Patents

Literature

146results about How to "Resistant to yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

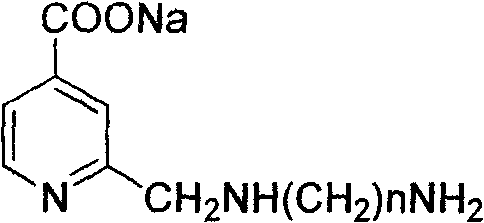

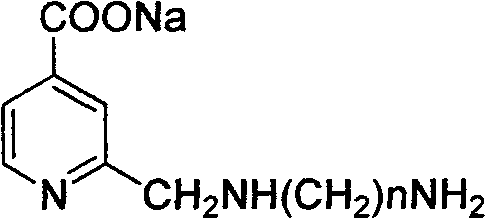

Preparation method of anionic aqueous polyurethane dispersoid for fabric coating and decoration

The invention relates to a preparation method of an anionic aqueous polyurethane dispersoid for fabric coating and decoration. The preparation method is operated according to the following steps that: (a) polyether polyol, polyester polyol and diisocyanate are subjected to polymerization reaction for 2 to 4 hours at 70 to 90 DEG C under the effect of catalysts; (b) acetone solvents and diamine hydrophilic chain extenders containing picolinic acid structures are added for taking reaction for 5 to 30 minutes at 40 to 65 DEG C, and polyurethane prepolymers are prepared; (c) the temperature is lowered to 20 to 40 DEG C, low-molecular-weight chain extenders and water are added and are emulsified through being stirred at high speed; (d) the acetone solvents are removed through reduced pressure distillation, and the anionic aqueous polyurethane dispersoid for fabric coating and decoration is obtained. Because diamine containing the picolinic acid structures is used as hydrophilic chain extenders, the regular pyridine ring structure is contained, the crystallization performance and the initial bonding intensity can be improved, meanwhile, a pyridine ring is an electron deficiency system, the color deepening caused by oxidation cannot easily occur, and the product has the yellowing resistance performance.

Owner:JIAXING UNIV +1

Polyol made from partialy hydrogenated, fully epoxidized natural oils

InactiveUS20110065821A1Low densityResistant to yellowingFatty acid hydrogenationFatty acid oxidationVegetable oilGram

A method is disclosed for making a polyol comprising: fully-epoxidizing a partially hydrogenated vegetable oil to obtain a fully-epoxidized vegetable oil derivative having an iodine value less than 4 g I2 / 100 gram, an EOC of from 4.0 to 5.7% and a Gardner color value of 2 or less; and then reacting the fully-epoxidized vegetable oil derivative with a ring opener to form a polyol having a hydroxyl number from 40 to 80 mg KOH / gram, a number average molecular weight of at least 1500 Daltons, a dynamic viscosity less than 10 pascal-seconds, and an EOC below 3.0 wt %.

Owner:CARGILL INC

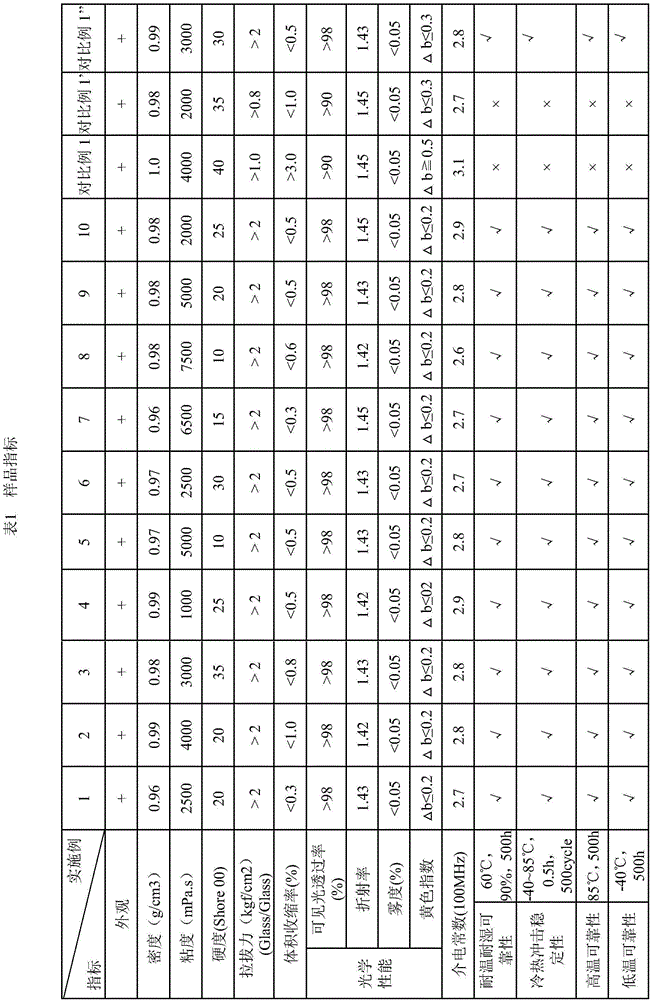

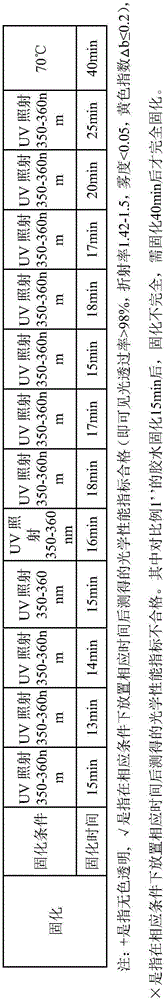

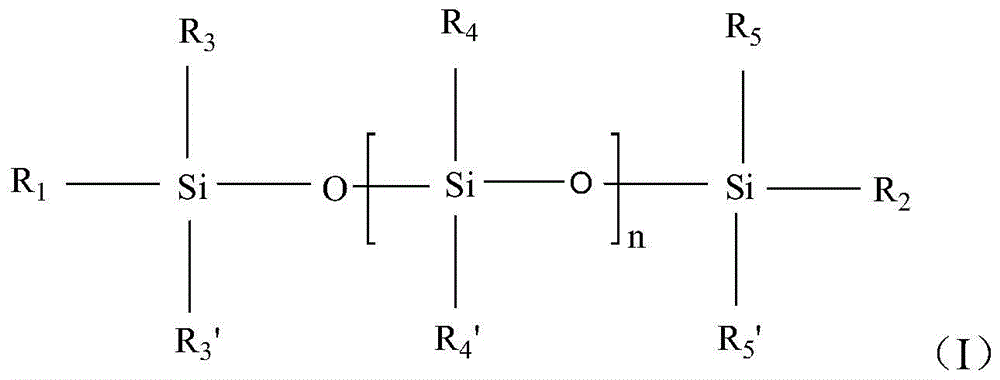

Optically transparent glue composition with organic silicone liquid and method for preparing optically transparent glue composition

ActiveCN105694800AGood effectSatisfy light transmittanceNon-macromolecular adhesive additivesUltravioletTackifier

The invention provides an optically transparent glue composition with organic silicone liquid.The optically transparent glue composition mainly comprises acrylate-terminated vinyl silicone oil, vinyl MQ silicone resin, vinyl MDT silicone oil, tackifiers, hydrogen-containing silicone oil, photoinitiators, catalysts, inhibitors and the like.The invention further provides a method for preparing the optically transparent glue composition.The method includes proportionally preparing materials; blending the materials to obtain mixtures; purifying the mixtures; defoaming the mixtures at high speeds and packaging the mixtures at high speeds.The optically transparent glue composition and the method have the advantages that glue with the organic silicone liquid can be simultaneously subjected to ultraviolet curing and heat curing, accordingly, the problem of incapability of completing curing on the peripheral edges of screens at one step can be solved, production processes and the manufacturing time can be greatly shortened, the reject ratio of finished products can be reduced, and effects of saving energy and time, reducing the production cost and improving the productivity can be realized; the glue is excellent in impact resistance, bending resistance, high-temperature and high-humidity resistance and yellowing resistance and low in dimensional contraction rate after being cured; bubble and impurities in the optically transparent glue with the organic silicone liquid can be prevented by the aid of the method.

