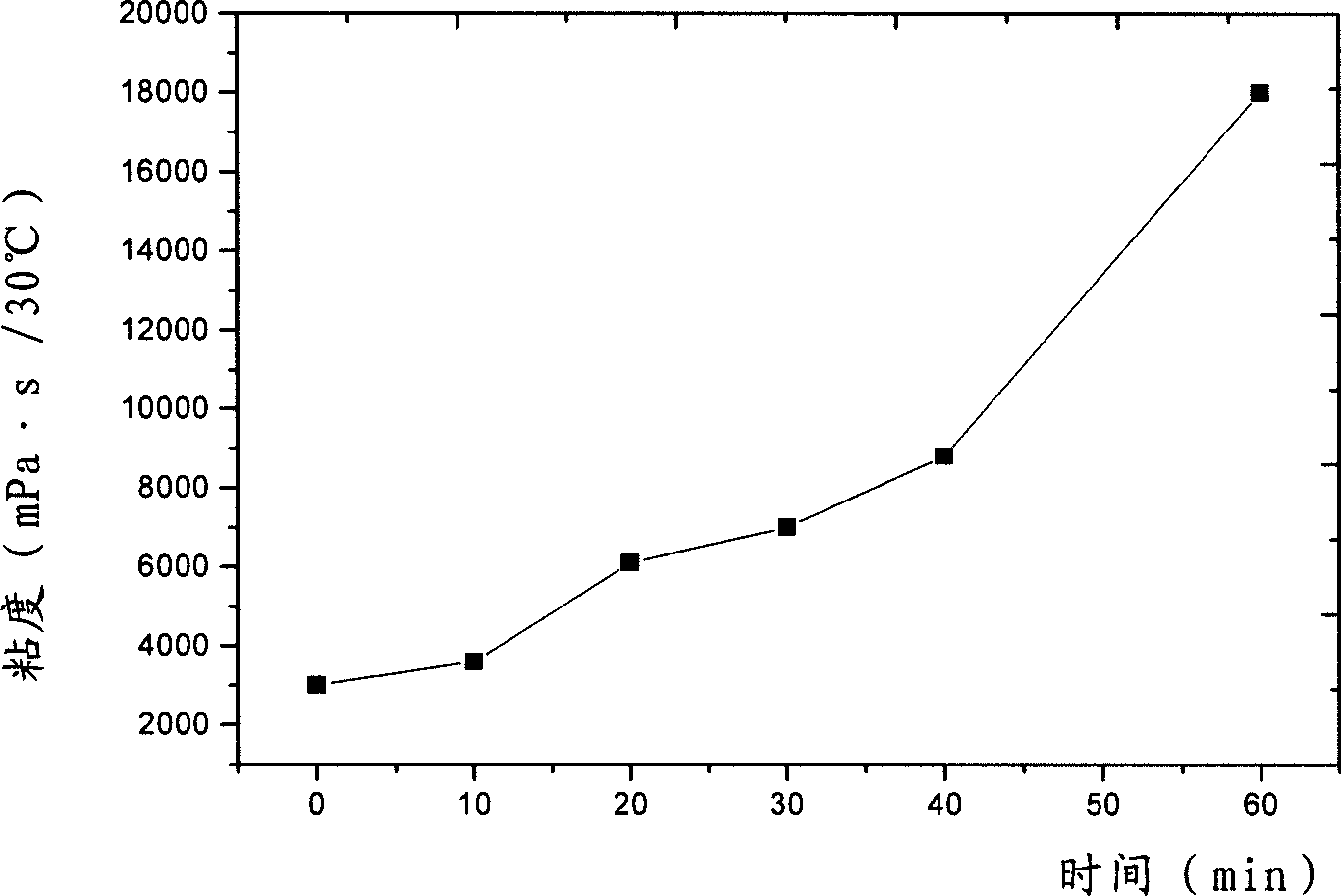

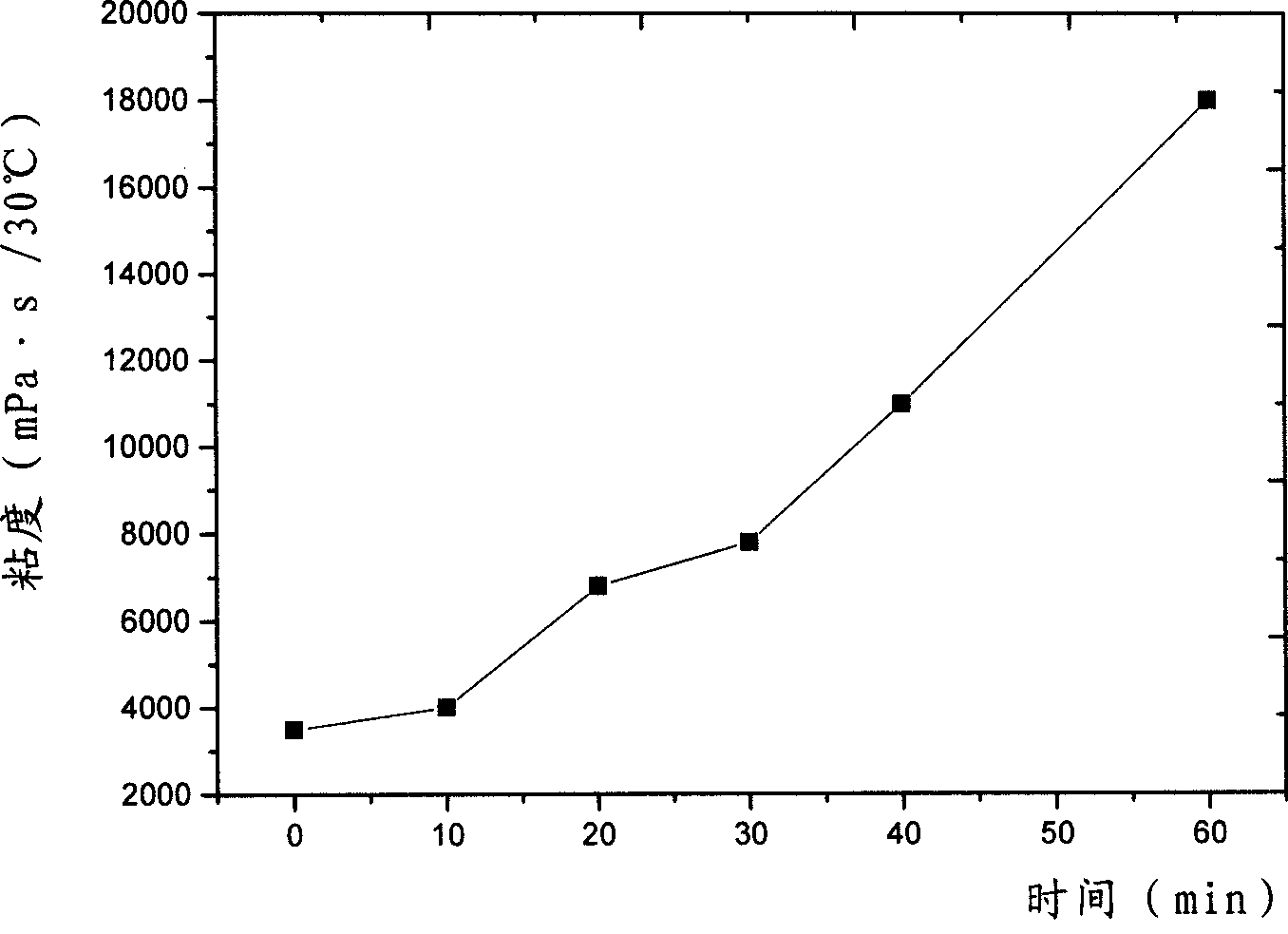

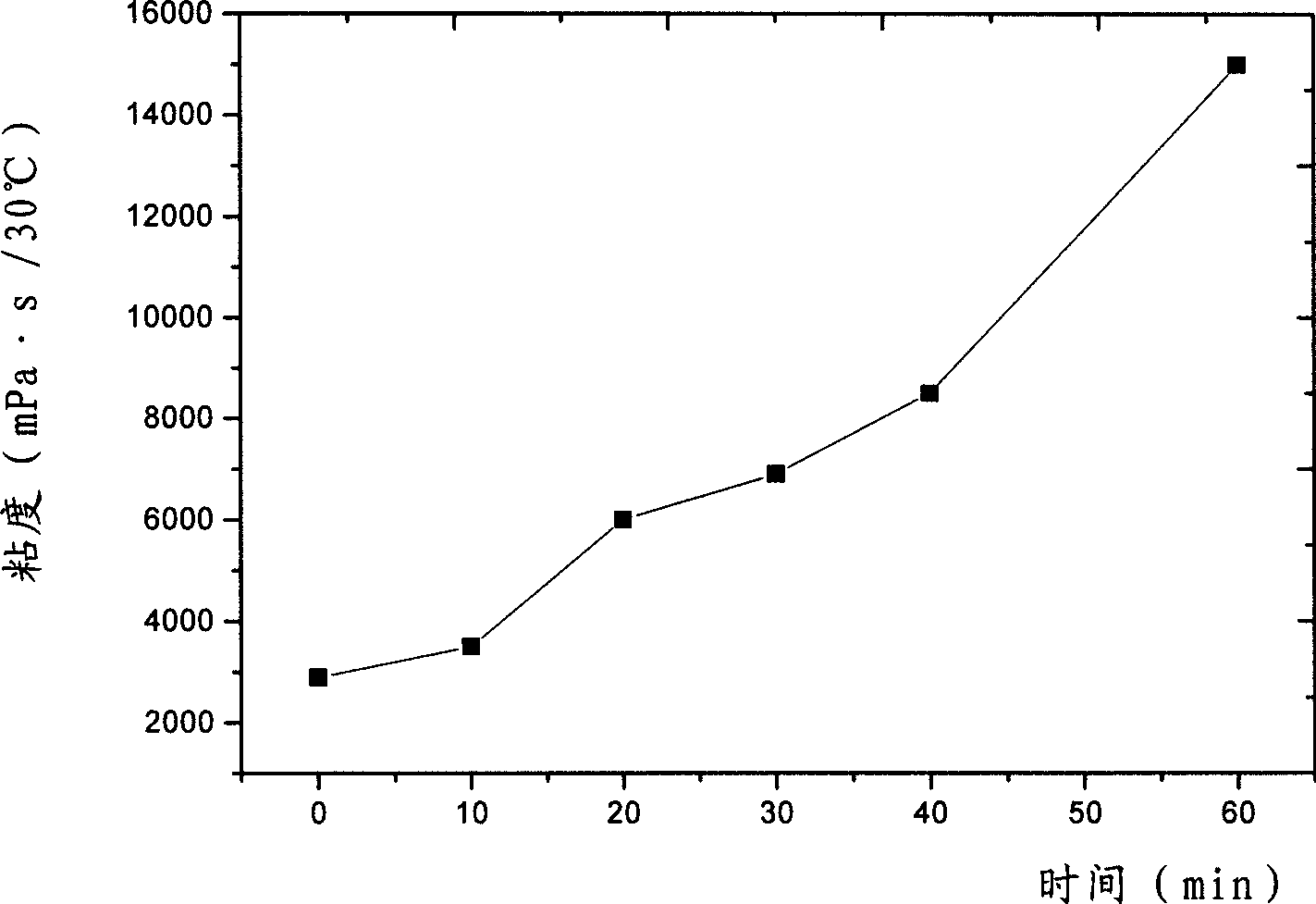

Adhesive for soft package compound and preparation method thereof

ActiveCN101544880AReduce contentReduce heat seal strengthPolyureas/polyurethane adhesivesChemical structurePolyester

The present invention discloses a macromolecule adhesive, particularly relates to an adhesive for a flexible package compound film and a preparation method thereof. The adhesive for a compound film includes a hydroxy polyester polymer component (A) and an isocyanate end capping prepolymer component (B), the preparation method is that firstly a polyester is synthesized by using a diatomic alcohol and a dibasic acid, a polyester is then synthesized by using a polyatomic alcohol and a dibasic acid, the polyester molecular mass is adjusted by selection and dosage proportion of the diatomic alcohol, the polyatomic alcohol and the dibasic acid chemical structure, so as to prepare the component (A); the diatomic alcohol reacts with a different isocyanate, and compose a isocyanate end capping prepolymer together with a biuret polymer of the isocyanate so as to prepare the component (B); the component (A) and the component (B) are mixed with each other at a certain proportionality to prepare a polyurethane adhesive for a double-component solvent-free type compound film. When using the adhesive, the coating amount of the adhesive is small, and a compound speed may arrive 300 m / min.

Owner:中山市康和化工有限公司

Laser machining apparatus with switchable laser system and laser machining method

ActiveUS20120205356A1Improve machine qualityLittle powerMetal working apparatusLaser beam welding apparatusPulse durationPicosecond

A laser machining apparatus and method for producing from a workpiece a rotating cutting tool having a cutting edge and a flank. The laser machining apparatus works in two different operating modes. In the first operating mode, a first laser head is used for machining the workpiece at high advance speeds of the workpiece relative to the first laser head to form a rough desired contour with pulses having a duration in the nanosecond range resulting in laser melt cutting. Subsequently, the laser machining apparatus is operated in the second operating mode generating laser pulses with having a pulse duration in the picosecond range. In the second operating mode, a second laser head is activated by means of an optical scanner system and directs the laser pulses onto a two-dimensional pulse area on the surface of the workpiece, the material removal is accomplished by laser ablation.

Owner:FRITZ STUDER AG

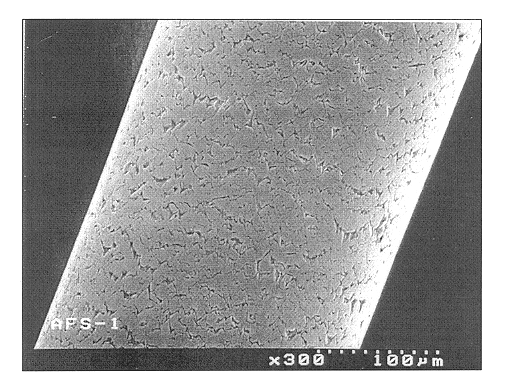

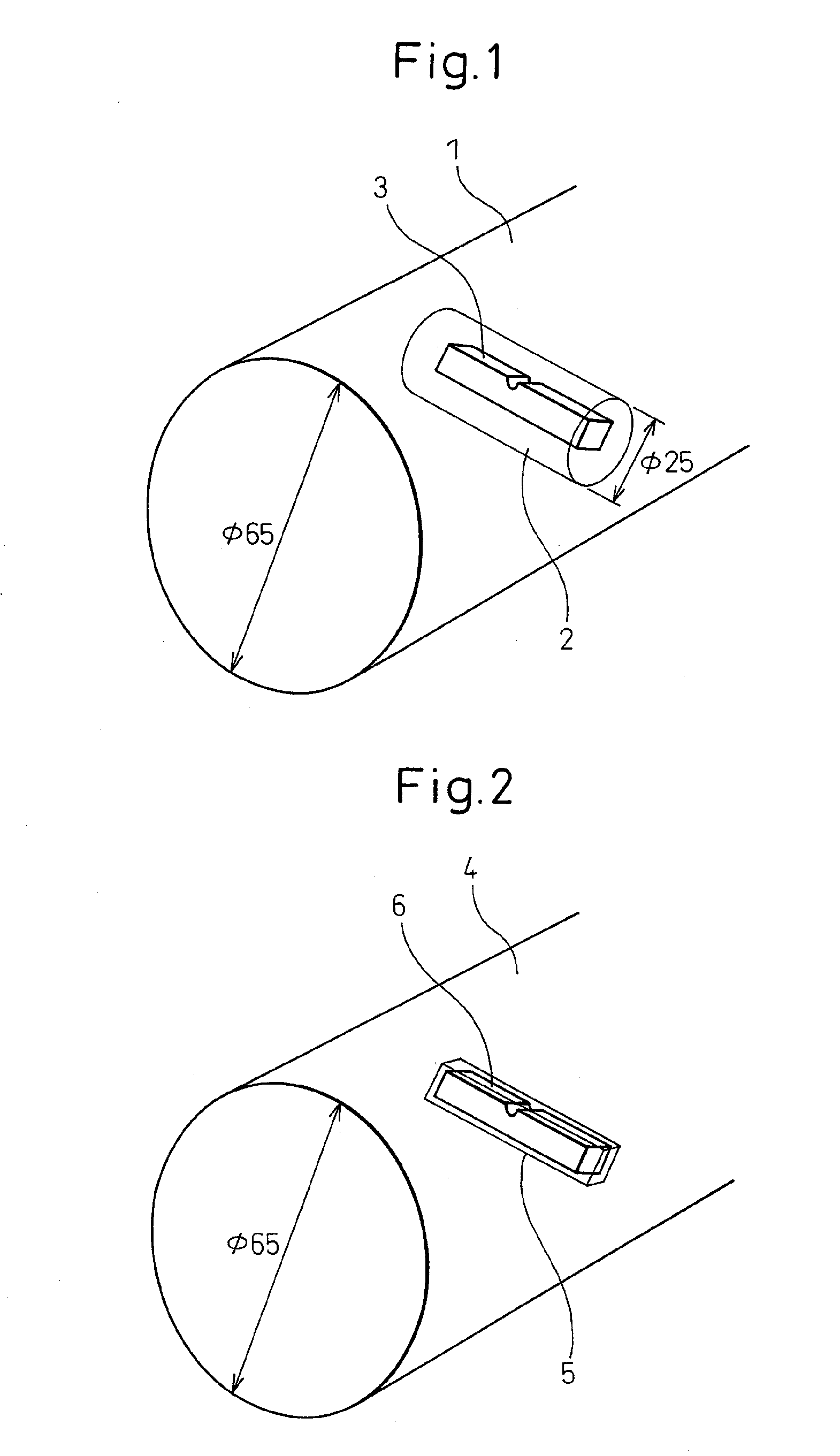

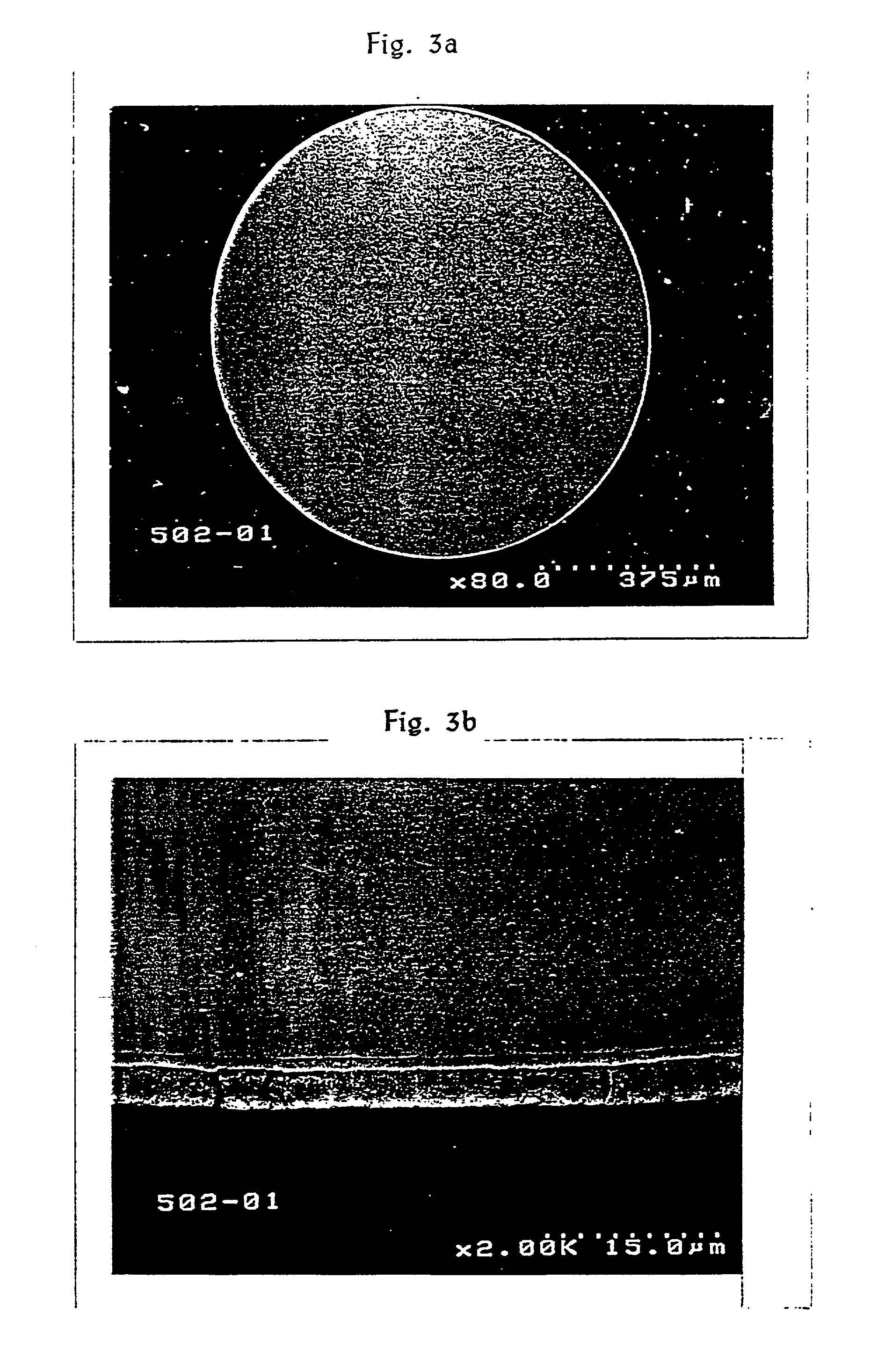

Method of manufacturing porous electrode wire for electric discharge machining and structure of the electrode wire

InactiveUS6306523B1Improve cooling effectNegative effectHot-dipping/immersion processesPretreated surfacesZincPorous electrode

The present invention relates to a porous electrode wire for use in electrical discharge machining and the method of manufacturing the same. The wire improves the machining speed at least 15% compared with a conventional zinc coated wire, which results from an increased cooling ability of the wire with a cooling liquid because of the increase in the surface area of the wire having porous surface morphology. Since the surface of the porous wire presents uniform profile of outer periphery rather than surface protrusions, it does not affect machining accuracy. Further, the porous nature of the wire is expected to improve flushability during the electrical discharge machining, providing spaces to eliminate particles of the machining. Therefore, in accordance with the method of the present invention, a zinc coated wire having improved performance of machining speed and flushability compared with a conventional coated wire can be provided without additional processes.

