Patents

Literature

45results about How to "With folding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

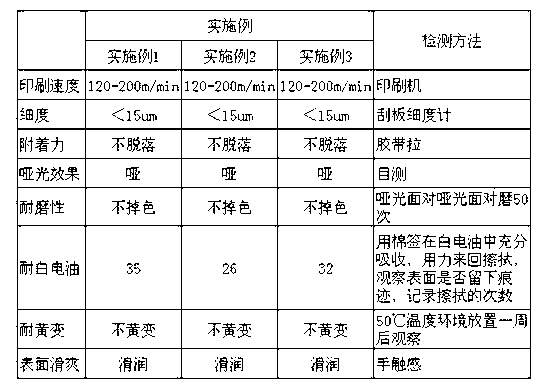

Surface printed solidified matte ink and preparation method thereof

The invention relates to surface printed solidified matte ink and a preparation method thereof. The surface printed solidified matte ink is formed by adding a curing agent into an ink base material according to a ratio of 6-10% and stirring, wherein the ink base material comprises the following ingredients: 23 parts of n-propyl ester, 10 parts of butyl acetate, 8 parts of a polyurethane resin, 10 parts of aldehyde ketone resin, 1 part of a flatting agent, 40 parts of light removing slurry, 7 parts of ternary chlorine vinegar resin, 0.5 part of an antifoaming agent and 0.5 part of a dispersing agent; the n-propyl ester, the butyl acetate, the polyurethane resin, the ternary chlorine vinegar resin and the aldehyde ketone resin are firstly ground, combined with the flatting agent and the light emitting slurry, and are subjected to high-speed dispersion, the ingredients are filtered and packaged into finished products, and 6-10% of the curing agent is added, thus obtaining the ink which can be used for printing. The matte ink can be used for directly printing in a matte manner to form a film, personal hollow printing or conventional covering printing is realized, the adhesive force is high, the surface is smooth, the matte effect is remarkable, and the production cost is lowered. The surface printed solidified matte ink is applicable to printing on coiling drums of wall paper, chrome paper, kraft paper, leatherette paper and various special types of paper, and meanwhile the ink is applicable to printing on PE (Poly Ethylene), PET (Polyethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), pearly luster films and twisting films with corona layers.

Owner:ZHUANGLI PRINTING CHAOAN COUNTY

Manufacturing method for hydrolysis-resistant clothing leather

The invention discloses a manufacturing method for hydrolysis-resistant clothing leather. The method comprises the steps of mixing 5-10 kg of dimethyl formamide and 0.5-2 kg color paste uniformly; filtering the mixture; adding 100-120 kg of dimethyl formamide and 20-30 kg of wood powder to the above mixture, stirring uniformly and swelling; adding 100 kg of a polyurethane wet resin, stirring uniformly, defoaming and coating the obtained mixture on the textile fabric fiber; immersing in a solution of 18-22% dimethyl formamide to make the mixture solidified, squeezing water, washing with water and drying to obtain a wet base; mixing 100 kg of polyurethane dry resin, 10-20 kg of dimethyl formamide, 10-15 kg of butanone, 15-20 kg of toluene, 0.5-1.0 kg of an auxiliary agent and 3-5 kg of a toner uniformly and coating the obtained mixture on release paper to obtain a dry veneer; adhering the wet base to the dry veneer, drying, separating from the release paper, washing with a water graining machine and drying. The obtained product has the effects of hydrolysis resistance, cold resistance and folding resistance, and can effectively prolong service life of the leather.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

Method for processing waste leather into top-layer leather

ActiveCN105500804AGood weather resistanceImprove impact resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsEngineeringPolyresin

The invention relates to the technical field of leather processing, in particular to a method for processing waste leather into top-layer leather. The method comprises steps as follows: selection: the waste leather produced after furniture production processing is selected for standby application; spraying of a hot-melt adhesive: the waste leather is laid flatly as one layer, and then a hot-melt adhesive material layer is sprayed on the waste leather; attachment of a resin film: the resin film is attached to the hot-melt adhesive material layer; attachment of cloth: a layer of cloth is attached to the resin film, and a finished leather product is prepared. The leather prepared with the method has good tensile strength and breaking resistance, and the added value of the finished leather product is high.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

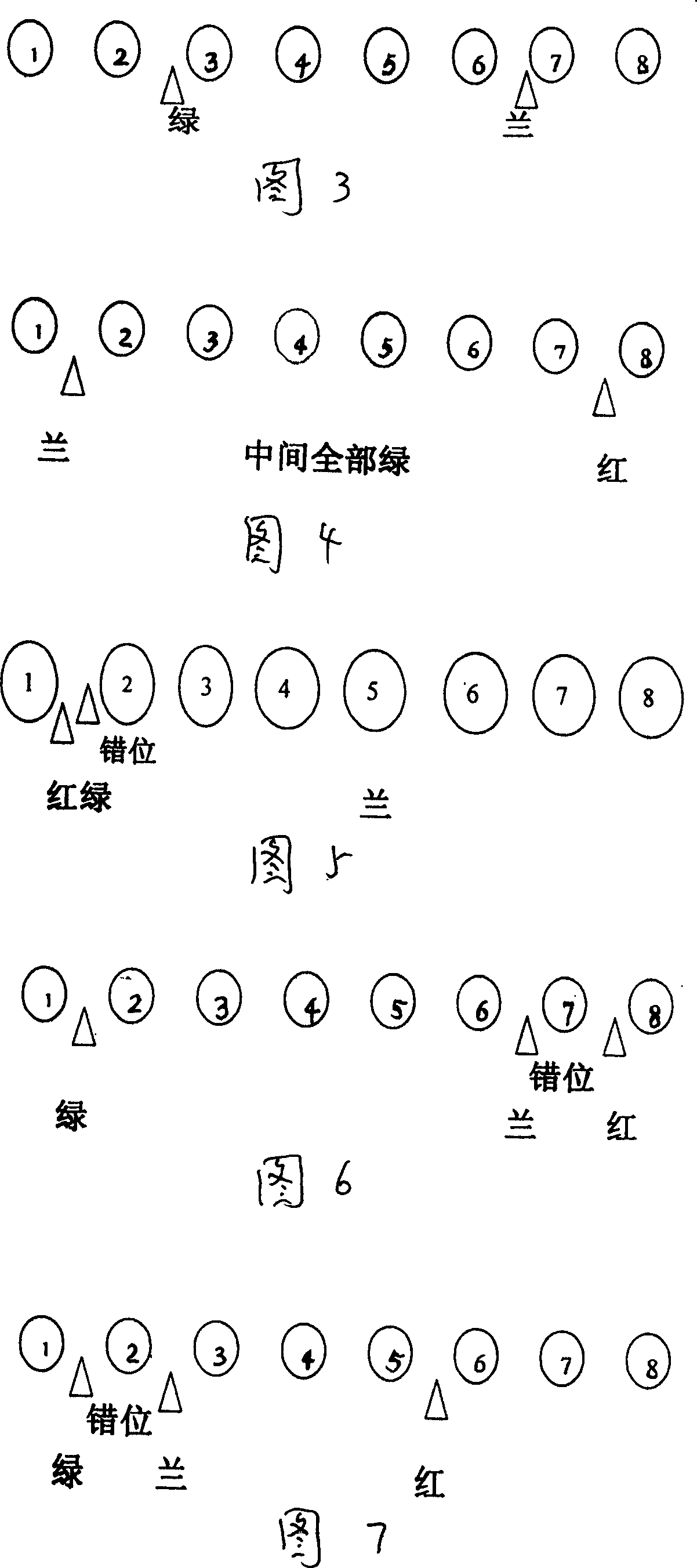

Local positioning anti-fake multiple-color paper board and its making process

InactiveCN101008165ANo loss of quantificationNo loss of thicknessSpecial paperPaper/cardboardCardboardPaper machine

