Single-component dealcoholized transparent silicone sealant, preparation method and application thereof

A silicone sealant, dealcoholized technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as unsatisfactory comprehensive performance, poor storage stability, and easy yellowing of rubber materials. Achieve good economic and social benefits, low production cost, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

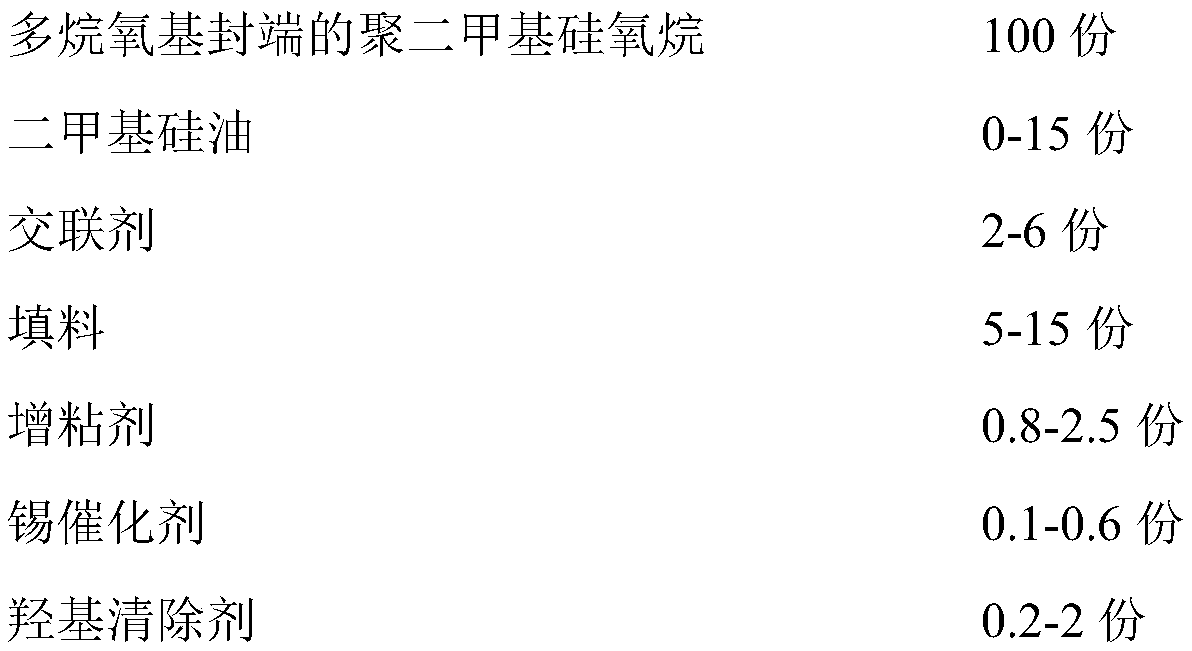

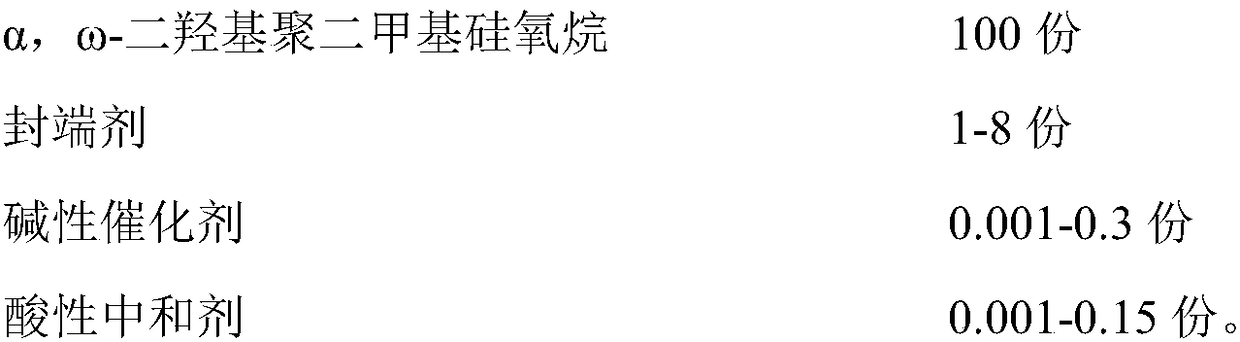

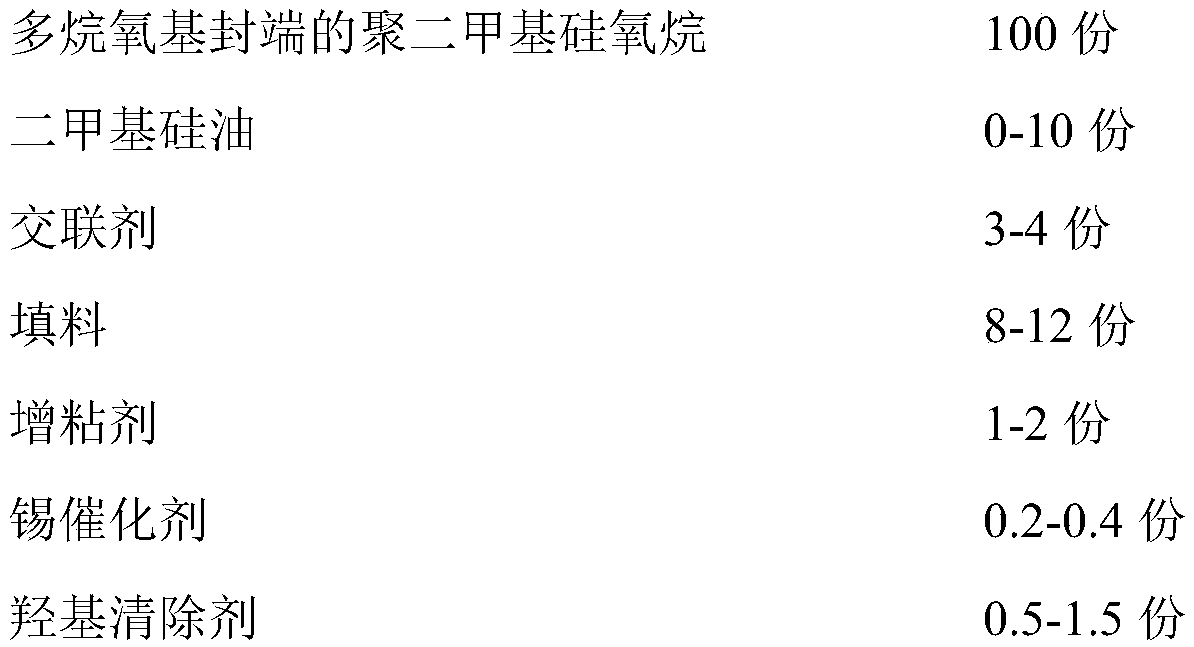

Method used

Image

Examples

Embodiment 1

[0041] A one-component dealcoholized transparent silicone sealant, prepared by the following method:

[0042] (1) Put 100 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa·s, 10 parts of dimethyl silicone oil, and 3 parts of tetramethoxysilane into a stirred tank, room temperature, vacuum Stir evenly in the state, then add 0.006 parts of sodium hydroxide, stir in vacuum for 30 minutes, then add 0.002 parts of acetic acid, and continue vacuum stirring for 70 minutes to obtain polydimethylsiloxane terminated by polyalkoxy groups.

[0043] (2) Add 100 parts of polyalkoxy-terminated polydimethylsiloxane and 4 parts of methyltrimethoxysilane to a planetary mixer, vacuumize and stir for 20 minutes, and add BET with a specific surface area of 150m 2 10 parts / g of hydrophilic fumed silica, vacuumed and stirred at high speed for 40min, followed by adding 1 part of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane, 0.5 parts of γ-glycidyl ether Oxypropyltrimethox...

Embodiment 2

[0045] A one-component dealcoholized transparent silicone sealant, prepared by the following method:

[0046] (1) Put 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mPa·s and 2 parts of tetramethoxysilane into a stirring tank, stir evenly under vacuum, and then add 0.004 parts Sodium hydroxide, stirred at room temperature in vacuum for 30 minutes, then added 0.0015 parts of acetic acid, and continued to stir in vacuum for 70 minutes to obtain polydimethylsiloxane end-capped with polyalkoxy groups.

[0047](2) Add 100 parts of polyalkoxy-terminated polydimethylsiloxane and 4 parts of vinyltrimethoxysilane to a planetary mixer, vacuumize and stir for 20 minutes, and add BET with a specific surface area of 150m 2 10 parts / g of hydrophobic fumed silica, vacuumed and stirred at high speed for 40 minutes, followed by adding 1 part of γ-aminopropyltrimethoxysilane, 0.5 parts of β-(3,4-epoxycyclohexane) ethyl trimethyl Oxysilane, 0.3 parts of dibutyltin bis...

Embodiment 3

[0049] A one-component dealcoholized transparent silicone sealant, prepared by the following method:

[0050] (1) Put 100 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 80000mPa·s and 2 parts of tetramethoxysilane into a stirring tank, stir evenly under vacuum, and then add 0.004 parts Potassium hydroxide, stirred at room temperature in vacuum for 30 minutes, then added 0.0015 parts of phosphoric acid, and continued to stir in vacuum for 70 minutes to obtain polydimethylsiloxane terminated by polyalkoxy groups.

[0051] (2) Add 100 parts of polyalkoxy-terminated polydimethylsiloxane and 3 parts of tetraethoxysilane to a planetary mixer, vacuumize and stir for 20 minutes, and add BET with a specific surface area of 150m 2 10 parts / g of hydrophilic fumed silica, vacuumed and stirred at high speed for 40min, followed by adding 1 part of γ-aminopropyltriethoxysilane, 0.5 parts of N-β-(aminoethyl)-γ-aminopropyl Trimethoxysilane, 0.3 parts of dibutyltin dilaurate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com