Improved thermosetting molded part production process and improved thermosetting molded part production mold structure

A production process and technology of molded parts, applied in the field of thermosetting molded parts, can solve problems such as expensive repair cost, pollute the environment, difficult to repair, etc., and achieve the effect of shortening the production process, strengthening mechanical and physical properties, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. These embodiments are only used to illustrate the present invention, and should not be interpreted as limiting the patent protection scope of the present invention.

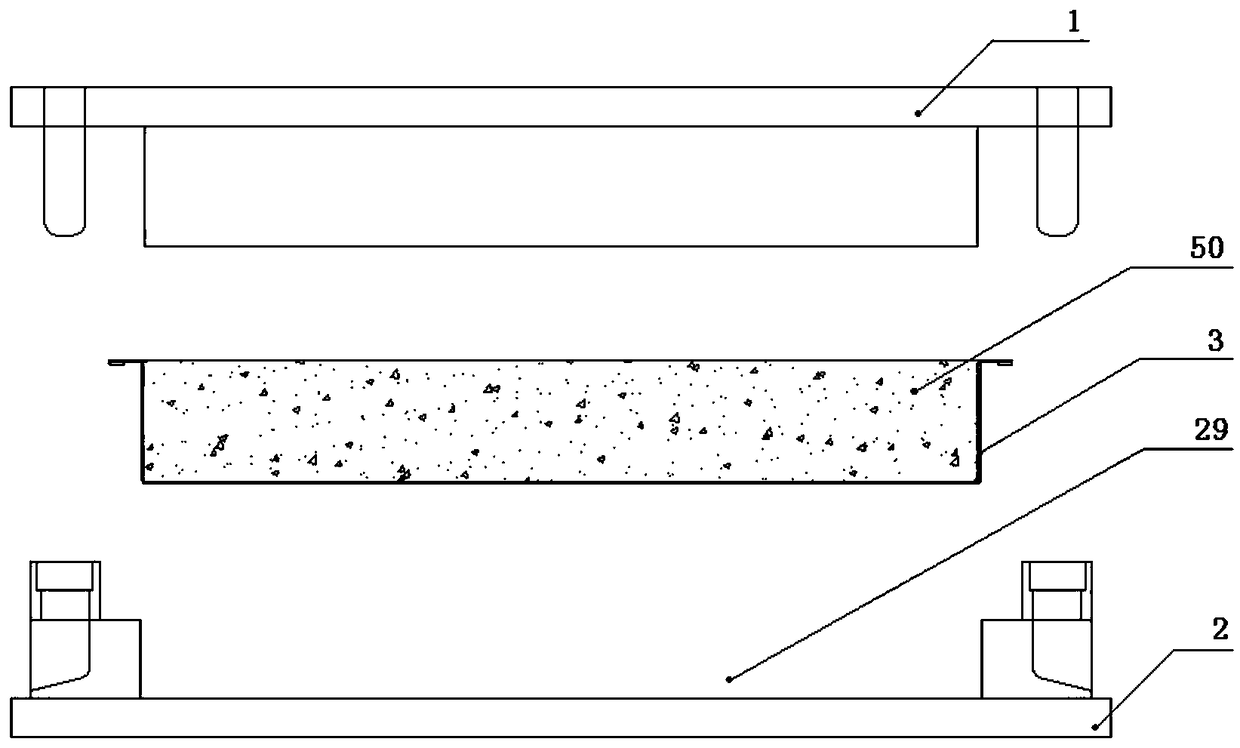

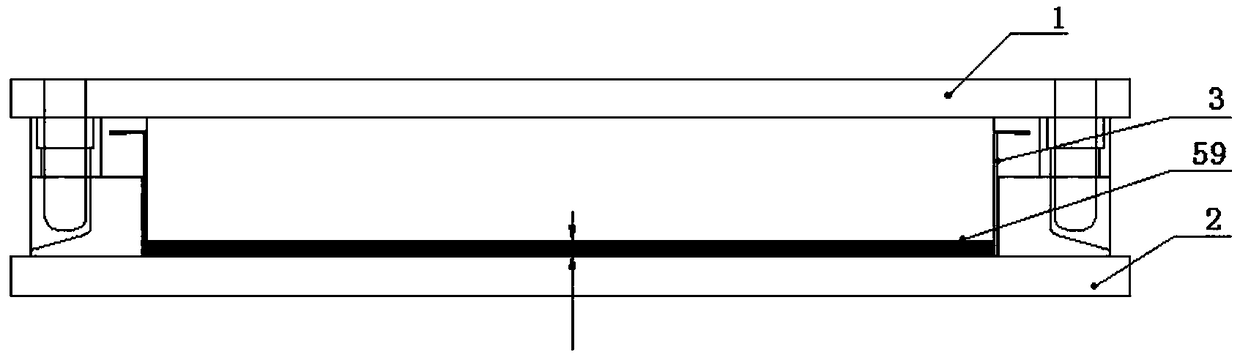

[0021] An improved production process of thermosetting molded parts, including molding material preparation, molding material filling and distribution, mold clamping, pressurization and temperature rise, molding material molding and curing into thermosetting molded parts, mold opening, and process of thermosetting molded parts ejection; its characteristics Yes: the said mold has at least one movable lining of the lower mold cavity with good thermal conductivity material; fill and distribute an appropriate amount of molding materials in the movable lining of the lower mold cavity in advance, and then put the movable lining of the lower mold cavity togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com