Crackle paint and preparation method thereof

The technology of crack paint and crack agent is applied in the field of acrylic crack paint and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

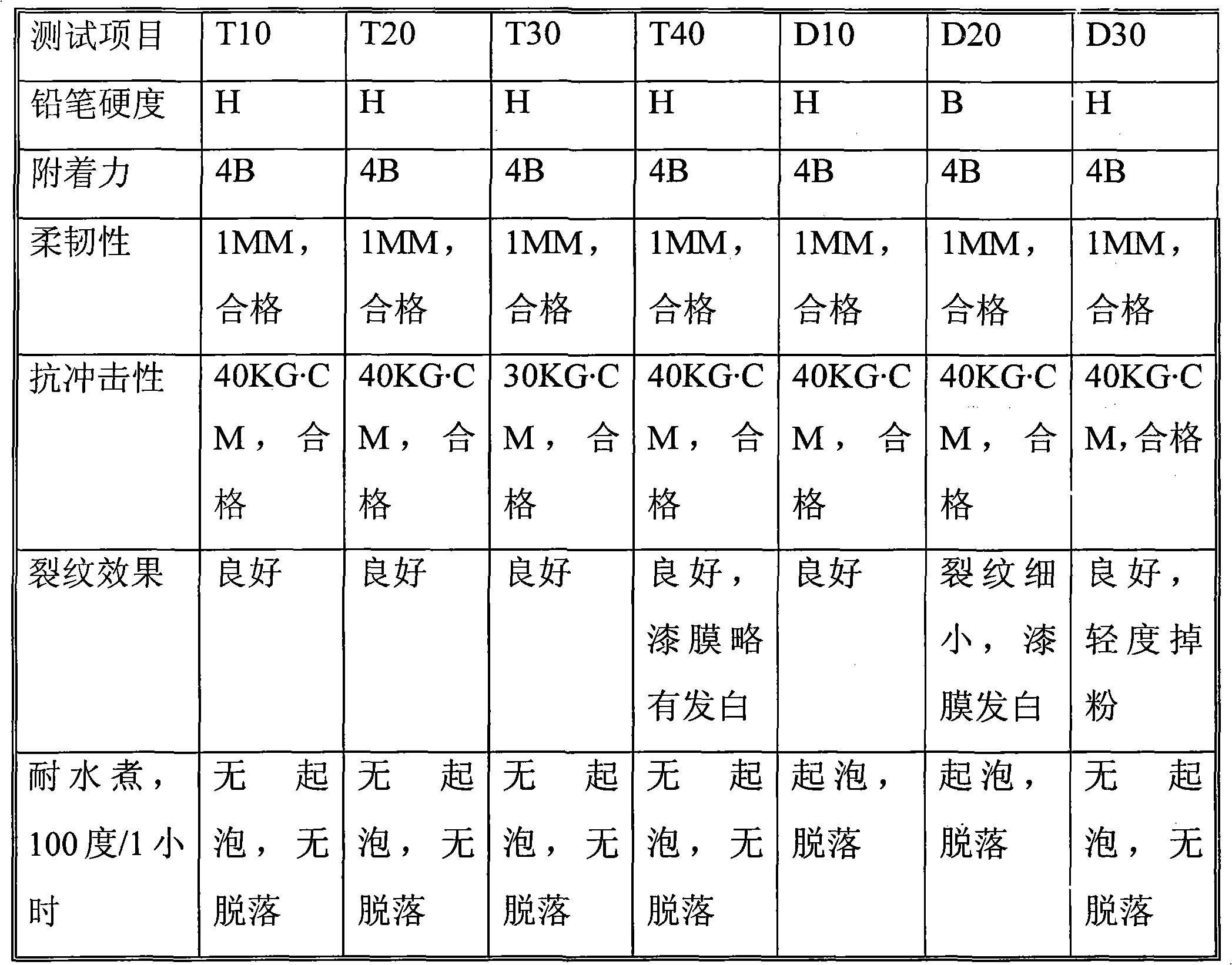

Image

Examples

preparation example Construction

[0021] The present invention also provides a preparation method of the above-mentioned cracked paint, which comprises adding thermoplastic acrylic resin, cracking agent and solvent into a container, mixing and stirring to obtain the cracked paint.

[0022] The specific preparation method is as follows,

[0023] 1) Weigh the thermoplastic acrylic resin according to the formula, add 1.5 times the solvent of the thermoplastic acrylic resin into the stirring container, add the weighed thermoplastic acrylic resin while stirring, and rotate at a speed of 10M / S until the solid resin is completely dissolved.

[0024] 2) Add the dissolved thermoplastic acrylic resin, wetting and dispersing agent and leveling agent according to the proportion of the formula, stir evenly, add ultra-fine mica and pigment, disperse and grind until the specified fineness is reached, add a small amount of solvent, adjust the viscosity, and filter .

[0025] 3) Weigh cellulose acetate butyrate according to t...

Embodiment 1

[0030] Preparation of crack paint primer: Weigh 80g of thermoplastic acrylic resin MB-2952, add 120g of solvent butyl acetate into the grinding tank, add the weighed MB-2952 while stirring, and rotate at 10M / S until the solid resin is completely dissolved. Then add 2.5g of pigment carbon black+50g of rutile titanium dioxide, 2.5g of wetting and dispersing agent (BYK-163), 4g of leveling agent (Afcona3670), 25g of ethyl 3-ethoxypropionate, mix well, and grind until The fineness reaches 25 microns, and the semi-finished product is obtained by filtering. Weigh 25g each of cellulose acetate butyrate CAB-381-0.5 and CAB-381-2, add 200g butyl acetate into the stirring container, add the weighed cellulose acetate butyrate while stirring, the speed is 10M / S, Until the cellulose acetate butyrate is completely dissolved. Add the dissolved cellulose acetate butyrate to the ground semi-finished product, add solvent butyl acetate and dilute the composition to 20s (Iwata 2# cup, 23° C.) to...

Embodiment 2

[0035] Same as Example 1, the difference is that the mica powder used is 2250 mesh mica powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com