Preparation method for semi-aromatic nylon

A semi-aromatic and nylon technology, used in the field of semi-aromatic nylon and its preparation, can solve the problems of low initial viscosity of prepolymer, easy oxidation of polymer, high equipment requirements, etc., and achieve the effect of shortening time, difficult curing and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

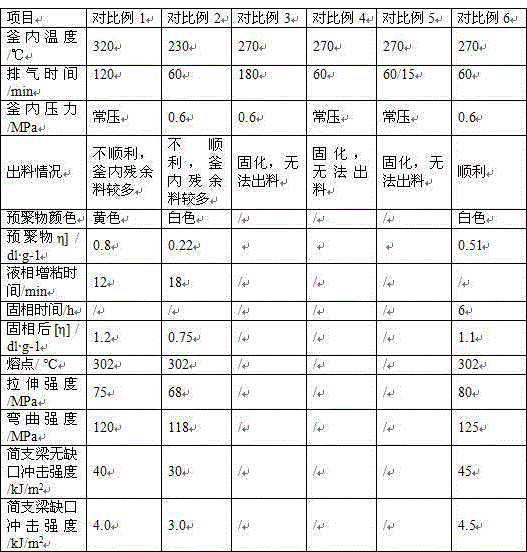

Examples

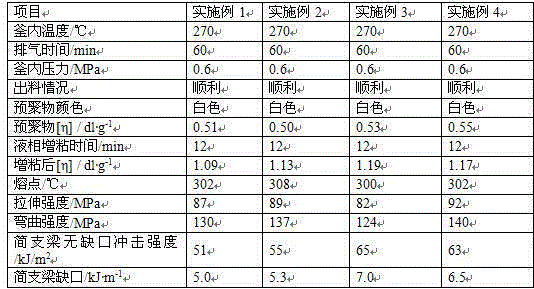

Embodiment 1

[0070] A kind of preparation method of semi-aromatic nylon of the present invention, comprises the following steps:

[0071] 1. Preparation of prepolymer:

[0072] Weigh nylon salt mixture, end-capping agent, catalyst, antioxidant and deionized water according to the following parts by mass: 50 parts of nylon 6T salt, 40 parts of nylon 66 salt, 10 parts of nylon 1010 salt, 0.5 part of end-capping agent benzoic acid , 0.2 parts of catalyst sodium hypophosphite, 0.5 parts of antioxidant 1098, 25 parts of deionized water;

[0073] Add the above-mentioned raw materials in parts by mass into the polymerization reactor, close the polymerization reactor, replace the air in the polymerization reactor with nitrogen three times, and then fill in nitrogen until the pressure in the polymerization reactor is 0.15 MPa higher than the atmospheric pressure; When the temperature reaches 220°C, make the pressure inside the kettle reach 2.2MPa, keep the temperature and pressure stable, and full...

Embodiment 2

[0078] A kind of preparation method of semi-aromatic nylon of the present invention, comprises the following steps:

[0079] 1. Preparation of prepolymer:

[0080] Weigh the nylon salt mixture, end-capping agent, catalyst, antioxidant and deionized water in the following parts by mass: 60 parts of nylon 6T salt, 10 parts of nylon 6I salt, 30 parts of nylon 1010 salt, 0.6 part of end-capping agent benzoic acid , 0.2 parts of catalyst sodium hypophosphite, 0.5 parts of antioxidant 1098, 30 parts of deionized water;

[0081] Add the above-mentioned raw materials in parts by mass into the polymerization reactor, close the polymerization reactor, replace the air in the polymerization reactor with nitrogen three times, and then fill in nitrogen until the pressure in the polymerization reactor is 0.15 MPa higher than the atmospheric pressure; When the temperature reaches 220°C, make the pressure inside the kettle reach 2.3MPa, keep the temperature and pressure stable, and fully reac...

Embodiment 3

[0086] A kind of preparation method of semi-aromatic nylon of the present invention, comprises the following steps:

[0087] 1. Preparation of prepolymer:

[0088] Weigh the nylon salt mixture, end-capping agent, catalyst, antioxidant and deionized water in the following parts by mass: 50 parts of nylon 6T salt, 40 parts of nylon 66 salt, 10 parts of nylon 1212 salt, 0.5 part of end-capping agent benzoic acid , 0.2 parts of catalyst sodium hypophosphite, 0.5 parts of antioxidant 1076, 30 parts of deionized water;

[0089] Add the above-mentioned raw materials in parts by mass into the polymerization reactor, close the polymerization reactor, replace the air in the polymerization reactor with nitrogen three times, and then fill in nitrogen until the pressure in the polymerization reactor is 0.15 MPa higher than the atmospheric pressure; When the temperature reaches 220°C, make the pressure inside the kettle reach 2.4MPa, keep the temperature and pressure stable, and fully reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com