Hair-planting machine

A technology of hair machine and hair nozzle, which is applied in the field of brush machinery, can solve the problems of low hair planting efficiency, time-consuming and manpower, and achieve the effect of saving time and manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples illustrate the present invention, but the present invention is not limited to the following examples.

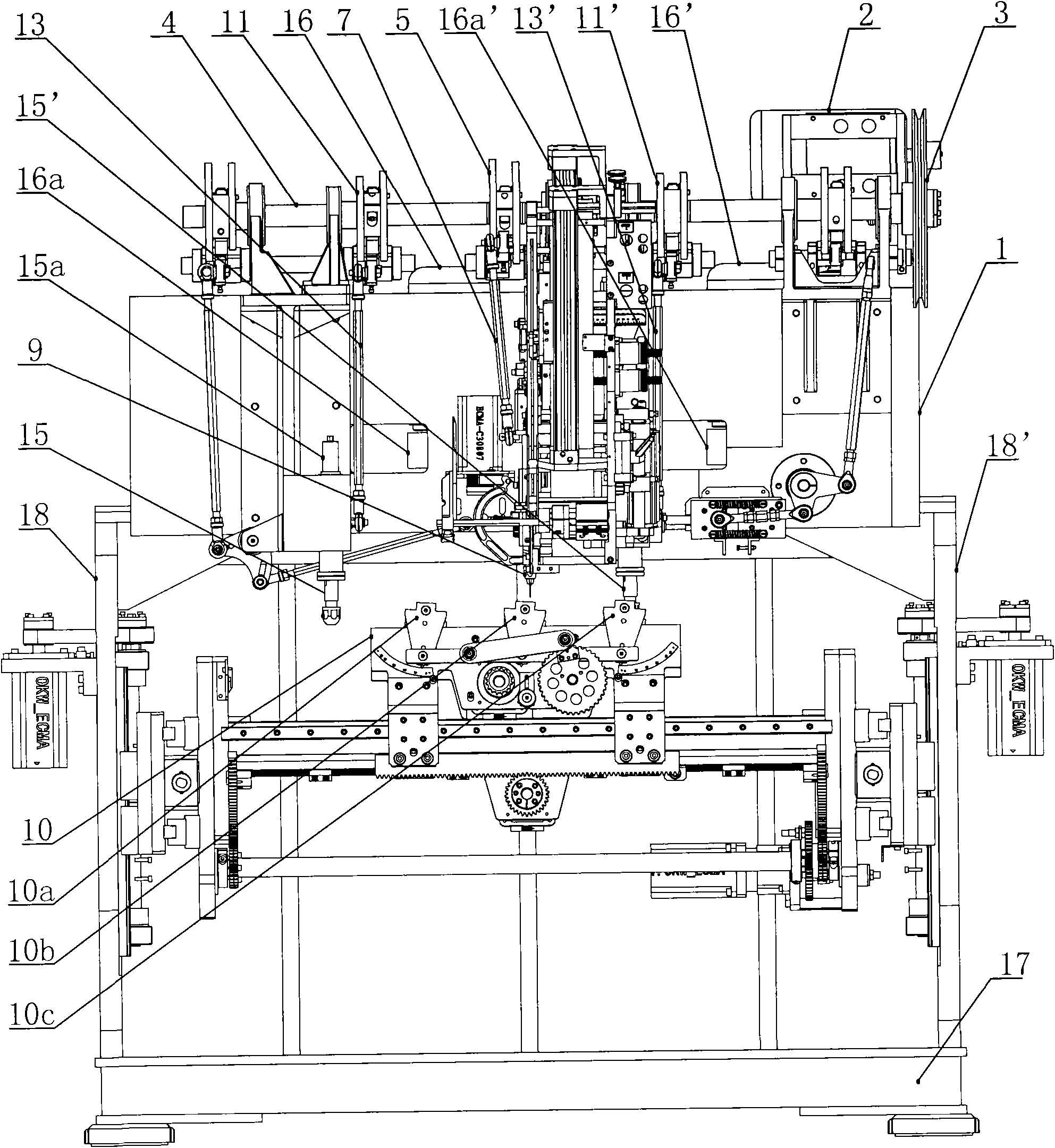

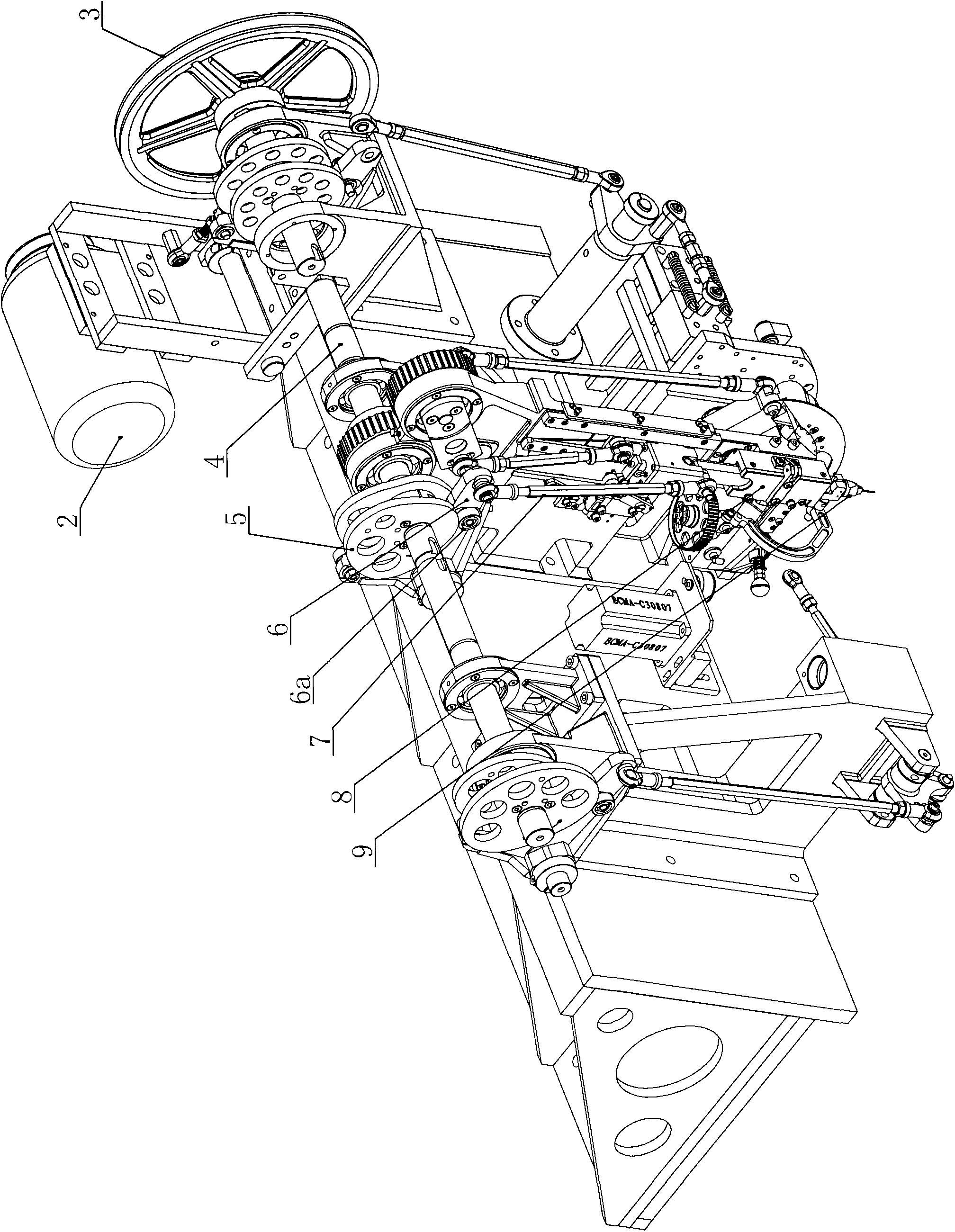