Owner:SEONG KI CHUL

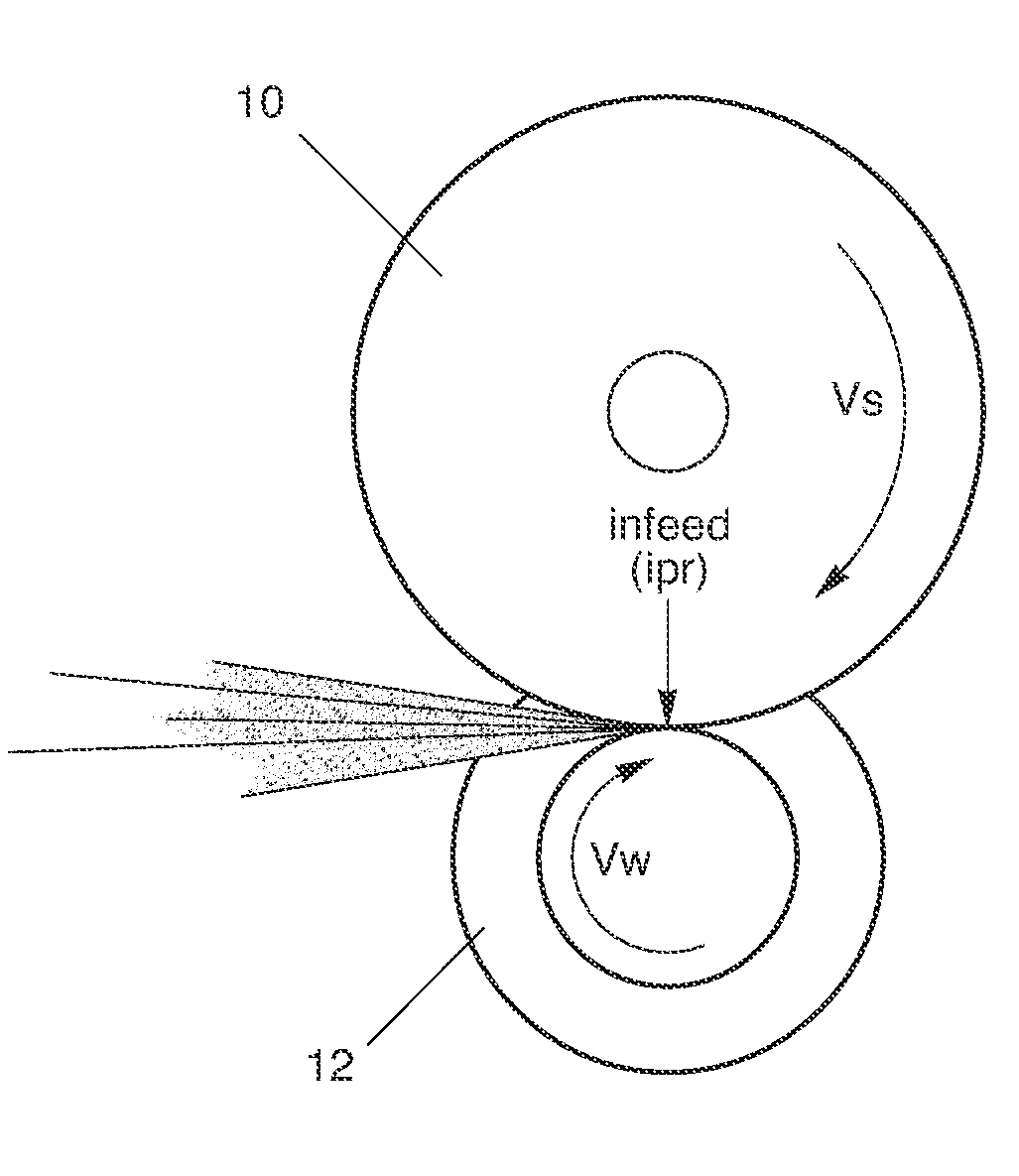

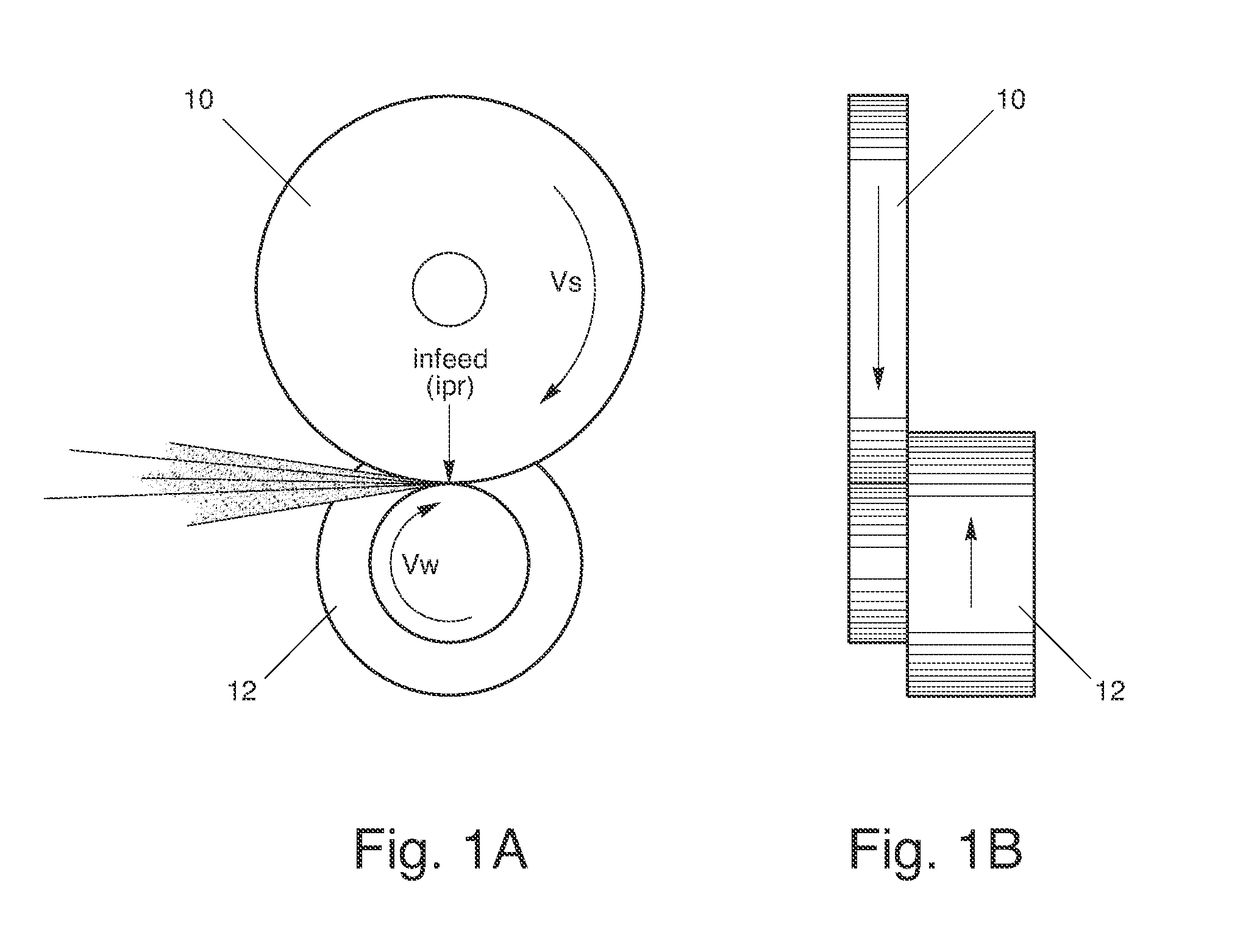

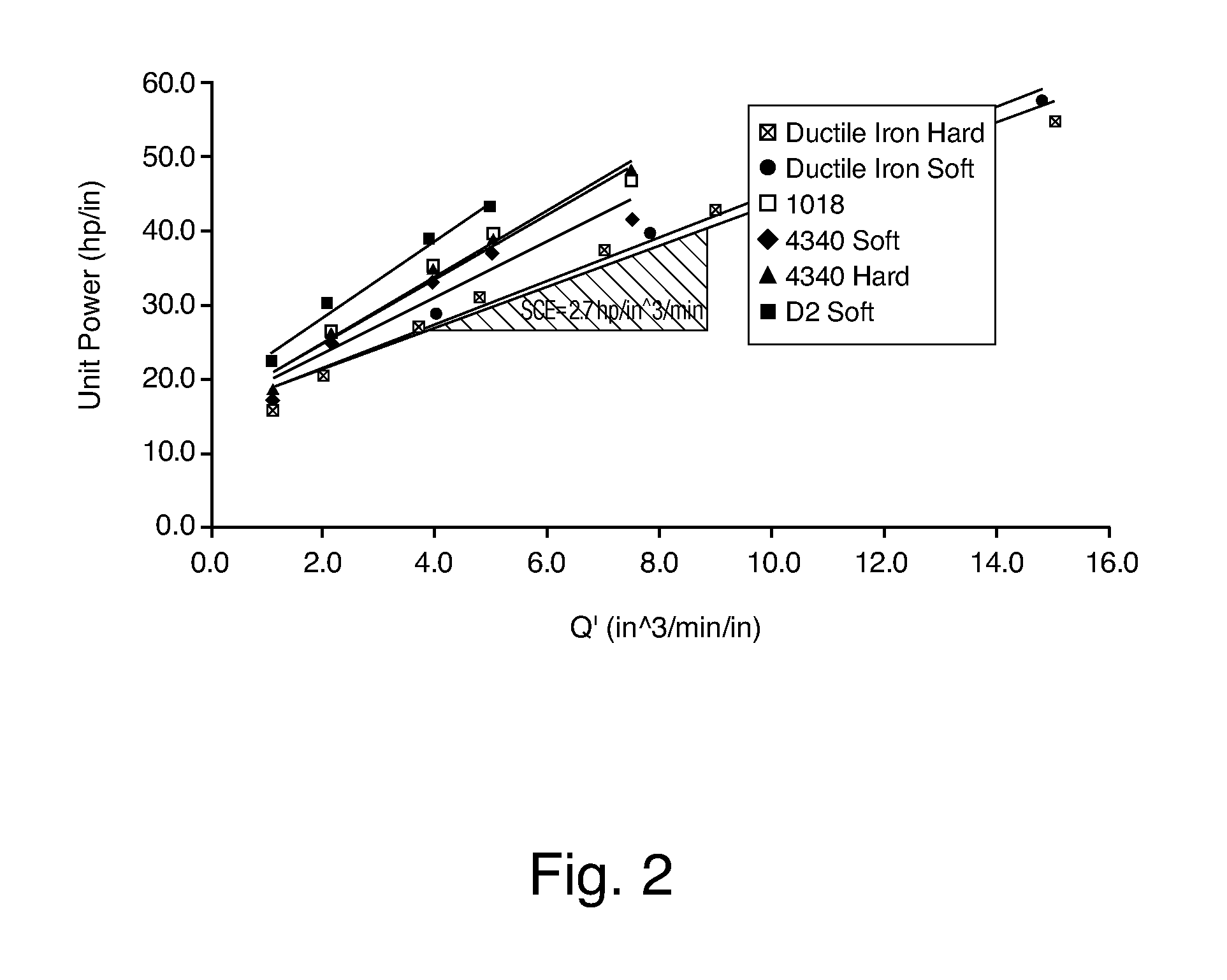

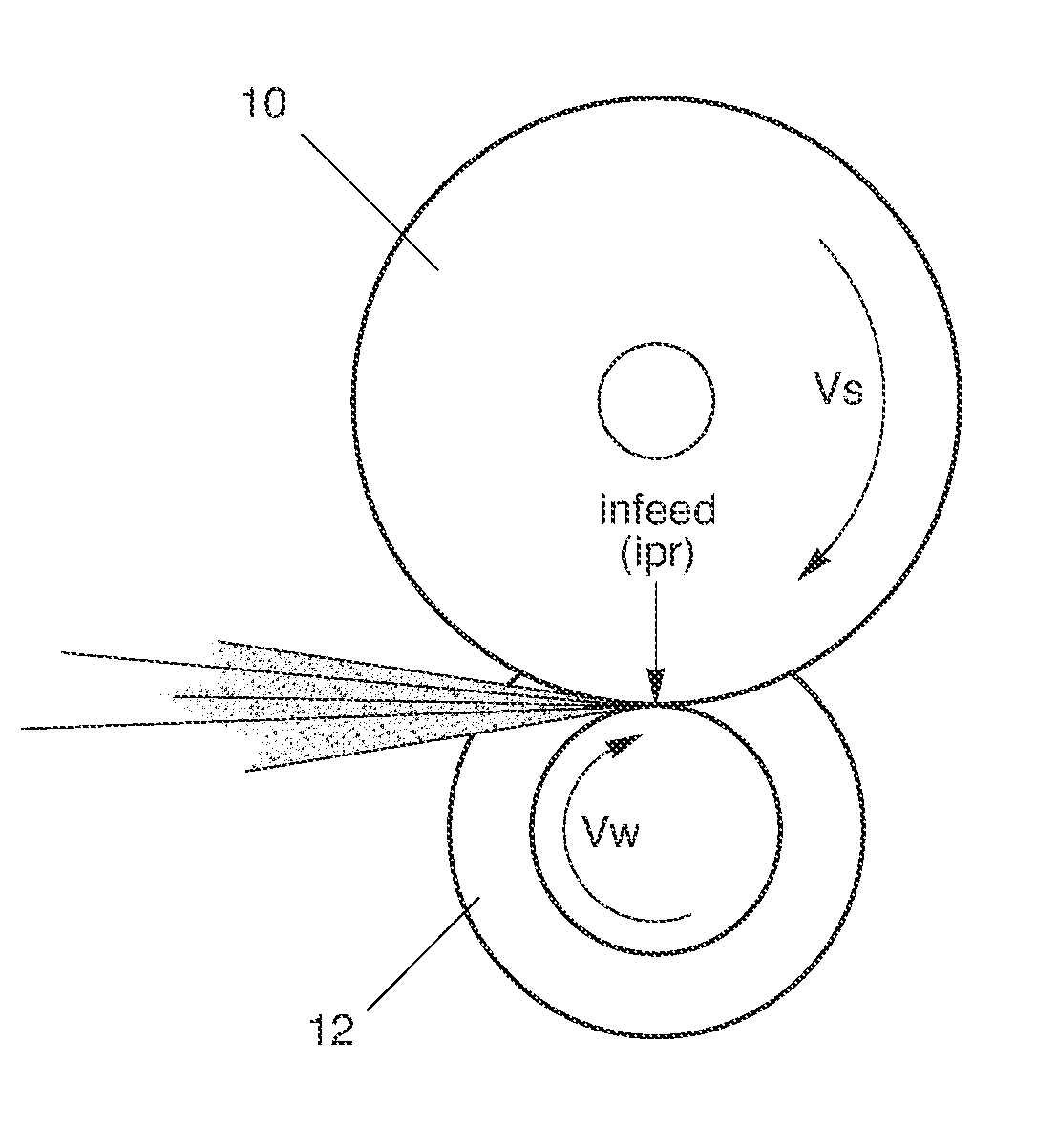

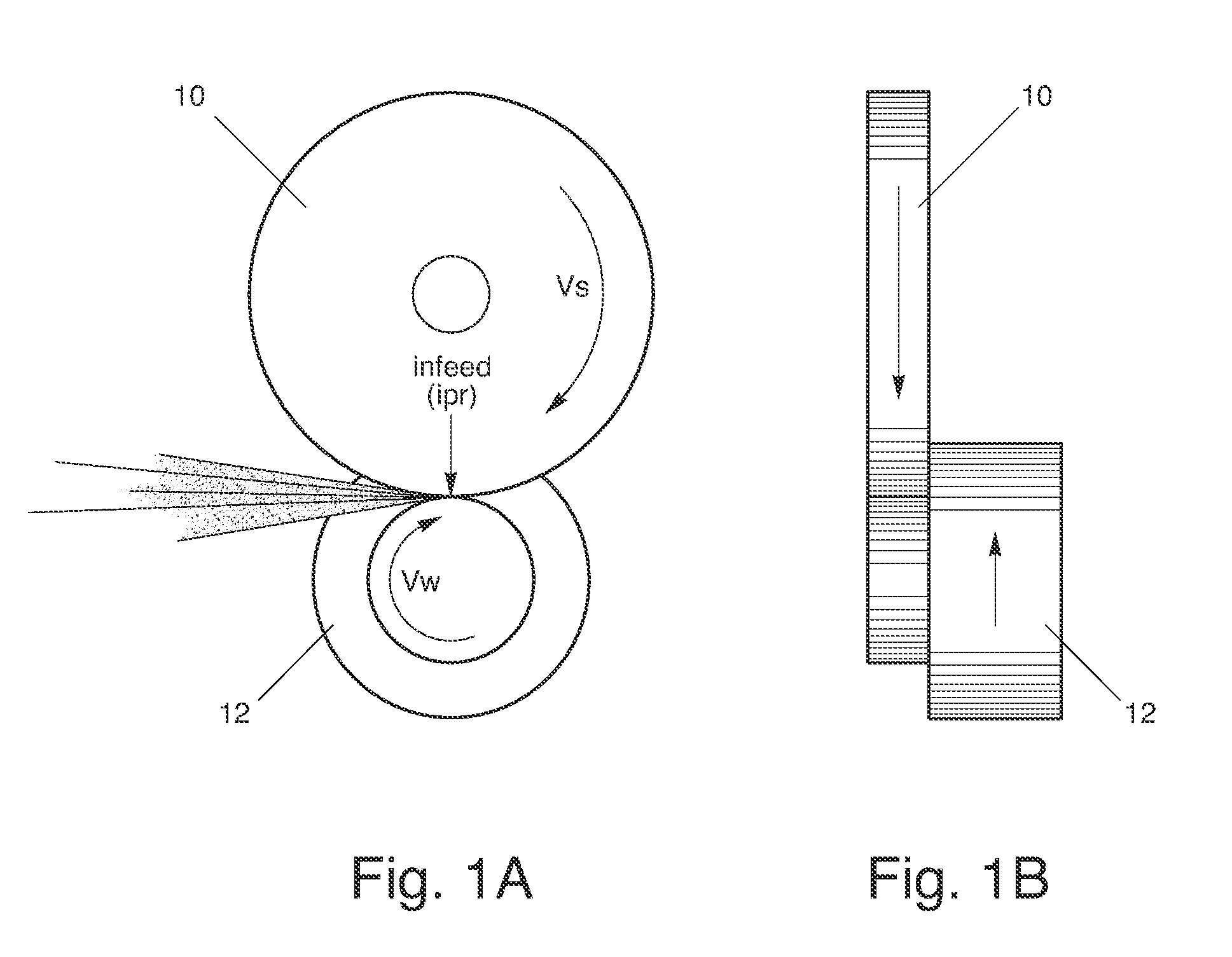

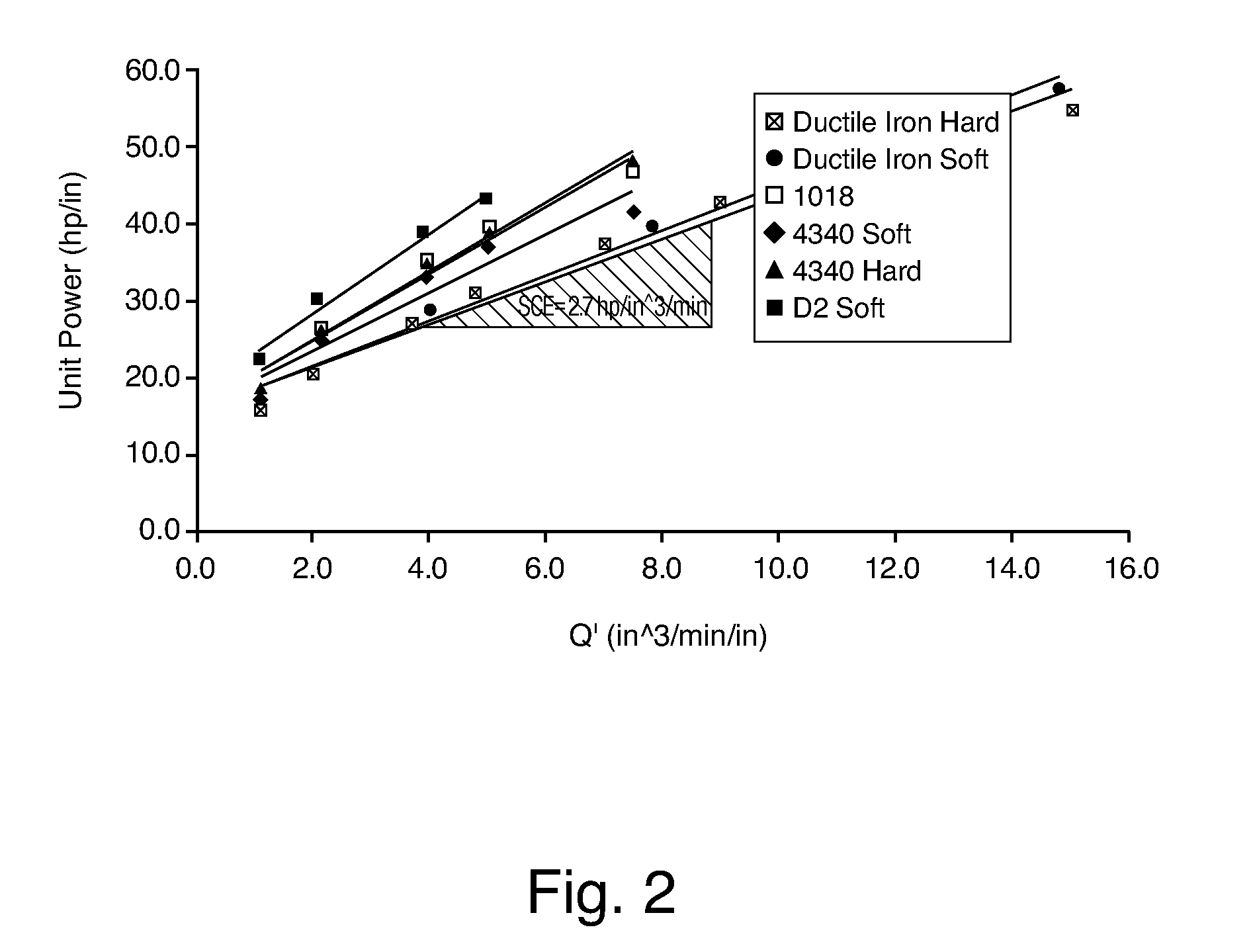

Techniques for cylindrical grinding

ActiveUS20090093198A1High surface finishShort processing timeRevolution surface grinding machinesAbrasion apparatusMaterial removalMetallurgy

Methods for cylindrical grinding a workpiece are disclosed. The method includes cylindrical grinding, with a bonded abrasive wheel having a permeable structure that includes interconnected porosity, a workpiece at a specific cutting energy of less than about 12 Hp / in3·min (29.7 J / mm3), and a material removal rate of at least about 1 in3 / min·in (10.8 mm3 / sec / mm)grinding. The bonded abrasive wheel may include at least about 3 volume percent of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1, or agglomerates thereof. In one embodiment, the workpiece is ground in the presence of a water soluble oil.

Owner:SAINT GOBAIN ABRASIVES INC +1

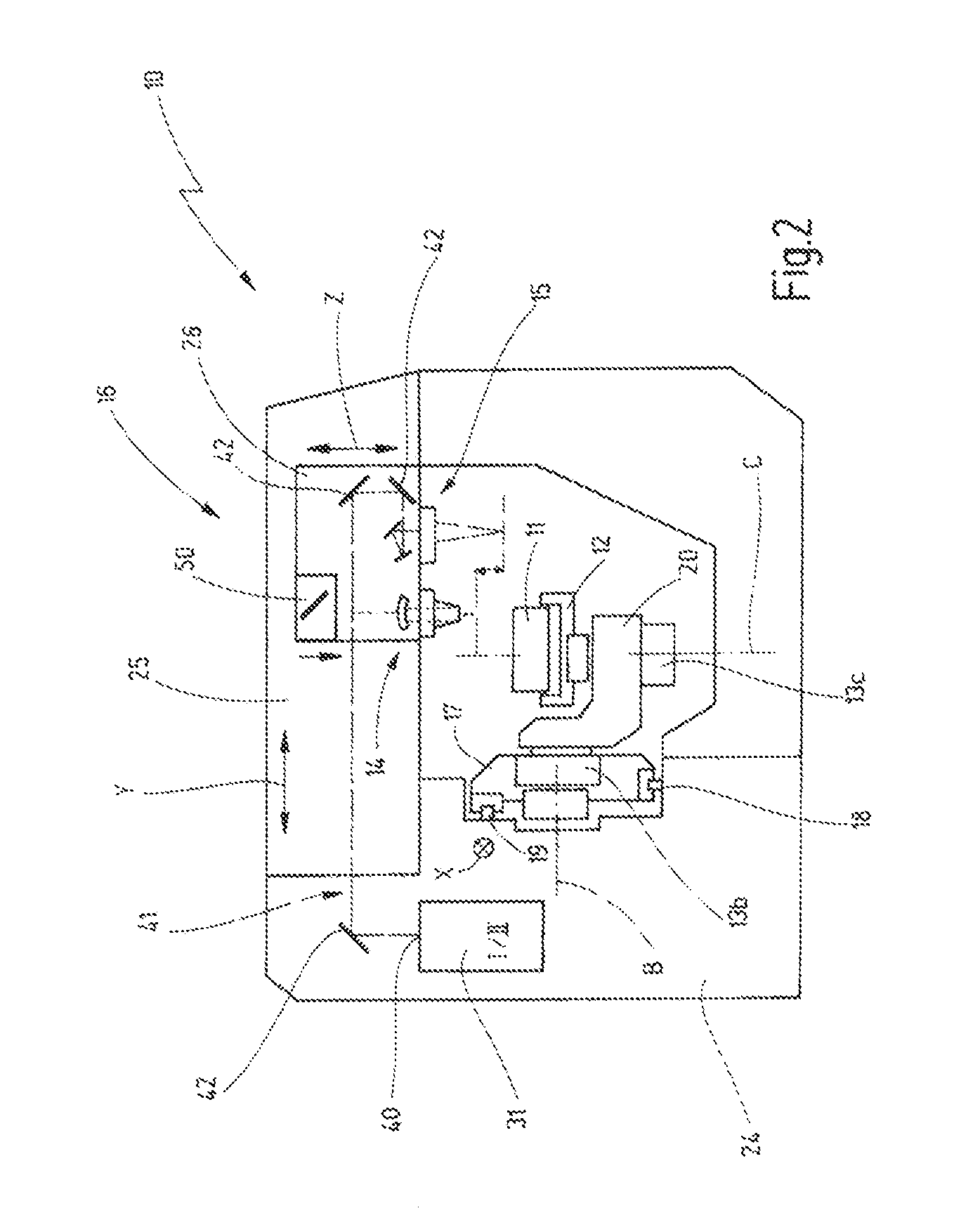

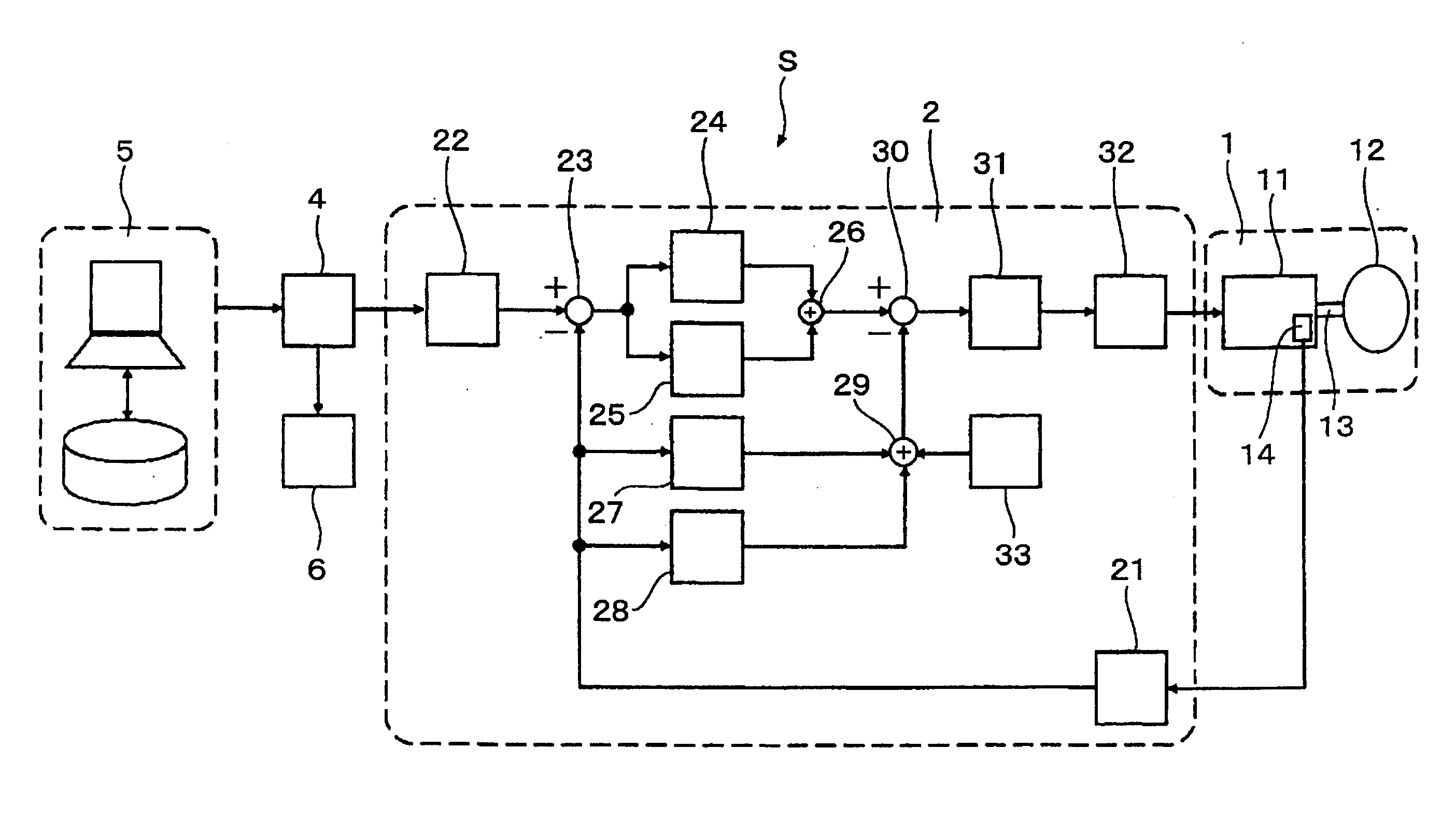

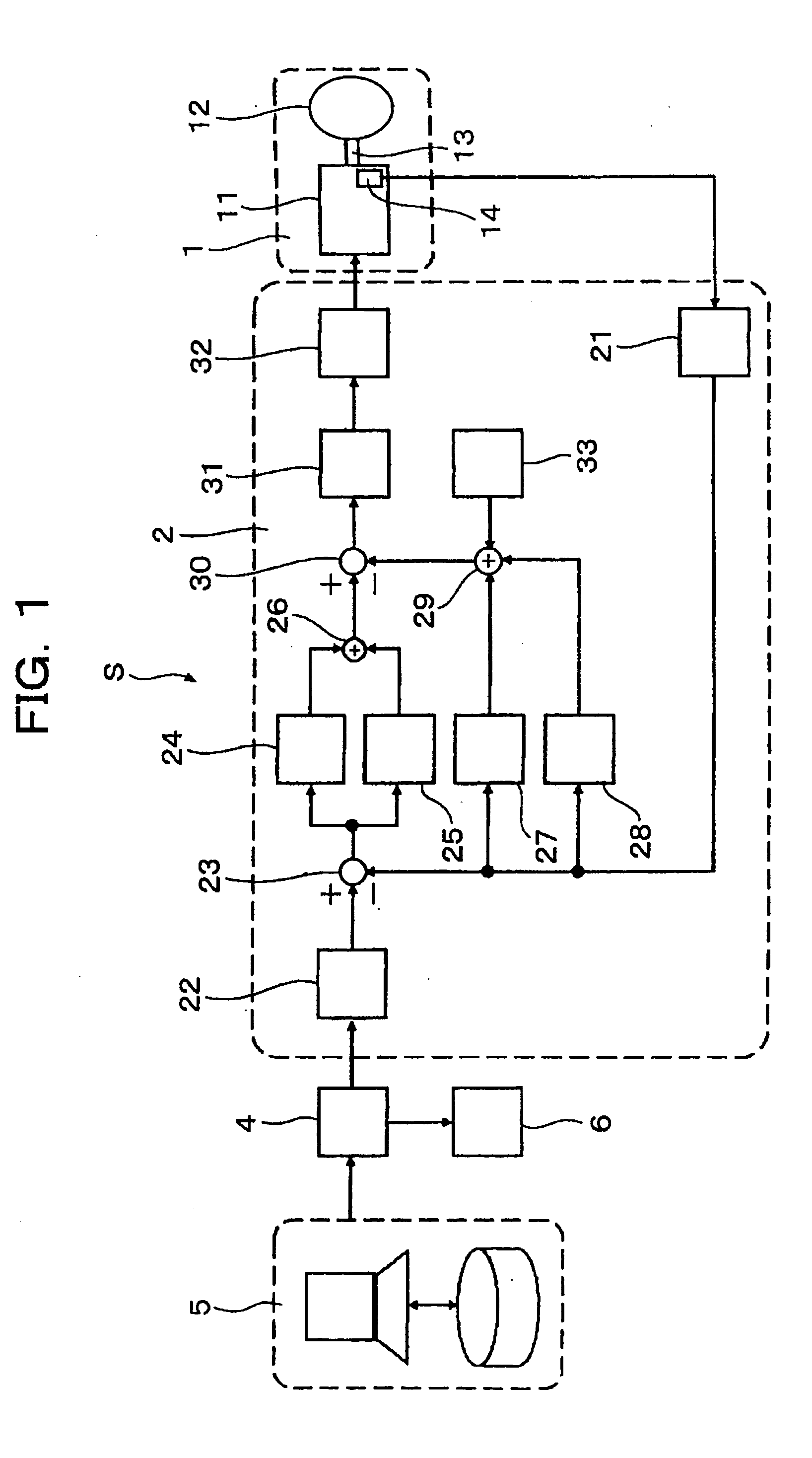

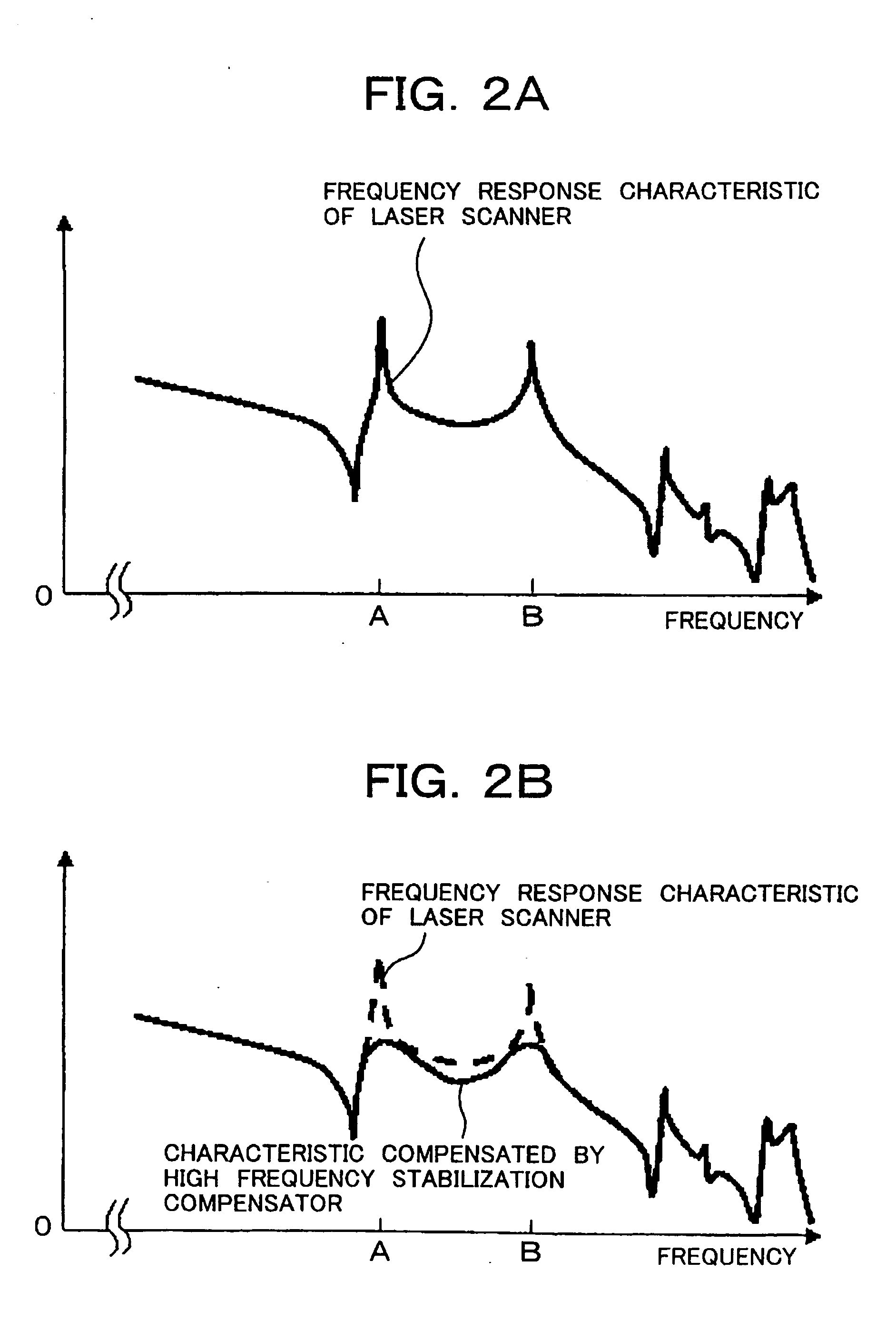

Scanner system

ActiveUS20050128553A1Rapid positioningIncrease machine speedComputer controlSimulator controlEngineeringControl theory

A scanner system includes a servo control unit. A rotation angle of a rotating shaft supporting a mirror is detected, and an error of the detected value with respect to a commanded value is integrated by an integral compensator so that the detected value is able to track the commanded value. A tracking error proportional compensator is disposed in parallel with the integral compensator so as to add a correction value proportional to the error to the integrated value of the error. A plurality of gains are prepared for each of the integral compensator, the tracking error proportional compensator, a detected value proportional compensator and a detected value differential compensator of the servo control unit. Each gain is changed in accordance with a travel angle of the commanded value. Thus, the mirror can be positioned quickly so that the machining speed can be improved.

