Axial Flux Machine

a technology of axial ribs and axial ribs, which is applied in the direction of dynamo-electric machines, dynamo-electric components, magnetic circuit shapes/forms/construction, etc., can solve the problems of loss of rigid structure in which a bearing can be mounted to support the rotor, costing machines to machine radial ribs, and adding length to the axial dimension of the motor, so as to achieve the effect of increasing the stiffness of the ro

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

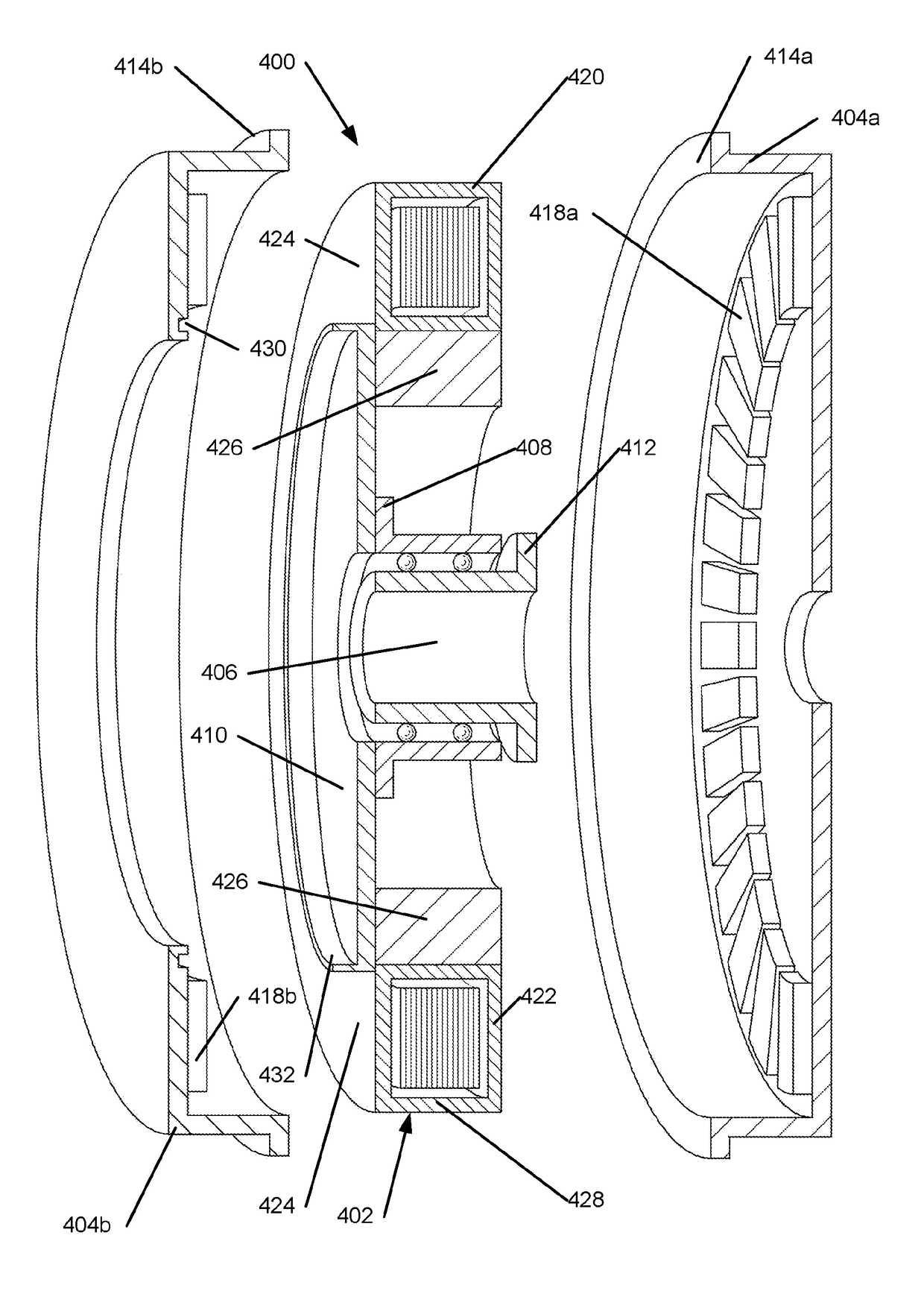