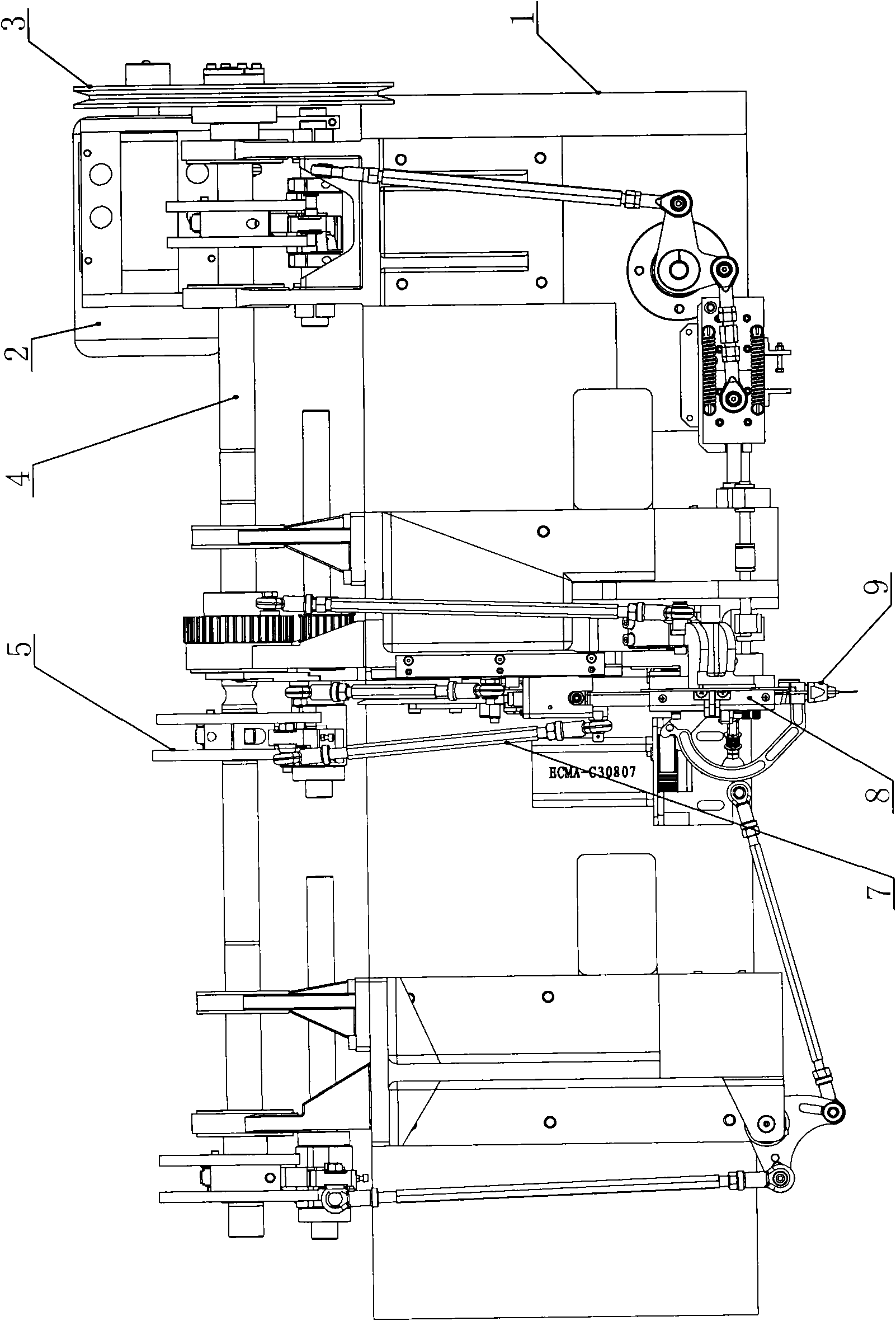

[0018] Such as figure 1 As shown, the tufting machine of the present invention includes a frame 1 on which a main motor 2, a main shaft 4, a brush workbench 10 and a nozzle movement mechanism are installed, and the main motor 2 is connected to the main shaft 4 through a main shaft pulley 3.

[0019] The brushing machine workbench comprises a base 17 and wall panels connected to the both sides of the base 17. The inner sides of the left wall panel 18 and the right wall panel 18' are respectively provided with a lift movement support, a front and rear movement support and a swing support. The lift movement supports on both sides are respectively It can move up and down along the vertical guide rails on the left and right wall panels. The front and rear movement brackets are respectively located inside the lifting movement brackets and can move for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com