Patents

Literature

76results about How to "Solve the problem of corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

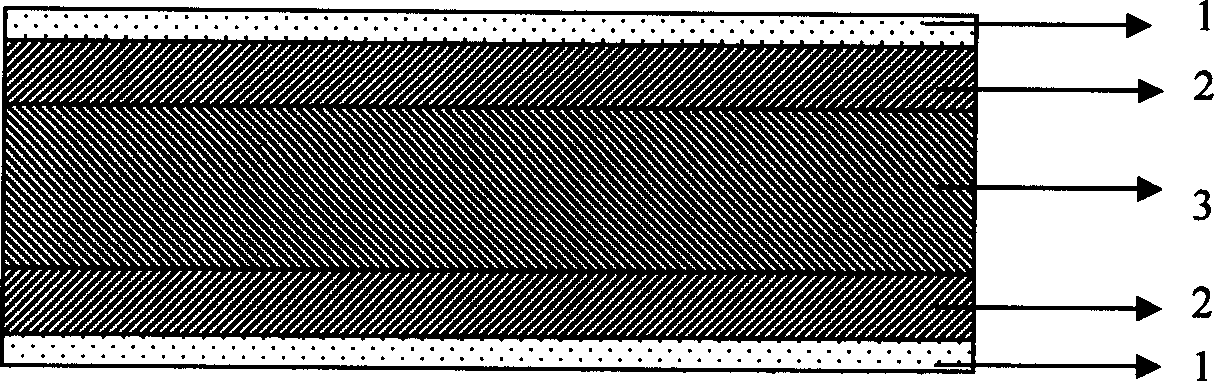

Nickel substitute laminated composite metal belt, foil, sheet for saving pure nickel

InactiveCN1824497AImprove corrosion resistanceHigh strengthMetal layered productsProduction lineInter layer

The present invention relates to a kind of nickel-substituted laminated composite metal tape, foil and sheet material which can be substituted for pure nickel tape, foil and sheet material. Said composite metal tape, foil and sheet material has a laminated structure in which more than five layers of metal are distributed, in which two outer layers are thin nicked layers, other intermediate layers are non-nickel metal layers formed from stainless steel, copper or copper alloy and low-carbon steel. Said invention can be extensively used in the fields of electric cell, electric tool, information communication and special lamps, etc.

Owner:佛山精密电工合金有限公司

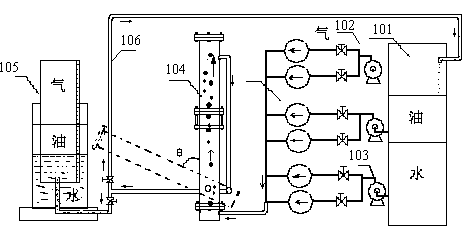

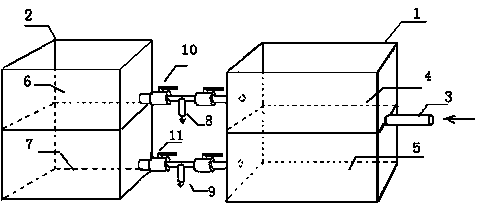

Oil-gas-water three-phase multifunctional detection system

The invention provides an oil-gas-water three-phase multifunctional detection system. The system comprises an oil-gas-water separation and storage tank, a gas flow generating and regulating device, a liquid flow generating and regulating device and a multifunctional well casing device, wherein the oil-gas-water separation and storage tank is a device used for separation of oil-gas-water mixed fluid, liquid storage and liquid parameter adjustment, the gas flow generating and regulating device is a device for generating gas, providing power for flow of gas, indicating gas flow, and regulating the gas flow to enable the flow to be constant, the liquid flow generating and regulating device is used for providing power for flow of liquid, indicating liquid flow, and regulating the liquid flow to enable the flow to be constant, and a replaceable shaft is arranged in the multifunctional well casing device and is driven by the multifunctional well casing device to deflect.

Owner:CHINA PETROLEUM & CHEM CORP +1

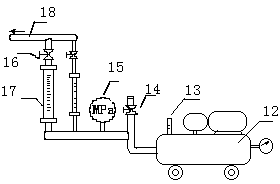

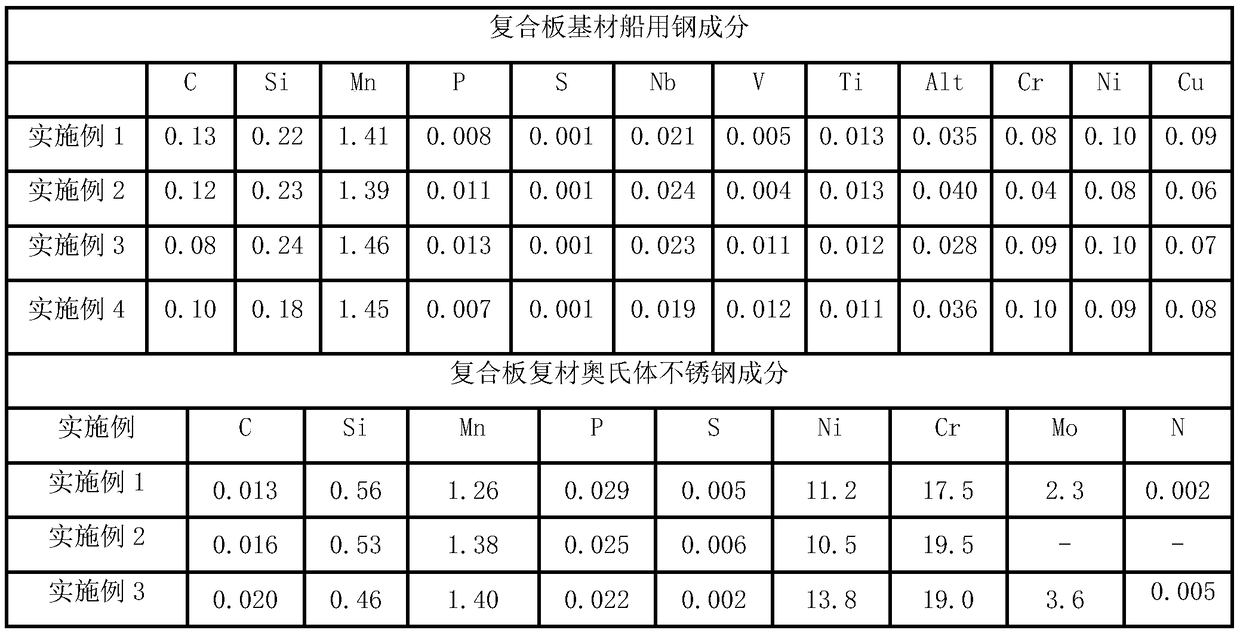

TMCP type marine austenitic stainless steel composite plate and preparation method thereof

InactiveCN108943911ASolve the problem of corrosion resistanceSimple processLamination ancillary operationsLaminationAustenitic stainless steelAusforming

The invention discloses a TMCP type marine austenitic stainless steel composite plate and a preparation method thereof and relates to the technical field of bimetal composite manufacture. The preparation method comprises blank preparation, surface grinding, isolating agent brush-coating, assembly blank sealing, electron beam soldering and sealing, heating, rolling and cooling, straightening, and cutting separation. The TMCP type marine austenitic stainless steel composite plate effectively solves the problem of corrosion resistance of the composite austenitic stainless steel in the composite plate, and in the blank preparation process, the steps of drilling and vacuuming are avoided. The preparation method has simple processes and a high rolling yield.

Owner:NANJING IRON & STEEL CO LTD

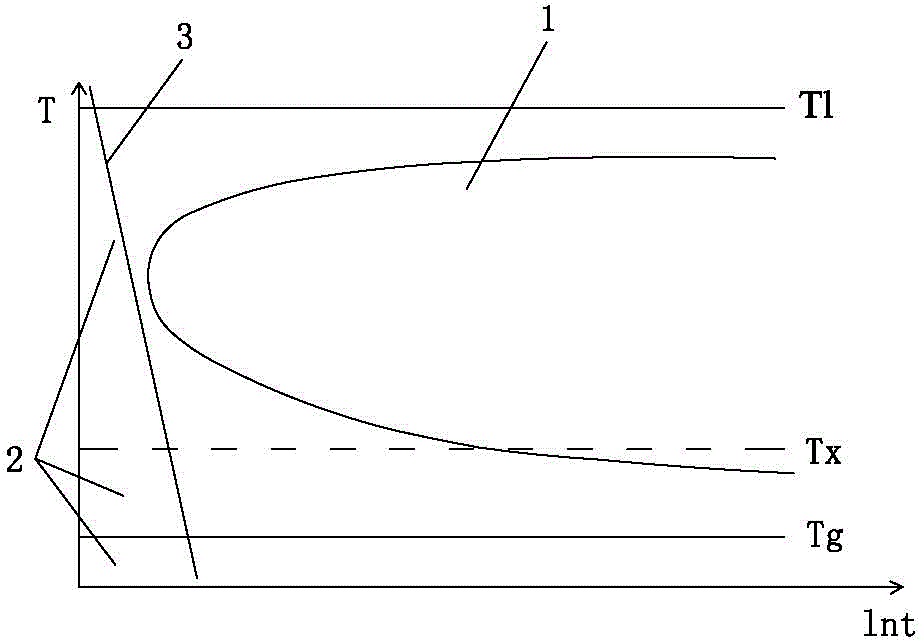

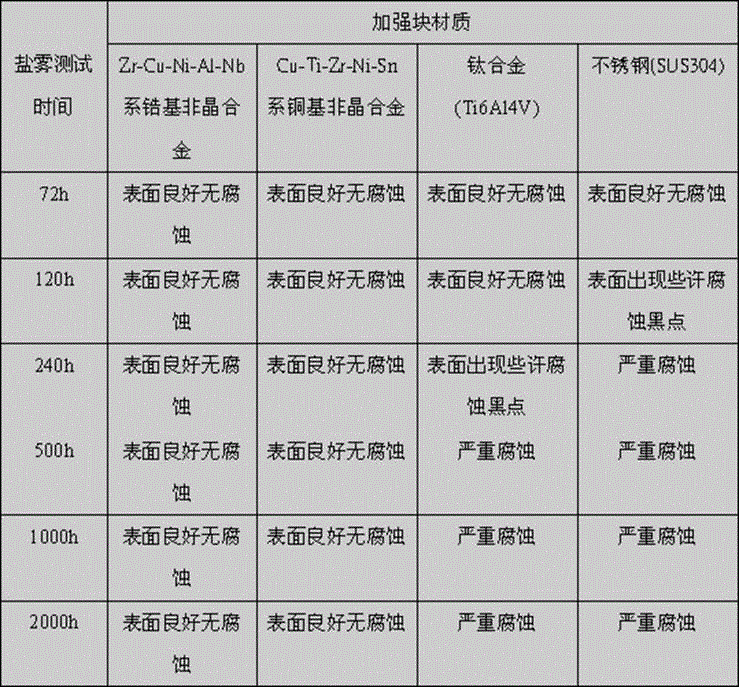

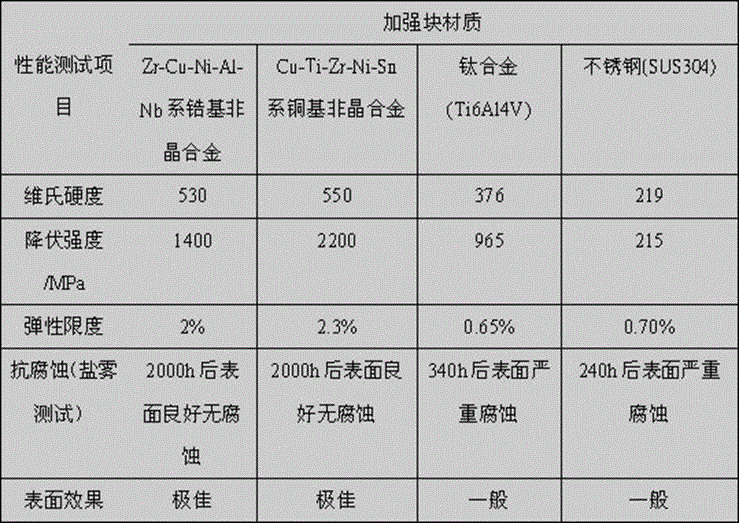

Mobile phone shell and amorphous alloy reinforcement block thereof and manufacturing method of amorphous alloy reinforcement block

The invention relates to the technical field of application of amorphous alloy, in particular to a mobile phone shell and an amorphous alloy reinforcement block thereof and a manufacturing method of the amorphous alloy reinforcement block. The reinforcement block is the amorphous alloy reinforcement block made of zirconium-based amorphous alloy, copper-based amorphous alloy, titanium-based amorphous alloy, nickel-based amorphous alloy, palladium-based amorphous alloy or iron-based amorphous alloy. The reinforcement block is 400-600 in hardness, 1000-3000MPa in strength and 2-3% in elastic limit, and is non-corrosive on the surface after 500-2000h salt spray test. Amorphous-alloyed alloy ingot is adopted in the method to manufacture the amorphous alloy reinforcement block through a die casting molding method, a melt spinning method, a suction casting method, a rapid discharge molding method, a continuous casting method or a thermoplastic molding method. The amorphous alloy reinforcement block manufactured by the method has the advantages of high strength, high hardness, high elasticity and anti-corrosion, and the situation that a mobile phone is bent when the mobile phone shell is highly stressed can be avoided.

