Graphite cable connected in flat-body manner

A graphite cable and flat body technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of cable burnout due to the current level, difficulty in completing operations with ordinary cables, and low structural strength, etc., to meet the requirements of lightning current speed and increase Strength, the effect of increasing the bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

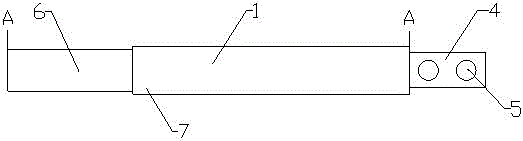

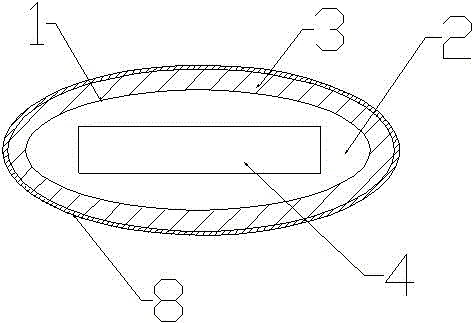

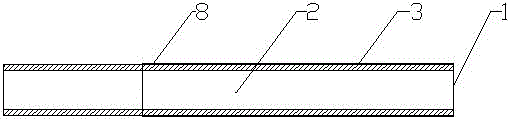

[0019] Such as figure 1 As shown in —3, a flat-body connected graphite cable includes a cable body 1, and a battery core 2 is arranged inside the cable body 1, and the battery core 2 has a flat plate structure, and the battery core 2 is provided with The graphene layer 3 has a thickness of 2 mm. One end of the battery core 2 is provided with a stainless alloy connector 4, and the stainless alloy connector 4 is provided with a connection hole 5.

[0020] The cable body 1 is divided into a buried part 6 and an above ground part 7.

[0021] The buried part 6 of the cable body 1 is not provided with an insulating layer, and the above-ground part 7 is provided with an insulating layer 8 on the periphery of the graphene layer 3, and the insulating layer 8 is coated with anticorrosive paint.

[0022] The battery core 2 and the stainless alloy connecting piece 4 are welded by welding.

[0023] When the present invention is in use, the buried part of the cable body is buried undergroun...

Embodiment 2

[0025] Such as figure 1 As shown in —3, a flat-body connected graphite cable includes a cable body 1, and a battery core 2 is arranged inside the cable body 1, and the battery core 2 has a flat plate structure, and the battery core 2 is provided with The graphene layer 3 has a thickness of 2 mm. One end of the battery core 2 is provided with a stainless alloy connector 4, and the stainless alloy connector 4 is provided with a connection hole 5.

[0026] The cable body 1 is divided into a buried part 6 and an above ground part 7.

[0027] The buried part 6 of the cable body 1 is not provided with an insulating layer, and the above-ground part 7 is provided with an insulating layer 8 on the periphery of the graphene layer 3, and the insulating layer 8 is coated with anticorrosive paint.

[0028] The stainless alloy connector 4 has a rectangular parallelepiped flat structure.

[0029] The battery core 2 and the stainless alloy connecting piece 4 are welded by welding.

[0030]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com