Patents

Literature

95results about How to "Not easy to cure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

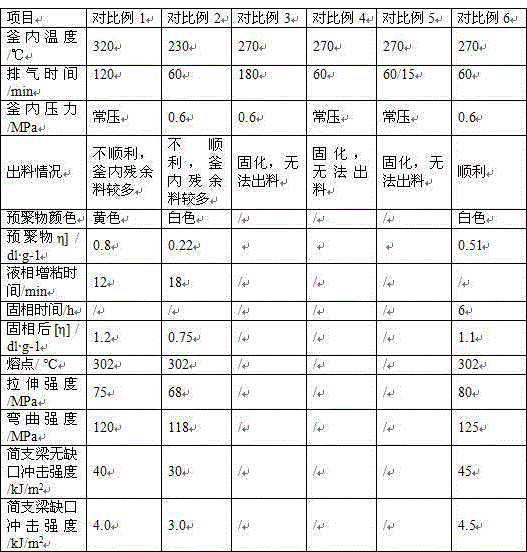

Preparation method for semi-aromatic nylon

A preparation method for semi-aromatic nylon comprises the following steps: weighing a nylon salt mixture, an end-capping reagent, a catalyst, an antioxidant and deionized water in parts by mass, adding the raw materials into a polymerization reaction kettle, and closing the reaction kettle, wherein an inert atmosphere is kept in the kettle; raising the temperature in the kettle to over 160 DEG C by heating and raising the pressure to over 1.2MPa, wherein the raw materials added into the polymerization reaction kettle fully react; then continuously raising the temperature in the kettle to over 250 DEG C, releasing vapor in the polymerization reaction kettle to gradually reduce the pressure in the kettle to be less than 0.8MPa, and finally discharging a prepolymer obtained by reaction out of the kettle; firstly crushing the obtained prepolymer; and then fusing the prepolymer through an extruder and conveying the prepolymer to a liquid phase viscosity-increasing kettle to quickly and effectively improve the viscosity of the prepolymer so as to obtain a semi-aromatic nylon product. According to the method provided by the invention, discharge is smooth and the yield is high, and the prepolymer with moderate viscosity is obtained, so that the viscosity is quickly and effectively increased in the later stage preferably.

Owner:株洲时代工程塑料科技有限责任公司

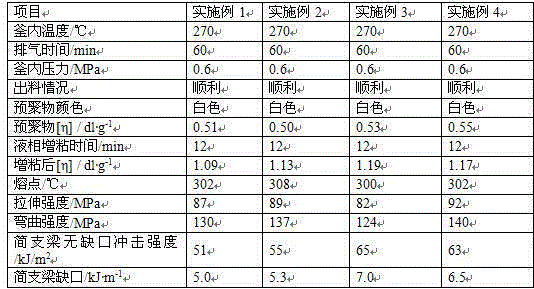

Crackle paint and preparation method thereof

InactiveCN102031049ANo need to worry about unusable problemsSave the supporting processCoatingsAcrylic resinTG - Triglyceride

The invention provides a crackle paint, comprising thermoplastic acrylic resin, crack agent and solvent, wherein the temperature of Tg (triglyceride) of the thermoplastic acrylic resin is 70-80 DEG C, and the crack agent is mica powder with the average particle size of 2000-3000 meshes. The invention also provides a preparation method of the crackle paint, comprising the steps of adding the thermoplastic acrylic resin, crack agent and solvent into a container, mixing and stirring. The invention has the advantages of simple steps when using the crackle paint provided by the invention and smallpossibility of picking of the crackle paint layer after being sprayed.

Owner:BYD CO LTD

Castor oil modified polyurethane adhesive combination for artificial turf gum

InactiveCN101921569ALow costImprove machinabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveChemistry

The invention discloses a castor oil modified polyurethane adhesive combination for an artificial turf gum. The adhesive combination wholly or partially substitutes petro-derived polyalcohol polyurethane adhesive by using renewable material-derived castor oil as polyalcohol to reduce cost, improve processability and ensure environmental friendliness, and simultaneously based on the synergetic effects of modified nano inorganic fillers and the castor oil, maintains the required important performance of the artificial turf, such as withdrawal force, processability, viscosity and curing rate. The polyurethane adhesive combination for the artificial turf gum comprises the following components in portions by weight: 50-98 portions of castor oil, 0-50 portions of polyalcohol, 2-30 portions of chain extender, 0.1-3 portions of catalyst, 0.1-3 portions of surfactant, 0.1-3 portions of pigment, 0.1-3 portions of thixotropic agent, 100-300 portions of modified nano inorganic filler and 10-100 portions of organic polyisocyanate.

Owner:COCREATION GRASS CO LTD

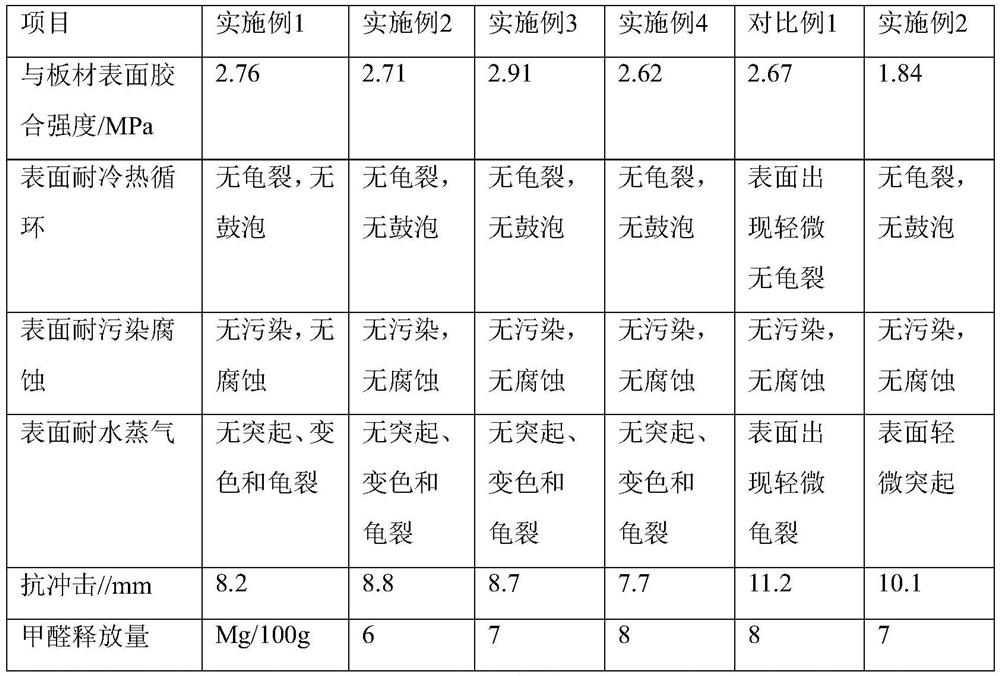

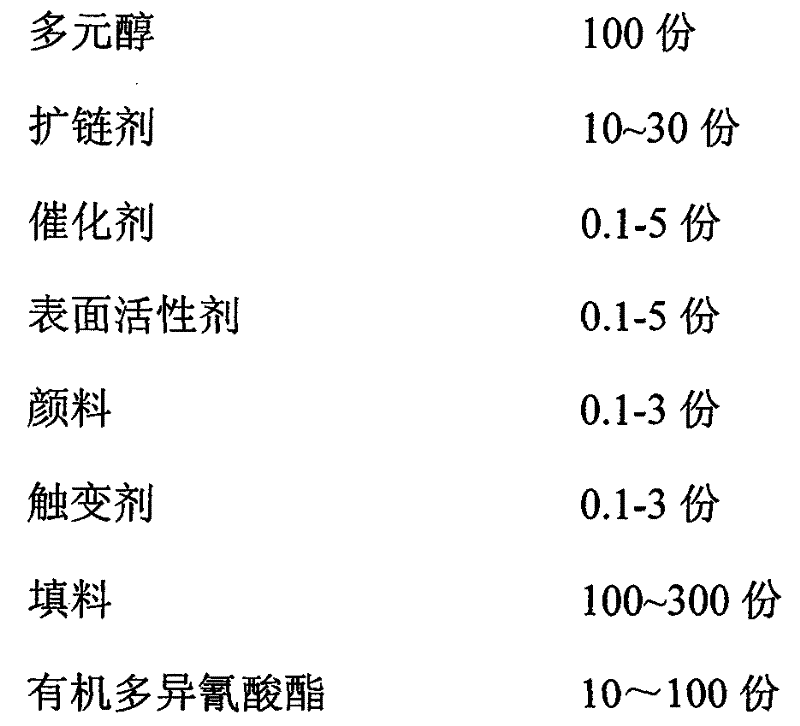

Polyurethane adhesive composition for artificial grassplot back glue

ActiveCN101508881ANot easy to cureNo performance improvementPolyureas/polyurethane adhesivesPolyurethane adhesiveSurface-active agents

The invention discloses a polyurethane adhesive composition used for application of gum in artificial grass, and the withdrawal force showed by bottom back of the artificial grass using the polyurethane adhesive, and the cost is lower. The polyurethane adhesive composition used for the application of gum in the artificial grass comprises the components based on the parts by weight: 100 parts of polylol, 10-30 parts of chain extendor, 0.1-5 parts of catalyst, 0.1-5 parts of surface active agent, 0.1-3 parts of pigment, 0.1-3 parts of thixotropic agent, 100-300 parts of filler and 10-100 parts of organic polyisocyanates.