Owner:DONGGUAN PROMETAL TECH CO LTD

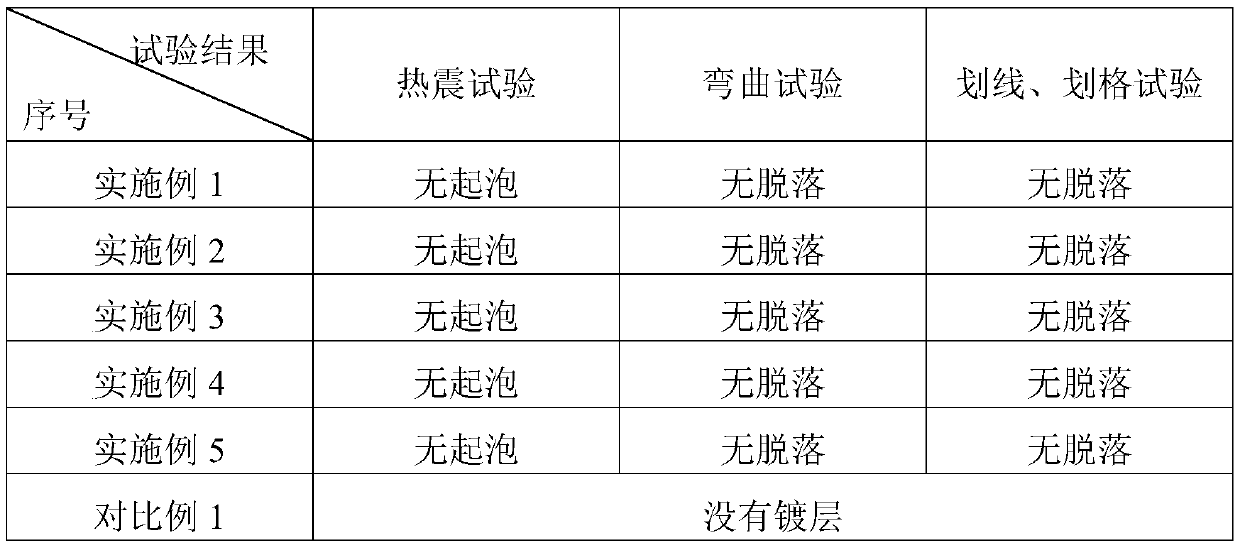

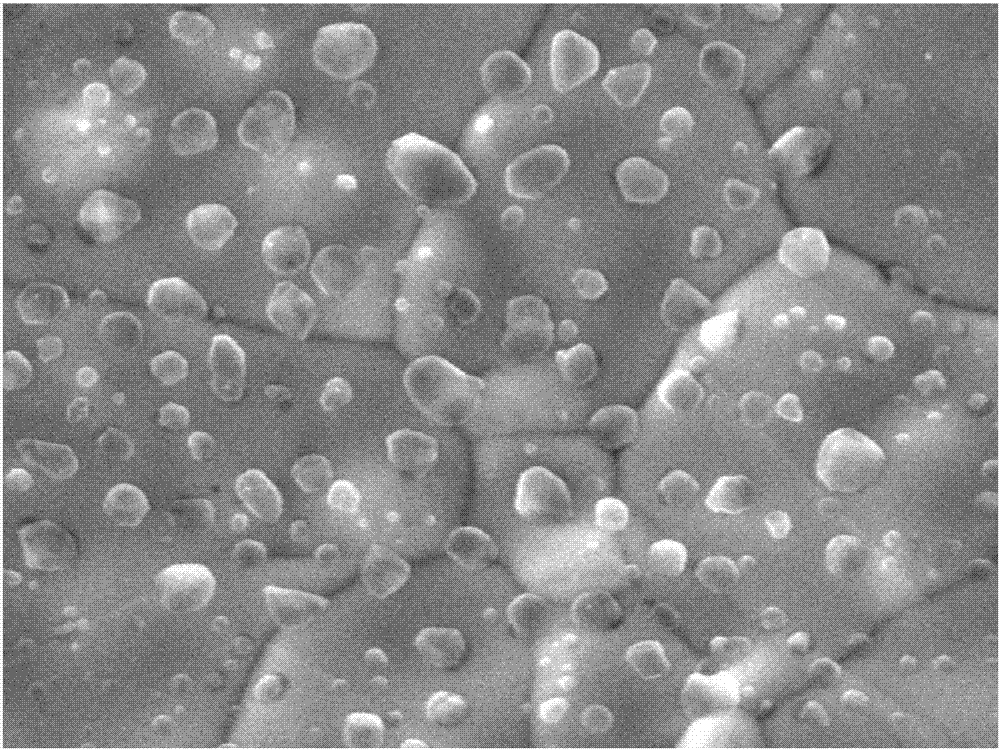

Composite chemical nickel and phosphor plating method

ActiveCN101514449AImprove bindingImprove corrosion resistanceLiquid/solution decomposition chemical coatingSodium acetateHigh adhesion

The invention relates to a composite chemical nickel and phosphor plating method, characterized by comprising the following steps: 1) the pH value of the chemical nickel and phosphor plating solution containing nickel sulfate with the concentration being 26 to 30 g / l, sodium hypophosphite with the concentration being 23 to 27 g / l, sodium citrate with the concentration being 38 to 42 g / l and sodium acetate with the concentration being 23 to 27 g / l is adjusted to be 9 to 10, neodymium(III) sulfate octahydrate is mixed with the chemical nickel and phosphor plating solution uniformly at the addition amount is 0.4 to 0.8 g / l, the above solution is plated on the pretreated neodymium iron boron magnet under the effect of the ultrasonic wave for 10 to 60 minutes to obtain a nickel and phosphor plating layer with the crystal grain size of 5 to 8 nm; 2) the pH value of the chemical nickel and phosphor plating solution containing nickel sulfate with the concentration being 22 to 26 g / l, sodium hypophosphite with the concentration being 28 to 32 g / l, sodium citrate with the concentration being 43 to 47 g / l and sodium acetate with the concentration being 28 to 32 g / l is adjusted to be 4.2 to 5.6, the plated neodymium iron boron magnet in the step(1) is placed into the chemical nickel and phosphor plating solution in the step(2) for plating for 30 to 120 minutes, the amorphous nickel and phosphor plating layer is obtained. Compared with the prior art, the plating layer has high adhesion and good corrosion resistance, the thickness of the plating layer can be reduced and the loss of the magnetic property can be lowered.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

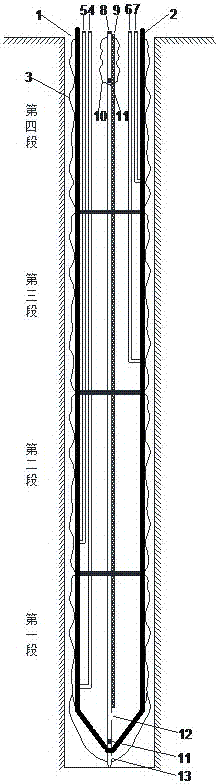

Construction technology for concrete filled steel tube mold bag pile compound retaining structure

InactiveCN107130633ASolve the problem of corrosion resistanceSolve quality problemsArtificial islandsUnderwater structuresRiver regulationQuickening

The invention discloses a construction technology for a concrete filled steel tube mold bag pile compound retaining structure. The construction technology is characterized by comprising the following steps: (1) surveying and setting out; (2) vertically forming a hole; (3) manufacturing and mounting a steel tube; (4) manufacturing and mounting a grouting tube; (5) manufacturing and mounting a water draining system through a mold bag; (6) performing a grouting construction process. According to the construction technology for the concrete filled steel tube mold bag pile compound retaining structure, the problems that the construction field is narrow, the large-scale equipment close to the surrounding constructions is difficult to be carried into the field for construction, the influence on the surrounding constructions is great in the implantation process and especially the shallow basis of the constructions is influenced in the processes of river regulation and bank construction can be solved, and meanwhile, the quickening of the project progress is benefited, the project cost is lowered, a protecting layer meeting the code requirement is formed in the manner of wrapping the steel tube with a recycled material concrete through mold bag grouting and the problem of the steel tube corrosion resistance of the concrete filled steel tube in the foundation basis application process can be solved.

Owner:蔡荪萍

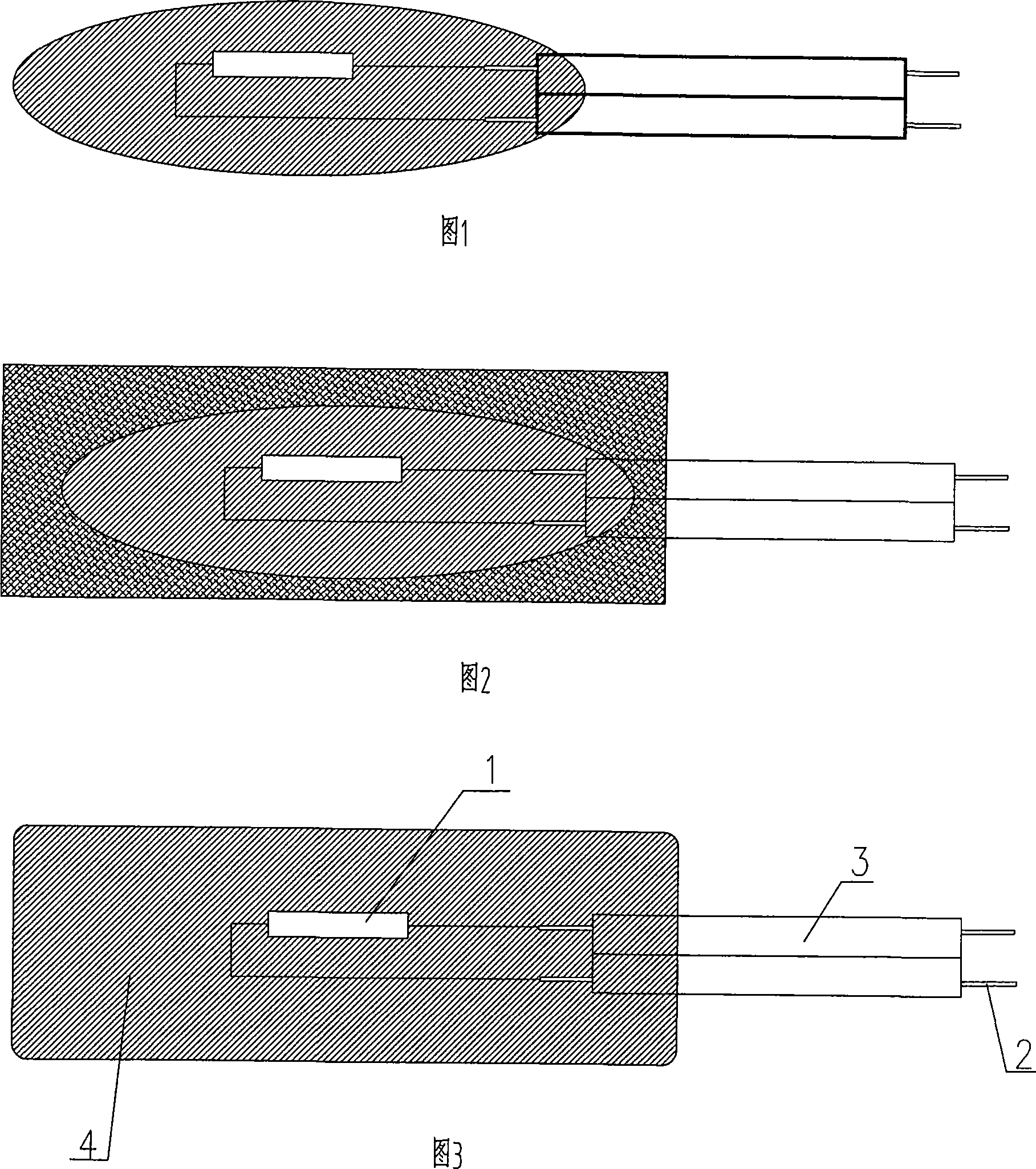

Manufacturing method of temperature sensor

InactiveCN101135591AImprove waterproof performanceSolve the problem of corrosion resistanceThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceInsulation layer

The method comprises: after connecting the thermistor to the wire by using soldering or welding, using a material which is identical with the wire insulation layer as the covering layer of the thermistor; heating and pressing it in order to make the covering layer combine with the isolation layer.

