Patents

Literature

47results about How to "Has no rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

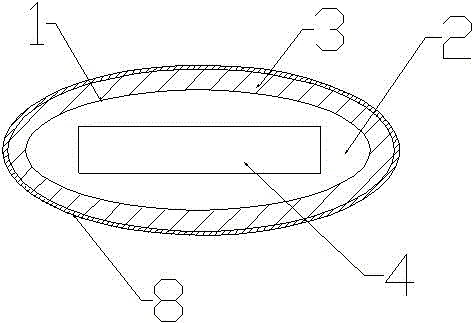

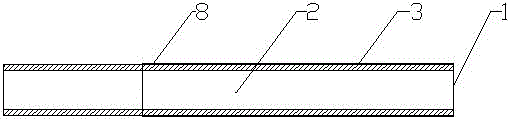

Sandwich metal plate

ActiveCN108397679APermanent service lifeLow intensitySheets/panelsMetal layered productsThermal insulationEngineering

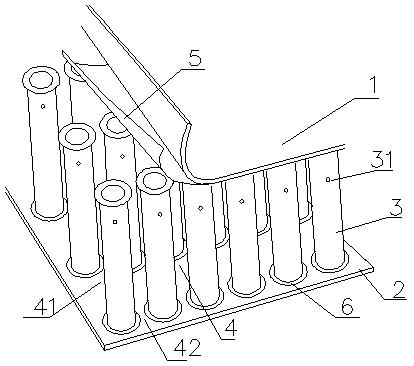

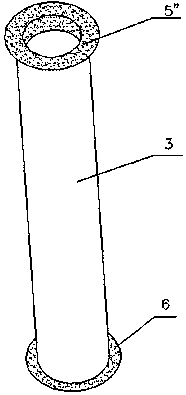

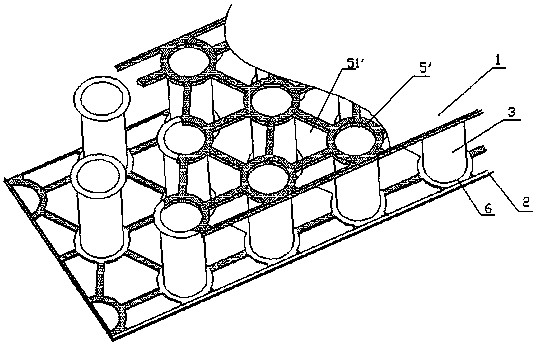

The invention relates to a sandwich metal plate. The sandwich metal plate comprises an upper panel, a lower panel and a plurality of core tubes, wherein the multiple core tubes are arranged between the upper panel and the lower panel, penetrating air passages are arranged among the multiple core tubes, and the core tubes as well as the upper panel and the lower panel are brazed through fore-and-aft and / or left-and-right circulating heating by utilizing high-temperature gas through the air passages. On one hand, the sandwich metal plate has the advantages of light weight, high strength, heat insulation and the like, and on the other hand, the sandwich metal plate cannot be deformed by heat difference, so that the permanent service life of the sandwich metal plate is guaranteed.

Owner:张跃

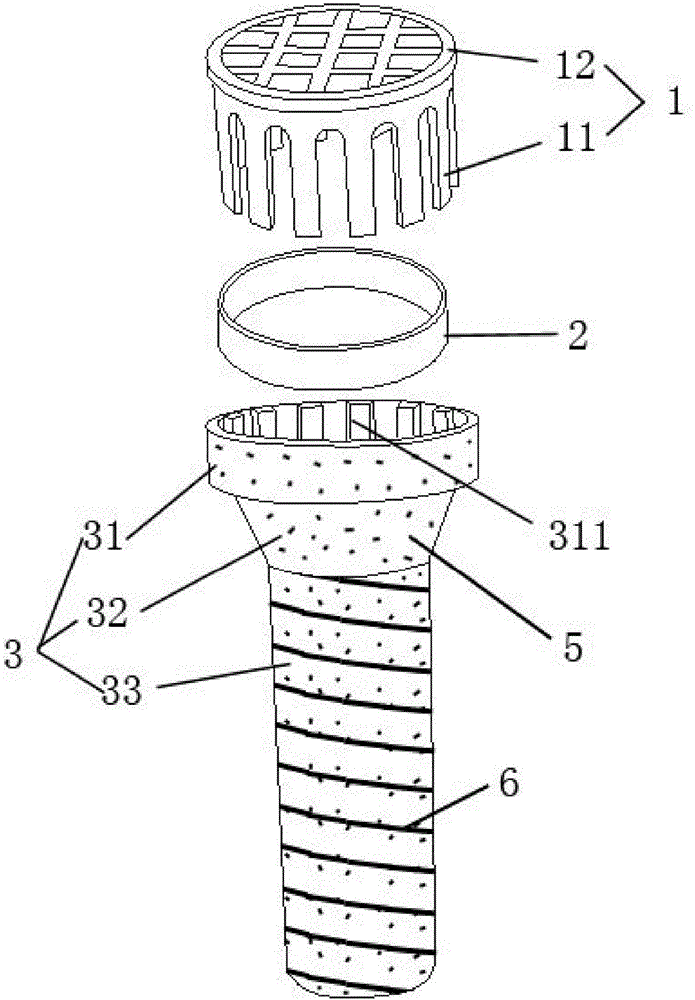

High-strength energy-saving environment-friendly burglarproof water drain pipe for bridge

InactiveCN104315259AImprove anti-theftSolve the anti-theftCorrosion preventionPipe elementsSurface layerHigh intensity

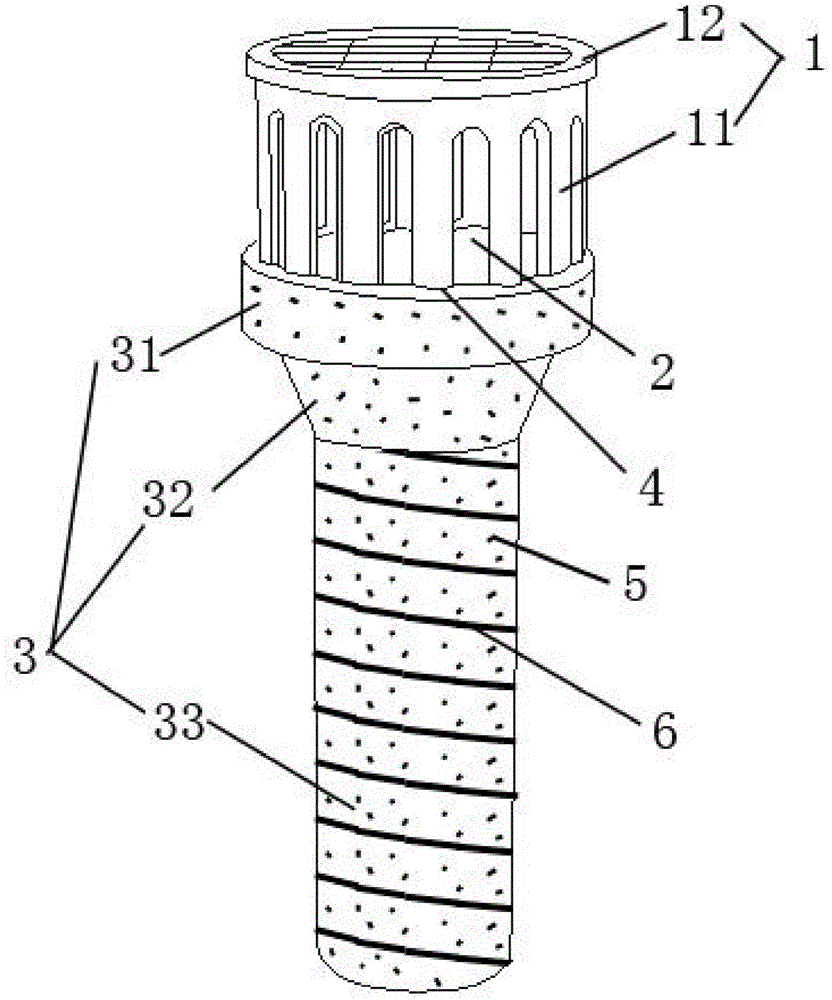

The invention discloses a high-strength energy-saving environment-friendly burglarproof water drain pipe for a bridge. The water drain pipe comprises a water drain pipe, and a filter screen and a water collection hole fixed ring which are molded once, wherein the filter screen consists of a filter plate and splicing teeth arranged at the edge of the filter plate; the water drain pipe consists of a large-diameter straight pipe and a small-diameter straight pipe which are connected through a conical pipe; lugs are uniformly arranged on the inner wall of the large-diameter straight pipe; the water collection hole fixed ring is adhered with the lugs in the large-diameter straight pipe; splicing holes are formed by gaps between the water collection hole fixed ring and the lugs; the splicing teeth on the filter screen are arranged in the splicing holes and are respectively adhered with the water collection hole fixed ring and the large-diameter straight pipe; a pitted surface layer is arranged on the outer surface of the water drain pipe; a pitted surface layer on the small-diameter straight pipe is provided with spiral concave-and-convex grooves. The high-strength energy-saving environment-friendly burglarproof water drain pipe has the advantages of high in anti-corrosion property, acid-alkali resistant, anti-aging, free of rusting energy-saving, environment-friendly, and the like; the load of bridge is reduced, the engineering quality is improved, the service life of the pipe is greatly improved, the maintenance cost is reduced, and the burglar prevention problem is radically solved.

Owner:WUXI ZHONGLIAN ELECTRONICS EQUIP

Method for making colour-glazed porcelain plate

The invention discloses a glazed ceramic board making method, adopting the steps of: 1) applying glaze on a mud blank ceramic board; 2) simultaneously sintering the blank and glaze; 3) making glaze post- processing on the ceramic board sintered with glaze, such as colored drawing, or pasting decal paper, or tracing design in gold, etc; 4) decorating firing. And it can act as sign boards and other pendants, and as compared with the existing materials, such as wood, metal, plastics, and even white ceramic board, has characters of stainlessness, not decoloring, not rotting, not deforming, easy to care, etc, thus a new variety of porcelain.

Owner:傅涛

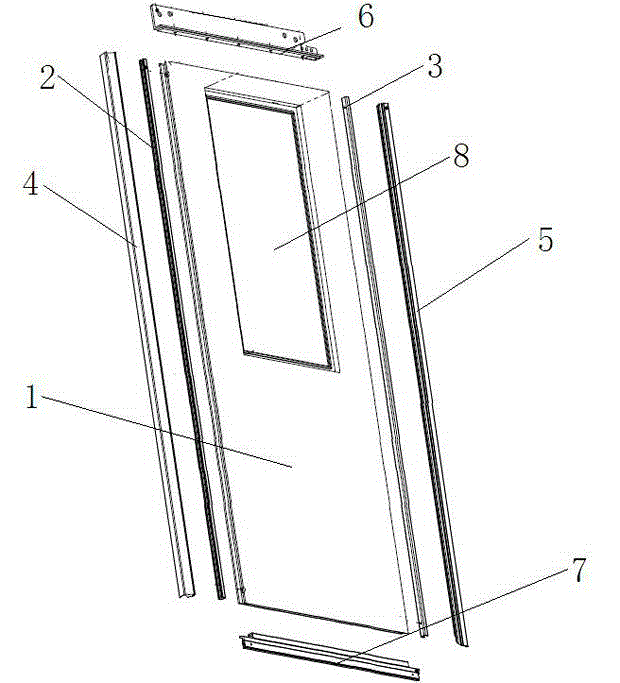

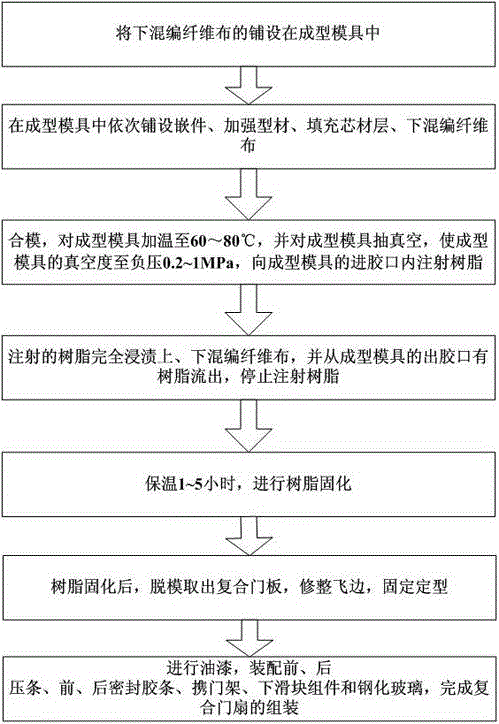

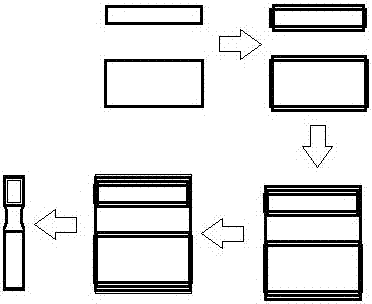

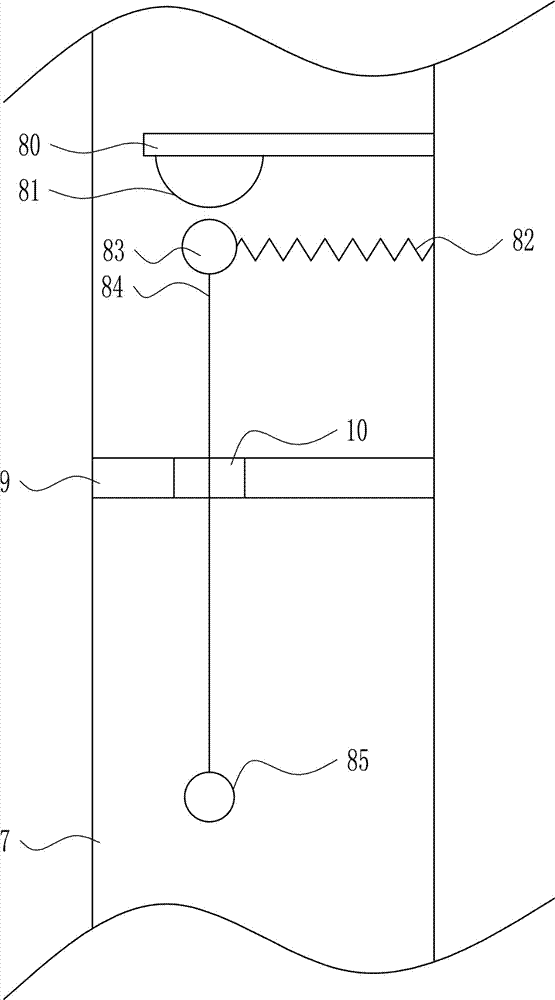

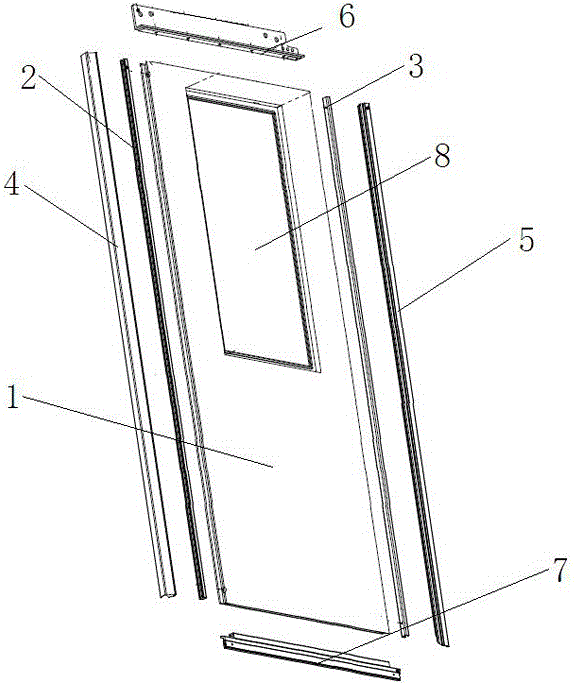

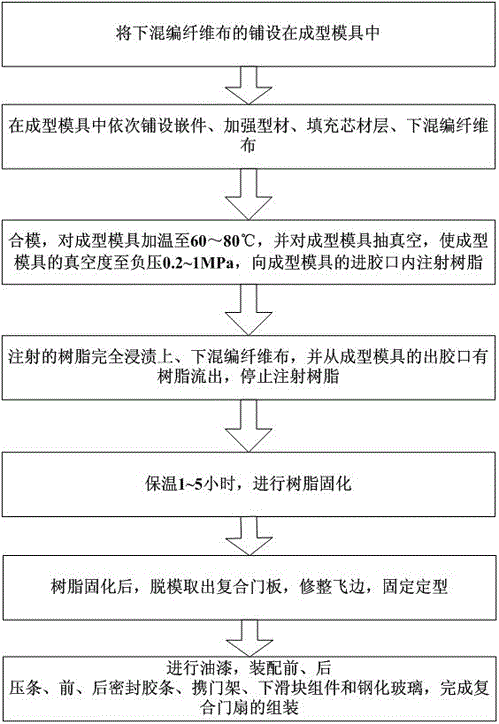

Integrally formed composite door leaf and manufacturing method of composite door leaf

ActiveCN104912450AImprove sound insulationImprove ride comfort performanceSealing arrangementsDoor leavesEngineeringFiber-reinforced composite

