Two-component addition type liquid silicone rubber and preparation method thereof

A liquid silicone rubber and addition molding technology, applied in the field of silicone rubber manufacturing, can solve the problems of the influence of silicone rubber components and the inability to meet various use requirements, and achieve high transparency, increase market competitiveness, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

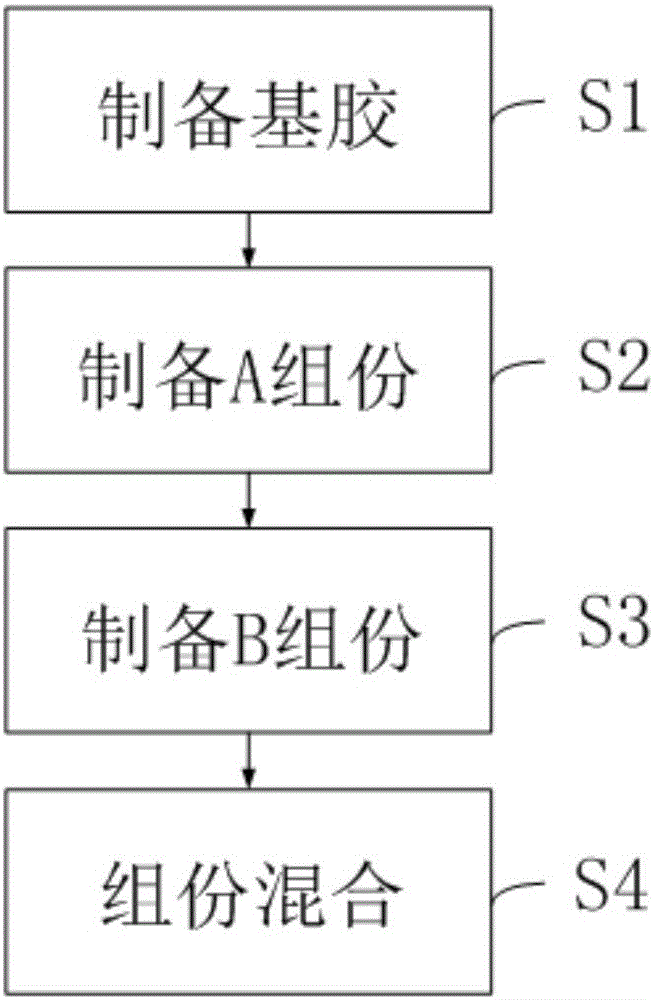

Method used

Image

Examples

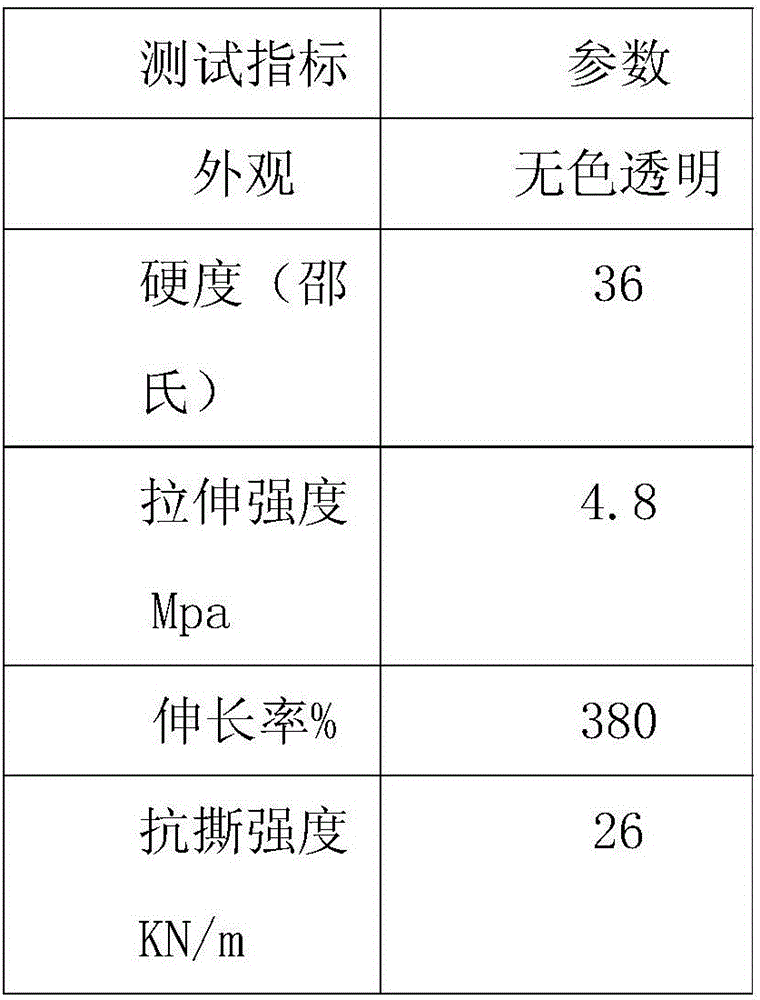

Embodiment 1

[0021] A two-component addition type liquid silicone rubber, which is composed of component A and component B at a mass ratio of 10:100, wherein the formula raw materials of component A include the following components in parts by mass: vinyl silicone oil 100kg, content of 5000PPM platinum catalyst 2.5kg, accelerator 0.8kg, leveling agent 0.kg; component B formula raw materials include the following components in parts by mass: base rubber 100kg, hydrogen-containing crosslinking agent 3.8kg, inhibitor 0.16kg, Vinyl silicone oil 23kg; the base rubber is composed of 156kg vinyl silicone oil and 39kg white carbon black reinforcing filler. The vinyl silicone oil has a viscosity of 1000-5000mpa.s at 25°C. The vinyl silicone oil is prepared by mixing 100 parts