Owner:常州市科文传感器材料有限公司

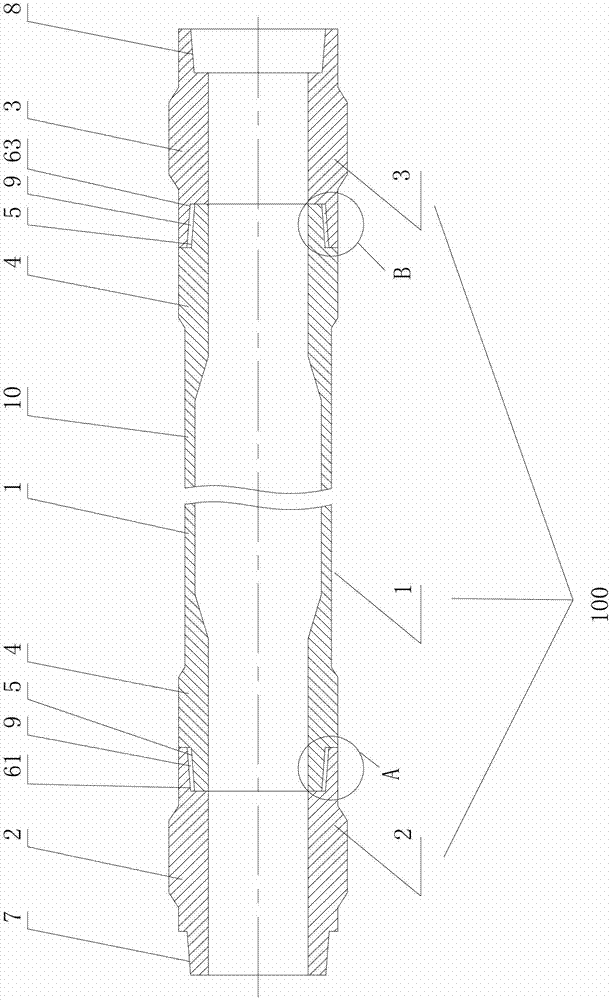

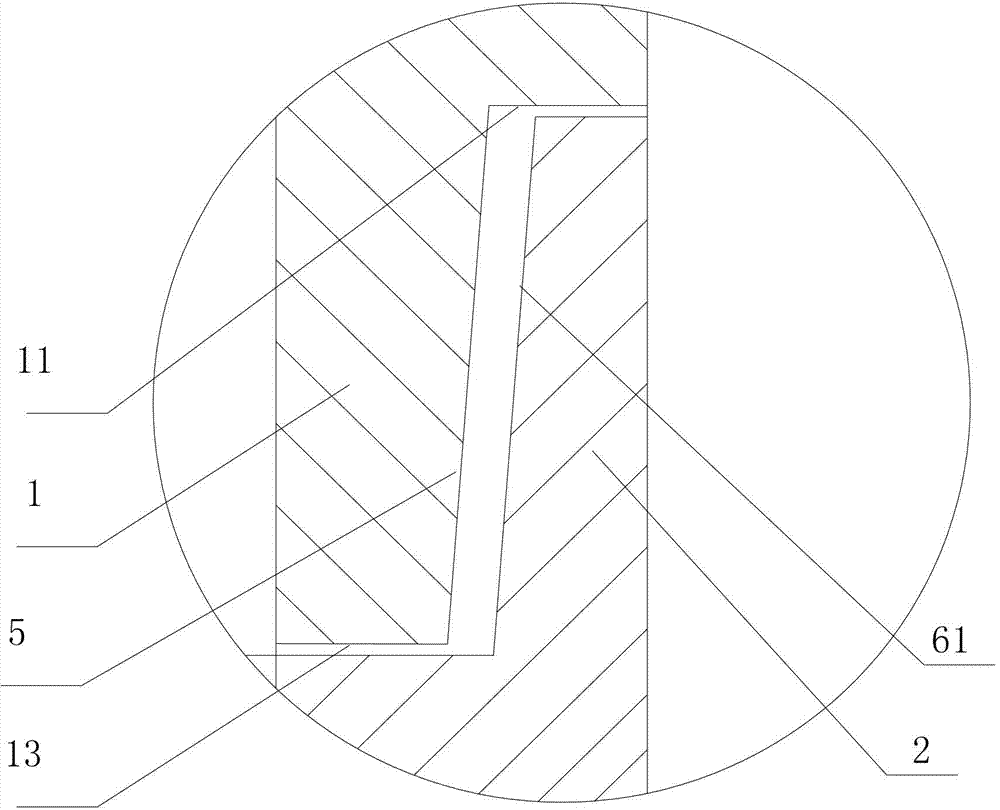

Threaded connection type all-aluminum alloy drill stem

ActiveCN102900377ASolve the problem of corrosion resistanceNot low tensile strengthDrilling rodsDrilling casingsConnection typeTorsional strength

The invention provides a threaded connection type all-aluminum alloy drill stem. The threaded connection type all-aluminum alloy drill stem comprises an aluminum alloy drill stem pipe body and aluminum alloy drill stem joints which are connected at the end parts of the aluminum alloy drill stem pipe body through threads; the threaded connection performance between the aluminum alloy drill stem pipe body and the aluminum alloy joints and the threaded connection property between the aluminium alloy joints such as the tensile strength, torsional strength and sealing performance are not lower than the performance of an aluminum alloy drill stem with steel joints; compared with the aluminum alloy drill stem with the steel joints, the threaded connection type all-aluminum alloy drill stem is anticorrosive; and compared with an integral type all-aluminum alloy drill stem, the threaded connection type all-aluminum alloy drill stem has the advantages of simple machining technology, low cost and higher cost performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-strength fastening bolt production technology

The invention belongs to the technical field of bolt processing, and aims at providing a high-strength fastening bolt production technology. The high-strength fastening bolt production technology comprises the following steps of: step 1. selecting a steel product; step 2. carrying out spheroidizing annealing; step 3. shelling and descaling; step 4. drawing; step 5. carrying out cold forging and shaping; step 6. carrying out thread machining; step 7. carrying out heat treatment; step 8. detecting; step 9. tempering; step 10. carrying out secondary detection; and step 11. plating an anti-corrosion layer. Bolts screened out finally through material selection, annealing, descaling, drawing, cold forging, heat treatment, screening and tempering have the characteristic of high strength. The bolts have the characteristic of corrosion resistance by coating the surfaces of the bolts with Fe-Ni-Cr alloy coatings, and can be prevented from be corroded under harsh physicochemical conditions, and thus, the shape and strength of the bolts are maintained.

Owner:森冈精机(南通)有限公司

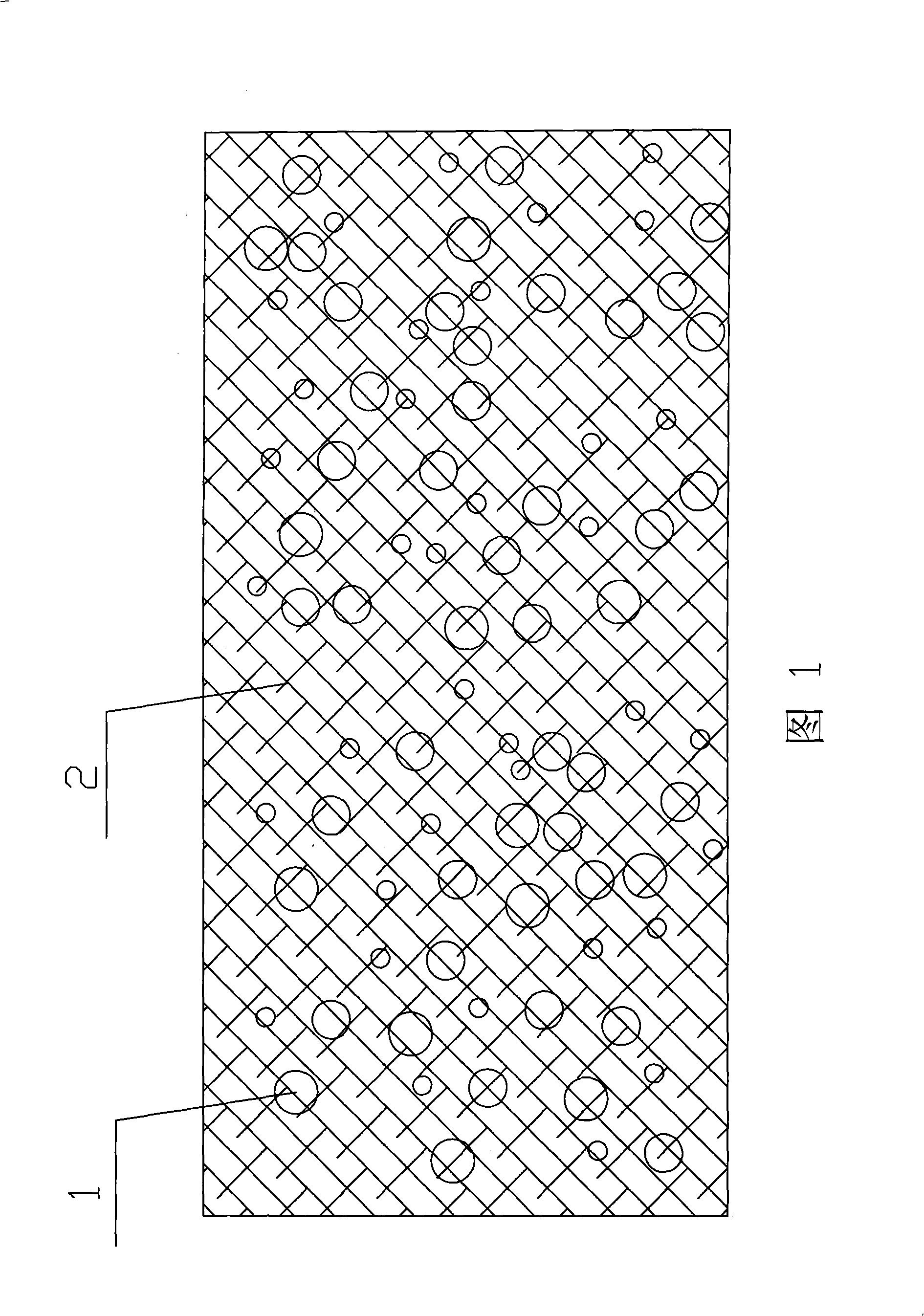

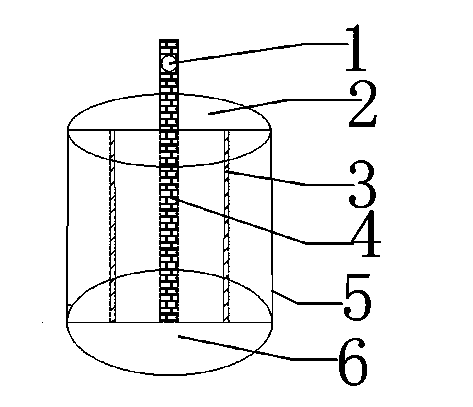

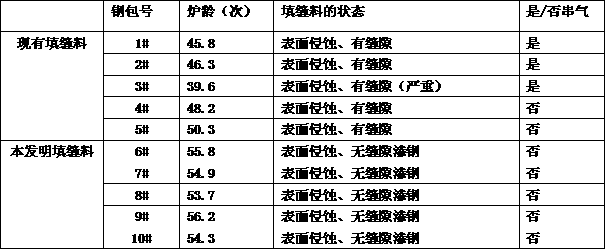

Carbon fiber autoclaved aerated concrete slab and application thereof

The invention relates to an autoclaved aerated concrete slab containing carbon fibers and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises building concrete structural slabs (1), wherein the concrete is autoclaved aerated concrete, and the concrete in the structural slabs is provided with carbon fibers (2). The product can be used as precast elements for buildings, such as floor slabs, roof slabs and wall slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

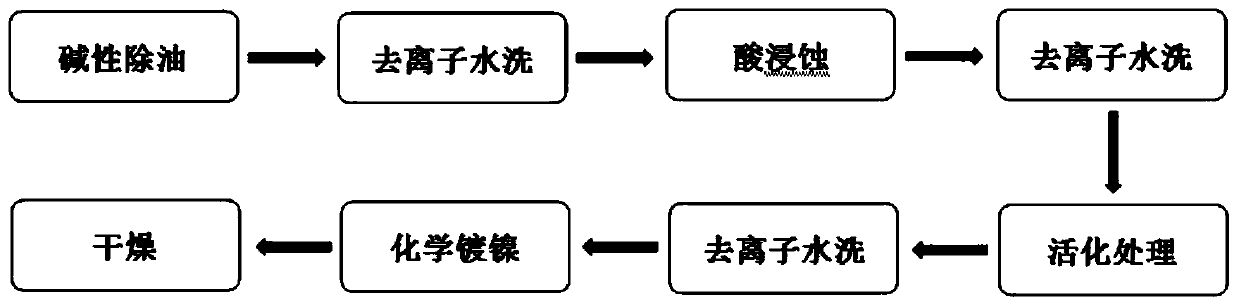

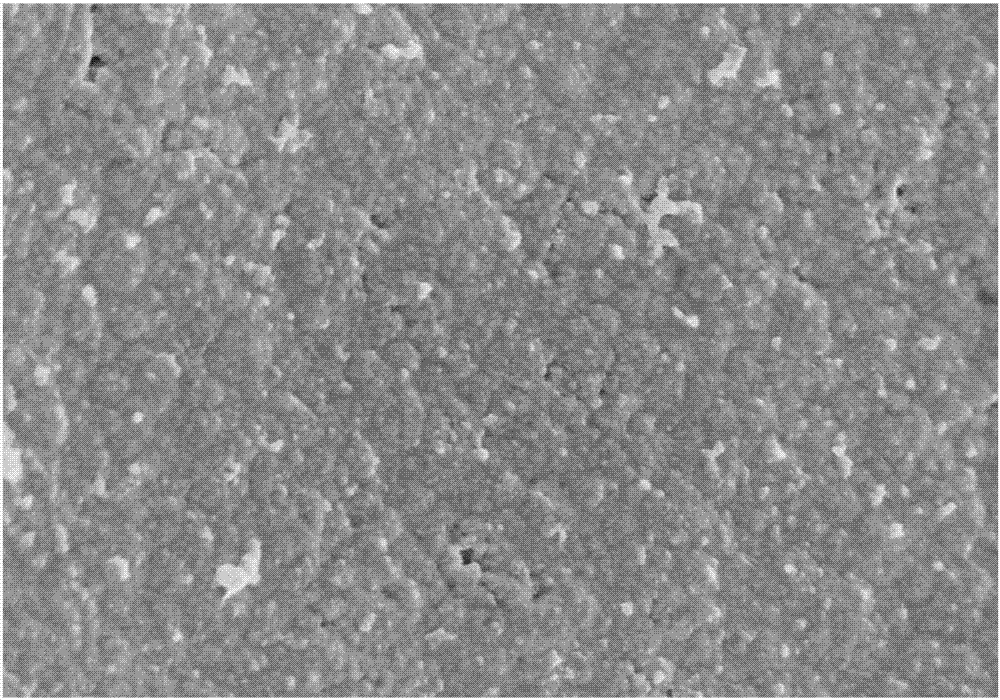

Aluminum alloy electroless nickel plating mixed metal activation method

InactiveCN110117783AImprove bindingSolve the problem of corrosion resistanceLiquid/solution decomposition chemical coatingActivation methodElectroless nickel

