Odor-free yellowing-resistant UV (ultraviolet) curing coating and preparation method thereof

A technology of curing coatings and ultraviolet light, which is applied in the direction of polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of low odor and yellowing resistance, and achieve good yellowing resistance, low curing odor, The effect of good yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

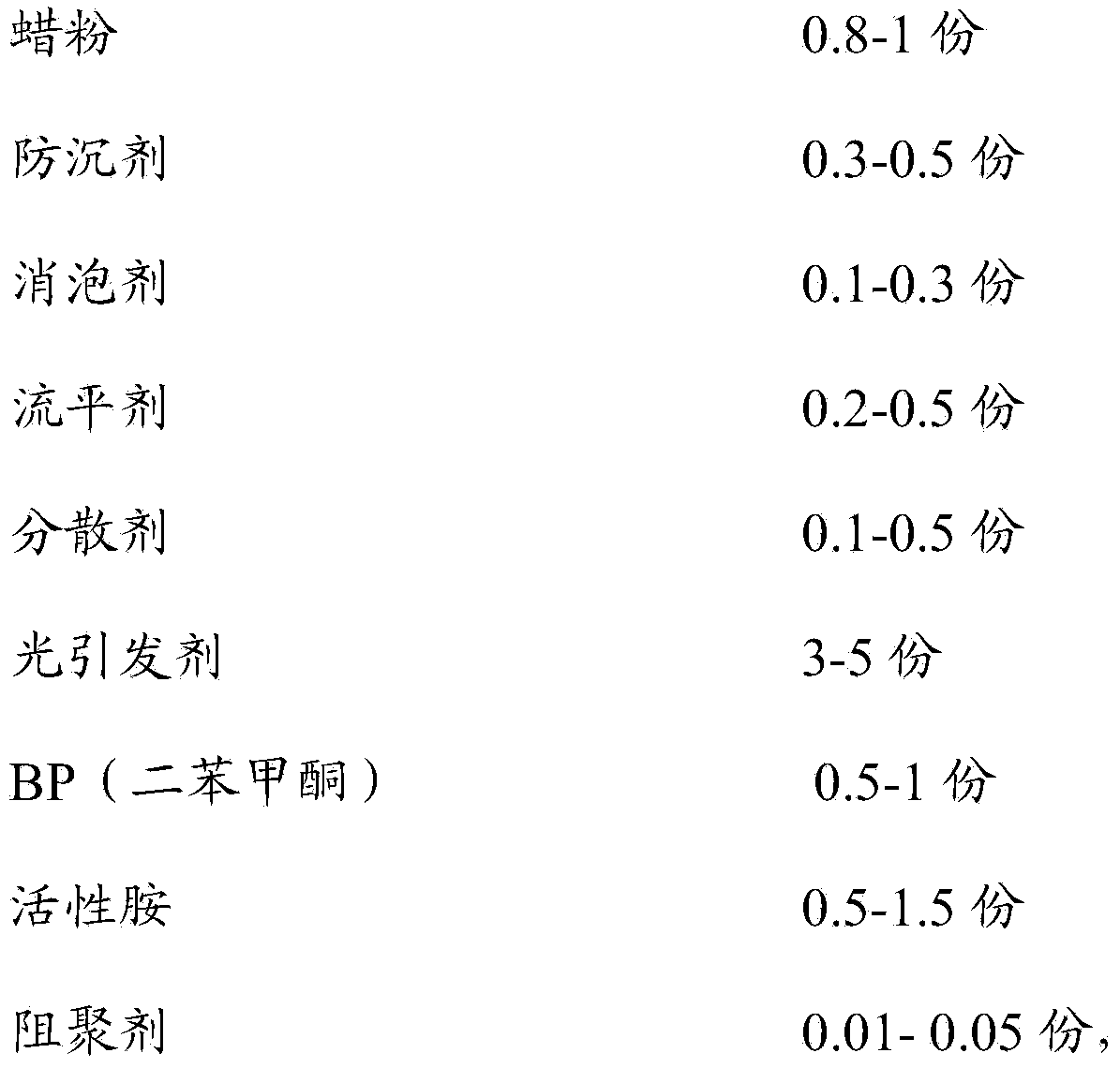

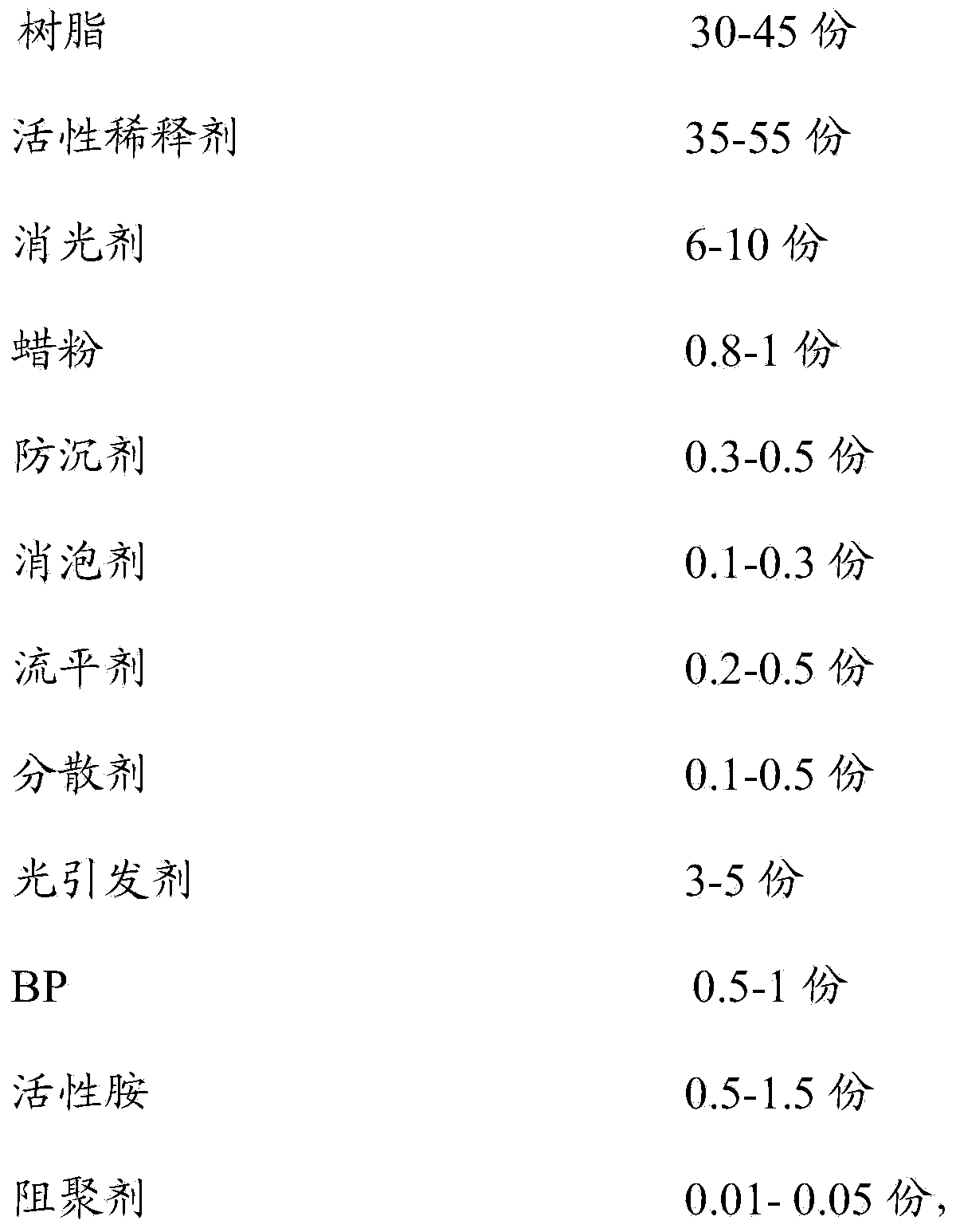

[0038] In this embodiment, a kind of anti-yellowing UV-curable paint with clean taste comprises the following components in parts by weight: 35.5 parts of resin, 0.02 part of hydroquinone polymerization inhibitor, 45 parts of EM231 reactive diluent, and Degussa OK412 matting powder 10 parts, Degussa R972 fumed silica anti-settling agent 0.3 parts, TEGO920 defoamer 0.1 part, BYK333 silicone leveling agent 0.3 parts, BYK2009 dispersant 0.2 parts, 184 photoinitiator 5 parts, BP 1 part , 1.5 parts of 1113D active amine, 1 part of BYK996 wax powder, of which,

[0039] The resins are modified epoxy acrylate resins, aliphatic polyurethane acrylate resins and hyperbranched polyester acrylate resins with a mass ratio of 10:10:15.5.

[0040] The preparation method of the above-mentioned clean odor and anti-yellowing type UV-curable coating comprises the following steps:

[0041] Put in the resin, active diluent, photoinitiator, BP and active amine in sequence, and disperse at a medium ...

Embodiment 2

[0045] In this embodiment, a kind of anti-yellowing UV-curable paint with clean taste comprises the following components in parts by weight: 37.5 parts of resin, 0.02 part of hydroquinone polymerization inhibitor, 45 parts of EM231 reactive diluent, and Degussa OK412 