The invention discloses an integrally formed composite door leaf and a manufacturing method of the composite door leaf. The composite door leaf comprises a composite door plate, a front press strip, a back press strip, a front sealing rubber strip, a back sealing rubber strip, a door carrying frame, a lower slide block assembly and tempered glass, wherein the tempered glass is arranged on the upper half part of the composite door plate and forms an observation region; the door carrying frame is fixed above the composite door plate through screw bolts; the lower slide block assembly is fixed under the composite door plate through screw bolts; the front press strip and the back press strip are arranged at the two side edges of the composite door plate; the front sealing rubber strip and the back sealing rubber strip are arranged on the press strips of the symmetrical sides; and the sealing of the composite door leaf is realized. The composite door plate comprises an upper fiber reinforced composite panel, a filling core material layer, a reinforcing sectional material, an embedding element and a lower fiber reinforced composite panel which are in sequential distribution from top to bottom. Compared with a conventional aluminum alloy door leaf, the composite door leaf achieves the goals of simplifying production flow processes, saving the energy and reducing the cost, improves the taking comfort of a rail vehicle, and has good application prospects.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

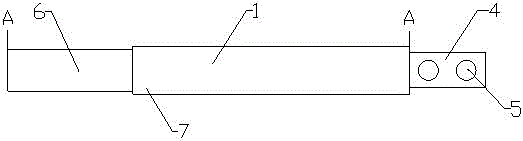

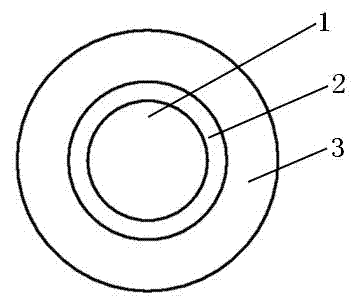

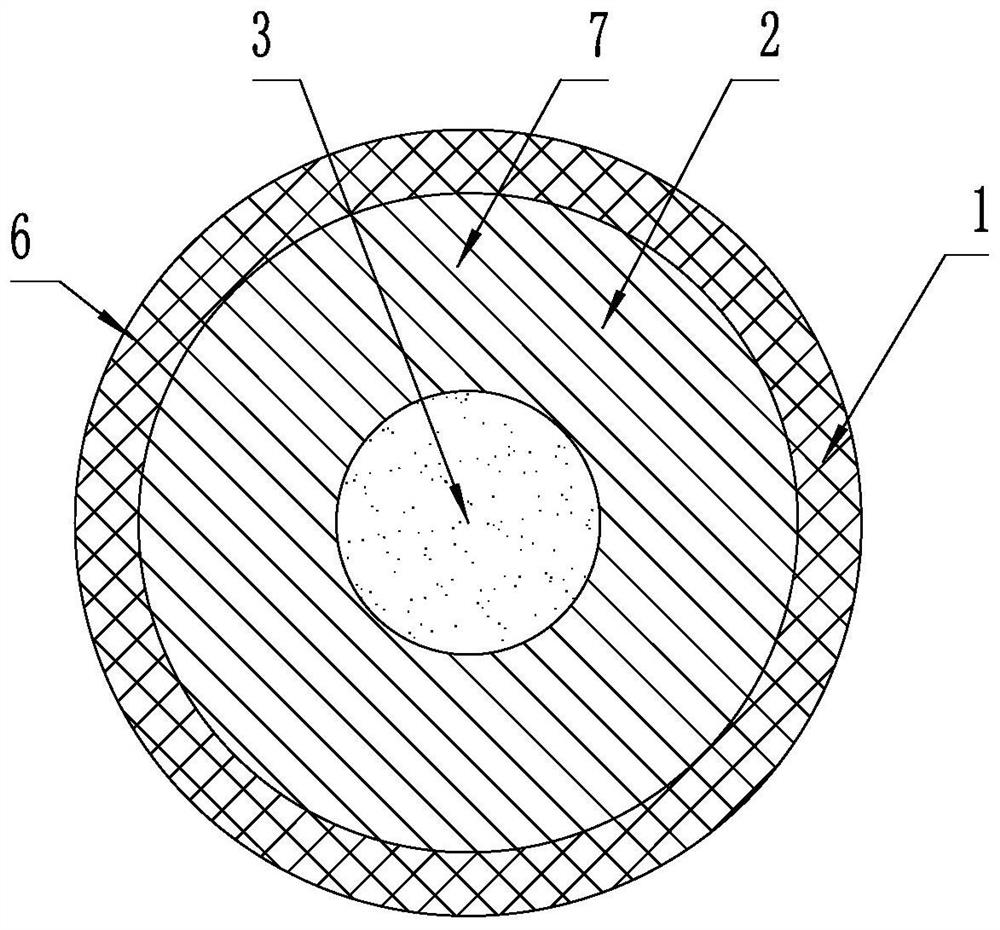

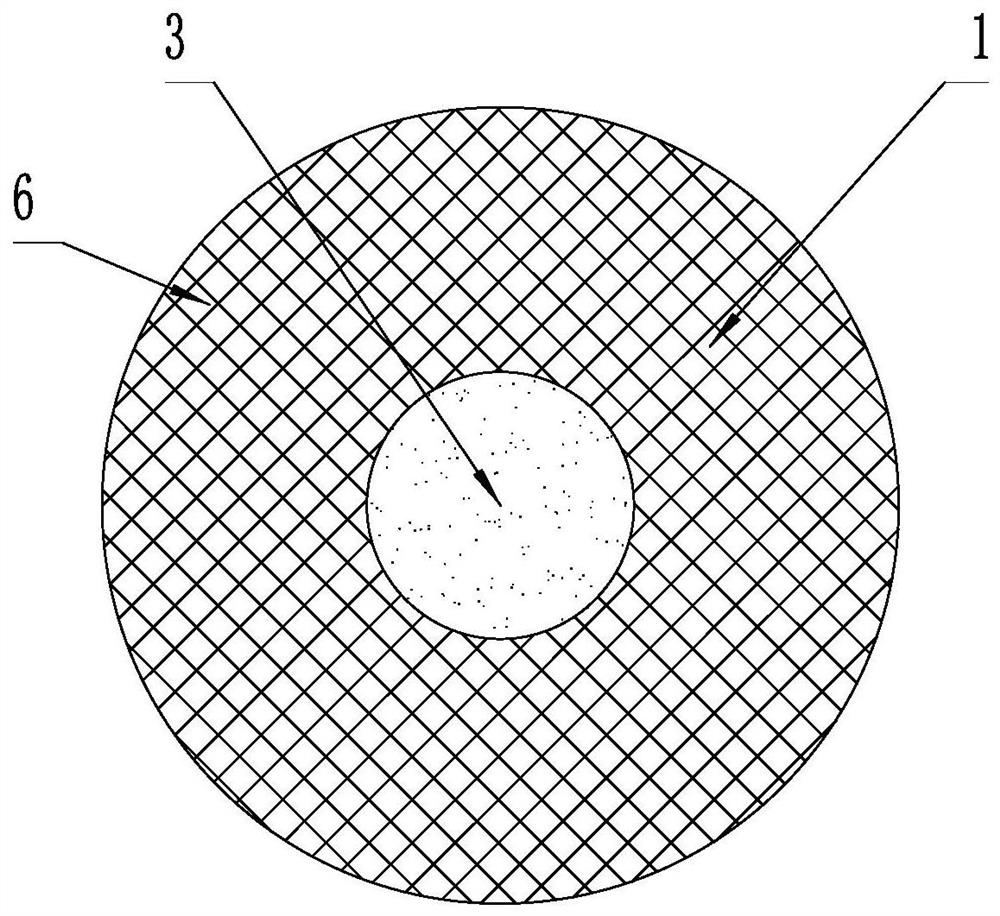

Graphite cable connected in flat-body manner

InactiveCN104103337AHigh strengthStable grounding resistanceMetal/alloy conductorsInsulation layerGraphite

The invention relates to a graphite cable for connection of a flat body. The graphite cable comprises a cable body, wherein the cable body is divided into a buried part and an overground part, the buried part of the cable body is not provided with an insulation layer, the overground part is provided with an insulation layer at the periphery of a grapheme layer, the insulation layer is coated with anti-corrosion paint, a core is arranged in the cable body and has a flat plate structure, the grapheme layer is arranged at the periphery of the core, the thickness of the grapheme layer is 1-3 millimeters, one end of the core is provided with a unoxidizable alloy connection piece, the unoxidizable alloy connection piece is of a rectangular flat structure, two connection holes are arranged in the unoxidizable alloy connection piece, and the core and the unoxidizable alloy connection piece are connected by means of welding. The graphite cable has the advantages of simplicity in structure, high safety factor, and convenient use.

