Polyurethane adhesive composition for artificial grassplot back glue

A polyurethane adhesive and artificial turf technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve carboxylated styrene-butadiene latex difficult to pull out force, rubber surface cracking, carboxylated styrene-butadiene latex thorn nasal odor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

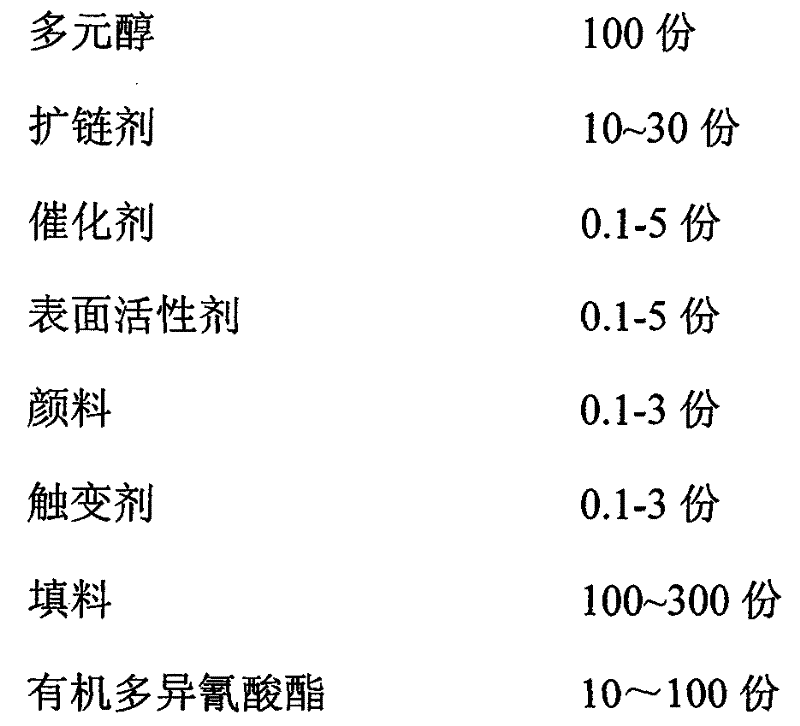

Method used

Image

Examples

Embodiment 1

[0028] Preparation of polyurethane adhesive composition for artificial turf back: at room temperature, quickly mix 100g polyether polyol, 17.6g diethylene glycol, 2.4g nickel diacetylacetonate, 1.5g fumed silica 1.2g Anionic surfactant, 0.9g of pigment and 170g of calcium carbonate are put into the mixing tank, and the high-speed disperser is used to stir rapidly for 3 minutes, and the stirring speed is 400 rpm; then add 61.6g of diphenylmethane diisocyanate, and stir rapidly 1 minute, make it mix evenly, the viscosity is 8500mPa·s. Use polyurethane adhesive of the present invention to be coated on the bottom back of artificial turf, so that its glue amount is 800g / m 2 , then heated and cured at 100°C for 5 minutes, and then left to stand at room temperature for 24 hours. According to the ISO4919 standard, use a universal tensile machine to test the force required to pull the grass silk out of the bottom back. The pull-out force of the lawn using the polyurethane adhesive of...

Embodiment 2

[0030] Preparation of the polyurethane adhesive composition for the back of the artificial turf: at room temperature, quickly mix 100g polyether polyol, 17.6g diethylene glycol, 2.9g nickel diacetylacetonate, 1.2g fumed silica, 1.2 The anionic surfactant of g, 0.9g pigment and 300g calcium carbonate are put into mixing tank, use high-speed disperser to stir rapidly 3 minutes, the speed of stirring is 400 rpm; Then add 61.6g diphenylmethane diisocyanate, quickly Stir for 1 minute to make it evenly mixed, the viscosity is 11500mPa·s. Use polyurethane adhesive of the present invention to be coated on the bottom back of artificial turf, so that its glue amount is 800g / m 2 , then heated and cured at 100°C for 5 minutes, and then left to stand at room temperature for 24 hours. According to the ISO4919 standard, use a universal tensile machine to test the force required to pull the grass silk out of the bottom back. The pull-out force of the lawn using the polyurethane adhesive of ...

Embodiment 3

[0032] Preparation of polyurethane adhesive composition for artificial turf bottom: at room temperature, quickly mix 100g polyether polyol, 17.6g diethylene glycol, 2.4g nickel diacetylacetonate, 2g fumed silica, 1g Anionic surfactant and 0.5g of cationic surfactant, 0.9g of pigment and 100g of calcium carbonate are put into the mixing tank, and the high-speed disperser is used to stir rapidly for 3 minutes, and the stirring speed is 400 rpm; then add 61.6g Diphenylmethane diisocyanate, stirred rapidly for 1 minute to make it evenly mixed, the viscosity is 6600mPa·s. Use polyurethane adhesive of the present invention to be coated on the bottom back of artificial turf, so that its glue amount is 800g / m 2, then heated and cured at 100°C for 5 minutes, and then left to stand at room temperature for 24 hours. According to the ISO4919 standard, use a universal tensile machine to test the force required to pull the grass silk out of the bottom back. The pull-out force of the lawn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com