The invention provides an aluminum alloy electroless nickel plating mixed metal activation method. The method comprises the following steps that surface oil removal, deoxidizing film treatment and acid cleaning are performed on an aluminum base material in sequence, then the aluminum base material is placed in activation liquid for activation, the activation treatment temperature is 20-50 DEG C, and the activation time is 1-5 min. By means of the aluminum alloy electroless nickel plating mixed metal activation method provided by the invention, a prepared nickel plating layer has the characteristics of being uniform and compact, wear resistant, corrosion resistant, good in binding force and the like, the problems existing in the prior art of the tedious process, environmental pollution, slow beginning plating time, poor plating layer adhesion force and the like are solved, the production cost can further be reduced, and the aluminum alloy electroless nickel plating mixed metal activation method is suitable for large-scale industrial production.

Owner:GUANGDONG UNIV OF TECH

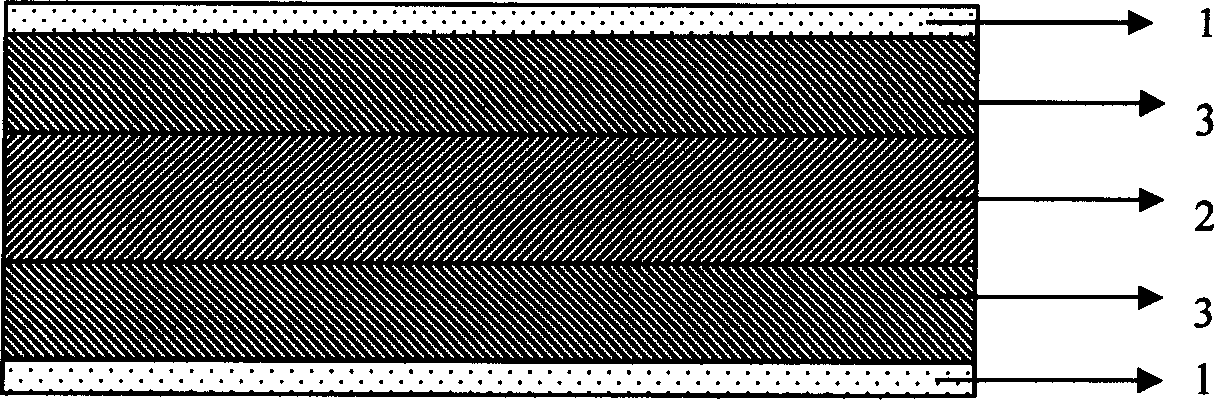

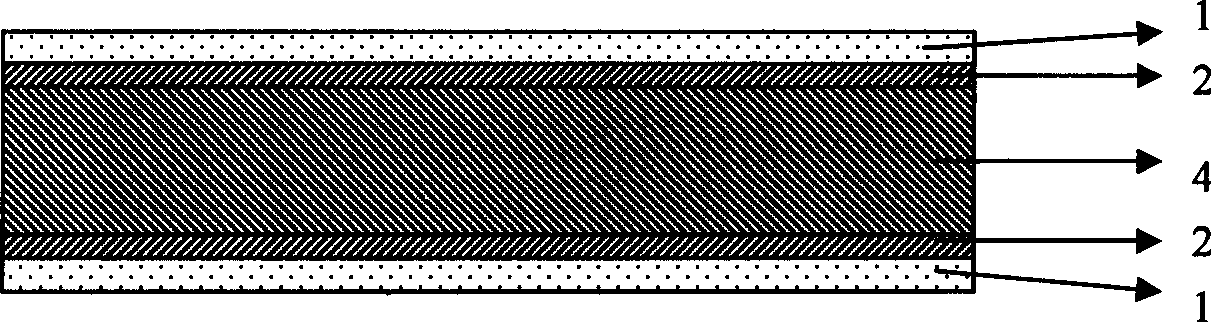

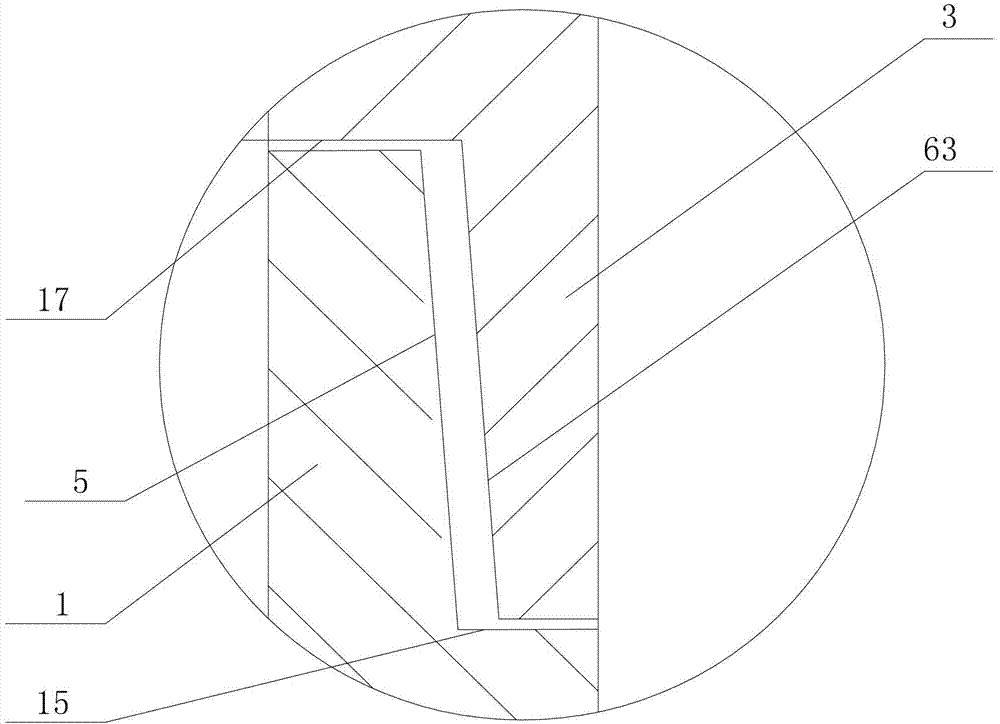

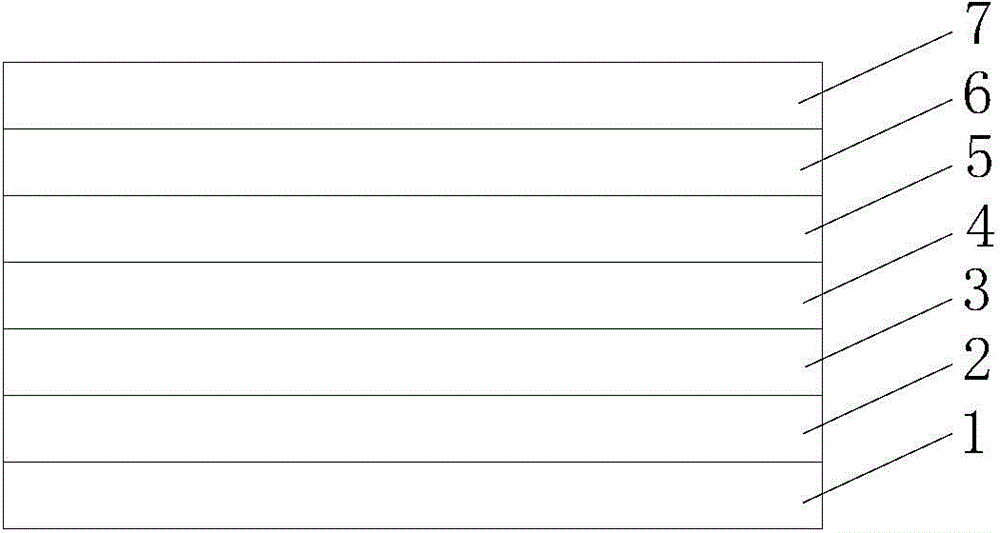

Sheet metal of multi-layer structure

InactiveCN103407222AImprove corrosion resistanceSolve the use environment requirementsMetal layered productsTotal thicknessCarbon steel

The invention discloses a sheet metal of a multi-layer structure. The sheet metal is characterized by comprising four layers of metal layers which are parallelly distributed, the two outermost layers are made of nickel, the sum of the thicknesses of the two outermost layers does not exceed 30% of the total thickness of the sheet metal, and the two middle layers are made of stainless steel, copper or copper alloy and low-carbon steel according to a certain proportion.

Owner:张家港保税区金企鹅贸易有限公司

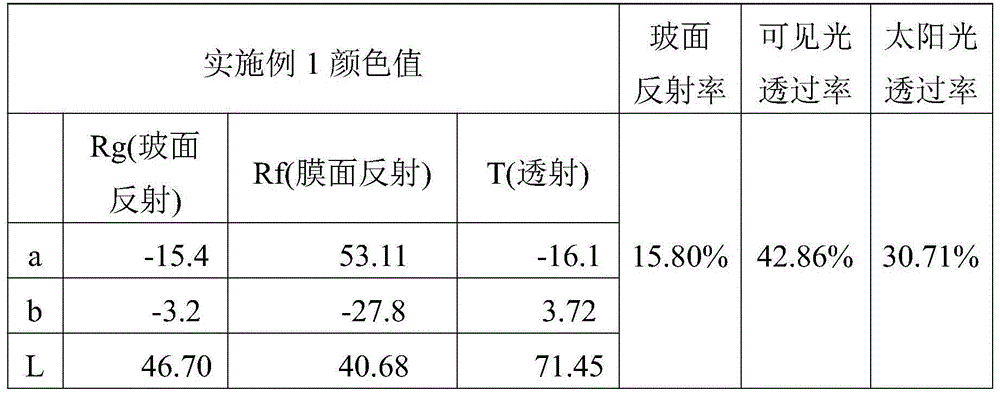

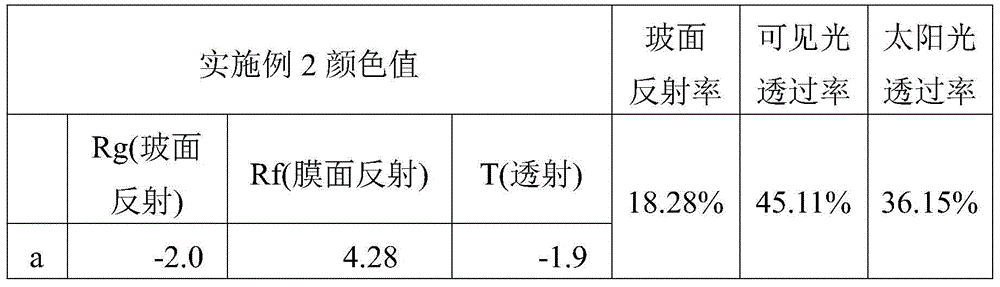

Solar control coated glass capable of being used in one piece and preparation method of solar control coated glass

ActiveCN104609740AWide color adjustment rangeImprove scratch resistanceCoatingsWeather resistanceOptoelectronics

The invention discloses a solar control coated glass capable of being used in one piece and a preparation method of the solar control coated glass. The coated glass comprises a glass substrate and a coating layer arranged at one side surface of the glass substrate, wherein the coating layer sequentially comprises a dielectric barrier layer, a first sacrificial layer, a functional layer, a second sacrificial layer, a dielectric support layer and a top protective layer which are sequentially arranged from the glass substrate to the outer side. The solar control coated glass capable of being used in one piece according to an embodiment of the invention is good in weather resistance and excellent in decorative effect and can be used in one piece.