Owner:COCREATION GRASS CO LTD

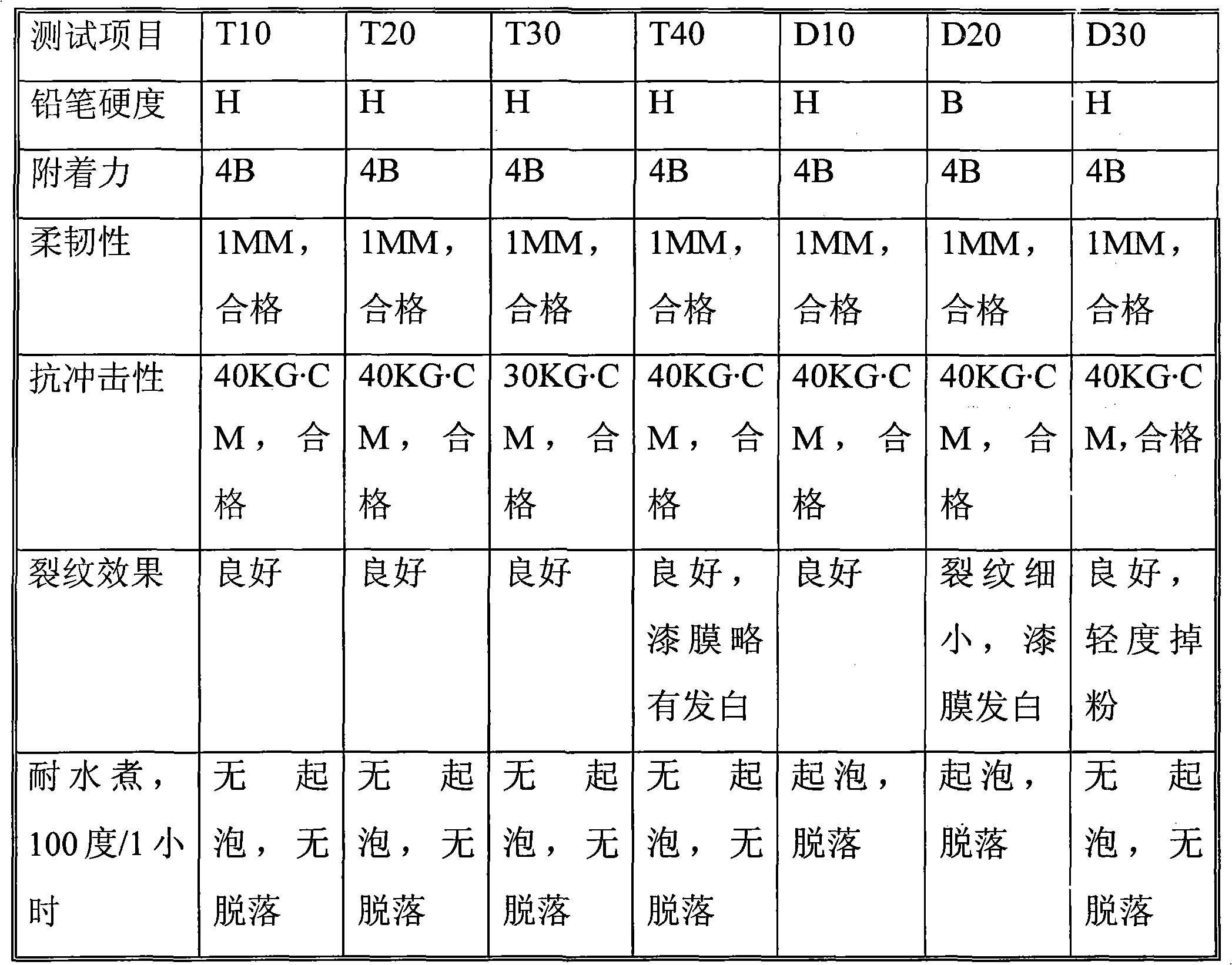

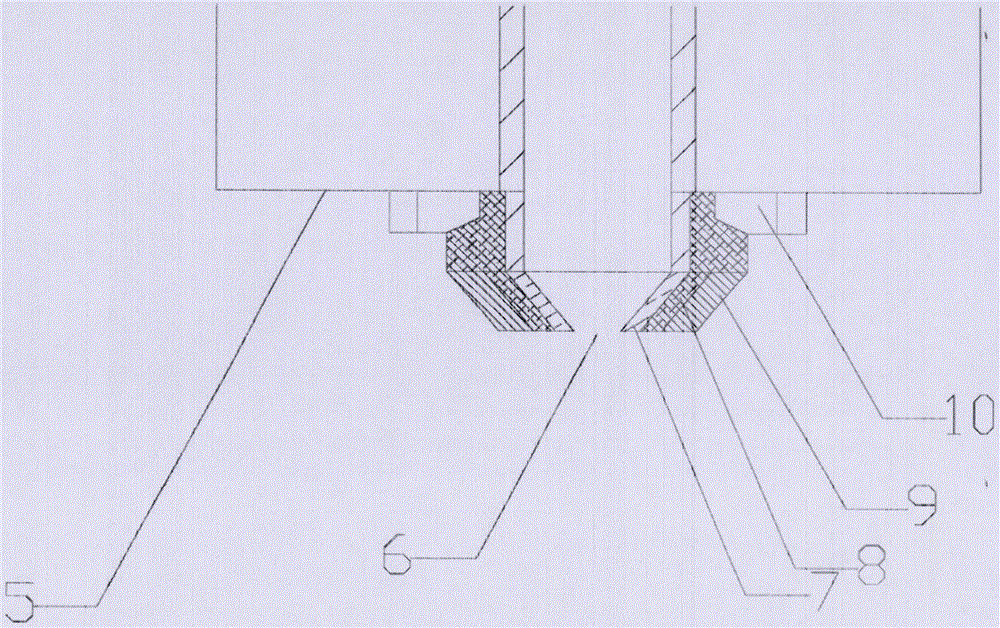

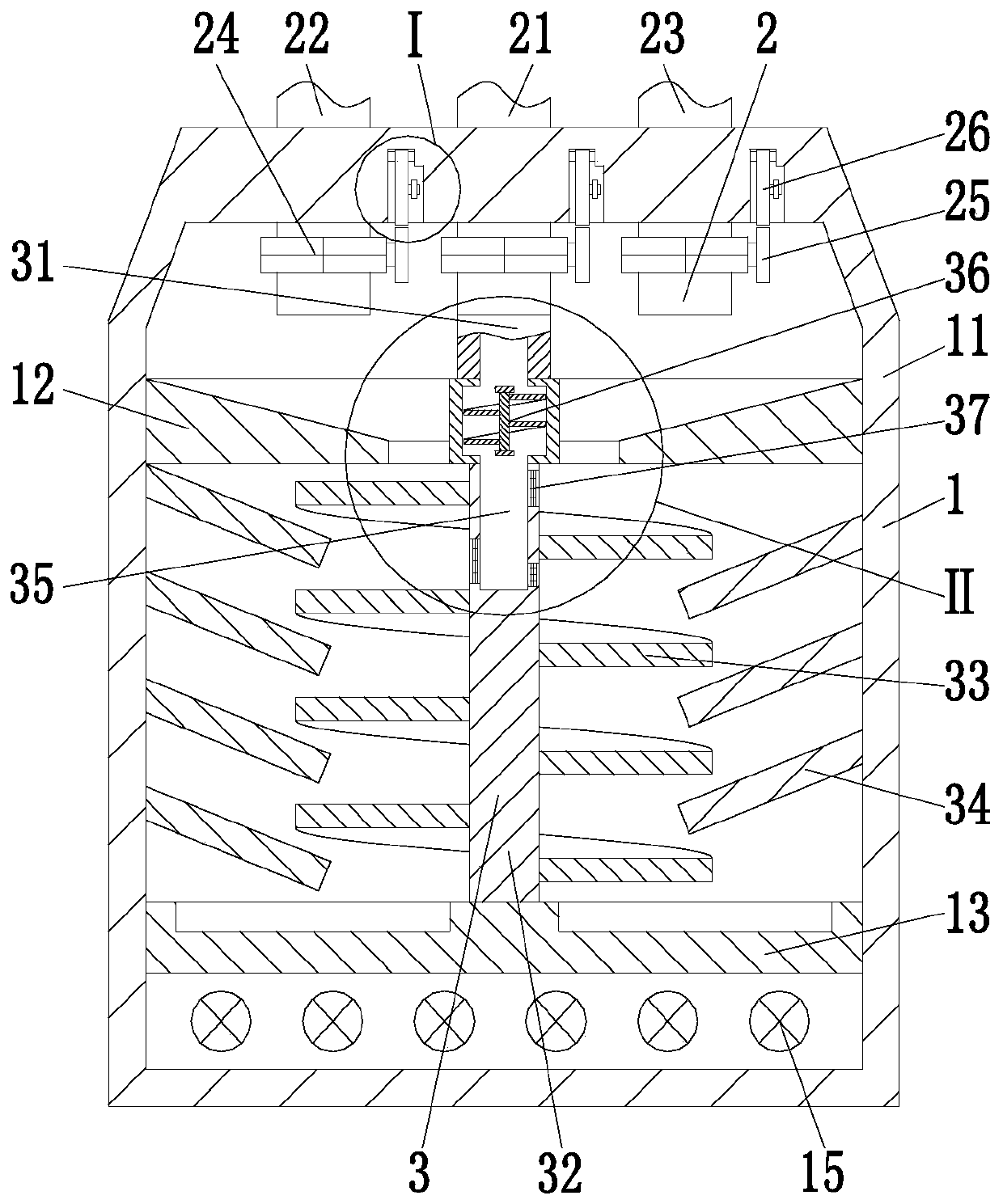

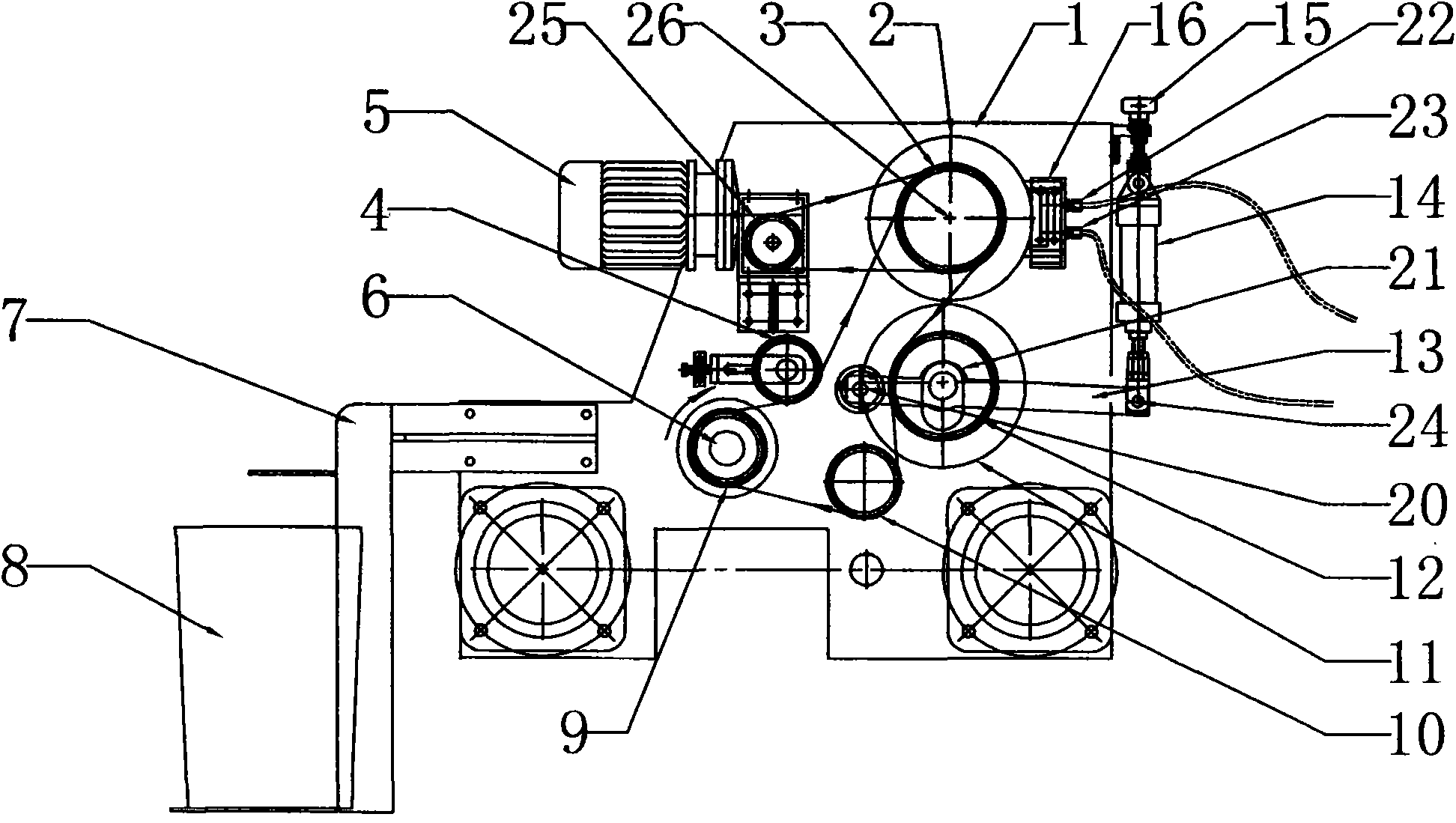

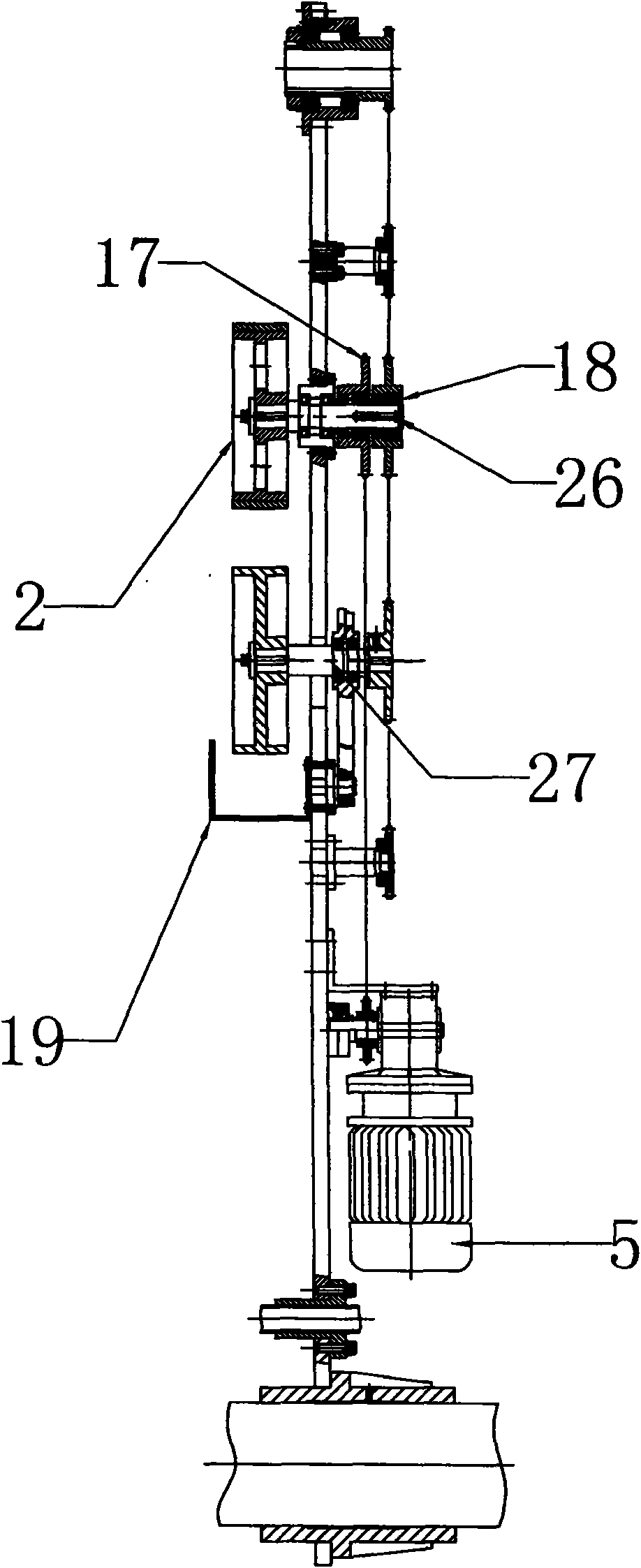

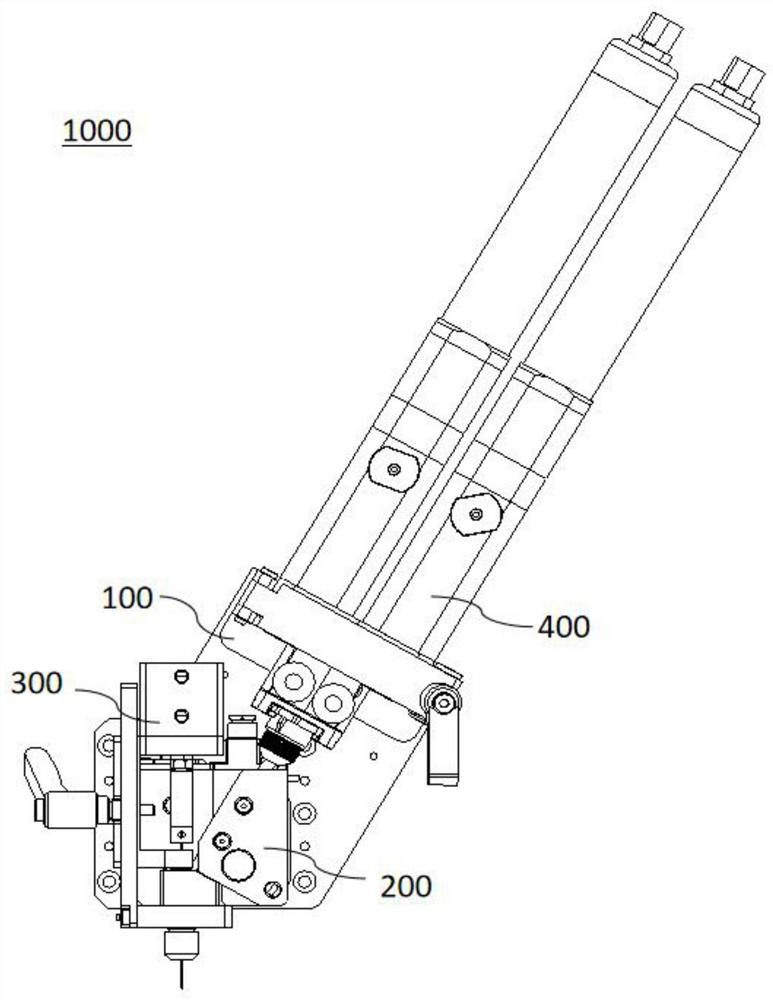

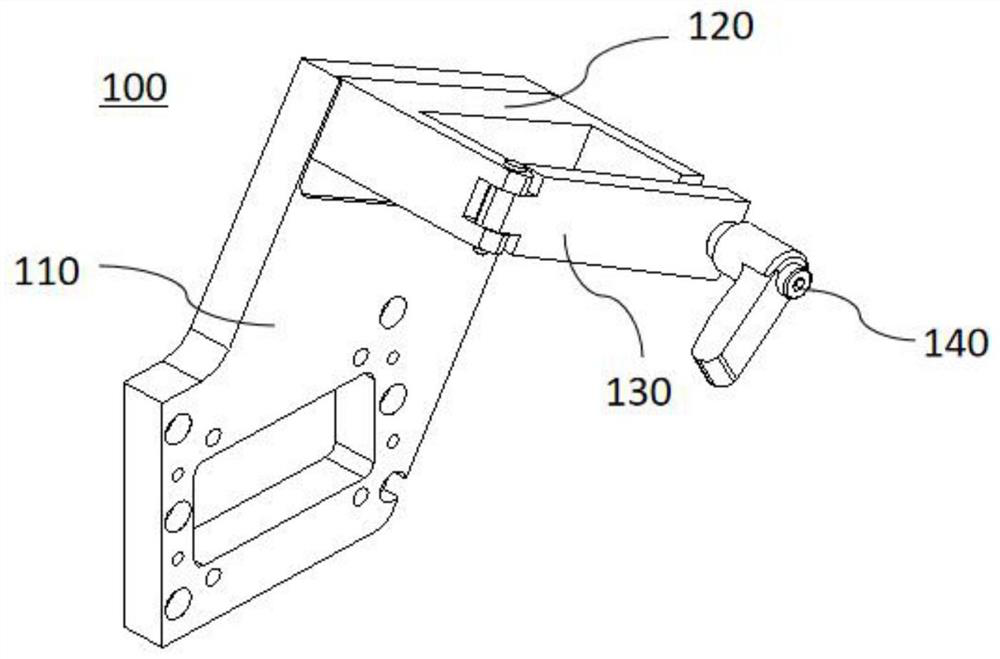

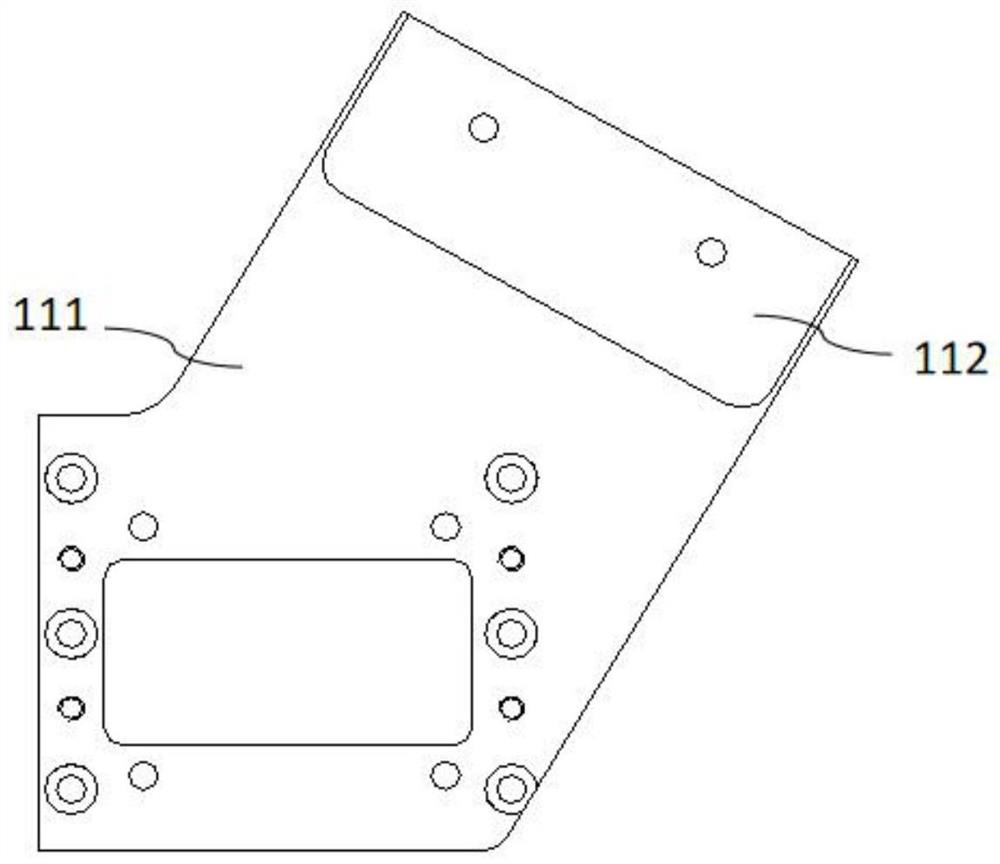

Cyclic heating high efficiency 3D printer nozzle device

InactiveCN106426912ANot easy to cureSolve obstaclesManufacturing heating elements3D object support structuresHeat conductingThermal insulation

The invention relates to a cyclic heating high efficiency 3D printer nozzle device, including a base plate, the middle of the base plate is provided with a feeding tube, the main body of the feeding tube is located below the base plate, the lowermost of the feeding tube is a nozzle, the upper outer side of the feeding tube is provided with a heat dissemination component, the outside of the lower part of the feeding tube is a heating component, the outer wall of the nozzle is constructed from multiple layered structures, the inner layer is a main heat conducting layer, which is touched and fixed with an elastic thermal preservation layer outside the main heat conducting layer, the outer side of the elastic thermal insulation layer is an outer wall, the top of the elastic thermal preservation layer is provided with a compression rod, the inside of the feeding tube is provided with a rotating shaft, the rotation of which is driven by a motor, the heat dissemination component includes a heat dissemination tube and a liquid heat dissemination device connected with the heat dissemination tube, the liquid heat dissemination device is connected with a control device, the control device through controlling a temperature sensor provided on the heat dissemination tube performs a heat disseminating control to the materials in the feeding tube. The device has good performance on heating and disseminating heat, and has obvious effect on anti clogging.