Owner:郑州市三维配电设备有限公司

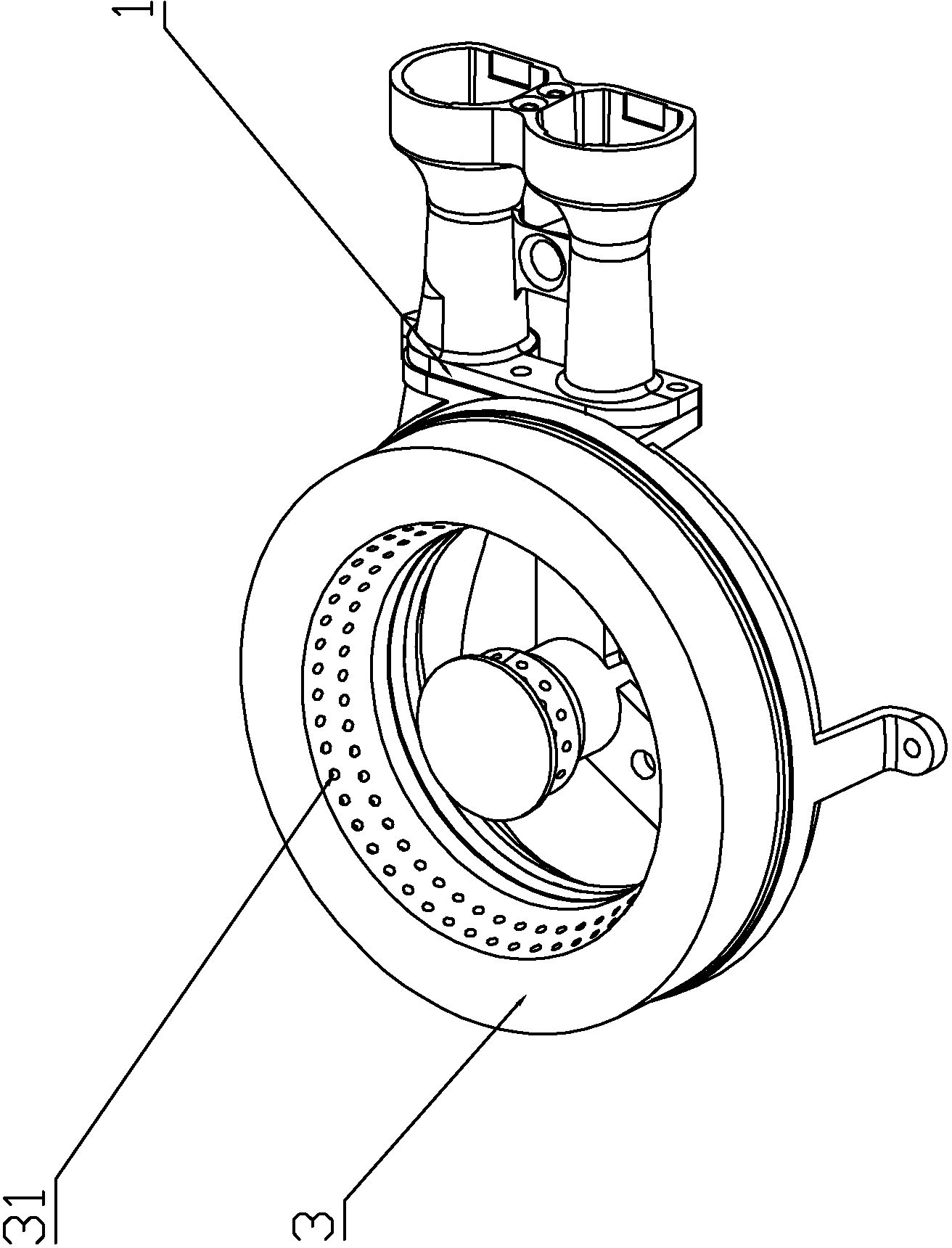

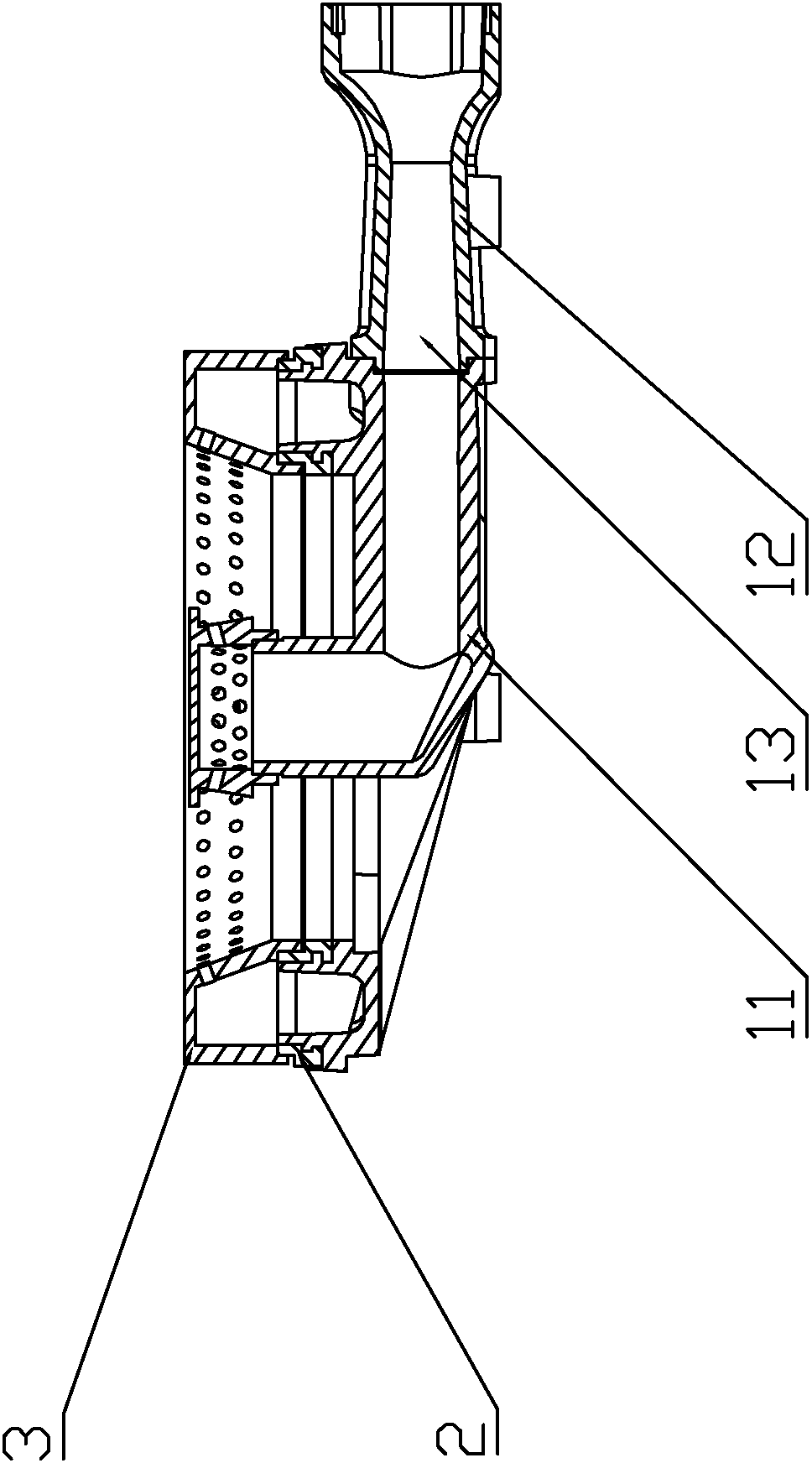

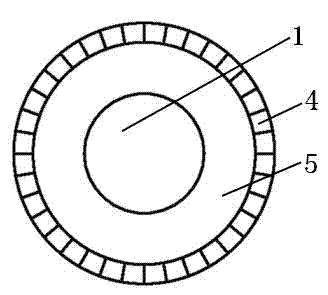

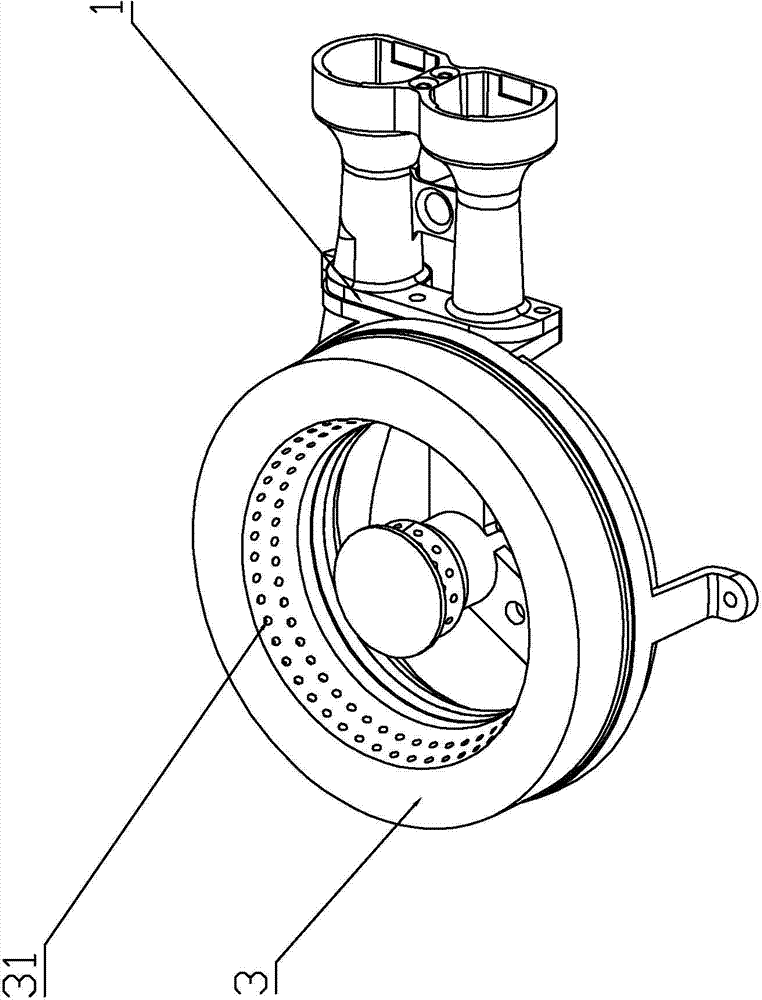

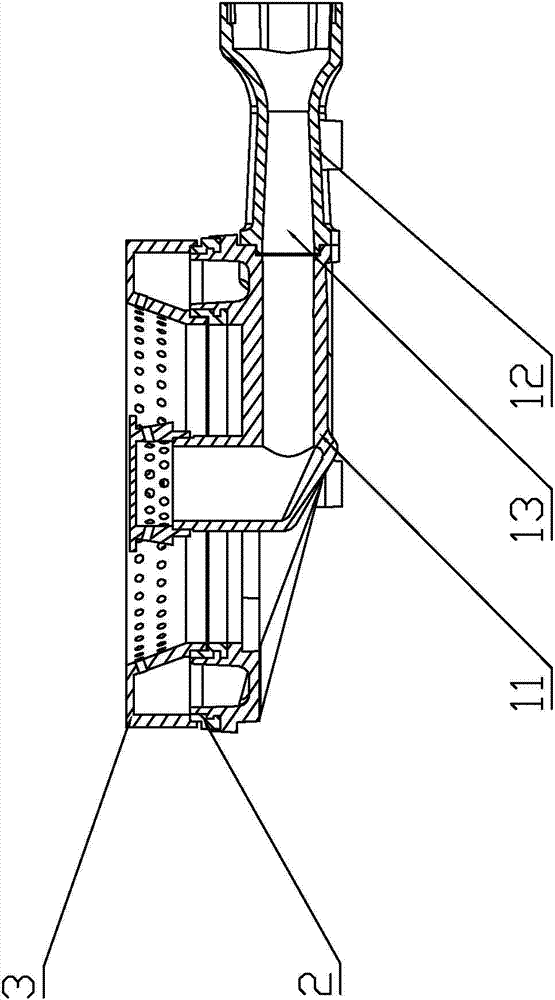

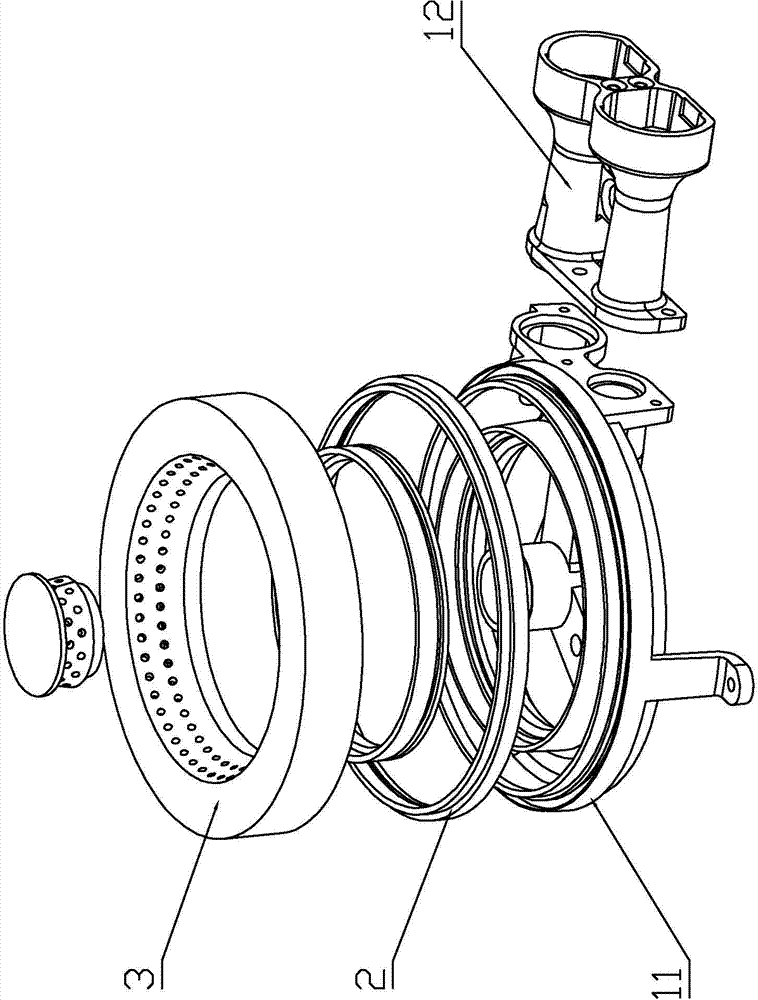

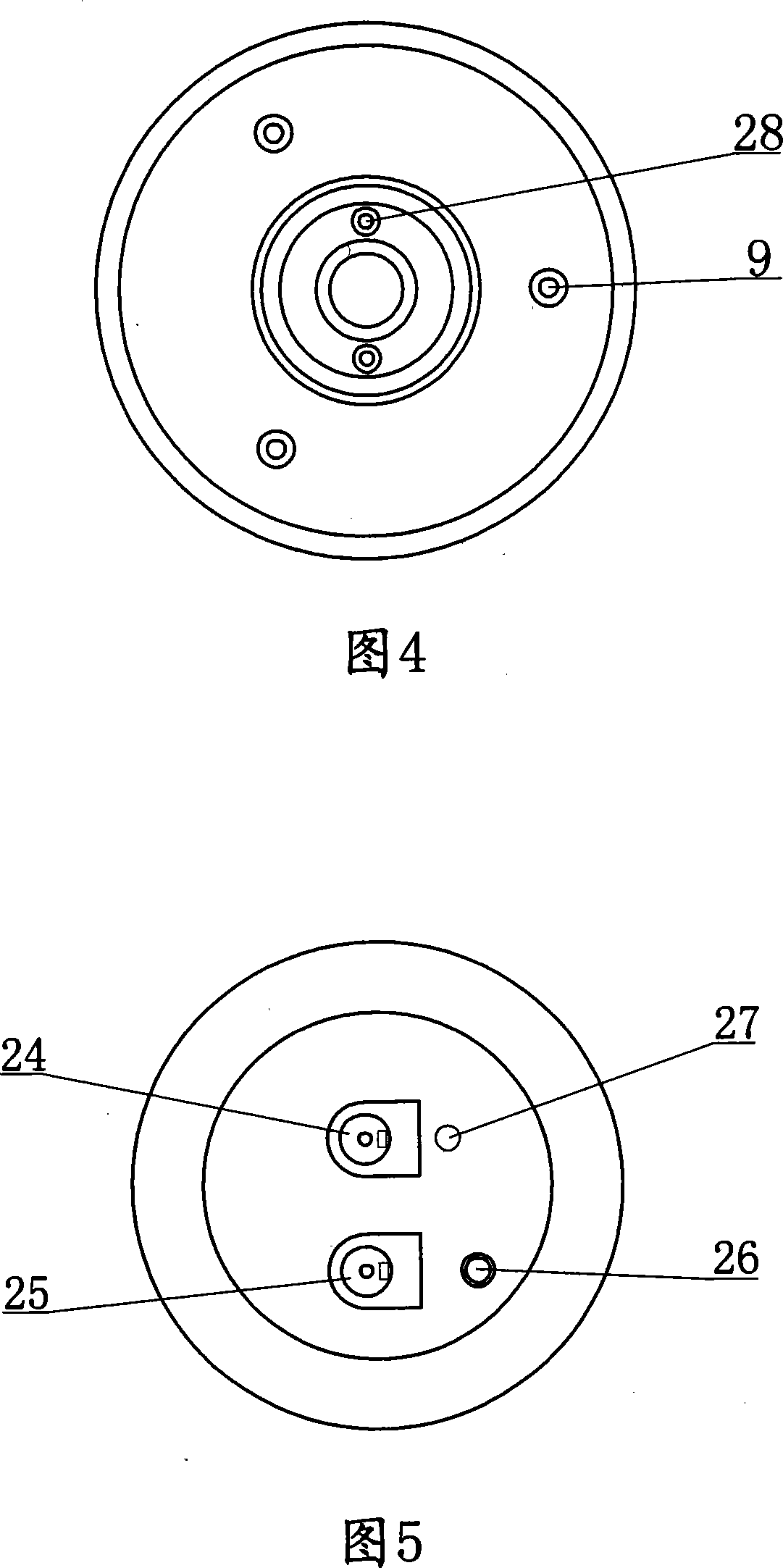

Internal combustion burner for domestic gas stove

ActiveCN103307599AImprove high temperature resistanceAccelerated corrosionGaseous fuel burnerFar distanceHeat losses

The invention relates to an internal combustion burner for a domestic gas stove. The internal combustion burner for the domestic gas stove comprises a furnace head main body and an outer ring fire distributor, wherein fire outlet holes are formed in the outer ring fire distributor. The internal combustion burner for the domestic gas stove is mainly characterized by also comprising a connecting seat, wherein the connecting seat is made of a high-temperature-resistant material capable of resisting the temperature above 700 DEG C; the connecting seat is mounted on the furnace heat main body; the outer ring fire distributor is mounted on the connecting seat; the fire outlet holes are rotary fire outlet holes; the central axis of each rotary fire outlet hole is staggered with the central axis of the outer ring fire distributor. The internal combustion burner for the domestic gas stove has the characteristics of avoiding big heat loss caused by far distance between the fire outlet holes of the internal combustion burner and the pot bottom, improving the high-temperature resistance and the corrosion resistance of the internal combustion burner, and improving the reliability of the internal combustion burner.

Owner:GUANGDONG VANWARD ELECTRIC

Sponge city integrated system

PendingCN106894492AGuarantee long-term use stabilityImprove toughness and strengthFatty/oily/floating substances removal devicesSewerage structuresWater storageGlass fiber

The invention discloses a sponge city integrated system and belongs to the technical field of water storage and utilization. The sponge city integrated system comprises a water storage device and further comprises a flood discharge device, the water storage device comprises a glass fiber reinforced plastic tank and a water storage tank, a first partition and a second partition divide the glass fiber reinforced plastic tank into a first water treatment chamber, a second water treatment chamber and a third water treatment chamber, a sediment separator is arranged above the first water treatment chamber, a water treater is arranged above the third water treatment chamber, and an overflowing device is fixedly connected on the water storage tank; the flood discharge device comprises an infiltration well, a shallow-layer cage way and a deep-layer cage way, a flood discharge draining pipe is connected on a sewage pipe, penetrates the glass fiber reinforced plastic tank and is connected with the deep-layer cage way, and the overflowing device is arranged on the glass fiber reinforced plastic tank and connected with the shallow-layer cage way through a pipeline. The sponge city integrated system can convert rainwater and sewage into domestic water, is efficient and environment-friendly, discharges flood through the shallow-layer cage way, the infiltration well and the deep-layer cage way and has good flood discharge effect and universal applicability.

Owner:张铁耀

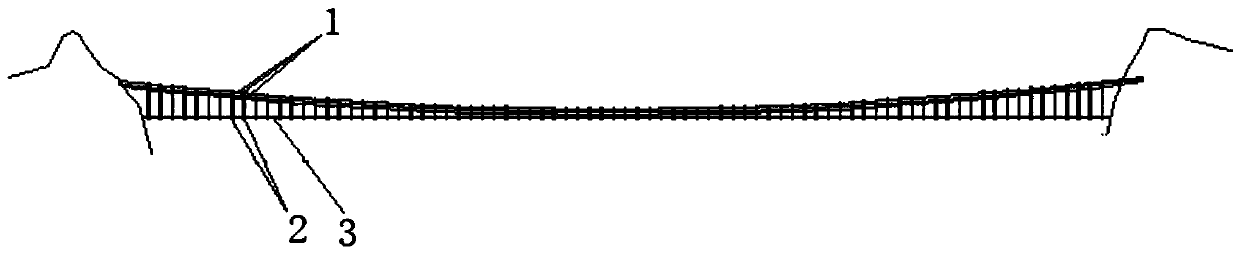

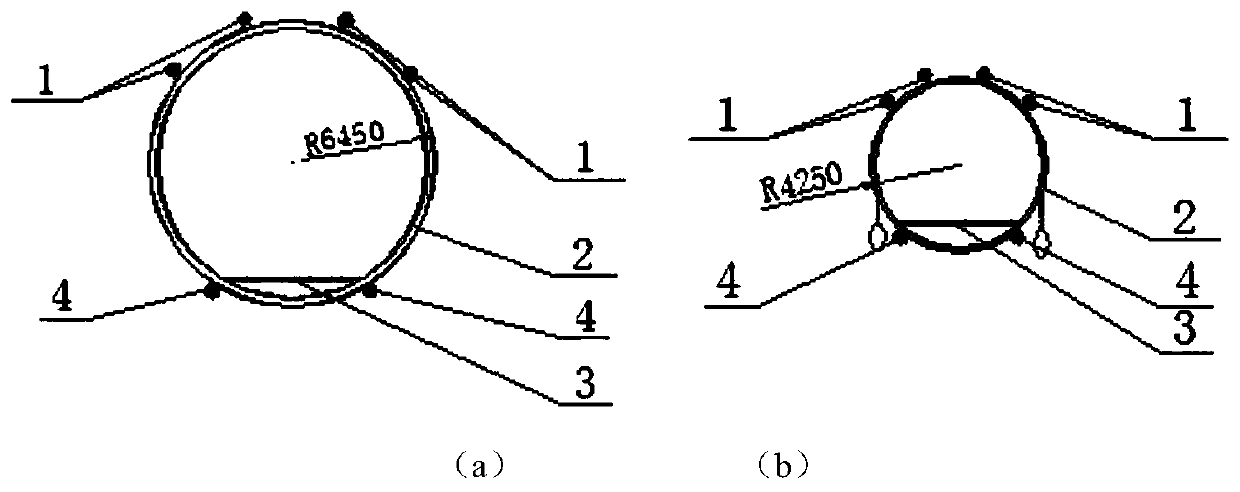

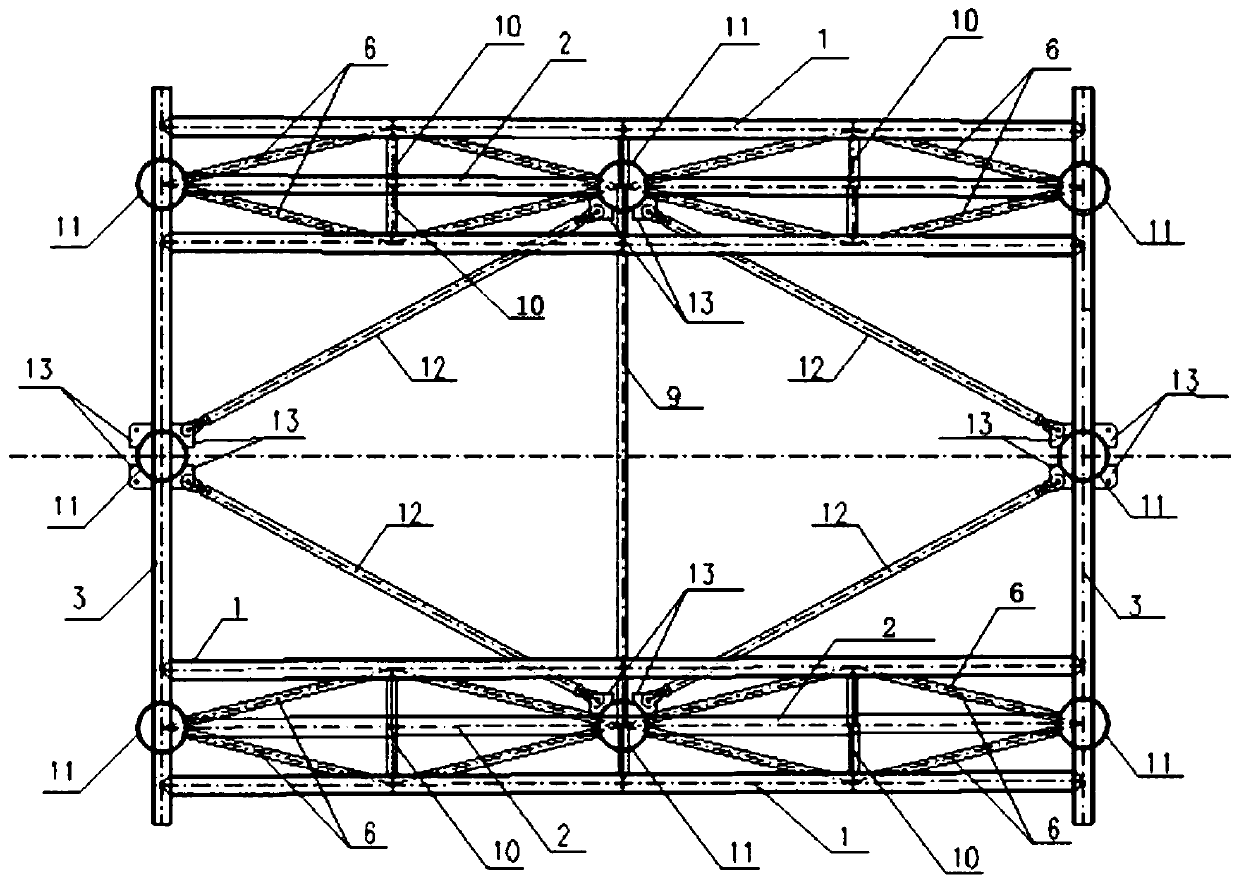

Circular ring suspender and welded hollow spherical joint stiffening beam glass suspension bridge

The invention belongs to the technical field of bridges, and discloses a circular ring suspender and welded hollow spherical joint stiffening glass suspension bridge. The circular ring suspender and welded hollow spherical joint stiffening glass suspension bridge adopts a pattern of audio frequency as a design characteristic; the concept of a spatio-temporal tunnel is introduced to architecture and landscape, a circular ring with variable diameter is adopted to set off a pedestrian passageway, and visitors just like walk in the suspended spatio-temporal tunnel; or the call and the sound wave in an open country reverberate among distant mountains. According to the circular ring suspender and welded hollow spherical joint stiffening glass suspension bridge, due to the diversity of the changeof the adopted plane and space, the visitors feel different space changes in the traveling process, the visual fatigue for spanning an ultra-long bridge body is reduced, and therefore the interestingness of the glass gallery bridge is increased, and in addition, the visitors are personally on the scene in the high altitude where transparent glass is erected, so that the visitors can better fell the charm of the nature and the excitement brought by being high up in the air.