Owner:CHINA BUILDING MATERIALS ACAD +1

Anti-waxing coating for oil pipelines

InactiveCN104403536APrevent waxingPrevent water repellentAntifouling/underwater paintsSynthetic resin layered productsEpoxyPolyester

The invention relates to an anti-waxing coating for oil pipelines. The anti-waxing coating is composed of primer and finish paint, wherein the weight ratio of the primer to the finish paint is 100:(2-5); the primer comprises 10-30% of polyurethane, 5-15% of epoxy resin, 5-15% of unsaturated polyester, 1-8% of inorganic fillers, 2-10% of a flatting agent, 0.05-2% of a defoaming agent and the balance of a solvent; the finish paint is a perfluorinated polyether derivative. The invention further provides a preparation method of the anti-waxing coating for oil pipelines. The anti-waxing coating is hydrophobic, oleophobic, corrosion-resistant, low in surface energy, high in anti-waxing efficiency and high in bonding strength with a substrate, can be used for solving the problems of waxing prevention of inner walls of oil storing equipment and oil refining equipment, and can further be used for solving the problems of antifouling and algae prevention of ships, racing boats or submarines, as well as antifouling and algae prevention of buildings.

Owner:SHANGHAI INST OF TECH

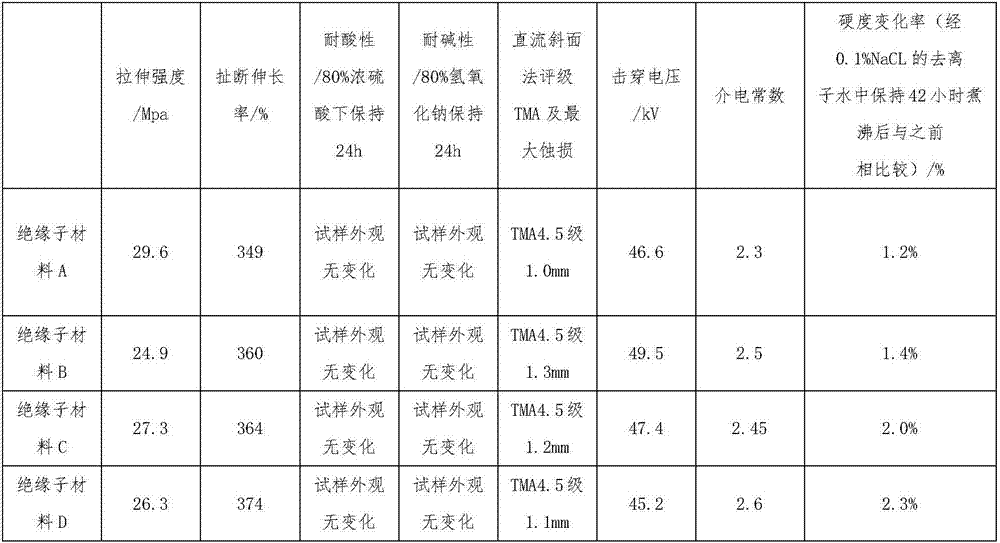

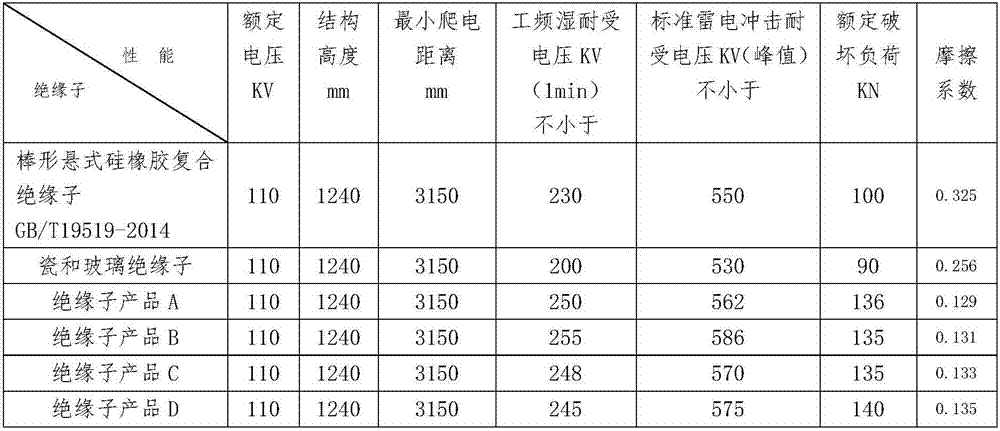

Polymeric crystalline silicon insulator material for direct-current power transmission as well as preparation method and application thereof

InactiveCN107151367AIncrease internal stressImprove process flow properties and mold release performancePlastic/resin/waxes insulatorsPolypropyleneCorrosion

The invention discloses a polymeric crystalline silicon insulator material for direct-current power transmission as well as a preparation method and application thereof. Raw materials of the polymeric crystalline silicon insulator material comprise phenolic latex, silicone, polyethylene, polypropylene and an ultraviolet absorber. The polymeric crystalline silicon insulator material for the direct-current power transmission is used for manufacturing a direct-current power transmission insulator. An insulator made by adopting the polymeric crystalline silicon insulator material not only can meet the electrical performance and the mechanical performance requirement of a conventional insulator, but also can meet a service life requirement, can also solve the electric corrosion resistance problem and the aging problem of a chute boot material under a direct-current voltage, has anti-fouling and self-cleaning functions, is high in cost performance, is energy-saving and environment-friendly and is free from pollution; after reaching a service life period, a product can be recycled.

Owner:JIANGSU JINSANLI POWER EQUIP

Surface coating method of aluminum alloy wheel

PendingCN111763944AImprove bindingImprove stress residueVacuum evaporation coatingPretreated surfacesTitanium fluorideOxygen ions

The invention discloses a surface coating method for an aluminum alloy wheel. The surface coating method comprises the following steps of S1, grinding and polishing the aluminum alloy wheel; S2, cleaning the aluminum alloy wheel; S3, immersing the aluminum alloy wheel in a titanium fluoride / zirconium fluoride solution, thereby forming an Al2O3.ZrO2.TiO2 conversion film on the surface of the aluminum alloy wheel; S4, ionizing oxygen with the concentration of 99.999% through radio frequency, and forming oxygen ions to treat the surface of the aluminum alloy wheel; S5, adding acetylene gas whilecarrying out magnetron sputtering coating; and S6, spraying a transparent protective layer, baking and curing. The coating film is better in corrosion resistance, low in cost and low in energy consumption, toxic metal such as hexavalent chromium is not contained, and the technological process is green and environmentally friendly.

Owner:CITIC DICASTAL

Pipe for transporting poisonous gas

InactiveCN110440093AStrong enoughSufficiently corrosiveAnti-corrosive paintsEpoxy resin coatingsToxic gasWear resistant

The invention discloses a pipe for transporting poisonous gas. The pipe comprises a pipe body, wherein the inner wall of the pipe body is coated with a corrosion-resistant layer, a plurality of wear-resistant protrusions are arranged on the inner wall of the pipe body, the top surfaces of the wear-resistant protrusions penetrate through the corrosion-resistant layer and is arranged in an inner cavity of the pipe body, a protective layer is arranged on the outer wall of the pipe body, the pipe body is a cement pipe, and the protective layer is a polymer cement-based waterproof coating layer. The pipe is high in corrosion resistance and can effectively prevent corrosive substances in the poisonous gas from corroding the pipe, so that the service life of the pipe can be remarkably prolonged.