Owner:HITACHI SEIKO LTD

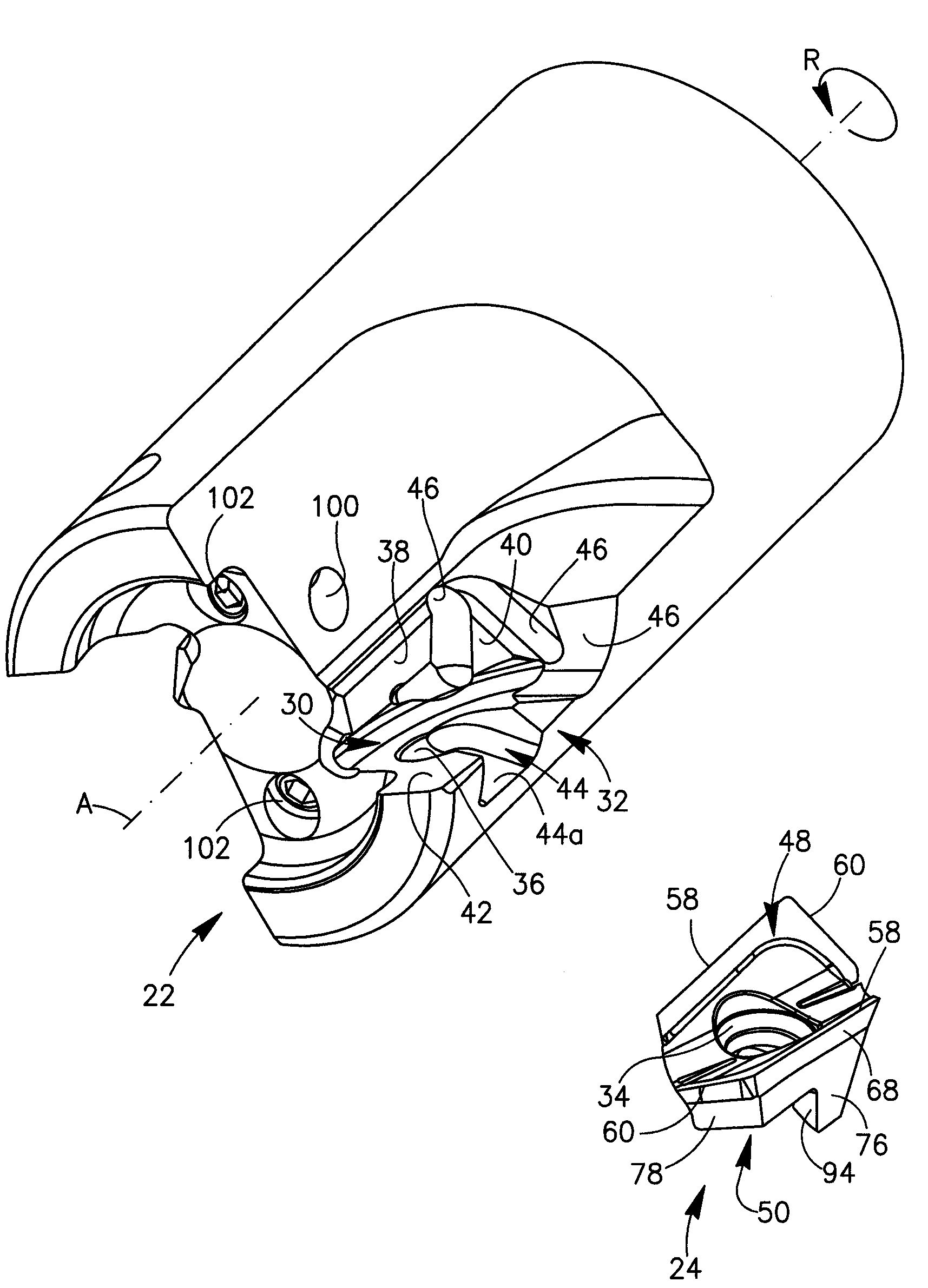

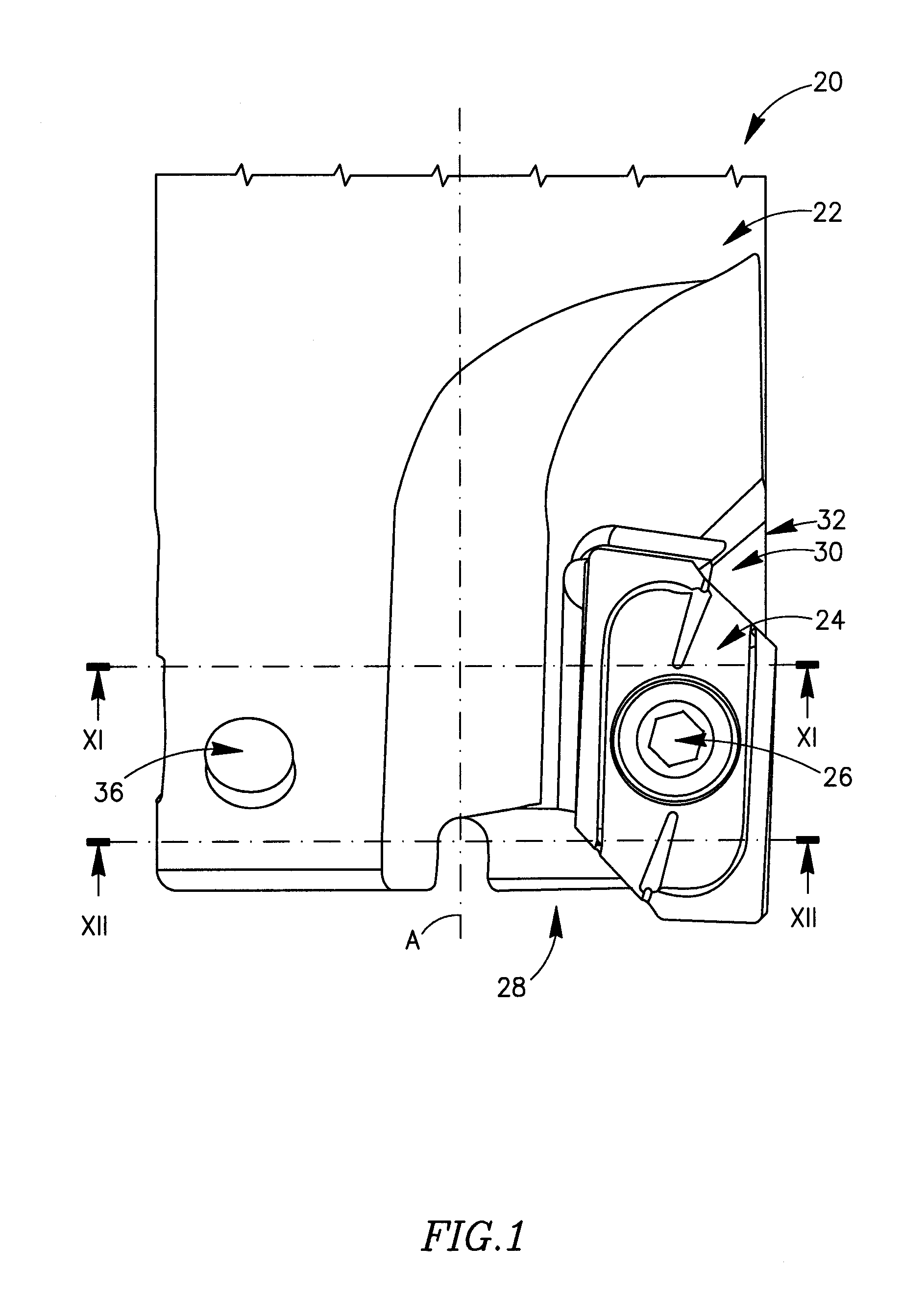

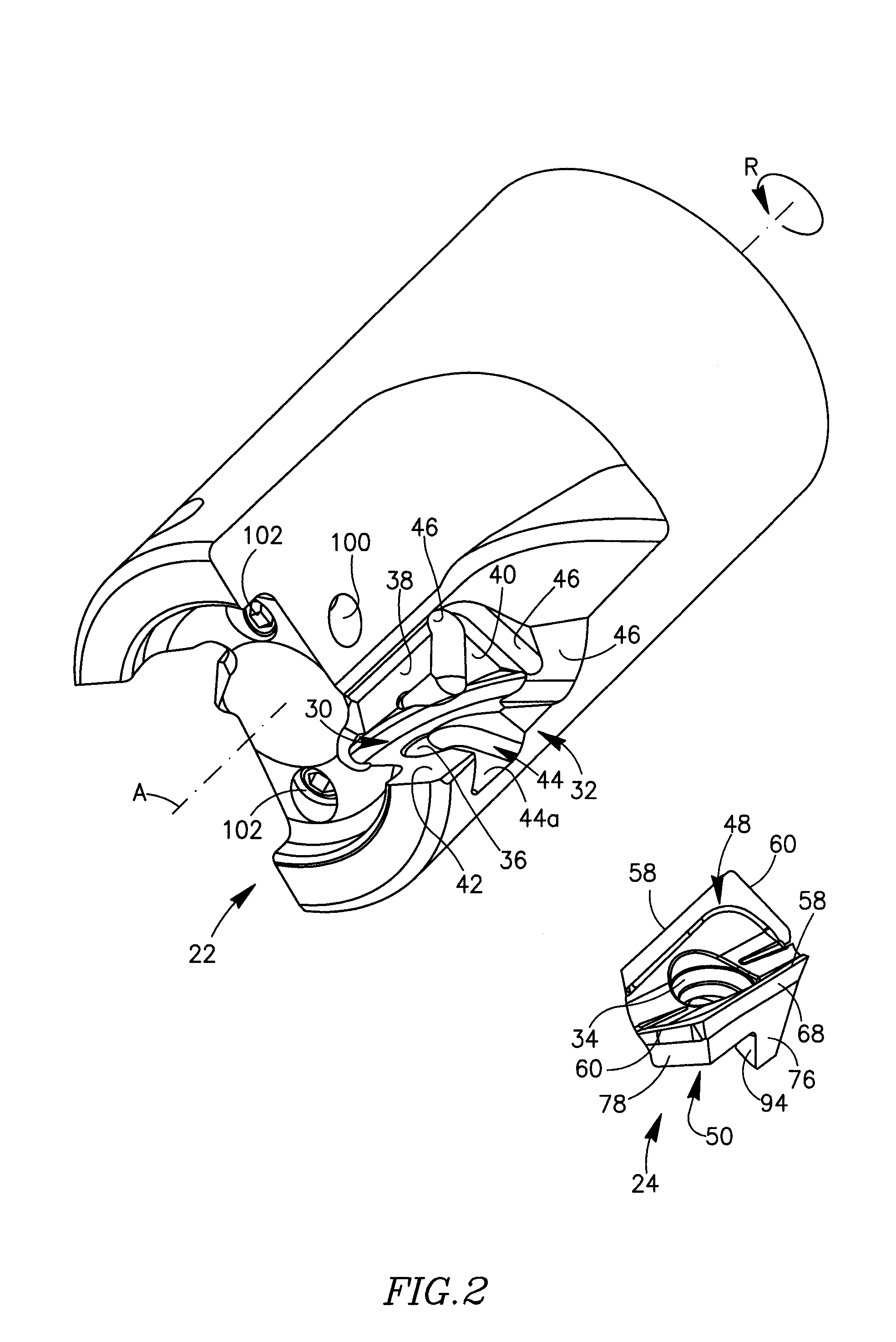

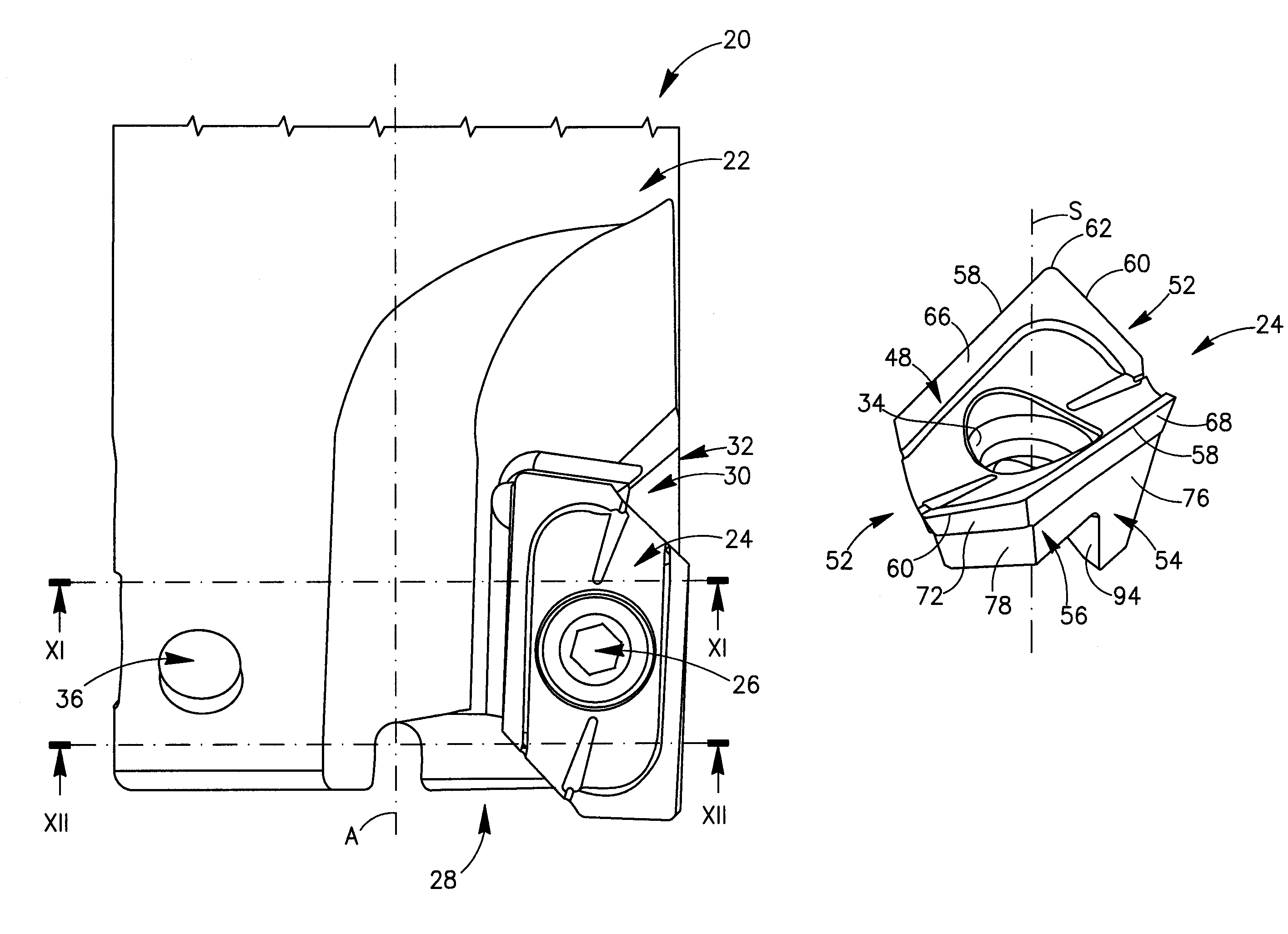

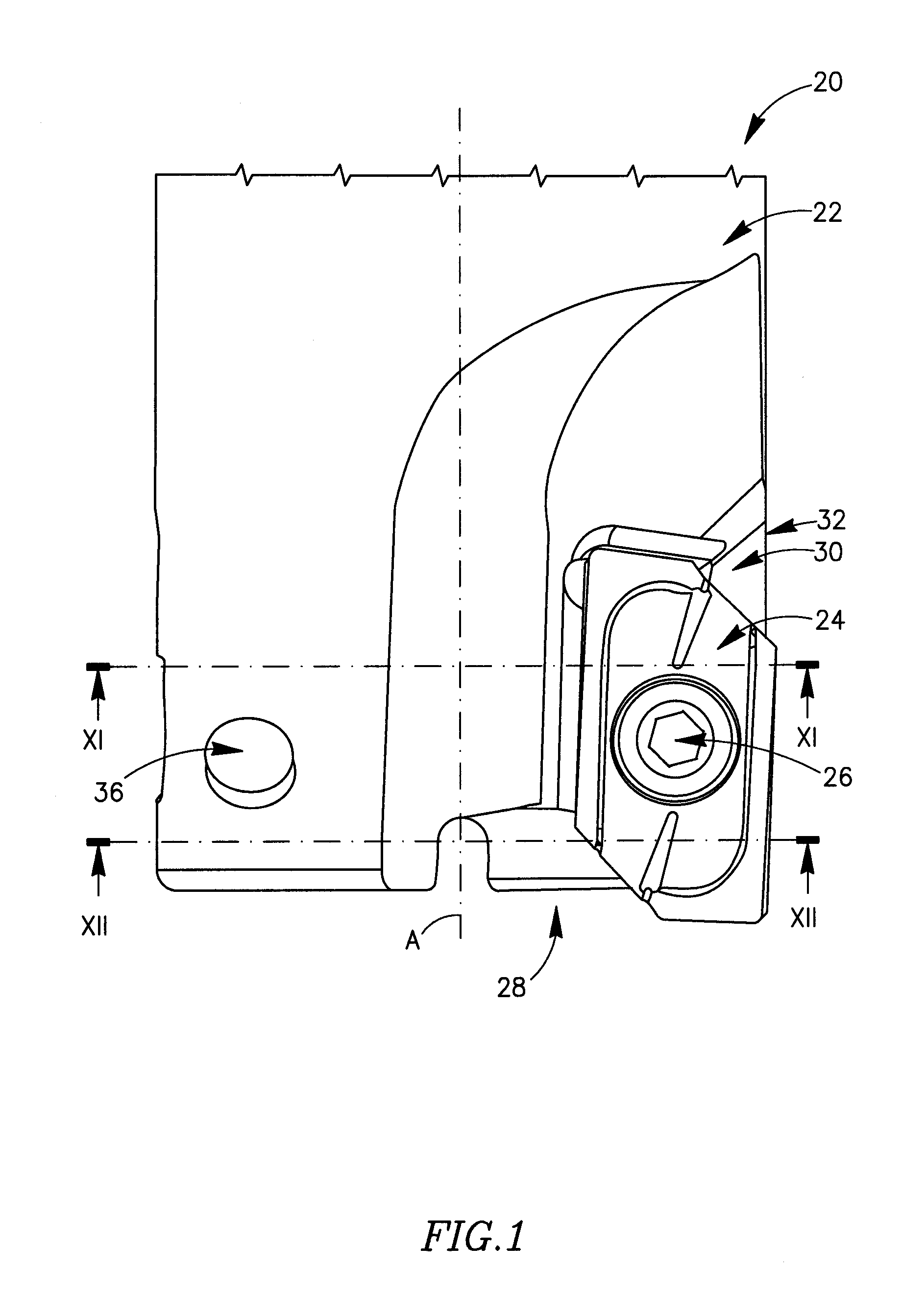

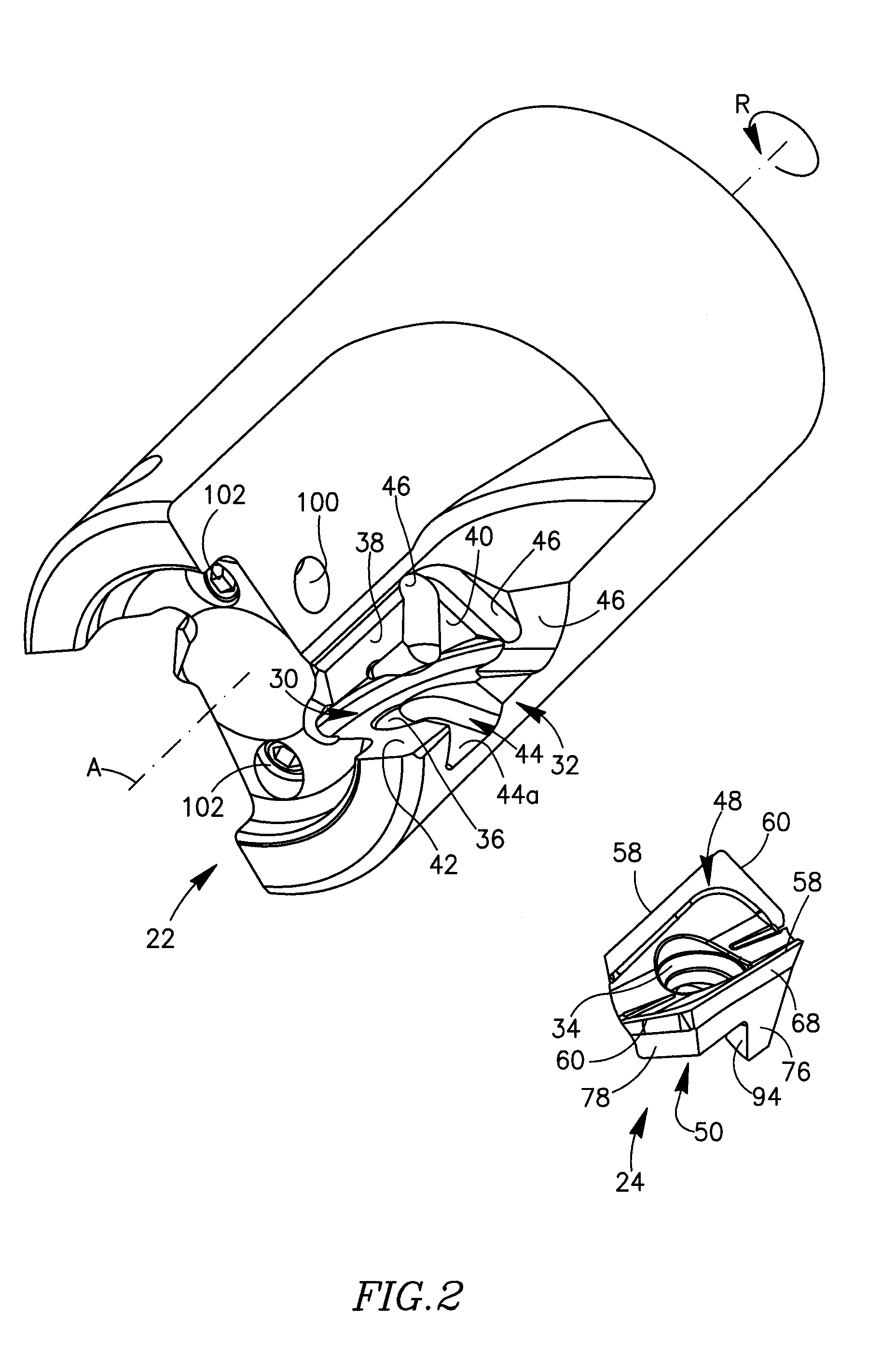

Cutting Insert and Cutting Tool Therefor

InactiveUS20090169313A1Reduce shear forceGuaranteed uptimeMilling cuttersShaping cuttersEngineeringAbutment

A cutting tool has at least one cutting insert seated therein. The cutting insert has a longitudinal axis, an upper surface, a lower surface and a peripheral surface that extends between the upper surface and the lower surface. At least a portion of an intersection between the upper surface and the peripheral surface constitutes a cutting edge. The lower surface has at least one set of base abutment surfaces, each set including at a least one major base abutment surface and at least one minor base abutment surface, the major and minor base abutment surfaces of a given set being spaced apart from one another along the longitudinal axis. When the lower surface has two such sets of base abutment surfaces, the major and minor base abutment surfaces of the first set are longitudinally displaced from the corresponding major and minor base abutment surfaces of the second set. Furthermore, the major and minor base abutment surfaces of the first set lie on a first base abutment plane while the major and minor base abutment surfaces of the second set lie on a second base abutment plane, the first and second base abutment planes forming a first non-zero angle therebetween.

Owner:ISCAR LTD

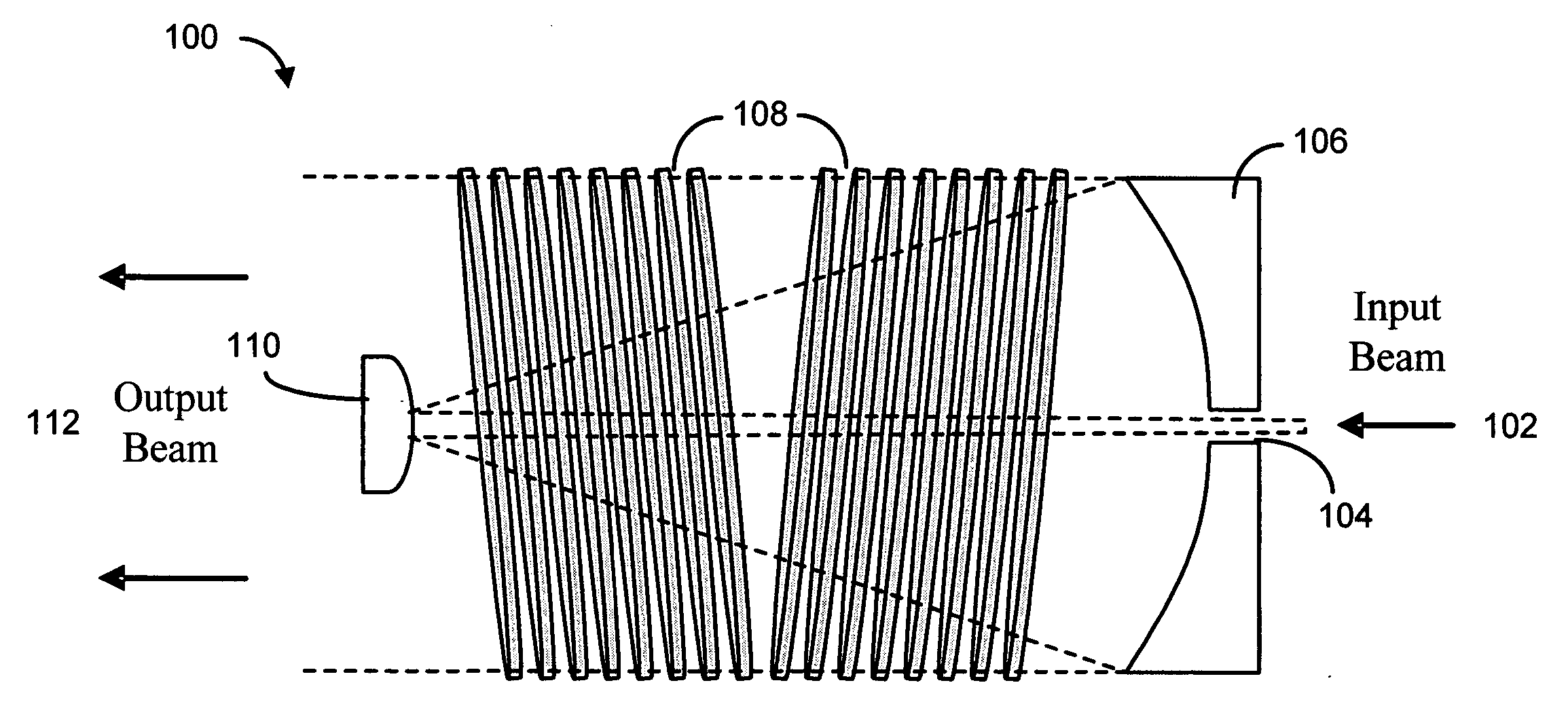

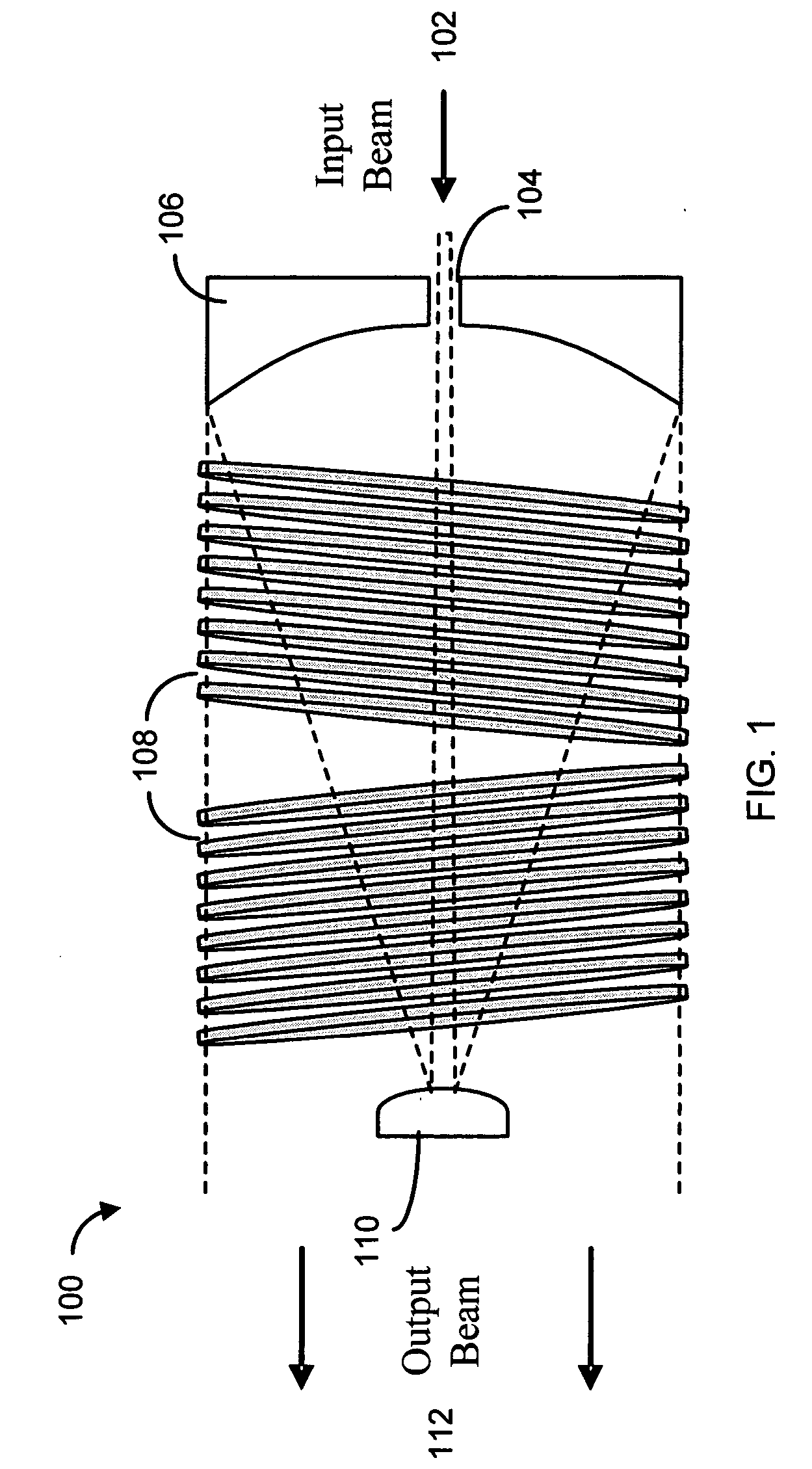

Amplifying of high energy laser pulses

InactiveUS20050213630A1Remove heatImprove efficiencyLaser detailsDiagnosticsAudio power amplifierLight beam

The present invention provides a method of amplifying a beam of laser pulses by producing an amplified collimated beam of pulses using an amplifier, spatially spreading the amplified collimated beam of pulses into an expanded beam of pulses, introducing the expanded beam of pulses into the amplifier a second time to produce a twice amplified beam of pulses, recollimating the twice amplified beam of pulses to produce a twice amplified collimated beam of pulses such that the twice amplified collimated beam of pulses is of essentially the same cross-section as the amplifier, and introducing the twice amplified collimated beam of pulses into the amplifier a third time to produce a thrice amplified collimated beam of pulses such that the re-collimated beam sweeps essentially the entire volume of the amplifier.