Owner:CHONGQING JIAOTONG UNIVERSITY

Preparation method of antibacterial stainless steel cutter with nano titanium nitride coating

ActiveCN112251745AHigh melting pointHigh hardnessMaterial nanotechnologyNitrogen compoundsTitanium coatingSolution treatment

The invention discloses a preparation method of an antibacterial stainless steel cutter with a nano titanium nitride coating. The preparation method specifically comprises the following steps: firstly, preparing nano titanium nitride particles by using an ammonia gas reduction method; then adding a metal element with an antibacterial function into a stainless steel matrix, and carrying out solution treatment to obtain an antibacterial stainless steel matrix; and finally, compounding the nano titanium nitride particles onto an antibacterial stainless steel cutter material matrix by using a coldspraying technology to obtain the antibacterial stainless steel cutter with the nano titanium nitride coating. The titanium nitride coating reinforced antibacterial stainless steel cutter material prepared by combining the titanium nitride coating and the antibacterial stainless steel has the good characteristics of high hardness, high strength, high wear resistance, bacterial resistance and no rust.

Owner:XI'AN POLYTECHNIC UNIVERSITY

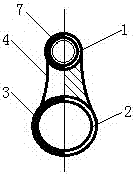

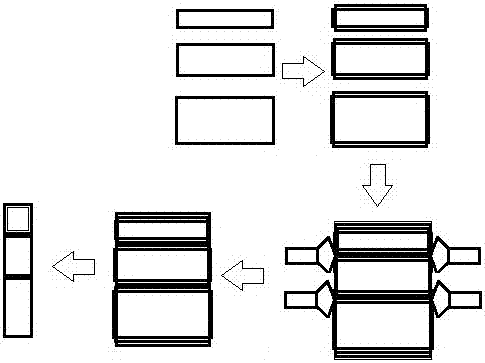

Preparing method of fishing pole guide hole

The invention relates to the field of fishing instruments, in particular to a preparing method of a fishing pole guide hole. The preparing method is characterized by comprising the steps of preparing at least two pole-like dies, wherein one pole-like die is matched with an assembled fish pole in size, and the other pole-like die is matched with an assembled guide ring in size; the second step of twining carbon fiber cloth on the two pole-like dies separately to obtain two tubular blanks; the third step of fixing the two tubular blanks in a mutually parallel mode, and then twining the carbon fiber cloth on the outer surfaces of the two tubular blanks to form guide hole blanks; the fourth step of coating the outer surfaces of the guide hole blanks with BOPP thin film and then putting the guide hole blanks into a curing oven to perform curing molding treatment; the fifth step of conducting demolding and removing the BOPP thin film after the curing treatment, then conducting incision to obtain the guide hole which is composed of a guide wire part and a fishing pole part, embedding the guide ring into the guide wire part, and then conducting finishing and polishing to obtain the fishing pole guide hole. The fishing pole can be directly covered with the prepared fishing pole guide hole, the fishing pole guide hole is light in weight, high in modulus, and resistant to corrosion and rust, thus the cost of the fishing pole is reduced, and the fun in fishing is improved.

Owner:WEIHAI DONGAO FISHING TACKLE LTD

Portable fuel oil storing and transporting bag

The invention discloses a portable fuel oil storing and transporting bag. The bag is made by, by weight, 65-78 parts of synthesis fiber, 12-17 parts of polymer composite material, 3-7 parts of antistatic agent and 7-15 parts of nano coating material. The portable fuel oil storing and transporting bag is convenient to use, high in thermostability, resistant to wear, high temperature and high pressure, supportive of recycling, convenient for carrying, small in size, free of rusting corrosion and low in cost, and the antiexplosion problem caused in industrial production is solved. Consequently, the portable fuel oil storing and transporting bag has the advantages of convenience for carrying, low cost, light weight, flame retardance, foldability, wear resistance, falling resistance, high sealability, freeness of toxicity and smell and convenience for filling.

Owner:ZHEJIANG OCEAN UNIV

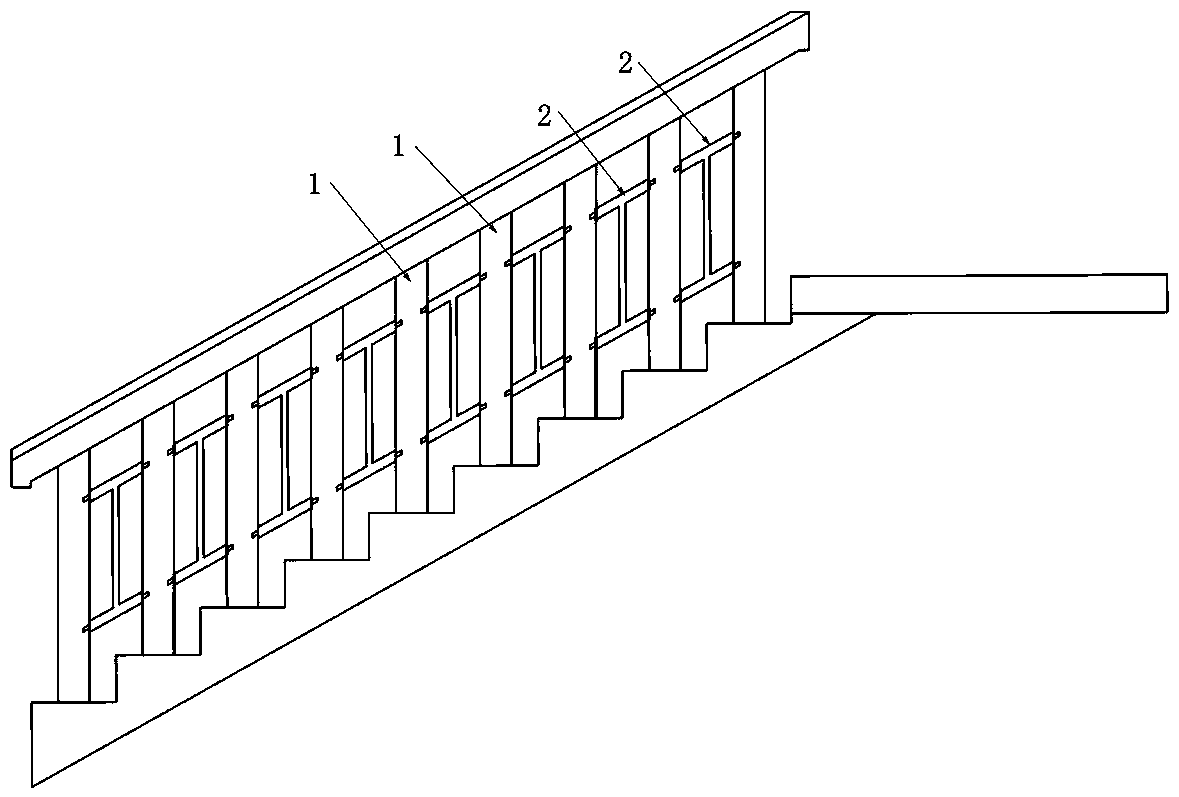

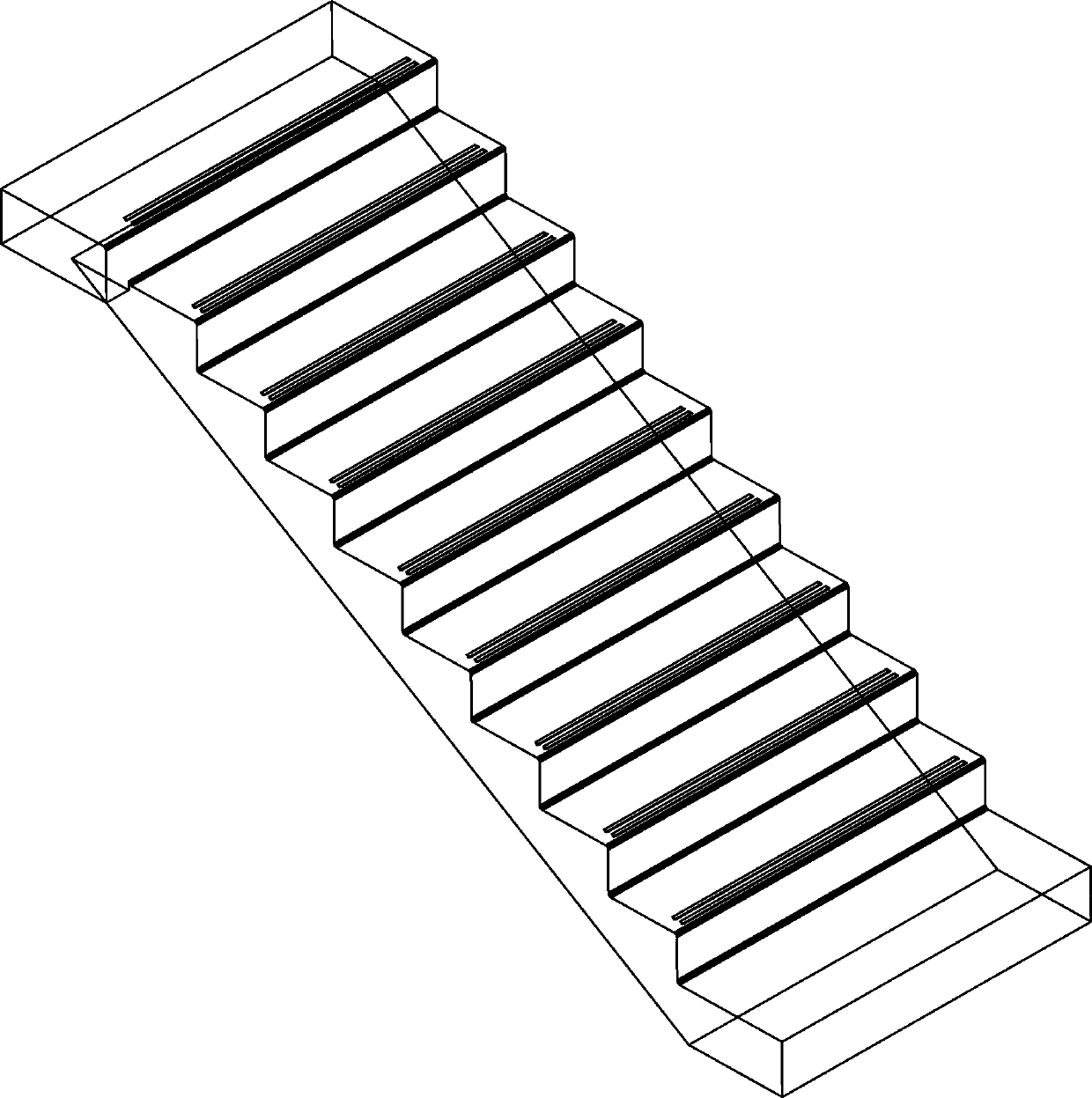

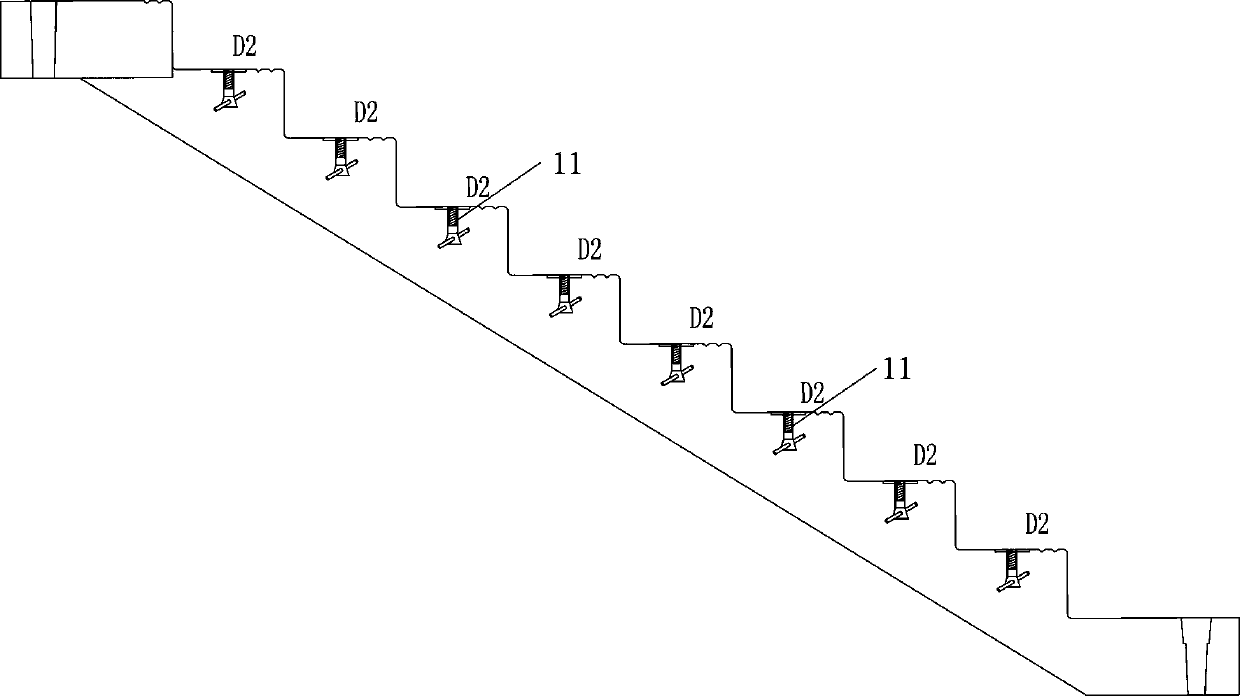

Single railing body and novel railing assembly type stair railing and construction method thereof

The invention relates to a single railing body. The single railing body comprises an integrated stand column, wherein upper cross rods are integrally connected to the top end of the integrated stand column; a U-shaped connector is pre-buried in the bottom end of the integrated stand column; one end of each upper cross rod is a first connecting end, the other end of each upper cross rod is a secondconnecting end; and the first connecting end of one upper cross rod can be matched with the second connecting end of the other upper cross rod. The invention further provides a construction method ofa novel railing assembly type stair railing. The single railing body is simple in structure and convenient to use, factory prefabrication and on-site assembly are adopted, a welding machine gas cylinder and a grinding tool do not need to be used, and connection and mounting can be achieved only through assembly, and assembly is completed. The surface of the stair railing can be subjected to various treatment modes such as spraying and coating and oxidation, the surface color is diversified, the texture is high, and the defects of the market are overcome. The joints are connected through connecting pieces, the defect that a vertical pipe and a main pipe in a stainless steel handrail need to be connected through a manual grinding process can be overcome, and connection and mounting can be completed through assembly and bolts.

Owner:山东海龙建筑科技有限公司

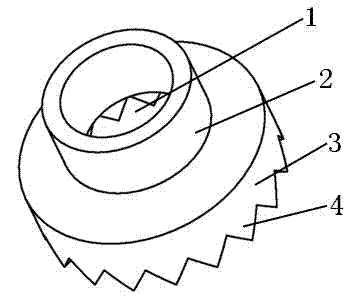

Ceramic smashing mechanism

The invention belongs to the technical field of ceramics and crushing, and in particular relates to a ceramic crushing mechanism, which is characterized in that it includes a connecting part and a crushing part, the connecting part is located above the crushing part and both are integrally formed; the connecting part is in the shape of a circular column And the hollow part through the upper and lower parts of the connecting part is the connecting cavity; the inside of the crushing part has a hollow container chamber, and the edge of the crushing part is circular cylindrical and the edge of the crushing part has a plurality of teeth distributed along the circular column. The diameter of the cavity is larger than the diameter of the connection cavity, the connection cavity communicates with the container cavity, and the container cavity does not completely penetrate the upper surface of the crushing part; on the orthographic projection of the upper surface of the crushing part, the connection part is located in the center and the connection cavity The center of circle of the chamber coincides with the center of circle of the holding chamber and the center of circle where the outer edge of the pulverized parts is located. The invention has the following main beneficial effects: wear resistance, wide temperature adaptation range, acid and alkali resistance, high mechanical strength, easy cleaning, no rust, and easy replacement.