Owner:新纶光电材料(深圳)有限公司

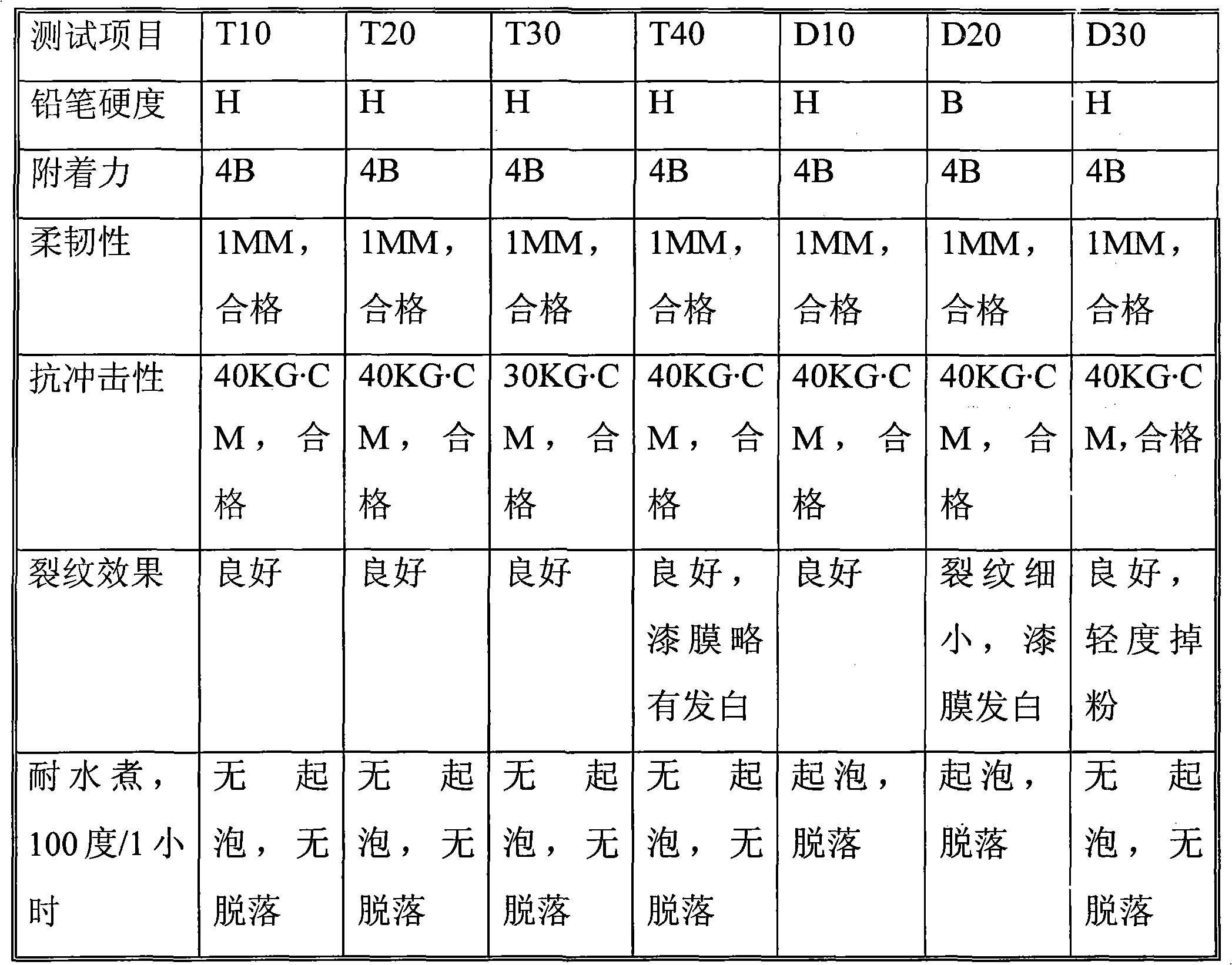

Crackle paint and preparation method thereof

InactiveCN102031049ANo need to worry about unusable problemsSave the supporting processCoatingsAcrylic resinTG - Triglyceride

The invention provides a crackle paint, comprising thermoplastic acrylic resin, crack agent and solvent, wherein the temperature of Tg (triglyceride) of the thermoplastic acrylic resin is 70-80 DEG C, and the crack agent is mica powder with the average particle size of 2000-3000 meshes. The invention also provides a preparation method of the crackle paint, comprising the steps of adding the thermoplastic acrylic resin, crack agent and solvent into a container, mixing and stirring. The invention has the advantages of simple steps when using the crackle paint provided by the invention and smallpossibility of picking of the crackle paint layer after being sprayed.

Owner:BYD CO LTD

Waterborne polyurethane material and preparation method thereof

InactiveCN102746818AResistant to yellowingNon-toxicPolyureas/polyurethane adhesivesPolyurethane dispersionNon toxicity

The invention relates to a waterborne polyurethane material and a preparation method of the material, in particular to a waterborne polyurethane material for laminating and compounding of foods or drugs in the packaging process and a preparation method of the material. The waterborne polyurethane material is prepared by compounding the following components by weight: 100 parts of anti-yellowing waterborne polyurethane dispersion, 0.01-0.2 parts of leveling agent and 0.01-0.2 parts of de-foaming agent. The waterborne polyurethane material has the advantages of yellowing resistance, non-toxicity, non-combustibility, safety in use, environmental protection and the like. The requirements of the laminating and compounding process on the waterborne polyurethane material are comprehensively considered, and the bonding strength and appearance in the laminating and compounding process are improved through carrying out chain extension for multiple times and adding the leveling agent and the waterborne de-foaming agent, wherein the T stripping strength and the readily oxidizable substance in the laminating and compounding process meet the industrial requirements for laminating and compounding of the foods or the medicines.