Owner:HUNAN RUIDU TECH

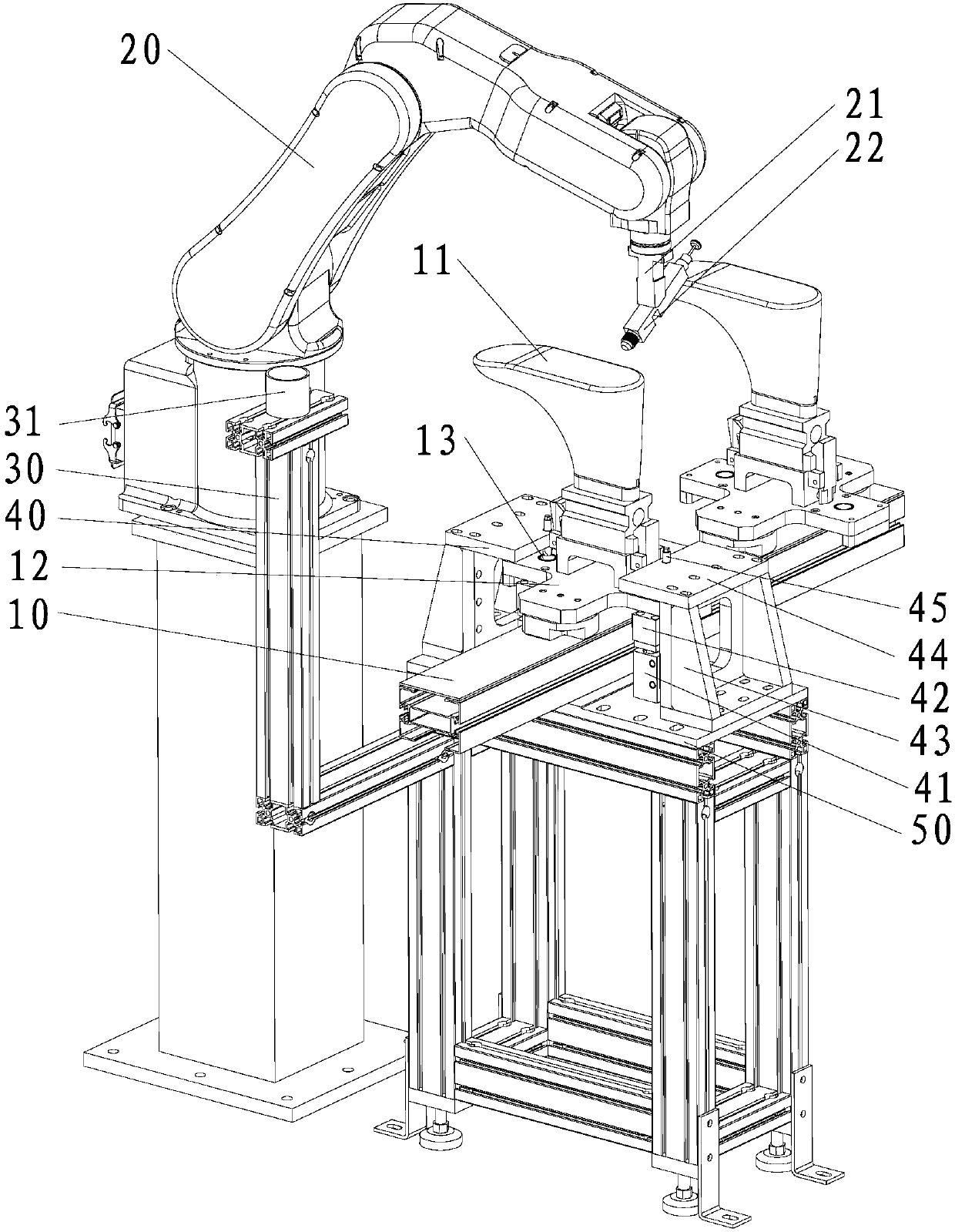

Device for spraying adhesive to shoe vamp

The invention provides a device for spraying an adhesive to a shoe vamp. The device comprises a conveyor, a multi-joint manipulator and a support, wherein the multi-joint manipulator and the support are located beside the conveyor, an adhesive cup is fixedly connected to the support, the tail end joint of the multi-joint manipulator is fixedly connected with a spray gun rack, a spray gun is installed on the spray gun rack, and an included angle formed by the spray gun and the tail end joint of the multi-joint manipulator is 45 degrees. Due to the fact that the included angle formed by the spray gun and the tail end joint of the multi-joint manipulator is 45 degrees, the spray gun is naturally and obliquely arranged after the tail end joint of the multi-joint manipulator is arranged vertically, the adhesive can be simultaneously sprayed to stitch positions of the inside of the bottom of the shoe vamp and the side edge of the shoe vamp during adhesive spraying, namely simultaneous adhesive coating of the stitch positions of the inside of the bottom of the shoe vamp and the side edge of the shoe vamp can be achieved through one-time adhesive spraying action, and the production efficiency is relatively higher. In addition, due to the fact that the adhesive cup is arranged, an adhesive brush can be soaked in the adhesive cup when the adhesive spraying action is not executed and is not prone to curing, frequent spray gun and spray head replacement is also not needed, and the cost is relatively lower.