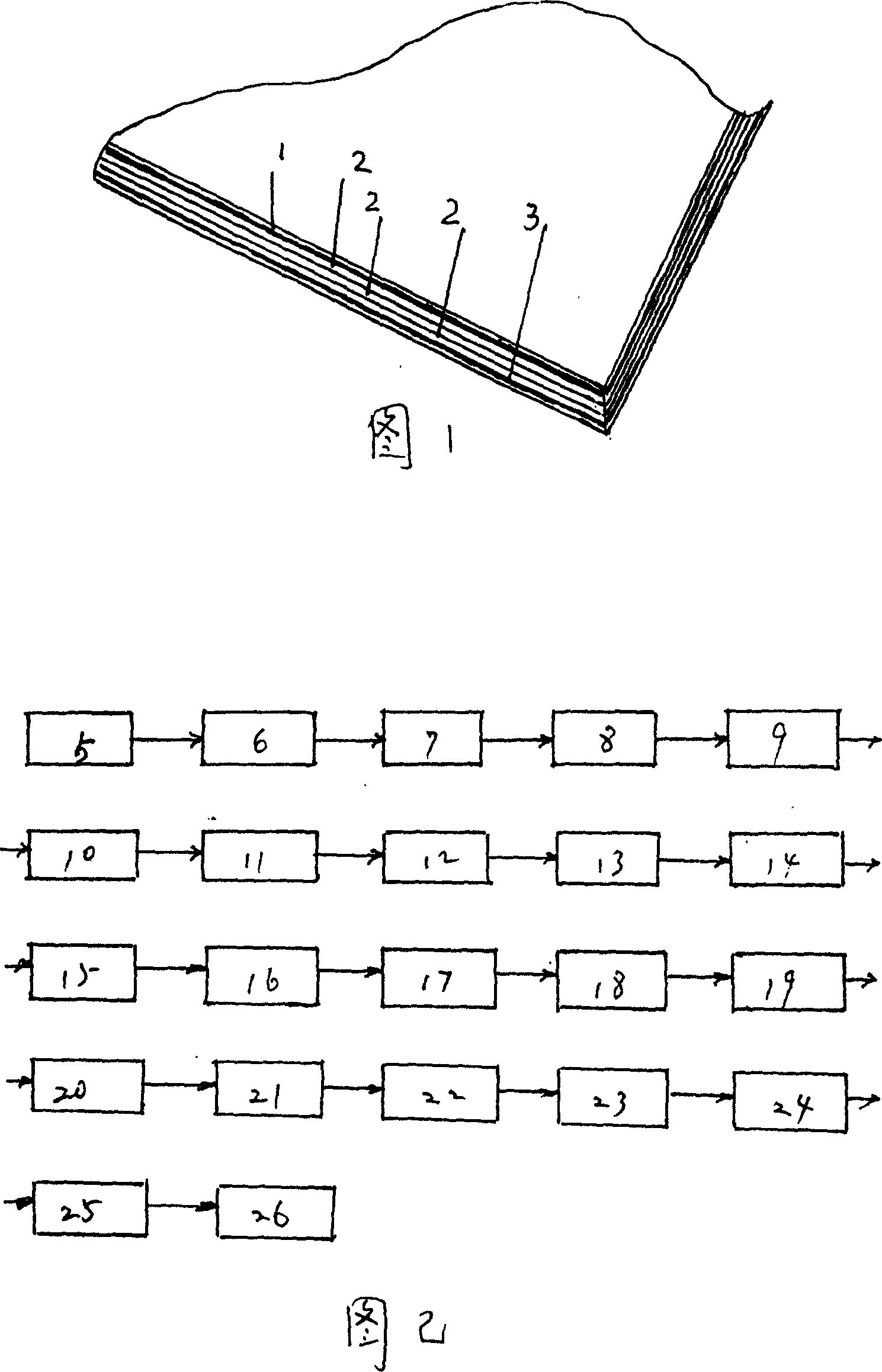

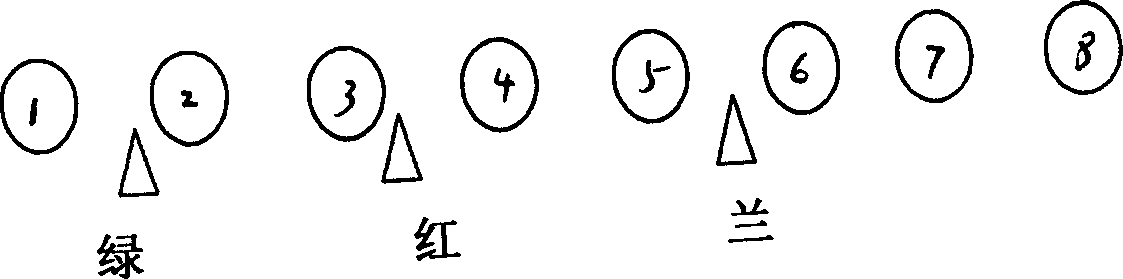

The invention relates to a positioning colorful false-proof white paper plate and relative production. The invention at least utilizes the face pulp the linear pulp, the pulp corn and the bottom pulp to obtain the multilayer pulp to be processed into the paper plate via the paper machine. The invention is characterized in that the face pulp and / or the bottom pulp is positioned and plated with at least one dye to be combined between the multilayer pulps; the face pulp and / or bottom pulp is positioned plated with at least two dyes combined between the multilayer pulps; the multilayer pulp has at least three layers, while the corn pulp is plated with at least one dye combined between interlayer pulp. And the production comprises the productions of face pulp, corn pulp and bottom pulp, the papering on the paper machine, drying, and plating, calendaring, and coiling. In the papering process, the dye is plated on the multilayer pulp, face pulp or the bottom pulp between several mesh cages of paper machine, and via the dye position, the invention designs special baffle plate to realize positioning and separating, to hold the dyed part on the pulp and separate the part without dye and position the dye. Therefore, the invention has false-proof function, simple recognition, low cost and high quality.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

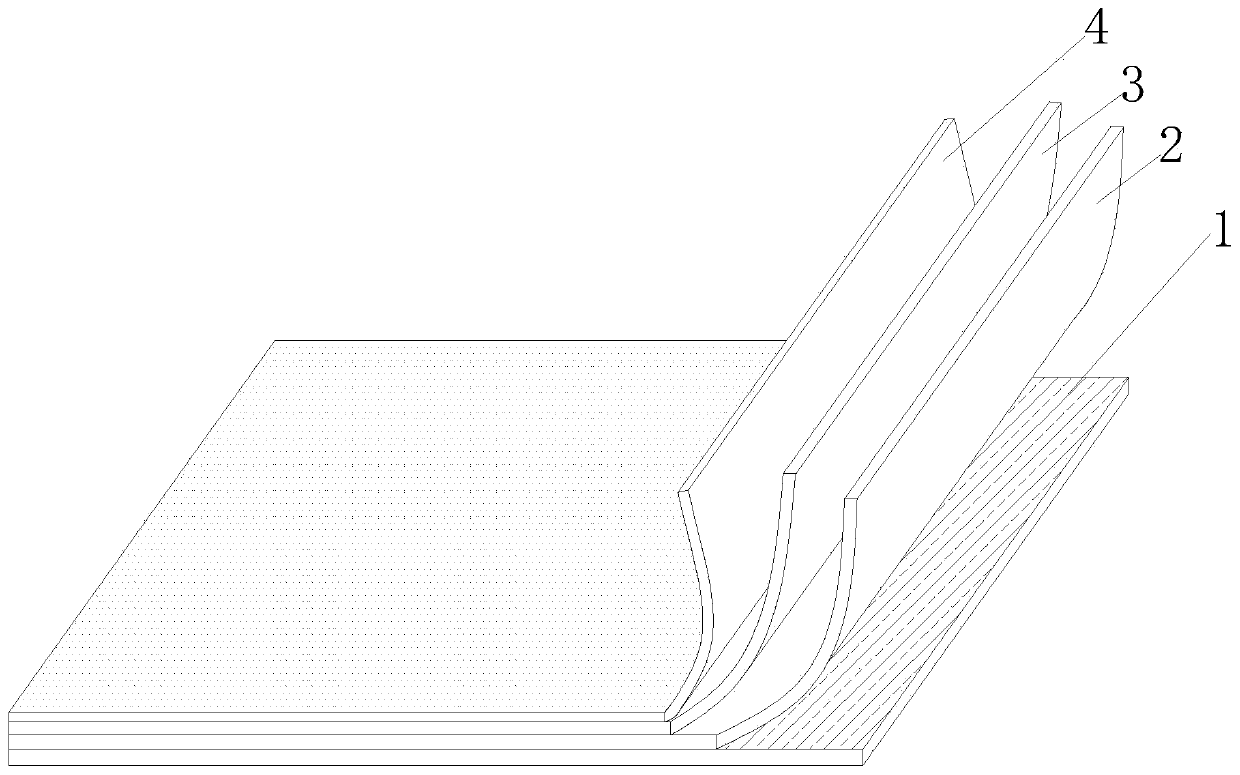

Anti-aging hydrolysis-resistant PU synthetic leather fabric and preparation method thereof

InactiveCN110952337ASimple processSimple production operationBiochemical fibre treatmentPolymer chemistryAnti bacteria

The invention discloses an anti-aging hydrolysis-resistant PU synthetic leather fabric, which comprises a base cloth layer, a wet polyurethane layer, a dry polyurethane layer and an antibacterial layer, wherein the wet polyurethane layer is coated on the top of the base cloth layer, the dry polyurethane layer is coated on the top of the wet polyurethane layer, the antibacterial layer is coated onthe top of the dry polyurethane layer, and air holes are formed in a surface of the antibacterial layer. The invention also discloses a preparation method of the anti-aging hydrolysis-resistant PU synthetic leather fabric. The synthetic leather produced by the process method has the advantages of being resistant in wear and cold, hard to crack, resistant in solvent, heat and tearing, soft, bright,comfortable in hand feeling and the like, the synthetic leather is good in stability, more environment-friendly, low in cost and high in physical property, and the anti-aging performance of the PU synthetic leather is improved when the super-strong hydrolysis resistance is provided, so that the PU synthetic leather fabric is durable.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

