A kind of electrolytic solution, preparation method and lithium-ion battery containing same

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of reduced Coulombic efficiency, rupture and regrowth, and poor contact, and achieve the effects of improving mechanical properties, avoiding mass transfer obstruction, and improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

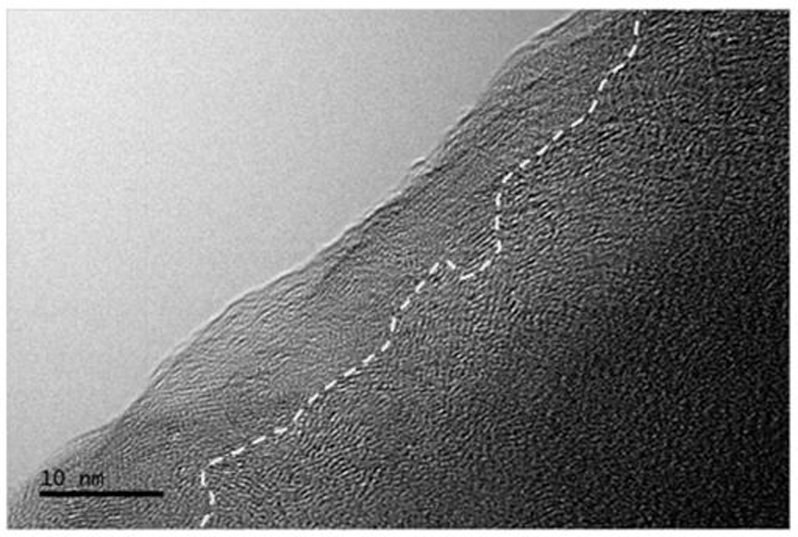

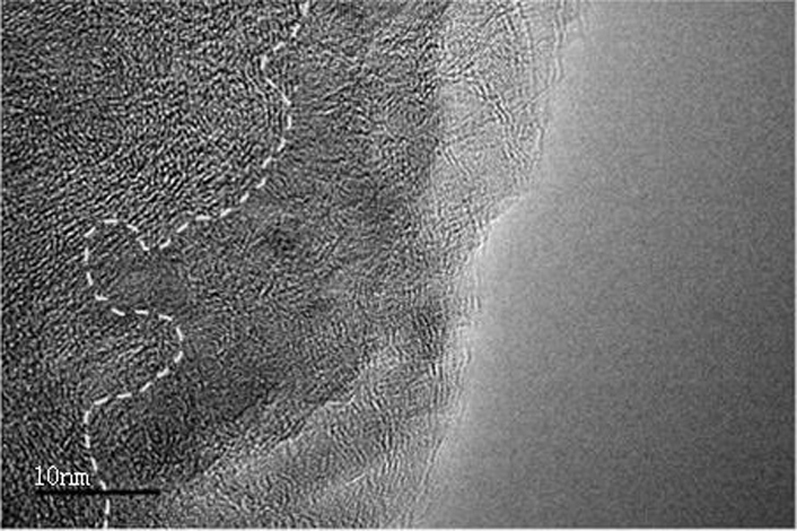

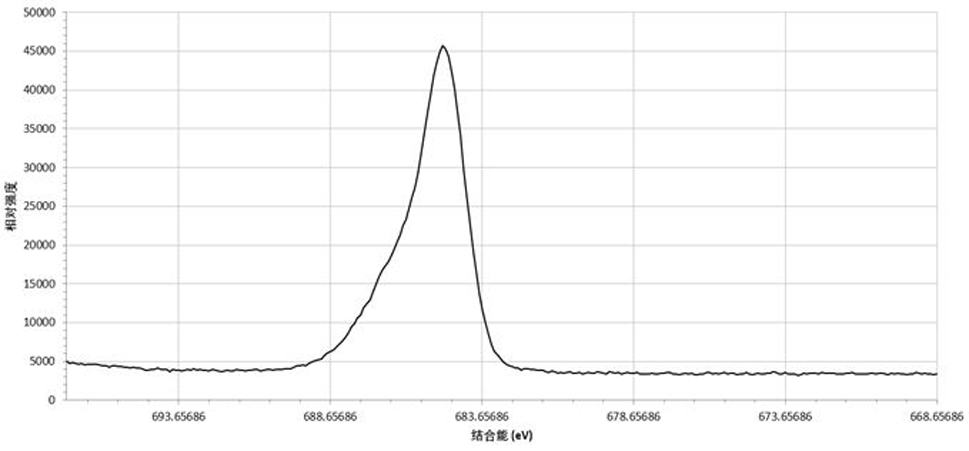

Image

Examples

Embodiment

[0052] A preparation method for the electrolyte of a non-aqueous lithium-ion battery, prepared by the following steps:

[0053] (1) In an argon atmosphere, mix the first solvent and the second solvent in the formulated amount to obtain a mixed solvent;

[0054] (2) In an argon environment, add the lithium salt and fluorine-containing additives in the formulated amount into the mixed solvent, and mix evenly to obtain the electrolyte.

[0055] The electrochemical performance of the battery was tested according to the following methods 1 and 2 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com