Owner:NANJING TECH UNIV

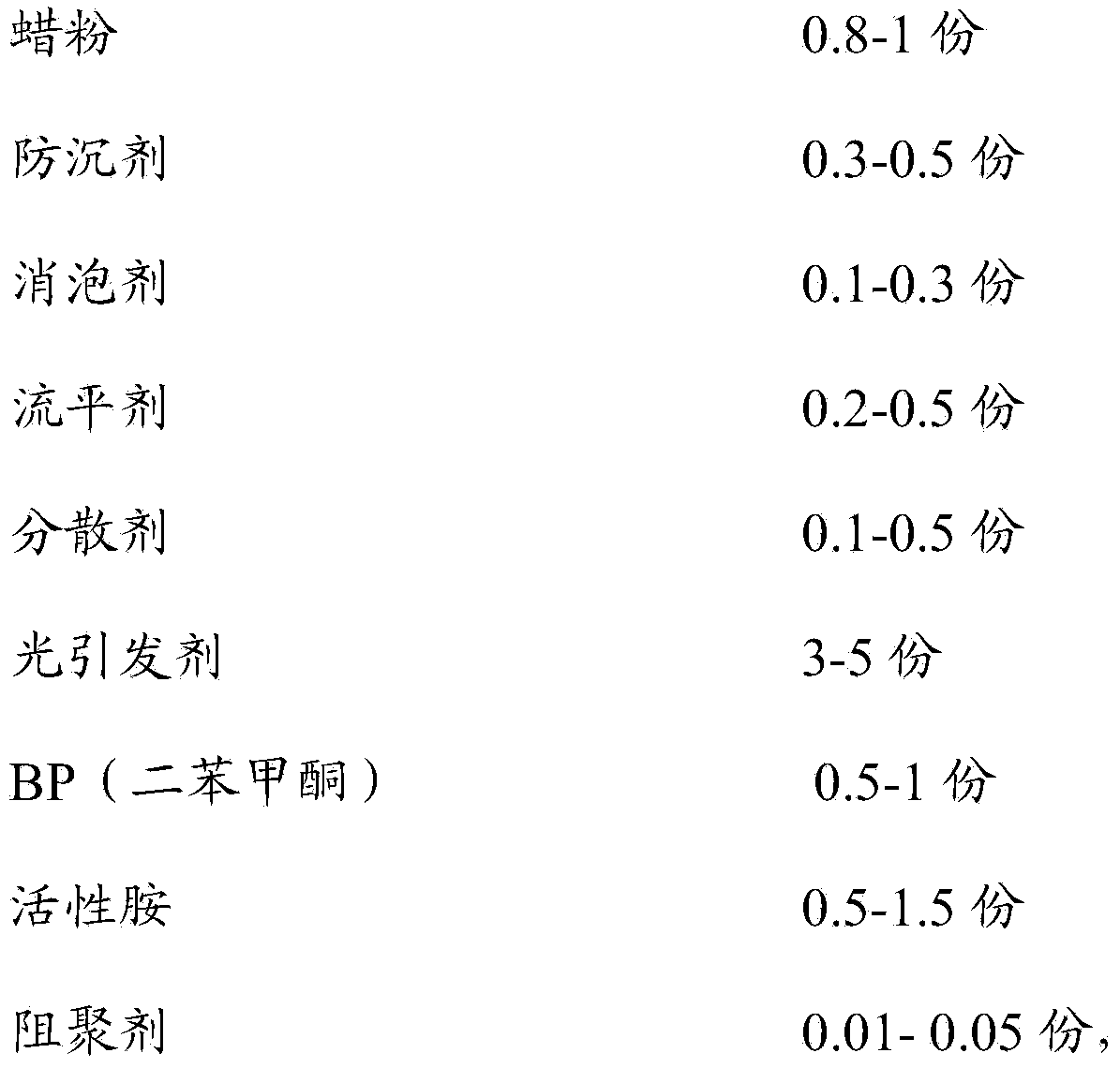

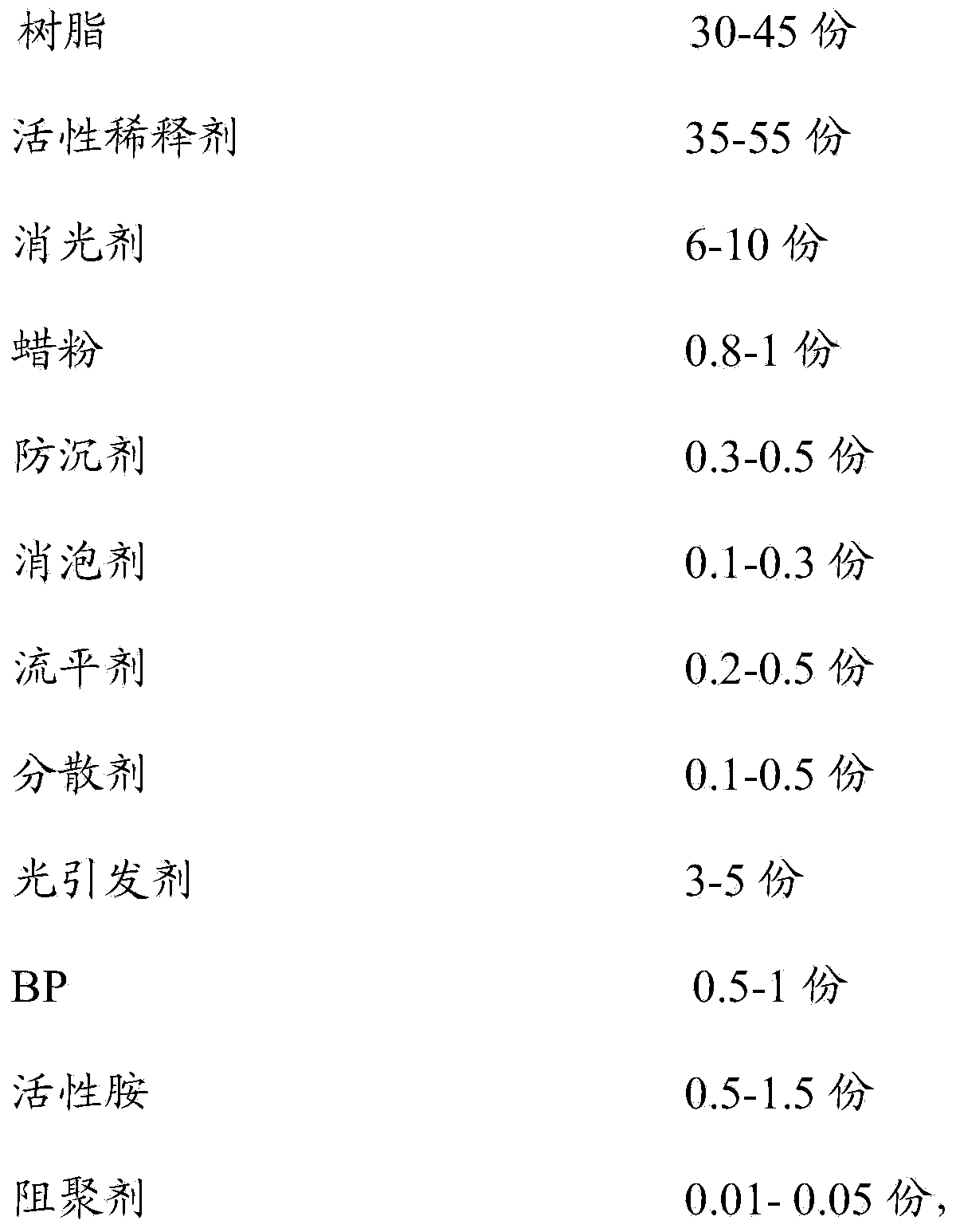

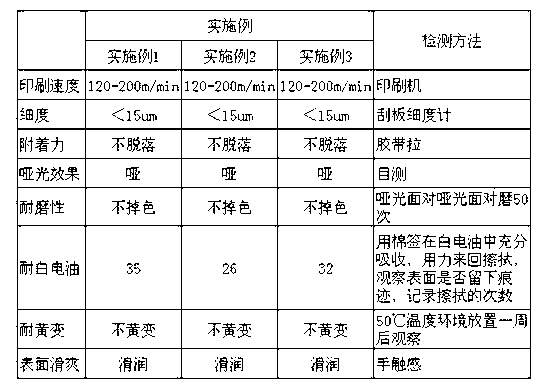

Odor-free yellowing-resistant UV (ultraviolet) curing coating and preparation method thereof

ActiveCN104341979ALow curing odorModerate hardnessPolyurea/polyurethane coatingsEpoxy resin coatingsWaxPhotoinitiator

The invention discloses an odor-free yellowing-resistant UV (ultraviolet) curing coating and a preparation method thereof. The odor-free yellowing-resistant UV curing coating comprises the following components in parts by weight: 30-45 parts of resin, 35-55 parts of reactive diluent, 6-10 parts of delustering agent, 0.8-1 part of wax powder, 0.3-0.5 part of anti-settling agent, 0.1-0.3 part of defoaming agent, 0.2-0.5 part of flatting agent, 0.1-0.5 part of dispersing agent, 3-5 parts of photoinitiator, 0.5-1 part of BP, 0.5-1.5 parts of active amine and 0.01-0.05 part of polymerization inhibitor, wherein the resin is modified epoxy acrylic ester resin, aliphatic urethane acrylate resin and hyperbranched polyester acrylate resin. The odor-free yellowing-resistant UV curing coating disclosed by the invention has the performances of low odor and high yellowing resistance, and can meet higher requirements of the UV curing coating on low odor and yellowing resistance in the furniture industry.

Owner:CARPOLY CHEM GRP

Surface printed solidified matte ink and preparation method thereof

The invention relates to surface printed solidified matte ink and a preparation method thereof. The surface printed solidified matte ink is formed by adding a curing agent into an ink base material according to a ratio of 6-10% and stirring, wherein the ink base material comprises the following ingredients: 23 parts of n-propyl ester, 10 parts of butyl acetate, 8 parts of a polyurethane resin, 10 parts of aldehyde ketone resin, 1 part of a flatting agent, 40 parts of light removing slurry, 7 parts of ternary chlorine vinegar resin, 0.5 part of an antifoaming agent and 0.5 part of a dispersing agent; the n-propyl ester, the butyl acetate, the polyurethane resin, the ternary chlorine vinegar resin and the aldehyde ketone resin are firstly ground, combined with the flatting agent and the light emitting slurry, and are subjected to high-speed dispersion, the ingredients are filtered and packaged into finished products, and 6-10% of the curing agent is added, thus obtaining the ink which can be used for printing. The matte ink can be used for directly printing in a matte manner to form a film, personal hollow printing or conventional covering printing is realized, the adhesive force is high, the surface is smooth, the matte effect is remarkable, and the production cost is lowered. The surface printed solidified matte ink is applicable to printing on coiling drums of wall paper, chrome paper, kraft paper, leatherette paper and various special types of paper, and meanwhile the ink is applicable to printing on PE (Poly Ethylene), PET (Polyethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), pearly luster films and twisting films with corona layers.

Owner:ZHUANGLI PRINTING CHAOAN COUNTY

Aqueous decoration leather

ActiveCN103556487AIncrease speedLow costLamination ancillary operationsSynthetic resin layered productsSurface layerHazardous substance

The invention provides an aqueous decoration leather. A method for preparing the aqueous decoration leather comprises the following steps: 1, an aqueous wet process: pressing a base cloth, directly coating an aqueous polyurethane foam slurry, drying, reeling, and carrying out semi-finished product bass examination; and 2, an aqueous dry process: directly coating a polyurethane surface layer slurry on a release paper, drying, applying with a semi-finished product bass, drying, reeling, and carrying out finished product examination. The method substantially improves the workshop speed, reduces the cost and increases the output by utilizing the combination of the wet method bass and the dry method coating transfer process. The aqueous decoration leather has the advantages of flame retardation, yellowing resistance, hydrolysis resistance, mildew resistance, water resistance, and zero content of harmful substances comprising DMF, formaldehyde, o-benzene compounds and the like.

Owner:ZHEJIANG WUZHOU IND

Preparing method for soft rubber NdFeB (neodymium iron boron) magnet

ActiveCN103578735AHigh strengthImprove toughnessPermanent magnetsInductances/transformers/magnets manufactureState of artPre treatment

The invention discloses a preparing method for a soft rubber NdFeB (neodymium iron boron) magnet and solves the problems that during the machining of the soft rubber NdFeB magnet in the prior art, the binding strength with rubber is lower, magnetic powder is easily stripped from the surface of a product, the tenacity is poor, cracking easily occurs, and the surface coating is easy to crack and strip. The method comprises the following steps of (1) surface modifying; (2) burdening; (3) open refining; (4) closed refining; (5) smashing; (6) tabletting; (7): laminating; (8) cutting; (9) spraying and (10) magnetizing. The raw materials of the NdFeB magnet and sprayed components of the coating are modified, before being subjected to the surface modifying, the rapid quenched NdFeB magnetic powder is preprocessed, and the drying process after the coating is sprayed is also optimally designed. The soft rubber NdFeB magnet manufactured by the preparing method has excellent strength and tenacity as well as excellent magnetic performance, and the binding strength of the coating at the surface of the soft rubber NdFeB magnet and the soft rubber NdFeB magnet is strong, so cracking difficultly occurs.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

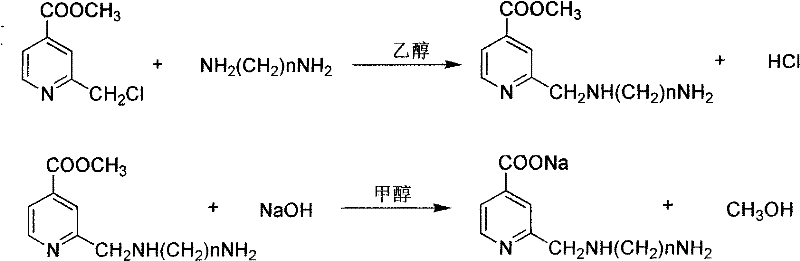

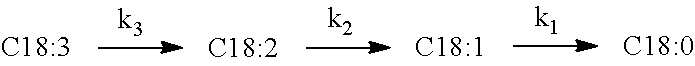

Heat-resistant yellow-stain-resistant epoxy acrylate low polymer and preparation method of UV (ultraviolet) ink

ActiveCN104962130AHeat resistantHeat-resistant and yellowing-resistantOrganic chemistryInksPolymer sciencePolyethylene terephthalate glycol

The invention discloses a heat-resistant yellow-stain-resistant epoxy acrylate low polymer and a preparation method of UV (ultraviolet) ink. The heat-resistant yellow-stain-resistant epoxy acrylate low polymer is prepared through a following method comprising the following steps of carrying out an addition-esterification reaction on triglycidyl isocyanurate and an acrylic organic acid under the action of a catalyst, so as to obtain triglycidyl isocyanurate acrylate, then reacting the triglycidyl isocyanurate acrylate with an acid anhydride to obtain an acid anhydride modified triglycidyl isocyanurate acrylate, finally, adding a viscosity reducer and a reactive thinning agent into the acid anhydride modified triglycidyl isocyanurate acrylate, and regulating system viscosity to obtain the heat-resistant yellow-stain-resistant epoxy acrylate low polymer. The heat-resistant yellow-stain-resistant epoxy acrylate low polymer is adopted for the UV ink prepared by the invention; the defect that conventional UV ink is easy to yellow is overcome; moreover the UV ink is high in adhesive force, is wide in the serviceable range to base materials, and can be printed on the upper surfaces of base materials of PE (polyethylene), PP (polypropylene), PET (polyethylene terephthalate), glass, a circuit board and the like in a screen printing manner. The UV ink prepared by the invention has high glossiness, excellent heat resistance and yellow stain resistance, and is further wide in application range.