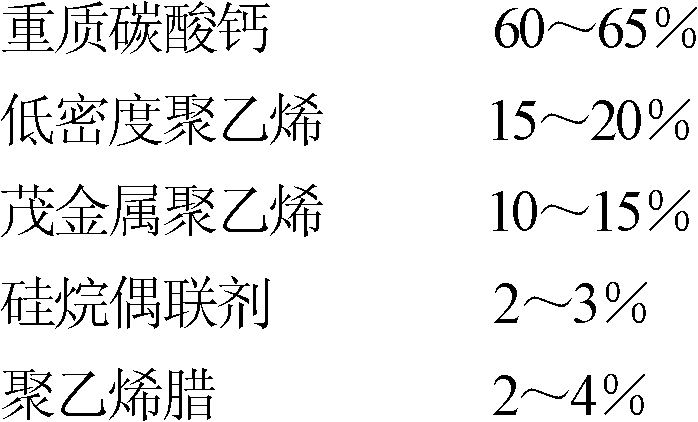

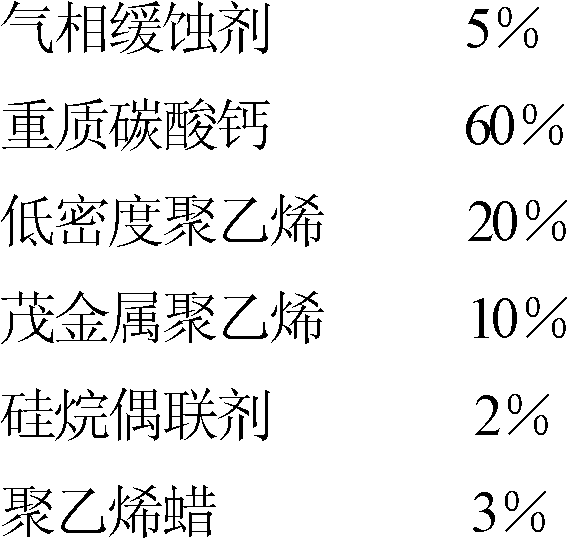

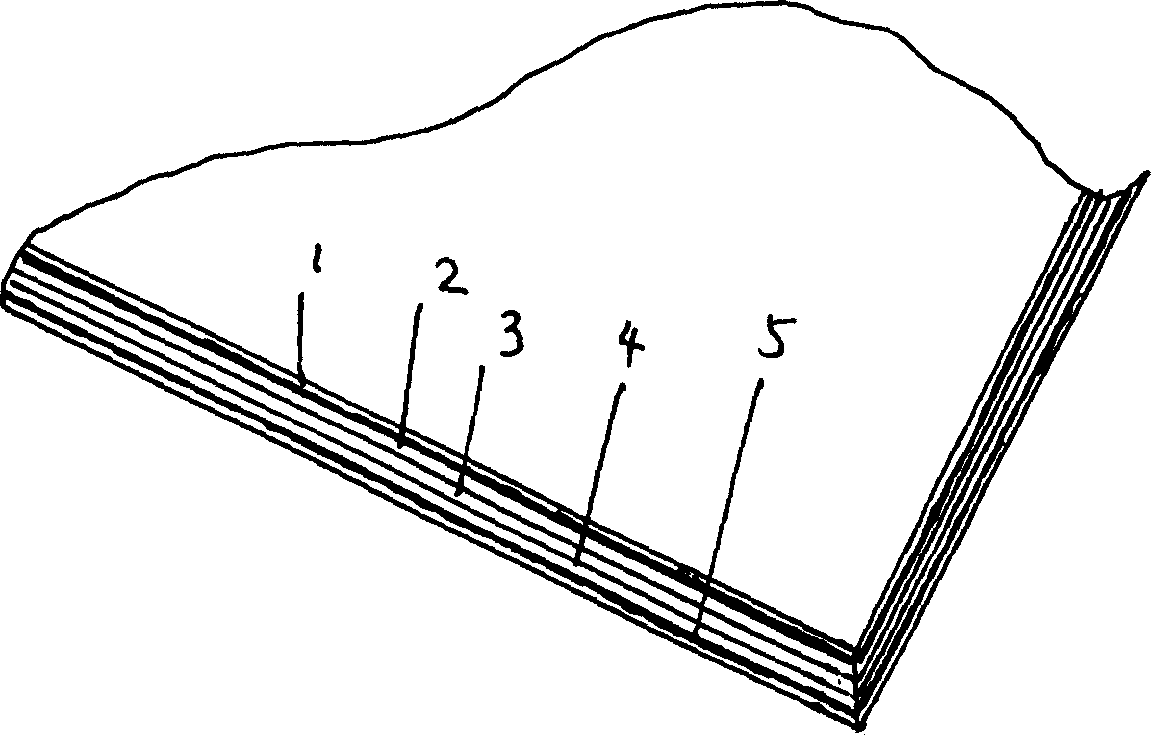

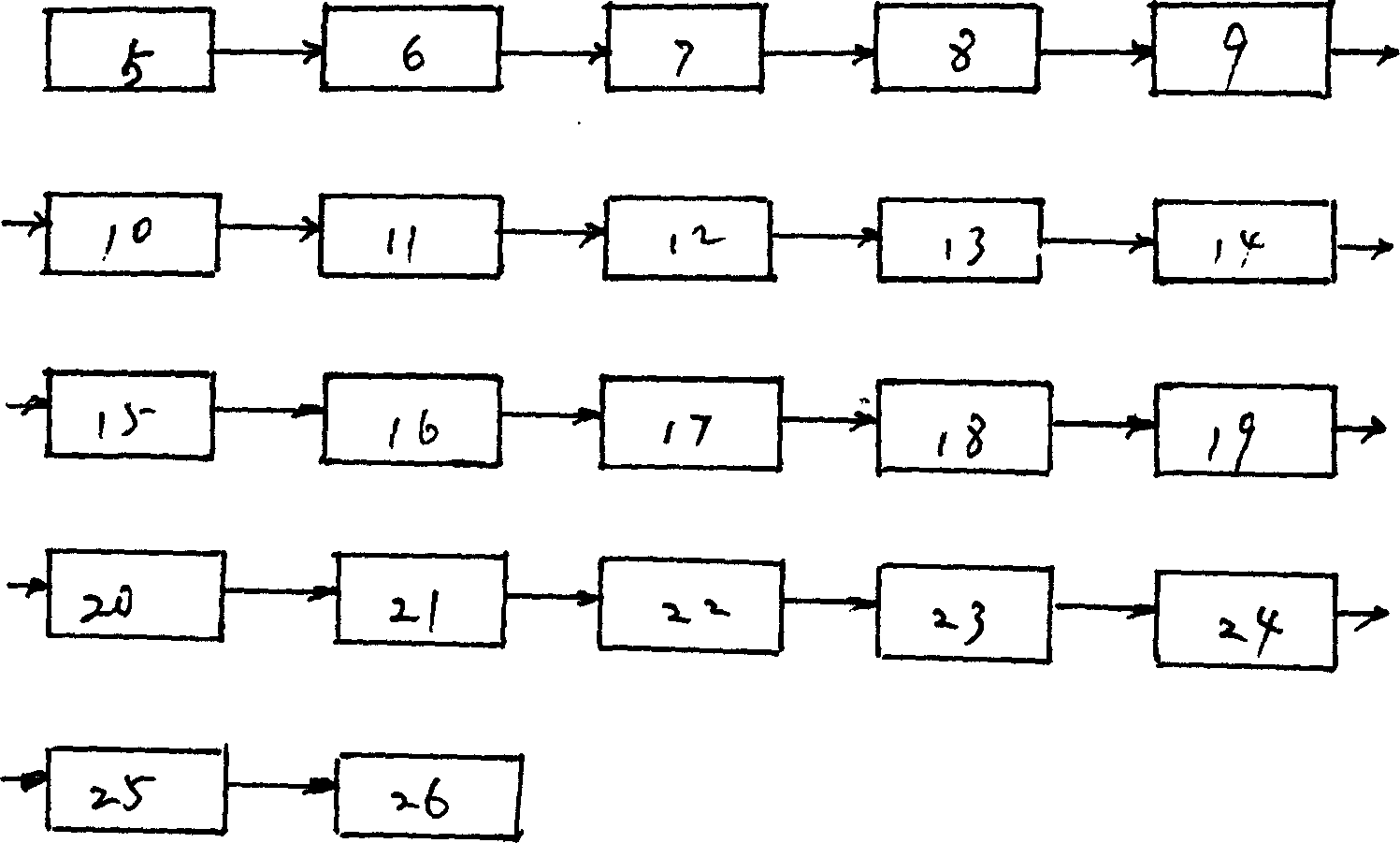

Volatile antirust synthetic paper and preparation method thereof

The invention relates to volatile antirust synthetic paper and a preparation method thereof, and belongs to the technical field of volatile antirust technology. The volatile antirust synthetic paper mainly comprises a volatile corrosion inhibitor, heavy calcium carbonate, low density polyethylene resin, metallocene polyethylene, a silane coupling agent, and polyethylene wax. According to the invention, polymer is used as a base raw material; heavy calcium carbonate is modified; the volatile corrosion inhibitor and various processing additives are added; the synthetic paper is prepared through forming process such as extrusion granulation process, film blowing, calendaring, curtain coating, and the like by using the characteristics of polymer interface chemistry principles and polymer modification. The invention has great social benefits to energy saving, natural resource protection, and environment improvement.

Owner:沈阳防锈包装材料有限责任公司

Located multicolour anti false coated white paperboard and production process thereof

InactiveCN1786344ANo loss of quantificationNo loss of thicknessFibreboardPaper/cardboardWhiteboardCardboard

The invention relates to location multicolor fake prevention coated manila and its production technique. It is made by surface coating and paper machine-made to form single side patent white board formed by starch, core, bottoming multilayer pulp. Its production technique includes the following steps: producing starch, core, and bottoming pulp; copying paper; drying; coating; press polish; and balling up. In copying paper process, coloring pigment is sprayed on the multilayer pulp to make the place with coloring pigment stay on the pulp surface. Thus the invention has the advantages of visual fake prevention discrimination, low cost, and good quality.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

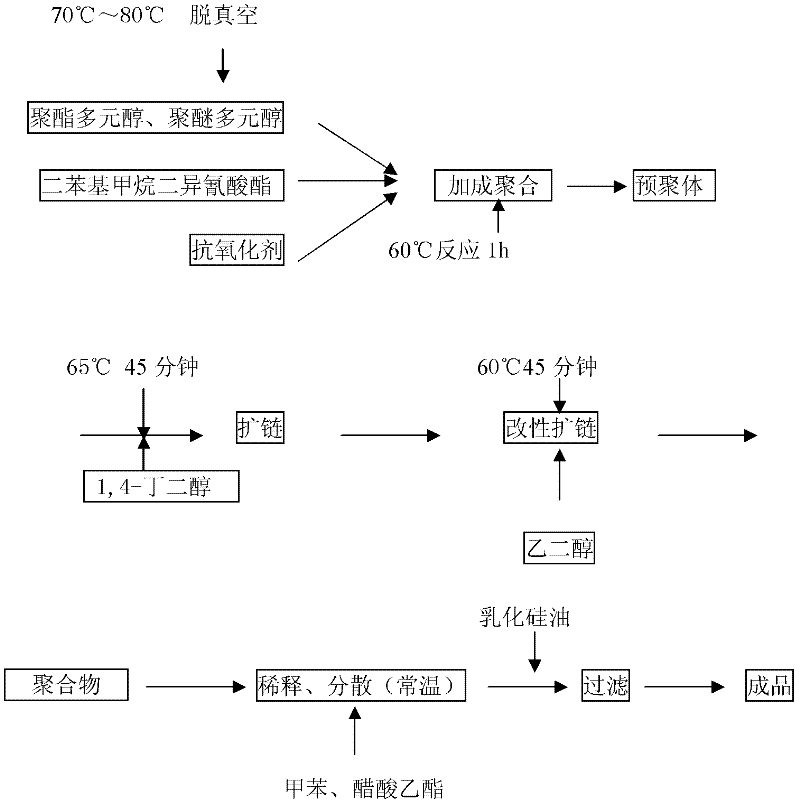

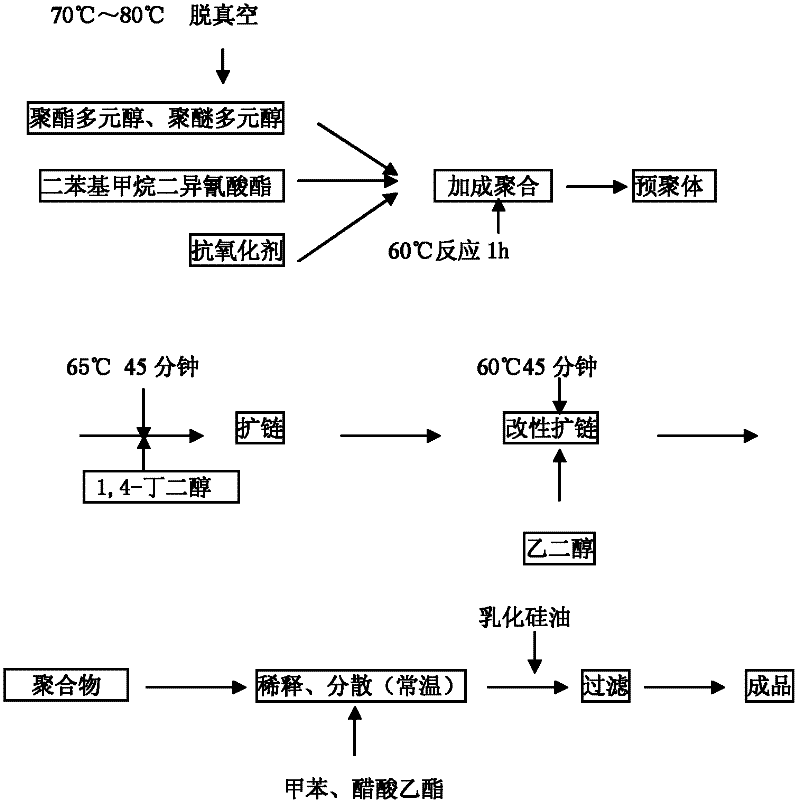

Crystal oil slippery resin used for synthetic leather and preparation method thereof

InactiveCN102604037AIncrease the relative molecular massImprove performanceFibre treatmentPolyesterAntioxidant

The invention relates to a crystal oil slippery resin used for synthetic leathers and a preparation method thereof. The crystal oil slippery resin is prepared from the following raw materials in parts by weight: 35-50 parts of dimethylformamide, 8-15 parts of polyether polyol, 4-8 parts of polyester polyol, 10-30 parts of methylene diphenyl diisocyanate, 0.5-1.8 parts of 1,4-butanediol, 3-6 parts of glycol, 10-20 parts of toluene, 10-20 parts of ethyl acetate, 3-5 parts of emulsified silicone oil and 0.01-0.03 part of antioxidant. Compared with the prior art, the crystal oil slippery resin disclosed by the invention has the beneficial effects that the crystal oil slippery resin can not only overcome the defects that oleoresin is tacky, poor in temperature resistance and the like, but also has the advantages of high temperature resistance, folding resistance, ageing resistance and the like. The crystal oil slippery resin used for the synthetic leathers is simple in process, convenient to produce and low in cost and can be directly applied to the posterior production procedure of the synthetic leathers; and third edition printing or spray coating can be adopted for the process.