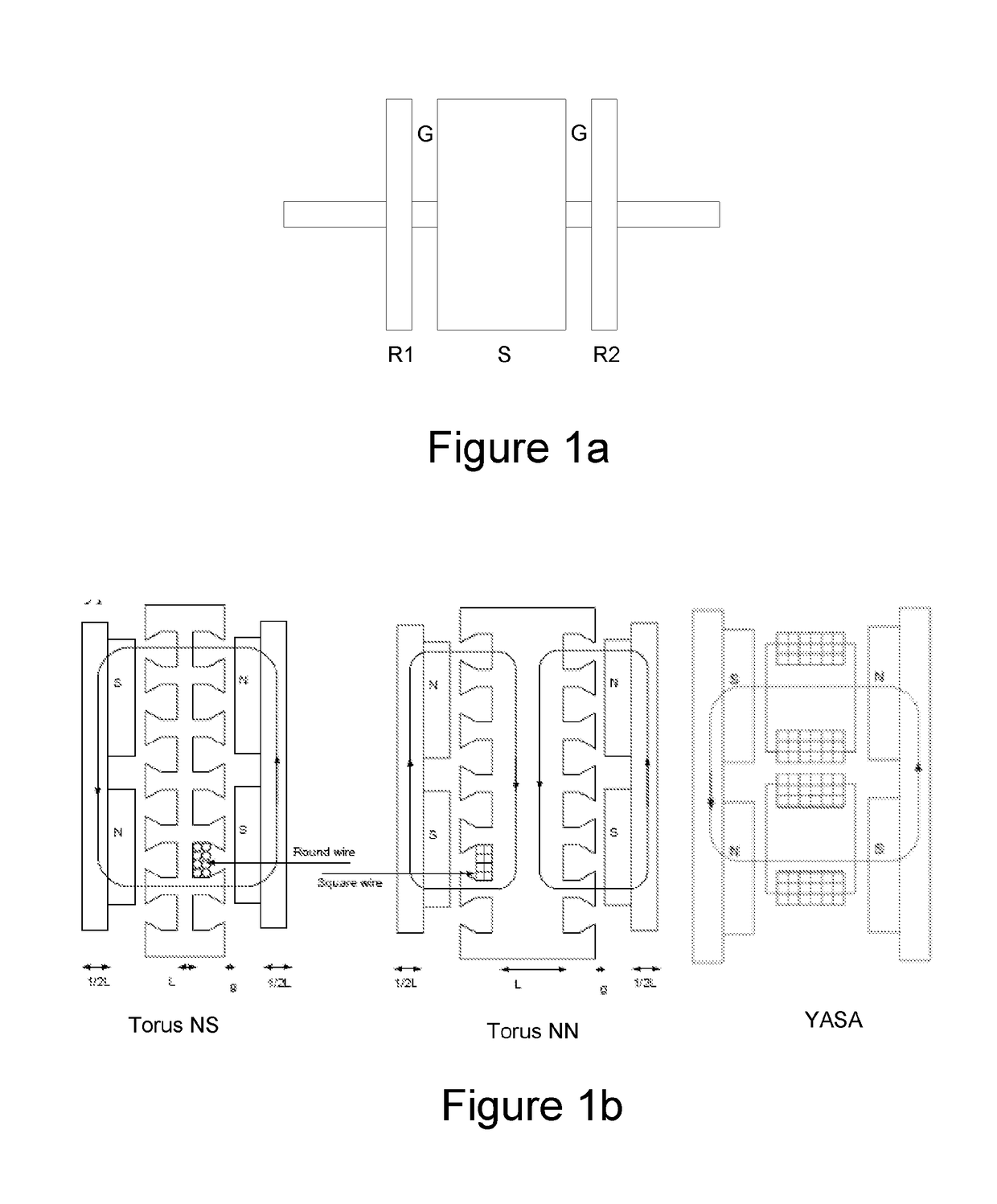

Embodiment Construction

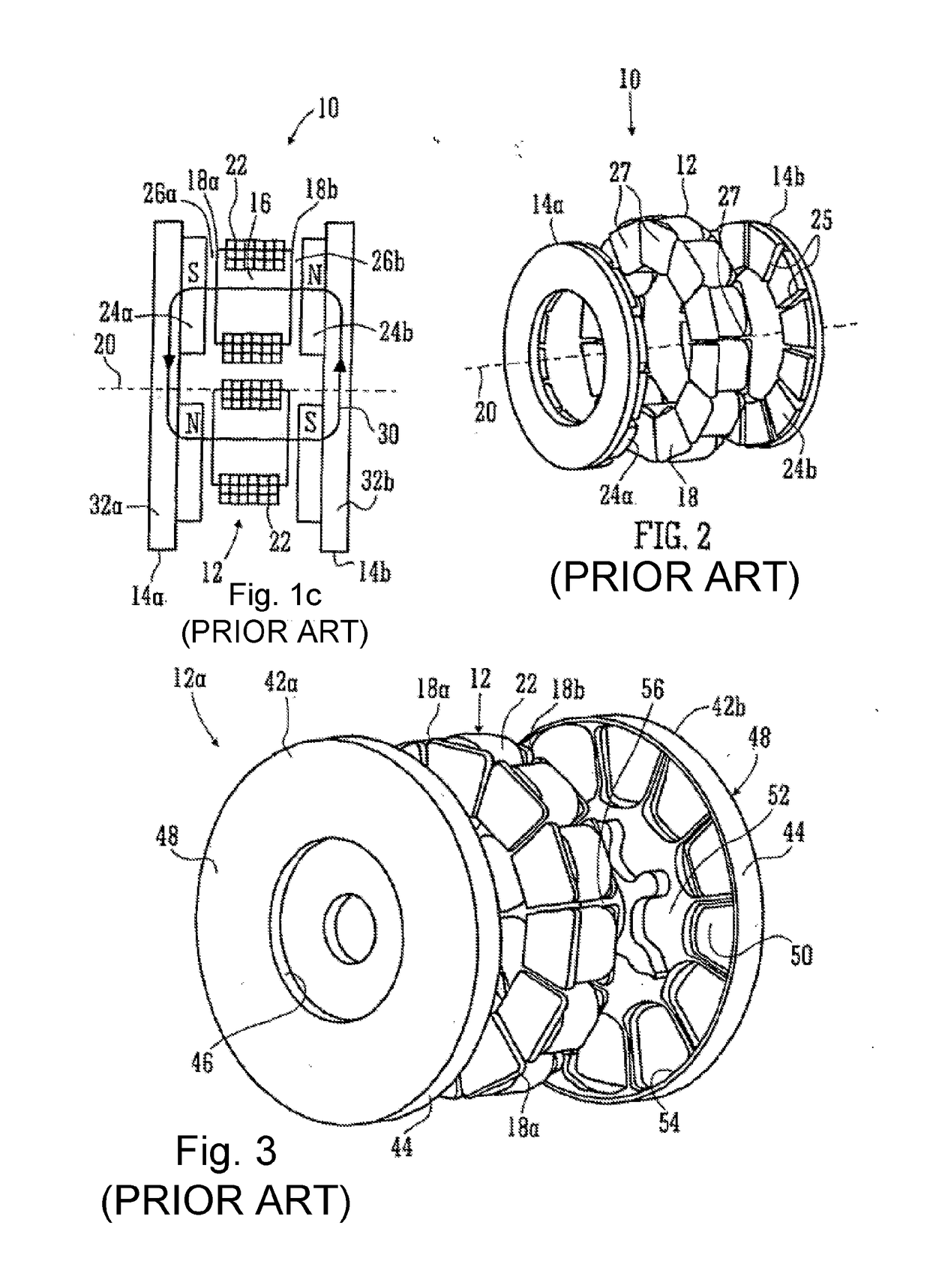

[0051]Referring first to FIGS. 1c, 2 and 3, which are taken from our PCT application WO2012 / 022974, FIG. 1c shows a schematic illustration of a yokeless and segmented armature machine 10.

[0052]The machine 10 comprises a stator 12 and two rotors 14a,b. The stator 12 is a collection of separate stator bars 16 spaced circumferentially about a rotation axis 20 of the rotors 14a,b. Each bar 16 has its own axis (not shown) which is preferably, but not essentially, disposed parallel to the rotation axis 20. Each end of each stator bar is provided with a shoe 18a,b which serves a physical purpose of confining a coil stack 22, which stack 22 is preferably of square / rectangular section insulated wire so that a high fill factor can be achieved. The coils 22 are connected to an electrical circuit (not shown) that, in the case of a motor, energizes the coils so that the poles of the resultant magnetic fields generated by the current flowing in the coils is opposite in adjacent stator coils 22.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com