Owner:RAYDIANCE

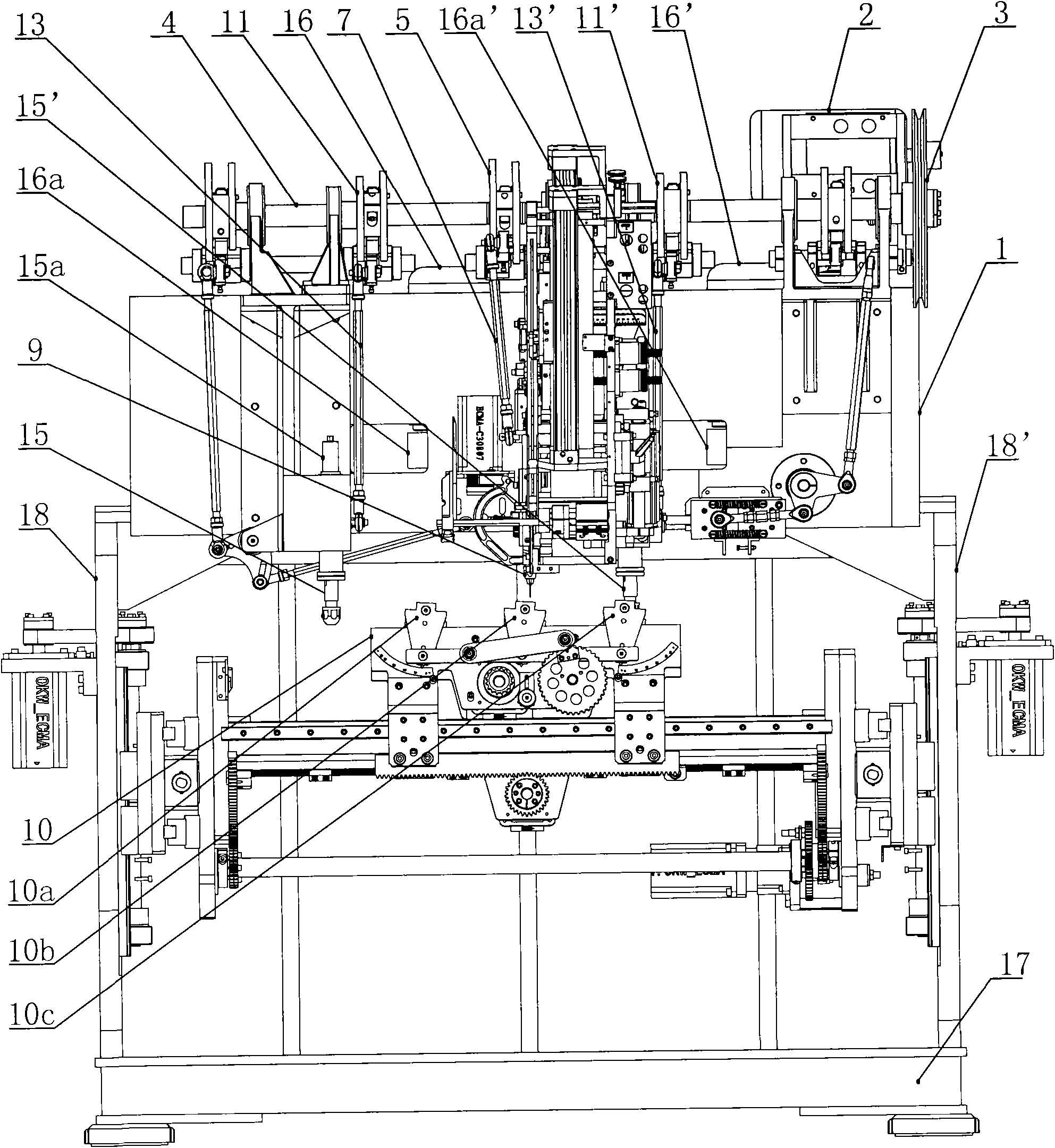

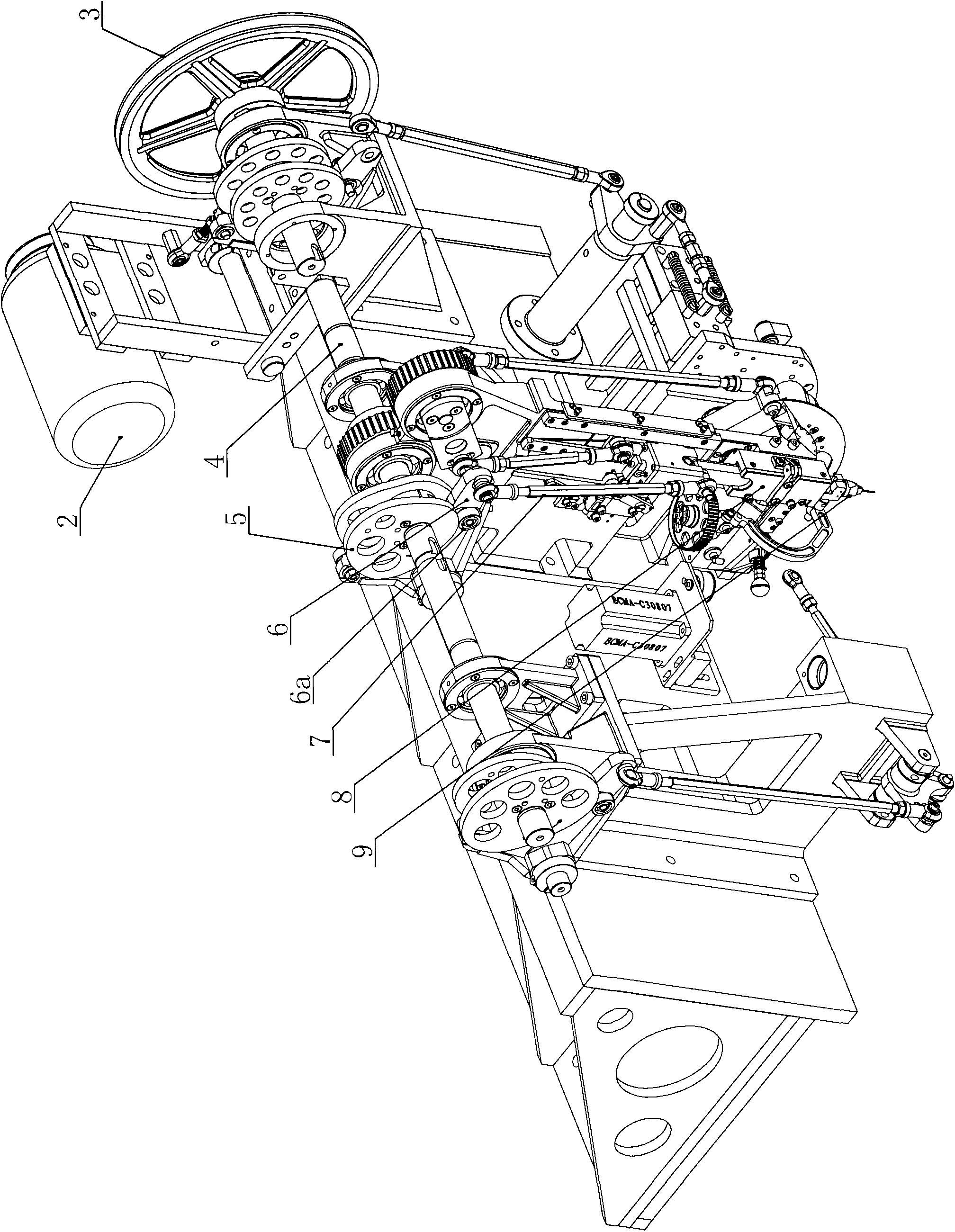

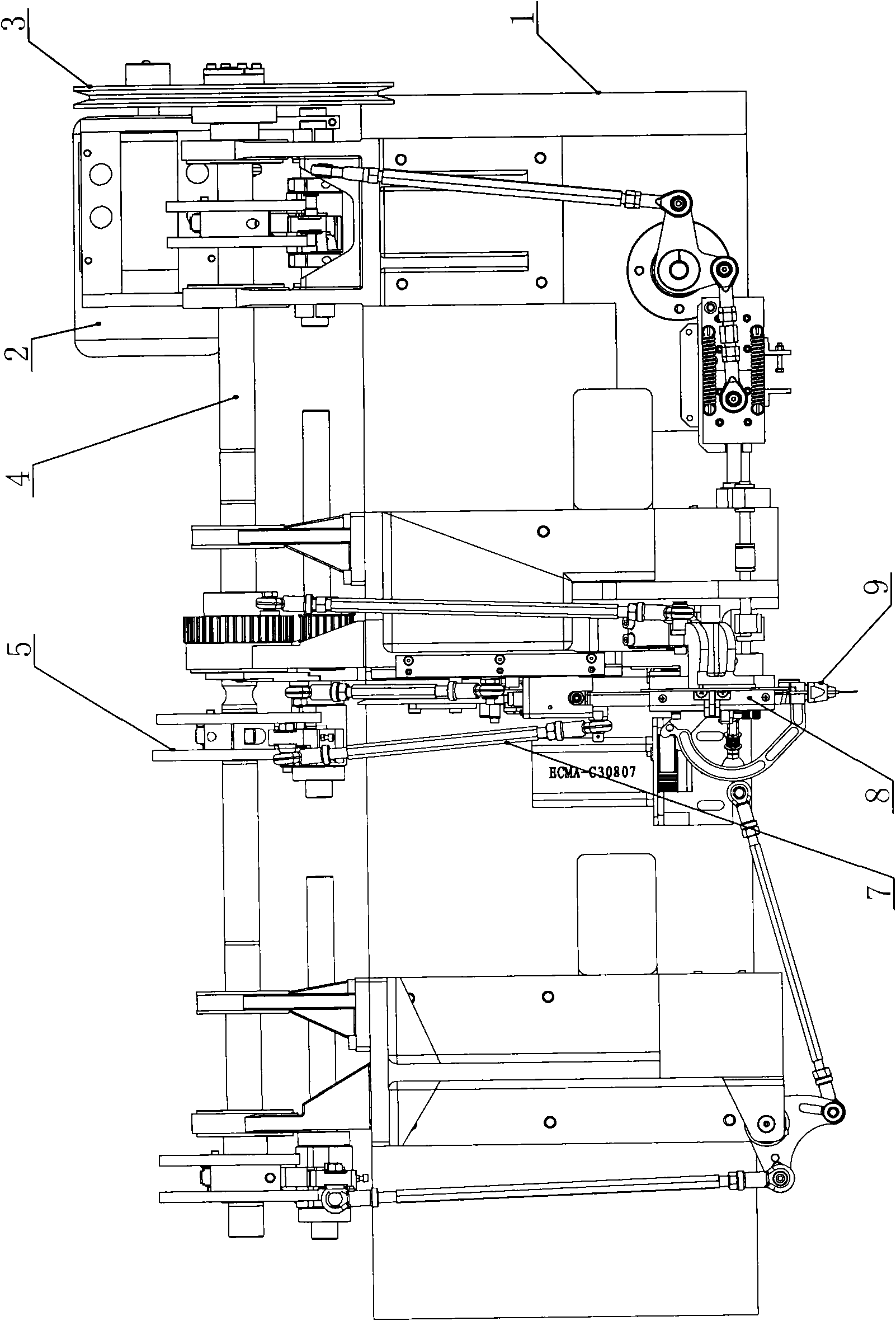

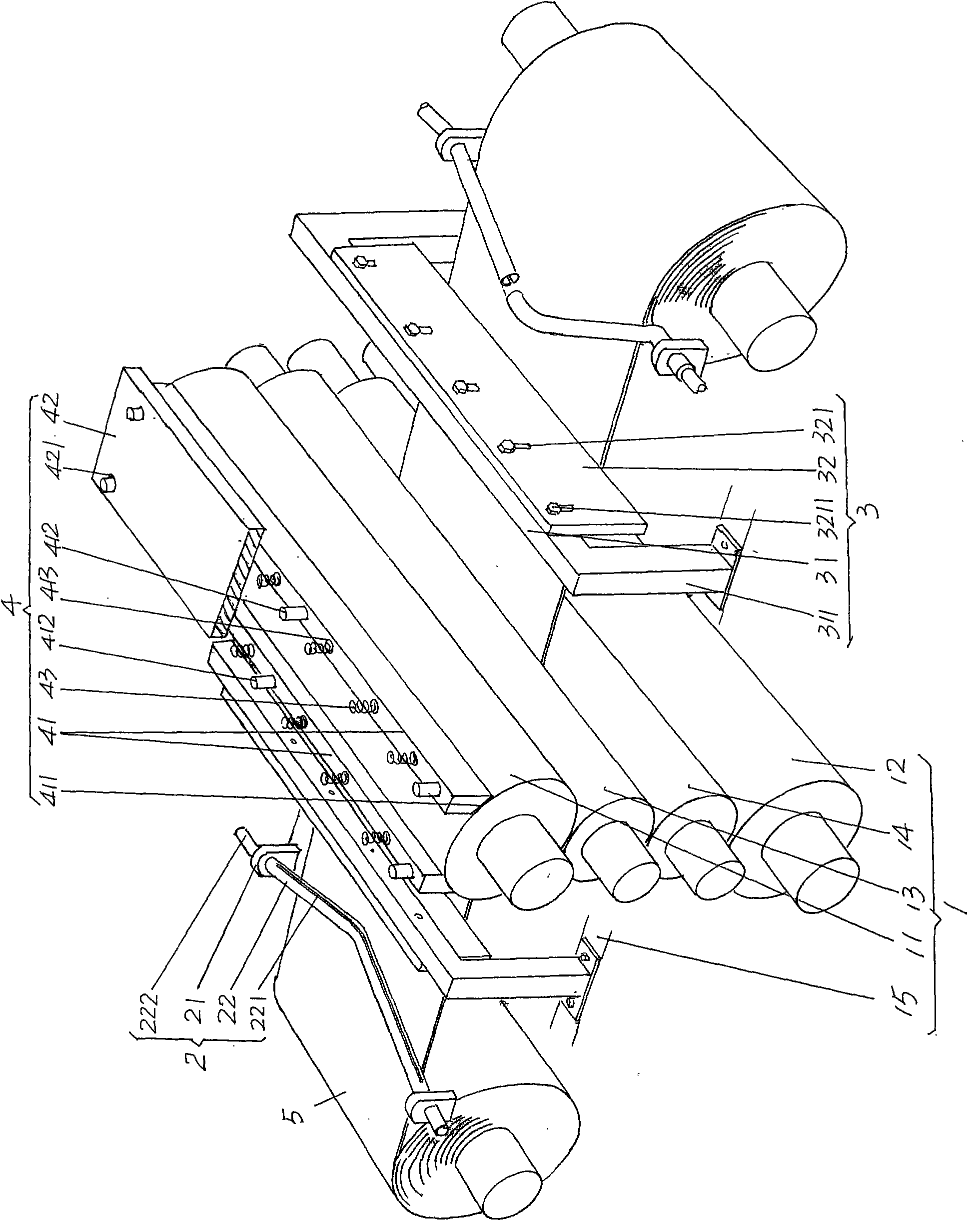

Hair-planting machine

The invention discloses a hair-planting machine in the field of hairbrush machinery. A stander is provided with a main motor, a main shaft, a brush body workbench, a hair mouth movement mechanism and drilling mechanisms, wherein the main motor drives the main shaft to rotate; a hair mouth conjugate cam and drilling conjugate cams are all arranged on the main shaft; the upper ends of drilling conjugate rockers are meshed with the corresponding drilling conjugate cams, while lower ends are hinged with the upper ends of corresponding drilling connecting rods; the lower ends of the drilling connecting rods are hinged with the middle parts of corresponding drill stems; the drill stems are positioned in drill stem holes of corresponding drill stem seats and can slide up and down along the corresponding drill stem holes; the upper ends of each drill stem are provided with a drill stem driving wheel and are driven through belts by corresponding drill stem drive motors, while the lower ends are provided with a drill bit and are parallel to a hair mouth; two sets of drilling mechanisms are positioned on the two sides of the hair mouth respectively; a space between a first drill bit and the hair mouth is twice that between a second drill bit and the hair mouth; and drilling and hair planting are sequentially finished after a bottom plate of a brush body is fixed on the workbench without replacing a fixture and recalibrating positions. Therefore, time and labor are greatly saved and the production efficiency is improved.

Owner:YANGZHOU HAIXING CNC BRUSH MACHINERY

Process for metalworking fluid from heavy alkylate

InactiveUS20050215440A1Component is toxicHigh specific and latent heatWork treatment devicesLiquid carbonaceous fuelsMetalworking fluidVegetable oil

The process relates to composition of metalworking fluid and for its preparation based on heavy alkyl benzenes having 22 to 26 carbon atoms to replace mineral oil and process for the same. A process for heavy alkylate based less toxic metalworking fluid composition comprising of heavy alkyl benzene, one emulsifier which is a sodium oleate, sulfonate or mixtures thereof, a vegetable oil as lubricity booster, an antioxidant, a fungicide, an extreme pressure additive, an antirust, a co-surfactant, a coupling agent and alkali component. The process comprising of removing of insoluble matter from the heavy alkylate, addition of emulsifier, additives, coupling agent and co-surfactant, homogenizing the mixture at 20-120° C., followed by conditioning of the metal working fluid concentrate which can be used as emulsion in water.

Owner:COUNCIL OF SCI & IND RES

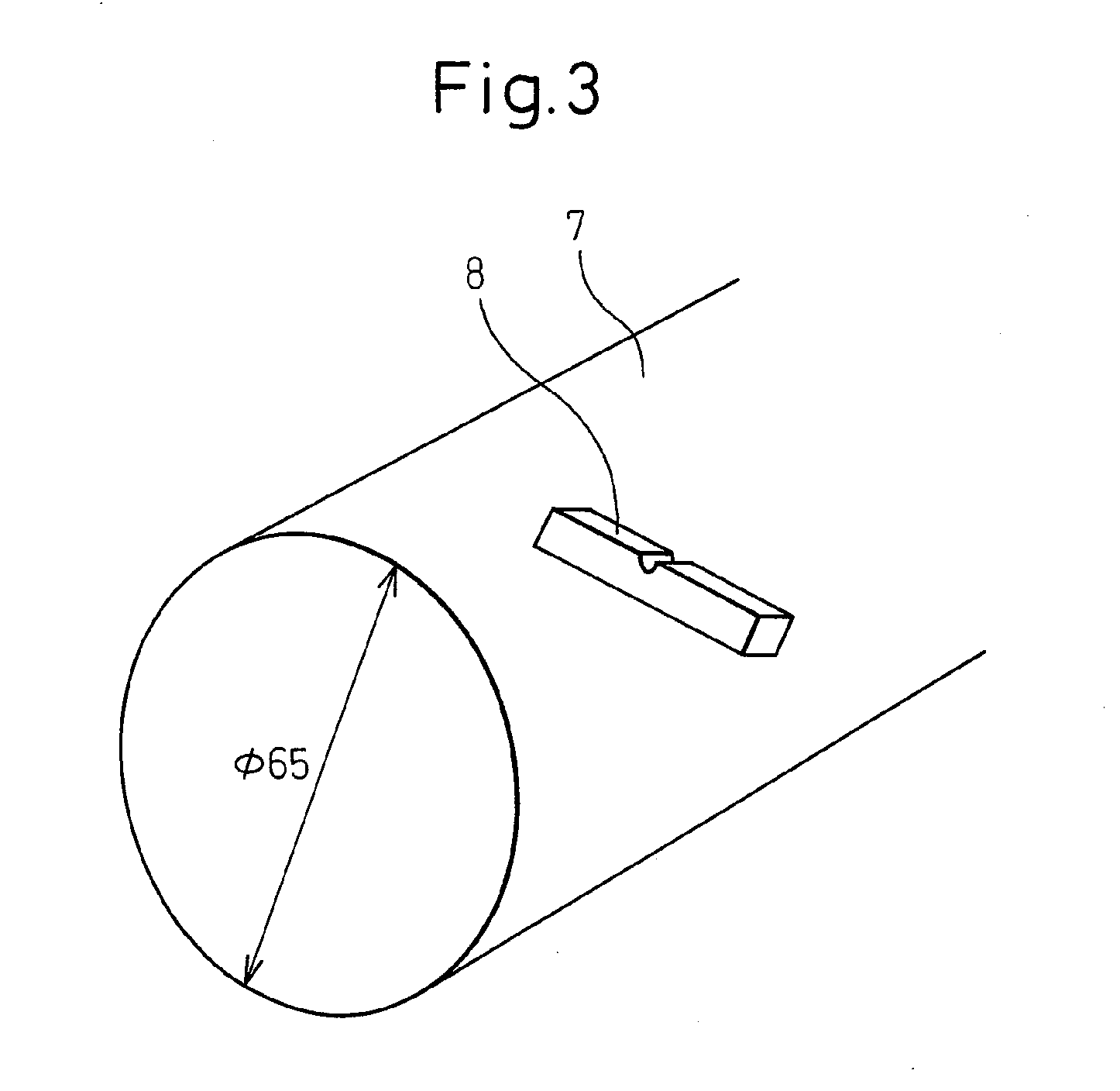

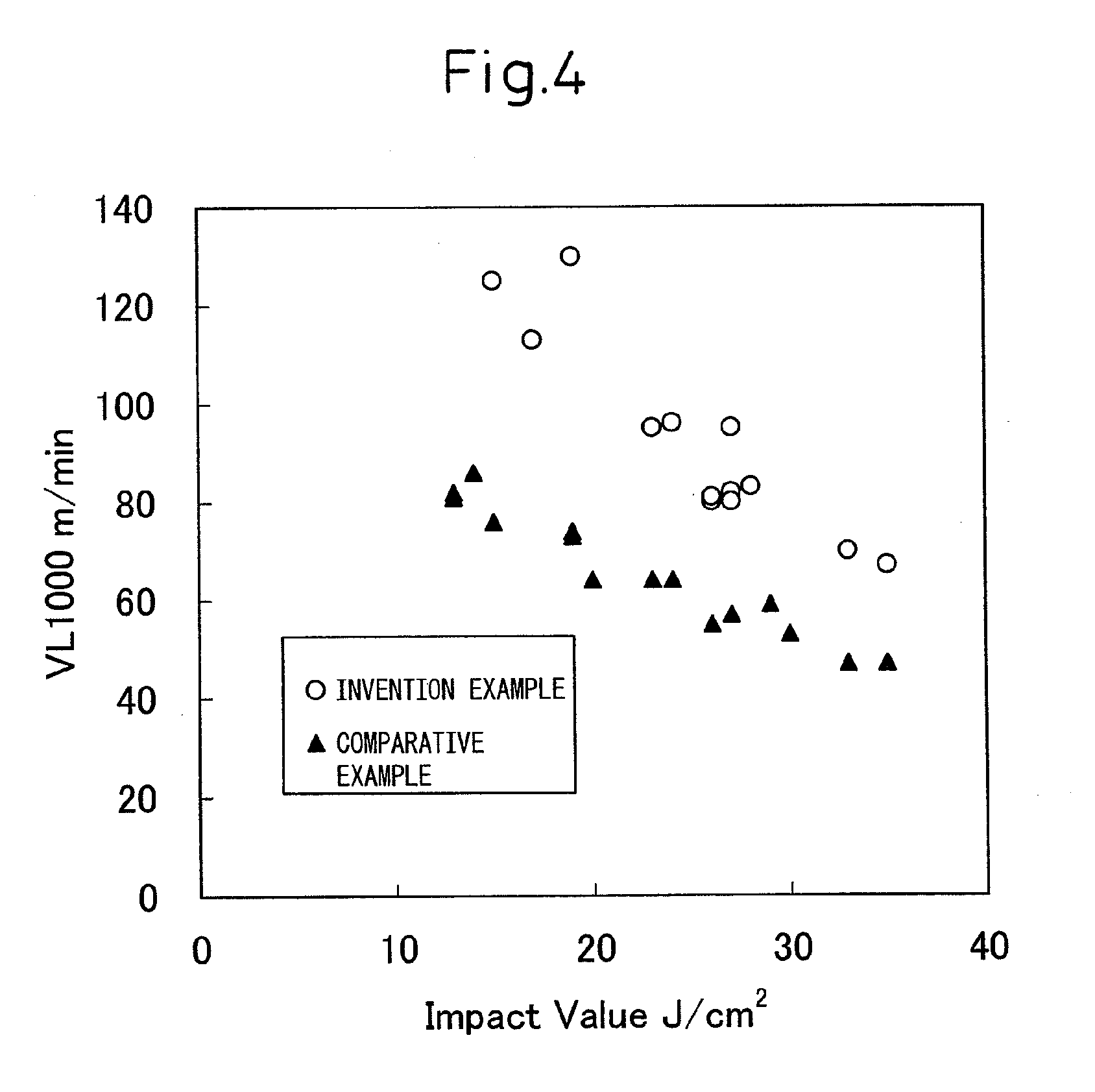

Hot-working steel excellent in machinability and impact value

Provided is a hot-working steel excellent in machinability and impact value comprising, in mass %, C: 0.06 to 0.85%, Si: 0.01 to 1.5%, Mn: 0.05 to 2.0%, P: 0.005 to 0.2%, S: 0.001 to 0.35%, and Al: 0.06 to 1.0% and N: 0.016% or less, in contents satisfying Al×N×105≦96, and a balance of Fe and unavoidable impurities, total volume of AlN precipitates of a circle-equivalent diameter exceeding 200 nm accounting for 20% or less of total volume of all AlN precipitates.

Owner:NIPPON STEEL CORP

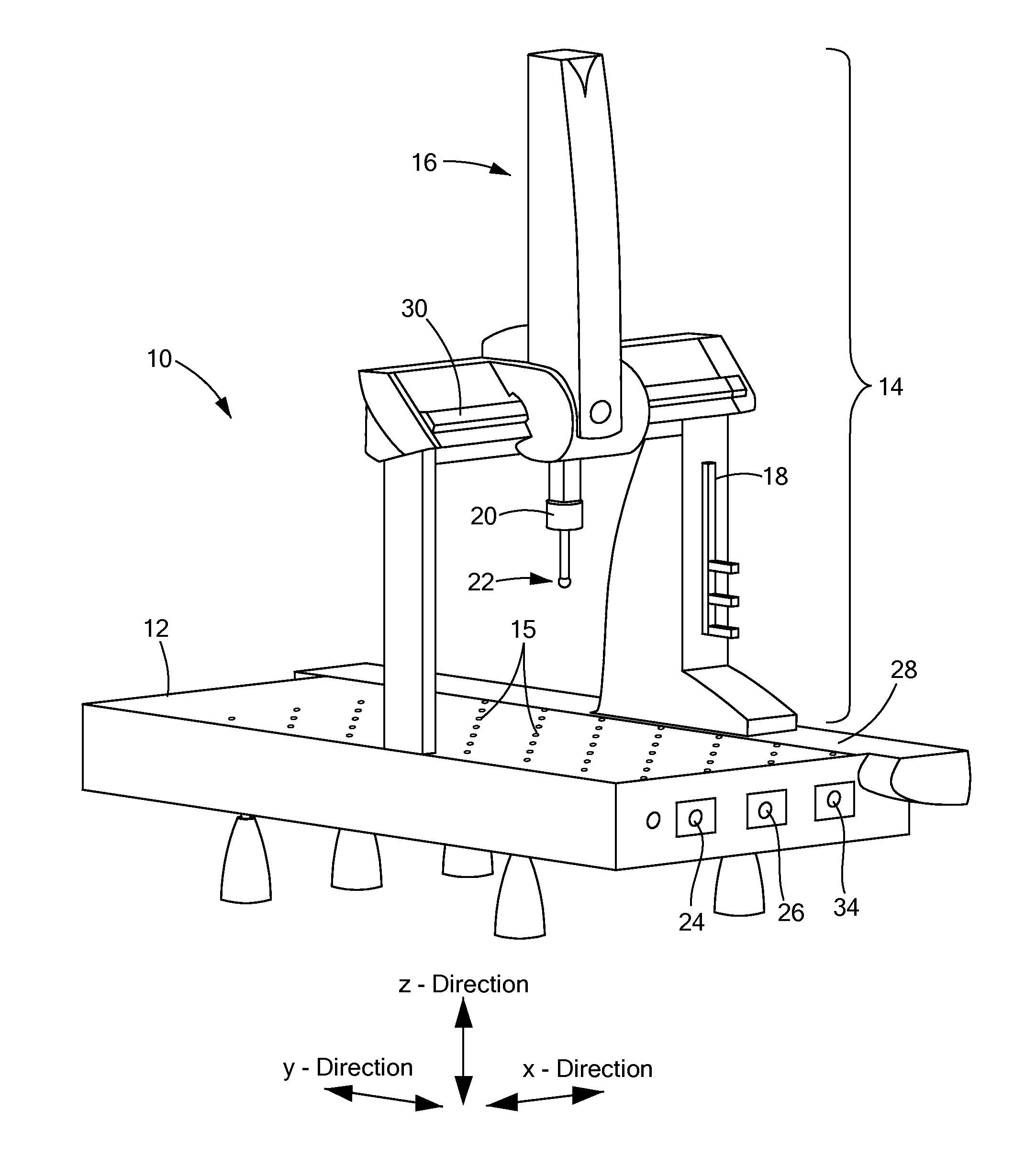

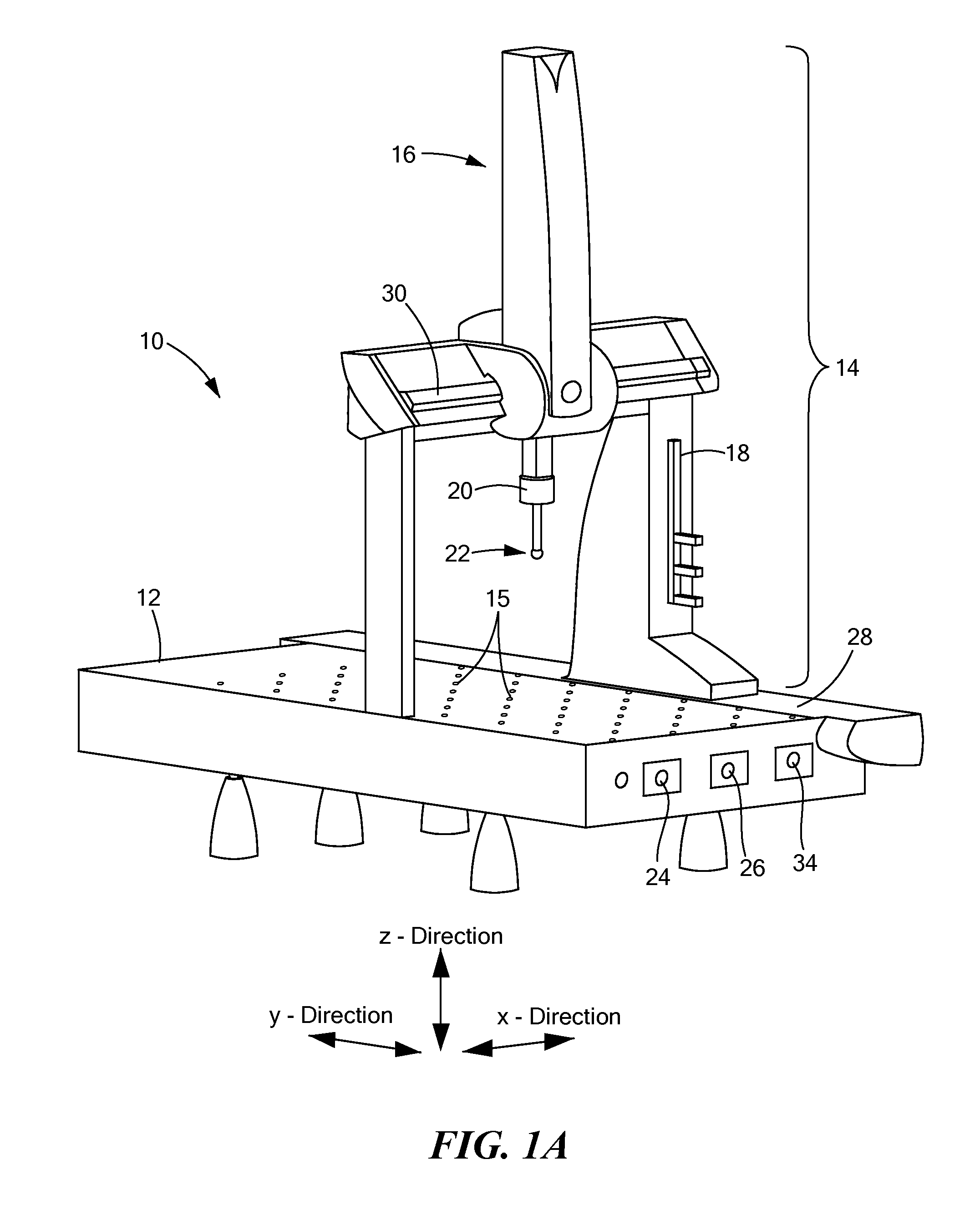

Method and Apparatus for Controlling a Surface Scanning Coordinate Measuring Machine

ActiveUS20130185948A1Minimizing tip touchdown impactIncrease machine speedComputer controlSimulator controlMethod selectionAngular degrees

A method improves surface scanning measure machine speed while minimizing tip touchdown impact on the surface of the object being measured. Specifically, the method controls a surface scanning measuring machine having a probe head with a distal probe tip that contacts the surface of an object to be measured. To that end, the method selects a nominal initial contact point (on the surface) having a normal vector, and then moves the distal probe tip toward the nominal initial contact point along an approach path. The approach path has a generally linear portion that generally linearly extends from the nominal initial contact point to some non-contacting point spaced from the surface. The generally linear portion forms an angle of between about 20 degrees and about 60 degrees with the normal vector.