Owner:建德市顺发化工助剂有限公司

Super folding-resistant nano cellulose film and preparation method thereof

The invention discloses a super folding-resistant nano cellulose film and a preparation method thereof, and belongs to the field of biomacromolecule materials. The preparation method comprises the following steps: (1) carrying out carboxymethylation modification of cellulose fibers; (2) adding water into the carboxymethylation modified fibers for dispersing, and carrying out high-pressure homogenization treatment to obtain nano cellulose fibers; and (3) diluting the nano-crystalline cellulose fibers with water, adding the diluted nano-crystalline cellulose fibers into a culture dish for evaporation drying to obtain the super-folding-resistant nano cellulose film. The nano cellulose film is capable of maintaining high polymerization degree and length of the fibers in preparation process; folding resistance is 20000 to 40000; tensile strength is 150-220 MPa, the light transmittance is larger than 90%, the thermal stability is good (the initial thermal degradation temperature is 250 DEGC or above), the yellowing index value (delta YI) is smaller than 3% after heating for 20 min at the temperature of 150 DEG C, and therefore the application prospects in the fields of energy sources,electronic devices and the like is promising.

Owner:SOUTH CHINA UNIV OF TECH

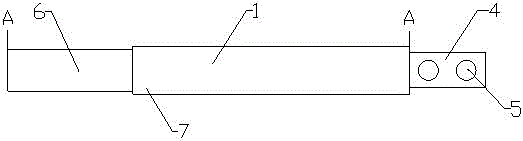

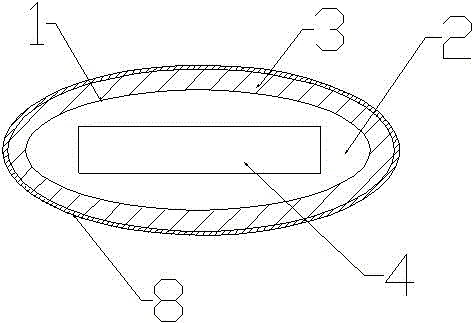

Graphite cable connected in flat-body manner

InactiveCN104103337AHigh strengthStable grounding resistanceMetal/alloy conductorsInsulation layerGraphite

The invention relates to a graphite cable for connection of a flat body. The graphite cable comprises a cable body, wherein the cable body is divided into a buried part and an overground part, the buried part of the cable body is not provided with an insulation layer, the overground part is provided with an insulation layer at the periphery of a grapheme layer, the insulation layer is coated with anti-corrosion paint, a core is arranged in the cable body and has a flat plate structure, the grapheme layer is arranged at the periphery of the core, the thickness of the grapheme layer is 1-3 millimeters, one end of the core is provided with a unoxidizable alloy connection piece, the unoxidizable alloy connection piece is of a rectangular flat structure, two connection holes are arranged in the unoxidizable alloy connection piece, and the core and the unoxidizable alloy connection piece are connected by means of welding. The graphite cable has the advantages of simplicity in structure, high safety factor, and convenient use.

Owner:郑州市三维配电设备有限公司

Post-crosslinked elastic transfer film emulsion and preparation method thereof

The present invention discloses a post-crosslinked elastomeric transfer film emulsion and a preparation method thereof. The emulsion comprises the following components in parts by weight: 1-5 parts of acrylic acid, 6-15 parts of epoxy resin, 1-3 parts of triethylene tetramine, 20-40 parts of butyl acrylate monomer, 50-70 parts of styrene, 1-5 parts of acrylamide, 0.5-1.5 parts of initiator, 2-4 parts of emulsifier, and 0.3-1 part of antifoaming agent. The preparation method of the emulsion comprises the steps of dissolving epoxy resin, preparing a pre-emulsion, synthesizing an emulsion and the like. According to the technical scheme of the invention, the above post-crosslinked elastic transfer film emulsion is adopted to replace the BOPP and PE films of film-coated products, and is high in light, high in brightness, abrasion resistant, folding resistant, degradable, recyclable, good in environmental protection property and low in cost. The post-crosslinked elastic transfer film emulsion can be used as the oil polish of paper packages and can also be used as the water-based paint glossy topcoat.

Owner:成都金箭桥包装材料有限公司

Novel utilization method of phosphogypsum

InactiveCN105524325ASolve the accumulationSolve the use problemCovering/liningsLayered productsComposite filmPhosphogypsum

The present invention provides a novel utilization method of phosphogypsum. The novel utilization method comprises: S1, drying phosphogypsum for 5-25 min at a temperature of 150-180 DEG C, and directly calcining phosphogypsum for 1-2 min at a temperature of 500-600 DEG C to form modified phosphogypsum; S2, cooling the modified phosphogypsum; S3, removing toxic impurities from the modified phosphogypsum; and S4, carrying out mixing treatment on the modified phosphogypsum and polyethylene to form the film layer. The method further comprises coating a coating layer on one side or both sides of the film layer to form the phosphogypsum film, wherein the phosphogypsum film can be further prepared into wallpaper, environmental protection paper, packaging materials, composite films, phosphogypsum composite profiles, and the like, and has broad application, and the problems of soil resource occupation and serious pollution of the phosphogypsum can be fundamentally solved.