Owner:佛山市南海区赛聚机械制造有限公司

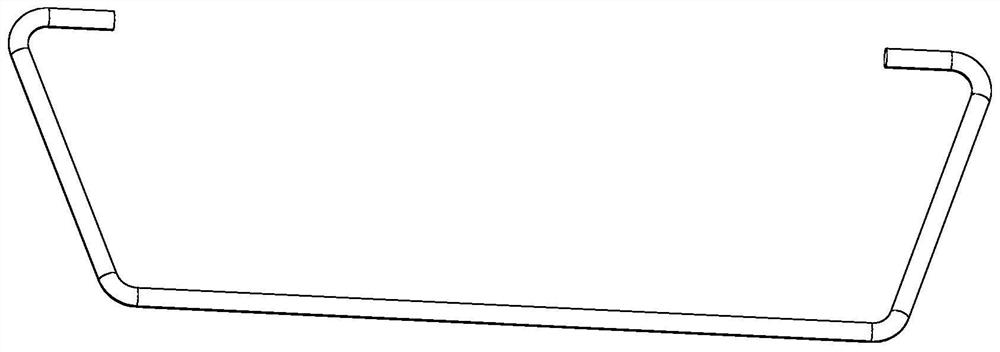

Preparation method of composite transverse stabilizer bar and transverse stabilizer bar prepared by preparation method

The invention discloses a preparation method of a composite transverse stabilizer bar and the transverse stabilizer bar prepared by the preparation method. The preparation method comprises the following steps of step 1, preparing a transverse stabilizer bar preform according to the designed size and shape of the transverse stabilizer bar, specifically, preparing a central layer and a wrapping layer of the transverse stabilizer bar according to design requirements, and splicing a central layer material rod and the wrapping layer to form the transverse stabilizer bar preform; step 2, curing thetransverse stabilizer bar preform, specifically, putting the transverse stabilizer bar preform into a mold, and injecting resin into the mold to be cured; and step 3, post-curing and post-processing the transverse stabilizer bar. According to the preparation method, the bar body of the manufactured transverse stabilizer bar comprises the central layer and one or more wrapping layers wrapping the central layer, the wrapping layer is a composite material weaved by reinforced fibers, and the bar body is of a solid structure or an internal hollow structure. The preparation method is high in efficiency, and the prepared stabilizer bar has the advantages of being light in weight, high in strength and not prone to rusting.

Owner:ZHEJIANG SCI-TECH UNIV

Internal combustion burner for domestic gas stove

The invention relates to an internal combustion burner for a domestic gas stove. The internal combustion burner for the domestic gas stove comprises a furnace head main body and an outer ring fire distributor, wherein fire outlet holes are formed in the outer ring fire distributor. The internal combustion burner for the domestic gas stove is mainly characterized by also comprising a connecting seat, wherein the connecting seat is made of a high-temperature-resistant material capable of resisting the temperature above 700 DEG C; the connecting seat is mounted on the furnace heat main body; the outer ring fire distributor is mounted on the connecting seat; the fire outlet holes are rotary fire outlet holes; the central axis of each rotary fire outlet hole is staggered with the central axis of the outer ring fire distributor. The internal combustion burner for the domestic gas stove has the characteristics of avoiding big heat loss caused by far distance between the fire outlet holes of the internal combustion burner and the pot bottom, improving the high-temperature resistance and the corrosion resistance of the internal combustion burner, and improving the reliability of the internal combustion burner.

Owner:GUANGDONG VANWARD ELECTRIC

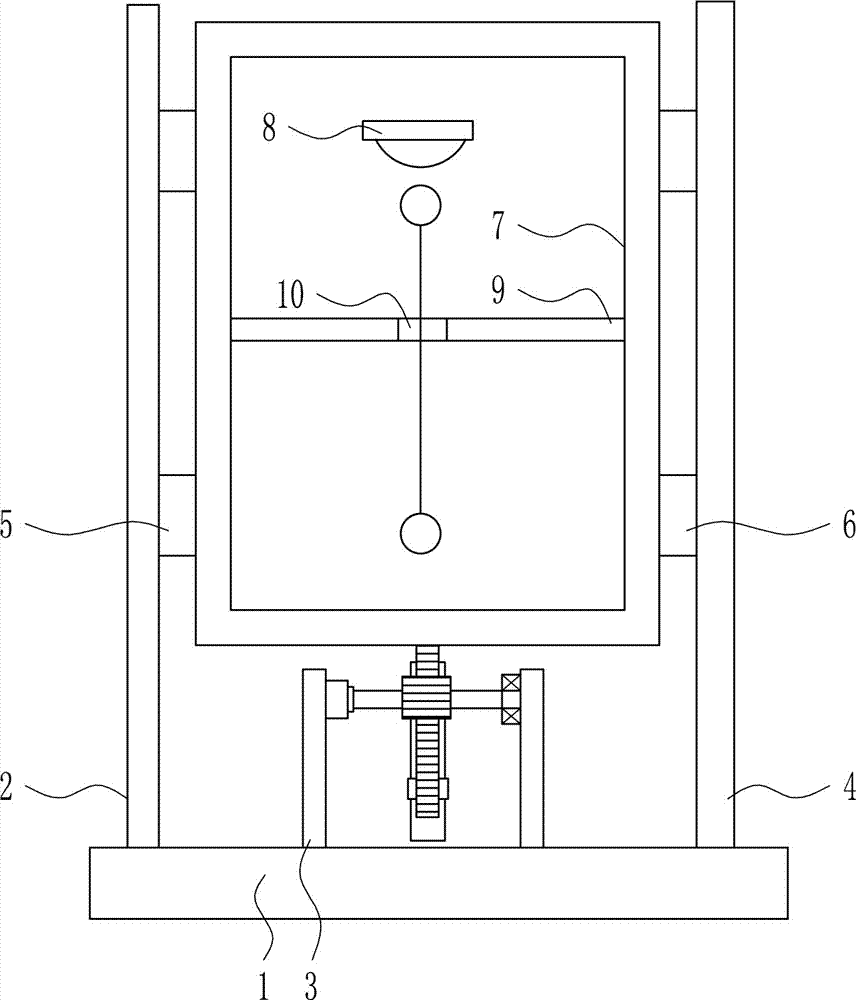

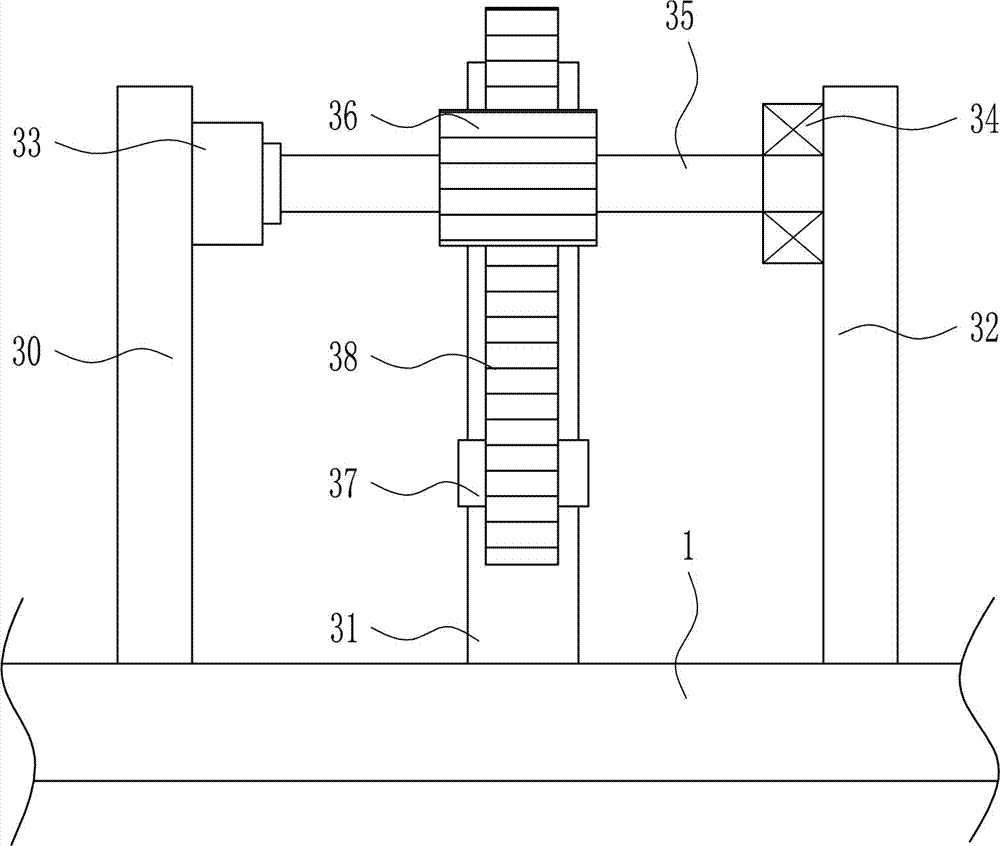

Responder used for entertainment interaction

InactiveCN107195151AHeight adjustableEasy to judgeMechanical audible signallingMechanical transmission signalling systemsRing deviceWhite powder

The invention relates to a quick answering device, in particular to a quick answering device for entertainment interaction. The technical problem to be solved by the present invention is to provide an answering device for entertainment interaction. In order to solve the above-mentioned technical problems, the present invention provides such a quick answer device for entertainment interaction, which includes a base, a left slide rail, a lifting device, a right slide rail, a left slide block, a right slide block, a box, etc.; There are left slide rail, lifting device and right slide rail in sequence from right to left, left slide rail is slidably connected to left slide rail, right slide rail is slidably connected to right slide rail, and the left slide rail and right slide rail are connected There is a box body, the bottom of the box body is connected with the top of the lifting device, a bell device is arranged on the upper part of the rear wall of the box body, and a partition plate is arranged between the left and right walls of the box body. The present invention achieves the effect of accurately and intuitively judging the person who has the qualification to answer the question. When the contestant pulls the pull ring, the device will quickly make a sound and scatter white powder.

Owner:鄂星峄

Resin glass fiber formula, and resin glass fiber tile produced therethrough

The invention discloses a resin glass fiber formula, and a resin glass fiber tile therethrough. The formula includes, by weight, 50-70 parts of resin glass fiber powder, 10-30 parts of PP prepreg scrap and 10-30 parts of epoxy resin; and the particle size of the resin glass fiber powder is 60-100 meshes, the copper content of the resin glass fiber powder is less than 3%, and the water content of the resin glass fiber powder is less than 15%. The resin glass fiber tile is produced from, by weight, 50-70 parts of the resin glass fiber powder, 10-30 parts of the PP prepreg scrap and 10-30 parts of the epoxy resin; and the particle size of the resin glass fiber powder is 60-100 meshes, the copper content of the resin glass fiber powder is less than 3%, and the water content of the resin glassfiber powder is less than 15%.

Owner:YANCHENG TIANSHUN MACHINERY TECH CO LTD

An integrally formed composite door leaf and its manufacturing method

ActiveCN104912450BImprove sound insulationImprove ride comfort performanceSealing arrangementsDoor leavesFiber-reinforced compositeEngineering

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

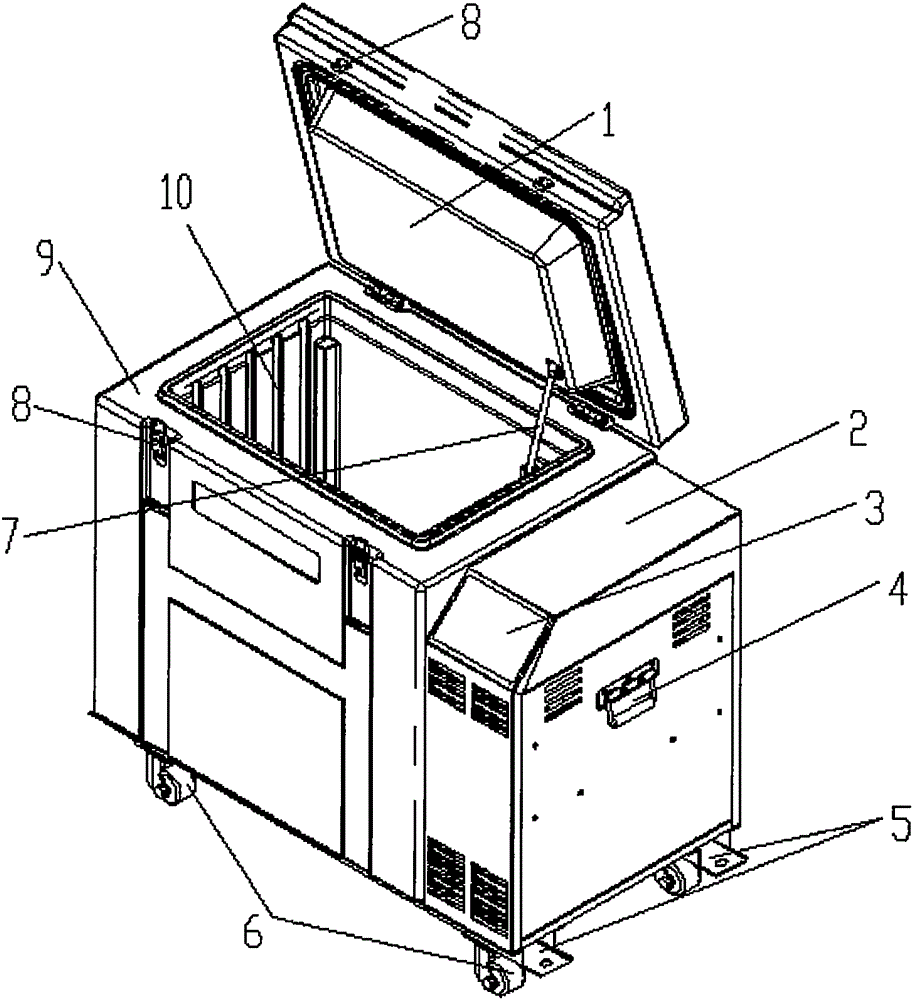

Alkali-resistant and corrosion-resistant refrigerator

InactiveCN105202848ALightweightReduce volumeLighting and heating apparatusDomestic refrigeratorsRefrigeration compressorBlow molding

The invention discloses an alkali-resistant and corrosion-resistant refrigerator. The refrigerator comprises a cold storage refrigerator body and a refrigeration case, wherein the cold storage refrigerator body is made of polyethylene plastic through one-time blow molding, a refrigerator cover made of the polyethylene plastic through one-time blow molding is arranged at the upper part of the cold storage refrigerator body, the refrigeration case is arranged on one side surface of the cold storage refrigerator body, a refrigeration system is arranged in the refrigeration case and comprises a refrigeration compressor, a condenser, a controller and an evaporator, the evaporator is arranged in the cold storage refrigerator body, and the refrigeration compressor, the condenser and the controller are arranged in the refrigeration case. According to the alkali-resistant and corrosion-resistant refrigerator, the refrigerator body is made of HDPE (high density polyethylene) through one-time blow molding by a blow molding machine, so that the refrigerator has anti-rust, alkali-resistant, acid-resistant, salt-resistant and corrosion-resistant properties, is wide in application range, and is mainly used for storing scientific research and medical articles and widely applied to storage of medicines, biological products, vaccines, genetic engineering, blood, culture bacteria and the like.

