Distributor device and method for filling cigarette strand machine

A technology of dispensers and bundles, which is applied in the fields of application, tobacco, and manufacturing of paper cigarettes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

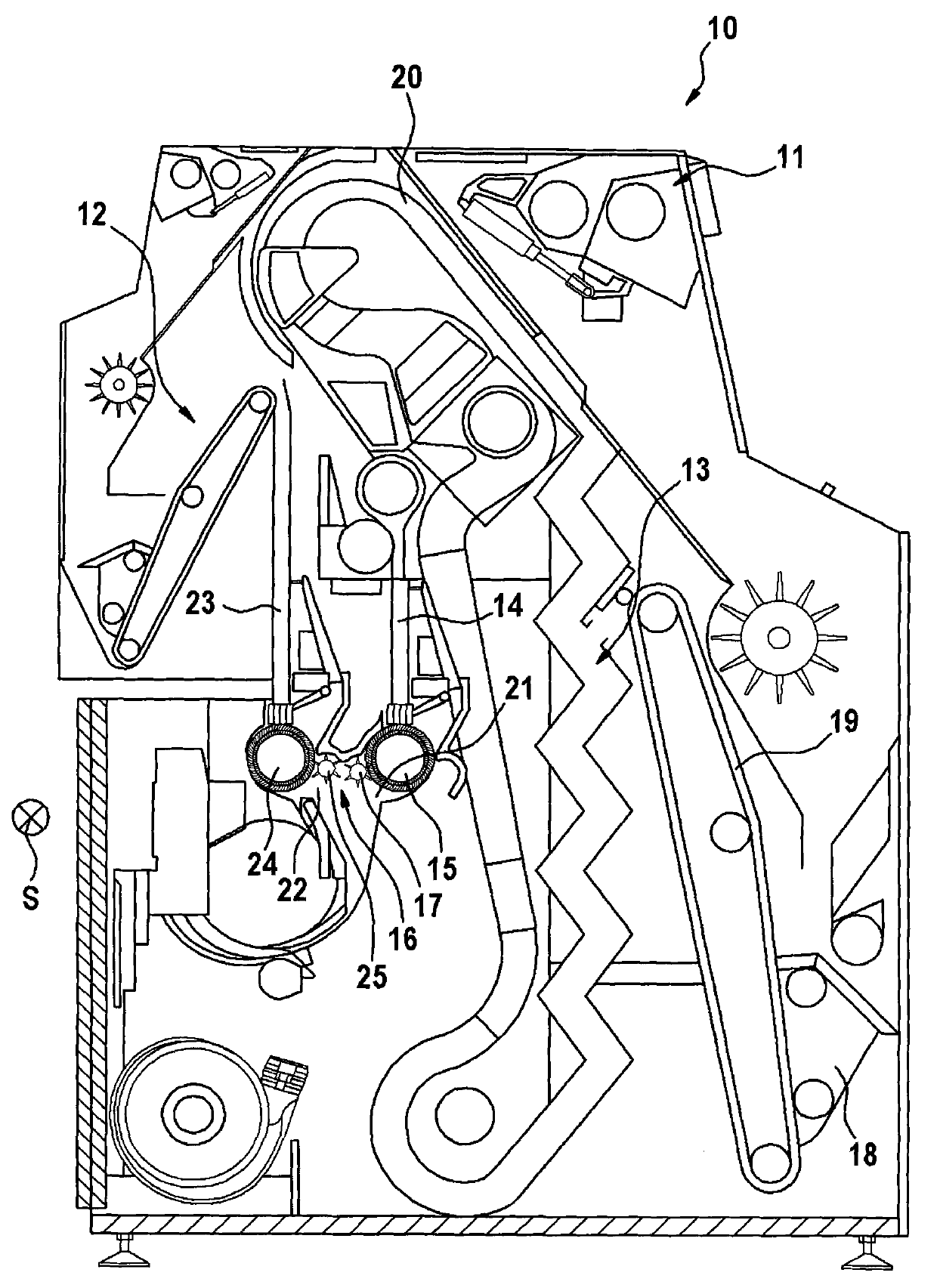

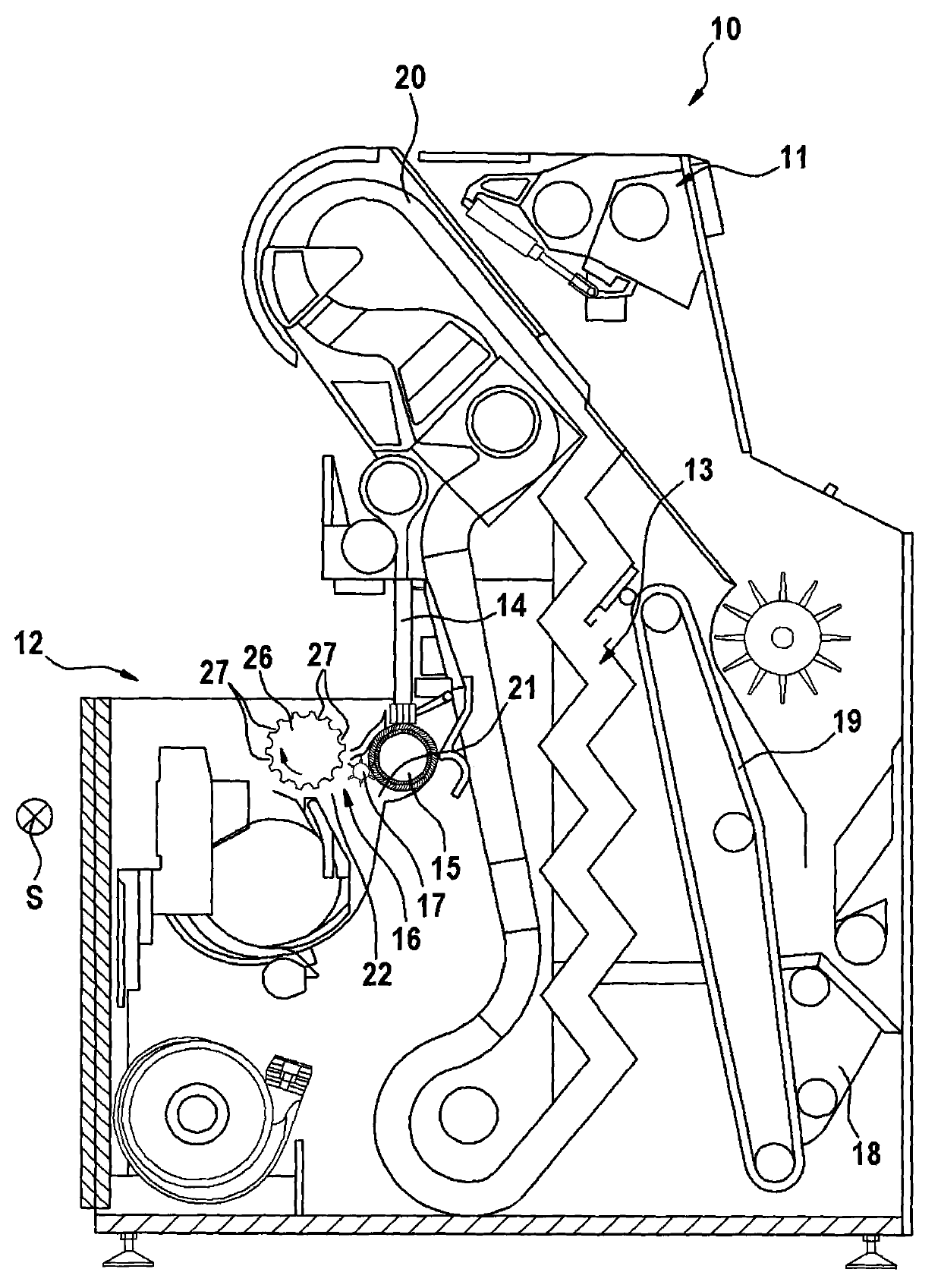

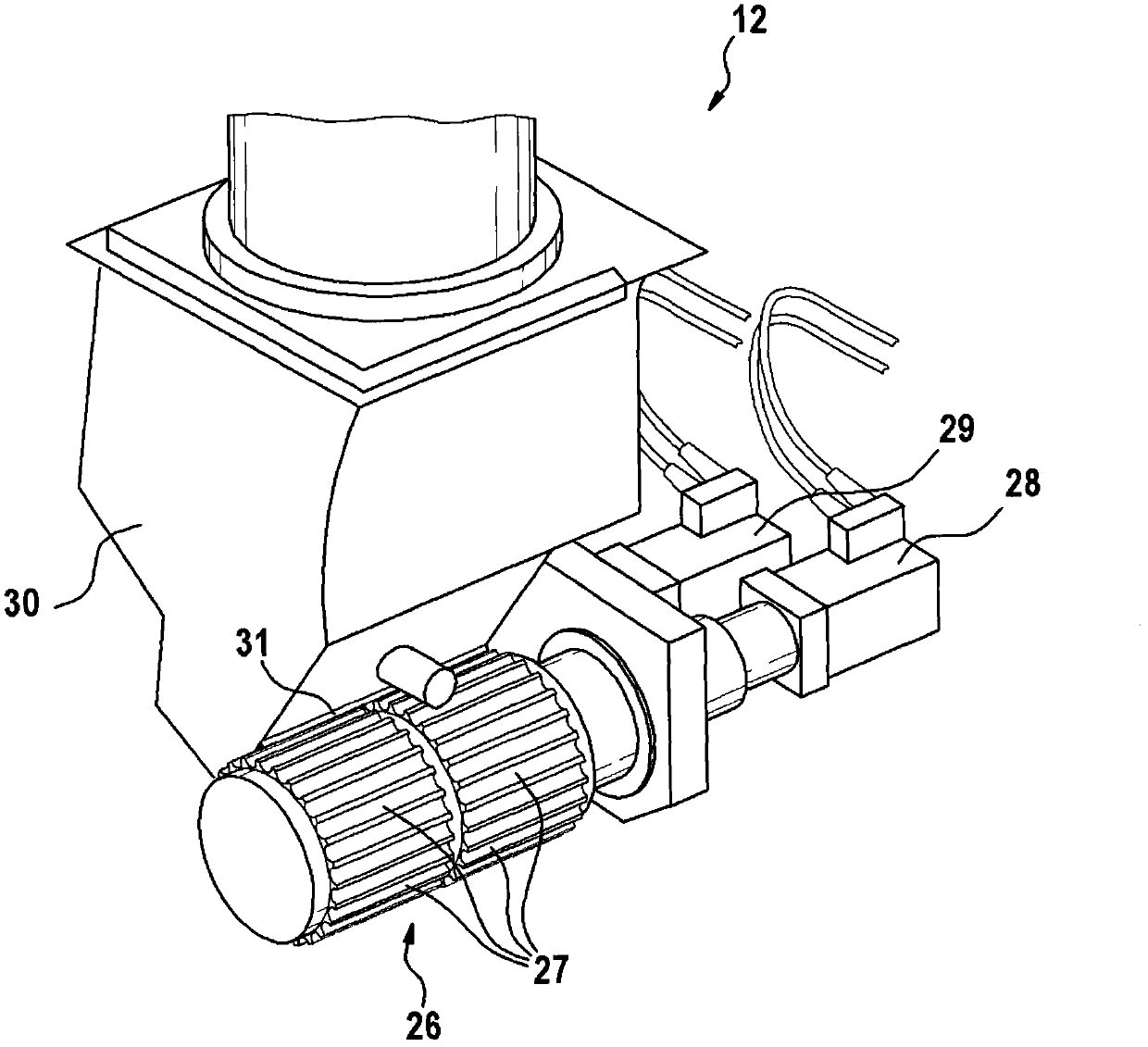

[0022] The dispenser device according to the invention is used for feeding single-bundle or multi-bundle cigarette rod machines with a tobacco mixture formed from a plurality of mixture components, wherein the dispenser device always has at least two separate and separate external inlets for the mixture components.

[0023] The dispenser device 10 depicted in the drawing comprises a device for inputting a first mixture component M 1 The input device 11 and for delivering another mixture component M 2 The delivery device 12. Mixture component M 1 and M 2 Each can be made from one mixture component or from multiple mixture components. Below, the mixture component M 1 Also known as the principal component, and the mixture component M 2 called auxiliary components. In addition, the dispenser device 10 has a function for dispensing one of the mixture components M 1 or M 2 The separator 13 which separates the part to be processed from the part not to be processed. Arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com