Owner:杨刚

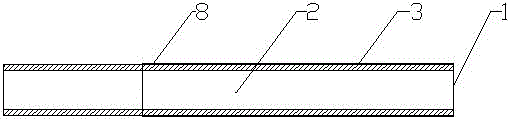

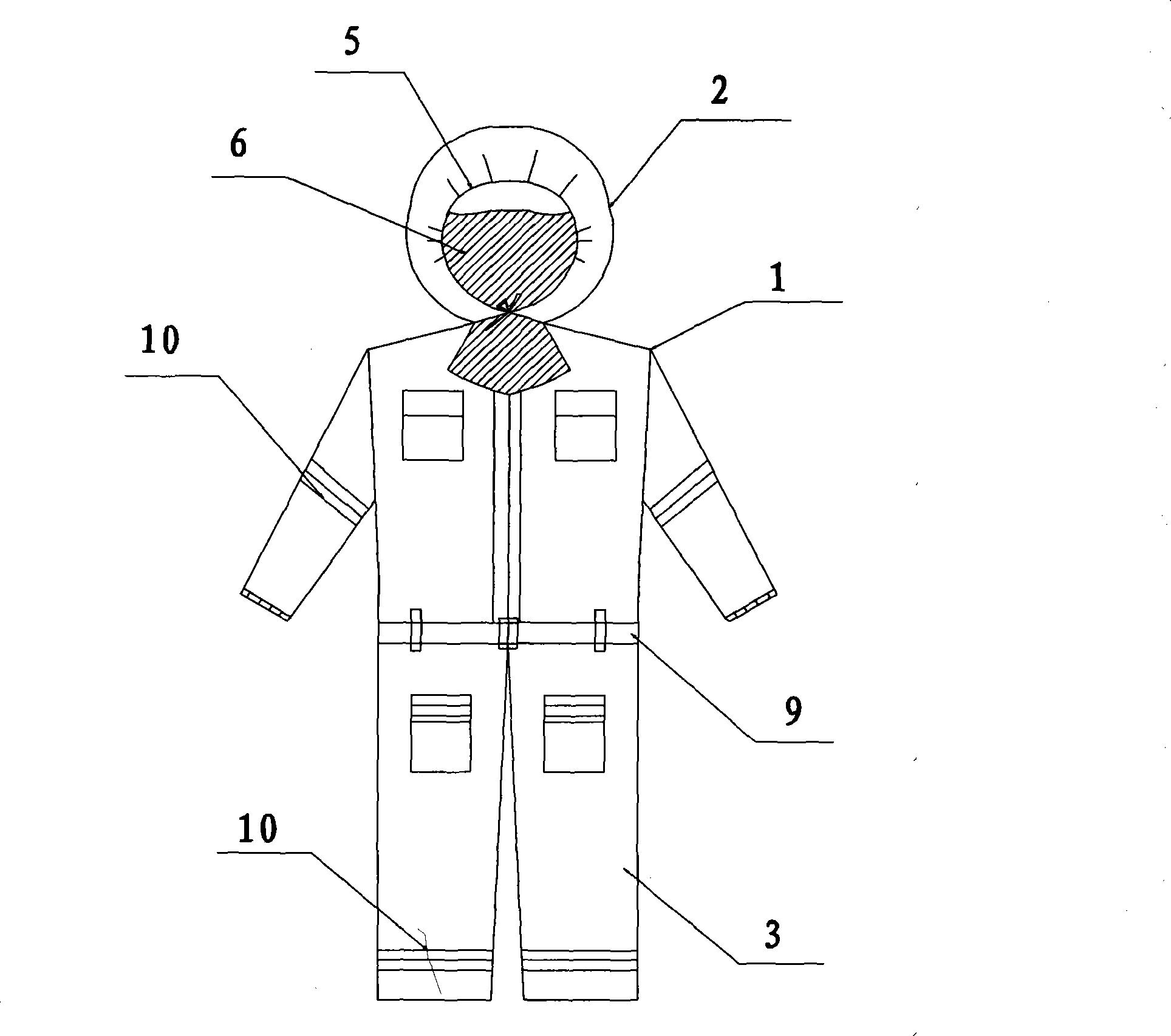

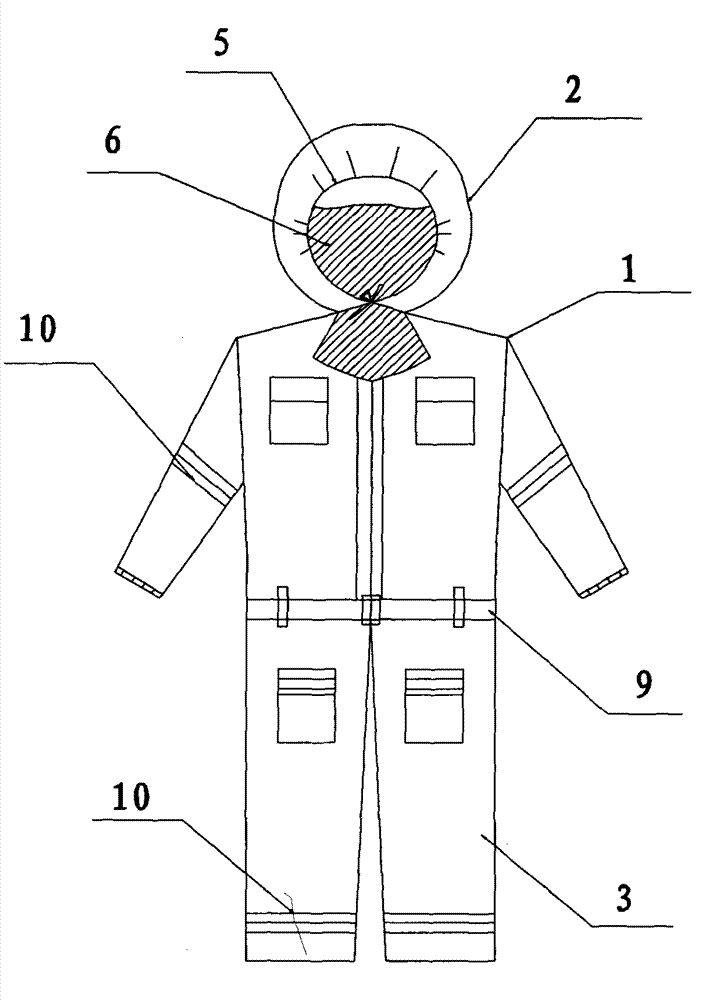

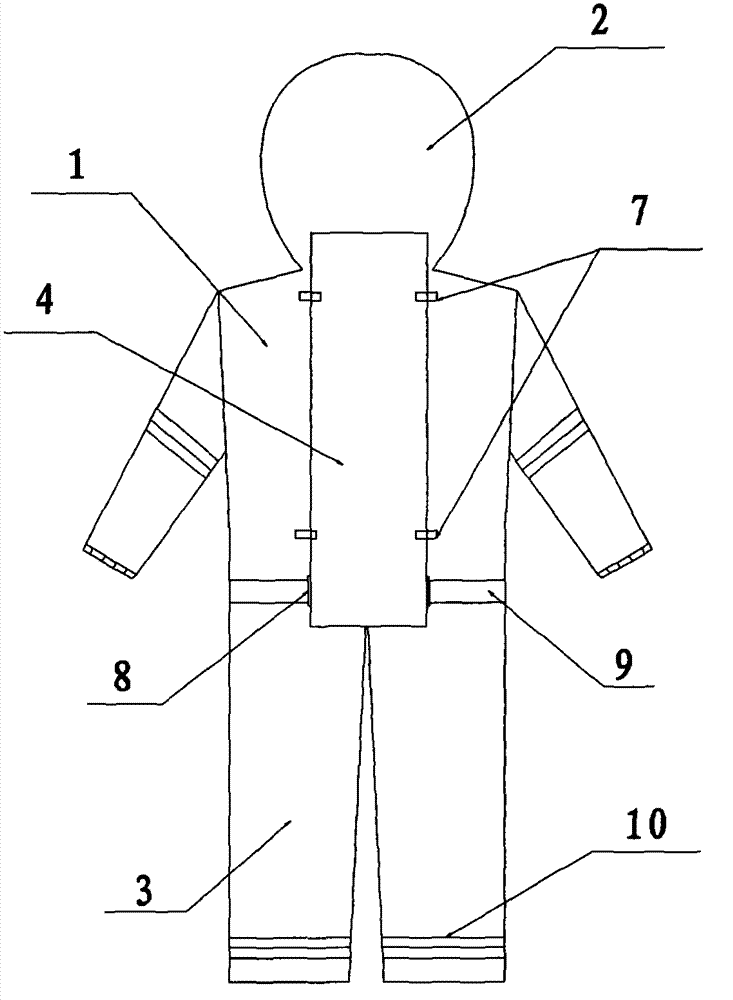

Multifunctional protective suit

ActiveCN104041956AEasy to wearFlexibleFibre treatmentProtective garmentEngineeringTemperature resistance

The invention discloses a multifunctional protective suit. The multifunctional protective suit comprises a coat, a hood and trousers, which are connected integrally. The back of the coat is integrally connected with a backpack capable of containing air bottles; a tightening band is arranged on the hood, and a protective block is arranged on the front part of the hood; rapid-pulling tightening buckles are arranged on the upper part, the lower part, the left part and the right part of the backpack; openings are formed in the left side and the right side of the lower part of the backpack; a waistband is arranged at the joint of the coat and the trousers, and penetrates through the openings; the outer layer of shell fabrics of the multifunctional protective suit is coated with high-temperature-resistant silica gel. The multifunctional protective suit disclosed by the invention is convenient to wear and high in sealing performance; the outer layer is coated with the high-temperature-resistant silica gel, so that the finished clothing has the prosperities of high temperature resistance, watertightness, abrasion resistance, folding resistance, static electricity resistance and the like.

Owner:QINGDAO MEIKANG FIREPROOF MATERIALS

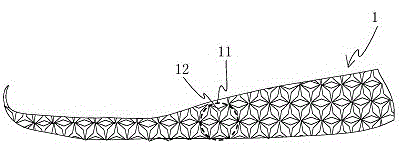

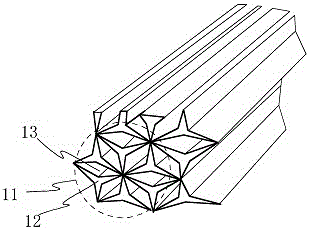

Folding-resistant shock-absorbing shoe sole

The invention relates to a shoe sole and provides a folding-resistant shock-absorbing shoe sole which has excellent shock absorption and bending performance and has the advantage of light weight and simple structure. The shoe sole comprises a shoe sole body composed of multiple shock-absorbing units. Each shock-absorbing unit comprises a plurality of shock-absorbing transverse strips, each shock-absorbing transverse strip is composed of three side edges, a shared connection edge is arranged among every three side edges, and an included angle of 120 degrees is formed between every two side edges. The shock-absorbing transverse strips in each shock-absorbing unit share a vertex connection part, and a parallelogram hollowed-out part is formed between every two adjacent shock-absorbing transverse strips. Every two adjacent shock-absorbing units share a parallelogram hollowed-out part.

Owner:QIERTE CO LTD

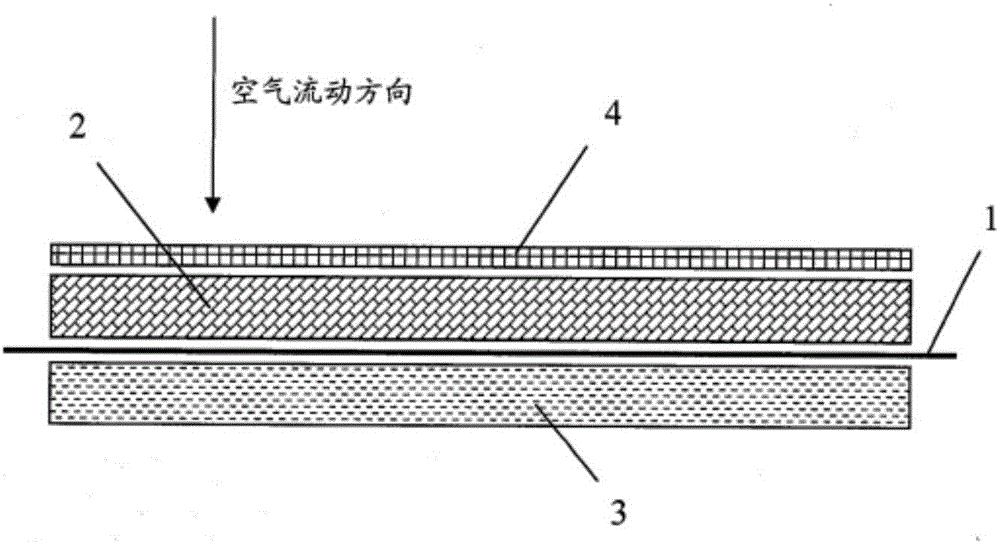

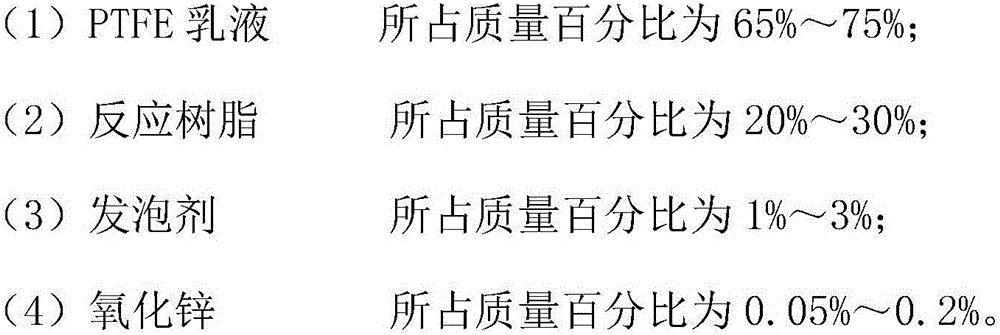

PTFE (polytetrafluoroethylene) foaming coating finishing agent and preparation method of composite filter of coating thereof

InactiveCN106422527AEasy to prepareLow costSynthetic resin layered productsMembrane filtersEpoxyEmulsion

The invention discloses a PTFT (polytetrafluoroethylene) foaming coating finishing agent and a preparation method of a composite filter and a coating; the PTFE foaming coating finishing agent is composed of foaming agent, zinc oxide, PTFE emulsion and reaction resin; the preparation method includes steps of orderly adding azodicarbonamide, zinc oxide, PTFE emulsion, acrylic resin, and waterborne epoxy resin in a beaker, and evenly mixing; placing the foaming coating fluid in an oven at 140-180 DEG C for foaming, and obtaining the foaming coating finishing agent. The foaming coating finishing agent can prepare the coating the coating PTFE composite filter and the foaming coating PTFE composite filter. Compared with the prior art, the coating finishing agent is simple in preparation method, low in raw material cost, and can be evenly coated on the surface of the filter; the filter also has the advantages of the PTFE fiber and PPS fiber at the same time; besides, the filter has the beneficial effects of oxidization resistance, high temperature resistance, and corrosive resistance.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Skin-core polypropylene composite plastic high imitation rattan and preparation method thereof

InactiveCN109535460AWith matte effectWith tensile strengthCoatingsPolypropylene compositesFolding endurance