Owner:ZHONGKE MEILING CRYOGENICS CO LTD

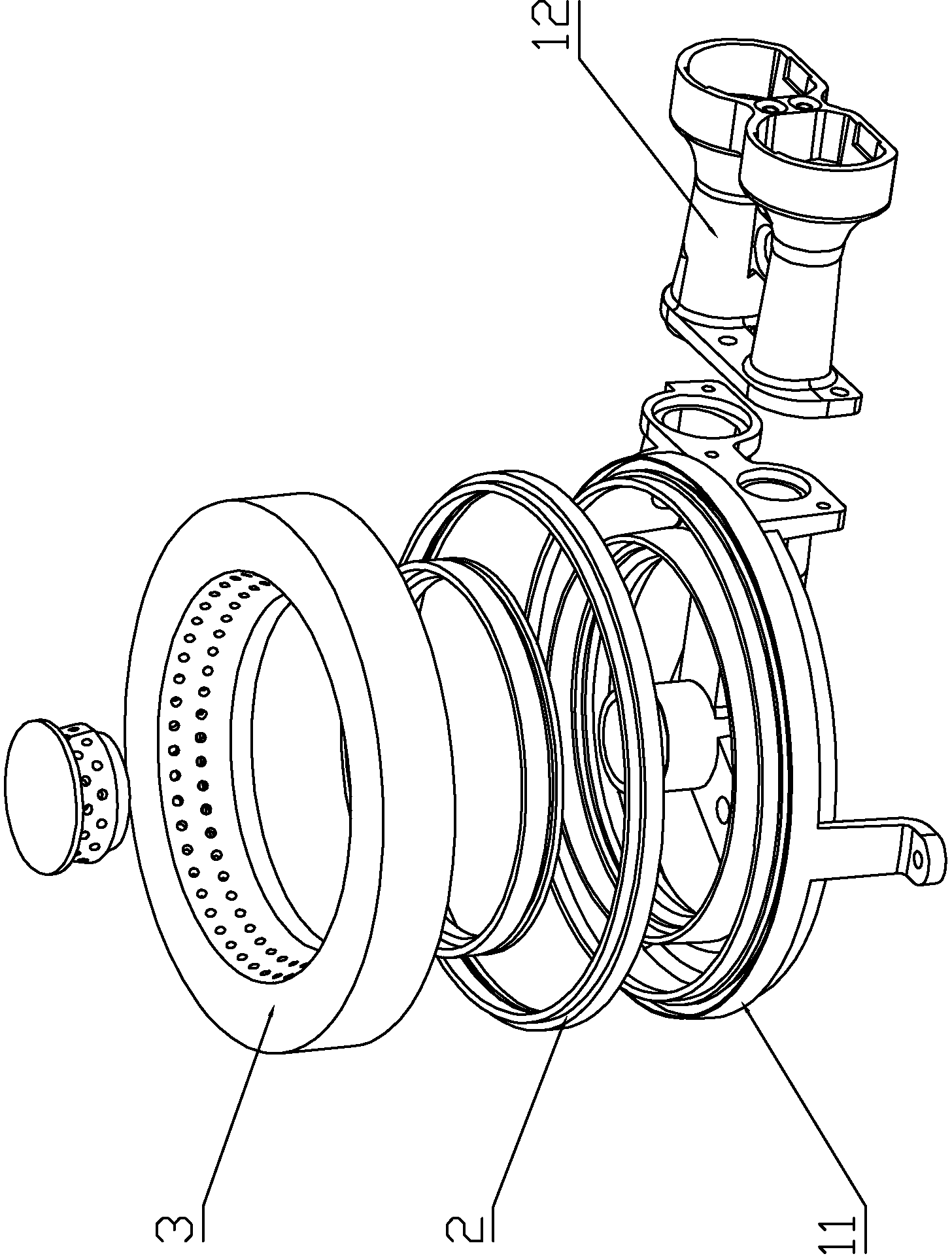

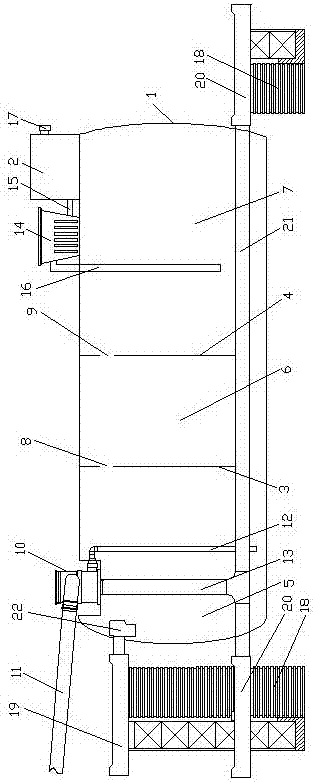

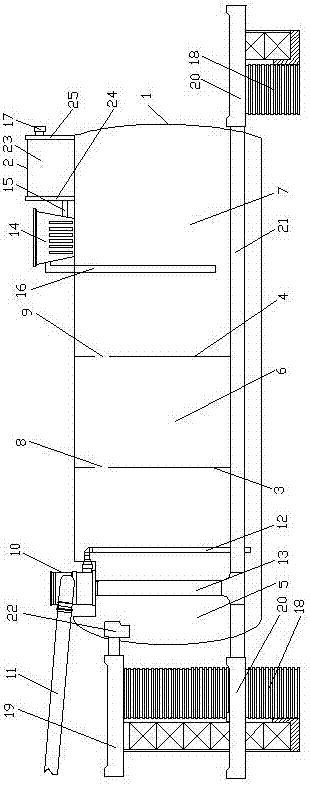

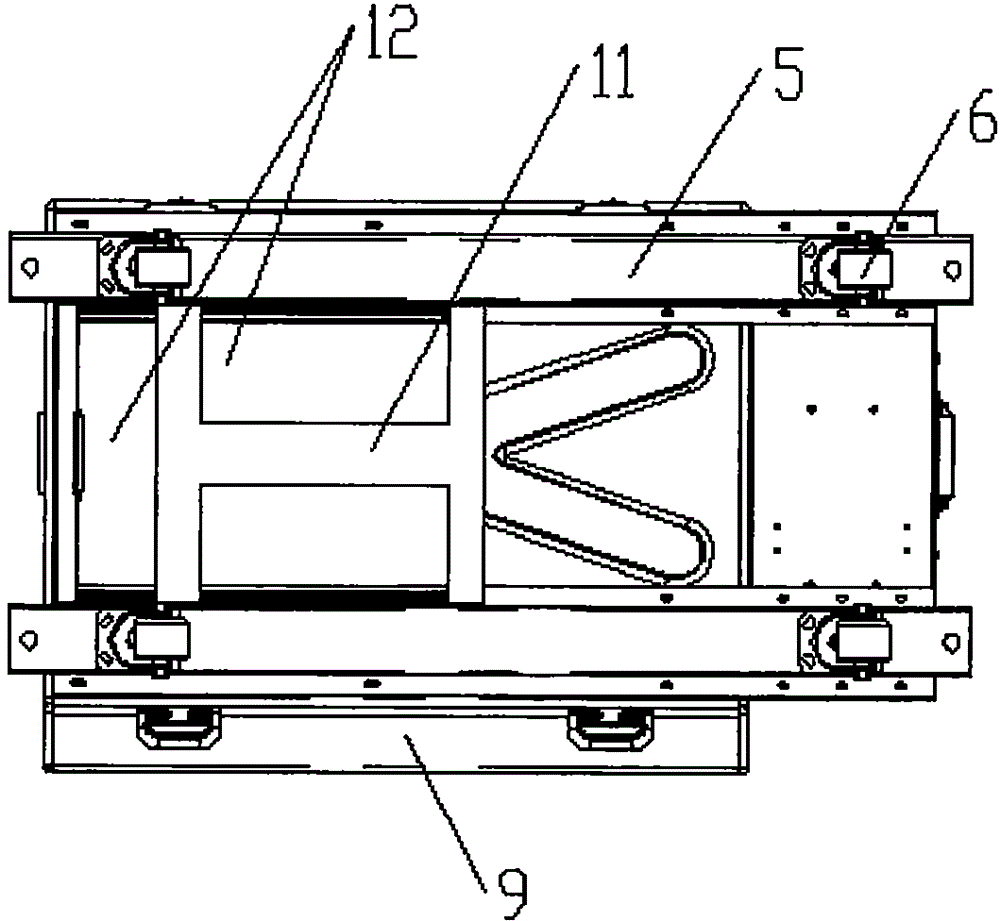

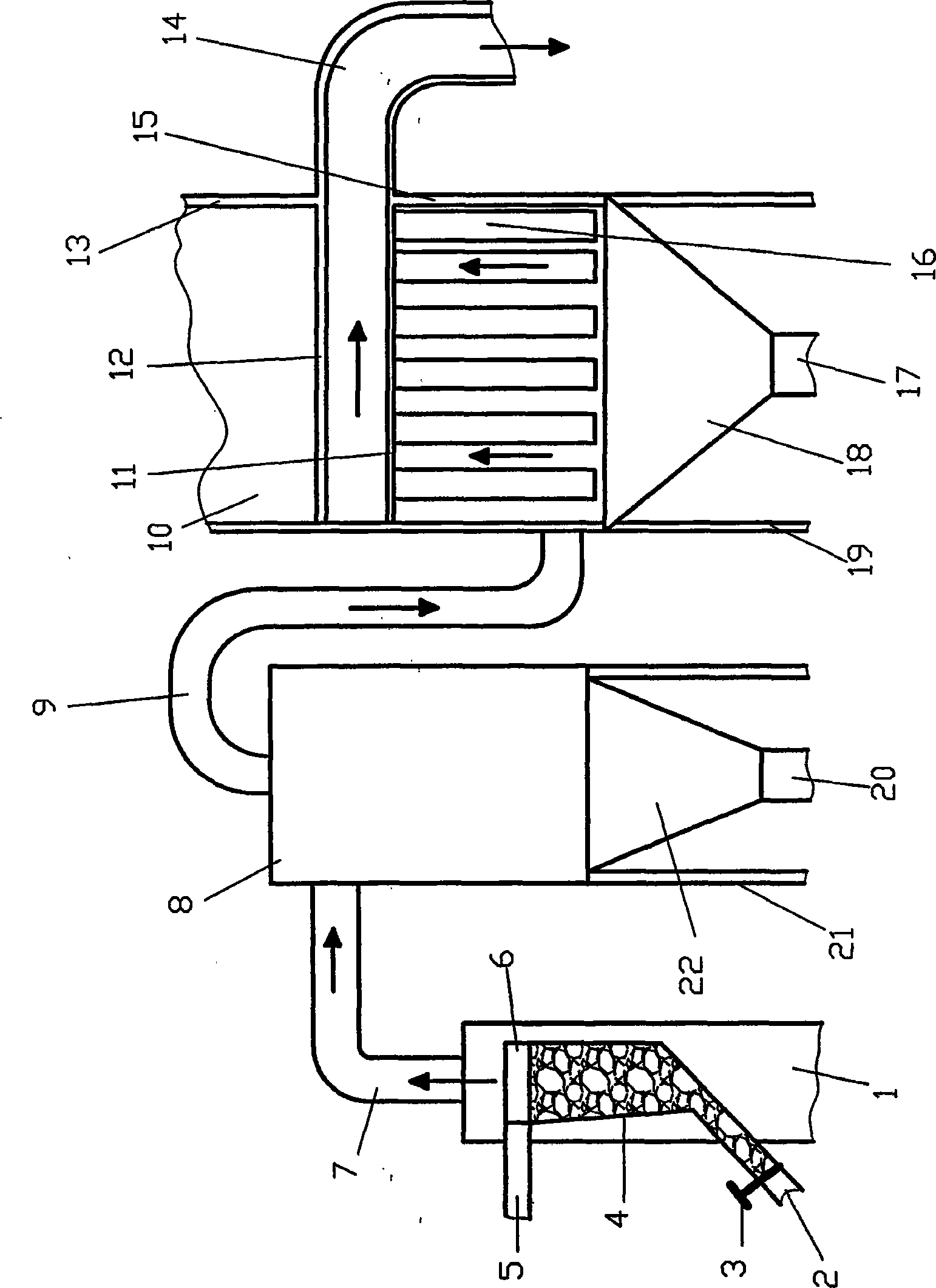

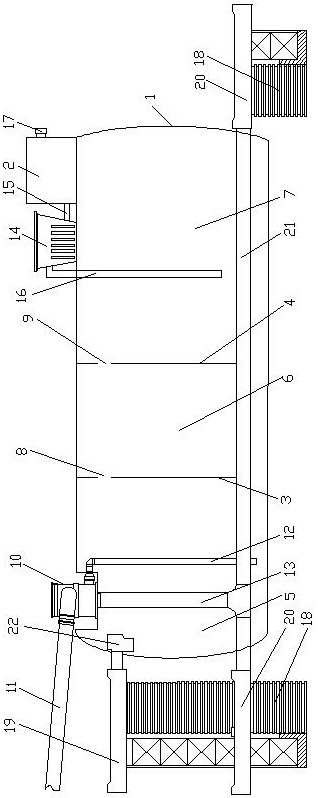

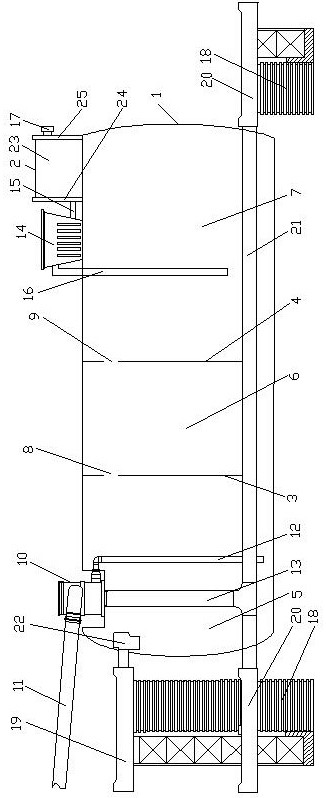

Residual-heat baking-material multi-cyclone dust remover for corundum smelting furnace

InactiveCN104236319AHas no rustAnti-sunPreheating chargesWaste heat treatmentPolyvinyl chlorideCyclonic spray scrubber

The invention relates to a residual-heat baking-material multi-cyclone dust remover for a corundum smelting furnace. The residual-heat baking-material multi-cyclone dust remover for the corundum smelting furnace comprises a furnace flue, a ventilated material bin, a ventilated material-bin feeding opening, a conveyor, a first-stage smoke-guiding pipe, a cyclone dust remover, a second-stage smoke-guiding pipe and a dust remover. When the residual-heat baking-material multi-cyclone dust remover for the corundum smelting furnace is in a working state, high-temperature waste gas is formed by waste gas and residual heat which are produced during the production of the corundum smelting furnace, and the preheating processing is carried out on a furnace material stored in the ventilated material bin when the high-temperature waste gas passes the furnace flue, so that the temperature of the furnace material is increased to 300 to 400 DEG C from a normal temperature; coarse particles and partial dust in the waste gas can be disposed by the cyclone dust remover; then, the waste gas is sucked into the dust remover through the second-stage smoke-guiding pipe and is purified and filtered into up-to-standard exhaust gas through a cloth bag, and the up-to-standard exhaust gas enters the atmosphere through a fan and a waste-gas discharging pipe. The wall plates of a filtering box are manufactured by welding PVC (Polyvinyl Chloride) foam plastic plates. Therefore, the residual-heat baking-material multi-cyclone dust remover for the corundum smelting furnace has the positive effects of no corrosion, sunburn resistance, rain-wetting resistance, easiness in constriction and low manufacturing cost.