Owner:FOSHAN SOUTHERN PACKAGING +2

Preparation and construction process for bottom-coating used for mineral cotton ceiling floor

InactiveCN101565580AHas a three-dimensional textureUnique three-dimensional textureLiquid surface applicatorsStarch dervative coatingsMildewUltimate tensile strength

The invention discloses a preparation and a construction process for a bottom-coating used for a mineral cotton ceiling floor. The bottom-coating used for the mineral cotton ceiling floor is a liquid-type layer material. The construction process comprises five procedures of testing substrate plates, spraying and coating the bottom-coating, high-temperature baking, re-spraying bottom-coating and re-baking at high temperature. The bottom-coating used for the mineral cotton ceiling floor has the advantages of strong stereoscopic feeling, strong decoration, excellent fireproof and moisture-proof function, reinforcing the tensile strength of the plate, mildew resistance, reducing noise, long service life, yellowing resistance, low VOC, convenient construction, etc. The bottom-coating used for the mineral cotton ceiling floor is matched with the mineral cotton ceiling floor, has unique stereoscopic feeling, can change the visible effect of the room space and is applicable to the decoration of the ceiling decorative surfaces of various top-grade buildings.

Owner:鳄鱼制漆(上海)有限公司

Nano sterilizing anionic double-component aqueous wood paint

InactiveCN101880500ANo pollutionWon't hurtAntifouling/underwater paintsPaints with biocidesAcrylic resinLacquer

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano sterilizing anionic double-component aqueous wood finishing paint and a preparation method thereof. The nano sterilizing anionic double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano sterilizing anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, strong sterilization and mildew prevention, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

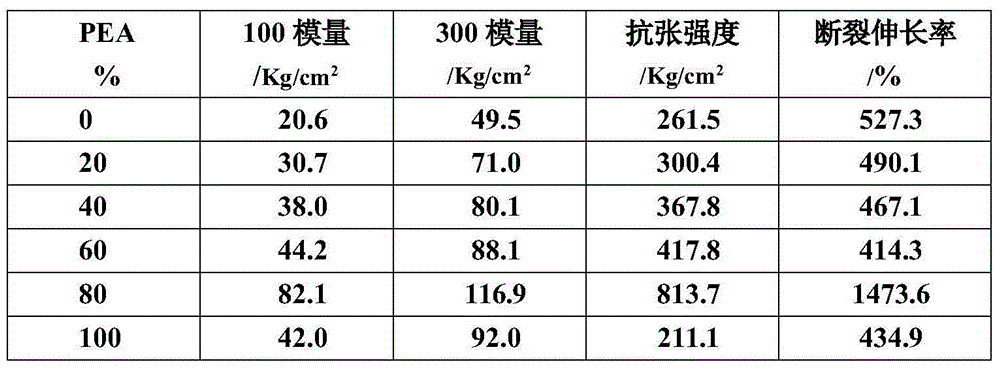

Waterproof moisture-permeable waterborne polyurethane fabric coating material and preparation method thereof

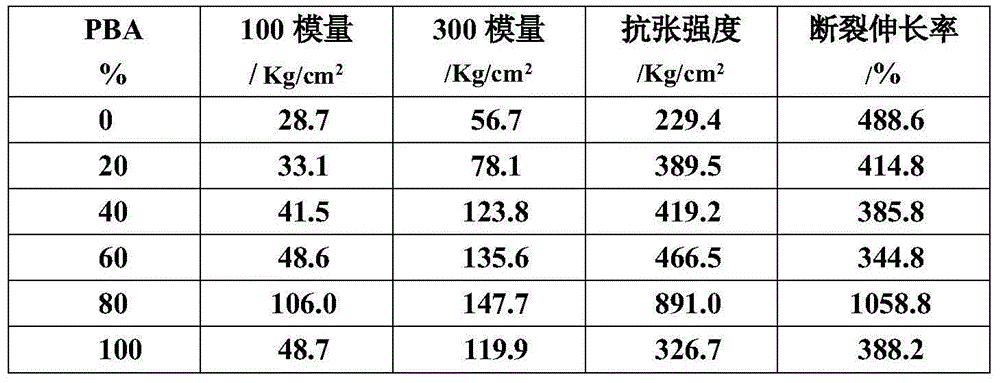

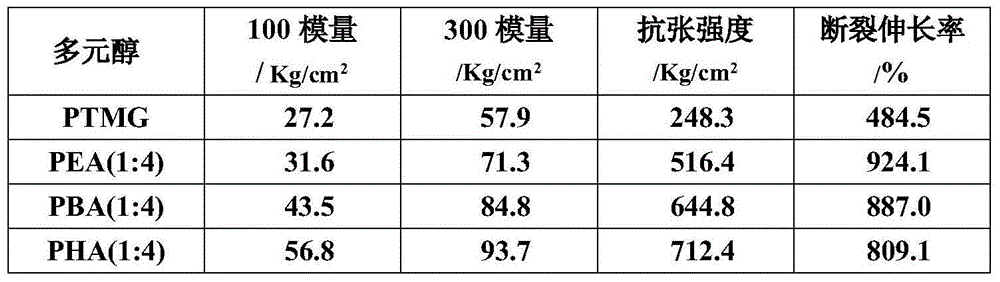

The invention discloses a waterproof moisture-permeable waterborne polyurethane fabric coating material with an excellent mechanical performance and a preparation method thereof. The material is obtained by emulsifying a waterborne polyurethane prepolymer butanone mixture which is formed in a manner than alkali is neutralized by an ethylenediamine aqueous solution, carrying out chain extension, defoaming and removing butanone by evaporation. The waterborne polyurethane prepolymer is prepared from the following components in percentage by mass according to the total mass of the waterborne polyurethane prepolymer: 30-40wt% of a diisocyanate, 50-60% of a polymer-dihydric alcohol, 3.8-5.8% of a hydrophilic chain extender-2,2-dimethylolbutanoic acid, 0.5-6.0% of micromolecule dihydric alcohol and 0.01-0.03% of an organic metal tin catalyst. The molecule structure and the micro-phase separation degree of a soft segment and a hard segment of the coating material are optimized; the water vapor transmission rate and the water pressure resistance of a fabric after coating meet the coating finishing requirement of a Dacron fabric on the market; the mechanical performance is excellent, wherein the tensile strength exceeds 800Kg / cm<2>, and the elongation at break is greater than 1700%.