The invention discloses a skin-core polypropylene composite plastic high imitation rattan and a preparation method thereof. The high imitation rattan is prepared by the steps of: a. mixing a polypropylene matrix, a toughening agent, a compatilizer, a physical foaming agent, an antioxidant and a pigment, then conducting melt extrusion and foaming to obtain a foamed polypropylene rattan-imitating substrate; b. adding a soluble pore-forming agent, straw glue and inorganic whisker into an organic solvent to prepare a viscous outer wall solution; and c. impregnating the rattan-imitating substrate in the outer wall solution, then conducting washing and drying curing, thus obtaining the skin-core polypropylene composite plastic high imitation rattan. The method has the beneficial effects that: the high imitation rattan prepared by the method provided by the invention has a rough and matt surface, has appearance, texture and density similar to those of natural rattan, also has soft texture like natural rattan, completely achieves the performance of natural rattan, at the same time has high tensile strength and folding endurance, good mechanical properties and good durability, thus having wide application range.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Rich mineral paper tableware, and preparation method thereof

The invention discloses rich mineral paper tableware, and a production method thereof. The rich mineral paper tableware comprises calcium carbonate, polyethylene, polypropylene, an anti-oxidant, a resin, ACR adhesive, a composite stabilizing modifier, and wood fiber powder. The production method comprises following steps: (1) the raw materials are delivered into a mixer for high speed mixing at a certain ratio; (2) modification is carried out, wherein a mixture obtained via high speed mixing is subjected to full dispersing and kneading so as to obtain a strip material or a plate material; (3) pelleting is carried out, wherein a pelletizer is used for preparing material particles from the obtained strip material or the plate material, so that it is convenient for transporting, raw materials can be provided for a plurality of parallel production lines, and production efficiency is increased; and (4) production is carried out, wherein the material particles are subjected to extrusion and blow moulding so as to obtain needed products.

Owner:杨金龙

multifunctional protective clothing

Owner:QINGDAO MEIKANG FIREPROOF MATERIALS

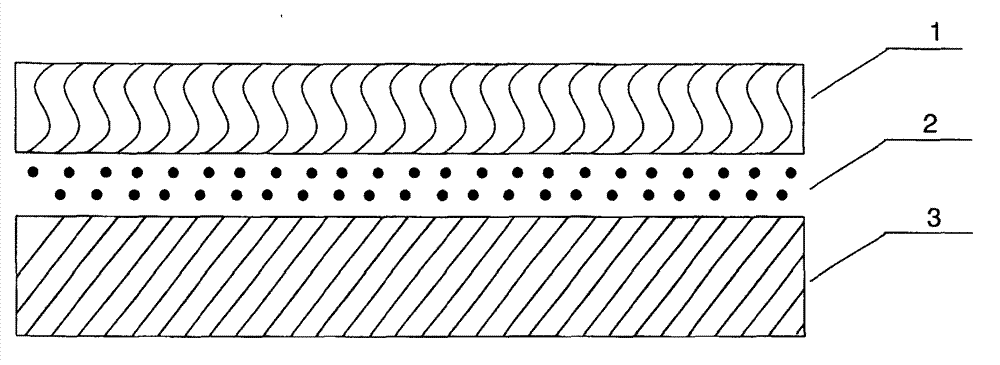

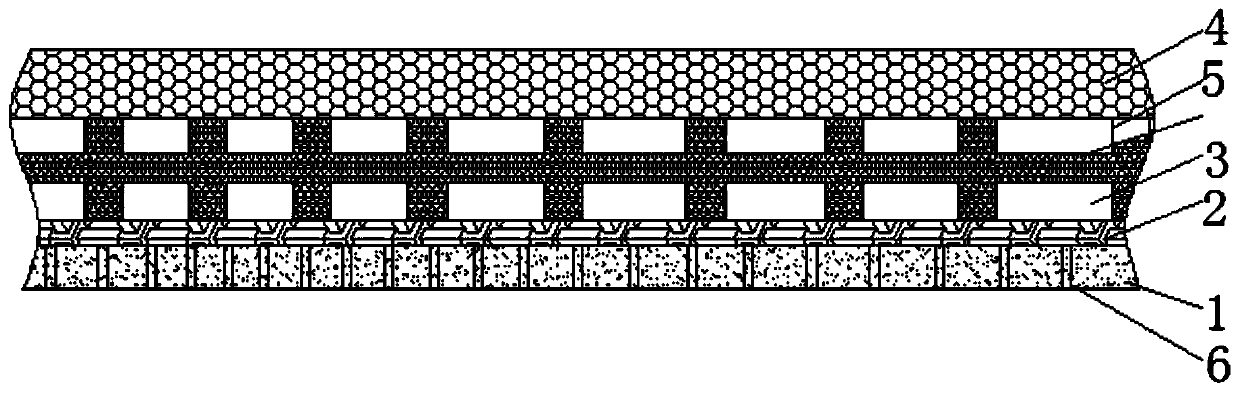

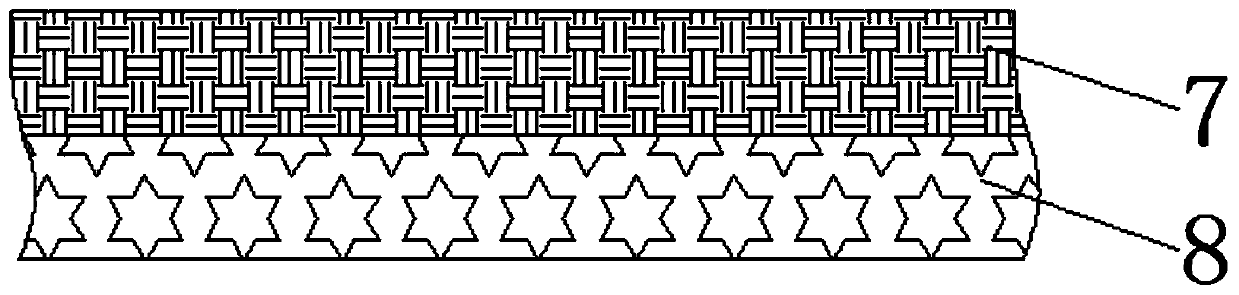

Low-carbon and environment-friendly stone paper composite wall cloth

InactiveCN102966225AWaterproofOil-resistantCovering/liningsPaper/cardboard layered productsTemperature resistancePolyester

The invention discloses low-carbon and environment-friendly stone paper composite wall cloth which comprises a surface layer, an intermediate layer and a lining layer, wherein the surface layer is made of recycled polyester silk twisted jacquard fabric; the intermediate layer is made of silicone adhesive; the lining layer is made of stone paper; and the back side of the surface layer is coated with the silicone adhesive as the intermediate layer and is compounded with the stone paper on the lining layer to form the low-carbon and environment-friendly stone paper composite wall cloth. According to the low-carbon and environment-friendly stone paper composite wall cloth disclosed by the invention, due to adoption of a three-layer composite structure, respective advantages are fully exerted; and the low-carbon and environment-friendly stone paper composite wall cloth has the functions and the characteristics of three-dimensional and embossed luxurious effects, fineness, smoothness, mildew resistance, permeability, favorable color fastness, water resistance, oil resistance, stain resistance, pest resistance, flame retardance, high temperature resistance, low possibility of ageing, no toxicity or peculiar smell, safety, environment friendliness, tearing resistance, folding resistance, degradability and the like and is low-carbon, environment-friendly and healthy stone paper composite wall cloth in the modern building and decoration industries.

Owner:SHAOXING SHULILE TEXTILE PROD

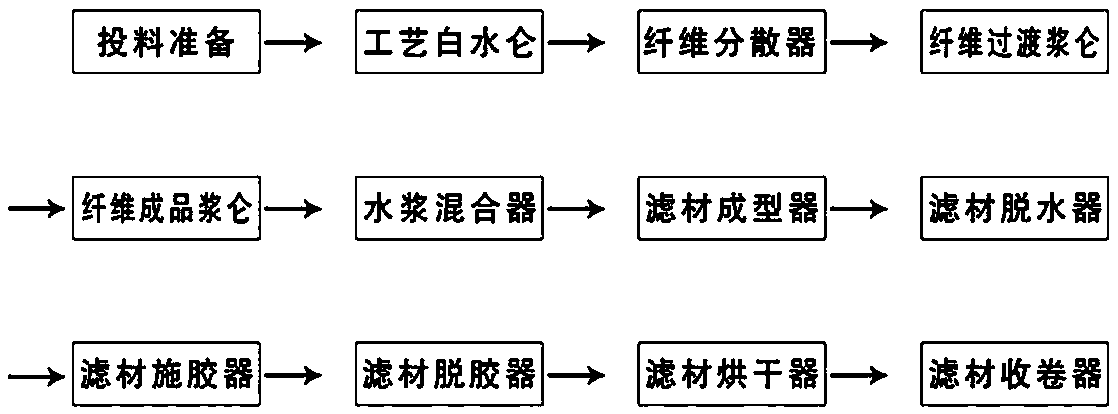

Environment-friendly filtering material

InactiveCN108096926AWith folding resistanceTear resistantFiltration separationAdditive ingredientTear resistance

The invention relates to an environment-friendly filtering material, which is prepared from the ingredients including softwood pulp, vinylon ultrafine fiber, vinylon insoluble fiber, vinylon water-soluble fiber and vinylon high-intensity fiber. A filtering material product has the characteristics of folding resistance, tearing resistance, damage resistance, good water-resistant performance and high wet intensity. According to different user requirements, the formula proportioning ratio of the environment-friendly filtering material is regulated to produce the filtering material product conforming to the requirements in aspects of filtering precision and ventilation degree. In addition, in the production process of the filtering material product, generated leftover bits and pieces and excessive materials and replaced waste filtering materials after the use can be combusted and placed in the land and are are biodegradable; no harm is caused on the human body; pollution cannot be caused on the environment and the air; the environmental protection is facilitated. The environment-friendly filtering material belongs to an ideal environment-friendly filtering material.

Owner:刘洪亮

Thermoplastic moldable TPU (Thermoplastic Polyurethane) filament as well as preparation method and application thereof

InactiveCN109610042AHigh response rateLow boiling water shrinkageConjugated synthetic polymer artificial filamentsArtifical filament manufactureSpecific weightPolyvinylidene fluoride

The invention provides a thermoplastic moldable TPU (Thermoplastic Polyurethane) filament which is composed of raw materials of TPU, polyvinylidene fluoride, polyvinyl butyral, an ultraviolet absorbent, a lubricant and an antioxidant, wherein the weight-average molecular weight of the polyvinylidene fluoride is 450000-540000, or is 550000-650000. The TPU filament is made of the polyvinylidene fluoride of the specific weight-average molecular weight, the TPU and other raw materials, the TPU filament made of the raw materials has the characteristics of being good in cold resistance and fractureresistance, high in rebound rate, that is, the rebound rate after extreme extension is as high as 98%, low in low boiling water shrinkage rate, approximate to zero shrinkage in boiling water, light and transparent, good in molding effect, and not liable to deform after molding; for the thermoplastic moldable TPU filament made by using an environmental-friendly melting and spinning process, a conventional TPU membrane pressing process is avoided, processes can be simplified, and the production cost can be lowered.