by mass of octamethylcyclotetrasiloxane and 0.01-0.5 parts by mass of tetramethyldivinyl di Mix siloxane, add 0.02-0.8 parts by mass of siloxane-potassium hydroxide prepolymer under stirring, heat up to 90-110°C for polymeriza...

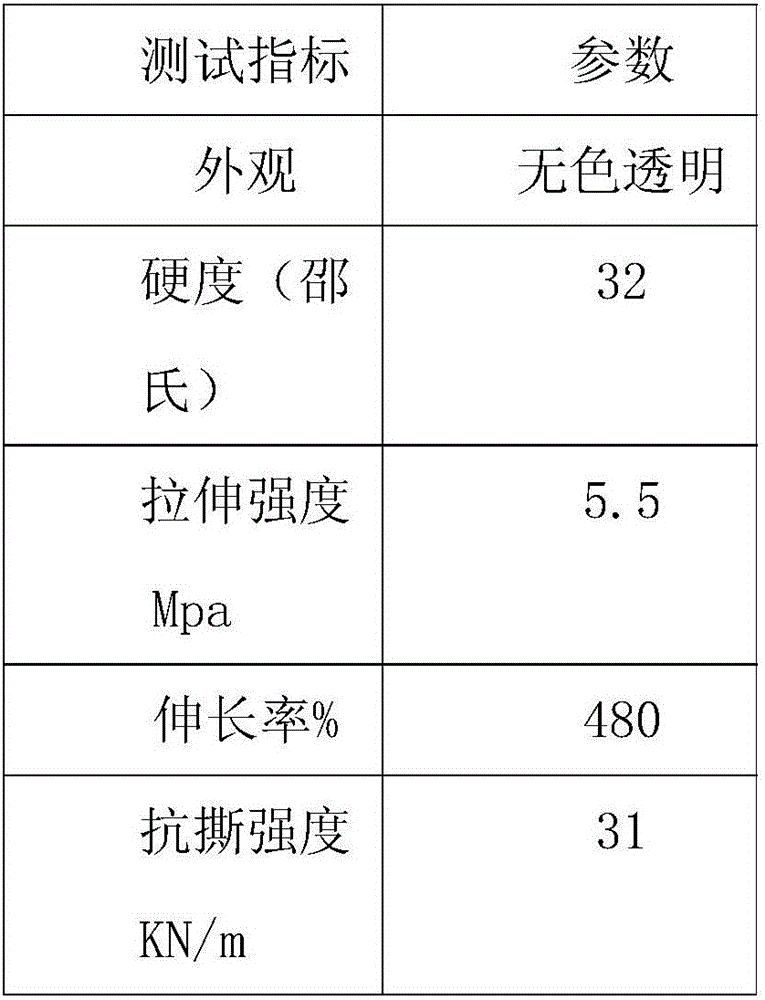

Embodiment 2

[0030]A two-component addition type liquid silicone rubber, which is composed of component A and component B at a mass ratio of 2:100, wherein the formulation raw materials of component A include the following components in parts by mass: vinyl silicone oil 100kg, content of 5000PPM platinum catalyst 5kg, accelerator 1.2kg, leveling agent 0.2kg; component B formula raw materials include the following components in parts by mass: base rubber 100kg, hydrogen-containing crosslinking agent 27kg, inhibitor 0.15kg, vinyl silicone oil 9kg; the base rubber is composed of 168kg vinyl silicone oil and 40kg white carbon black reinforcing filler. The vinyl silicone oil has a viscosity of 1000-5000mpa.s at 25°C. The vinyl silicone oil is prepared by mixing 100 parts by mass of octamethylcyclotetrasiloxane and 0.01-0.5 parts by mass of tetramethyldivinyl di Mix siloxane, add 0.02-0.8 parts by mass of siloxane-potassium hydroxide prepolymer under stirring, heat up to 90-110°C for polymerizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com