Owner:HEXAGON TECH CENT GMBH

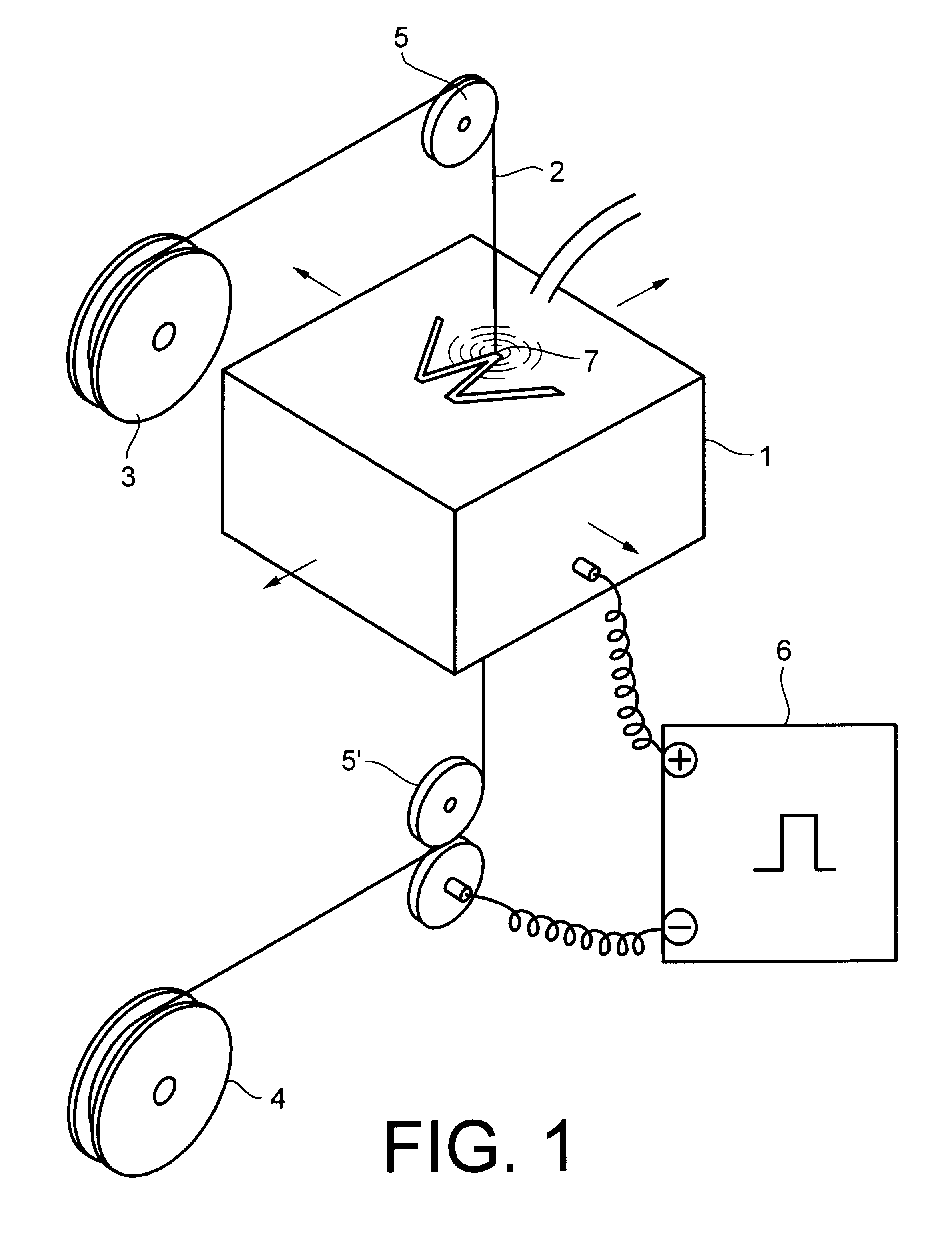

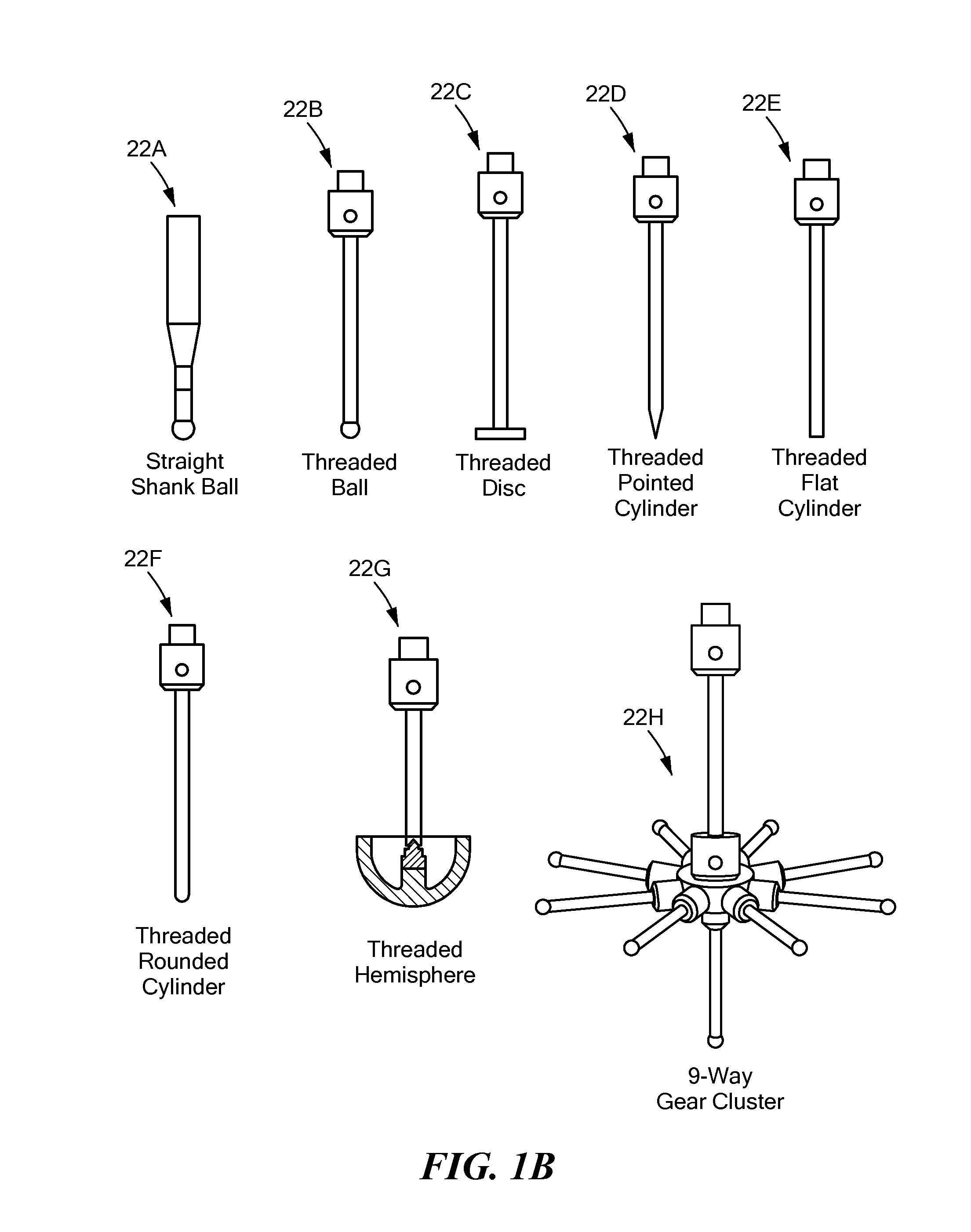

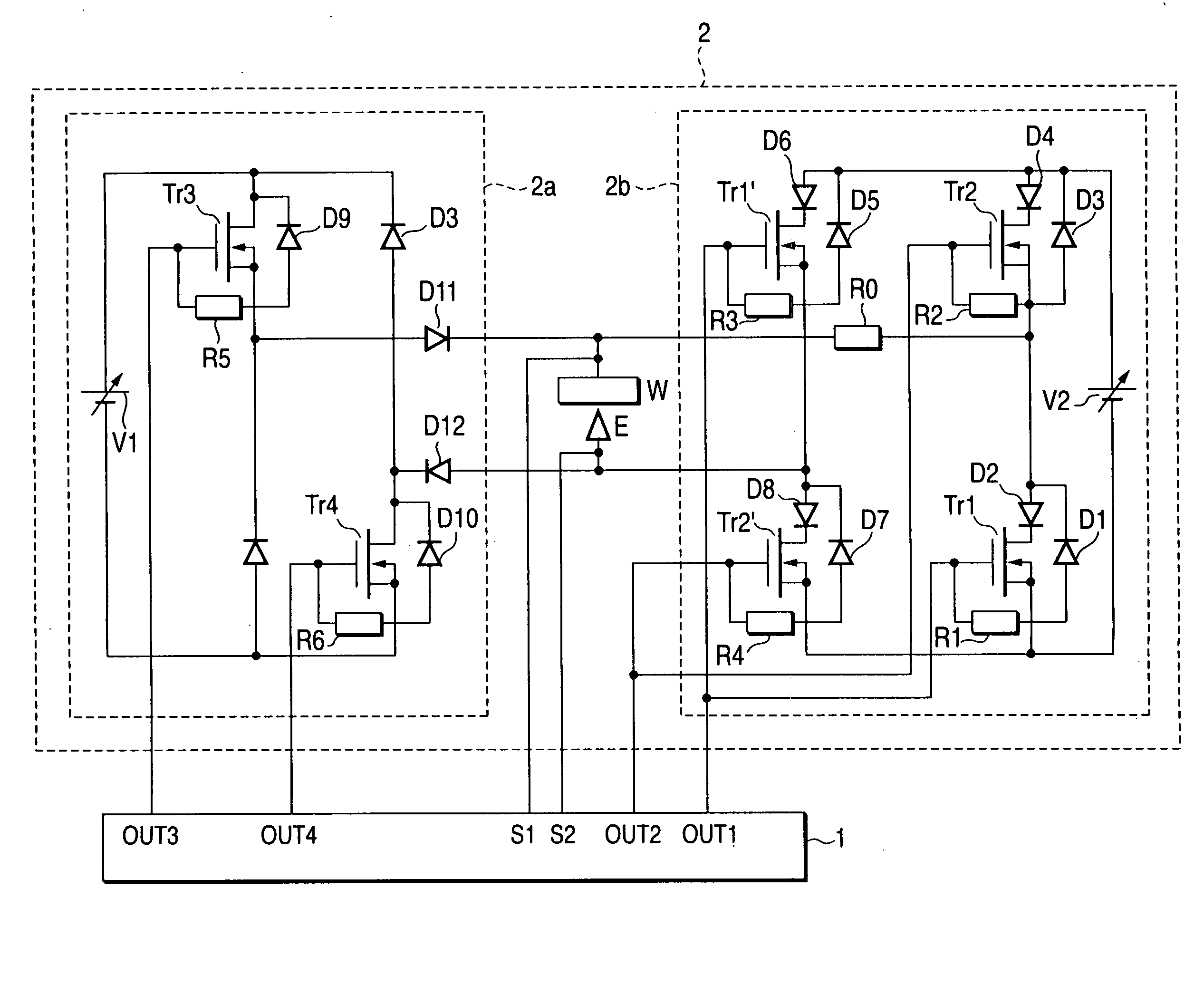

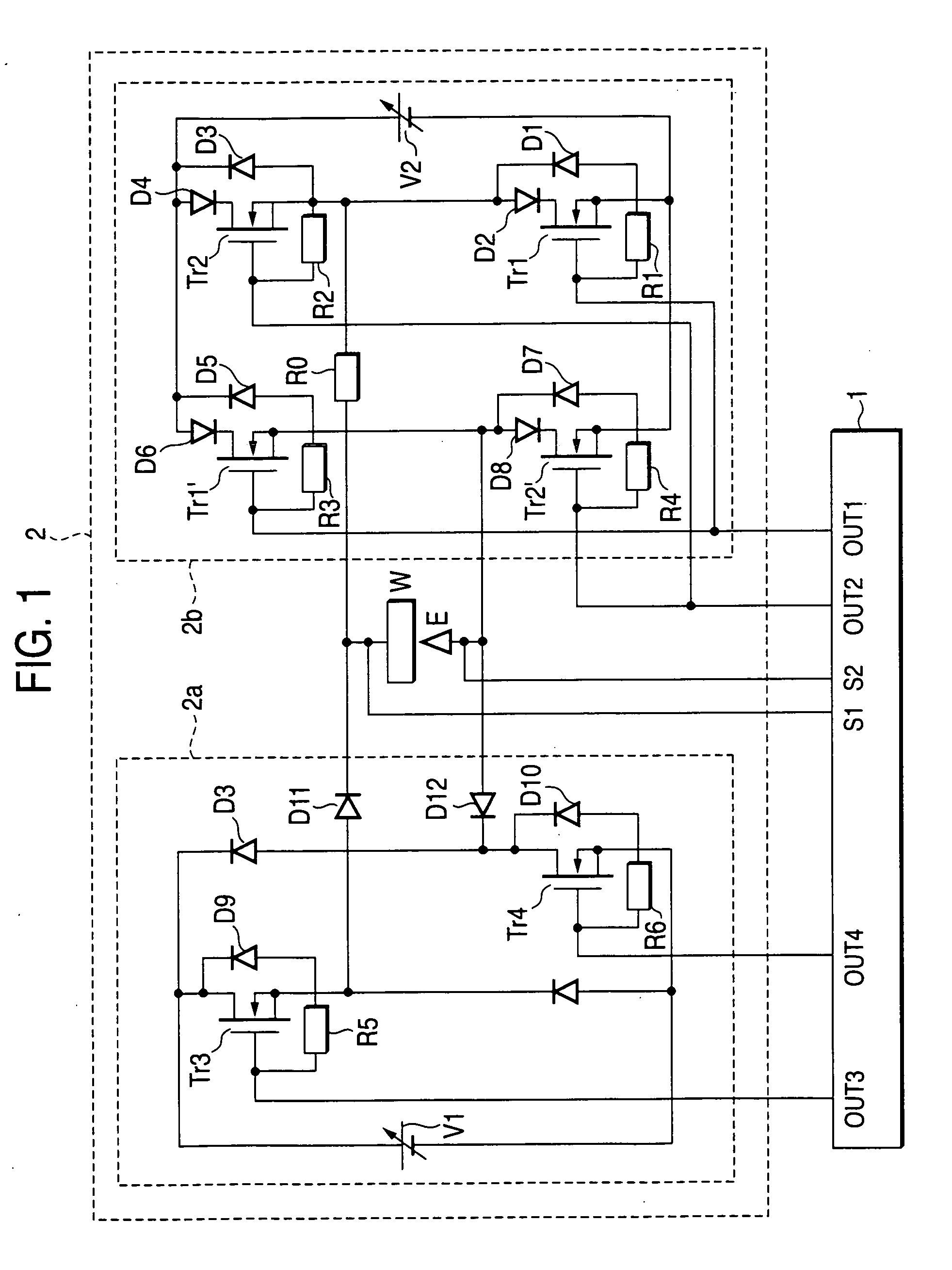

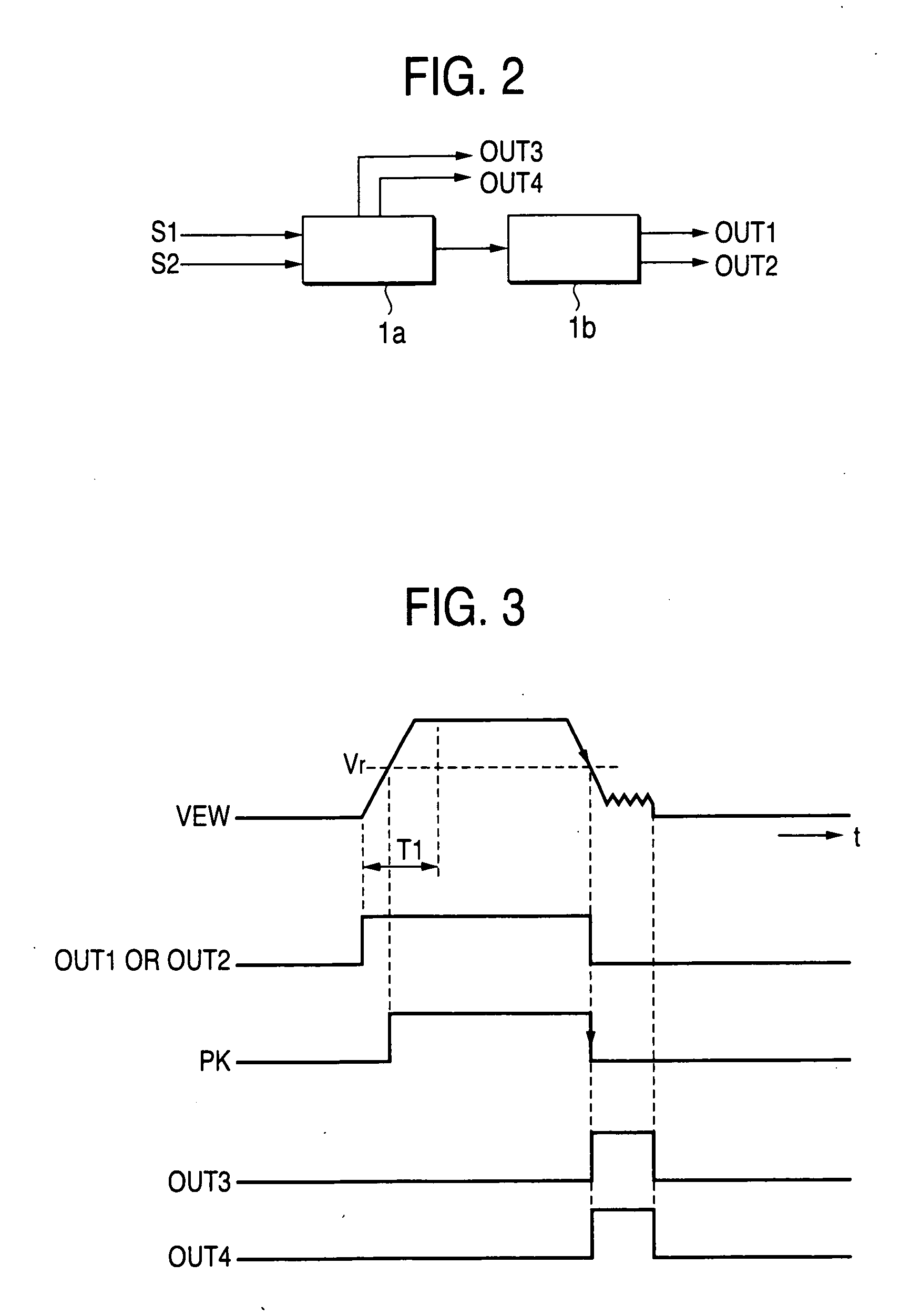

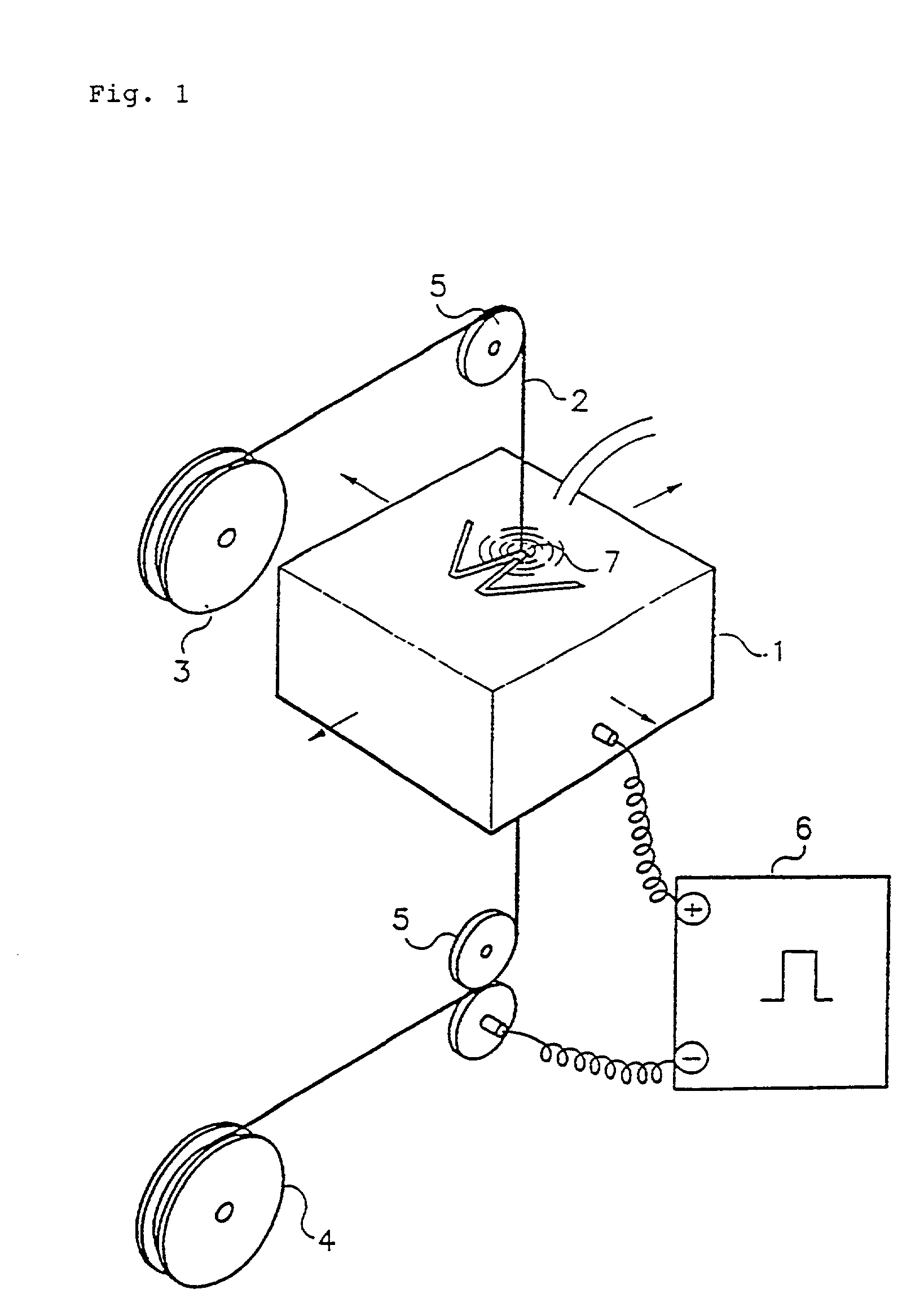

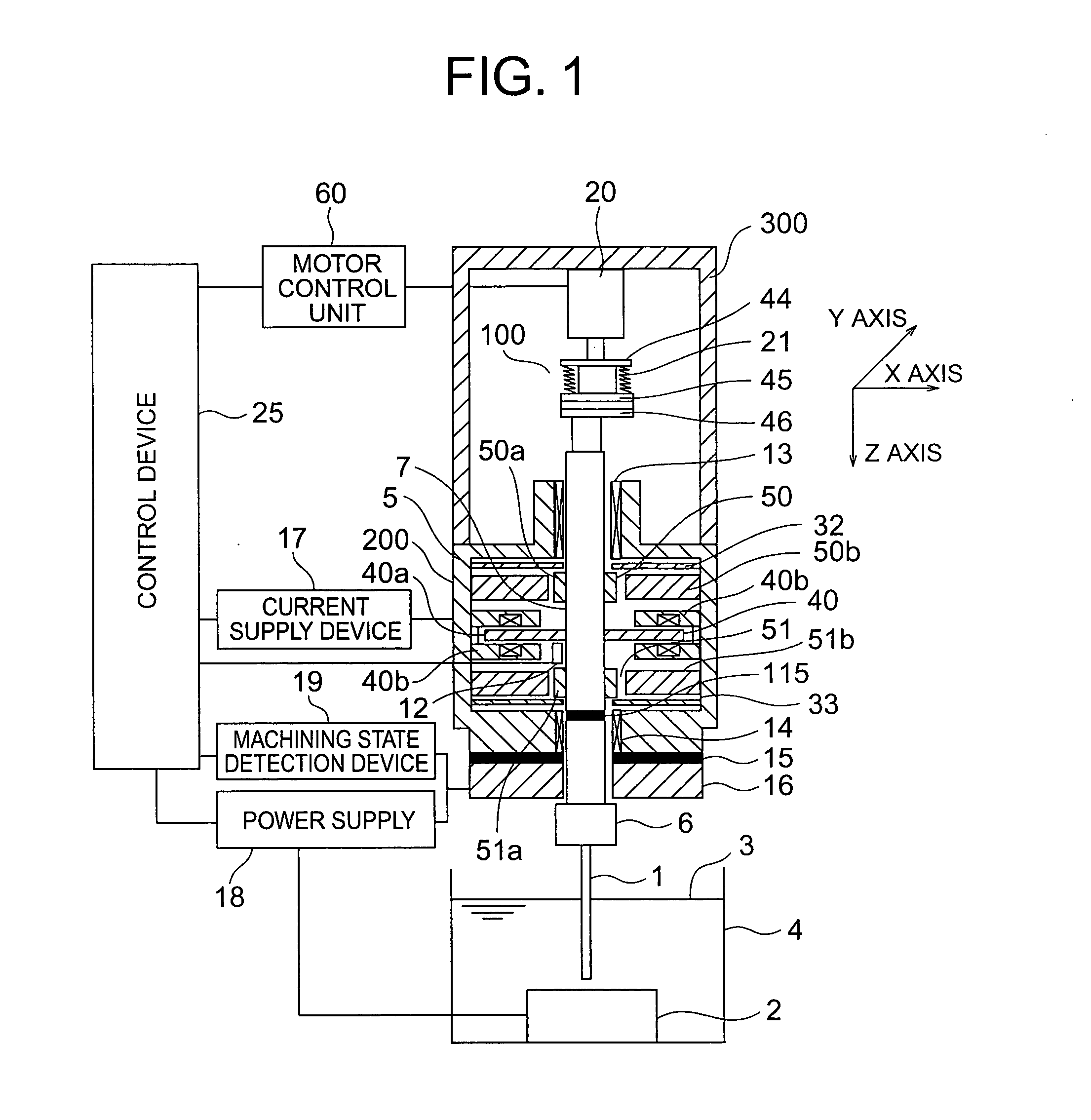

Electric power unit for machining of wire electric discharge machine

InactiveUS20050127041A1Improve efficiencyAvoid it happening againElectric circuitsElectric dischargeElectrical polarity

An electric power unit for machining of a wire electric discharge machine for machining a workpiece (W) in which an electric discharge inductive pulse voltage is impressed upon between electrodes of a wire electrode (E) and workpiece (W), after insulation between the electrodes has been broken by the pulse voltage and electric discharge has been induced, a pulse voltage for machining is impressed upon between the electrodes so as to conduct machining on the workpiece (W). The electric power unit for machining of a wire electric discharge machine includes an electric discharge state discriminating means (1a) for discriminating a state of electric discharge generated between the electrodes and an impression voltage selecting means (1b) for inverting the polarity of the electric discharge inductive pulse voltage from the previous electric discharge inductive pulse voltage when an electric discharge state between the electrodes is discriminated to be abnormal (Y1) or open (Y3) by the electric discharge state discriminating means (1a) and for making the polarity of the electric discharge inductive pulse voltage to be the same as the polarity of the previous electric discharge inductive pulse voltage when the electric discharge state between the electrodes is discriminated to be normal (Y2) by the electric discharge state discriminating means. Thus the machining efficiency is improved.