Owner:SOUTHEAST UNIV

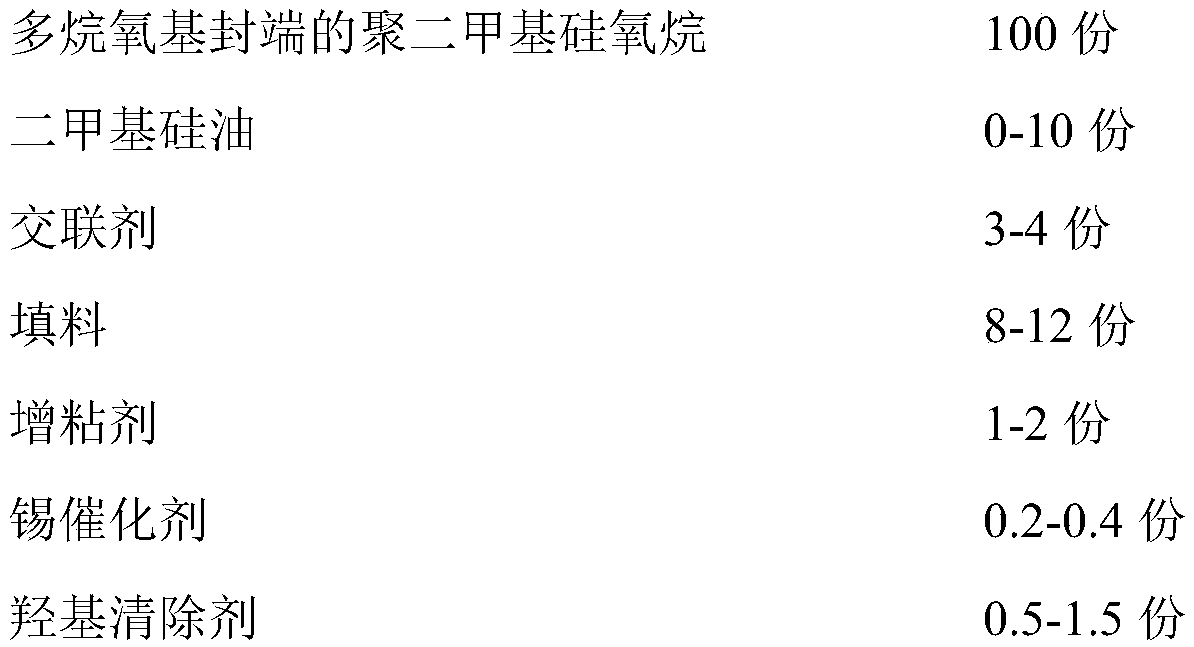

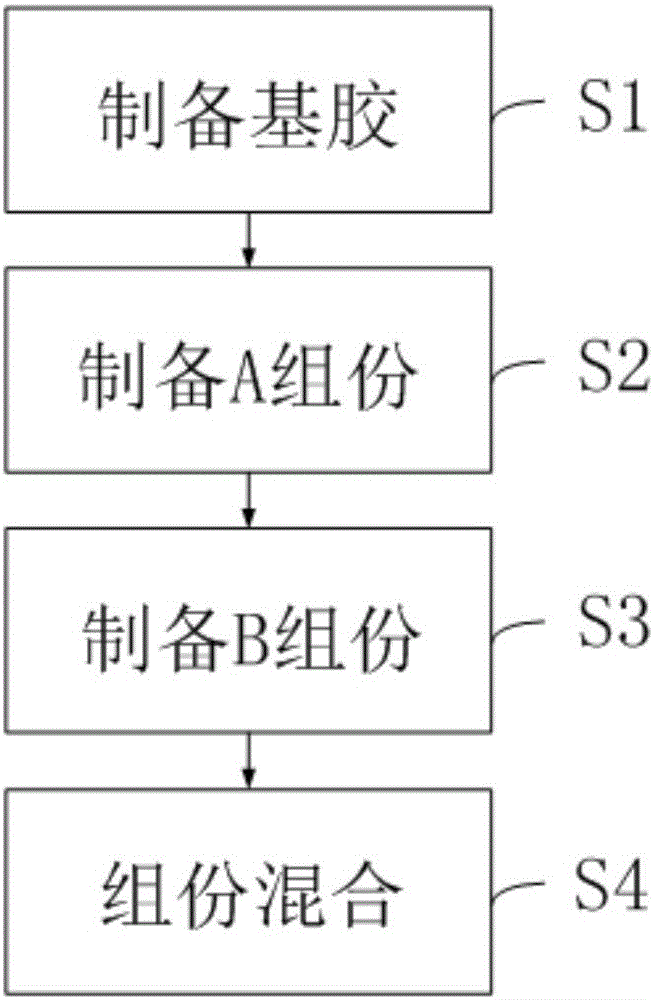

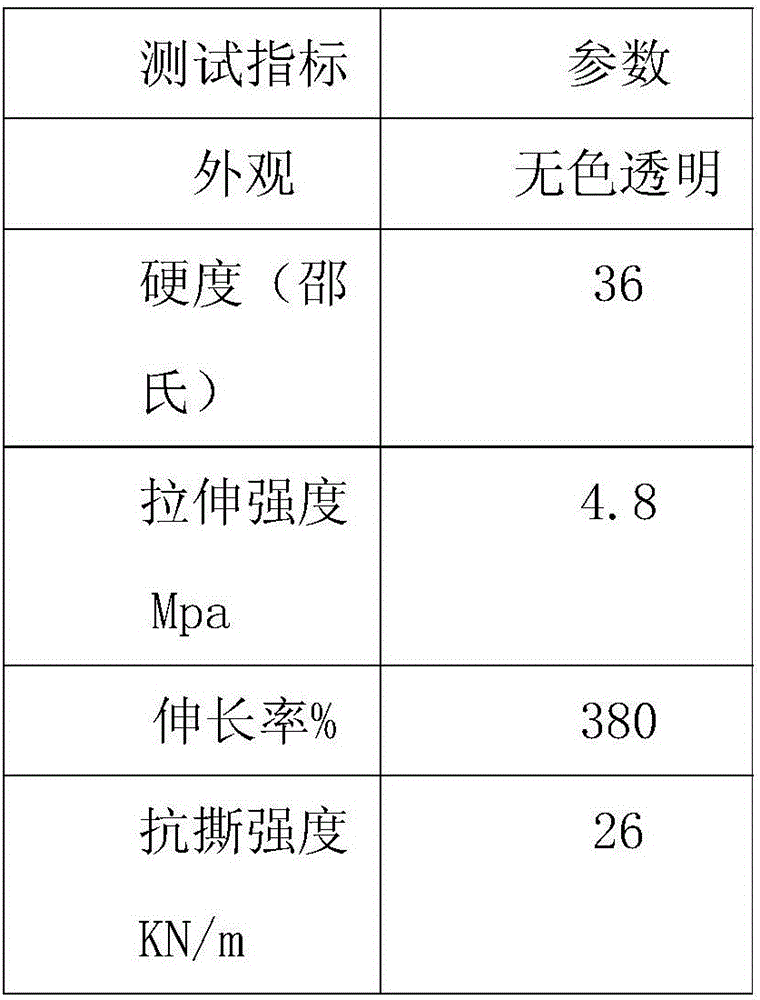

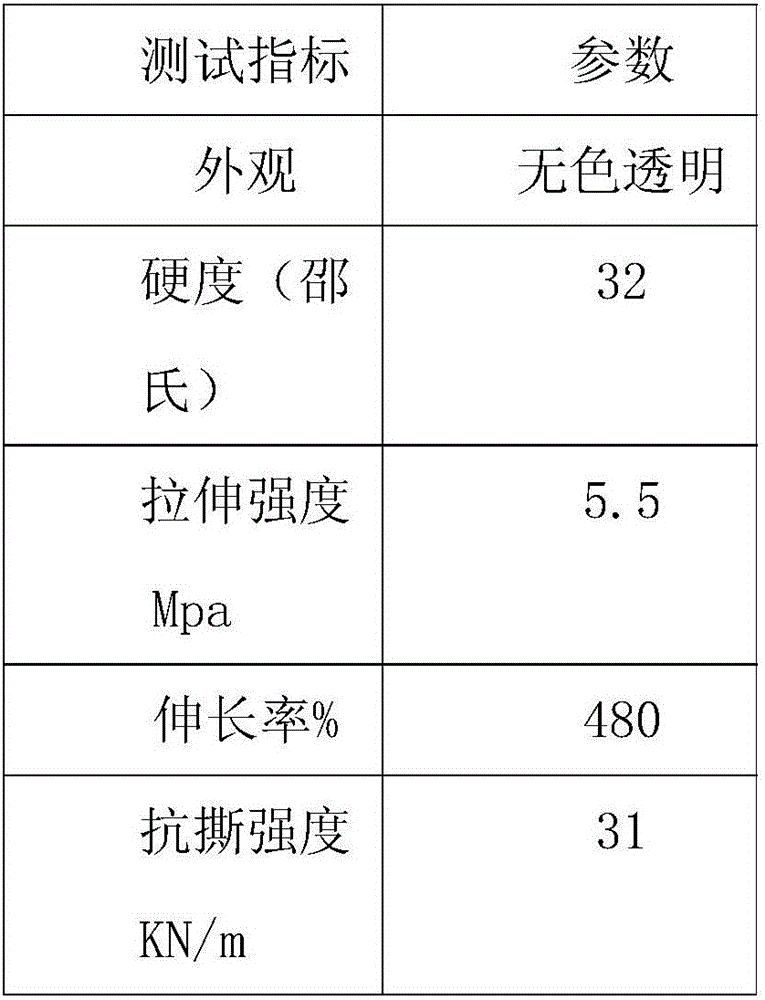

Single-component dealcoholized transparent silicone sealant, preparation method and application thereof

ActiveCN109280533ASimple processReduce manufacturing costNon-macromolecular adhesive additivesLED lampSilicone oil

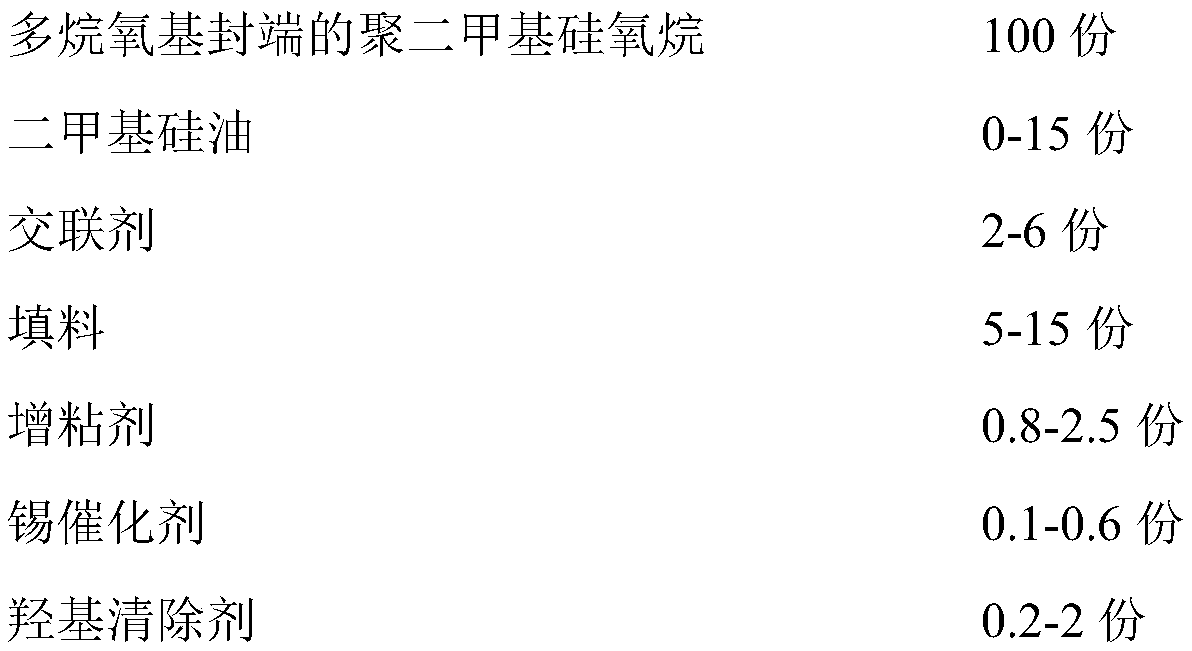

The invention relates to single-component dealcoholized transparent silicone sealant, a preparation method and an application thereof and belongs to the technical field of organic silicon sealant. Thesealant is prepared from, by weight, 100 parts of polyalkoxy-terminated polydimethylsiloxane, 0-10 parts of dimethyl silicone oil, 2-6 parts of a crosslinker, 5-15 parts of filler, 0.8-2.5 parts of atackifier, 0.1-0.6 parts of a tin catalyst and 0.2-2 parts of a hydroxyl group remover. The sealant has great transparency, is convenient to use and good in storage stability, has good adhesive force, is anti-yellowing and is free of corrosion and pollution on a base material. The sealant can be extensively used for sealing adhesion of electronic appliances, circuit boards, mirrors, art crafts, LED lamps and the like.