Owner:张浩

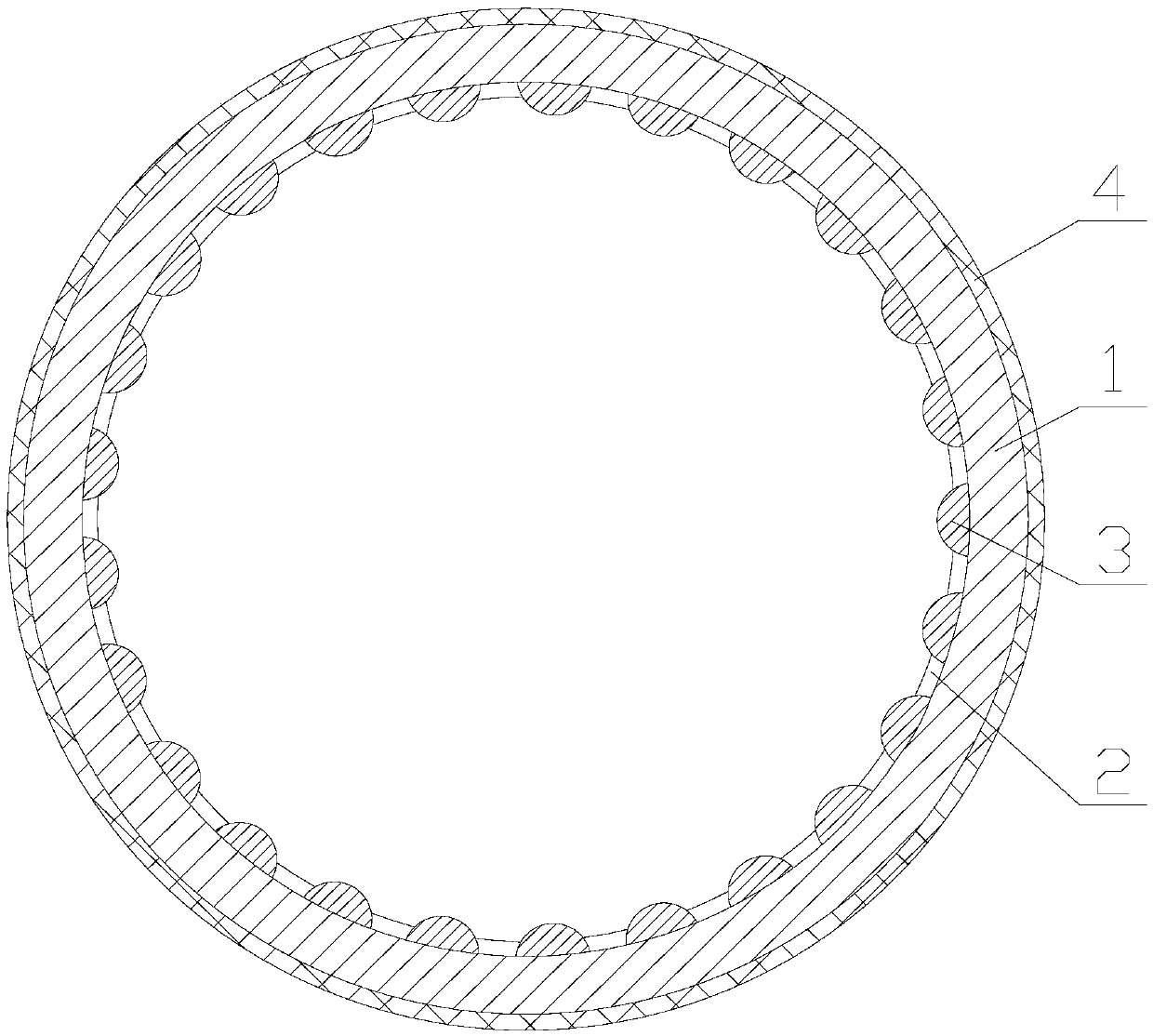

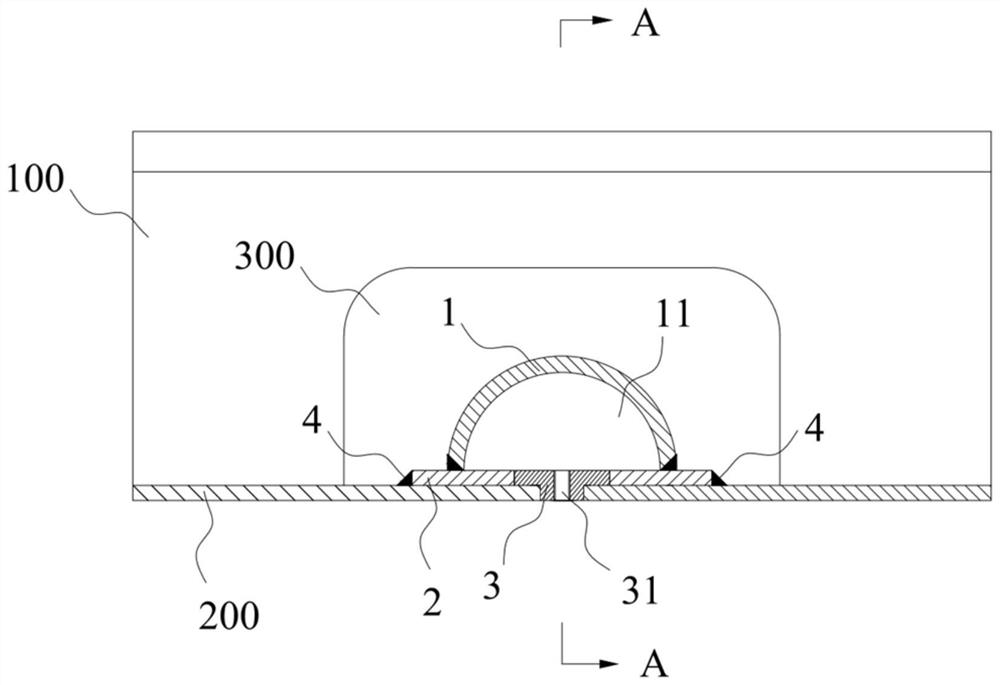

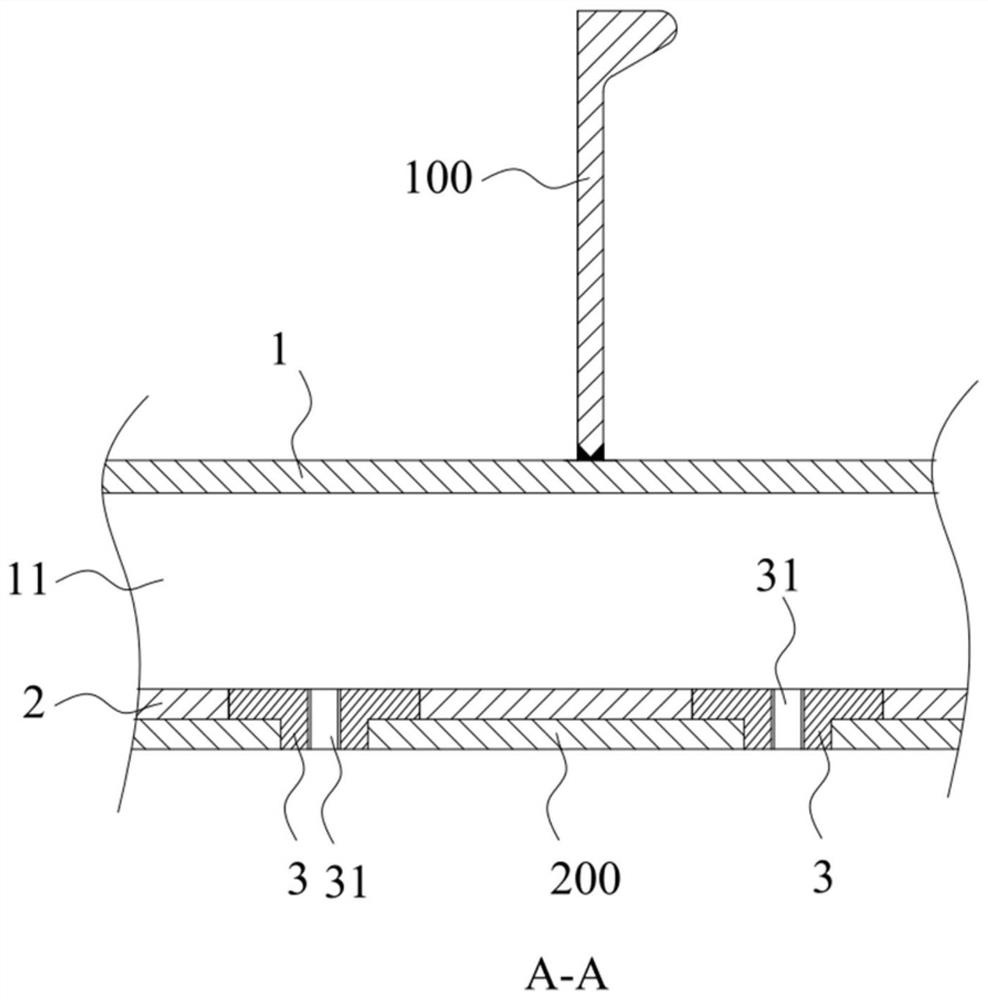

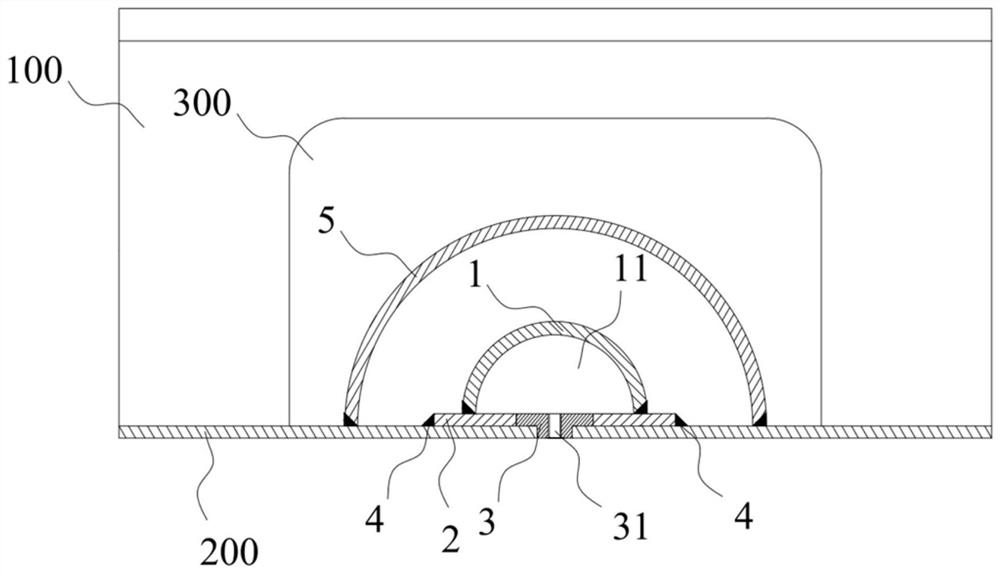

Corrosion-resistant pressure stabilizing cavity structure suitable for air layer drag reduction ship

PendingCN112810748AImprove corrosion resistanceGuaranteed tightnessWatercraft hull designHydrodynamic/hydrostatic featuresMechanical engineeringHull

The invention discloses a corrosion-resistant pressure stabilizing cavity structure suitable for an air layer drag reduction ship, and relates to the technical field of ship energy conservation and drag reduction. The pressure stabilizing cavity comprises multiple PE pipes and a base plate, the multiple PE pipes extend in the width direction of the ship body, and the multiple PE pipes are distributed in parallel in the length direction of the ship body at intervals and penetrate through longitudinal ribs of the ship; the PE pipe is provided with a first opening, the first opening extends in the width direction of the ship body, and the two sides, in the width direction of the first opening, of the PE pipe are connected with the ship bottom plate to form a pressure stabilizing cavity; the base plate extends in the width direction of the ship body, is made of a corrosion-resistant material and is located between the PE pipe and the ship bottom plate, and the base plate is in sealed connection with the PE pipe and the ship bottom plate; a first through hole is formed in the base plate, a second through hole communicated with the first through hole is formed in the ship bottom plate, and the pressure stabilizing cavity is communicated with the outside of the ship body through the first through hole and the second through hole. The pressure stabilizing cavity is made of a PE material, so that the corrosion-resistant effect is better; and the base plate made of the corrosion-resistant material also reduces the corrosion of the ship bottom plate.

Owner:CSIC SHANGHAI MARINE ENERGY SAVING TECH DEV CO LTD

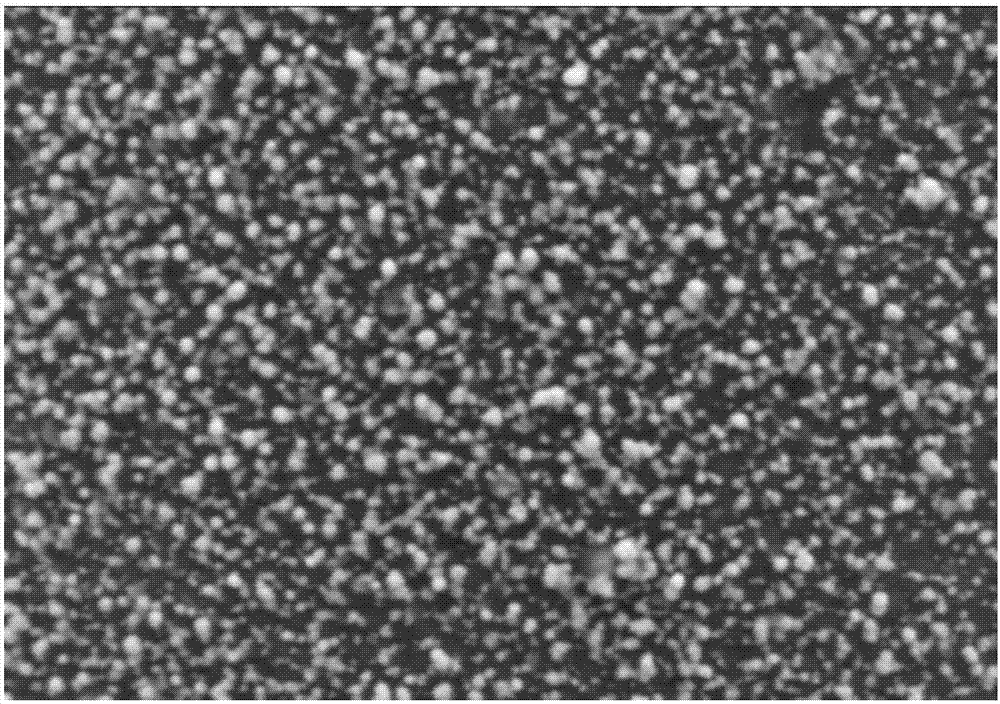

A kind of water-based nano-ceramic composite coating and coating method thereof

ActiveCN106349926BSolve the real problemEasy to processPretreated surfacesAnti-corrosive paintsCeramic compositeNanoceramic

The invention discloses a preparation method of a water-based nano ceramic composite coating. The water-based nano ceramic composite coating is prepared from the following components in parts by mass: 5 to 15 percent of water-based acrylic polymer, 5 to 20 percent of silica sol solution, 23 to 40 percent of siloxane, 2 to 15 percent of alcohols, 10 to 15 percent of deionized water and a trace amount of metal oxide. The preparation method of the casing comprises the following steps: stirring at normal temperature and normal pressure for 20 to 60 minutes by a reactor, and generating reaction to form composite resin; then adding 10 to 40 percent of pigment and 0.1 to 5 percent of weak acid; stirring at the normal temperature and the normal pressure for 5 to 60 minutes and curing, thereby finishing the preparation of the coating.

Owner:国钛(福建)新材料有限公司

Anti-oxidation counter weight device resistant to self-excited vibration for high voltage overhead transmission line

ActiveCN103915805AEasy to installWeld firmlyDevices for damping mechanical oscillationsSelf excitedEngineering

The invention discloses an anti-oxidation counter weight device resistant to self-excited vibration for a high voltage overhead transmission line. The anti-oxidation counter weight device comprises counter weight sheets and is characterized in that the counter weight sheets are provided with counter weight sheet installation barrels relatively matched with the counter weight sheets, and each counter weight sheet installation barrel is mainly composed of a barrel body, a barrel cover and a barrel bottom. A sleeving hole A is formed in the middle of each counter weight sheet, the two sides of the counter weight sheet are respectively provided with a sleeving hole B, the cross sections of the sleeving hole A and the sleeving hole B are respectively circular, and the diameter of the sleeving hole A is larger than that of the sleeving holes B. The anti-oxidation counter weight device is simple in structure and ingenious in design. A traditional counter weight sheet is simply transformed. The additional counter weight installation barrels matched with the counter weight sheet enable the counter weight sheets to be prevented from being in contact with the outside, and the counter weight device is resistant to oxidation, corrosion and the like. Meanwhile, the counter weight device is convenient and fast to install, and supporting rods are arranged between the counter weight sheets, so that the counter weight sheets fit firmly.

Owner:ANHUI WEI LONG POWER EQUIP

Preparation method for composite material of lightweight structure

ActiveCN107142448AReduce weightImprove integritySolid state diffusion coatingSurface layerEnergy absorption

The invention belongs to the field of composite metal materials, and particularly relates to a preparation method for a composite material of a lightweight structure. The preparation method comprises the steps that under the condition of vacuum heat treatment, Al-Ti-Sic alloy powder is loaded on the surface layer of a porous matrix material by adopting a thermal permeation technology, the surface of the alloy powder is coated with polyurethane resin, and then the alloy powder is dried. A high-strength alloy coating is loaded on the surface layer of the matrix material, the compactness and strength of the internal hole connection structure of the matrix material are kept, the tensile strength and the extensibility of the material are effectively enhanced, and the impact resistance is improved. An automobile fender and the related structural members made of the material are high in impact resistance and energy absorption performance, and more superior in size-mass ratio.