Owner:郑州市广智成套机械设备有限公司

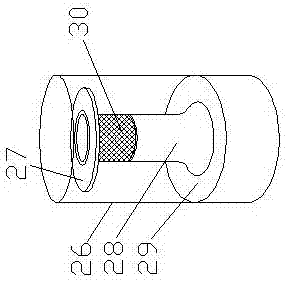

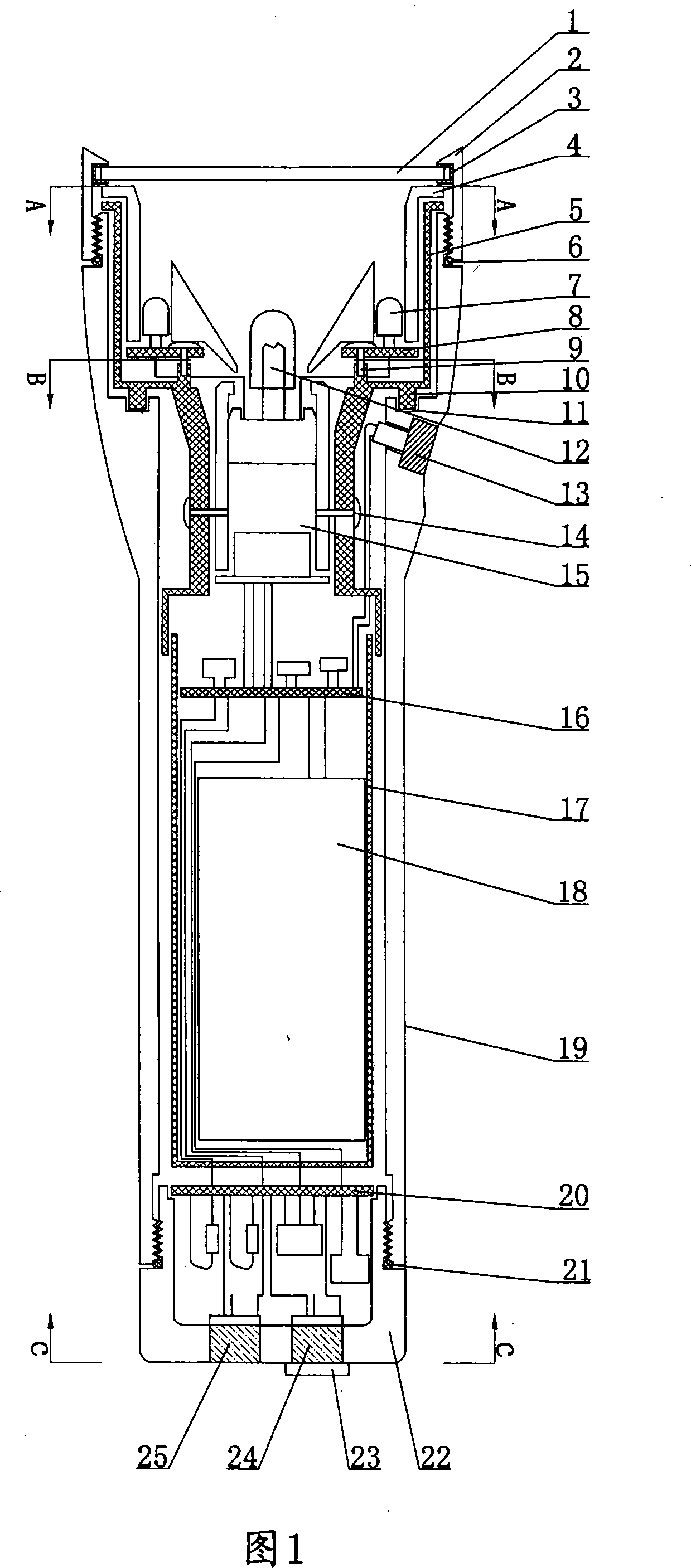

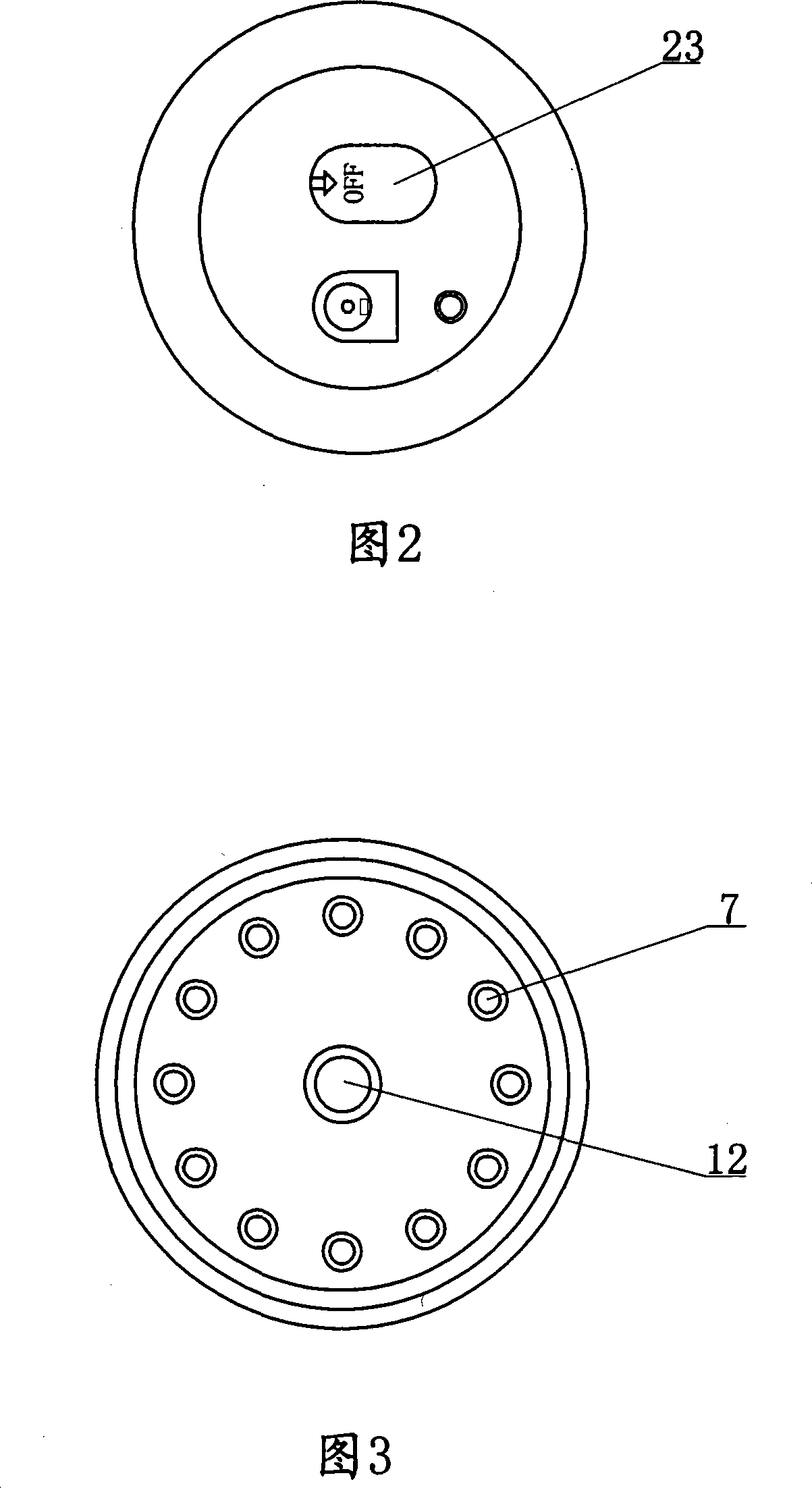

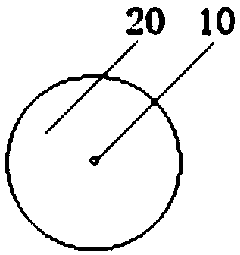

Multifunctional searchlight

InactiveCN101144571AHigh strengthLarge capacityBatteries circuit arrangementsPoint-like light sourceMicrocontrollerElectrical battery

The invention relates to a multifunctional searchlight, which comprises a luminous body casing (2), a battery casing (19), and a tail hood (22). A lithium battery (18) is arranged in the inner cavity of the battery casing, a luminous body base (15) is fixed on a lamp base (15), a plurality of light emitting diodes (7) are embedded in the inner wall of a refractive body (4), the light emitting diodes and a strong bulb (12) fixed on the lamp base are respectively connected with a control circuit board (16) driven by a single-chip microcomputer through conducting wires, a power output interface (24) and a charging interface (25) are arranged on the tail hood (22), the large capacity lithium battery (18) provides booster power for a voltage boosting integrated circuit board (20) through a control circuit board driven by the single-chip microcomputer, the power output interface is connected with the voltage boosting integrated circuit board (20) through conducting wires, and the charging interface is connected with the control circuit board through conducting wires. The searchlight has large capacity, the power consumption is low, the lighting intensity is adjustable, and the searchlight can also output power through the power output interface.

Owner:袁红泉

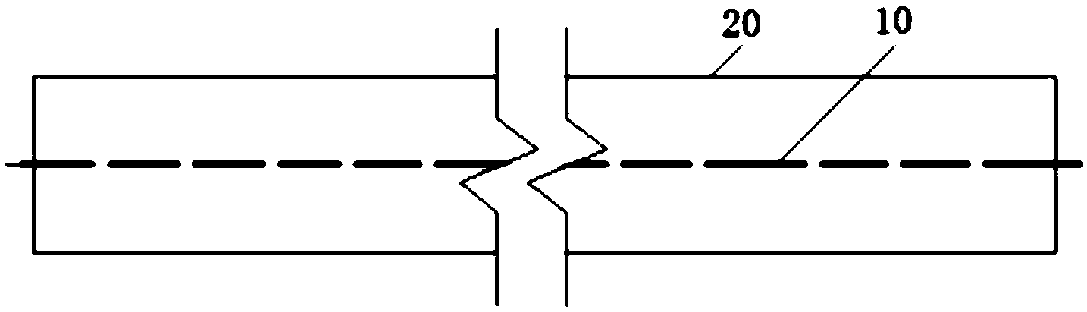

High-performance micro-prestressing-force thermoplastic intelligent fiber rod and manufacturing method thereof

The invention, which relates to fields of the building composite material, the sensor, the engineering detection, and solid mechanics, discloses a high-performance micro-prestressing-force thermoplastic intelligent fiber rod and a manufacturing method thereof. The fiber rod comprises a sensing fiber (10) and a thermoplastic rod body (20). The outside of the sensing fiber (10) is coated with the thermoplastic rod body (20). The sensing fiber (10) is a communication fiber with an applied micro-prestressing force; and the thermoplastic rod body (20) is a high-polymer-material-based coating element. The intelligent fiber rod has the following advantages: firstly, the weight is light, the density is 1900kg / m<3>, the rigidity and flexibility are high, and the fiber rod also has corrosion-resistant, magnetism-free, electric insulation, eddy-loss-free, and eddy-interference-free functions; secondly, the intelligent fiber rod belongs to the passive sensor field and does not need a power supply, so that a problem of electrode corrosion can be solved; and thirdly, the service life is long; the base material thermoplastic unit is arranged inside the structure and isolated from the fiber and air, so that the service life is prolonged; and the functional material fiber is a piece of glass essentially and has the service life equal to the structure.

Owner:湖北同广和新材料有限公司

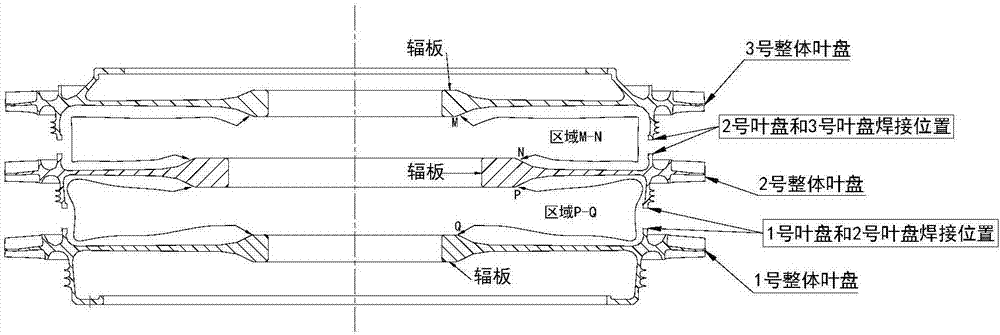

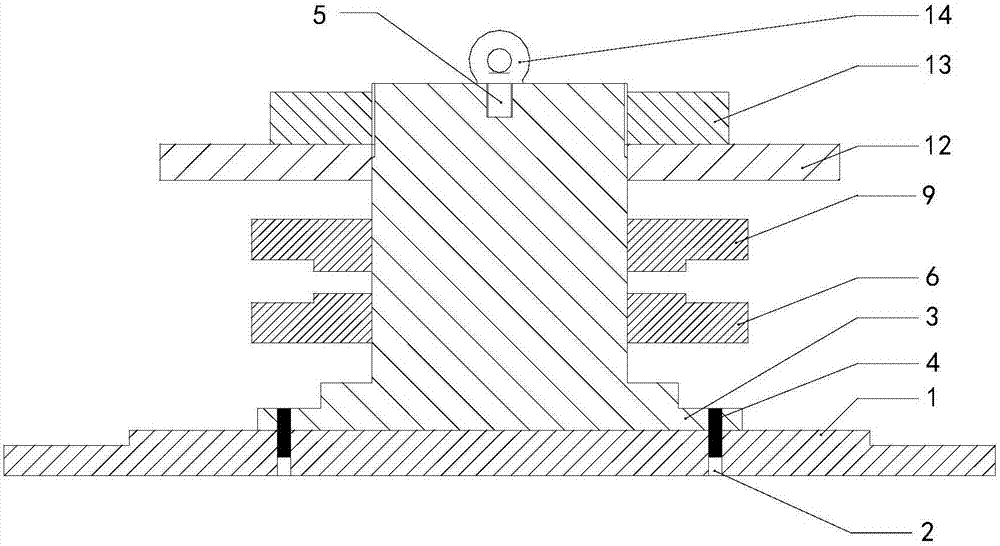

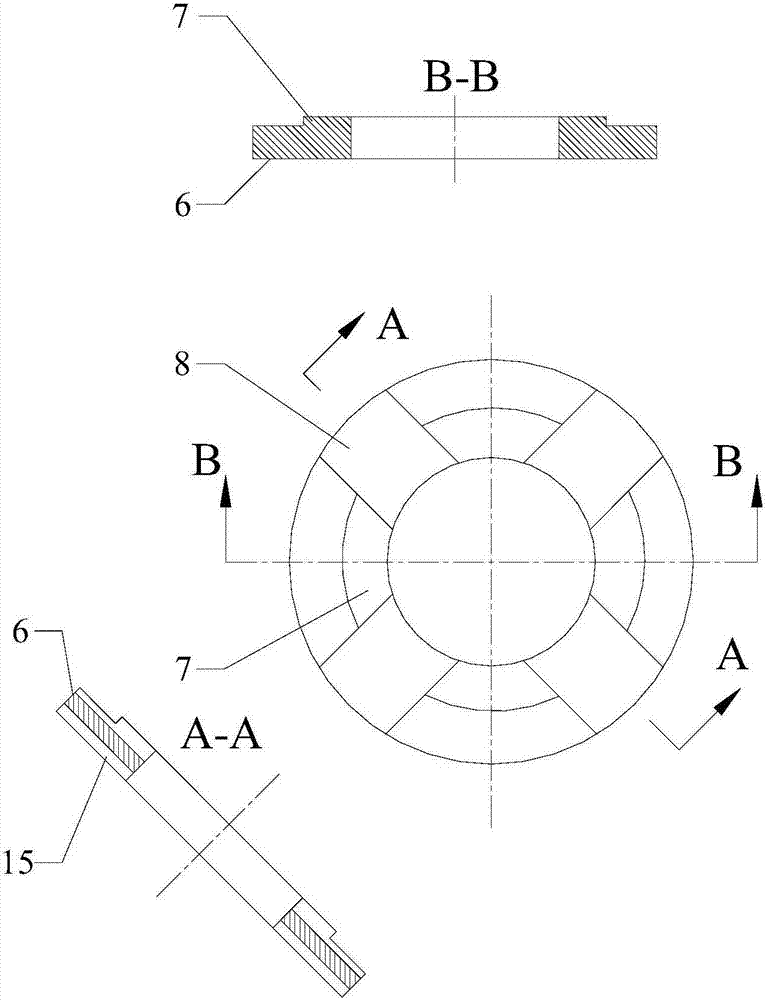

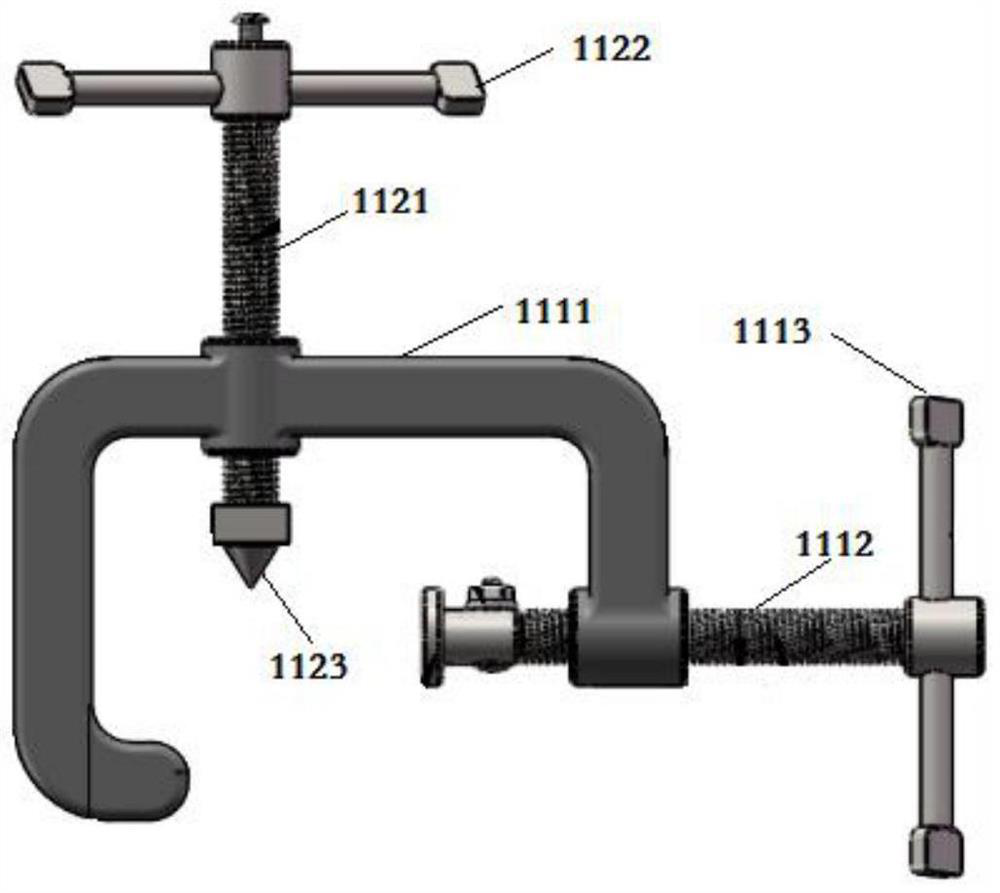

Fixture used for multistage overall blade disk electron beam welding

ActiveCN107953020AMake up for the deficiencies of scrappingGood welding performanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRejection rate

The invention discloses a fixture used for multistage overall blade disk electron beam welding. The fixture is composed of a base, a fixed stand column, a lower fixed partition block, an upper fixed partition block, a cover plate, a pressing nut and a hoisting lug ring; the fixed stand column, the lower fixed partition block, the upper fixed partition block, the cover plate and the pressing nut, and a to-be-welded first overall blade disk, a to-be-welded second overall blade disk and a to-be-welded third overall blade disk are sequentially assembled on the base from bottom to top in a staggered manner; and the hoisting lug ring is fixedly connected to the upper end face of the fixed stand column. The fixture is simple in structure, convenient to operate and use and high in reliability, welding of the multistage overall blade disks can be achieved at a time, the production efficiency of welding is improved, the problems that welding of a large-diameter wheel disk in the multistage overall blade disks cannot be easily controlled, and ununiform deformation can be very easily caused can also be solved, the rejection rate is reduced, and the production cost is reduced.