Owner:GUANGZHOU GLORYSTAR CHEM

Special halogen-free anti-static flame-retardant material for TPE (thermal plastic elastomer) molding and preparation method for special halogen-free anti-static flame-retardant material

The invention discloses a special halogen-free anti-static flame-retardant material for TPE (thermal plastic elastomer) molding. The special halogen-free anti-static flame-retardant material comprises the following raw materials: SEBS (styrene-ethylene-butadiene-styrene) rubber resin, a softening plasticizer, a flame retardant, an anti-static agent, polypropylene resin, an antioxidant, a light stabilizer and a processing aid. The invention further discloses a preparation method for the special halogen-free anti-static flame-retardant material. The preparation method is simple in process step and easy to realize, and can be used for quickly preparing the special halogen-free anti-static flame-retardant material product for TPE molding. The special halogen-free anti-static flame-retardant material for TPE molding is reasonable in formula, has the advantages of no halogen, yellowing resistance, good flame resistance, good adhesion property, high fluidity, difficulty for dust adhesion, easiness for injection molding and the like, effectively avoids release of harmful substances in a heating process due to no halogen and flame resistance, cannot threaten human health or environment, and can be widely applied to an outer film of a high-grade headphone wire plug, an outer film of a data wire plug and other wire products.

Owner:DONGGUAN JISU PLASTIC TECH

Double-ingredient epoxy seam beautifying glue

InactiveCN106381117AEasy to operateSafe and non-toxicNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyCrack resistance

The invention relates to seam beautifying glue, in particular to double-ingredient epoxy seam beautifying glue. An ingredient A is prepared from the following ingredients in percentage by weight: 60 to 90 percent of epoxy resin, 0 to 30 percent of plasticizers, 0 to 3 percent of anti-freezing agents, 0 to 15 percent of glitter powder, 1 to 10 percent of thixotropic agents, 0.01 to 1 percent of antifoaming agents and 0 to 20 percent of filling materials; an ingredient B is prepared from the following ingredients in percentage by mass: 65 to 95 percent of curing agents, 1 to 20 percent of thixotropic agents, 0 to 30 percent of plasticizers and 0 to 15 percent of glitter powder. The ingredient A and the ingreeinet B are respectively packaged after the preparation; the ingredient A and the ingredient B can be used after being uniformly mixed according to the weight ratio of 1:1. The construction operation is convenient; the advantages of safety, non-toxicity, wear resistance, waterproof performance, mildewproof performance, stain prevention, chemical medicine resistance, anti-cracking performance, fine crack resistance, yellowing resistance, rich color and the like are realized; the seam beautifying glue can be used as the seam beautifying glue by replacing the existing cement and can be used for performing color matching on ceramic tiles in different colors so as to achieve the decoration effect.

Owner:三友(天津)高分子技术有限公司

Waterborne polyurethane adhesive for synthetic leather and preparation method thereof

ActiveCN103450837ADelayed thermal oxidationExtended service lifePolyureas/polyurethane adhesivesIsophoroneEnvironmental resistance

The invention provides an environment-friendly and safe waterborne polyurethane adhesive for synthetic leather and a preparation method thereof. The polyurethane adhesive is prepared mainly from the raw materials such as polytetrahydrofuran glycol, dicyclohexylmethylmethane diisocyanate, phosphoric acid, dimethylolpropionic acid, trimethylolpropane polyoxypropylene polyoxyethylene ether, isophorone diamine and deionized water. In a using process of the waterborne polyurethane adhesive for synthetic leather, the volatilized gas is water vapor which is harmless to environment, thereby greatly reducing the cost for controlling environmental pollution. The waterborne polyurethane adhesive for synthetic leather is insensitive to the environmental factors such as acid, alkali and electrolyte, and avoids the phenomenon of emulsion breaking caused by adding various auxiliaries; meanwhile, by adding a proper amount of carboxylic chain extender into the formula, the obtained waterborne polyurethane adhesive for synthetic leather has excellent performance such as high strength, high wear resistance, yellowing resistance, aging resistance, low-temperature resistance, folding resistance and good permeability.

Owner:SHANDONG TIANQING TECH DEV

Self-cleaning type ultraviolet-curing transparent thermal-insulation coating and preparation method thereof

ActiveCN107236425AEasy to useResistant to yellowingAntifouling/underwater paintsPaints with biocidesOligomerThermal insulation

The invention relates to a self-cleaning type ultraviolet-curing transparent thermal-insulation coating and a preparation method thereof. The ultraviolet-curing transparent thermal-insulation coating is prepared from active oligomer, an ultraviolet initiator, modified nano functional unit / reactive fluorinated diluent mixed slurry, a multifunctional group reactive diluent, a leveling agent and a defoaming agent through compounding. The coating has the advantages of being non-toxic, safe to use, yellowing-resistant, non-inflammable, thermal-insulated, low in surface energy, good in light transmittance performance and the like and can be applied to curtain wall glass of buildings, automobile window glass and other situations.

Owner:NANJING UNIV OF TECH

Water double-component fatty polyurethane coating

InactiveCN1583913AHigh glossResistant to yellowingPolyurea/polyurethane coatingsEmulsion paintsResistHeavy water

This invention involves a heavy water type polyurethane of a fat clan of one pair of groups Coating, its characteristic lies in that A, two groups of one of B, its weight mixing To A:B=1000:27; one of group A is by the following groups Become things and weight percentage to make up, Polyurethane Xuan acid and resin of swimming skill solution is 60%-70%. Acrylic acid cream is 12%-20%, deionized water 15%-18%, additive is 0.4%; B The group one is plural third pyridine of nitrogen Solution, its molecular formula: C22H33O7, the stated additive is Flat pharmaceutical flows in swimming skill, disappear and steep the pharaceutical, surface auxiliary. Advantage of this invention Paint the membrane gloss high, wear-resisting, resist and row, able to bear many kinds of organic solution and chemistry to corrode, is also to bear Water, nonpoisonous, resist the ultraviolet ray, tastelessy, able to bear the yellow to change.

Owner:HUIHAO POLYTECHNIC COATING SHANGHAI

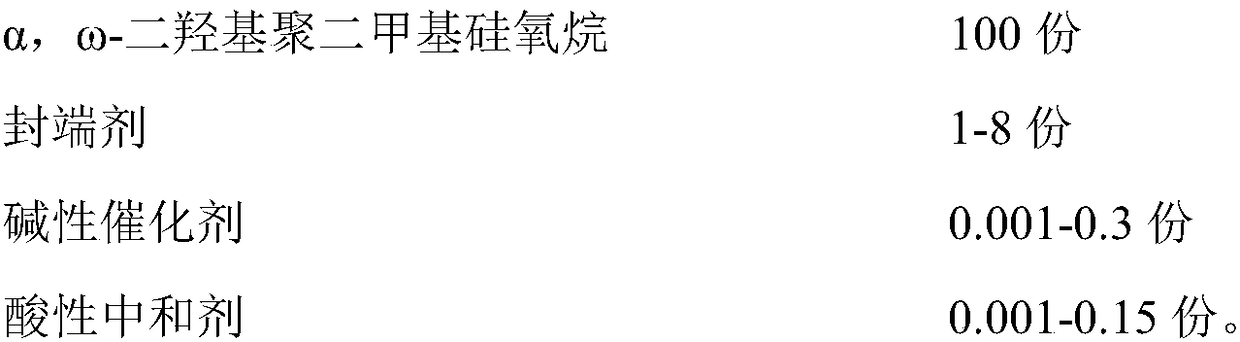

Two-component addition type liquid silicone rubber and preparation method thereof

The invention provides two-component addition type liquid silicone rubber and a preparation method of the two-component addition type liquid silicone rubber. The addition type liquid silicone rubber prepared through the method comprises a component A and a component B in a mass ratio of (2: 100) to (10: 100), wherein formula raw materials of the component A comprise the following components calculated in parts by mass: 95 to 105 parts of vinyl silicone oil, 2.0 to 5.0 parts of a platinum catalyst, 0.5 to 1.0 part of an accelerant, and 0.1 to 0.2 part of a leveling agent; formula raw materials of the component B comprise the following components calculated in parts by mass: 95 to 105 parts of base gum, 1.0 to 5.0 parts of hydrogen containing crosslinking agents, 0.05 to 0.1 part of an inhibitor, and 15 to 50 parts of vinyl silicone oil, wherein the base gum comprises 100 parts of vinyl silicone oil and 25 to 35 parts of white carbon black. The two-component addition type liquid silicone rubber and the preparation method of the two-component addition type liquid silicone rubber disclosed by the invention have the advantages that the addition type liquid silicone rubber with strong poison resistance, strong adhesive property, fast curing rate, high transparency, good full degree and high mechanical strength is provided and the prepared product can be widely used for manufacturing clothing trademarks (soft crystal adhesive) and anti-skid foot pads and the like (cambered surface adhesive).

Owner:镇江高美新材料有限公司

Cracking-resistant polyurethane white finish paint for wood ware

InactiveCN101555381AImprove crack resistanceResistant to yellowingLiquid surface applicatorsPolyurea/polyurethane coatingsCyclohexanoneWax

The invention discloses a cracking-resistant polyurethane white finish paint used for wood ware, which comprises three components: a component A, a component B and a component C and is characterized in that the component A is prepared by mixing and stirring coconut oil alkyd resin, wet dispersing agent, PMA, dimethylbenzene, rutile type titanium dioxide, butyl acetate, polyethylene wax paste, matting powder, wax powder, foam killer, flatting agent, cyclohexanone and n-butyl at high speed; the component B is prepared by mixing and stirring dehydrated n-butyl, HD1-90 and HRB which is the trimer of TD1; the component C is prepared by evenly mixing n-butyl and butyl acetate; and the weight percentage of the component A, the component B and the component C is 1:0.4-0.6:0.6-0.8. Aiming at overcoming the defects existing in the prior art, the invention provides the cracking-resistant polyurethane white finish paint used for wood ware, which is cracking resistant and yellowing resistant.