Owner:福建省华宝智能科技有限公司

Ultraviolet (UV) light-cured elastic-feeling paper gloss oil and construction method thereof

ActiveCN103590280AIncrease elasticityLow viscosityPaper coatingCoatingsPolymer scienceUltraviolet lights

The invention relates to the technical field of coatings and particularly relates to an elastic-feeling coating. Ultraviolet (UV) light-cured elastic-feeling paper gloss oil is composed of the following components in parts by weight: 18-22 parts of UV elastic resin, 22-28 parts of monomer, 8-12 parts of active amine, 3-7 parts of photoinitiator, 5-10 parts of elastic powder, 3-7 parts of gas phase silica matting powder, 0.5-2 parts of assistant and 22-26 parts of solvent, wherein the monomer is a mixture of isobornyl acrylate and 1,6-hexanediol diacrylate. The ultraviolet light-cured elastic-feeling paper gloss oil provided by the invention is suitable for high-speed roller coating, thereby improving the working efficiency, reducing the coating operation difficulty and avoiding personal injury.

Owner:HUIZHOU CHANGRUNFA PAINT

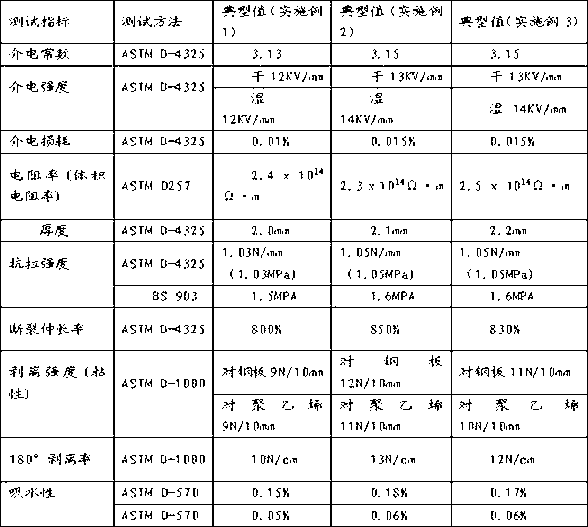

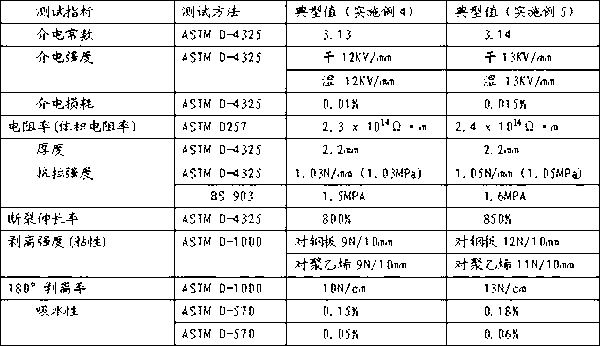

Power cable repairing adhesive tape and preparation method of the same

InactiveCN103131340AUnique cold flow characteristicsEasy curingNon-macromolecular adhesive additivesFilm/foil adhesivesPower cableMiddle molecular weight

The invention provides power cable repairing adhesive tape and a preparation method of the power cable repairing adhesive tape. The power cable repairing adhesive tape and the preparation method of the power cable repairing adhesive tape comprise, by weight ratio, 5-10% of butyl rubber, 5-10% of high molecular weight polyisobutene, 25-30% of middle molecular weight polyisobutene, 10-15% of low molecular weight polyisobutene, 40-50% of inorganic reinforcing powder, 0.5-1% of antioxidant 1010 and 0.5-1% of pigment. The repairing adhesive tape adopted by the power cable repairing adhesive tape is polymer which can never be solidified, wherein the repairing adhesive tape not only has ordinary adhesive performance, but also has unique cold flow characteristics, and can realize automatically repairing functions in the anti-erosion and repairing process to achieve the best sealing and anti-erosion effect.

Owner:CYG CHANGTONG NEW MATERIAL

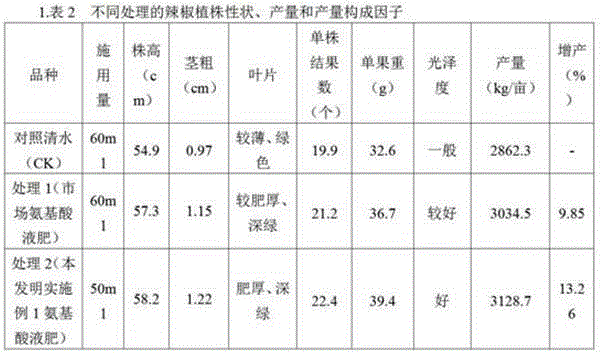

Amino acid liquid fertilizer

InactiveCN105218263APromote growth and developmentActivation activityFertilizer mixturesSulfateTrace element

The invention relates to an amino acid liquid fertilizer. The amino acid liquid fertilizer is prepared in the following steps: adding 112-130kg of amino acid, 334-44kg of zinc sulfate, 40-50kg of borax, 58-68kg of ferrous sulfate, 100-110kg of magnesium sulfate, 10kg of a chelating agent and 400-500kg of water, chelating, and adding water to obtain 1000L. The pH value of the amino acid liquid fertilizer is 5.6-6.2, the content of amino acid is 100g / L, the content of trace element zinc is 12g / L, the content of boron is 8g / L, the content of iron is 20g / L, and the content of magnesium is 20g / L; the amino acid liquid fertilizer is uniform and stable and has no precipitate. When in use, the amino acid liquid fertilizer is diluted by utilizing water and is sprayed onto the surface of crop leaves. By utilizing the amino acid liquid fertilizer, the required fertilizer of the crops during the entire growth period is uniform, and the demand of the crops on the amino acid and trace elements in the entire growth period can be satisfied. The crops adopting the amino acid liquid fertilizer can be matured in advance and consistent in mature period, full in grains, less in phenomenon such as flowering without fruiting, flower dropping and fruit dropping, good in fruit taste, high in quality, long in fruit harvesting period and excellent in quality, so that the amino acid liquid fertilizer is worth of being popularized.

Owner:安徽天河生物科技有限公司

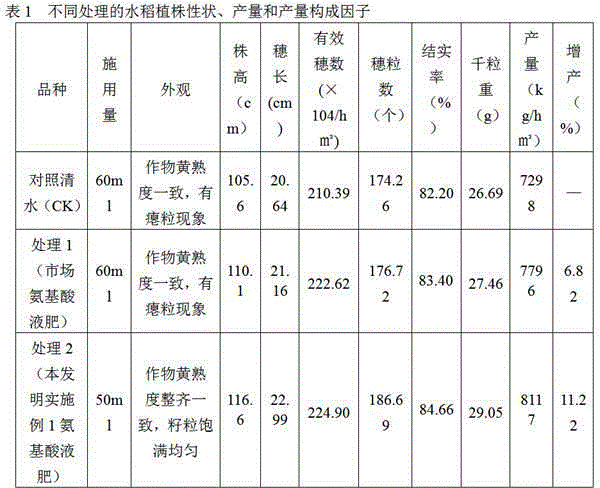

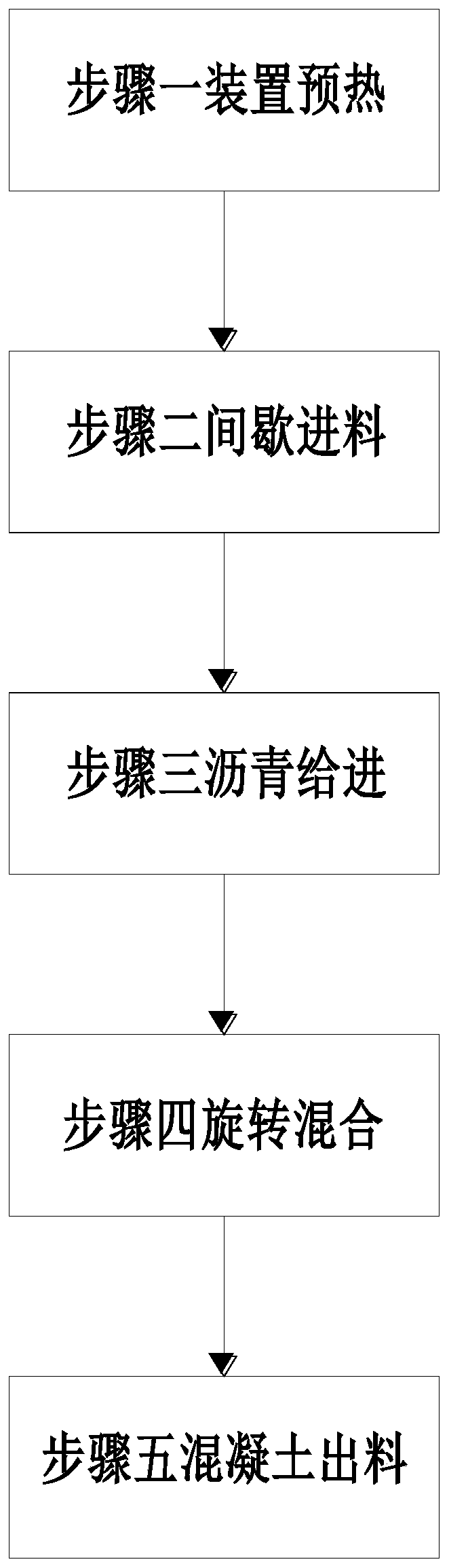

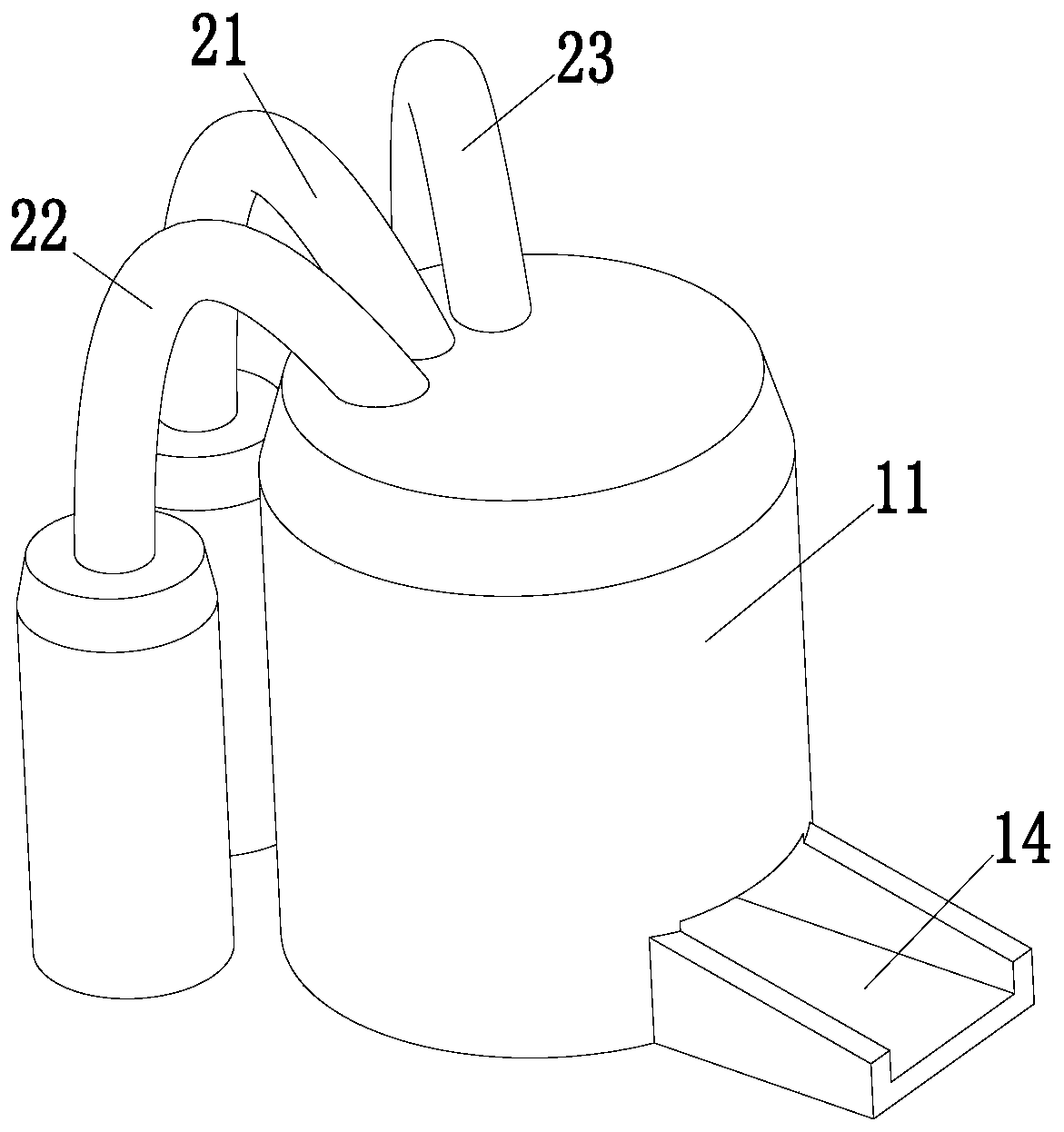

Preparation method of asphalt concrete

ActiveCN111300646AQuality improvementIncrease the degree of mixingCement mixing apparatusSold ingredients supply apparatusStructural engineeringAsphalt concrete

The invention relates to a preparation method of asphalt concrete. Concrete mixing equipment is adopted in the preparation method of the asphalt concrete. The concrete mixing equipment comprises a supporting heating device, an intermittent feeding device and a rotary mixing device. The supporting heating device is of a hollow structure. The intermittent feeding device is mounted on the upper end face of the interior of the supporting heating device. The rotary mixing device is mounted on the lower side of the interior of the supporting heating device. Through the preparation method of the asphalt concrete, the problems that when existing equipment is used for preparing the asphalt concrete, sandstone, cement and asphalt are mixed insufficiently due to continuous feeding, the mixture gets caked and hardened in a mixing device, the mixing device needs to be cleaned regularly, the processing efficiency is low, the quality of produced asphalt concrete is poor, the temperature and fluidityof asphalt in the conveying process are reduced when the existing equipment prepares the asphalt concrete, the asphalt solidifies easily and blocks a pipeline, and the processing efficiency is reducedduet to pipeline cleaning can be solved.

