Residual-heat baking-material multi-cyclone dust remover for corundum smelting furnace

A technology of cyclone dust collector and smelting furnace, which is applied to furnaces, preheating costs, waste heat treatment, etc., can solve the problems of health hazards, fine particle size of dust removal powder, and high incidence of silicosis, and achieve low cost and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

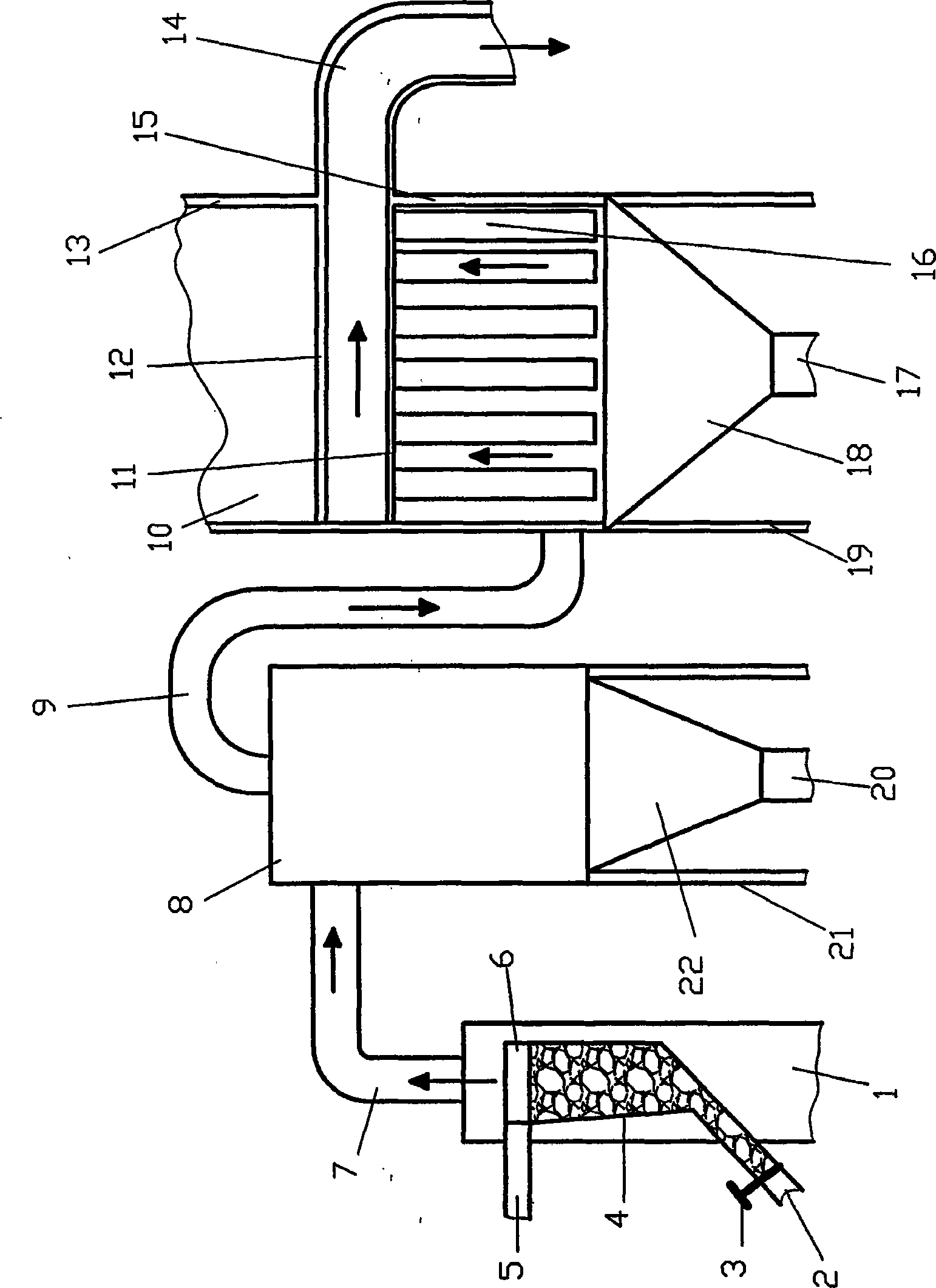

[0009] Specific embodiment: as shown in the figure, the corundum smelting furnace residual heat drying material multi-stage cyclone dust collector includes a kiln flue 1, a ventilating silo 4, a ventilating silo inlet 6, a conveyor 5, a first-stage Smoke guide pipe 7, cyclone dust collector 8, secondary smoke guide pipe 9, and dust collector 13; it is characterized in that a conveyor 5 is provided outside the kiln flue 1, and the end of the conveyor 5 extends to the kiln flue 1, and a ventilating silo inlet 6 is installed, and a ventilating silo 4 is installed below the ventilating silo inlet 6; The lower end is installed butt joint;

[0010] The top of the kiln flue 1 is provided with a primary smoke guide pipe 7, and the end of the primary smoke guide pipe 7 is connected to the cyclone dust collector 8; the top of the cyclone dust collector 8 is equipped with a secondary smoke guide pipe 9, and the secondary smoke guide pipe 9 The end of the smoke pipe 9 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com