Owner:方学平

Preparation method of acrylic-resin-modified water-based nitrocellulose emulsion for paint

The invention provides a preparation method of an acrylic-resin-modified water-based nitrocellulose emulsion for paint, which comprises the following steps: in an oxygen-free environment, reacting dehydrated dibutyltin dilaurate, isophorone diisocyanate tripolymer and N-methylpyrrolidone dissolved dimethylolpropionic acid at 40-45 DEG C for 1 hour, adding butanone dissolved nitrocellulose at 72 DEG C to react for 2 hours, cooling to 40 DEG C, regulating the pH value of the reaction solution to 8-9, cooling to room temperature, and adding water into the reaction solution while stirring uniformly to obtain a water-based nitrocellulose emulsion; and physically mixing the water-based acrylic emulsion and water-based nitrocellulose emulsion at room temperature to obtain the acrylic-resin-modified water-based nitrocellulose emulsion for paint. The preparation technique is simple; and the prepared acrylic-resin-modified water-based nitrocellulose emulsion for paint has the advantages of high stability, high flexibility, high adhesive force, certain fullness, yellowing resistance, water resistance and no pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Nano anionic double-component aqueous wood paint

InactiveCN101880506ANo pollutionGood flexibilityPolyurea/polyurethane coatingsAcrylic resinMaterials science

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano anionic double-component aqueous wood finishing paint and a preparation method thereof. The double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

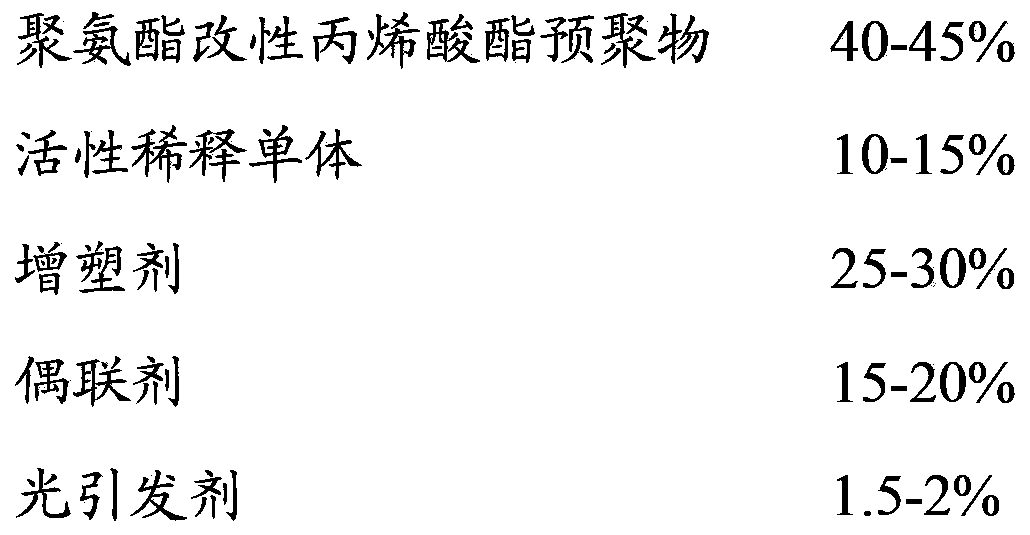

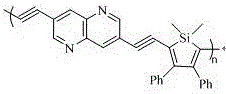

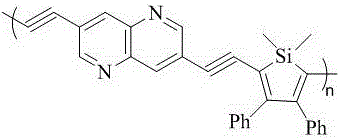

Preparation method of moisture-proof anti-yellowing liquid optical adhesive

ActiveCN103382382AMeet the viscosityFulfil requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceRefractive index

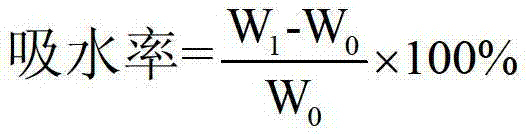

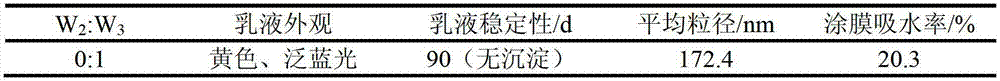

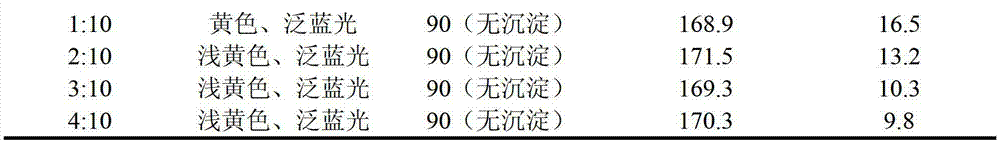

The invention belongs to the technical field of adhesive materials and discloses a preparation method of a moisture-proof anti-yellowing liquid optical adhesive. The raw materials of the moisture-proof anti-yellowing liquid optical adhesive comprise the components of, by weight percentage, 40-50% of polyurethane modified acrylate prepolymer, 10-18% of reactive diluent monomer, 20-32% of plasticizer, 12-20% of coupling agent, 1.5-3.0% of photoinitiator, 1.5-3.0% of antioxygen and 0.5-1.5% of anti-yellowing polymerization inhibitor. The method comprises mixing and heating the raw materials to a temperature of 30-70 DEG C for reaction for 0.5-2 hours, and vacuumizing the reaction products to remove bubbles and cooling the reaction products to obtain the moisture-proof anti-yellowing liquid optical adhesive. According to the preparation method of the moisture-proof anti-yellowing liquid optical adhesive, the polyurethane modified acrylate prepolymer, the reactive diluents monomer, the plasticizer, the coupling agent, the photoinitiator, the antioxygen and the like, which are provided with hydrophobicity and yellowing resistance, are taken as the raw materials; due to the synergistic effects of the components, the prepared liquid optical adhesive has the advantages of high light transmittance, high refractive index, yellowing resistance and good moisture-proof performance; the preparation method is simple and easy to operate.

Owner:SHENZHEN ANLI NEW MATERIALS

Corrosion-resistant low-temperature-curing cathode electrophoretic paint

InactiveCN105885640AImprove thermal stabilityImprove uniformitySiccativesAnti-corrosive paintsCross-linkEpoxy

The invention relates to the field of paint, in particular to corrosion-resistant low-temperature-curing cathode electrophoretic paint which comprises 1-2 parts of color paste, 4-6 parts of an emulsion and 5-7 parts of deionized water. The color paste comprises 20-30 parts of main resin, 5-10 parts of an alcohol-ether cosolvent, 3-8 parts of organic acid, 0.3-0.7 part of an emulsifier, 1-5 parts of a compound drier, 30-40 parts of deionized water, 3-7 parts of a first solid additive, 1.5-6 parts of a second solid additive, 6-9 parts of a first compound regulator, 7-11 parts of a second compound regulator, 8-14 parts of a third compound regulator, 3-7 parts of a fourth compound regulator composed of polyacrylate-2-cross-linked polymer and corrosion-resistant liquid, and 15-20 parts of a filler, and the emulsion comprises 40-50 parts of modified epoxy resin A, 10-20 parts of modified epoxy resin B, 10-30 parts of a cross-linking agent, 5-9 parts of a curing agent, 3-8 parts of monomolecular amine, 0.1-2 parts of an emulsifier, 0.1-2 parts of a neutralizing agent and 30-50 parts of deionized water. Different compound formulations are used in the emulsion and the color paste in an improved, so that the cathode electrophoretic paint is corrosion-resistant, supportive of low-temperature curing and resistant to yellowing.

