Gluing system of box pasting machine

A technology for gluing and gluing, which can be used in container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc. It can solve problems such as unenvironmental protection and hidden dangers to the physical safety of production workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

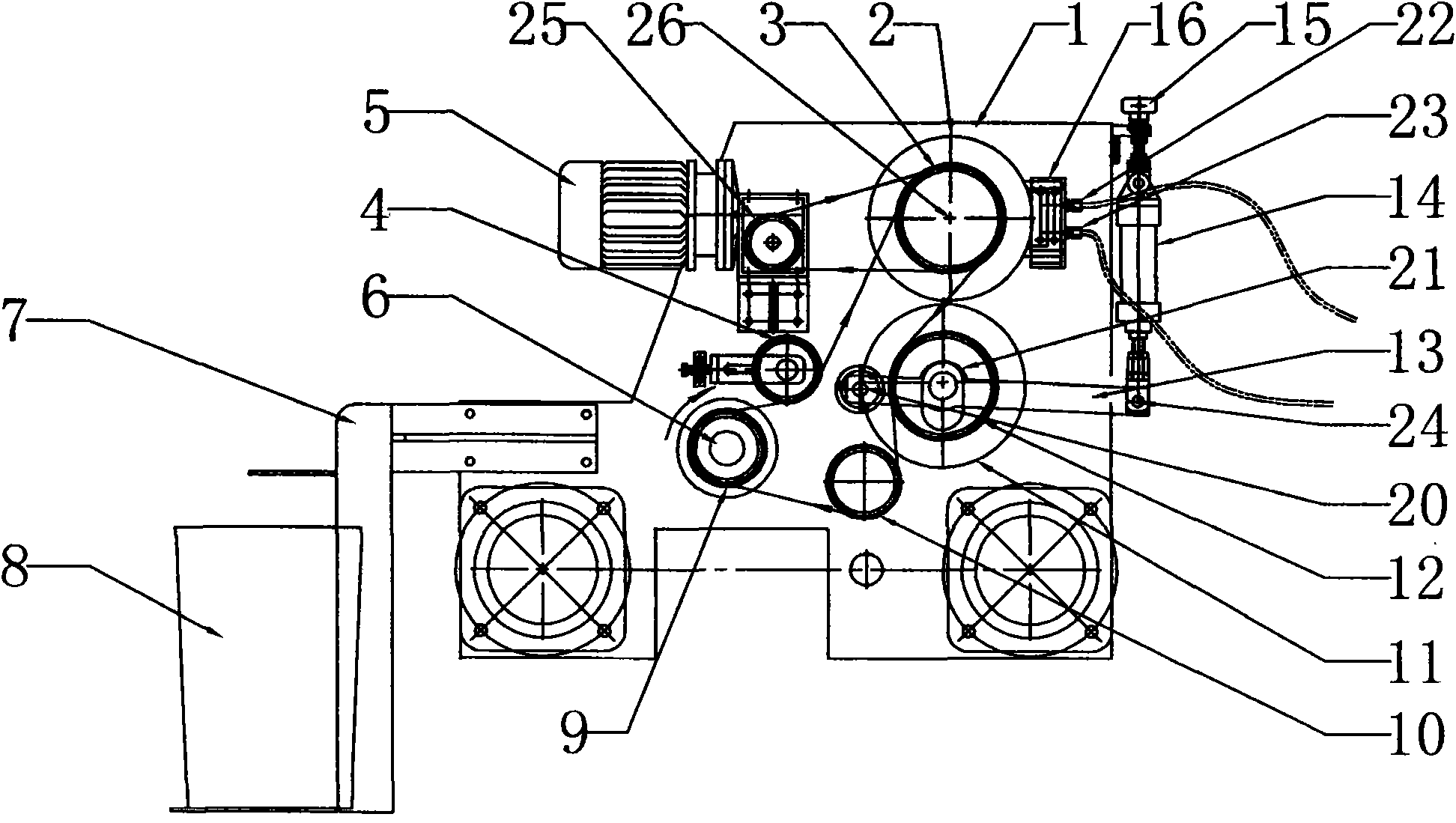

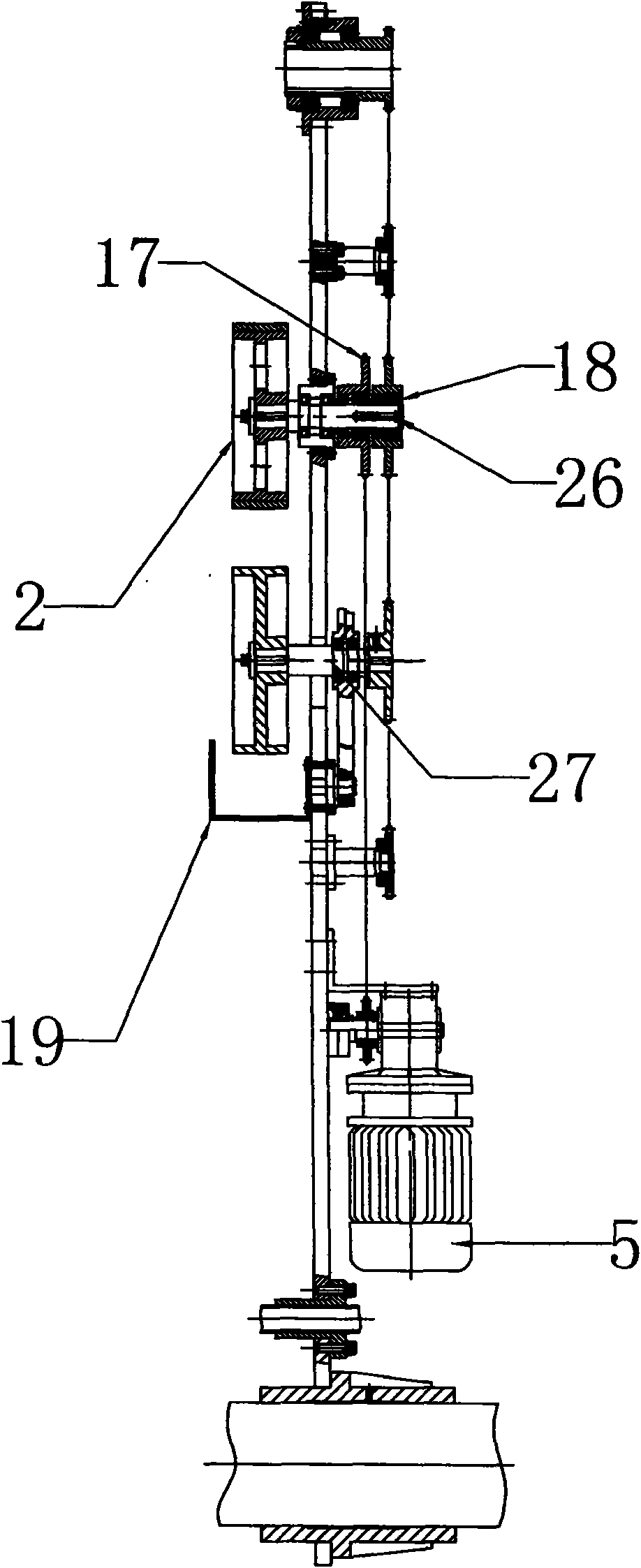

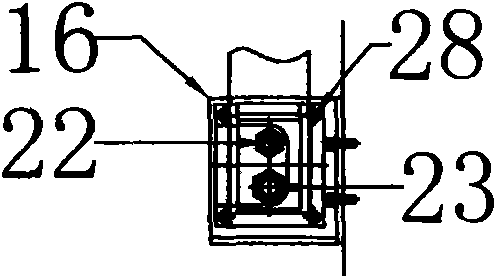

[0018] Attached below figure 1 To attach image 3 The present invention is further described, and the preferred embodiment of the present invention is: a glue application system of a box gluer, which includes a main machine side plate 1, a sizing wheel 2, a lower pressure wheel 11, a sizing wheel main shaft 26, an upper Glue box 16, one-way bearing 18 also include first power system, second power system, cylinder system; The sprocket 3, wherein the sizing wheel main shaft 26 and the motor 5 are respectively fixed on the main machine side plate 1, the motor sprocket 25 is fixed on the rotating shaft of the motor 5, and the first sizing wheel sprocket 3 is fixed on the sizing wheel main shaft 26, the first sizing wheel sprocket 3 is provided with a one-way bearing 18, the first sizing wheel sprocket 3 and the motor sprocket 25 are connected by a chain; the second power system is composed of the second sizing wheel sprocket 17, The lower pressure wheel sprocket 12, the transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com