Cyclic heating high efficiency 3D printer nozzle device

A 3D printer, cycle heating technology, applied in coating devices, processing heating elements, 3D object support structures, etc., can solve the problems of easy blockage of nozzles, low efficiency of nozzle filament output, and melting of nozzle filaments, etc., to prevent Premature softening of consumables, poor heat dissipation effect, and avoiding the accumulation of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

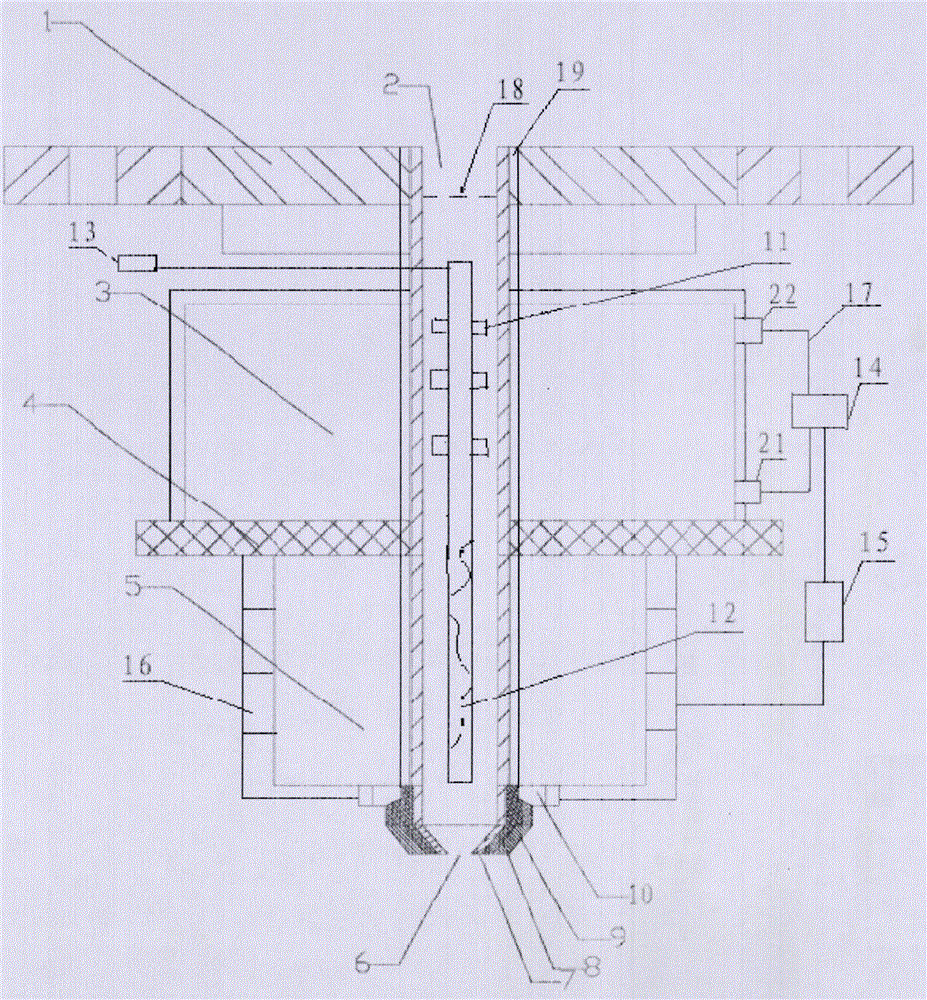

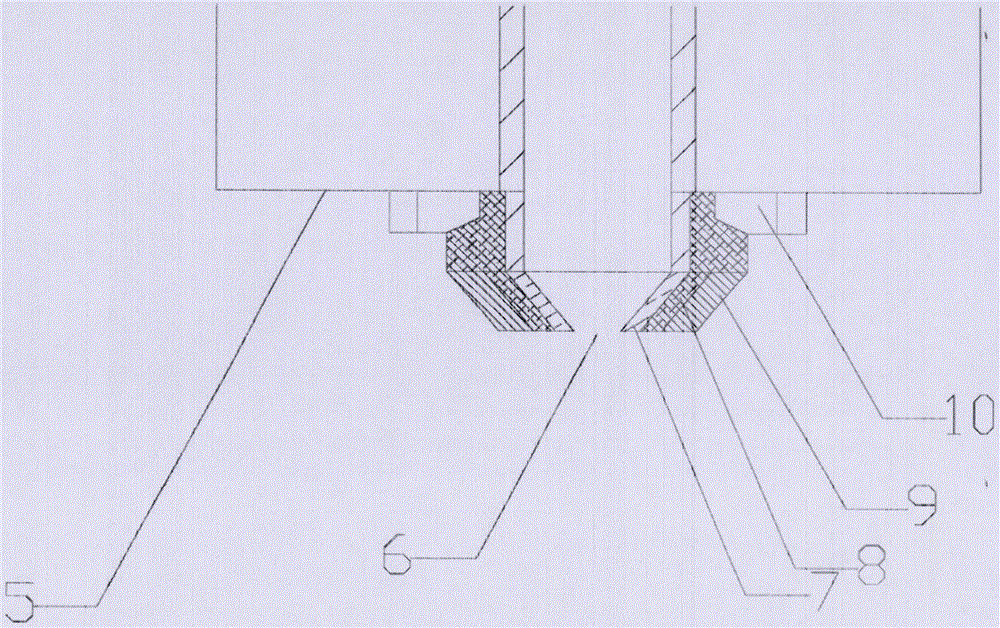

[0020] The following will combine figure 1 , figure 2 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0021] A high-efficiency 3D printer nozzle device capable of circulating heating, including a substrate 1, a feeding pipe 2 is arranged in the middle of the substrate 1, the main body of the feeding pipe 2 is located below the substrate 1, and the bottom of the feeding pipe 2 is a nozzle 6. In the feeding pipe The outer side of the upper part of 2 is provided with a heat dissipation part 3, which is used to ensure that the temperature of the material is the same as that of the outside world, so that the material in the feeding pipe can move normally in it, and the outside of the lower part of the feeding pipe 2 is a heating part 5, and the effect of the heating part 5 is to make the The temperature of the material increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com