Owner:GUANGDE RUIBANG PAINT

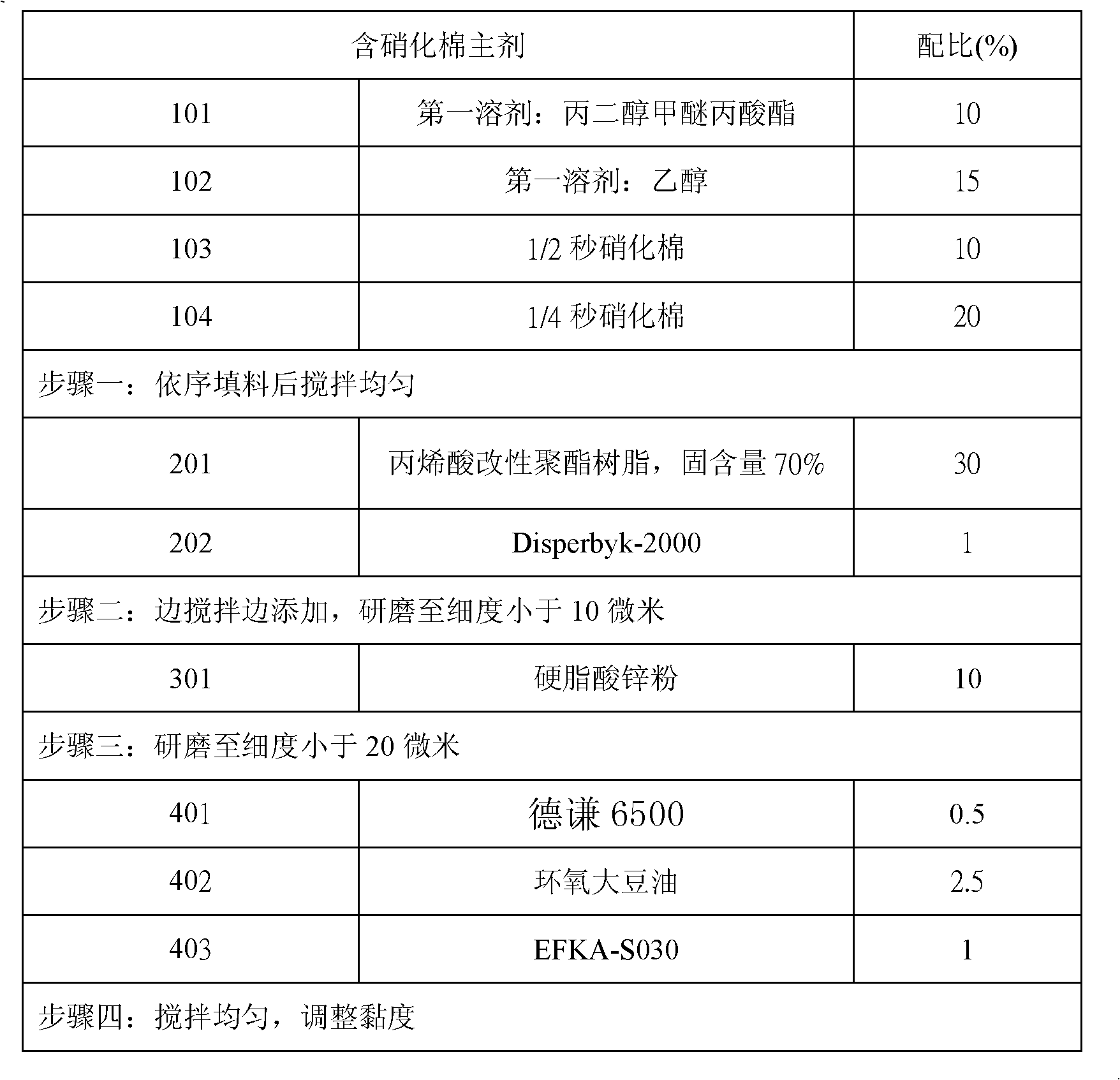

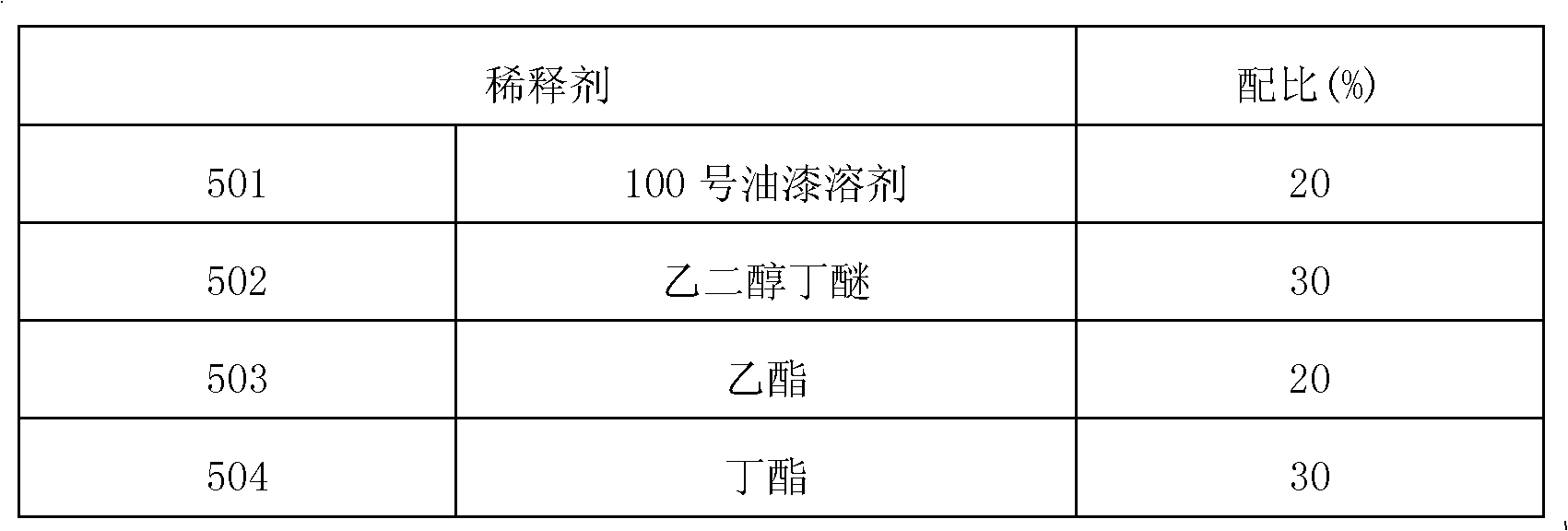

Yellowing-resistance nitrolacquer

The invention discloses a yellowing-resistance nitrolacquer and is characterized by comprising the following components in percentages by weight: 60-70% of nitrocotton-containing main agent, and 30-40% of diluent, wherein the nitrocotton-containing main agent comprises the following ingredients in the percentages by weight: 12-25% of nitrocotton, 20-25% of more than one polyester resin, 1-5% of epoxidized soybean oil, 6-21% of pigment or stuffing, 0.5-1% of dispersant, 0-0.5% of defoamer, 0.5-1% of flatting agent, 0.5-1% of gloss wax, 0-10% of extinction powder, and 12-18% of first solvent composed of more than one esters and alcohols; and the diluent is selected from any one or more than two of esters, ethers and aromatic hydrocarbons by mixing. The yellowing-resistance nitrolacquer of the invention has good transparency, hardness, scratch resistance and yellowing resistance.

Owner:SHANGHAI DABAO CHEM PROD +1

Glass curtain wall energy-saving paint and preparation method thereof

InactiveCN107099213ALower heat transfer coefficientReduce pollutionAntifouling/underwater paintsPaints with biocidesEpoxyThermal insulation

The invention discloses glass curtain wall energy-saving paint and a preparation method thereof, and relates-the technical field of energy-saving materials, the glass curtain wall energy-saving paint includes the following raw materials: 65-75 parts of modified waterborne epoxy resin, 45-55 parts of a thermal insulation filler, 20-25 parts of antibacterial powder, 20-23 parts of an ultraviolet absorbent, 15-17 parts of nano titanium dioxide, 10-15 parts of an additive and 70-80 parts of water. The glass curtain wall energy-saving paint has the advantages of coating uniformity, strong adhesion, good weatherability and good insulating performance, can effectively reduce the glass heat transfer coefficient, and is heat and ultraviolet radiation-blocking, thereby reducing energy consumption and light pollution to play an indoor and outdoor energy-saving role.

Owner:合肥市旺友门窗有限公司

Silicone rubber synthetic leather for outdoor furniture and manufacturing technology of silicone rubber synthetic leather

InactiveCN108729244AFulfil requirementsAging resistantFurniture partsCoatingsAging resistancePlatinum catalyst

The invention discloses silicone rubber synthetic leather for outdoor furniture. The silicone rubber synthetic leather for the outdoor furniture comprises substrate cloth which is covered with a silicone rubber layer for the outdoor furniture; the silicone rubber layer is covered with a matt hand feeling oil surface layer for the outdoor furniture and is prepared from the following raw materials in parts by mass: 100-200 parts of vinyl silicone rubber-based rubber, 5-10 parts of high vinyl silicone oil, 10-20 parts of vinyl MQ resin, 5-15 parts of methyl MQ resin, 5-20 parts of hydrogen-contained silicone oil, 1-2 parts of tackifier, 0.1-0.5 part of platinum catalyst, 5-20 parts of color paste pigment and 0.02-0.1 part of inhibitor. Liquid silicone rubber is used to prepare the outdoor used synthetic leather; the synthetic leather can well meet the requirement of the outdoor furniture to the synthetic leather, has the advantages of ageing resistance, hydrolysis resistance, yellowing resistance and the like and has the characteristics of waterproofness, ventilation, easiness in cleaning, nontoxicity and environmental protection at the same time.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

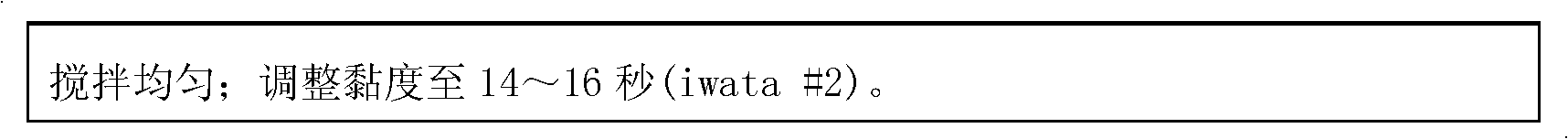

Polyurethane synthetic leather for high-grade electronic packages and certificates

ActiveCN104294606AGood protectionResistant to yellowingFibre treatmentLeather surface finishingPrepolymerIsocyanate

The invention discloses polyurethane synthetic leather for high-grade electronic packages and certificates. The polyurethane synthetic leather comprises a polyurethane synthetic leather base layer, wherein the outer surface of the polyurethane synthetic leather base layer is coated with a layer of colorless and transparent pulp, and then drying and curing are carried out to obtain the polyurethane synthetic leather; the colorless and transparent pulp is obtained by mixing and stirring a silicone-modified polyurethane prepolymer, polyisocyanate and an accelerant according to weight parts. The polyurethane synthetic leather disclosed by the invention has soft touch feel, has excellent yellowing resistance, wear resistance and antifouling property, has an excellent defending effect on pollution sources such as lipsticks, sweat stains, red wine, sunscreen cream and denim fabrics in the process of daily use, and simultaneously meets the requirement on environmental protection of European RoHS.

Owner:ANHUI ANLI MATERIAL TECH

Liquid optical transparent adhesive and preparation method thereof

InactiveCN106928870AReduce hardnessLow shrinkageOrganic non-macromolecular adhesive(Hydroxyethyl)methacrylatePolymer science

The invention discloses a liquid optical transparent adhesive which comprises the following components in parts by weight: 40-70 parts of low polymer, 30-50 parts of acrylate activated monomer, 1-5 parts of photoinitiator and 1-5 parts of assistant, wherein the low polymer is polyisoprene acrylate, polybutadiene acrylate or polyphenyldiene acrylate; the molecular weight of the low polymer is 15000-40000; the functionality degree of the low polymer is 2-3; and the activated monomer is one or two or a combination of more than two of methacrylate, isobornyl acrylate, hydroxyethyl methacrylate, hydroxypropyl methacrylate, ethoxylated nonyl phenol acrylate, lauryl methacrylate, butyl methacrylate, trimethylolpropane diacrylate and trimethylolpropane triacrylate. The adhesive effectively improves yellowing generated in a curing process, therebyimprovingthe quality of a product.

Owner:河源然生新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com