Owner:MITSUBISHI ELECTRIC CORP

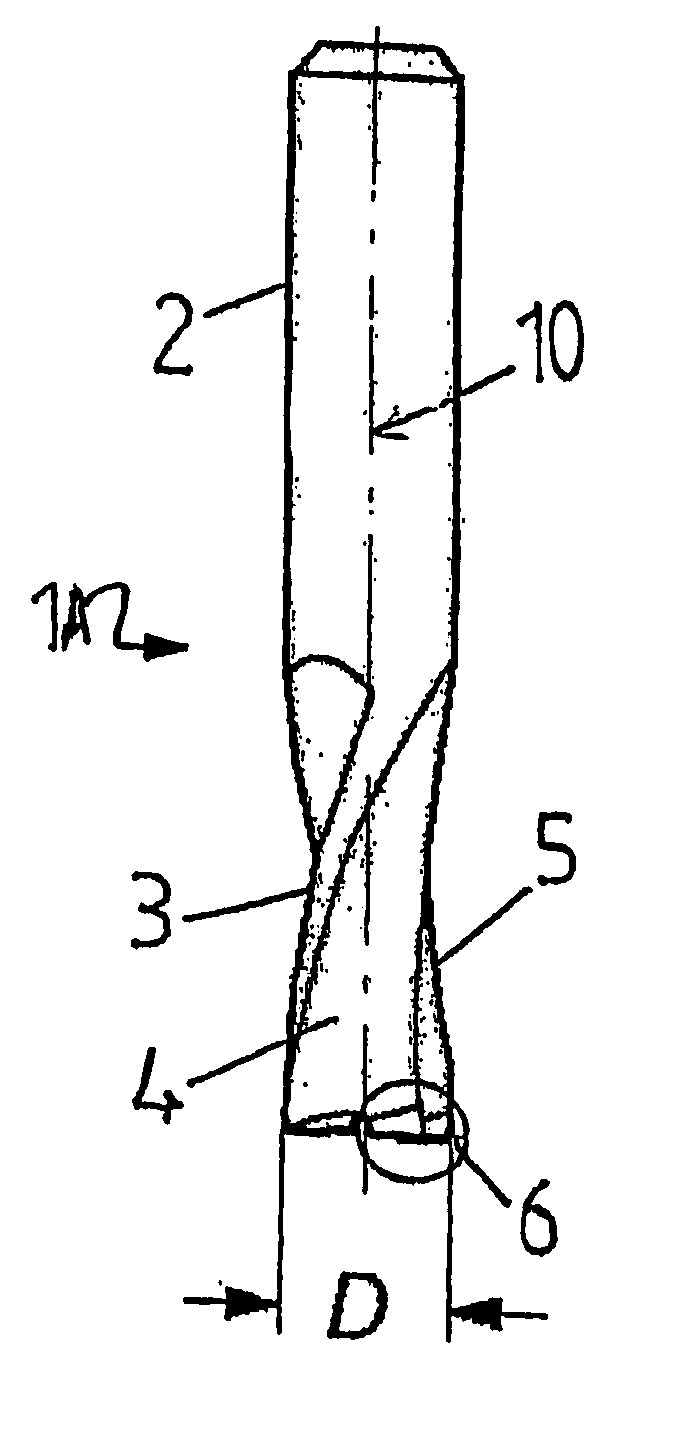

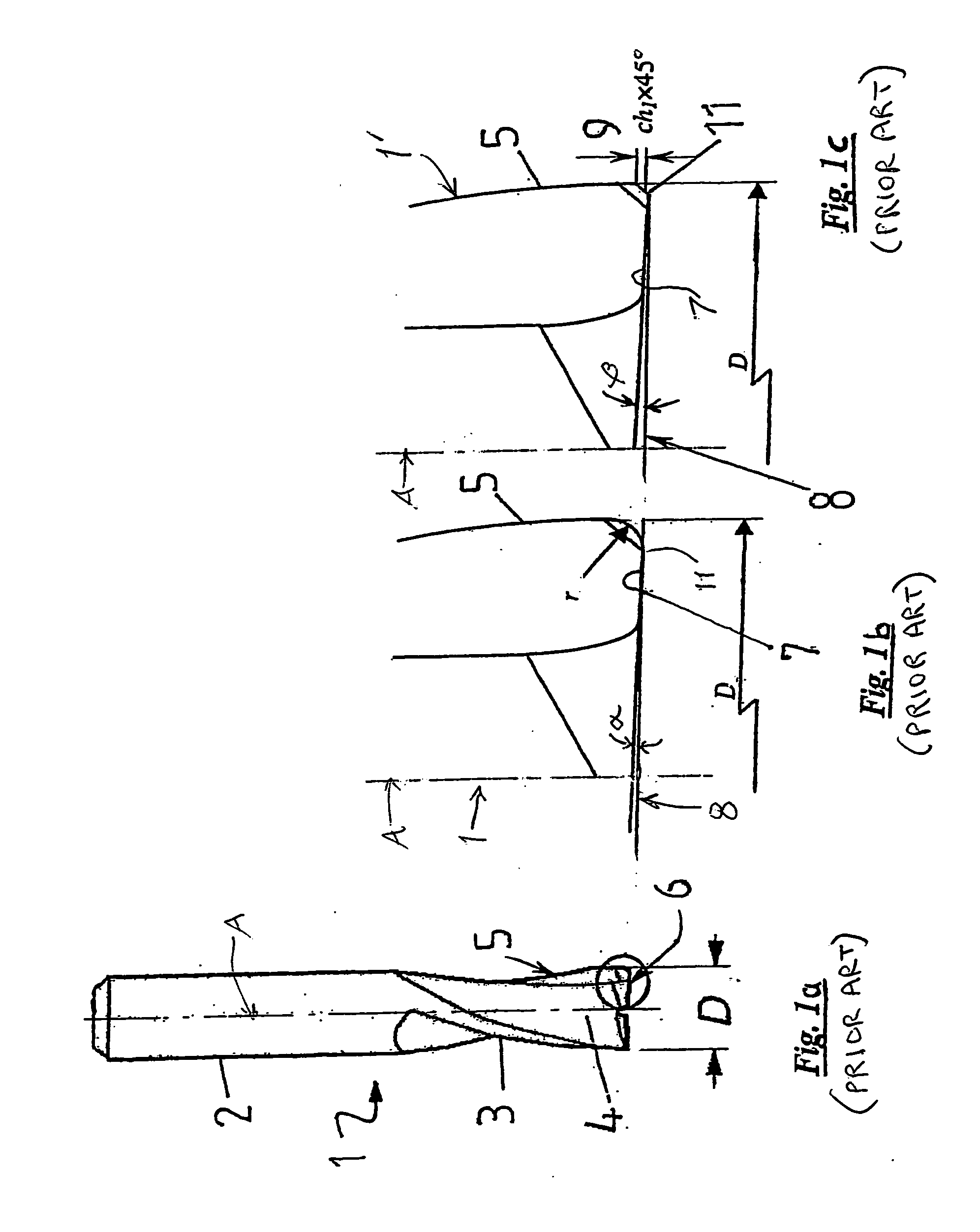

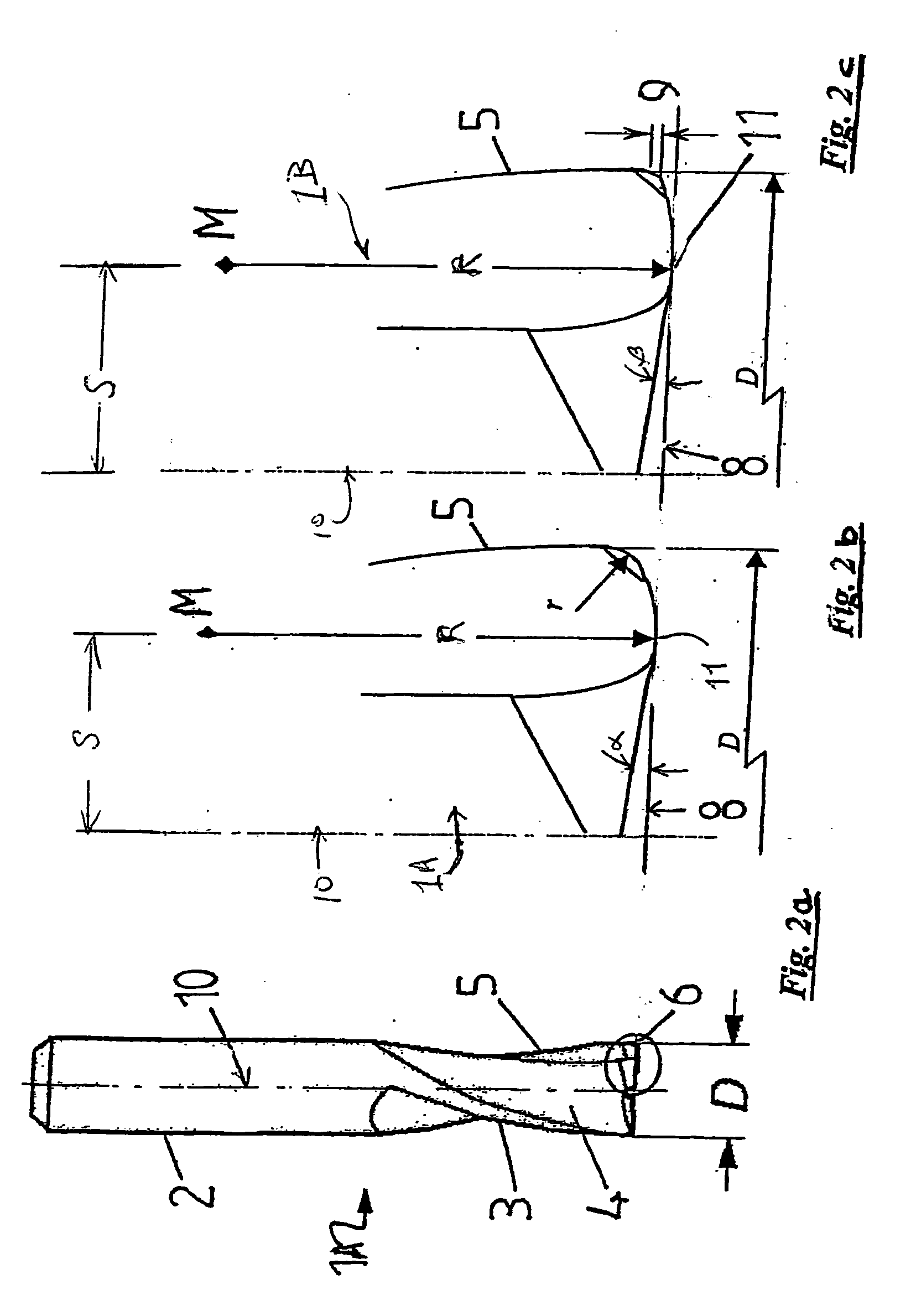

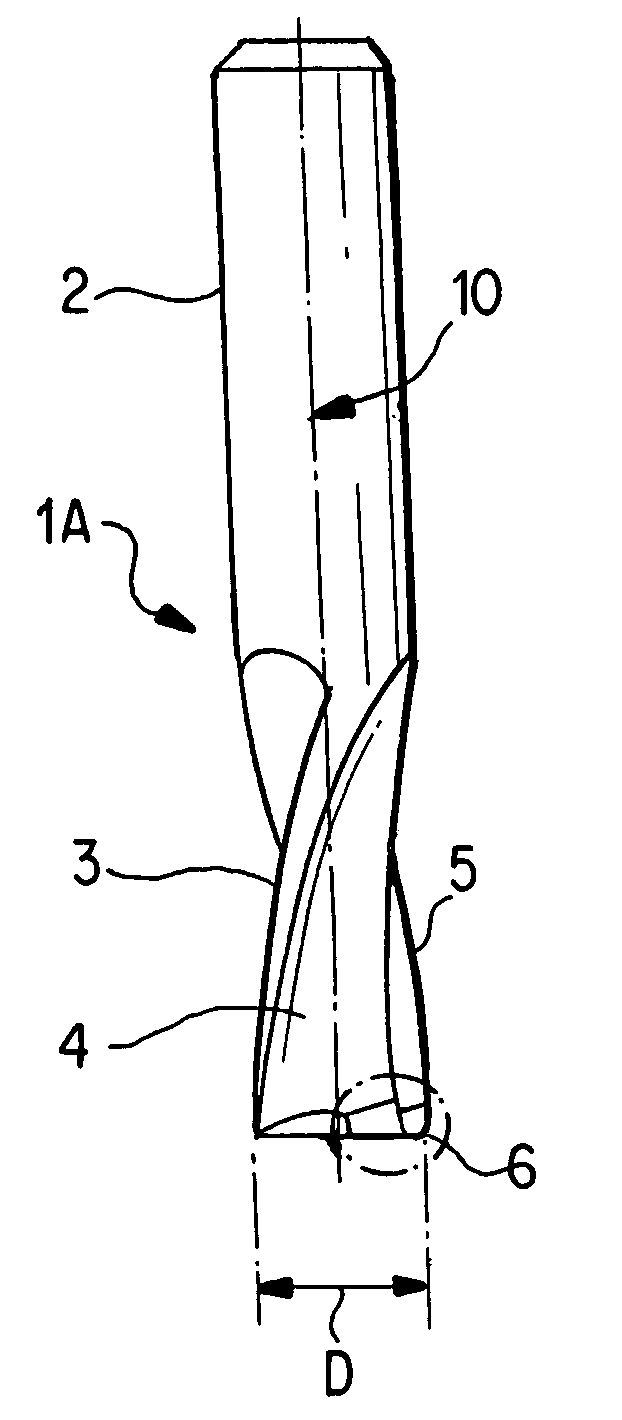

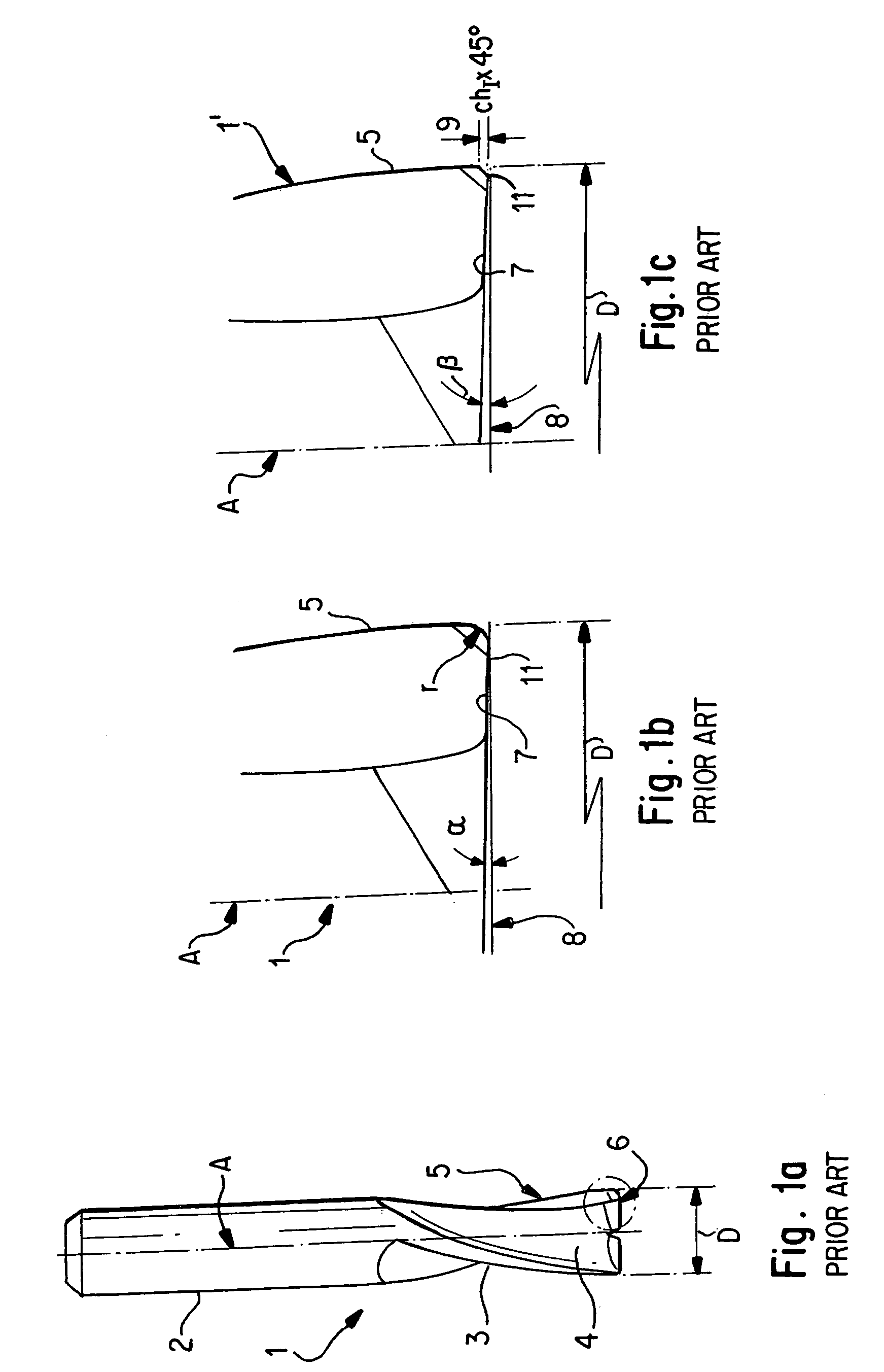

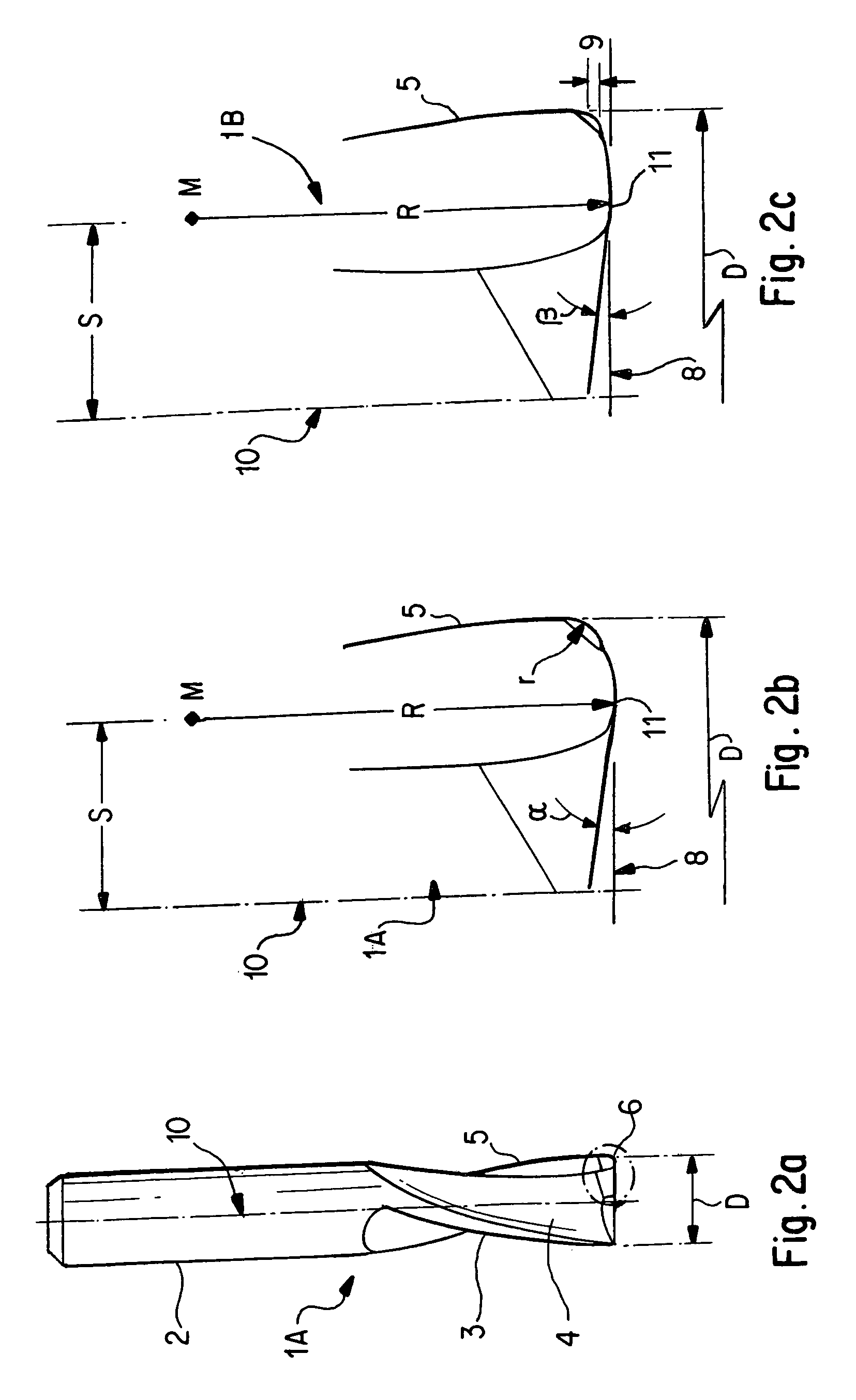

Shank milling cutter having a wiper radius

InactiveUS20050186037A1Easy surface processingExtend your lifeMilling cuttersShaping cuttersMilling cutterEngineering

A shank milling cutter includes a cutting portion which is intended to come into engagement with the workpiece, wherein the envelope surface of the cutting portion is substantially cylindrical. At least one major cutting edge is arranged at the peripheral surface of the cutting portion and at least one minor cutting edge (face cutting edge) is arranged at the end face of the cutting portion and with an end diameter D. The minor cutting edge, in projection onto a plane containing the milling cutter axis, has a convexly curved portion with a radius of curvature R>D / 2 and a center of curvature M located such that a distance from the center of curvature M to the axis is in a range from zero to a value smaller than D / 2.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

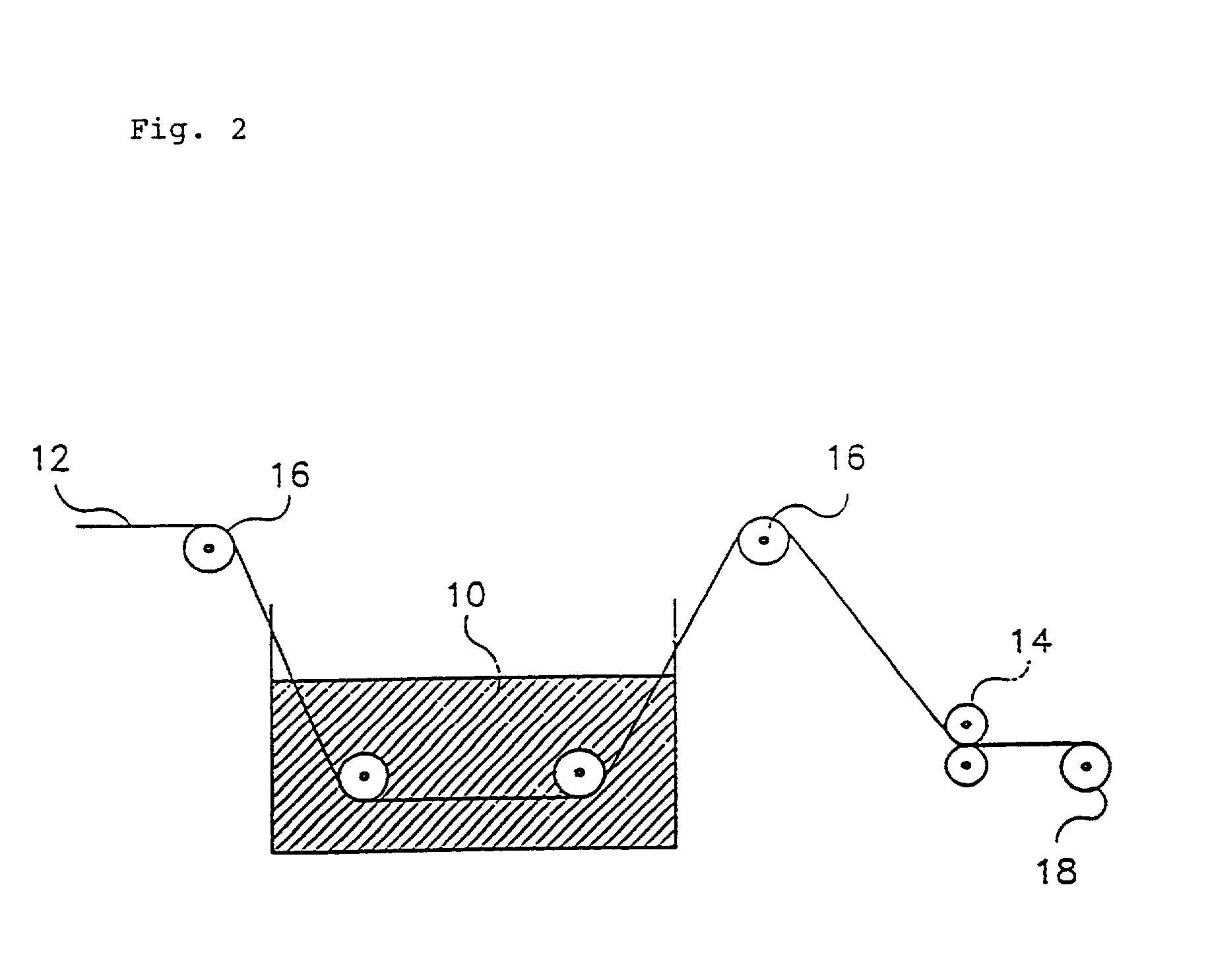

Removal device of emulsion remained on surface of strip steel used for cold rolling mill

InactiveCN101607269AIncrease machine speedBoost productivityWork treatment devicesMetal rolling arrangementsEmulsionZinc

A removal device of emulsion remained on the surface of strip steel used for a cold rolling mill belongs to the technical field of auxiliary facilities of the cold rolling mill. The cold rolling mill comprises a strip steel rolling mechanism which consists of an upper supporting roller, a lower supporting roller, an upper work roller and a lower work roller. The removal device of emulsion remained on the surface of strip steel comprises a pair of blowing mechanisms, a pair of strip steel surface emulsion scraping mechanisms and an upper supporting roller surface emulsion removing mechanism; the pair of strip steel surface emulsion scraping mechanisms are fixed on the rack of a cold rolling mechanism and corresponding to the two sides of the upper work roller and the lower work roller along the length direction; the pair of blowing mechanisms are positioned outside the pair of strip steel surface emulsion scraping mechanisms and fixed with the rack; and the upper supporting roller surface emulsion removing mechanism is fixed on a roller shaft seat of the upper supporting roller, corresponds to the above part of the upper supporting roller in the length direction and is contacted with the upper supporting roller. The removal device of emulsion remained on the surface of strip steel has the advantages that the speed of the cold rolling mill can be improved, the production efficiency is improved, and zinc plating quality of a follow-up zinc plating process can be guaranteed.