Owner:AECC AERO SCI & TECH CO LTD

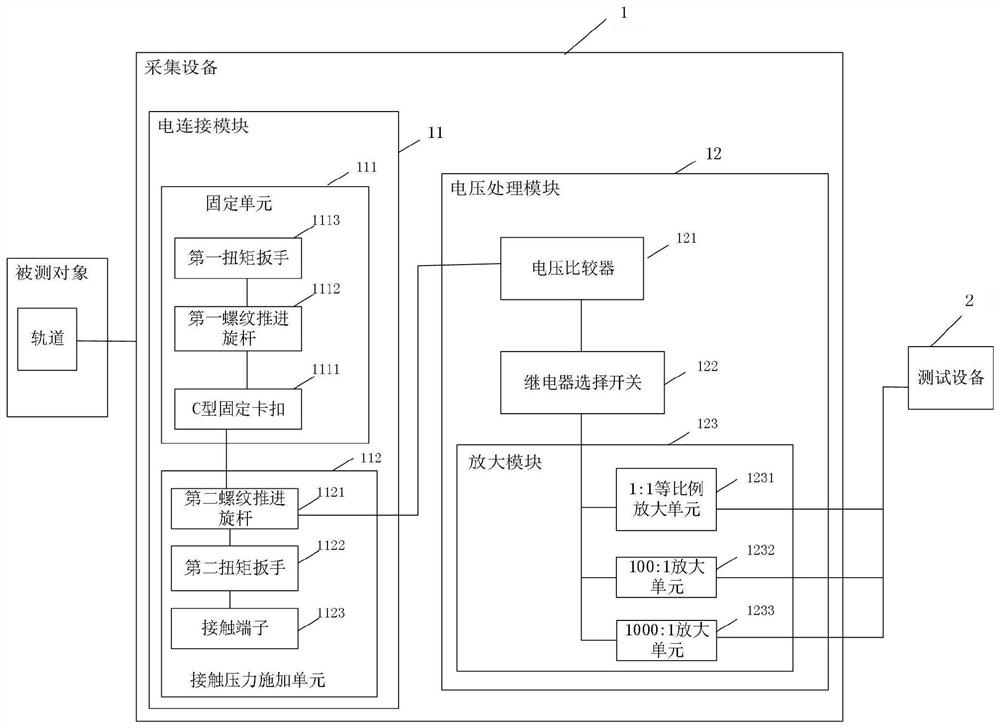

Track voltage measuring device and measuring method

PendingCN114355046AImprove installation firmnessWon't fall offResistance/reactance/impedenceAcquisition apparatusSignal on

The invention discloses a rail voltage measuring device and method, and belongs to the technical field of electrical measurement, the rail voltage measuring device comprises an acquisition device and a test device, and the acquisition device is connected with the test device; the acquisition device comprises an electric connection module and a voltage processing module, and the electric connection module is connected with the voltage processing module. According to the invention, weak voltage signals on the track can be amplified, and test errors caused by unreasonable contact form or poor contact can be avoided.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

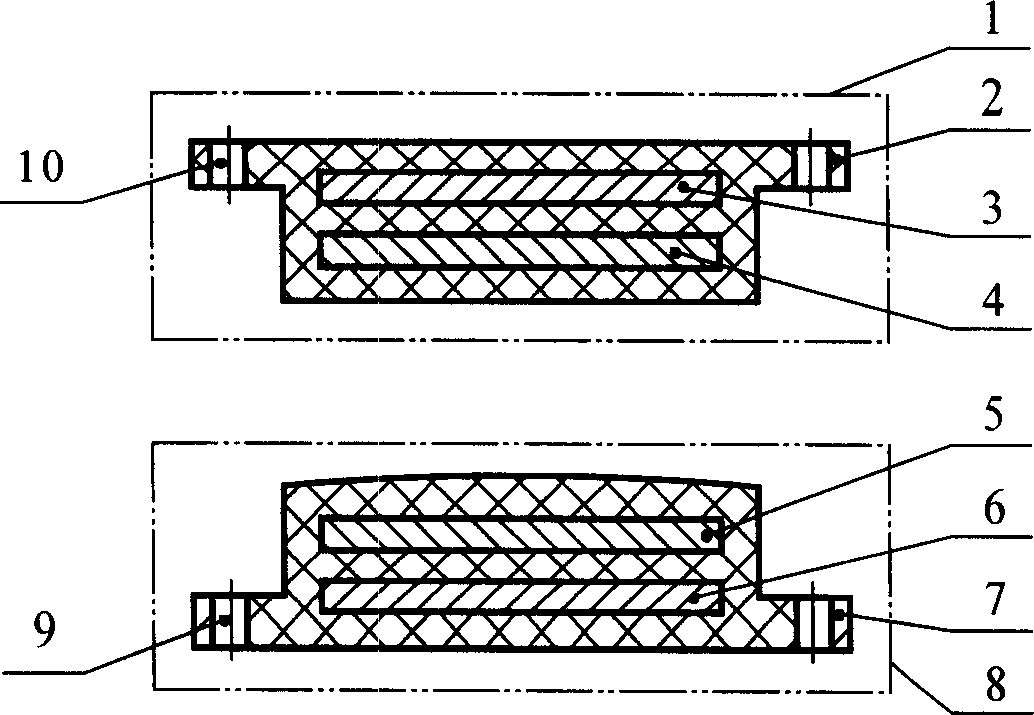

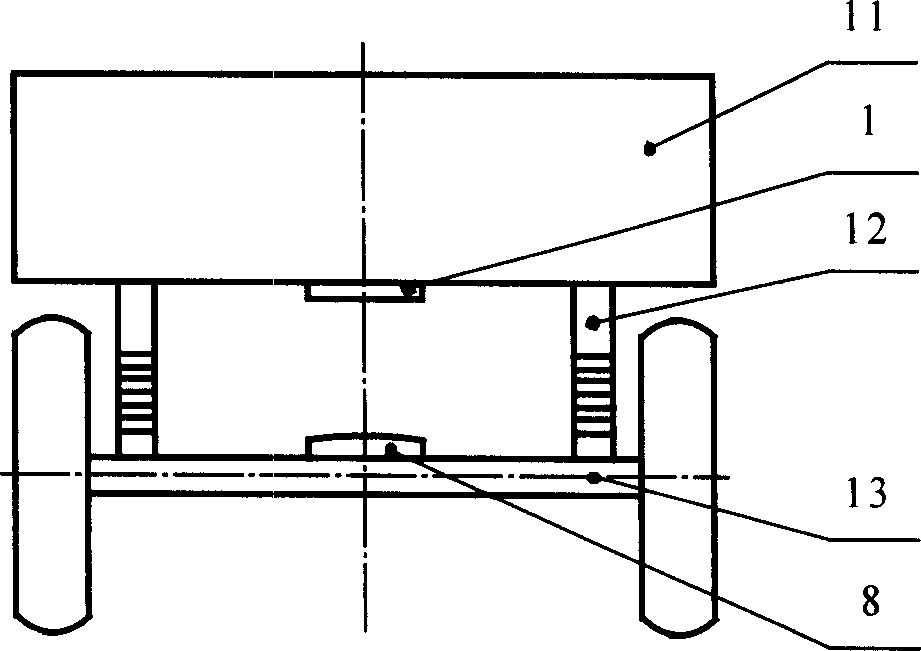

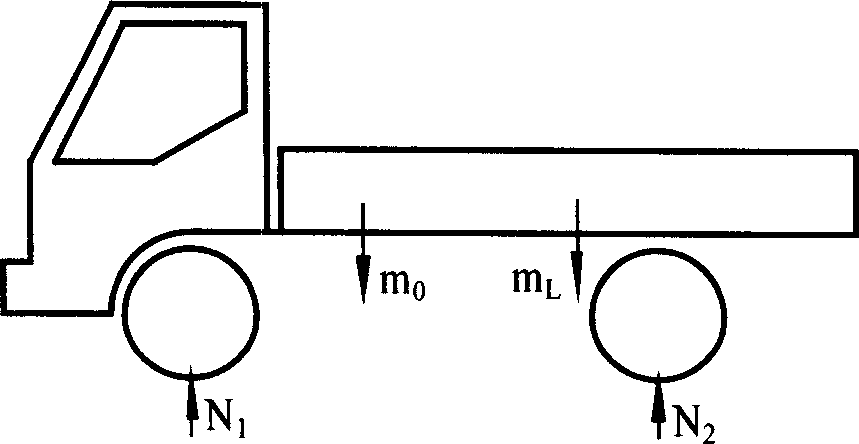

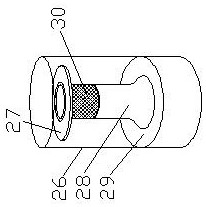

Vehicular capacitance sensor for vehicle loading sampling

InactiveCN1811353ANon-deformableHas no rustWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusBody compartmentEngineering

The present invention belongs to a vehicle-mounted type capacitive transducer for sampling vehicle load. Its key lies in that it mainly composed of capacitance upper electrode plate and capacitance lower electrode plate, the upper electrode plate is mounted in the bottom portion of platform, the lower electrode plate is mounted over the middle portion of wheel axle, two electrode plates are face-to-face oppositely and up-down mounted, over the every wheel axle of the vehicle a set of capacitive transducer is mounted respectively. Besides, said invention also provides the working principle of said vehicle-mounted type capacitive transducer and its operation method and steps for detecting vehicle load mass.

Owner:SHANGQIU NORMAL UNIVERSITY

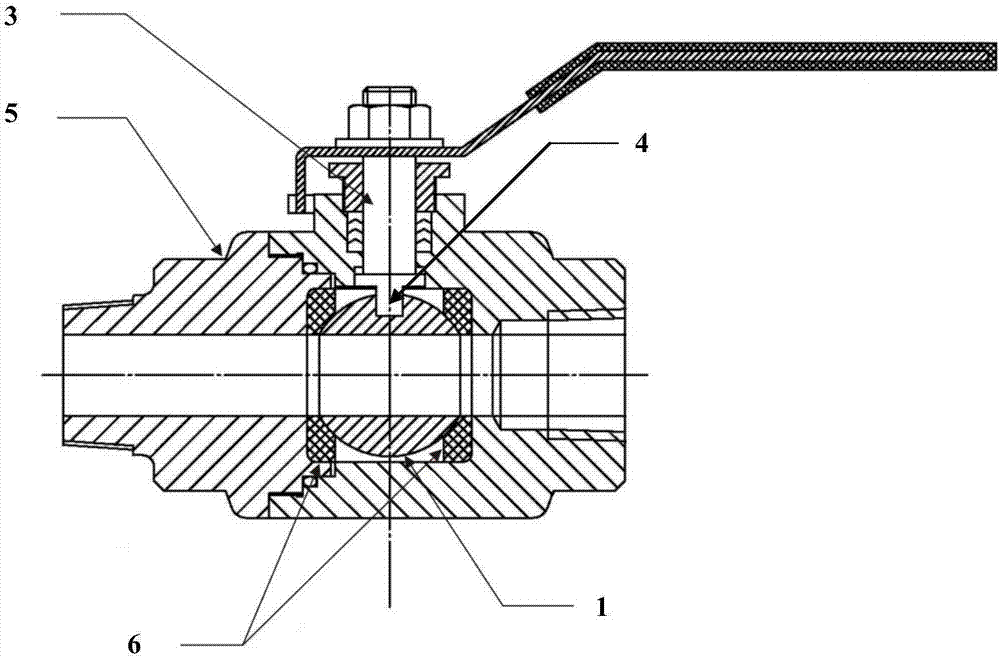

Spherical aluminum valve core, spherical valve and manufacturing technology of spherical aluminum valve core

PendingCN107448638AHigh hardnessSmooth and wear-resistantAnodisationPlug valvesManufacturing technologySpherical shaped

The invention provides a spherical aluminum valve core, a spherical valve and a manufacturing technology of the spherical aluminum valve core. The spherical aluminum valve core comprises an aluminum valve core body, the valve core body is spherical and is provided with a flow channel communicated with a pipeline and a connecting structure used for connecting a valve rod, and an aluminum oxide membrane layer is arranged at the outer circumference of the valve core body. The spherical aluminum valve core on the surface of aluminum oxide has the advantages of being high in rigidity, smooth, resistant to wear and resistant to rust, during installation, a lubricant does not need to be added, the problem that the service life of a spherical core in the spherical valve is shortened since the lubricant loses efficacy is avoided, and the defects in the prior art that the spherical core of the spherical valve is low in rigidity and poor in wear resistance, and lubrication is relied on the lubricant are overcome.

Owner:乐清市牵引机电厂

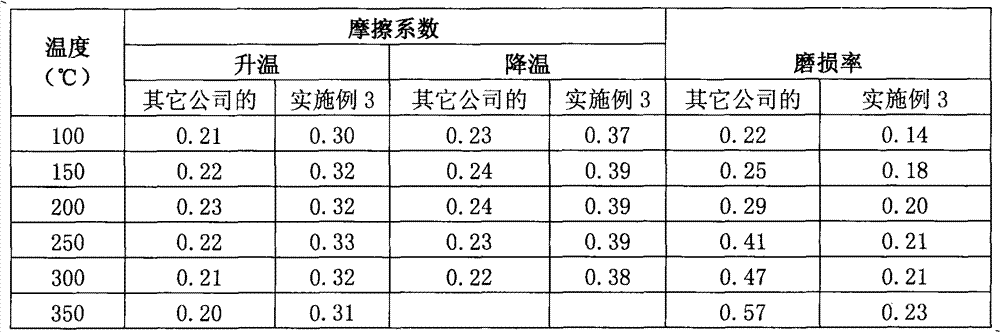

Rust resistance semi-metallic brake pad

A rust resistance semi-metallic brake pad comprises the following components according to parts by weight: 3 to 5 parts of tire powder, 3 to 5 parts of expansion graphite, 6 to 10 parts of superfine iron oxide powder, 9 to 13 parts of phenolic resin, 15 to 20 parts of stainless steel short fibre, 2 to 3 parts of cashew nut shell oil friction-type mix, 3 to 5 parts of foam ferrous powder, 3 to 5 parts of graphite particle, 10 to 15 parts of barites (600 meshes), 3 to 5 parts of chromite, 2 to 4 parts of magnetite, 3 to 5 parts of precipitated calcium carbonate, 2 to 3 parts of heavy magnesia, 9to 12 parts of acicular aedelforsite fibre, 1 to 2 parts of antimony sulphide, 0.5 to 1 part of copper sulphide. The invention is stainless, and has the characteristics of high friction coefficient,good and high capacity of temperature and decline resisting, long service life, and the like. The high temperature resistance thereof can reach 450 DEG C, friction coefficient is stable between 0.3 and 0.4, and the cost performance of the brake pad thereof is extremely high, and the brake pad can be especially applied to the front brake of light cars for long time and frequent use without damagingeither the brake drum or the brake disc.

Owner:摩擦一号制动科技(仙桃)有限公司

A kind of sponge city water treatment method

InactiveCN106968316BQuick to useWon't clogWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesWater useWater storage

The invention discloses a sponge city water treatment method. The method comprises the following steps that rainwater and sewage are introduced into a sediment separator of a sponge city integration system; sediment and water are separated by the sediment separator, clean water after separation is introduced into a first water treatment chamber and precipitated, the clean water acquired after being precipitated is introduced into a second water treatment chamber and a third water treatment chamber in sequence, and water purification treatment is conducted on the clean water in the third water treatment chamber through a water treatment machine; the clean water after water purification treatment is introduced into a water storage tank for storage and use in future; the sewage after separation by the sediment separator flows into a flood discharge drain pipe via a sewage pipe and is discharged through the flood discharge drain pipe; the water in the third water treatment chamber overflows to a shallow channel through an overflowing device, then flows into a deep channel through an infiltration well, and finally flows into the flood discharge drain pipe for flood discharging through the deep channel. According to the sponge city water treatment method, rainwater and sewage can be transformed into domestic water efficiently and in a environmentally friendly way, flood discharge can be conducted fast, and the method has a good flood discharge effect and universal applicability.

Owner:张铁耀

A production process of prestressed plastic steel PE composite pipe

ActiveCN108044963BHas no rustThere is no problem of reduced service lifeRigid pipesTubular articlesCarbon fibersMechanical engineering

The invention belongs to the technical field of PE composite pipe production and relates to a production process of prestressed plastic steel PE composite pipe. The steps are: immerse and pass the fiber into the thermosetting resin mixture, pultrude and heat, solidify into plastic steel wire under tension, and roll it into a coil for later use; weave the plastic steel wire into a net with a braiding machine on the surface of the base pipe; Glue is dispensed at the nodes of the mesh; a PE layer is extruded outside the plastic steel wire mesh that has been dispensed to make a composite pipe. The invention prepares the PE composite pipe by replacing the traditional steel wire with the extruded glass steel wire or carbon fiber steel wire, which has the advantage of not rusting. The coefficient is close. After the production of the pipe, it will not be delaminated due to the tension of thermal expansion and cold contraction, and will not form stress on the structure of the pipe. It can be fixed at the intersection of weaving with a glue dispenser to ensure uniform distribution and ensure the quality and stability of the pipe. sex.

Owner:SHANDONG BOYUAN COMPOSITE MATERIALS TECH CO LTD

Anti-rusting method of galvanized iron tower member

InactiveCN102335649BSolve the problem of corrosion resistanceSave moneyPretreated surfacesAnti-corrosive paintsLacquerSpray coating

The invention relates to an anti-rusting method of a galvanized iron tower member. The anti-rusting method is mainly used for solving the problems that, the galvanized iron tower member is not corrosion-resistant, easy to get rusty and short in service life, the structural strength is reduced, the potential safety hazard is generated, and collapse and power outage accidents of an iron tower are further caused in the prior art. The process of the method according to the invention is as follows: brush-coating a conductive glue solution with the repair function on the surface of the assembled galvanized iron tower member, further pressing the glue solution into gas holes, hair eyes, gaps and exposed scars in a galvanized layer through the high pressure method for tamping, blocking and sealing, spray-coating anti-aging, water-repellent and dirt-resistant clear lacquer on the surface of a glue film after the glue film is hardened, brush-coating a silicon rubber layer at the part which is 1m away from the member at the root part of the iron tower after the lacquer forms a film, and further preparing the product prepared by the method according to the invention. The anti-rusting method of the galvanized iron tower member is scientific, simple in process and convenient to use, and can save the material cost, the implementation can be followed after the galvanization process of a galvanization workshop, and the product has the advantages of corrosion resistance, rustless property, friction resistance, water resistance, pollution prevention, long service life of 30 years, maintenance-free updating, safety, reliability and significant economic benefits and can be widely used on land and in water.

Owner:SHANDONG HUAAN TOWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com