Owner:GUANGZHOU YUEWANG AGRI CO LTD

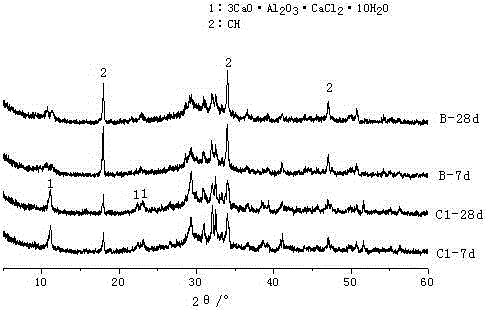

A kind of marine cement mixed with modified metakaolin

InactiveCN104108890BImprove resistance to chloride ion penetrationIncreased durabilityCement productionWork performanceSlag

The invention belongs to the technical field of building materials, and particularly relates to a marine cement doped with modified metakaolin. The marine cement doped with modified metakaolin is prepared by evenly mixing the following raw materials at a certain weight ratio: portland cement, slag powder, pulverized fuel ash, silica fume, white carbon black and modified metakaolin. The marine cement doped with modified metakaolin has the advantages of being simple in preparation technology, good in anti-cracking performance and the like; the chloride ion penetration resistance property of the concrete can be improved obviously, the anti-erosion capability of concrete in a large-volume water conservancy project under a marine environment can be solved, and the durability, strength and other working performances of a concrete structure in the water conservancy project under a marine environment can be enhanced.

Owner:TONGJI UNIV

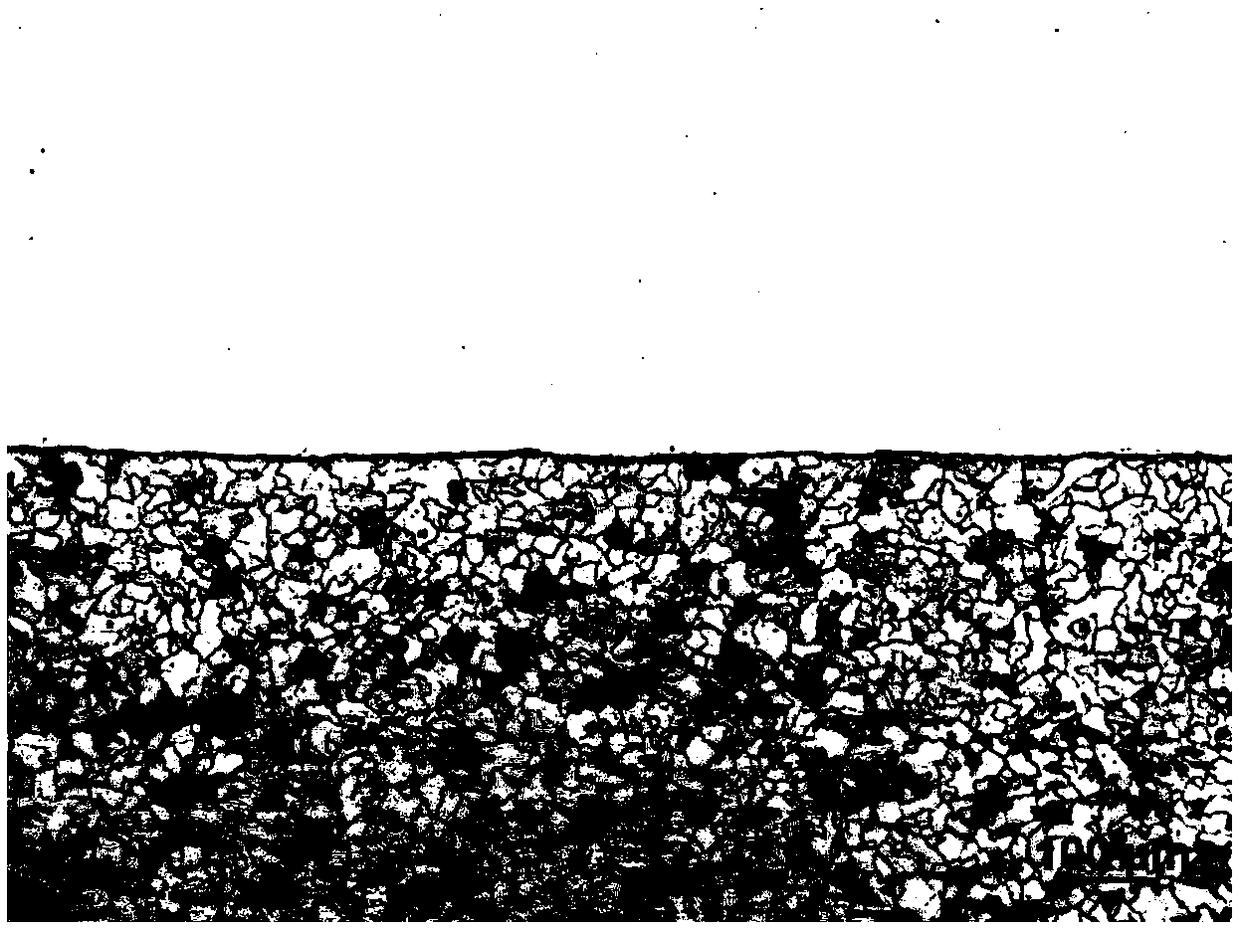

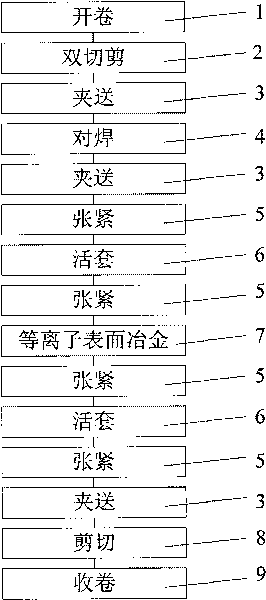

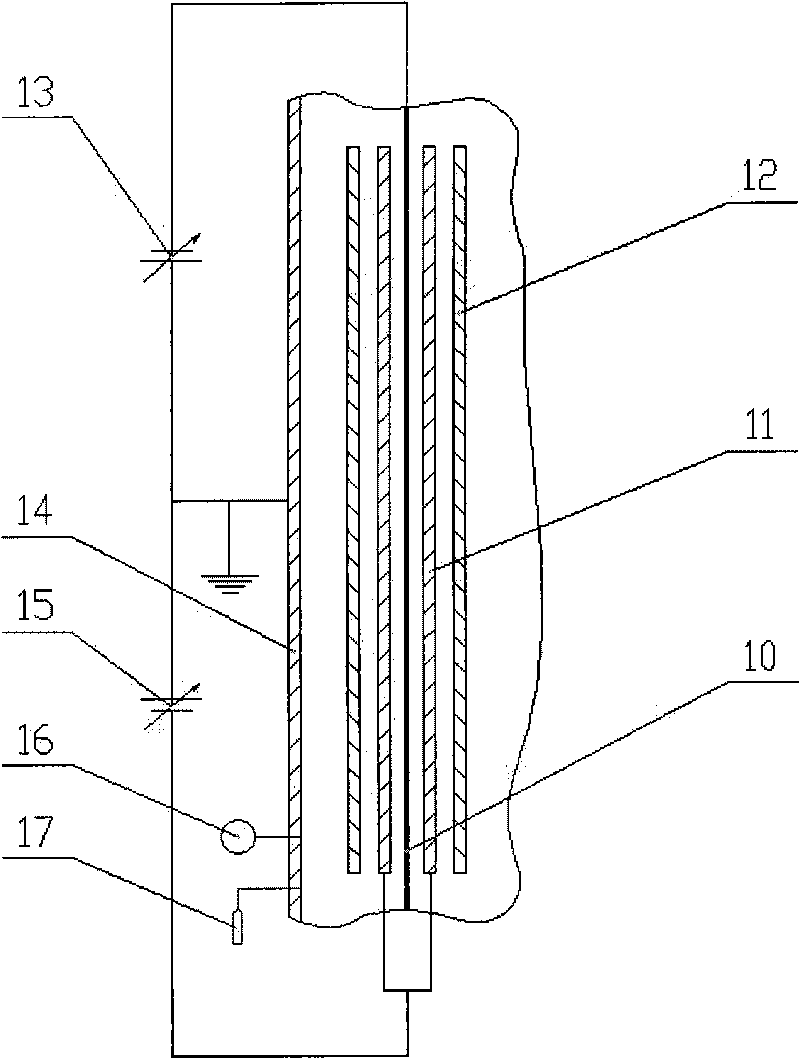

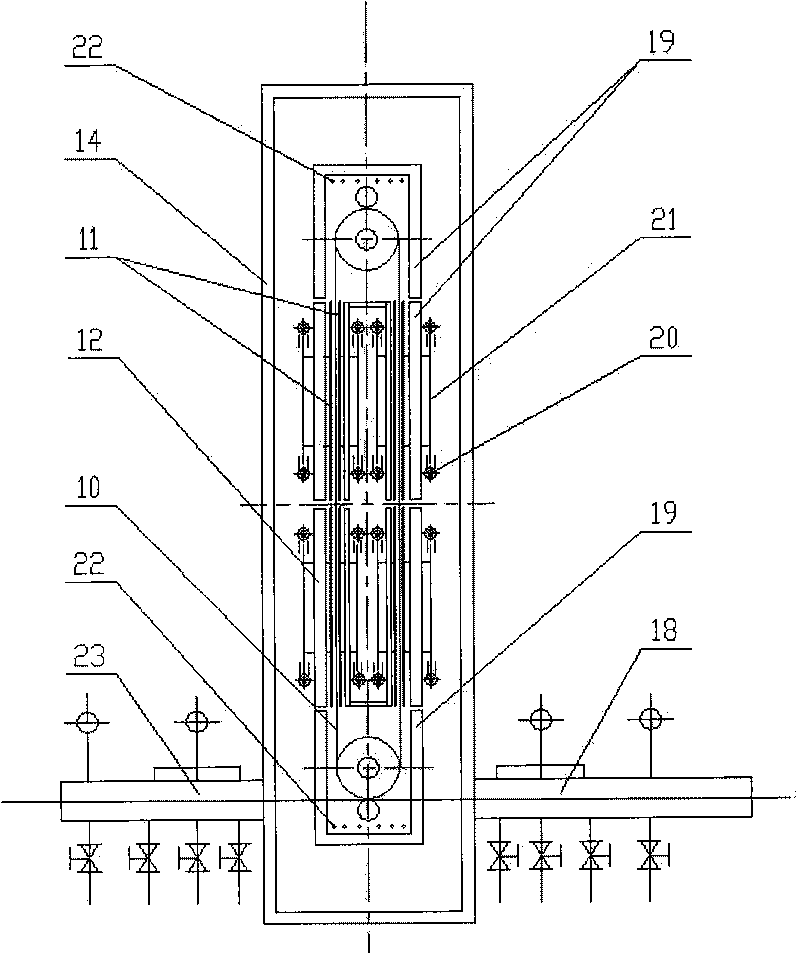

Method and device for producing plasma surface metallurgical metal wire

InactiveCN101736306AImprove the uniformity of the penetration layerImprove production efficiency and outputVacuum evaporation coatingSputtering coatingCarbon steelPlasma surface

The invention relates to a method and a device for producing a plasma surface metallurgical metal wire, comprising the following steps of: inputting a metal wire into a plasma chamber and carrying out plasma surface metallurgical treatment on the metal wire; and then outputting the treated metal wire, wherein the whole process is carried out in a protective atmosphere. The invention also provides a production device for realizing the production method, comprising an inlet transitional chamber, an outlet transitional chamber and at least one plasma surface metallurgical chamber, wherein the metal wire can continuously move among source electrodes to carry out the plasma surface metallurgical treatment. The production method and the production device can realize the plasma surface metallurgical treatment on the metal wire, acquire the metal wire with high performance and uniform infiltration layer and effectively solve the difficult problems of rust and corrosion of carbon steel wires and high strength, modulus and elasticity of stainless steel materials.