Owner:CHANGSHU HUAYE STEEL STRIP

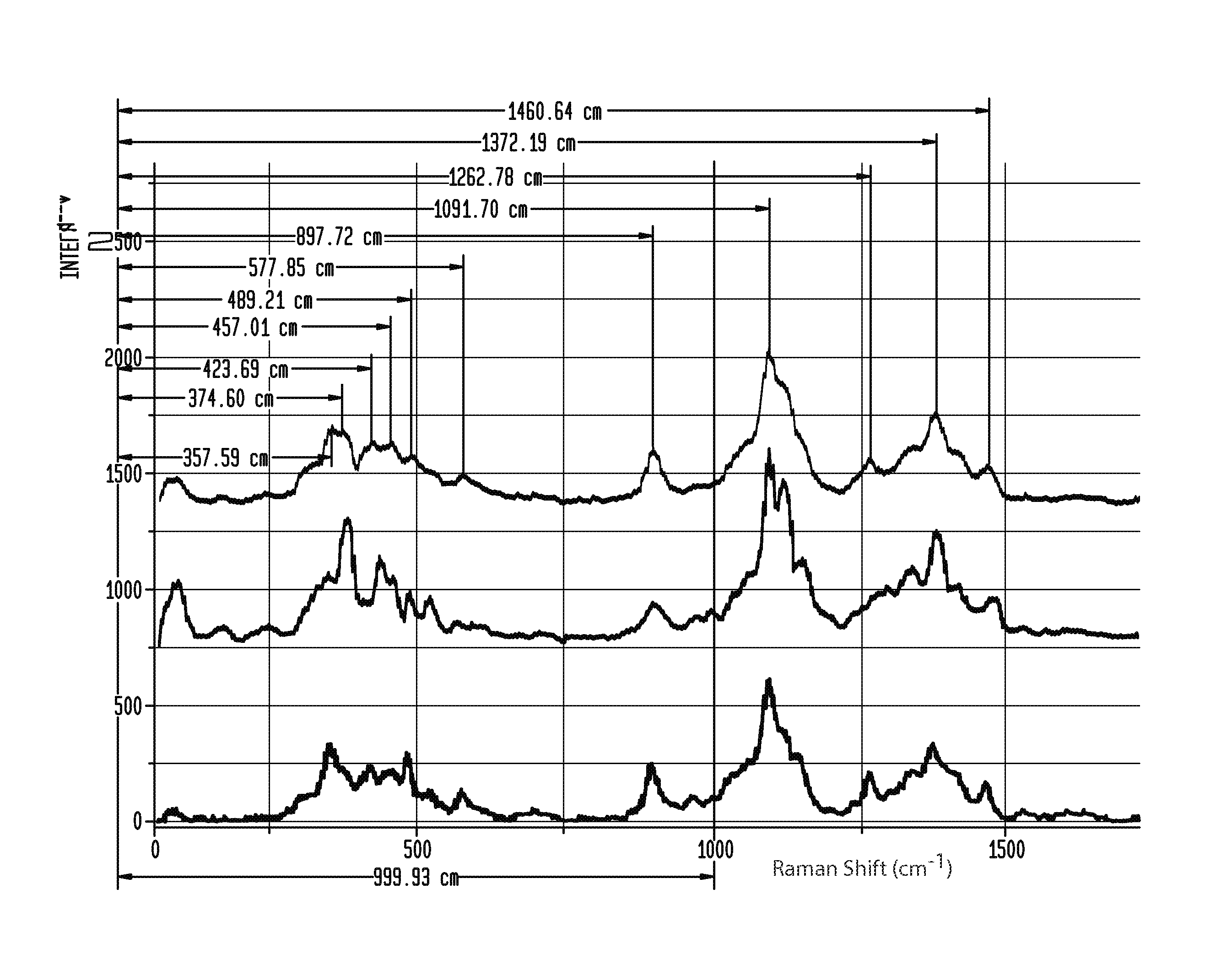

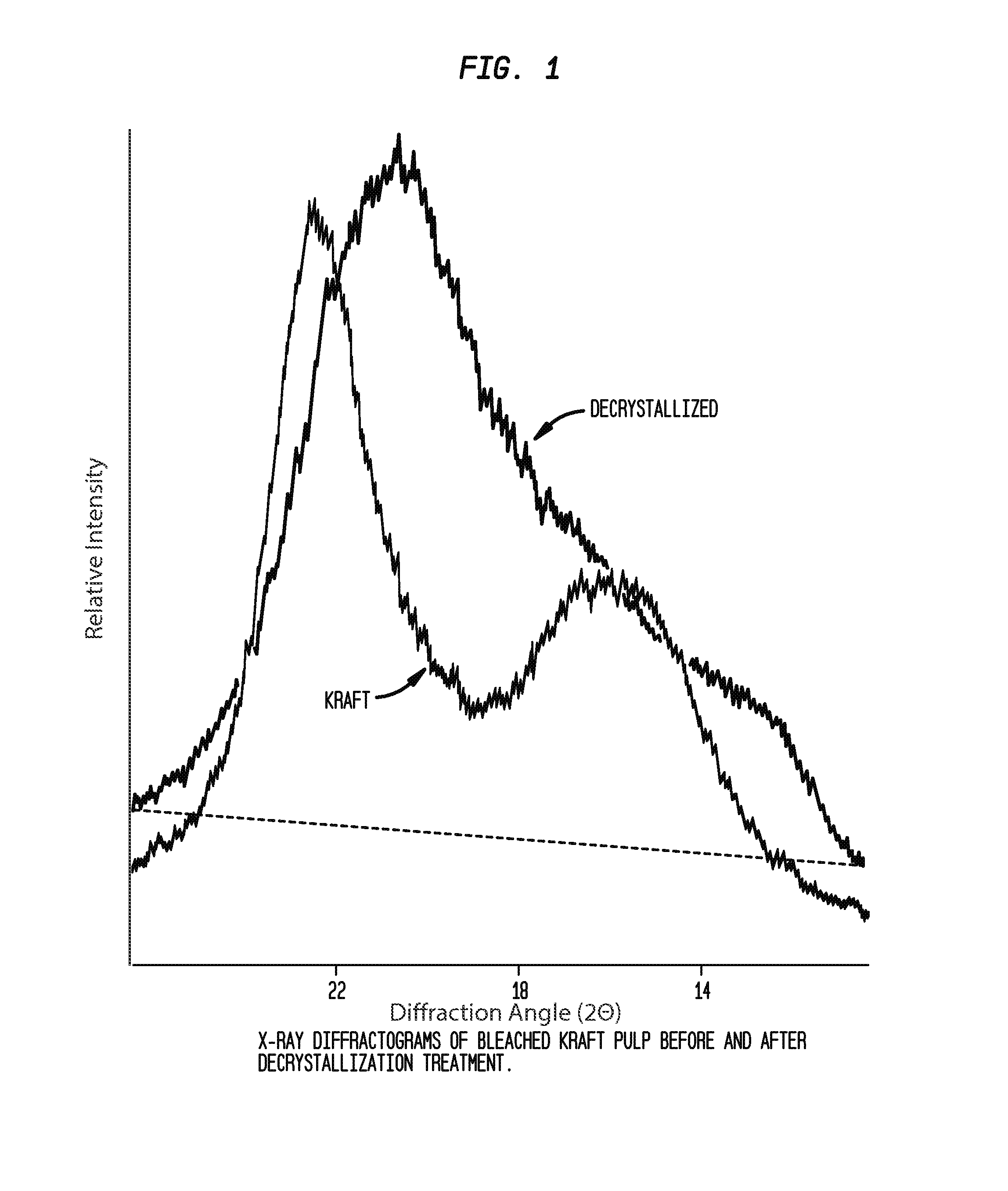

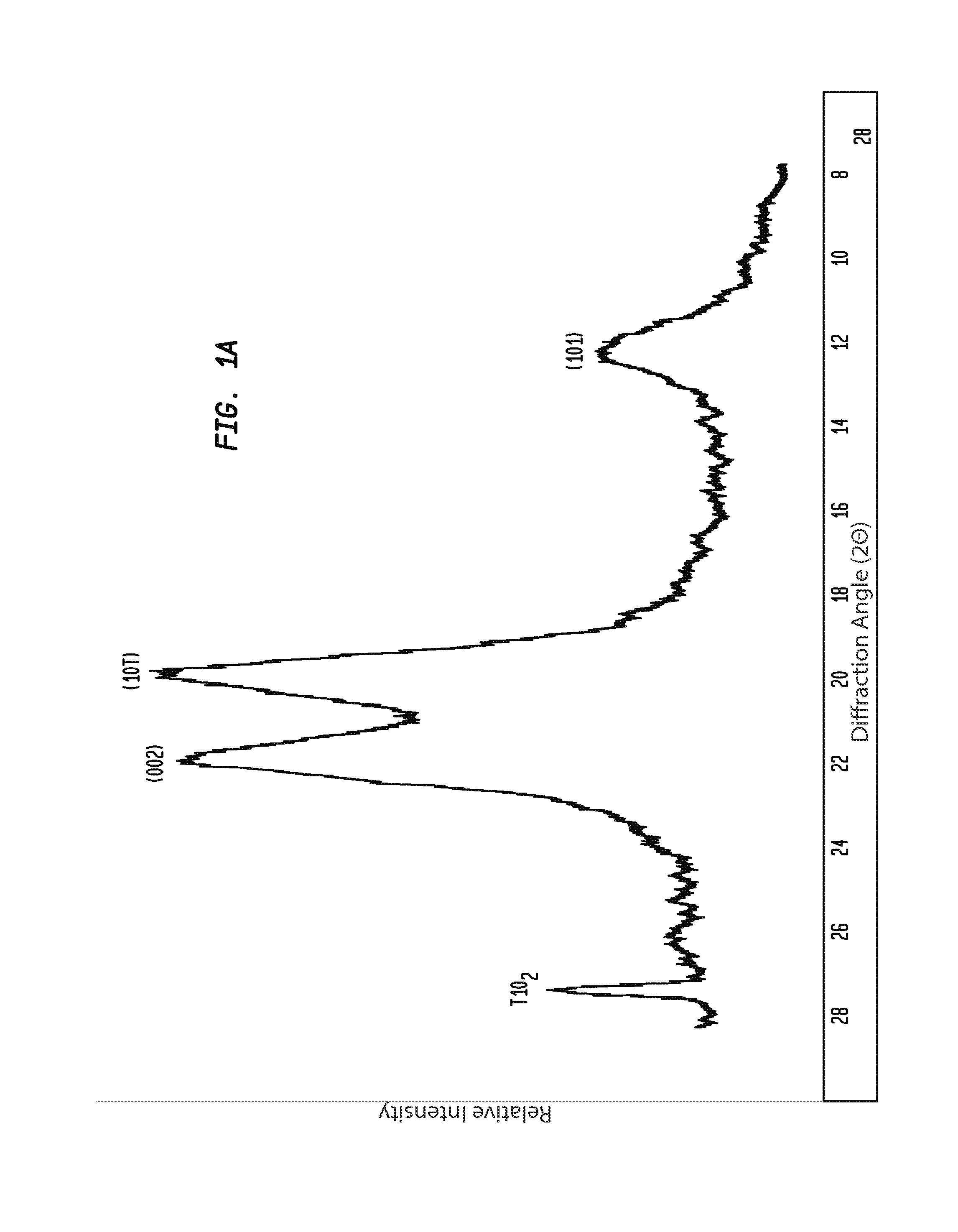

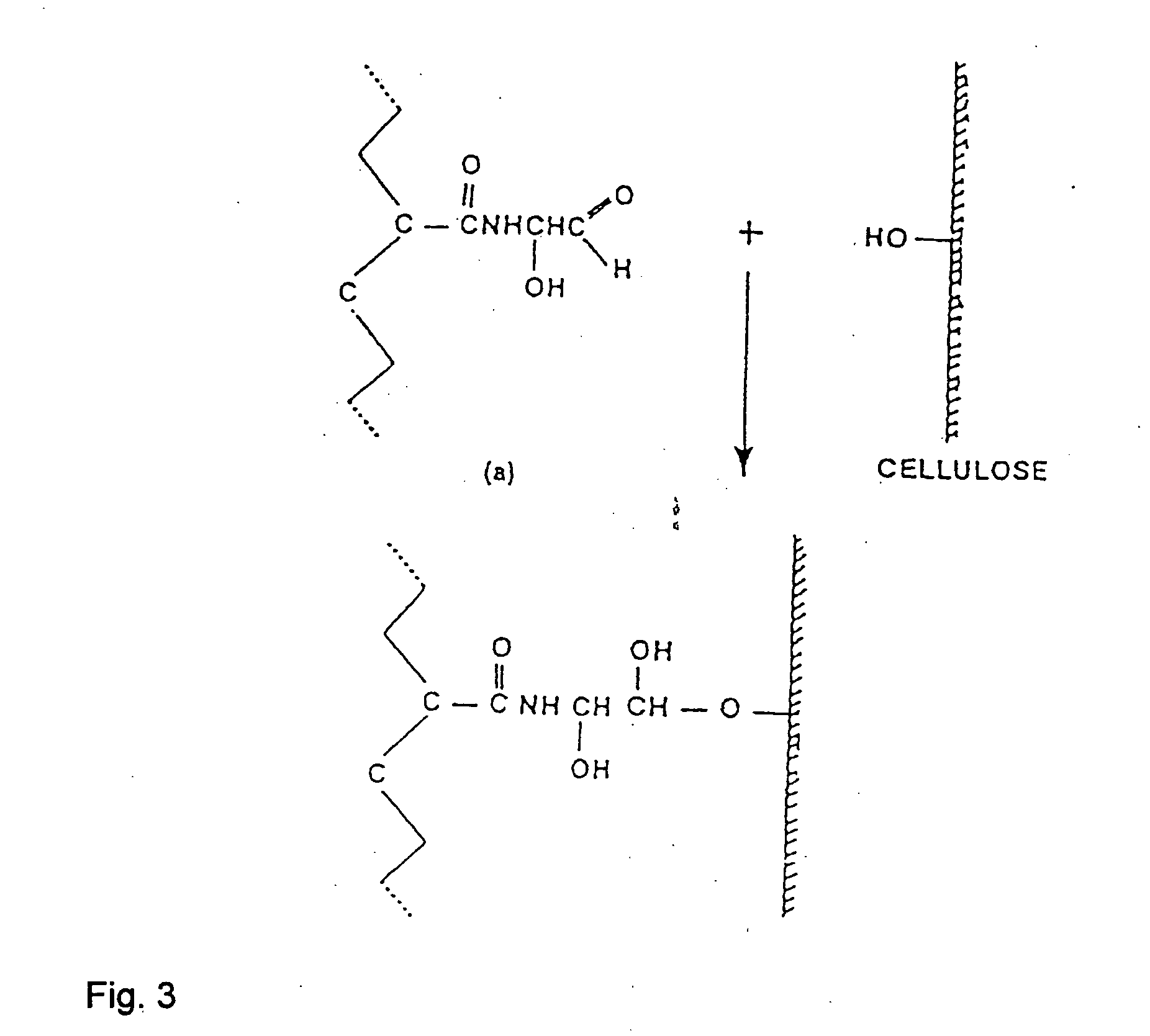

Tissue products incorporating nanoporous cellulose fiber

ActiveUS8741104B2Increasing chemical accessibilityPromote productionNon-fibrous pulp additionPaper after-treatmentPorosityMedicine

Fibrous cellulosic products incorporating both conventional cellulosic fibers and laterally expanded cellulose fibers exhibit exceptional porosity, bulk, absorbency and resiliency properties. Typical products include absorbent tissue products, absorbent fluff products and flat papers. The laterally expanded cellulose fibers exhibit: (i) a broadened X-Ray diffraction peak for the most prominent reflection having a width at half-height, (W1 / 2h)A, of at least about 3.0° 2Θ, (ii) broad overlapping maxima in their Raman spectrum between 285 and 500 cm−1, the height of the two tallest of said maxima in said spectrum between 285 and 500 cm−1 being between 35 and 50% of the height of the peak near 1098 cm−1 and (iii) a blue stain when treated with Graff C-stain, the stain exhibiting less red than the stains exhibited with bleached hardwood kraft fibers and bleached softwood kraft fibers.

Owner:CELLLOSE SCI INT

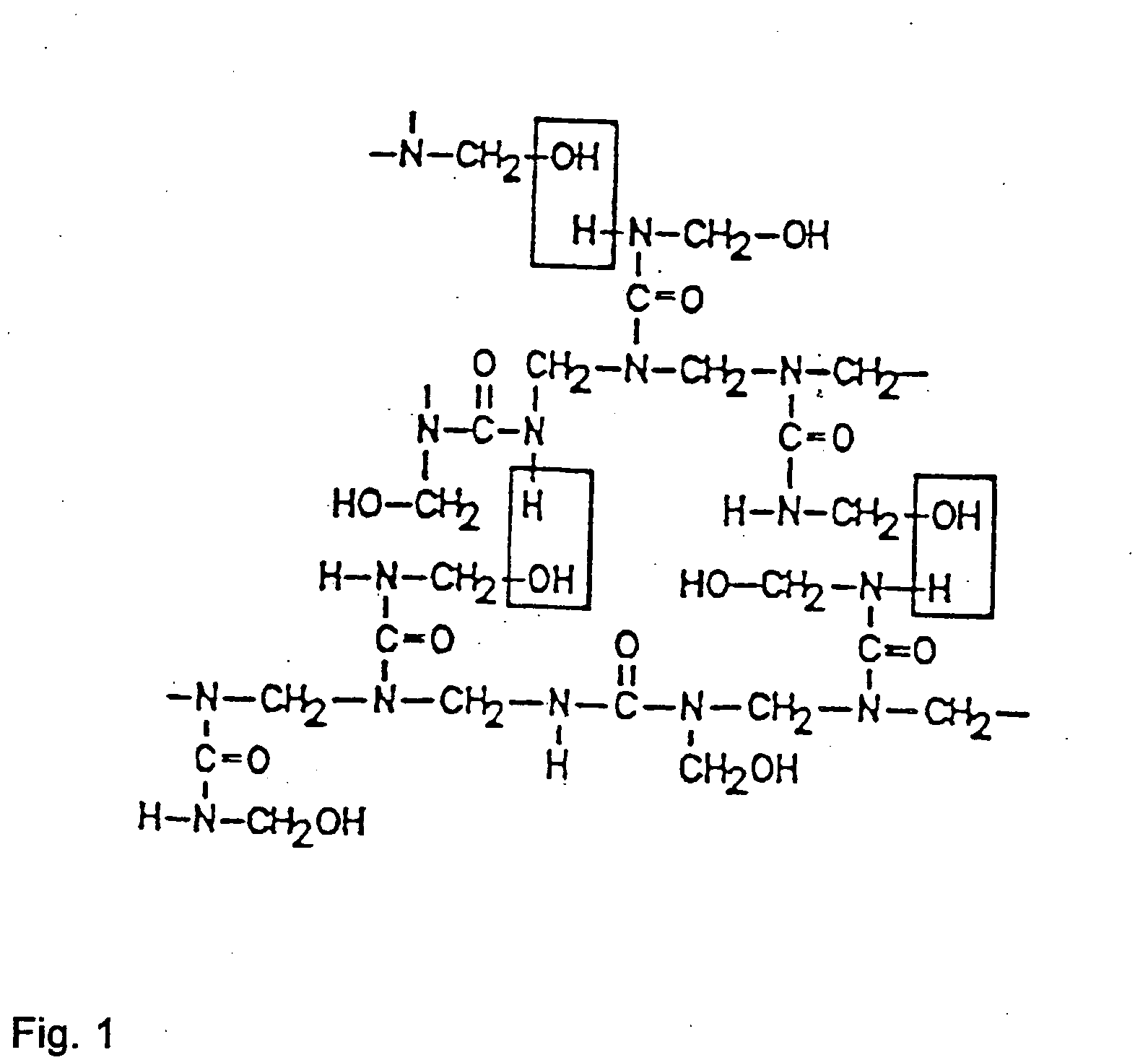

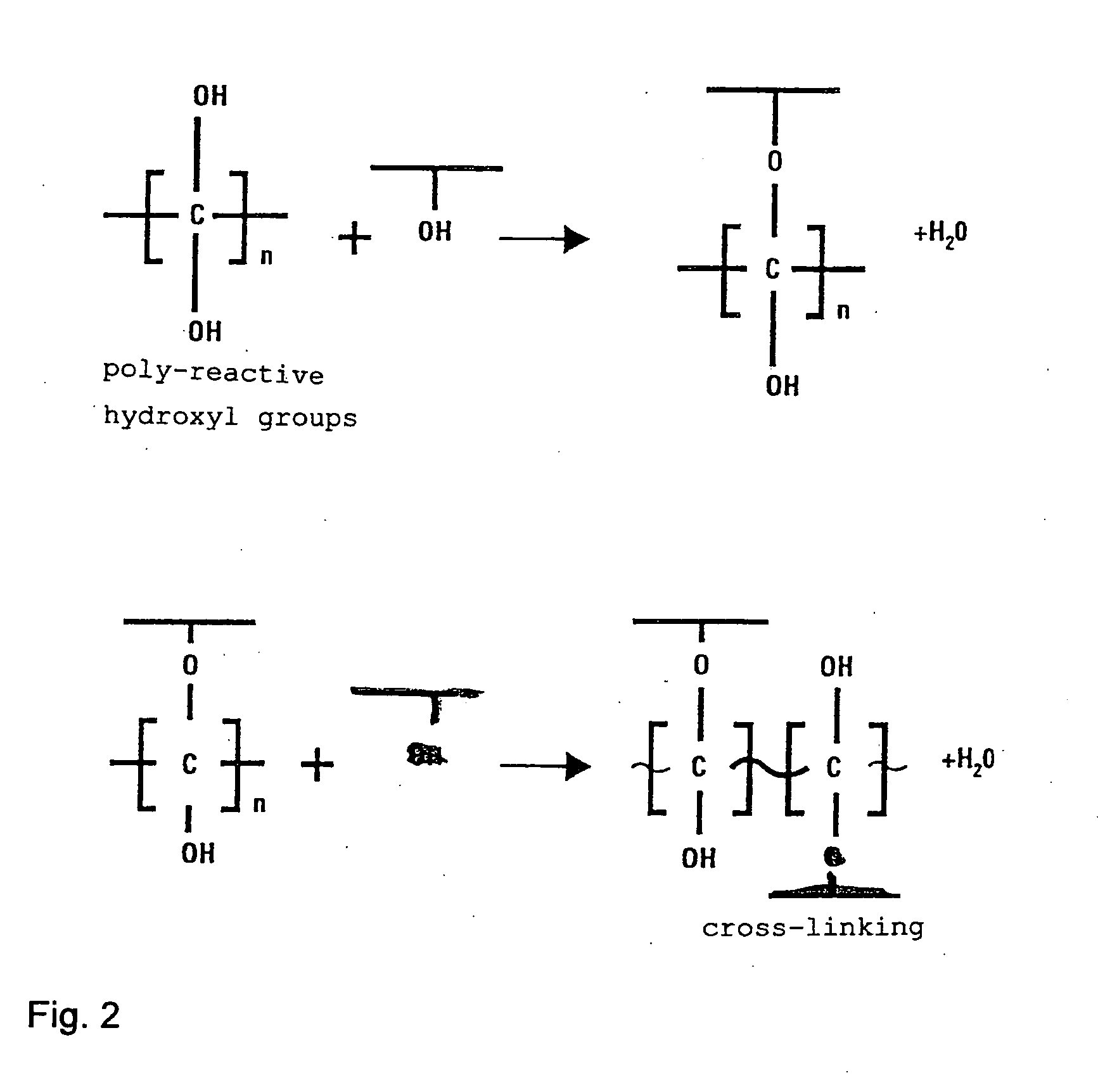

Multifunctionally usable coating dispersion for printing substrates

InactiveUS20060235129A1Increase contentLow production costNon-fibrous pulp additionNatural cellulose pulp/paperCross-linkPaperboard

The disclosure relates to a coating dispersion for coating printing substrates, especially paper and paperboard. Said dispersion is constituted of at least one defined percentage of water, a defined percentage of a swellable phyllosilicate and a defined percentage of a cross-linking agent. The cross-linking agent forms a bond with at least one functional group of the phyllosilicate as well as with at least one functional group of the printing substrate. The invention also relates to a method for producing a coated printing substrate onto which a coating dispersion is mechanically applied and dried, whereby the coating dispersion comprises at least the aforementioned components.

Owner:WEIPATECH

Porous electrode wire for use in electrical discharge machining and method of manufacturing the same

InactiveUS20010014411A1Increase machine speedImprove cooling effectHot-dipping/immersion processesSolid state diffusion coatingPorous electrodeZinc

The present invention relates to a porous electrode wire for use in electrical discharge machining and the method of manufacturing the same. The wire improves the machining speed at least 15% compared with a conventional zinc coated wire, which results from an increased cooling ability of the wire with a cooling liquid because of the increase in the surface area of the wire having porous surface morphology. Since the surface of the porous wire presents uniform profile of outer periphery rather than surface protrusions, it does not affect machining accuracy. Further, the porous nature of the wire is expected to improve flushability during the electrical discharge machining, providing spaces to eliminate particles of the machining. Therefore, in accordance with the method of the present invention, a zinc coated wire having improved performance of machining speed and flushability compared with a conventional coated wire can be provided without additional processes.

Owner:SEONG KI CHUL

Cutting insert and cutting tool therefor

InactiveUS8696254B2Reduce shear forceGuaranteed uptimeMilling cuttersShaping cuttersEngineeringAbutment

A cutting tool has at least one cutting insert seated therein. The cutting insert has a longitudinal axis, an upper surface, a lower surface and a peripheral surface that extends between the upper surface and the lower surface. At least a portion of an intersection between the upper surface and the peripheral surface constitutes a cutting edge. The lower surface has at least one set of base abutment surfaces, each set including at a least one major base abutment surface and at least one minor base abutment surface, the major and minor base abutment surfaces of a given set being spaced apart from one another along the longitudinal axis. When the lower surface has two such sets of base abutment surfaces, the major and minor base abutment surfaces of the first set are longitudinally displaced from the corresponding major and minor base abutment surfaces of the second set. Furthermore, the major and minor base abutment surfaces of the first set lie on a first base abutment plane while the major and minor base abutment surfaces of the second set lie on a second base abutment plane, the first and second base abutment planes forming a first non-zero angle therebetween.

Owner:ISCAR LTD

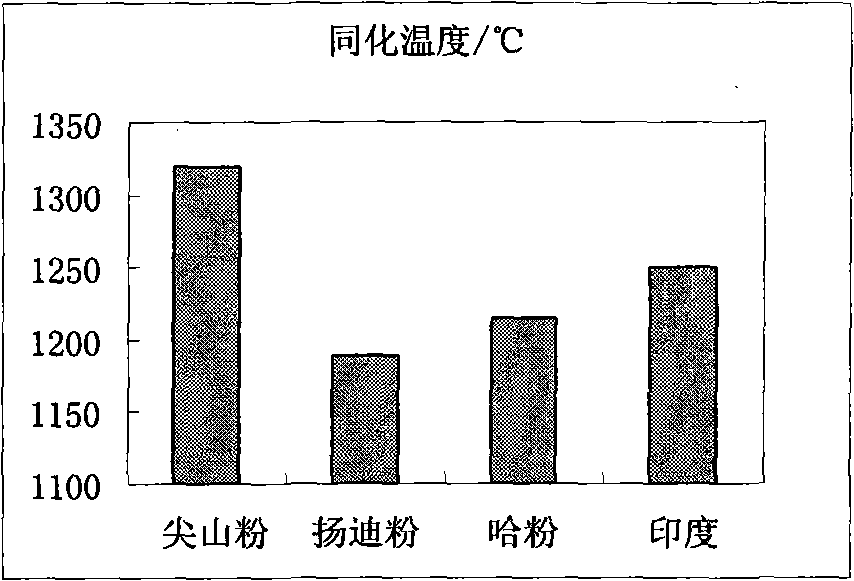

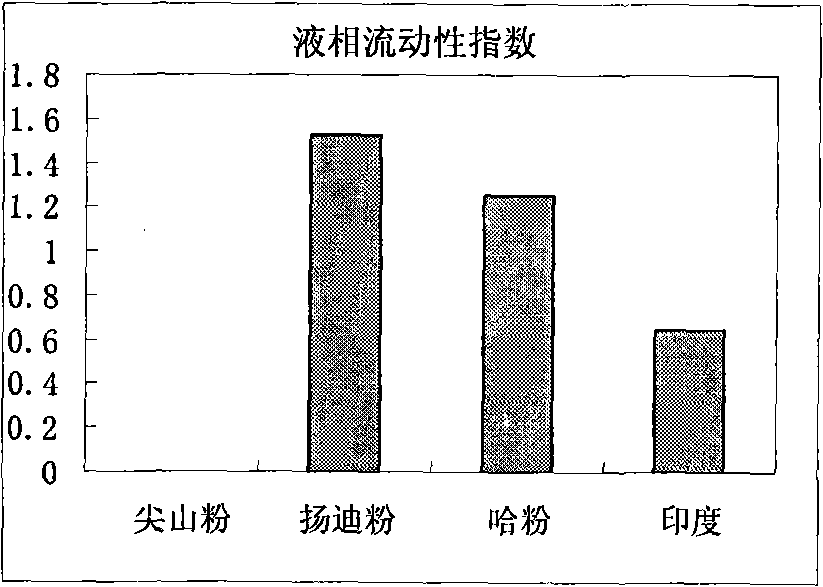

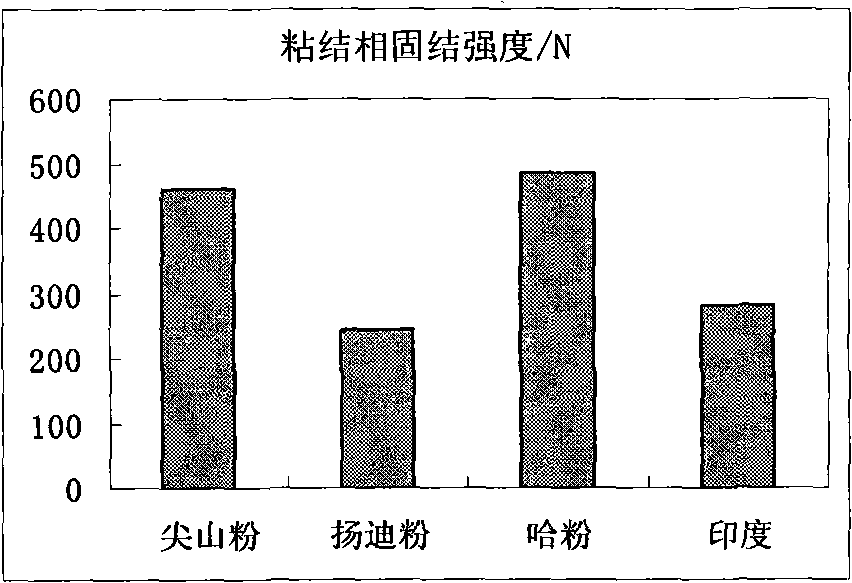

Method for sintering ore blending of Jianshan concentrate fines and limonite

The invention discloses a method for sintering ore blending of Jianshan concentrate fines and limonite, which comprises the following steps of: (1) preparing materials at a sintering site; (2) pre-humidifying Yangdi fines; (3) preparing iron materials; (4) blending the prepared iron materials, flux and fuel; (5) mixing the materials in a primary mixer; (6) pelletizing in a secondary mixer; (7) forcefully pelletizing in a ternary mixer; (8) distributing and pressing the materials; (9) igniting and keeping temperature; (10) sintering by pumping air; (11) cooling; (12) granulating. The method is mainly characterized in that: when the Yangdi fines are pre-humidified, the pre-humidifying moisture reaches 8.5 to 9.5 percent; in step (3), the iron materials comprise 40 to 50 parts of Jianshan fines, 33.5 to 43.5 parts of humidified Yangdi fines, 10 to 16 parts of pilbarablend (PB) fines and 0 to 4 parts of mixed fines; and in step (4), the mass part ratio of the mixed iron materials to blast-furnace return mine to lime to dolomite to coke powder is 77.8-78.8: 7-8: 4.8-5.7: 6-7: 2-3. In the invention, the ore blending is low in cost and cheap minerals are used rationally.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Shank milling cutter having a wiper radius

InactiveUS7094005B2Quality improvementGo fastMilling cuttersShaping cuttersMilling cutterEngineering

A shank milling cutter includes a cutting portion which is intended to come into engagement with the workpiece, wherein the envelope surface of the cutting portion is substantially cylindrical. At least one major cutting edge is arranged at the peripheral surface of the cutting portion and at least one minor cutting edge (face cutting edge) is arranged at the end face of the cutting portion and with an end diameter D. The minor cutting edge, in projection onto a plane containing the milling cutter axis, has a convexly curved portion with a radius of curvature R>D / 2 and a center of curvature M located such that a distance from the center of curvature M to the axis is in a range from zero to a value smaller than D / 2.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

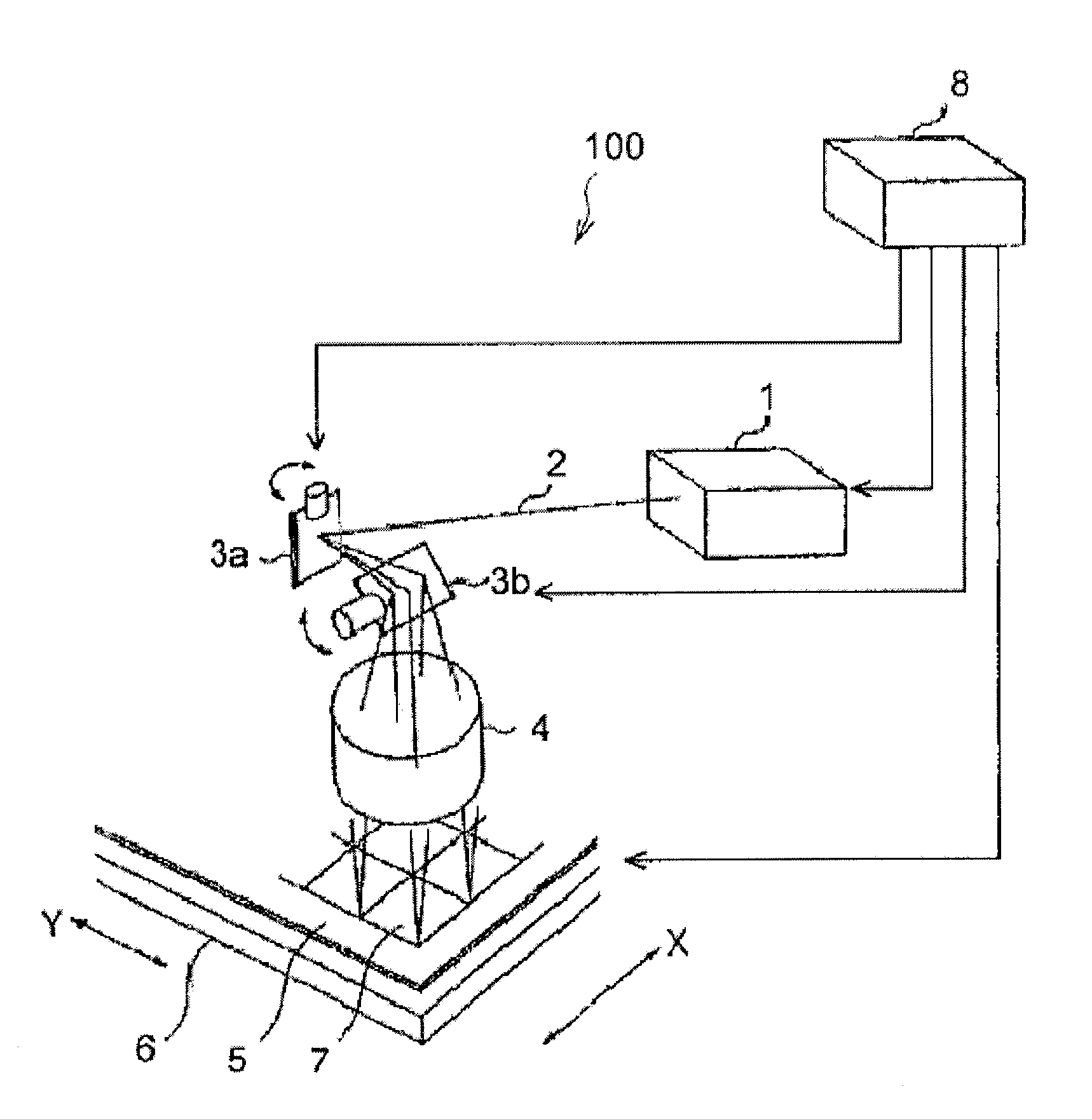

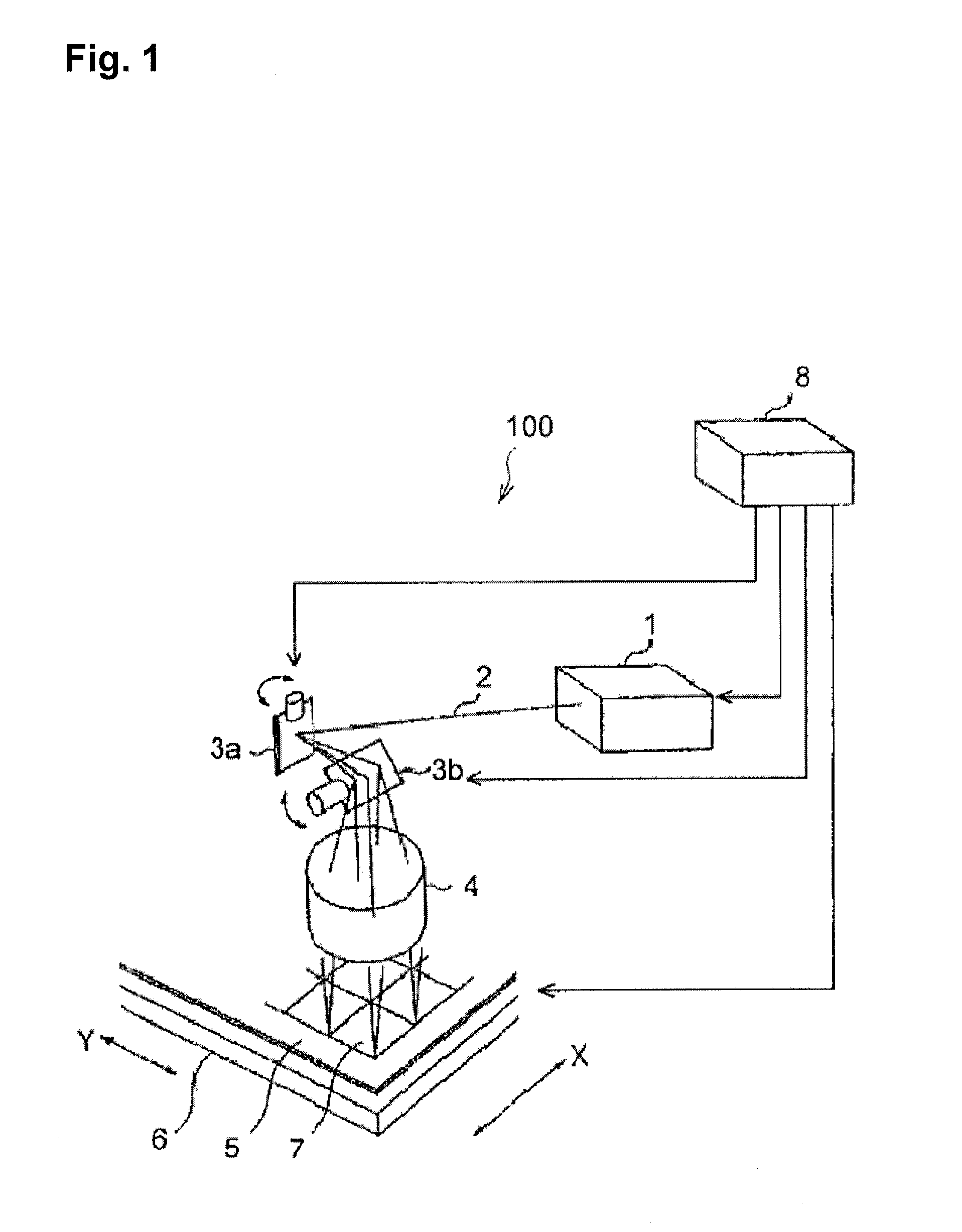

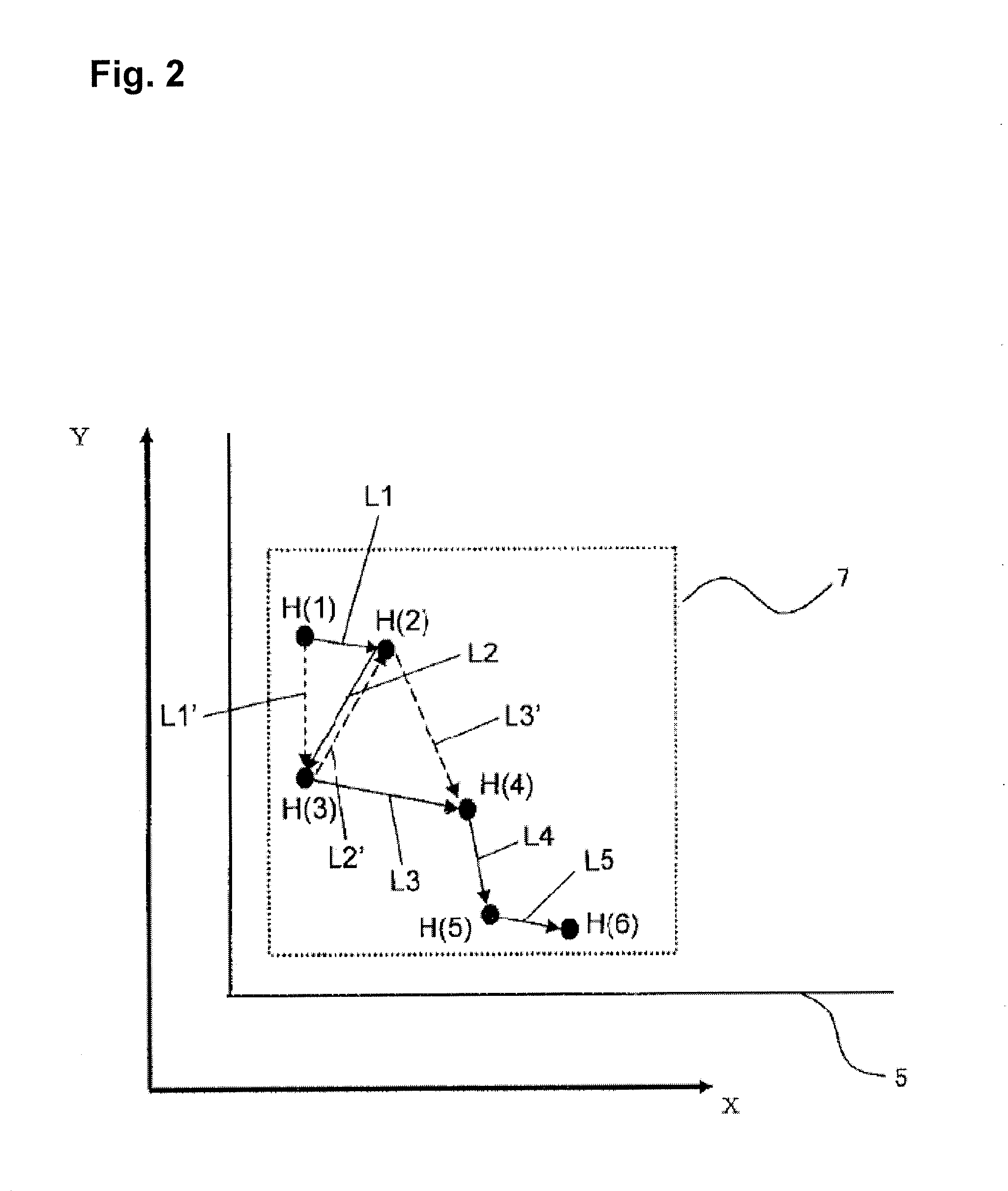

Laser machining method, laser machining apparatus, and laser machining program

ActiveUS20150021304A1Minimize changesImprove machine qualityForecastingCircuit board tools positioningShortest distanceEngineering

Variation in hole diameter due to heating effects is minimized even if the shortest machining route is set, and machining quality is improved. A printed circuit board to be scanned by a laser beam is divided into a plurality of scan areas (S1). An order of drilling within the scan area is sorted to obtain a scanning route with the shortest distance (S2). The order of the (N+1)th hole and the (N+2)th hole is swapped in each scanning area if it is determined that the distance between the Nth hole and the (N+1)th hole (here, N is an integer in a range of 1≦N≦“the maximum number of holes to be drilled in the area”−1″) is less than a predetermined threshold value, and that N+1 is not correspond to the maximum number of holes to be drilled in the scanning area (S3). The scanning area is machined and then machining each scanning area, specifically in machining the (N+1)th hole, after pausing for a period of a predetermined heat dissipation time if it is determined that the distance between the N-th hole and the (N+1)th hole swapped is less than the predetermined threshold value. Subsequently, machining is performed (S4).