Owner:浙江威克赛新材料科技有限公司

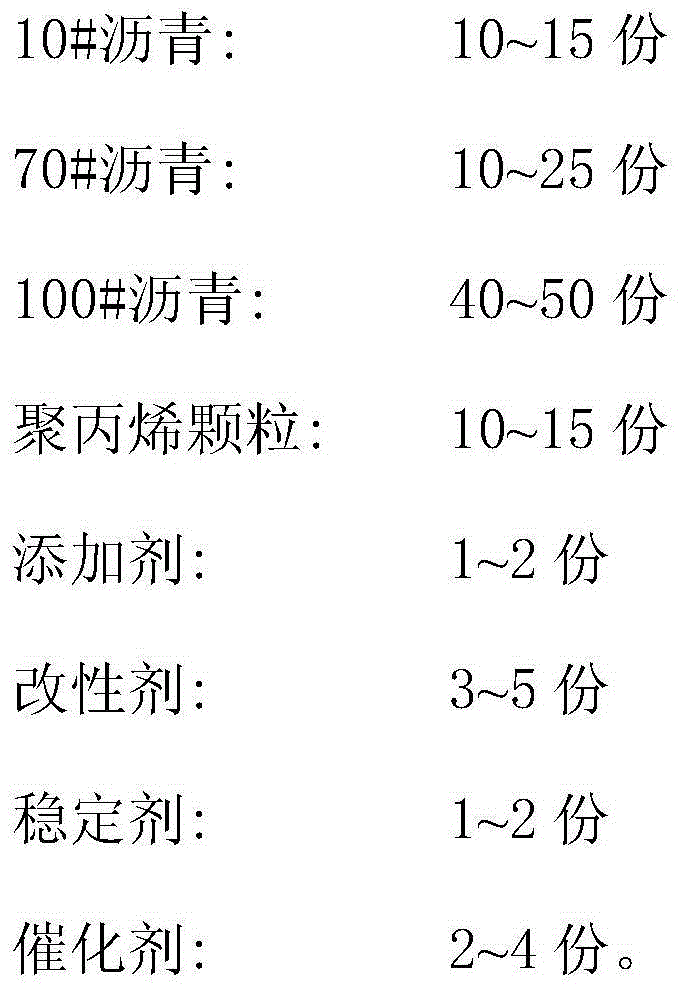

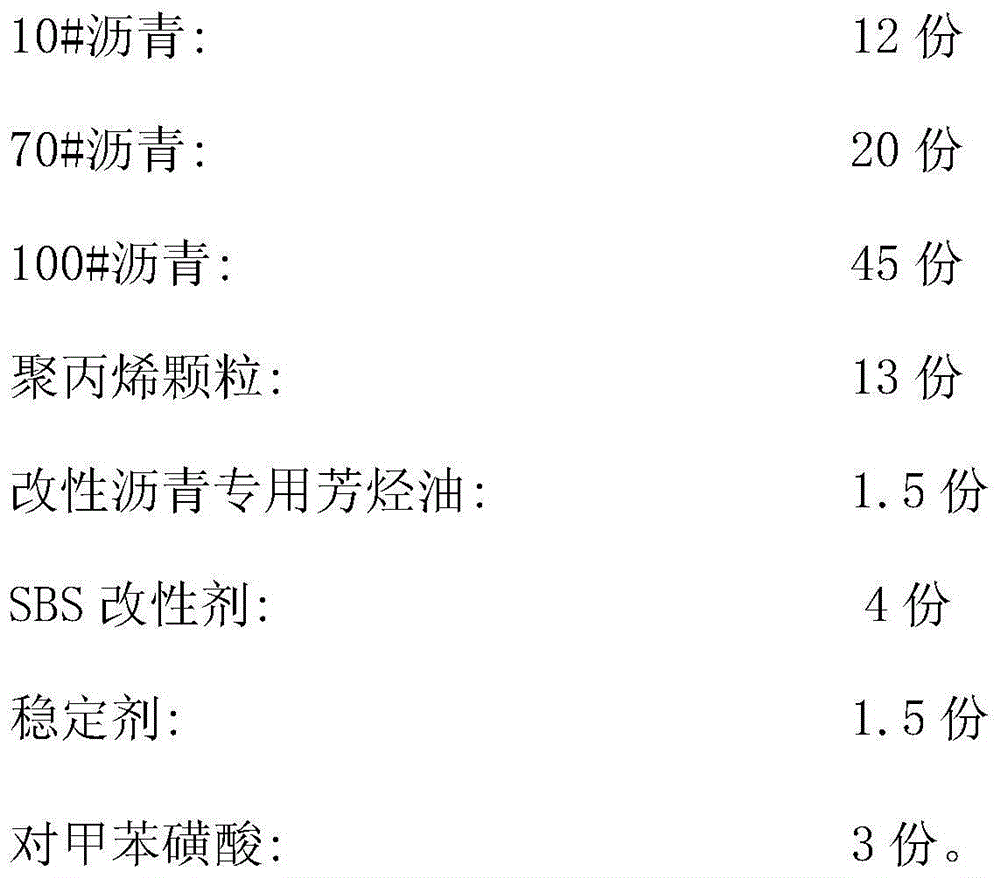

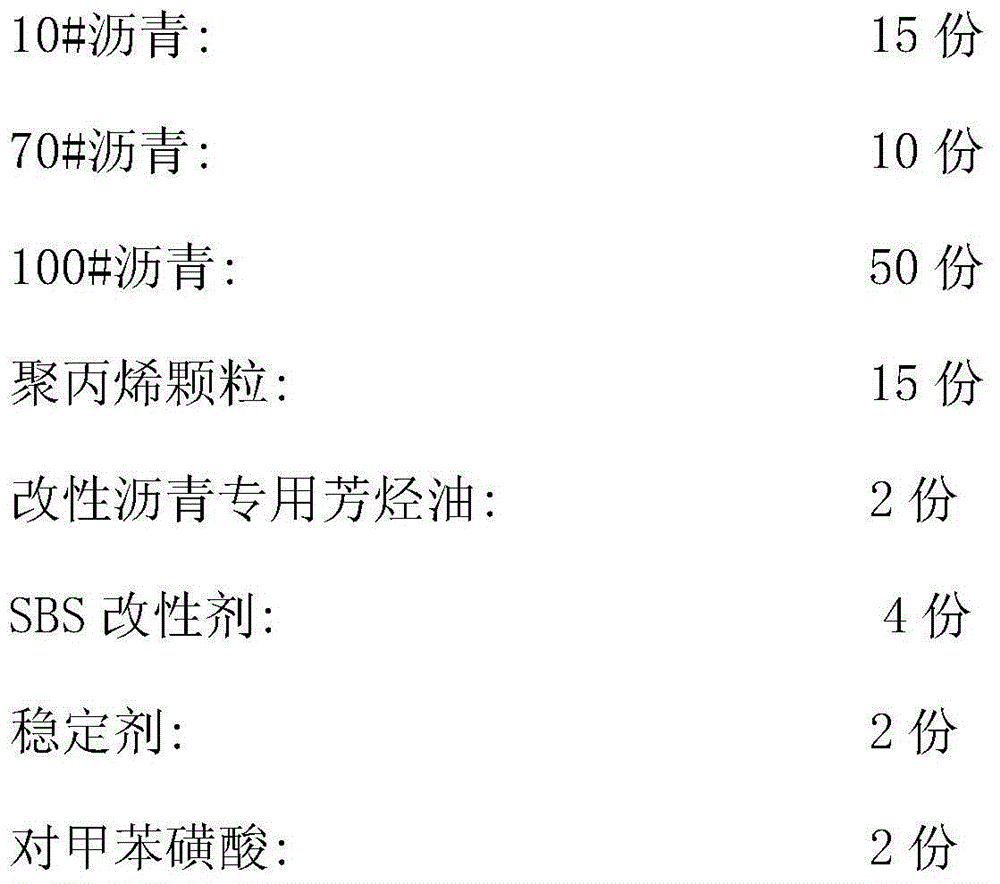

Non-curing rubberized asphalt waterproof paint

InactiveCN104530979AIncrease contentStop runningAnti-corrosive paintsBituminous coatingsCombustionBituminous waterproofing

The invention discloses a non-curing rubberized asphalt waterproof paint which is composed of the following components in parts by weight: 10-15 parts of 10# asphalt, 10-25 parts of 70# asphalt, 40-50 parts of 100# asphalt, 10-15 parts of polypropylene granule, 1-2 parts of additive, 3-5 parts of modifier, 1-2 parts of stabilizer and 2-4 parts of catalyst. The paint has high solid content, can not be easily cured, and can keep favorable waterproofness. The paint has the advantages of high durability, favorable corrosion resistance, favorable high / low temperature resistance, favorable ductility, high safety, environmental protection, low combustion tendency, high binding property, favorable flexibility, high elongation percentage and wide application range, can be bounded with various substances, can be self-repaired, ensures the effectiveness of waterproofness, is simple to use and convenient to operate, can form a complete and stable waterproof layer, and can prevent water from flowing on the waterproof layer.

Owner:ZHEJIANG CHUN MING WATERPROOF BUILDING MATERIALS

Novel anticorrosive material and preparation method thereof

InactiveCN106590372AWith self-cleaning functionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene

The invention discloses a novel anticorrosive material and a preparation method thereof. The anticorrosive material is prepared from the following raw materials in parts by weight: 80-200 parts of epoxy resin, 100-220 parts of alkyd resin, 20-30 parts of phenolic resin, 20-30 parts of silicone oil, 3-8 parts of graphene, 10-20 parts of a flatting agent, 3-8 parts of a curing agent and 30-80 parts of filler. The novel anticorrosive material has a self-cleaning function and strong corrosion resistance, is long-term effective in extreme environments, such as humid, acidic, alkaline environments and the like, has a long service life, can be stored for a long time and cannot be easily cured under a low-temperature condition, and can be easily cured when being used at a normal temperature, so that the spraying time can be reduced.

Owner:浩达船舶技术服务(天津)有限公司

Manufacturing method for surface sealant of LED flexible strip

InactiveCN102504176AWith anti-ultraviolet functionNot easy to change colorPolyureas/polyurethane adhesivesAlcoholUltraviolet

The invention discloses a manufacturing method for surface sealant of an LED flexible strip, which includes the steps: (1) preparing glue: preparing first glue and second glue required by glue dropping, wherein the first glue comprises cycloaliphatic isocyanate and polyhydric alcohol resin, and the second glue comprises cycloaliphatic isocyanate, polyhydric alcohol resin and phenyl mercuric acetate serving as catalyst; (2) mixing: mixing the first glue and the second glue according to the predetermined proportion, and vacuumizing the mixed glue; (3) dropping the glue: cleaning and baking the LED strip firstly, then fixing the LED strip onto an operating desk, and dropping the mixed glue on the surface of the LED strip; (4) removing bubbles: placing the LED strip dropped with the glue into a vacuum cabinet for removing the bubbles; and (5) baking: placing the glue into a drying oven for baking when the mixed glue on the surface of the LED strip is stirred with a needle and drawing of the glue is in the presence after thirty minutes. The surface sealant of the LED flexible strip manufactured by the method has an ultravioresistant function and is not easy to turn yellow.