Owner:JINJIANG DAYI WARP KNITTING

A kind of ultra-fold-resistant nano-cellulose film and preparation method thereof

The invention discloses a super-folding-resistant nano-cellulose film and a preparation method thereof, belonging to the field of biopolymer materials. The preparation method is as follows: (1) carboxymethylation modification of cellulose fibers; (2) adding water to disperse the carboxymethylation-modified fibers, and then undergoing high-pressure homogeneous treatment to obtain nano-cellulose fibers; ( 3) After diluting the nanocellulose fibers with water, add them to a petri dish to evaporate and dry to obtain a super-folding-resistant nanocellulose film. The nanocellulose film of the present invention has excellent physical properties due to the high degree of polymerization and length of the fiber maintained during the preparation process, the number of foldings is 20000-40000 times, the tensile strength is 150-220 MPa, and the light transmittance is >90%. , and has good thermal stability (the initial thermal degradation temperature is above 250°C), and the yellowing value (ΔYI) is less than 3% when heated at 150°C for 20 minutes. Therefore, it has broad application prospects in the fields of energy and electronic devices.

Owner:SOUTH CHINA UNIV OF TECH

Ice-surface antiskid warm-keeping sole material and preparation method thereof

PendingCN111037829AIncrease coefficient of frictionNot easy to slipDomestic articlesWear resistanceFine chemical

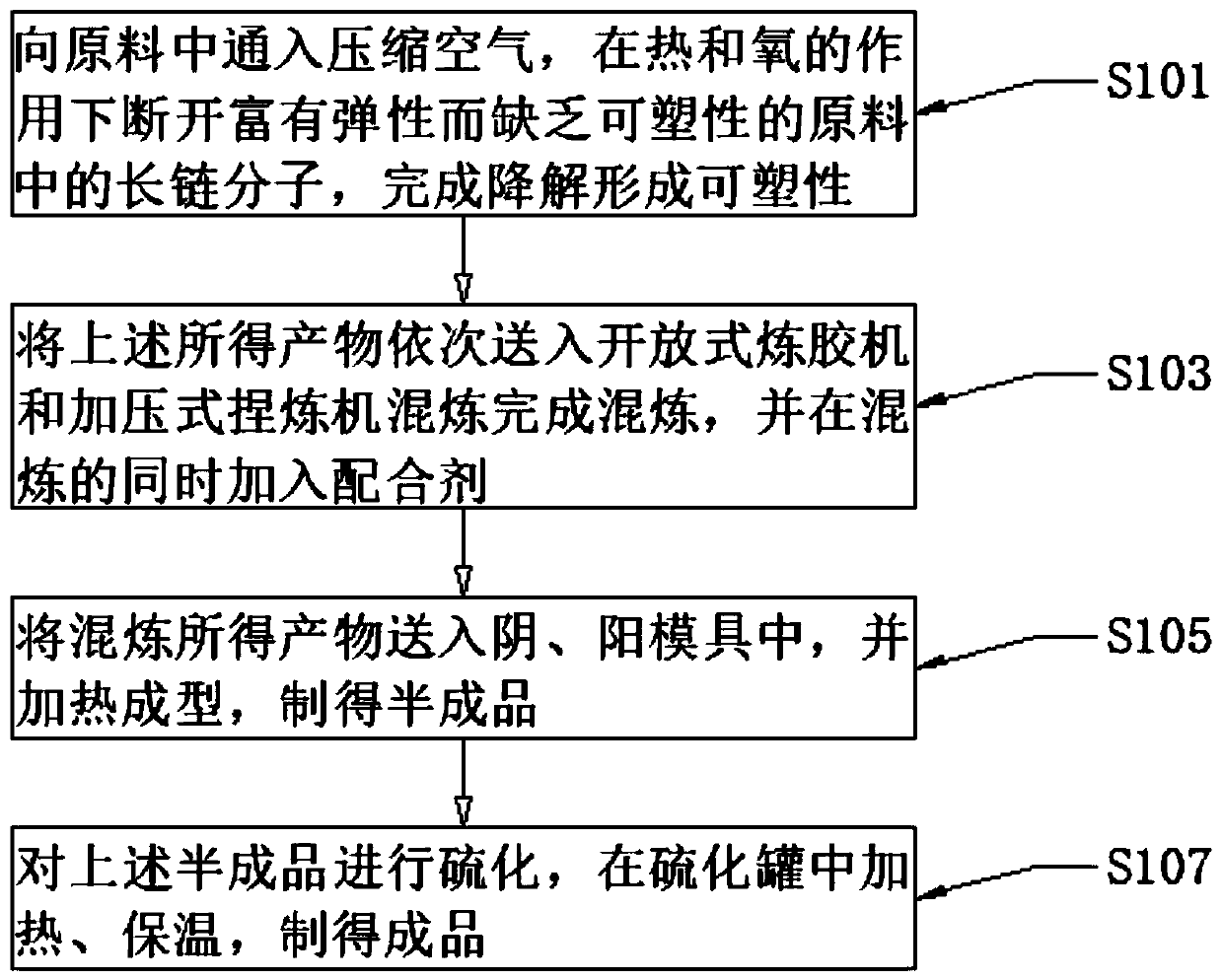

The invention relates to the technical field of sole materials and discloses a preparation method of an ice-surface antiskid warm-keeping sole. The method comprises the following steps of hot plastication: introducing compressed air into a raw material, breaking long-chain molecules in the raw material which is rich in elasticity and lack of plasticity under the action of heat and oxygen, and completing degradation to form plasticity; and mixing: sequentially feeding an obtained product into an open rubber mixing mill and a pressurized kneading mill for mixing to finish mixing, and adding a compounding agent while mixing. According to the invention, by adding a self-developed fine chemical formula material and functional trace formula elements, the material not only has the characteristicsof ice surface walking, large friction coefficient, difficulty in slipping, walking on dry ground and the same characteristics as common soles, but also has the characteristics of high elasticity, folding resistance, shock absorption, wear resistance, water resistance and the like. Meanwhile, various special materials are added in the material mixing process, so that the heat preservation effectof shoes is better.

Owner:扬州锦沃科技有限公司 +1

External packing box covered with outer film and manufacturing method thereof

The invention discloses an external packing box covered with an outer film, and relates to the technical field of packing boxes. The external packing box comprises a box body which comprises an anti-corrosion layer, an odor removal layer, a plastic plate and an adhesive from interior to exterior in sequence; the plastic plate is internally provided with cross grooves; through holes are formed in the anti-corrosion layer; the odor removal layer is composed of an adsorbent and a foam layer subjected to blending weaving; the adhesive comprises the raw materials of, by weight, 10-15 parts of polyurethane, 23-27 parts of polystyrene, 12-18 parts of ethylene-acetic acid and 20-25 parts of ethylene copolymer. According to the external packing box covered with the outer film and a manufacturing method thereof, the surface of the plastic plate can have the protection functions of being resistance to damp, water, dirt, abrasion, folding, chemical corrosion and the like through the adhesive, commodities in the packing box can be sufficiently protected, the toughness of the packing box can be improved through cooperation of the cross grooves and the alkene soft plastic layer, the situation that the packing box is deformed after being collided, and the commodities in the packing box are influenced is avoided, and the commodities are further protected.

Owner:广东唯美优越包装科技股份有限公司

Paper-imitating biodegradable resin and preparation method

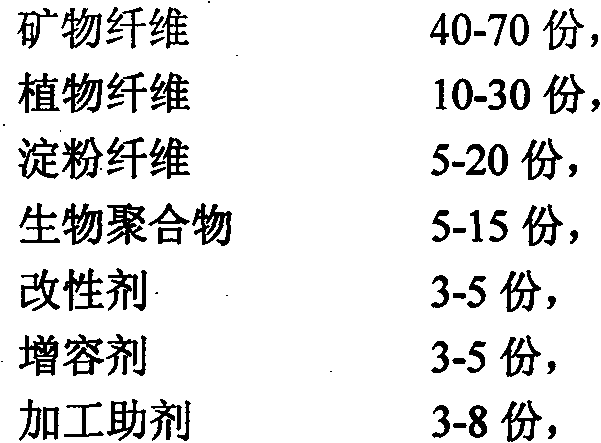

ActiveCN101914294BAvoid pollutionImprove rigidityInorganic fibres/flakesPaper/cardboardBiopolymerVegetable fibers

The invention discloses a paper-imitating biodegradable resin and a preparation method. For improving the degradability and natural recoverability of paper-imitating materials and making the paper-imitating materials have similar lightness, foldability and printing and writing performance as the conventional paper. The paper-imitating biodegradable resin uses mineral fibers, vegetable fibers and starch fibers as main components, and concretely comprises the following components in part by weight: 40 to 70 parts of mineral fibers, 10 to 30 parts of vegetable fibers, 5 to 20 parts of starch fibers, 5 to 15 parts of biopolymer, 3 to 5 parts of modifier, 3 to 5 parts of compatibilizer and 3 to 8 parts of processing assistant. The mineral fibers, vegetable fibers and starch fibers are interweaved through thermoplastic processing, and the preparation process is clear and pollution-free. The paper-imitating biodegradable resin can be processed into various paper-imitating products by hot plasticizing equipment, and the products, when discarded, can be swallowed and decomposed by microbes without polluting the environment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

A kind of utilization method of phosphogypsum

InactiveCN105524325BSolve the accumulationSolve the use problemCovering/liningsLayered productsComposite filmLand resources

The invention provides a method for utilizing phosphogypsum, the method comprising steps: S1: drying the phosphogypsum at 150-180°C for 5-25 minutes, and then directly calcining the phosphogypsum at 500-600°C for 1-2 Minutes later, modified phosphogypsum is formed; S2: cooling the modified phosphogypsum; S3: removing toxic impurities in the modified phosphogypsum; and S4: mixing the modified phosphogypsum with polyethylene to form a film layer, and the modified phosphogypsum The ratio of polyethylene is 85:15. The method further includes coating a coating layer on one side or both sides of the film layer to form a phosphogypsum film, and the phosphogypsum film can be further made into wallpaper, environmentally friendly paper, packaging materials, composite films and phosphogypsum composite profiles, etc., which utilize It can fundamentally solve the problem of phosphogypsum occupying land resources and causing serious pollution.

