Polyurethane synthetic leather for high-grade electronic packages and certificates

A technology of polyurethane and synthetic leather, which is applied in application, leather surface treatment, small raw leather/large raw leather/leather/fur treatment, etc. It can solve the problems of unsatisfactory high-end electronic product packaging leather, hardening, and uneven quality of synthetic leather. , to achieve an excellent protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Mix 40 parts of silicone-modified polyurethane prepolymer, 10 parts of polyisocyanate and 1.5 parts of accelerator triethylenediamine and stir evenly to obtain a colorless and transparent slurry with a viscosity of 500CPS / 25°C;

[0027] 2) the above-mentioned colorless transparent slurry is coated on the outer surface of the polyurethane synthetic leather base with 140 purpose printing rollers;

[0028] 3) Then dry it at 80°C and then cure it at 130°C for 5 minutes to obtain polyurethane synthetic leather.

[0029]

Embodiment 2

[0031] 1) Mix 80 parts of silicone-modified polyurethane prepolymer, 15 parts of polyisocyanate and 1.0 parts of accelerator dibutyltin dilaurate and stir evenly to obtain a colorless and transparent slurry with a viscosity of 800CPS / 25°C;

[0032] 2) the above-mentioned colorless transparent slurry is coated on the outer surface of the polyurethane synthetic leather base with 160 purpose printing rollers;

[0033] 3) Then dry it at 100°C and then cure it at 150°C for 3 minutes to obtain polyurethane synthetic leather.

[0034]

Embodiment 3

[0036] 1) Mix 100 parts of silicone-modified polyurethane prepolymer, 20 parts of polyisocyanate and 2 parts of accelerator stannous octoate and stir evenly to obtain a colorless and transparent slurry with a viscosity of 200CPS / 25°C;

[0037] 2) the above-mentioned colorless transparent slurry is coated on the outer surface of the polyurethane synthetic leather base with 120 purpose printing rollers;

[0038] 3) Then dry it at 90°C and then cure it at 140°C for 4 minutes to obtain polyurethane synthetic leather.

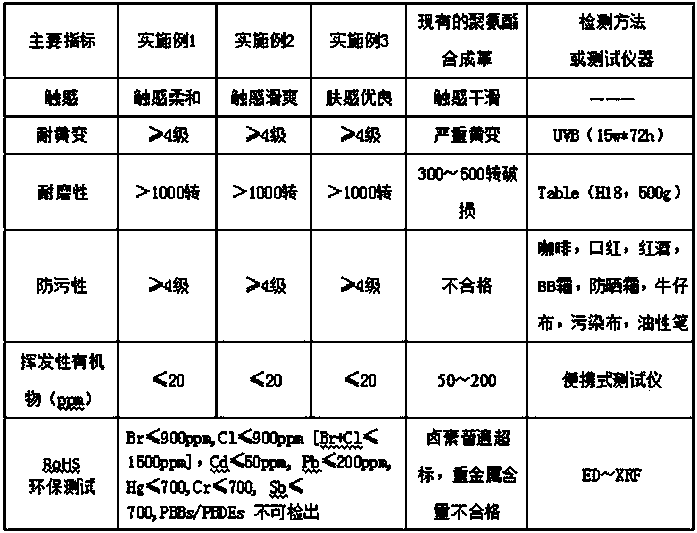

[0039] The performance indexes of the polyurethane synthetic leather prepared in the above examples 1-3 are compared with the existing polyurethane synthetic leather as shown in the following table:

[0040]

[0041] As can be seen from the above table, the polyurethane synthetic leather for high-grade electronic packaging and certificates of the present invention has excellent touch, yellowing resistance, and wear resistance compared with ordinary packaging leat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com