Owner:深圳市凯信光电有限公司

Traditional Chinese medicinal ointment for treating psoriasis

InactiveCN101987151AShort treatment timeQuick resultsHeavy metal active ingredientsHydroxy compound active ingredientsDiseaseSide effect

The invention relates to a traditional Chinese medicinal ointment for treating psoriasis, which is especially applicable to psoriasis and other diseases. The invention provides a traditional Chinese medicinal ointment for treating psoriasis, which can effectively treat psoriasis and does not have any side effect on human. The traditional Chinese medicinal ointment for treating psoriasis is prepared from the following raw materials in parts by weight: 26-50 parts of realgar, 25-35 parts of borneol, 1-2 parts of calomel, 21-28 parts of lightyellow sophora roots, 9.5-11 parts of frankincense, 12-13 parts of alum, 15-20 parts of radix angelicae pubescentis, 15-20 parts of peach kernels, 10-15 parts of red flower, 5-8 parts of cinnamon, 5-10 parts of mint, 20-40 parts of goldenlarch barks, 20-40 parts of cyrtomium fortunei, 10-20 parts of hairyvein agrimonia herbs, 10-20 parts of chinaberry barks, 10-12 parts of cornu bubali, 8-10 parts of dragon's blood, 13-18 parts of tobacco leaves and 13-18 parts of Chinese mugwort leaves.

Owner:梁慧珠

Gluing system of box pasting machine

The invention provides a gluing system of box pasting machine, comprising a side plate, a gluing wheel and a tightening sprocket; wherein a coating box is fixed on the side plate, one end of the coating box is against the surface of the gluing wheel fixed on the side plate; the gluing wheel is provided with a first gluing wheel sprocket, a second gluing wheel sprocket and a unilateral bearing; thefirst gluing wheel sprocket is connected on an electric motor by a chain; a hydraulic cylinder is fixed on the side plate, the top of the hydraulic cylinder is provided with a regulating lever, a push wheel sprocket is sequentially connected with a transition sprocket, a drive sprocket, a tightening sprocket and a second gluing wheel sprocket by the chain. After the invention adopts the structure, the gluing wheel is driven by two power systems, one is power input by box pasting wire transmission shaft and the other one is chain transmission, the gluing wheel can be automatically adjusted along with production speed change, thus better adapting the speed of paper box and remaining uniformity and steadiness of gluing; and the unilateral bearing is respectively arranged in the two power systems, thus not influencing respective operation each other.

Owner:佛山市南台精机科技有限公司

Anticorrosive oil-resistant paint

InactiveCN104403487AStable performanceExcellent performanceWax coatingsAnti-corrosive paintsEmulsionPliability

The invention discloses an anticorrosive oil-resistant paint. The anticorrosive oil-resistant paint comprises the following constituents according to the content ratio: 12 to 23 parts of m-xylene phenolic resin, 3.6 to 5.2 parts of phthalic acid dibutyl ester, 12 to 16 parts of a polymer resin emulsion, 5 to 8 parts of silicon alloy powder, 0.2 to 2.6 parts of modified inorganic silicate, 15 to 20 parts of chlorinated paraffin, 4 to 8 parts of sodium hexametaphosphate, 12 to 15 parts of methylcellulose, 0.2 to 0.8 part of an antifoaming agent, and 0.3 to 0.6 part of a thickening agent. By adopting the mode, the anticorrosive oil-resistant paint is stable in performance after a paint film is dried, more excellent in performances of oil resistance, water resistance and oil-water mixture resistance, good in adhesive force, and good in flexibility, abrasive resistance and shock resistance, has low probabilities of curing and blocking, and is suitable for long-term construction operation.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

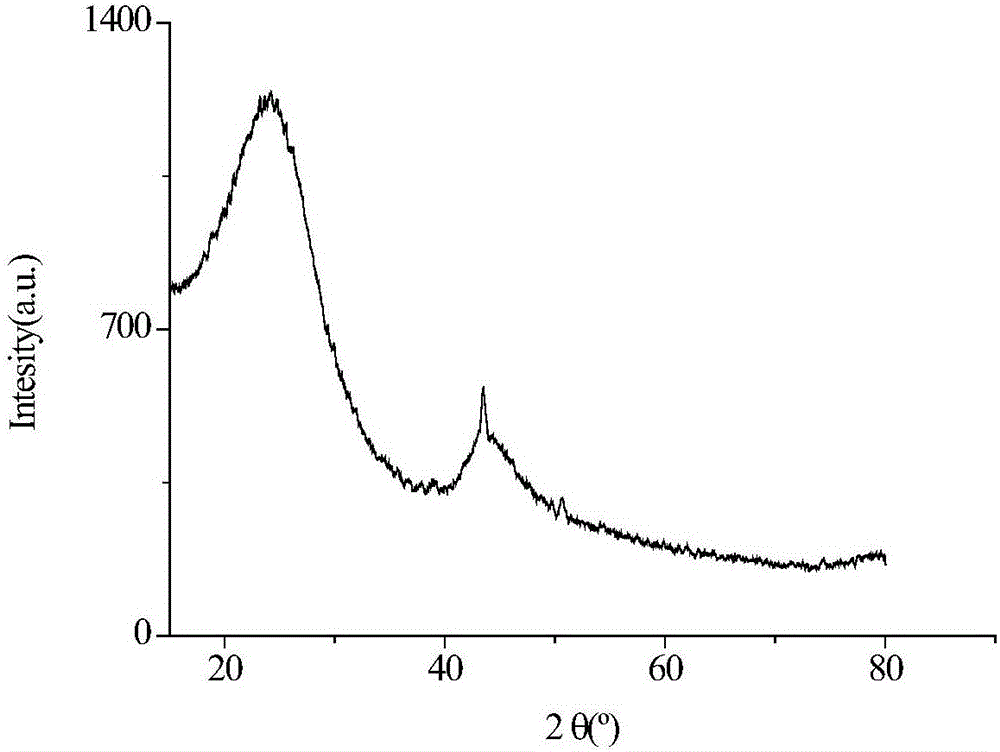

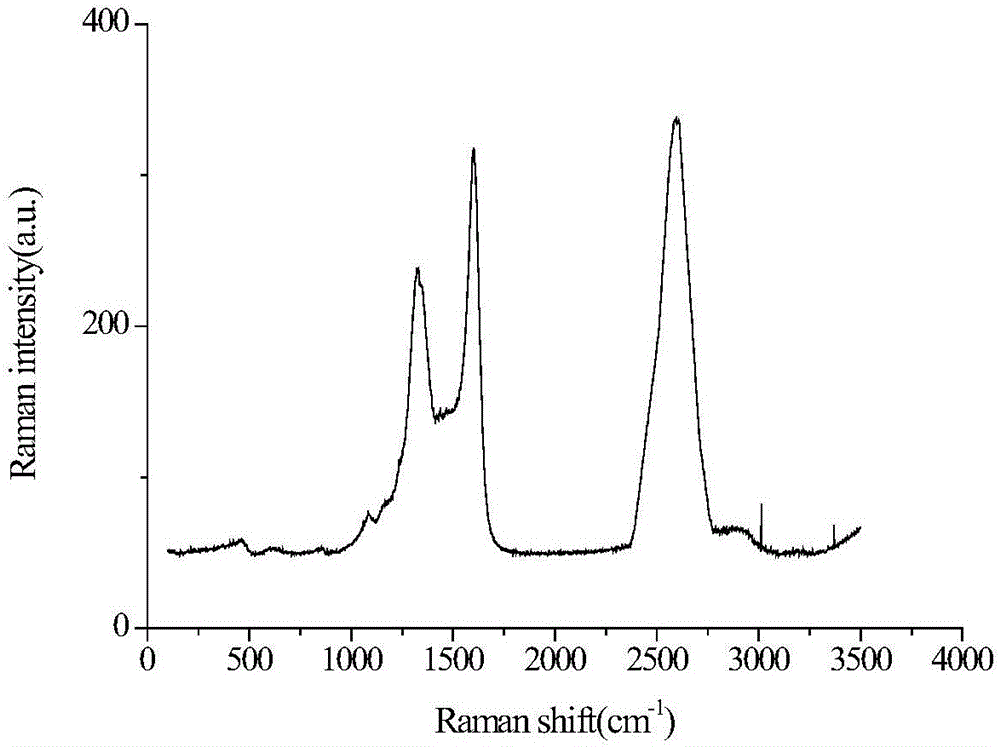

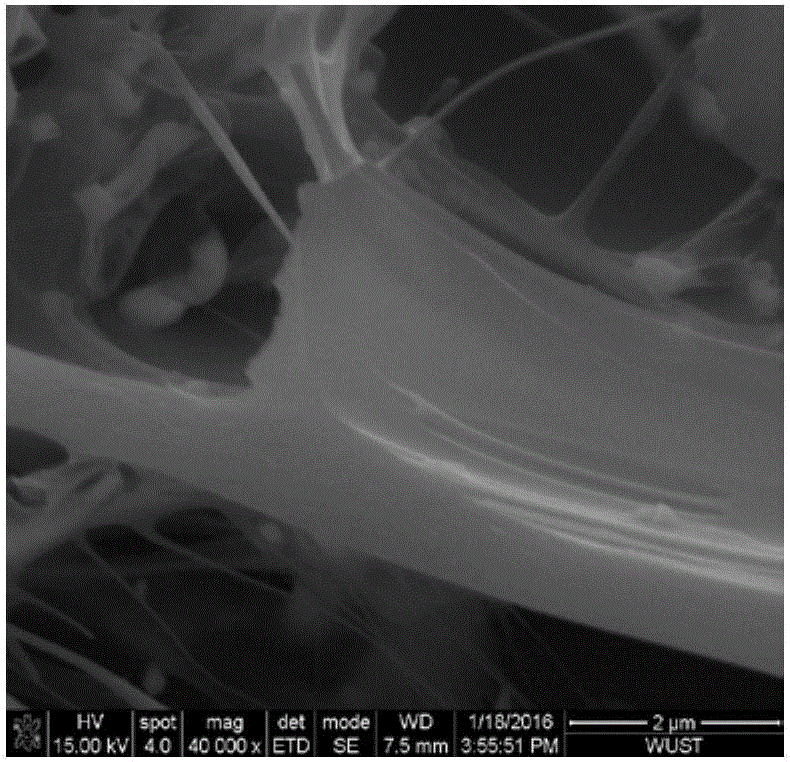

Modified phenolic resin capable of producing in-situ graphene and preparing method thereof

Belonging to the field of phenolic resin technplogy, the invention discloses modified phenolic resin capable of producing in-situ graphene and a preparing method thereof. This preparing method produces phenolic resin intermediate by mixing phenolic compounds, aldehyde compounds and acidic catalysts, and then adjusts PH between 6. 0-8. 0 to get modified water-holding phenolic resin by adding glycine or aminopolycanboxylic acid plus transition metal ions; after vacuum heating, adding ethanol or ethylene glycol to adjust viscosity, and then finally to obtain the modified phenolic resin which can produce in-situ graphene. This preparing method is easy and with mild operation condition allowing transition metal ions to be modified onto resins without the introduction of impurities, on the promise of a high generation rate which can be 0.1wt%-10wt% of in-situ graphene produced by the modified phenolic resin in low temperature.

Owner:WUHAN UNIV OF SCI & TECH

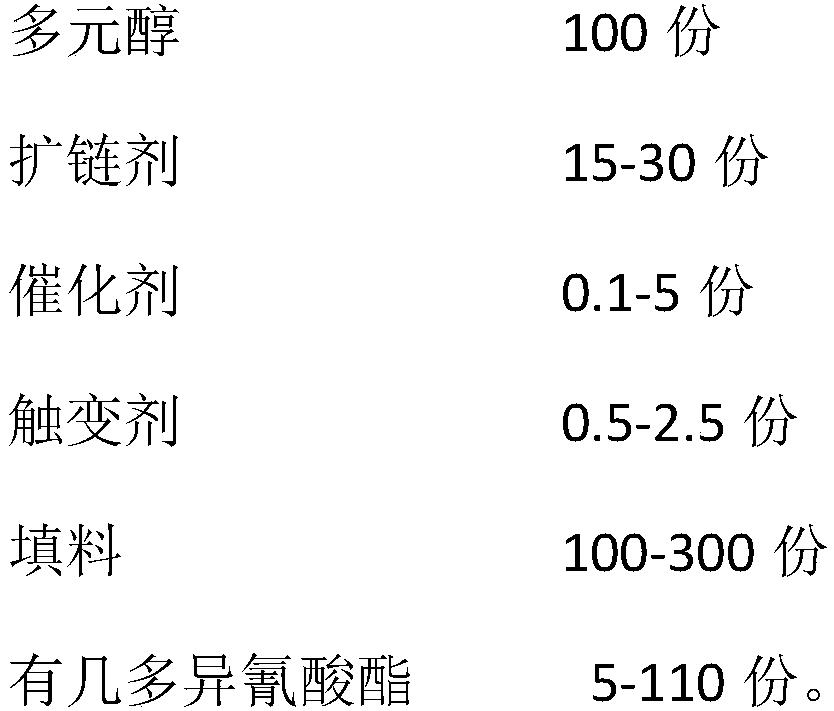

Polyurethane adhesive composition for lawn backing adhesive

InactiveCN109517572ANot easy to cureNo performance improvementNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveAlcohol

The invention discloses a polyurethane adhesive composition for a lawn backing adhesive. An artificial lawn using the polyurethane adhesive is characterized in that the pull-out force shown at the bottom back is greater than 40 N, and the cost is low. The polyurethane adhesive composition for the artificial lawn backing adhesive is prepared from the following components in parts by weight: 100 parts of polyhydric alcohol, 15 to 30 parts of chain extender, 0.1 to 5 parts of catalyst, 0.5 to 2.5 parts of thixotropic agent, 100 to 300 parts of filler, and 5 to 110 parts of organic polyisocyanate.