Owner:HITACHI SEIKO LTD

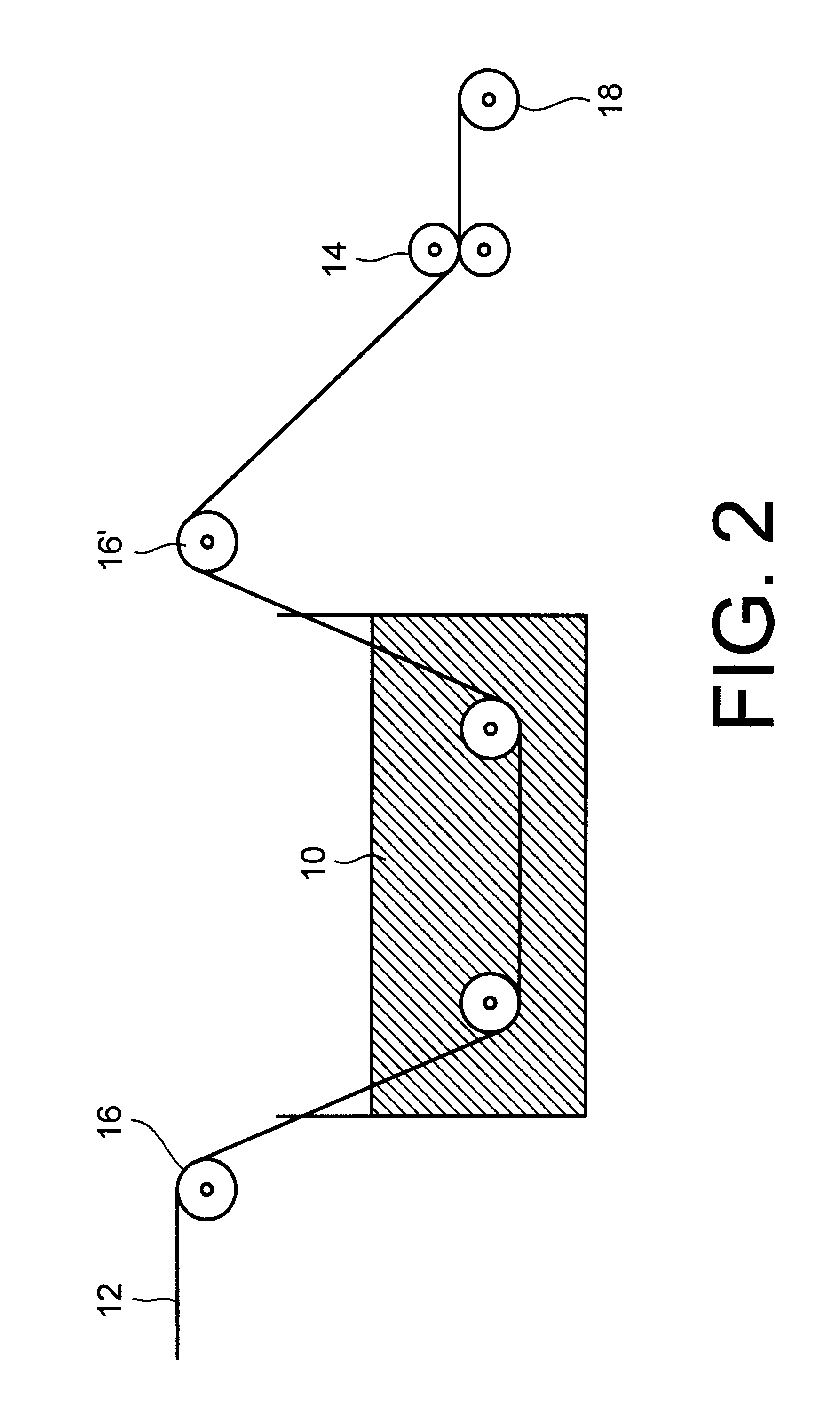

Techniques for cylindrical grinding

ActiveUS7658665B2Less-costly to disposeImprove working conditionsRevolution surface grinding machinesAbrasion apparatusMaterial removalMetallurgy

Methods for cylindrical grinding a workpiece are disclosed. The method includes cylindrical grinding, with a bonded abrasive wheel having a permeable structure that includes interconnected porosity, a workpiece at a specific cutting energy of less than about 12 Hp / in3·min (29.7 J / mm3), and a material removal rate of at least about 1 in3 / min·in (10.8 mm3 / sec / mm)grinding. The bonded abrasive wheel may include at least about 3 volume percent of a filamentary sol-gel alpha-alumina abrasive grain having an average length-to-cross-sectional-width ratio of greater than about 4:1, or agglomerates thereof. In one embodiment, the workpiece is ground in the presence of a water soluble oil.

Owner:SAINT GOBAIN ABRASIVES INC +1

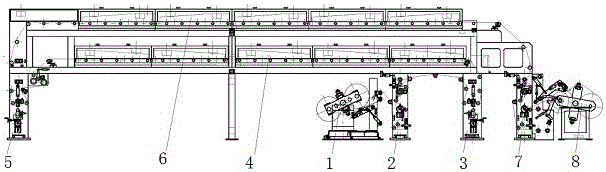

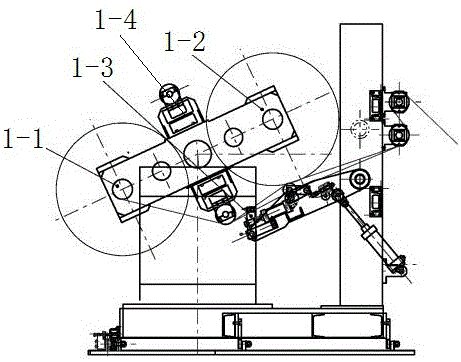

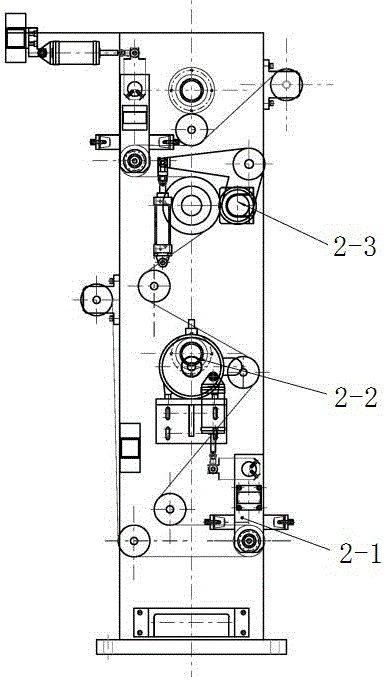

Double-sided high-speed gravure coating device and method for lithium battery

InactiveCN106626725AIncrease machine speedImprove work efficiencyRotary intaglio printing pressEngineeringCopper foil

The invention belongs to the technical field of gravure coating for lithium battery materials, and specifically relates to a double-sided high-speed gravure coating device and a method for a lithium battery. According to the double-sided high-speed gravure coating device for the lithium battery, coiled lithium battery materials, that is, aluminium foils or copper foils, sequentially pass through an unwinding mechanism, a charging traction mechanism and a front-surface coating mechanism from the left to right, then enter upwards a lower drying box and pass downwards through a back-surface coating mechanism, then pass upwards through an upper drying box from the left to right, and then pass downwards through a discharging traction mechanism and are led to a winding mechanism for winding. According to the double-sided high-speed gravure coating device and method for the lithium battery, a coating manner is changed into quantitative and same-direction high-speed coating adopting a cable from the original 'reverse coating adopting a micro-gravure roll', and the lengthened, high-temperature, high-air-quantity and energy-saving drying boxes are used, thus the drying time of the coated materials is shortened, and a machine speed can achieve 120m / min for completing one-time double-sided high-speed coating.

Owner:XIAN XINDA MACHINERY

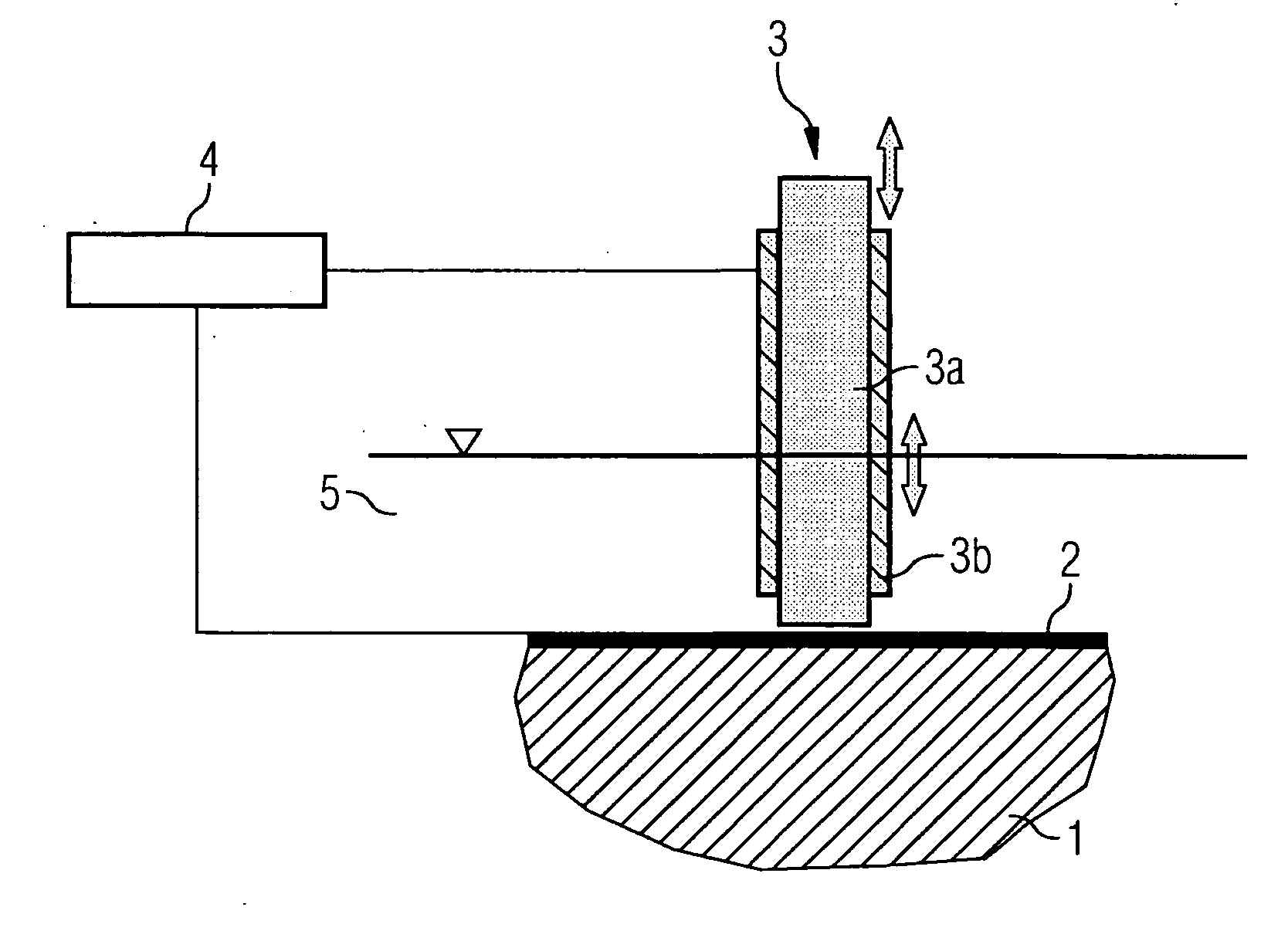

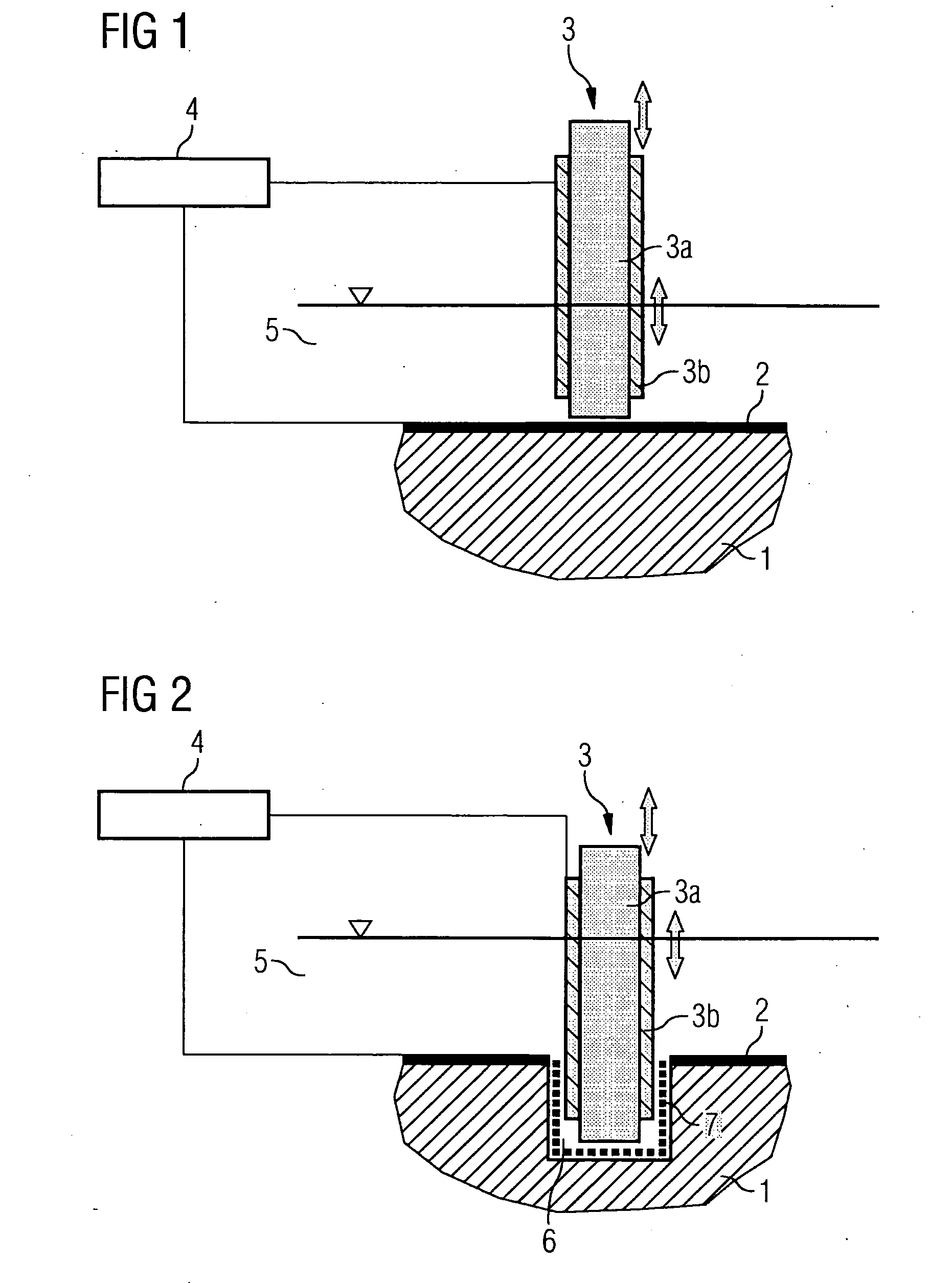

Electrode Arrangement for Electrical Discharge Machining on an Electrically Non-Conductive Material

InactiveUS20090200274A1Rapid and reliable formationErosion is goodArc welding apparatusElectrical-based machining electrodesConductive materialsElectrical discharge machining

The invention relates to an electrode arrangement for the electrical discharge machining of an electrically non-conductive material, which comprises a first component for removing the electrically non-conductive material and a second component for depositing an electrically conductive substance on the electrically non-conductive material.

Owner:SIEMENS AG

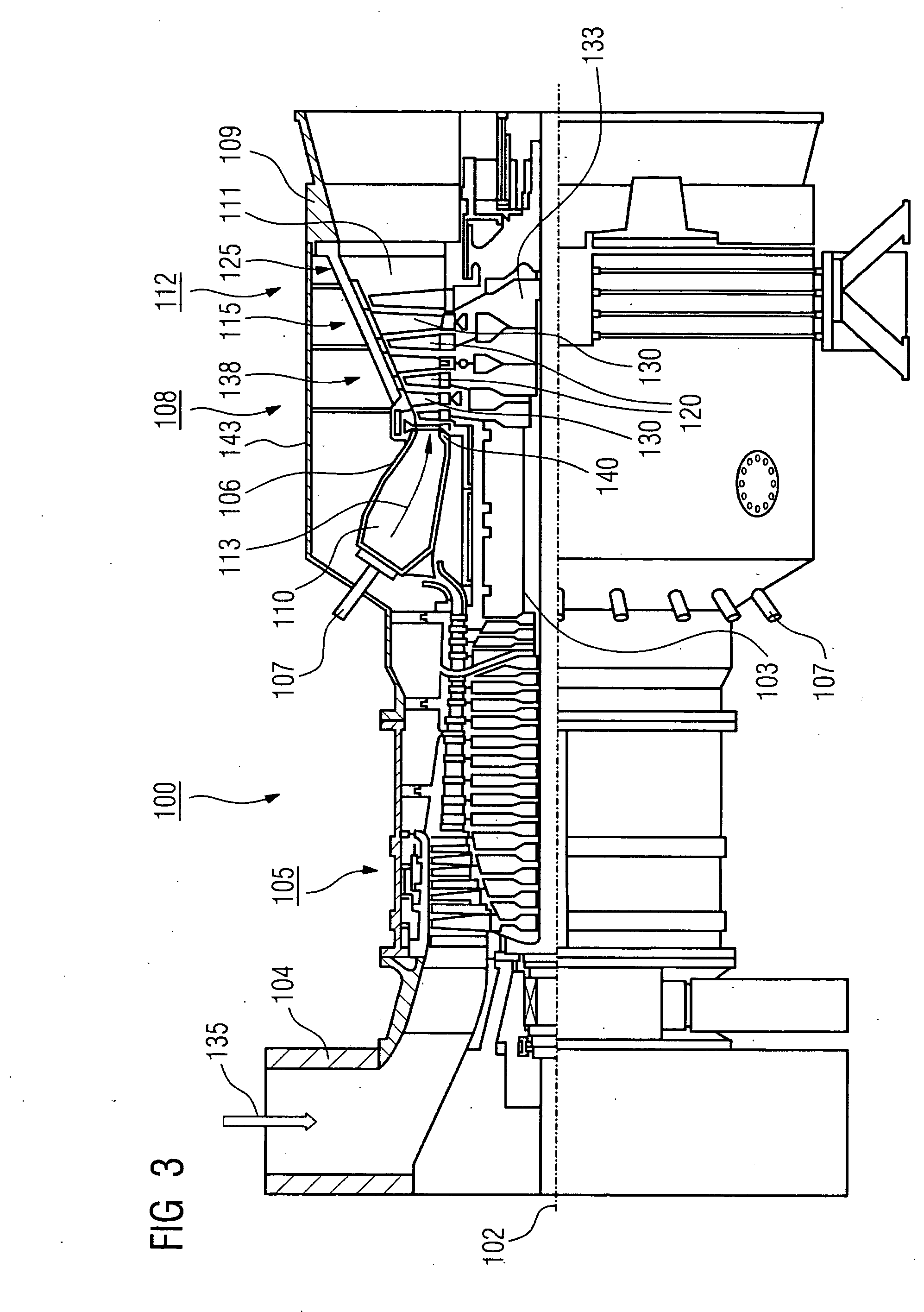

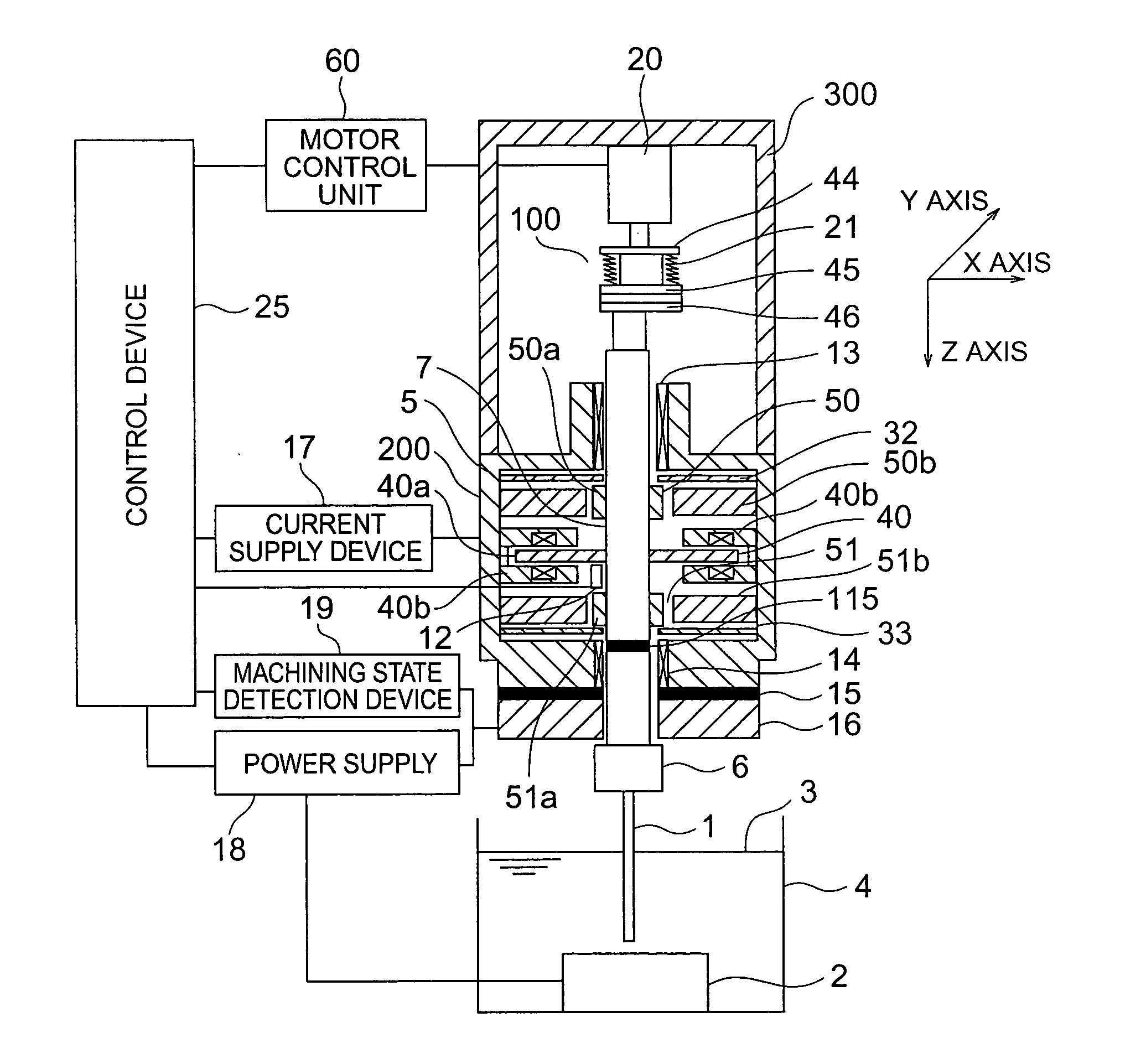

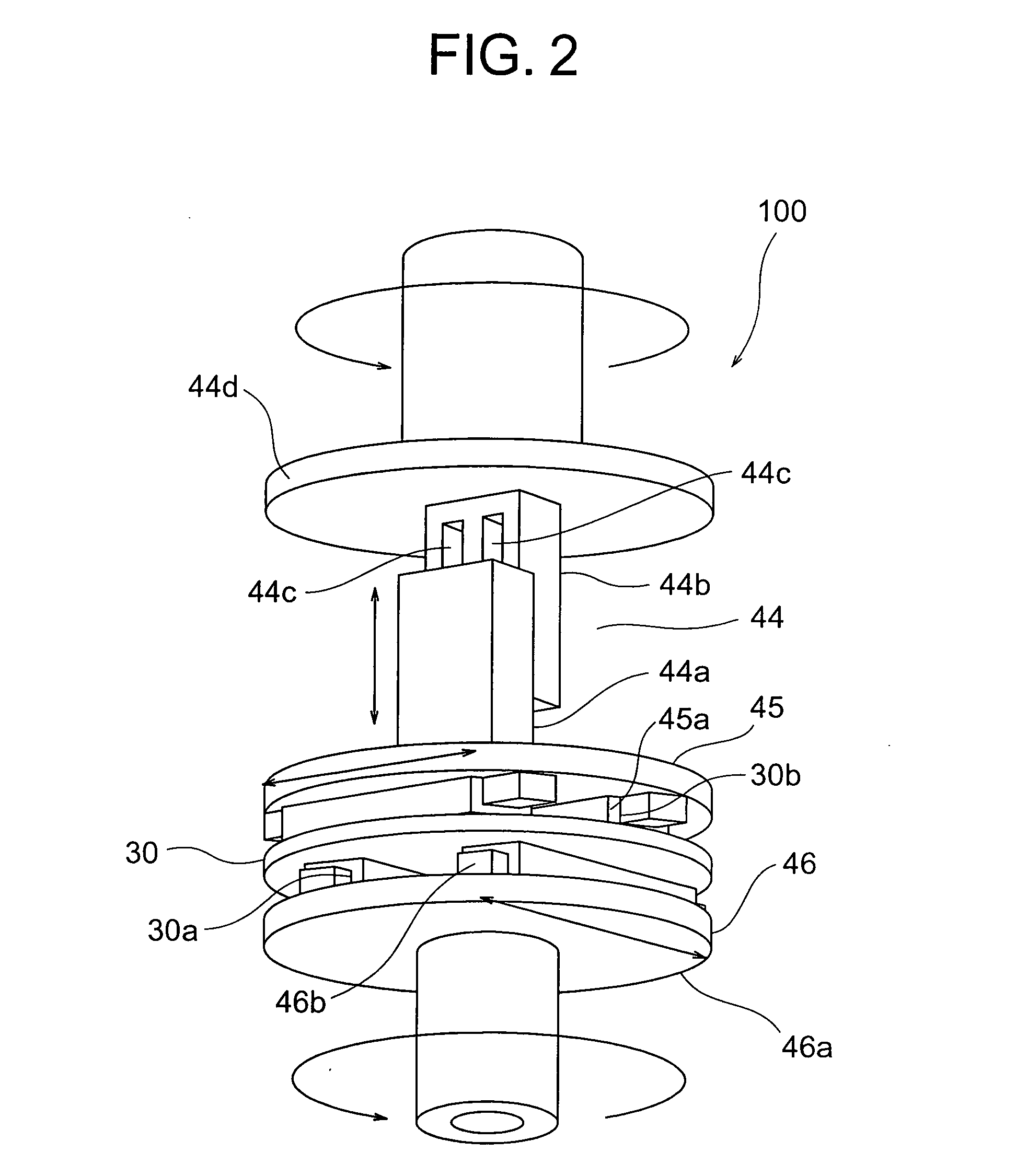

Electric discharge machining apparatus

InactiveUS20050016965A1Improve drivabilityIncrease machine speedElectrode vibration holdersResistance welding apparatusMagnetic bearingElectric discharge

An electric discharge machining apparatus has improved responsive drivability and improved machining speed. A tool electrode has a tip end directed toward a work piece, a voltage applied between the tool electrode and the work piece generating a discharge. A drive shaft is connected with the tool electrode. An electrode driving device has magnetic bearings for moving the drive shaft in three directions including a Z-axis direction which is an axial direction of the drive shaft, a Y-axis direction perpendicularly crossing the Z-axis direction, and an X-axis direction perpendicularly crossing the Y-axis direction and Z-axis direction, by supplying electric current to electromagnetic portions to control magnetic attraction. A movable coupling is connected with an end of the drive shaft and is movable in the three directions. An electric motor is connected with an end of the coupling for rotating the drive shaft through the coupling.

Owner:MITSUBISHI ELECTRIC CORP

Distributor device and method for filling cigarette strand machine

The invention relates to a distributor device and a method for filling a cigarette strand machine, in particular to a distributor device which comprises an input device for inputting a first mix ingredient M1, a conveyer for conveying the other mix ingredient M2, a separator, and a storage compartment arranged behind the separator, wherein an extracting roller which is arranged at the outlet side of the storage compartment is used for conveying the separated mix ingredients in the separator to a receiving cavity; at least the conveyer is not a returning device in the distributor device; and the distributor device has the advantages that the conveyer for conveying at least the other mix ingredient M2 is inserted into the receiving cavity in the manner as follows behind the storage compartment on the conveying direction T1 of the first mix ingredient M1 input by the input device and flowing by the separator: the cigarette mixture formed by the mix ingredients M1 and M2 can be made in the common receiving cavity at the earliest. Besides, the invention relates to a relevant method.

Owner:KOERBER TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com