Color adjustable anti-icing anti-fog electric heating film for civil aircraft port glass and preparation method thereof

A porthole glass, civil aircraft technology, applied in the direction of coating, can solve problems such as lack, and achieve the effects of soft and adjustable color, high film adhesion, excellent weather resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

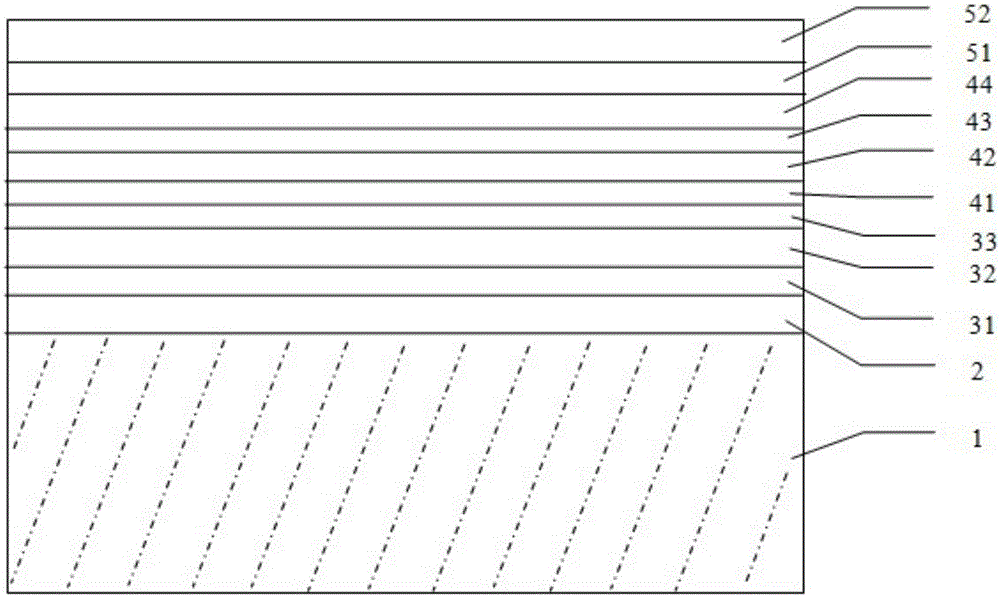

[0029] The present invention relates to a color-tunable anti-icing and anti-fog electric heating film for the porthole glass of a civil aircraft, which comprises a glass substrate, an isolation layer, An electric heating layer, a toning layer and a protective layer, the glass substrate sequentially includes an isolation layer, an electric heating layer, a toning layer and a protective layer from inside to outside.

[0030] The isolation layer is used to block the impurity ions in the glass substrate from entering the subsequent functional layer to affect the effect. The electric heating layer uses metal titanium to achieve low resistance. Metal titanium has excellent chemical stability and can increase the service life. The coloring layer uses metal and oxidation Realized by the combination of materials, the protective layer is made of indium tin oxide and silicon oxide, which has corrosion resistance and friction resistance, and is used to protect the film layer from the exter...

Embodiment 2

[0046] The difference between Embodiment 2 and Embodiment 1 is: a kind of adjustable anti-icing and anti-fog electric heating film for civil aircraft porthole glass of the present invention, the adjustable anti-icing and anti-fog electric heating film for civil aircraft porthole glass The electric heating film comprises a glass substrate, an isolation layer, an electric heating layer, a toning layer and a protective layer, and the glass substrate sequentially comprises an isolation layer, an electric heating layer, a toning layer and a protective layer from inside to outside.

[0047] The glass substrate is an aircraft porthole glass substrate; the isolation layer is a first silicon oxide layer 2, and the film thickness of the first silicon oxide layer is 35 nm.

[0048] The electric heating layer includes a first indium tin oxide layer 31, a metal titanium layer 32 and an indium tin oxide layer 33 from the inside to the outside, the film thickness of the first indium tin oxide...

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is: a kind of color-tunable anti-icing and anti-fog electric heating film for civil aircraft porthole glass of the present invention, the color-tunable anti-icing and anti-fog electric heating film for civil aircraft porthole glass The electric heating film comprises a glass substrate, an isolation layer, an electric heating layer, a toning layer and a protective layer, and the glass substrate sequentially comprises an isolation layer, an electric heating layer, a toning layer and a protective layer from inside to outside.

[0059] The glass substrate is an aircraft porthole glass substrate; the isolation layer is a first silicon oxide layer 2, and the film thickness of the first silicon oxide layer is 28nm.

[0060] The electric heating layer includes a first indium tin oxide layer 31, a metal titanium layer 32 and an indium tin oxide layer 33 from the inside to the outside, the film thickness of the first indium tin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com