Owner:陆欣瑜

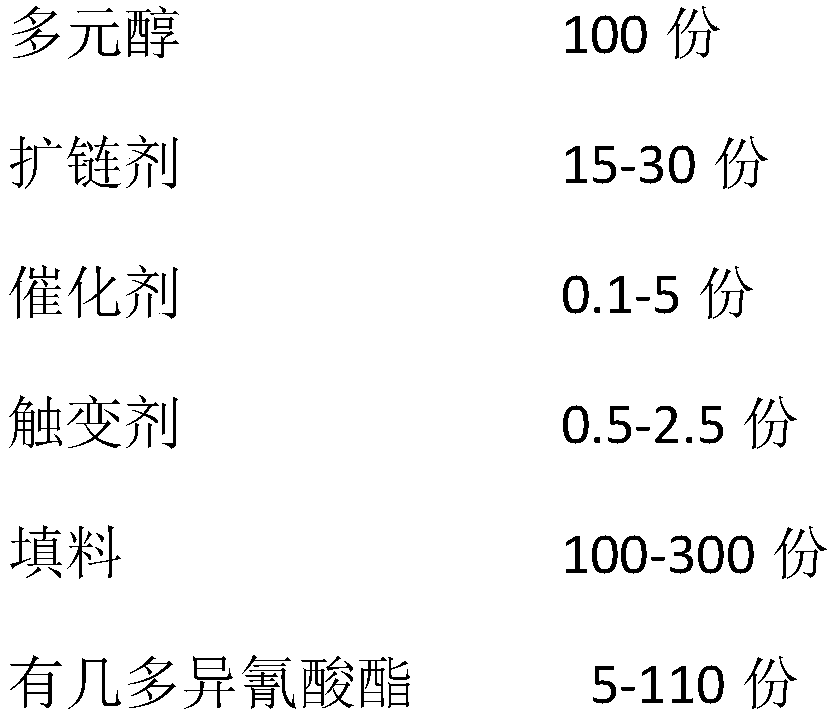

Weather-proof decorative paper and preparation method thereof

PendingCN112301797AGood weather resistanceAccelerated corrosionSpecial paperNon-macromolecular organic additionWeather resistanceProcess engineering

The invention relates to the technical field of decorative paper, in particular to weather-proof decorative paper and a preparation method thereof. The decorative paper comprises a base paper layer, an impermeable adhesive layer coating the surface of the base paper layer and a protective adhesive layer attached to the upper surface of the impermeable adhesive layer, and the base paper layer is provided with an ink pattern layer. The decorative paper has excellent weather resistance, corrosion resistance and mechanical properties, and is long in service life, good in appearance effect and highin practicability. The preparation method of the weather-proof decorative paper is simple, efficient, convenient to operate and control, stable in product quality and beneficial to industrial production.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

Double-component dispensing system

PendingCN112090685AShorten the lengthSmall sizeLiquid surface applicatorsCoatingsScrew pumpElectrical and Electronics engineering

The invention discloses a double-component dispensing system. The double-component dispensing system comprises a double-component screw pump, a mounting assembly, a refrigerating mechanism and a leakage stopping mechanism. The double-component screw pump comprises two container blocks, two glue pumping assemblies and a mixing pipe, wherein a mounting surface is arranged on one side of each container block, the two mounting surfaces are oppositely arranged and are detachably connected, a glue outlet flow channel of which the two ends communicate with each other is formed in each container block, each glue pumping assembly can be connected with any one of the container blocks so as to pump glue to the corresponding glue outlet flow channel, and one end of the mixing pipe communicates with the glue outlet flow channels of the two container blocks. The mounting assembly comprises a mounting support and a fastener. The refrigerating mechanism is arranged on one side of the mounting assembly, and at least one part of the mixing pipe is arranged in the refrigerating mechanism and is refrigerated by the refrigerating mechanism. The leakage stopping mechanism is arranged on one side of themounting assembly, and at least one part of the mixing pipe is arranged in the leakage stopping mechanism so that leakage of the mixing pipe is stopped by the leakage stopping mechanism. The double-component dispensing system has the advantages of simple structure, easiness in assembling and disassembling and the like.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Light curable colored coating

ActiveCN104804502AFast curingFast cross-linkingLuminescent paintsLuminescent compositionsPhosphorPhotoinitiator

The present invention provides a light curable colored coating, comprising a photoinitiator, a UV resin and a UV photosensitive phosphor, wherein the light curable colored coating is formed by mixing and then separating the photoinitiator, the UV resin and the UV photosensitive phosphor, wherein the mixture is applied to a substrate thereafter, and thus the curing time of the light curable colored coating is largely shortened.

Owner:钟志鸿

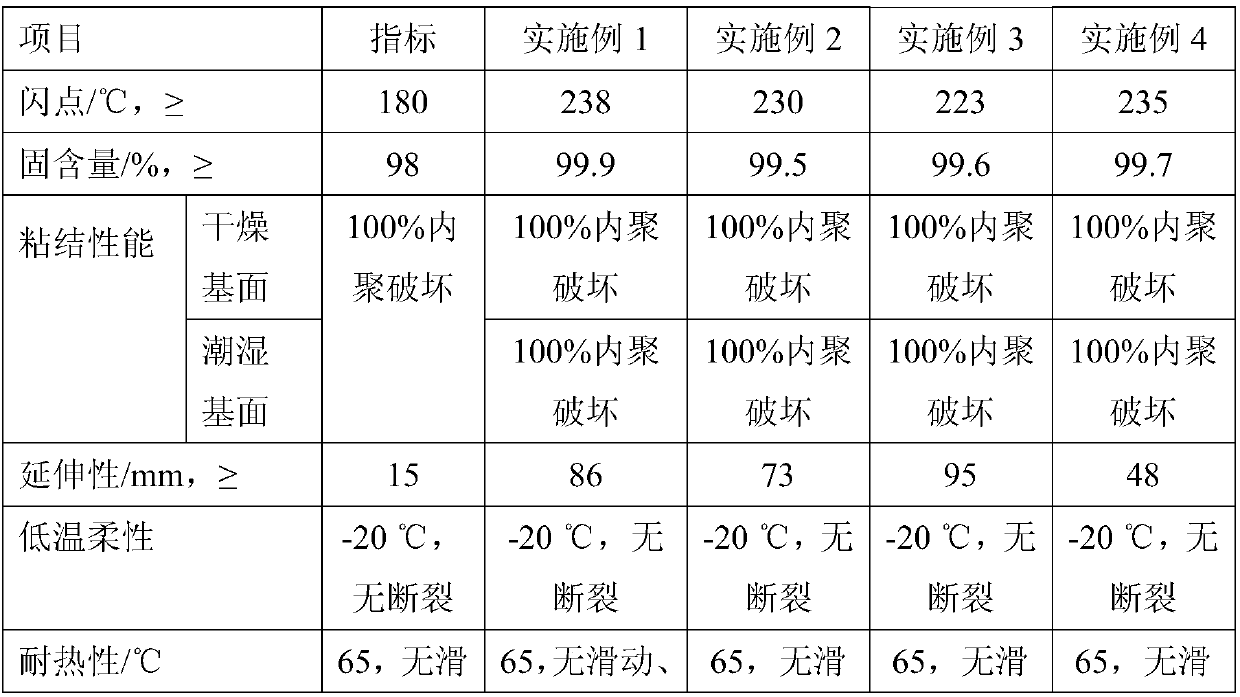

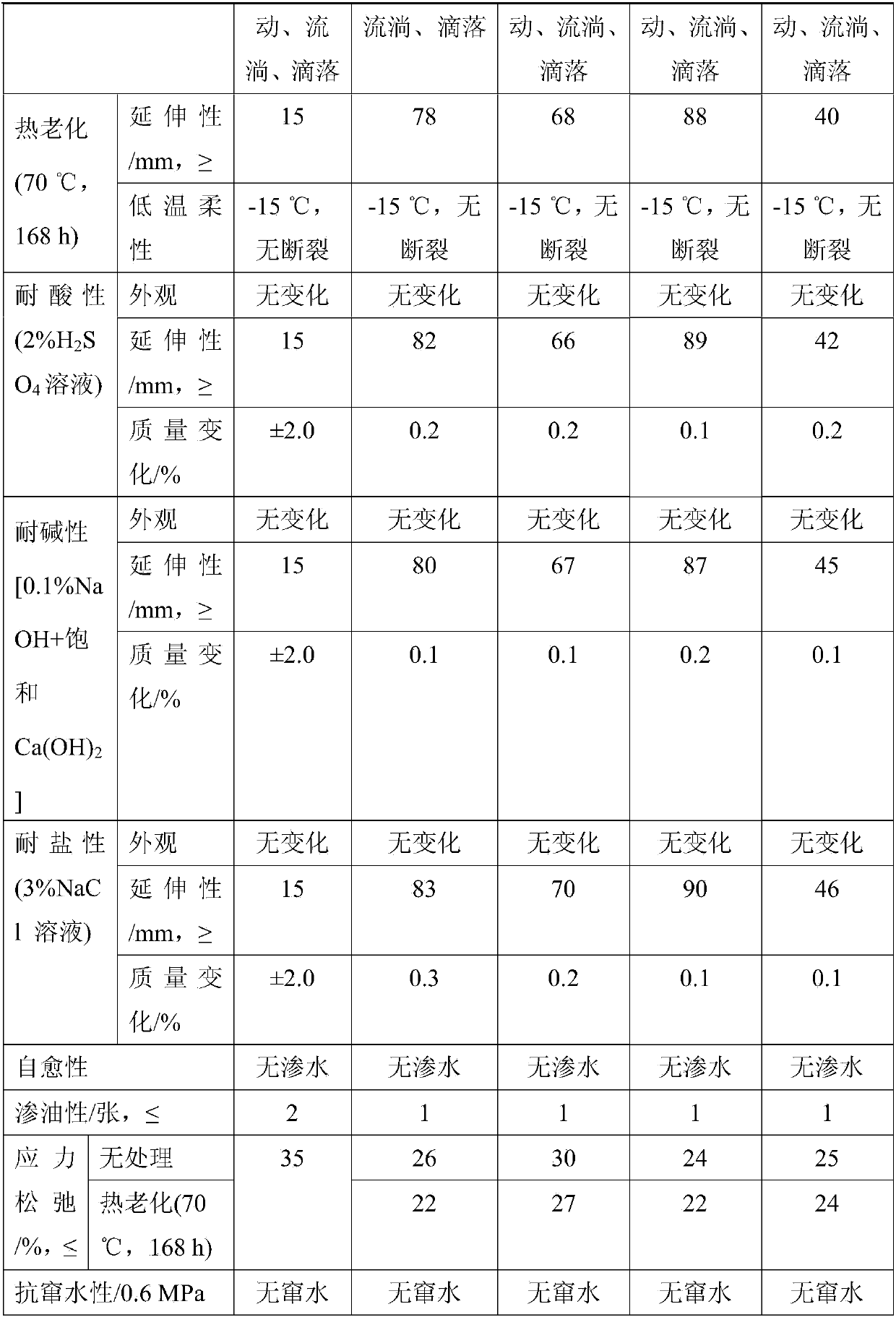

Non-curable rubber asphalt waterproof coating and preparation method thereof

InactiveCN109536025AGood high and low temperature performanceGood extensibilityOther rubber coatingsBituminous coatingsSelf-healingBituminous waterproofing

The invention belongs to the technical field of building waterproof materials, and in particular, relates to a non-curable rubber asphalt waterproof coating and a preparation method thereof. The non-curable rubber asphalt waterproof coating comprises the following raw materials in parts by weight: 35-65 parts of petroleum asphalt, 5-25 parts of a softener, 2-10 parts of styrene-butadiene block copolymer, 5-20 parts of tackifying resin, 5-25 parts of waste rubber powder, 5-20 parts of a filler and 0.5-3 parts of a surfactant. Cheap catalytic cracking oil slurry is introduced into the raw materials, fly ash collected from flue gas after coal combustion is used as a filler, and the prepared non-curable rubber asphalt waterproof coating can be guaranteed to have excellent high and low temperature performance, good extensibility, difficult curing, good cohesiveness, good flexibility, strong self-healing property and low cost. The invention also provides the preparation method, wherein the preparation method has the advantages of low cost, environmental protection, convenience, safety and reliability.

Owner:CHINA PETROLEUM & CHEM CORP

Slurry modifying agent and engineering slurry modifying method

The invention provides a slurry modifying agent. A small number of exciting agents are used for exciting the activity of ore slag and sludge; in addition, waterborne bonding agents such as cement andlime are mixed for replacing the conventional water hardening curing materials; mixed furnace is used for grading silt slurry soil particles, so that the intensity reaches the engineering soil requirements. The invention also provides an engineering slurry modifying method. Solid waste material of the ore slag, furnace slag and the like are used as major materials of the slurry modifying agent; the production and processing cost is low; the cut concretion water-resistant performance is good; argillization cannot easily occur; the intensity is high; the high popularization and use value are realized.