matting powder 8 parts, Degussa R972 fumed silica anti-settling agent 0.3 parts, TEGO920 defoamer 0.1 part, BYK333 silicone leveling agent 0.3 parts, BYK2009 dispersant 0.2 parts, TPO photoinitiator 5 parts, BP1 part, 1.5 parts of 1113D active amine, 1 part of BYK996 wax powder, of which,

[0046] The resins are modified epoxy acrylate resins, aliphatic urethane acrylate resins and hyperbranched polyester acrylate resins with a mass ratio of 8:8:21.5.

[0047] The preparation method of the above-mentioned clean odor and anti-yellowing type UV-curable coating comprises the following steps:

[0048] Put in the resin, active diluent, photoinitiator, BP and active amine in sequence, and disperse at a medium speed;

...

Embodiment 3

[0052] In this embodiment, a kind of anti-yellowing anti-odor UV-curable coating comprises the following components by weight: 30 parts of resin, 0.01 part of hydroquinone polymerization inhibitor, 35 parts of EM231 reactive diluent, and Degussa OK412 matting powder 6 parts, Degussa R972 fumed silica anti-settling agent 0.4 parts, TEGO920 defoamer 0.2 parts, BYK333 silicone leveling agent 0.2 parts, BYK2009 dispersant 0.1 parts, TPO photoinitiator 3 parts, BP 0.5 parts , 0.5 parts of 1113D active amine, 1 part of BYK996 wax powder, of which,

[0053] The resins are modified epoxy acrylate resins, aliphatic urethane acrylate resins and hyperbranched polyester acrylate resins with a mass ratio of 6:6:24.5.

[0054]The preparation method of the above-mentioned clean odor and anti-yellowing type UV-curable coating comprises the following steps:

[0055] Put in the resin, active diluent, photoinitiator, BP and active amine in sequence, and disperse at a medium speed;

[0056] Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com