Owner:BEIJING SHIJI HUIGUANG TECH DEV

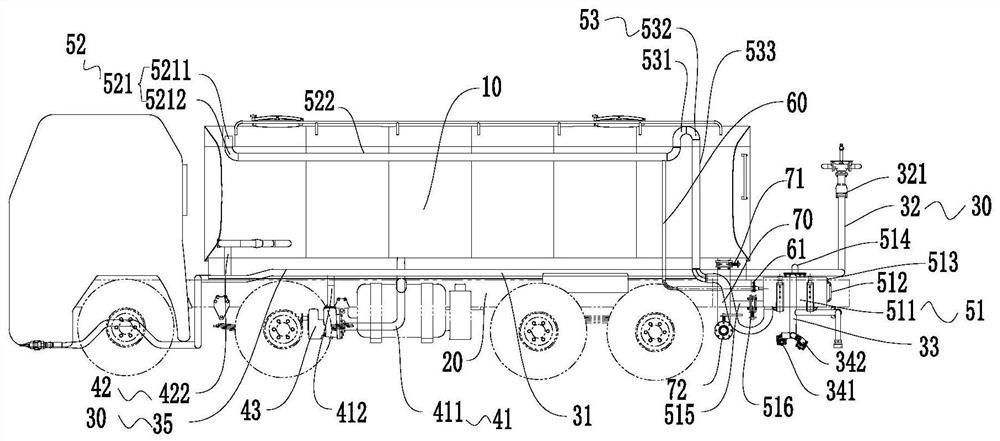

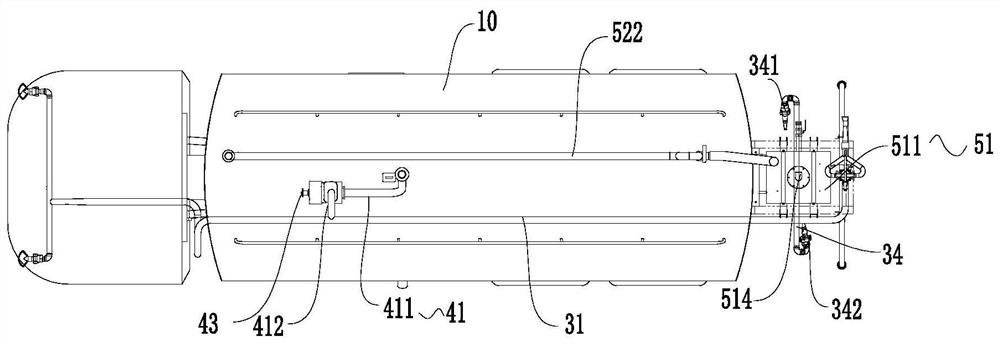

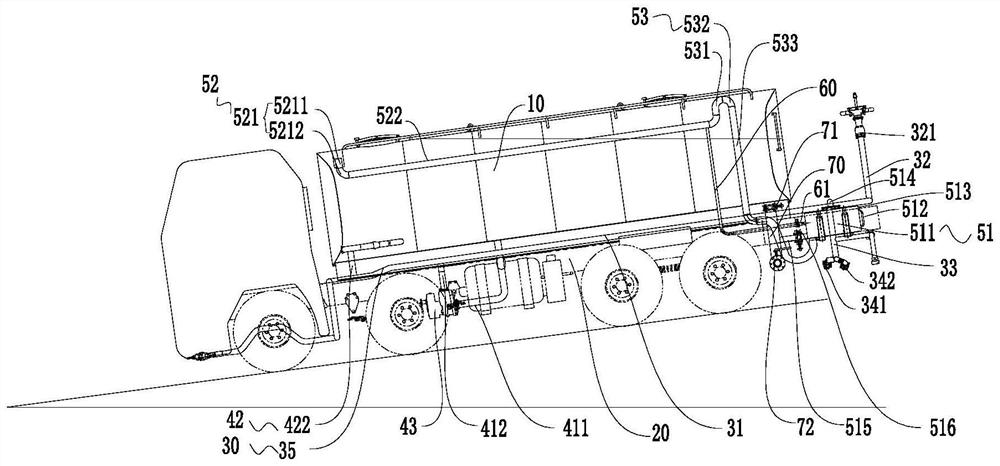

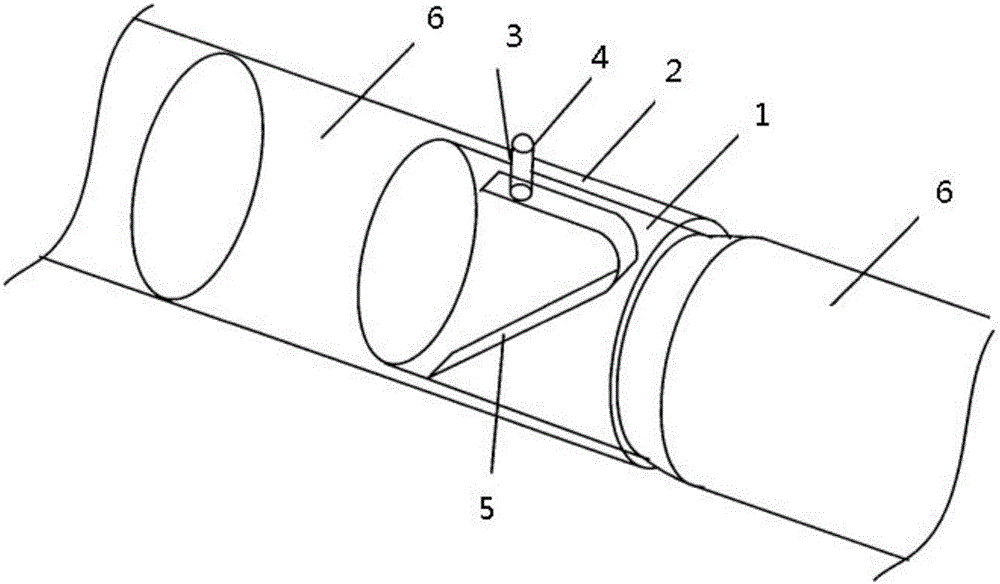

Sanitation vehicle

PendingCN113373843AUniform concentrationSolve the problem of corrosion resistanceWatering devicesRoad cleaningAgricultural engineeringTruck

The invention provides a sanitation vehicle. The sanitation vehicle comprises a tank body which is connected with the chassis; a pipeline system, wherein part of the pipeline system is connected with the chassis, the pipeline system comprises an operation pipeline and a circulation pipeline, the circulation pipeline comprises a liquid inlet pipeline, a liquid outlet pipeline and a driving part, the first end of the liquid inlet pipeline is communicated with the tank body, the second end of the liquid inlet pipeline is communicated with the operation pipeline, the first end of the liquid outlet pipeline is communicated with the operation pipeline, the second end of the liquid outlet pipeline is communicated with the tank body, and a driving part is positioned on the liquid inlet pipeline; wherein the driving part drives the liquid in the tank body to circulate for a preset time through the liquid inlet pipeline, the liquid outlet pipeline and the operation pipeline, and then drives the circulated liquid to be discharged through the operation pipeline for operation. By the adoption of the technical scheme, the sanitation truck is simple and reliable in structure, and the problem that in the prior art, a pipeline of a sanitation truck is not resistant to corrosion is solved.

Owner:BEIJING ENVIRONMENT SANITATION ENG GRP CO LTD

Wall hanging type empaistic picture preparation process

InactiveCN1634714BAvoid exposureSolve high temperature resistanceDecorative surface effectsSpecial ornamental structuresUltravioletPulp and paper industry

Owner:NORTHEAST FORESTRY UNIVERSITY +3

Manufacturing method of aluminum alloy petroleum drill rod

The invention relates to the field of metal equipment manufacturing methods, in particular to a manufacturing method of an aluminum alloy petroleum drill rod. The aluminum alloy petroleum drill rod is a hollow round pipe. The manufacturing method is characterized by comprising the following steps of casting, extrusion, drawing, correction, finishing and forming of an outer edge combining portion and an inner edge combining portion, manufacturing of a match-working drill locking hole and a locking ball, manufacturing of aluminum-alloy contracted pipes and rope arrangement inside the aluminum-alloy pipes. The manufactured drill rod is high in strength, the outer edge combining portion and the inner edge combining portion of the connecting portion are roll-formed by adopting a cold rolling process, a concentrated stress is small through annealing treatment, the lengths of the outer edge combining portion and the inner edge combining portion are 12%-15% of the total length of a tubular material semi-finished product, the strength of the bonding portion is ensured, the locking hole at the combined position of the outer edge combining portion and the inner edge combining portion which are adjacent is the match-working drill hole, the installing precision is high, the aluminum-alloy contracted pipes are connected by adopting ropes, and convenience is brought to installation and connection.

Owner:JIANGSU DESHENG ENERGY ENVIRONMENT PROTECTION EQUIP ENG CO LTD

A method for producing anhydrous hydrogen fluoride from ammonium fluoride acidolysis mixed liquor

ActiveCN106241740BHigh recovery rateReduce moisture contentHydrogen fluorideHydrogen fluorideAcid hydrolysis

The invention relates a fluorine-containing compound, in particular to a method for producing anhydrous hydrogen fluoride from an acid hydrolysis mixed solution of ammonium fluoride. The method comprises the following steps: 1) heating concentrated sulfuric acid to 170-220 DEG C, and keeping circulation; 2) spraying the acid hydrolysis mixed solution of ammonium fluoride to the surface of the circulating concentrated sulfuric acid, collecting gas, and performing cooling to obtain a hydrogen fluoride crude product; and 3) performing rectification and degassing on the hydrogen fluoride crude product to obtain an anhydrous hydrogen fluoride product. By use of the method provided by the invention, the anhydrous hydrogen fluoride product of which the content is more than 99.9% can be obtained, and the recovery rate of hydrogen fluoride is more than 92%. The method provided by the invention has the characteristics of simple process, low energy consumption, and safe and reliable operation, solves the problem of corrosion resistance of equipment, and improves the utilization rate of the equipment.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

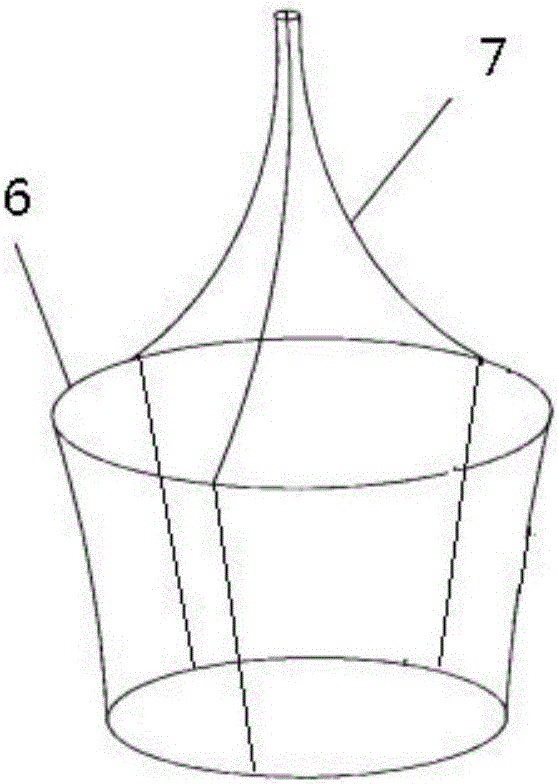

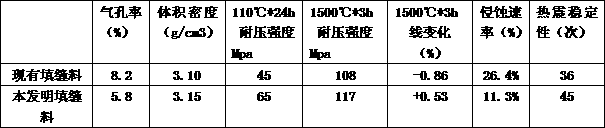

Steel ladle brick cup joint filler and preparation method thereof

The invention discloses a steel ladle brick cup joint filler which is prepared from raw materials: by weight parts, corundum, Al2O3 powder, fused magnesite, cement and composite additive, wherein Al2O3 powder is mixed from alpha-Al2O3 powder and rou-Al2O3 powder. The joint filler of new design and its construction solve the problem of air leakage of the steel ladle thoroughly, also solve the problem that corundum fluid has poor corrosion resistance and has poor protective effect to the periphery of the brick cup, improve production efficiency of steel mills, and reduce labor intensity.

Owner:ANHUI PROVINCE XIAO COUNTRY HUALONG REFRACTORY MATERIALS

Anti-rusting method of galvanized iron tower member

InactiveCN102335649ASave moneyMethod sciencePretreated surfacesAnti-corrosive paintsLacquerSpray coating

The invention relates to an anti-rusting method of a galvanized iron tower member. The anti-rusting method is mainly used for solving the problems that, the galvanized iron tower member is not corrosion-resistant, easy to get rusty and short in service life, the structural strength is reduced, the potential safety hazard is generated, and collapse and power outage accidents of an iron tower are further caused in the prior art. The process of the method according to the invention is as follows: brush-coating a conductive glue solution with the repair function on the surface of the assembled galvanized iron tower member, further pressing the glue solution into gas holes, hair eyes, gaps and exposed scars in a galvanized layer through the high pressure method for tamping, blocking and sealing, spray-coating anti-aging, water-repellent and dirt-resistant clear lacquer on the surface of a glue film after the glue film is hardened, brush-coating a silicon rubber layer at the part which is 1m away from the member at the root part of the iron tower after the lacquer forms a film, and further preparing the product prepared by the method according to the invention. The anti-rusting method of the galvanized iron tower member is scientific, simple in process and convenient to use, and can save the material cost, the implementation can be followed after the galvanization process of a galvanization workshop, and the product has the advantages of corrosion resistance, rustless property, friction resistance, water resistance, pollution prevention, long service life of 30 years, maintenance-free updating, safety, reliability and significant economic benefits and can be widely used on land and in water.

Owner:SHANDONG HUAAN TOWER CO LTD

Double-layer epoxy resin coating reinforcing steel bar

InactiveCN102943547ASimple structureExtended service lifeBuilding reinforcementsBuilding insulationsMetallurgyPowder coating

The invention belongs to the field of building materials, and in particular relates to a double-layer epoxy resin coating reinforcing steel bar which comprises a reinforcing steel bar body. The reinforcing steel bar is characterized in that a corrosion resisting layer and a wearing layer are coated at the periphery of the reinforcing steel bar body in sequence, wherein the corrosion resisting layer adopts seawater resisting type melting combined epoxy modified powder coating layer; and the wearing layer adopts a wearing resisting type melting combined epoxy modified powder coating layer. The double-layer epoxy resin coating reinforcing steel bar is simple in structure; due to the corrosion resisting layer, and the reinforcing steel bar is prevented from being corroded, so that the service life of the reinforcing steel bar is prolonged, and the construction quality is improved; and due to the outermost wearing layer, the reinforcing steel bar is prevented from being damaged in the transportation or construction process, so that the quality of the reinforcing steel bar is ensured.

Owner:SHANDONG DERUI ANTI-CORROSION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com