Owner:福建润土工程科技有限公司

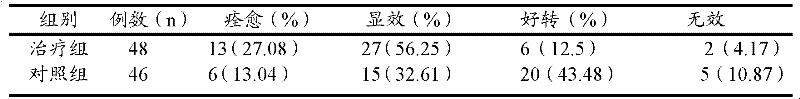

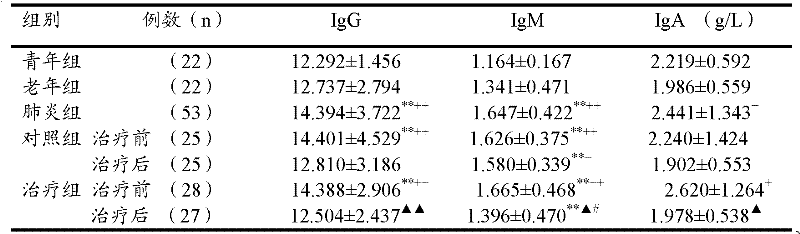

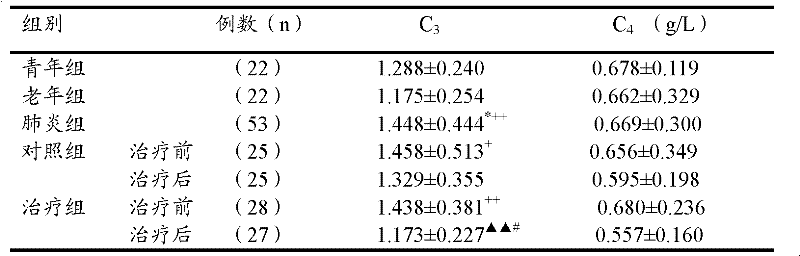

Medicinal composition for treating senile pneumonia and preparation method thereof

ActiveCN102397458AEnhance immune functionAvoid damageRespiratory disorderPlant ingredientsRadix OphiopogonisTraditional medicine

The invention relates to a medicinal composition for treating senile pneumonia and a preparation method thereof. The medicinal composition is prepared from the following raw materials and pharmaceutically acceptable accessories, by weight, 5-15 parts of Snakegourd Fruit, 3-9 parts of ginseng, 3-9 parts of Radix Ophiopogonis, 4-12 parts of rehmannia, 3-9 parts of Herba Houttuyniae, 3-9 parts of Isatis Root, 4-12 parts of Anemone chinensis, and 3-9 parts of Cortex Moutan. The medicinal composition of the invention has substantial effects on the senile pneumonia treatment.

Owner:YANGTZE RIVER PHARM GRP CO LTD

Preparation method of nitrogen-free furan resin

The invention discloses a preparation method of nitrogen-free furan resin, and belongs to the technical field of furan resin production. The method comprises the following steps: adding solid formaldehyde and furfuryl alcohol into a reaction kettle, performing stirring and mixing, and adjusting the pH value to 4.5-6 by using an acid; adding a catalyst zinc acetate under the acidic condition, performing a catalytic reaction at 130-150 DEG C, and maintaining the temperature for 3-5 h to obtain a polymer; adding an aldehyde removing agent and a coupling agent, and performing stirring for uniformmixing; and adjusting the obtained solution to be neutral by using a sodium hydroxide solution, performing continuous stirring, and discharging the obtained material to obtain the product. Raw materials in all above reaction stages comprise, by weight, 5-9 parts of solid formaldehyde, 95-100 parts of furfuryl alcohol, 0.2-0.5 part of zinc acetate, 6-10 parts of the aldehyde removing agent and 0.4-0.8 part of the coupling agent. The raw materials and the production process are improved to obtain the nitrogen-free furan resin having the advantages of no nitrogen, low free formaldehyde, low cost,energy saving, environmental protection and high strength nitrogen, and the nitrogen-free furan resin can be directly used for producing steel castings.

Owner:山东永创材料科技有限公司

Chelated fertilizer and preparation method thereof

InactiveCN103121876AIncrease profitEasy curingFertilizer mixturesTrace elementFerrous sulphate heptahydrate

The invention discloses a chelated fertilizer which comprises the following raw materials in parts by weight: 30-40 parts of sodium humate, 30-40 parts of ferrous sulfate heptahydrate, 8-12 parts of zinc sulphate monohydrate, 8-12 parts of manganese sulfate and 2-4 parts of boracic acid. The chelated fertilizer is prepared through the following steps of: (1) mixing: weighing the sodium humate, the ferrous sulfate heptahydrate, the zinc sulphate monohydrate, the manganese sulfate and the boracic acid, and uniformly mixing; and (2) chelating: smashing the mixture, and then stirring and chelating. The chelated fertilizer prepared according to the method can be used for supplementing sufficient trace elements to soil and is enhanced in fertilizer utilization ratio and difficult to solidify the soil.

Owner:王胜利

Self-emulsifying fluorosilicone-modified two-component waterborne epoxy anticorrosive coating

PendingCN110684439AImprove the environmentProtect healthAnti-corrosive paintsEpoxy resin coatingsEpoxyXylylene

The invention relates to the technical field of waterborne epoxy anticorrosive coatings and discloses a self-emulsifying fluorosilicone-modified two-component waterborne epoxy anticorrosive coating. The coating comprises the following components: waterborne resin, waterborne epoxy ester resin, DPOMA, hollow glass beads, a coalescing agent, zinc phosphate, an antirust pigment, a pigment filler, aluminum triphosphate, xylene, a neutralizer, composite silicate rock slices, composite silicate fibers, graphene, a thickener, a defoaming agent, an initiator, an assistant, a pH regulator, a silica soland a cosolvent. After the waterborne epoxy ester resin, the hollow glass beads, the antirust pigment and the coalescing agent are proportioned according to desired parts in the invention, the waterborne epoxy anticorrosive coating has excellent mildew-proof and corrosion-resistant effects and the like, improves the environment of a cabin in a ship and protects the health of workers when appliedto painting of a ship surface.

Owner:HANGZHOU MAKEDOLLAR ENVIRONMENTAL PROTECTION NEW MATERIAL

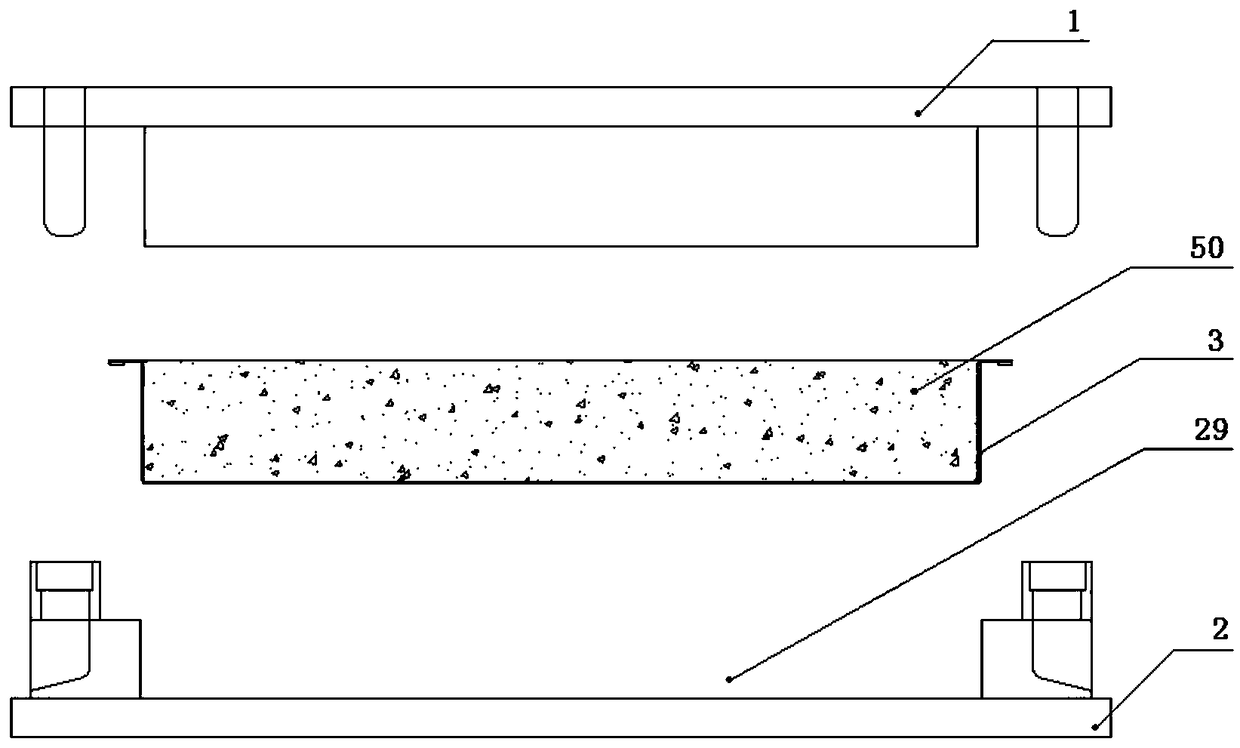

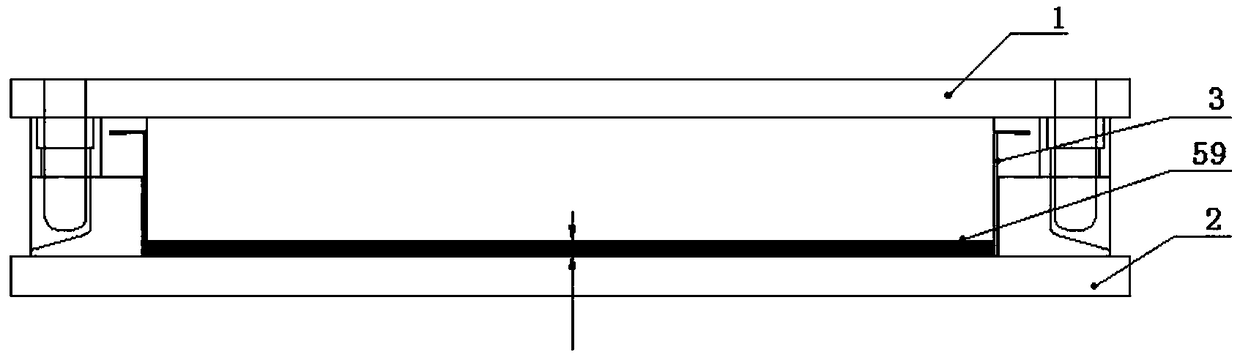

Improved thermosetting molded part production process and improved thermosetting molded part production mold structure

InactiveCN109129809AShorten the timeGood physical and mechanical propertiesWood working apparatusDomestic articlesEconomic benefitsComposite material

The invention provides an improved thermosetting molded part production process and an improved thermosetting molded part production mold structure which are invented for improving environmental economic benefits. The production process comprises the steps of preparing a molding material, filling and distributing the molding material, closing, pressurizing and heating molds, molding and curing themolding material into thermosetting molded parts, opening the molds and conducting mold stripping on the thermosetting molded parts. The mold structure is characterized in that the mold is provided with at least one lower mold cavity movable lining made of a good heat conduction material; the lower mold cavity movable linings are filled with the molding material distributed moderately in advance;the lower mold cavity movable linings and the filled molding material are transferred to lower mold cavities, and then the molds are closed and heated; the molding material is molded into the thermosetting molded parts in cavities defined by the lower mold cavity movable linings and upper molds; and then the molds are opened, the lower mold cavity movable linings and the thermosetting molded parts are taken out from the lower mold cavities, and then the thermosetting molded parts are taken out from the lower mold cavities.

Owner:陈敏芬

Polyurethane adhesive composition for artificial grassplot back glue

ActiveCN101508881BNot easy to cureNo performance improvementPolyureas/polyurethane adhesivesPolyurethane adhesiveSurface-active agents

The invention discloses a polyurethane adhesive composition used for application of gum in artificial grass, and the withdrawal force showed by bottom back of the artificial grass using the polyurethane adhesive, and the cost is lower. The polyurethane adhesive composition used for the application of gum in the artificial grass comprises the components based on the parts by weight: 100 parts of polylol, 10-30 parts of chain extendor, 0.1-5 parts of catalyst, 0.1-5 parts of surface active agent, 0.1-3 parts of pigment, 0.1-3 parts of thixotropic agent, 100-300 parts of filler and 10-100 parts of organic polyisocyanates.

Owner:COCREATION GRASS CO LTD

Low-surface-energy ultraviolet mixed curing coating for metal surface

InactiveCN104910809AImprove performanceImprove adhesionAntifouling/underwater paintsPaints with biocidesCoated surfaceUltraviolet

The invention provides a low-surface-energy ultraviolet mixed curing coating for a metal base material. The coating comprises amino silicon oil or amino silane modified epoxy monoacrylate, an ultraviolet initiator-heat curing agent mixed curing agent, a reactive diluent, pigment, a filler, a dispersing agent, an antifoaming agent and a leveling agent. The coating provided by the invention has the following beneficial effects: the coating composition provides preliminary bonding force through ultraviolet fast curing, and post-curing is realized under the effect of heat, thereby relieving the problem of high curing shrinkage of single ultraviolet curing; and after the curing, the coating has relatively strong adhesive force with the metal base material, the surface energy of the coating is relatively low, and thus, the coating has good anti-staining property.

Owner:SHENZHEN POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com