Modified phenolic resin capable of producing in-situ graphene and preparing method thereof

A technology of in-situ generation of phenolic resin, applied in the field of phenolic resin, can solve the problems of low yield and low yield of graphene, and achieve the effect of simple and easy control of process conditions, simple preparation method, and difficult curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

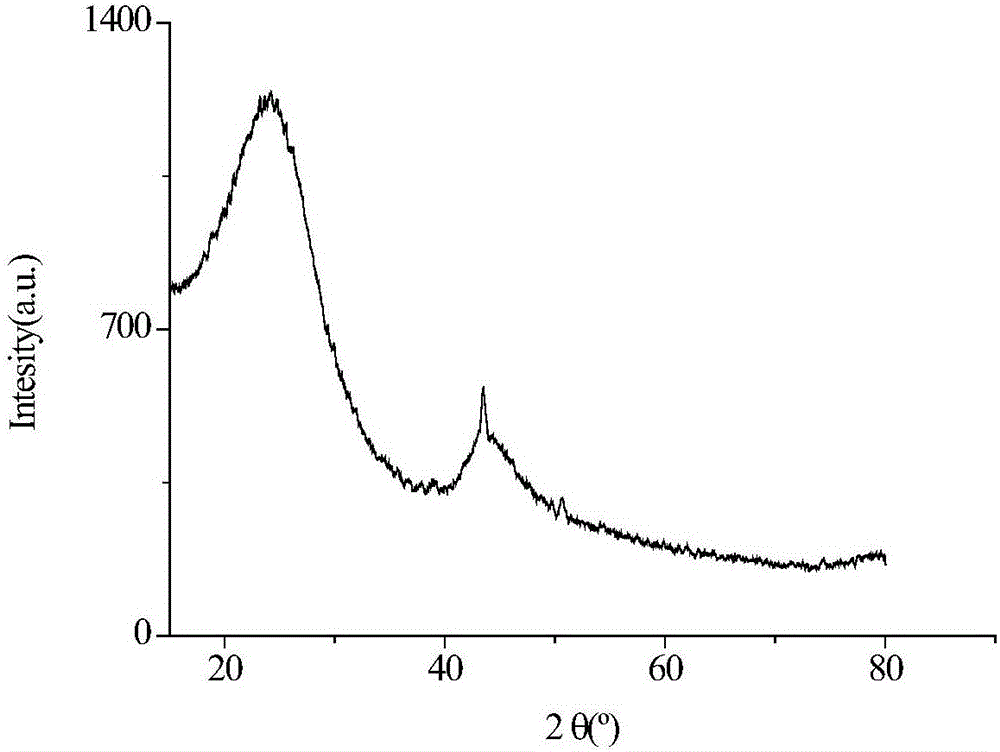

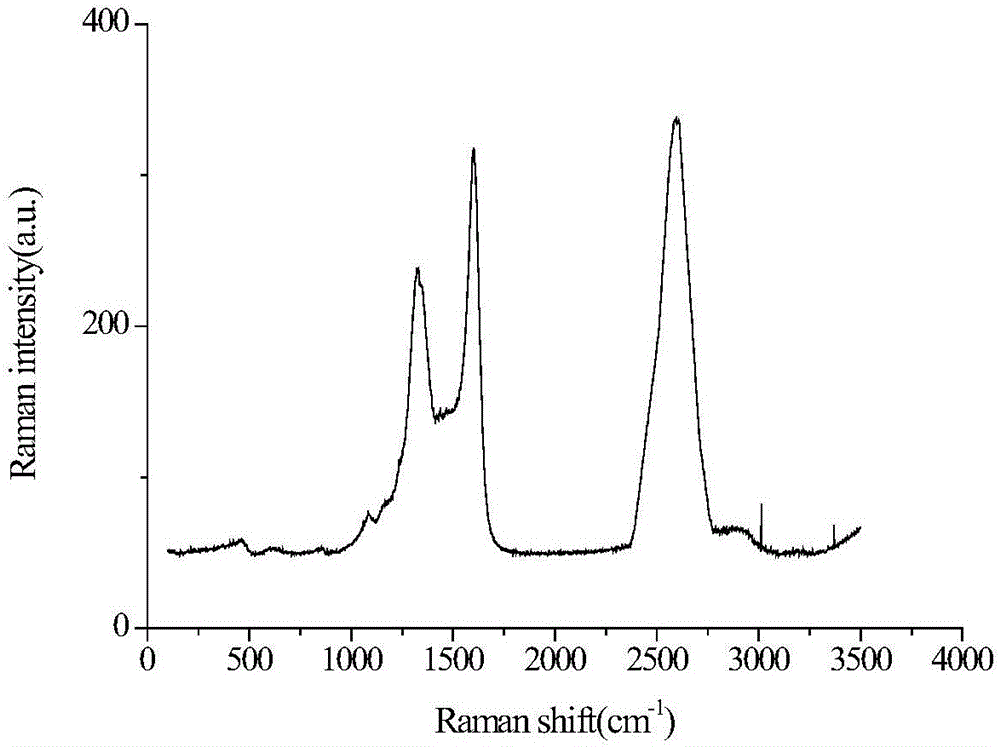

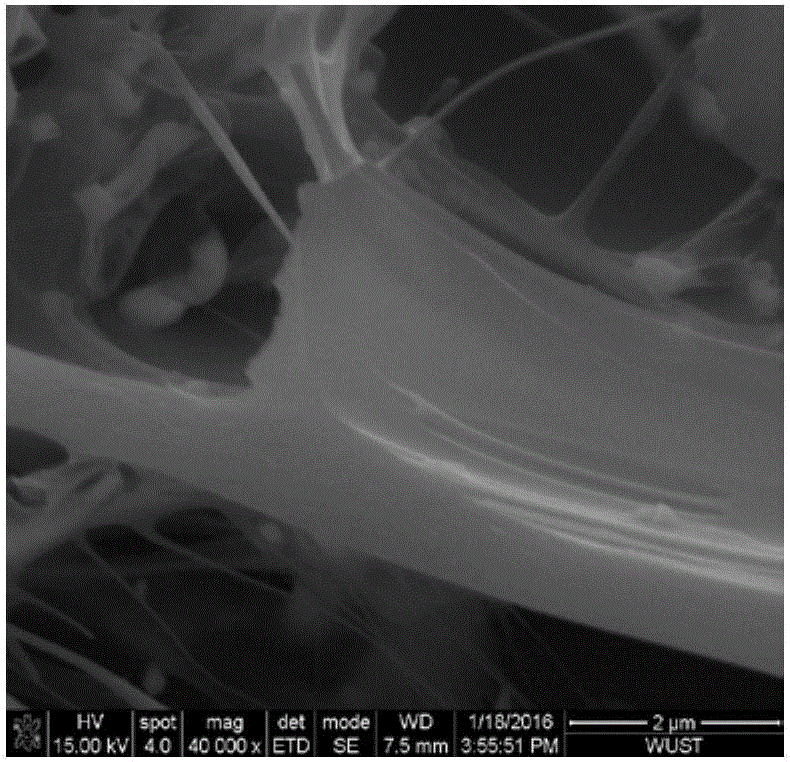

Image

Examples

Embodiment 1

[0027] This embodiment discloses a preparation method of a modified phenolic resin capable of generating graphene in situ, the preparation method comprising the following preparation steps:

[0028] 1) Preparation of phenolic resin intermediate product: Mix 0.1mol of phenol, 0.07mol of formaldehyde and 0.66g of hydrochloric acid, stir evenly, keep warm at 60°C for 60min, then raise the temperature to 80°C, keep warm for 120min to obtain phenolic resin Resin intermediates;

[0029] 2) Preparation of water-containing modified phenolic resin: adjust the acidity and alkalinity of the phenolic resin intermediate product prepared in the step 1) with ammonia water to ensure that the pH is between 6.0 and 6.4, then add 0.01mol of glycine, and heat the mixture at 80°C The temperature was kept at a temperature of 30 minutes, then the temperature was lowered to 50 ° C, and 0.001 mol of copper inorganic salt was added, and the temperature was kept for 30 minutes, and then the temperature ...

Embodiment 2

[0032] This embodiment discloses a preparation method of a modified phenolic resin capable of generating graphene in situ, the preparation method comprising the following preparation steps:

[0033] 1) Preparation of phenolic resin intermediate product: Take 0.1mol of p-cresol, 0.07mol of acetaldehyde and 0.11g of oxalic acid, mix them well, stir them evenly, keep them under the condition of 70°C for 30 minutes, then raise the temperature to 100°C, and keep them for reaction 180min, obtain phenolic resin intermediate product;

[0034] 2) Preparation of water-containing modified phenolic resin: adjust the acidity and alkalinity of the phenolic resin intermediate product prepared in the step 1) with ammonia water to ensure that the pH is between 6.4 and 6.8, then add 0.001mol of iminodiacetic acid, in Insulate and react at 100°C for 60 minutes, then lower the temperature to 70°C, continue to add 0.002 mol of nickel inorganic salt, heat for 60 minutes, and then cool the temperatu...

Embodiment 3

[0037] This embodiment discloses a preparation method of a modified phenolic resin capable of generating graphene in situ, the preparation method comprising the following preparation steps:

[0038] 1) Preparation of phenolic resin intermediate product: take 0.1 mol of hydroquinone, 0.07 mol of paraformaldehyde (average relative molecular weight is 600) and 0.77 g of sulfuric acid, mix them, stir them evenly, and keep them warm for 60 minutes at 65°C. Then the temperature was raised to 90° C., and the heat preservation reaction was carried out for 120 minutes to obtain the intermediate product of phenolic resin;

[0039]2) Preparation of water-containing modified phenolic resin: adjust the acidity and alkalinity of the phenolic resin intermediate product prepared in the step 1) with ammonia water to ensure that the pH is between 6.8 and 7.2, and then add 0.01mol of nitrilotriacetic acid at 90 ℃ for 30 minutes, then lower the temperature to 50 ℃, continue to add 0.001 mol of ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com