Owner:杨刚

Manufacturing method for hydrolysis-resistant clothing leather

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

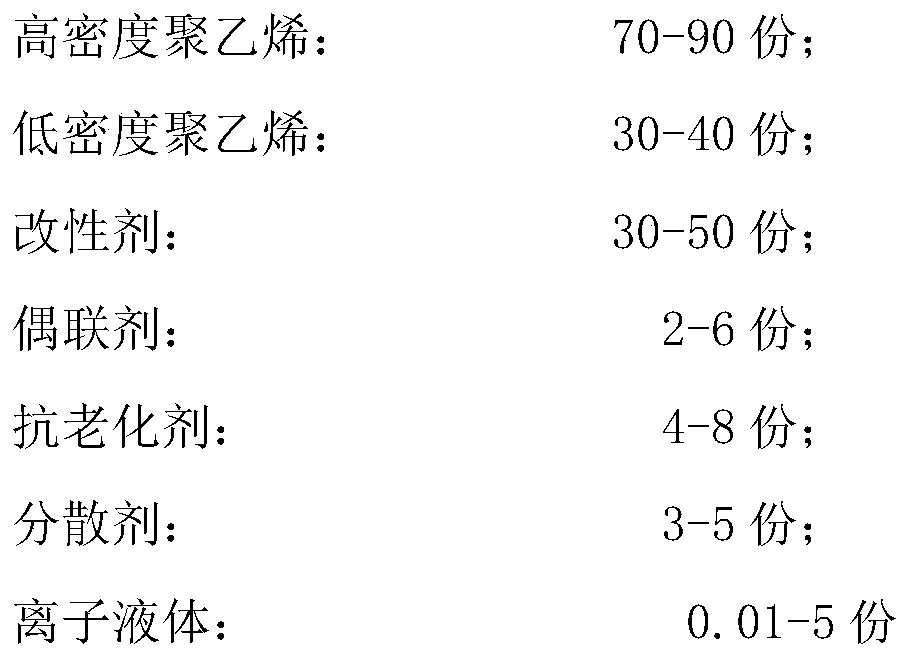

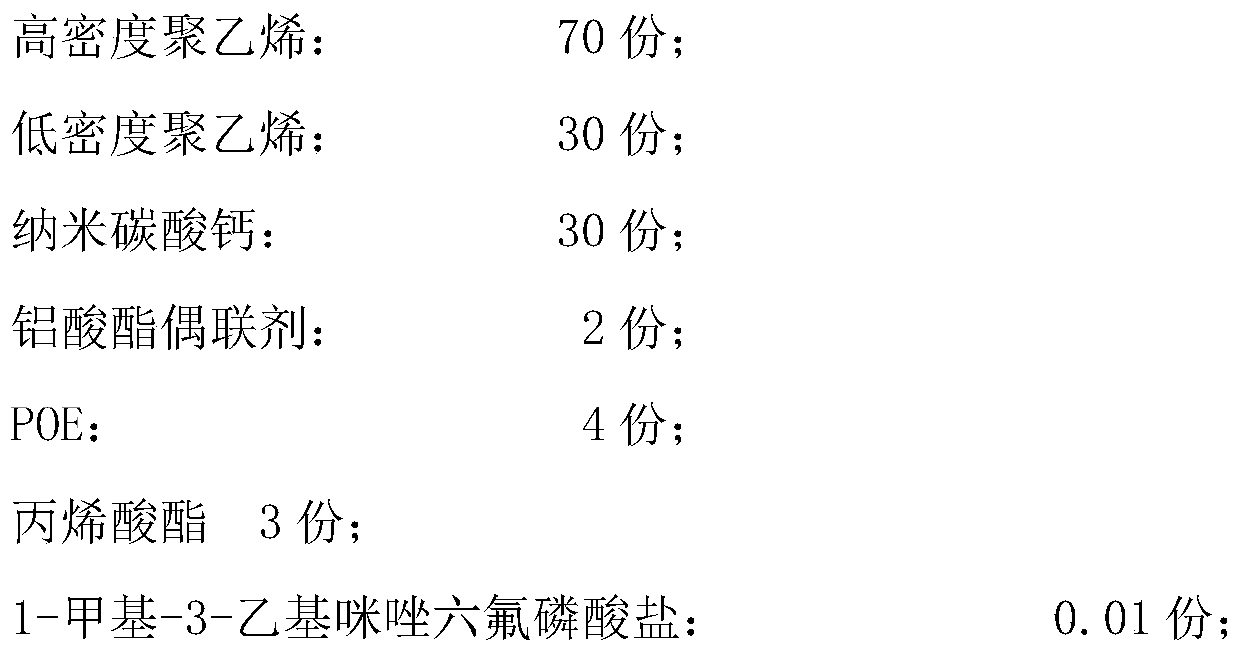

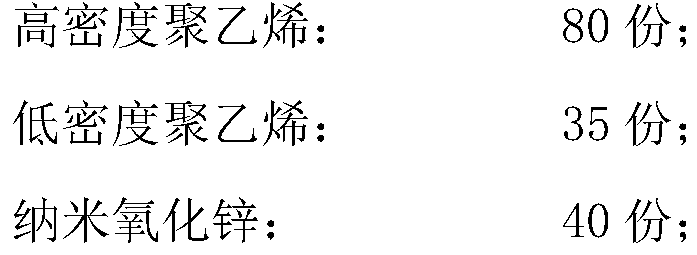

High-strength detonating tube and its preparation method

ActiveCN106317553BDoes not affect mechanical propertiesHigh tensile strengthBlasting cartridgesLow-density polyethyleneOligomer

Owner:ANHUI UNIV OF SCI & TECH

Gravure glue

InactiveCN105153973AGood ink fastnessImprove printed productHydrocarbon polymer adhesivesEmulsionEthyl ester

The invention discloses gravure glue. According to the gravure glue, a mixed monomer, an initiator, an emulsifier, a dispersing agent and water are used as raw materials. The dosage of the initiator is 0.2%-0.4% of the weight of the mixed monomer, the dosage of the emulsifier is 1%-2% of the weight of the mixed monomer, the dosage of the dispersing agent is 3%-6% of the weight of the mixed monomer, and the dosage of the water is 90%-110% of the weight of the mixed monomer. The mixed monomer is prepared from, by weight, 35%-65% of styrene, 25%-60% of butadiene and 5%-15% of ethyl acrylate. The bonding firmness of SBR latex and the fast permeability of acrylic based emulsion are combined together; paper using the gravure glue is good in aluminum layer and printing ink firmness, and the surface scraping phenomenon of the paper is avoided; besides, certain folding resistance is achieved, and the quality of finished printed products is improved.

Owner:江苏琛亚印材科技有限公司

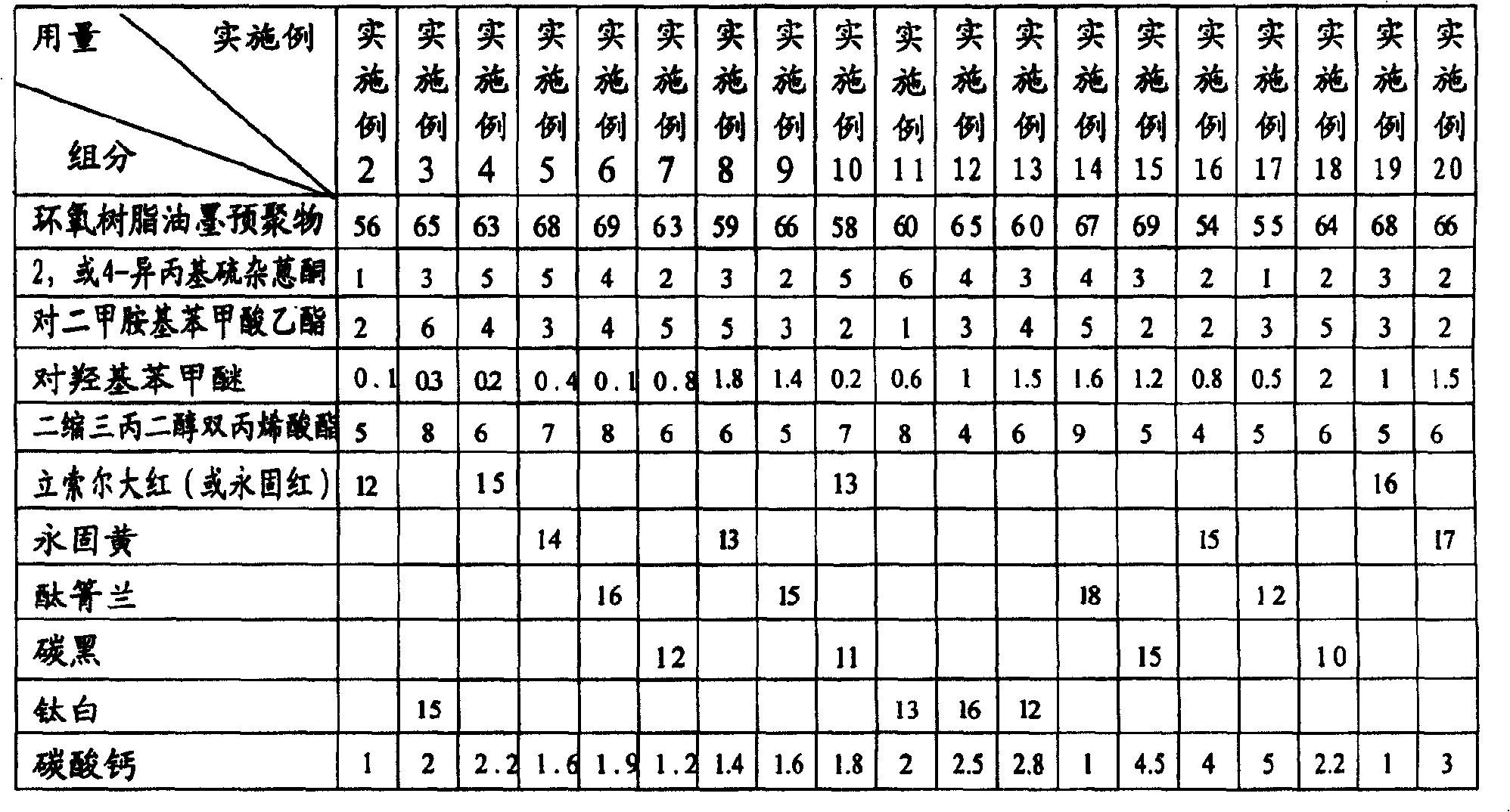

Ultraviolet cured offset printing ink

The invention discloses an ultraviolet light curing offset printing ink which is formed by epoxide resin printing ink pre-polymer, 2, or 4-isopropyl thioxanthone, dimethylin ethyl benzoate, triethylene glyceryl alcohol methyl acrylate, painting and calcium carbonate. It can adjust the painting ink by different painting craft with the ink moving speed: 2-35mm / normal temperature, the viscosity ratio: 100-300pa.s / 30 deg. and the drying time: 150-800s / normal temperature.

Owner:石家庄印钞有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com