Manufacturing method of temperature sensor

A technology for temperature sensors and manufacturing methods, applied to parts of thermometers, thermometers, instruments, etc., capable of solving problems such as poor sealing and waterproof performance of temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

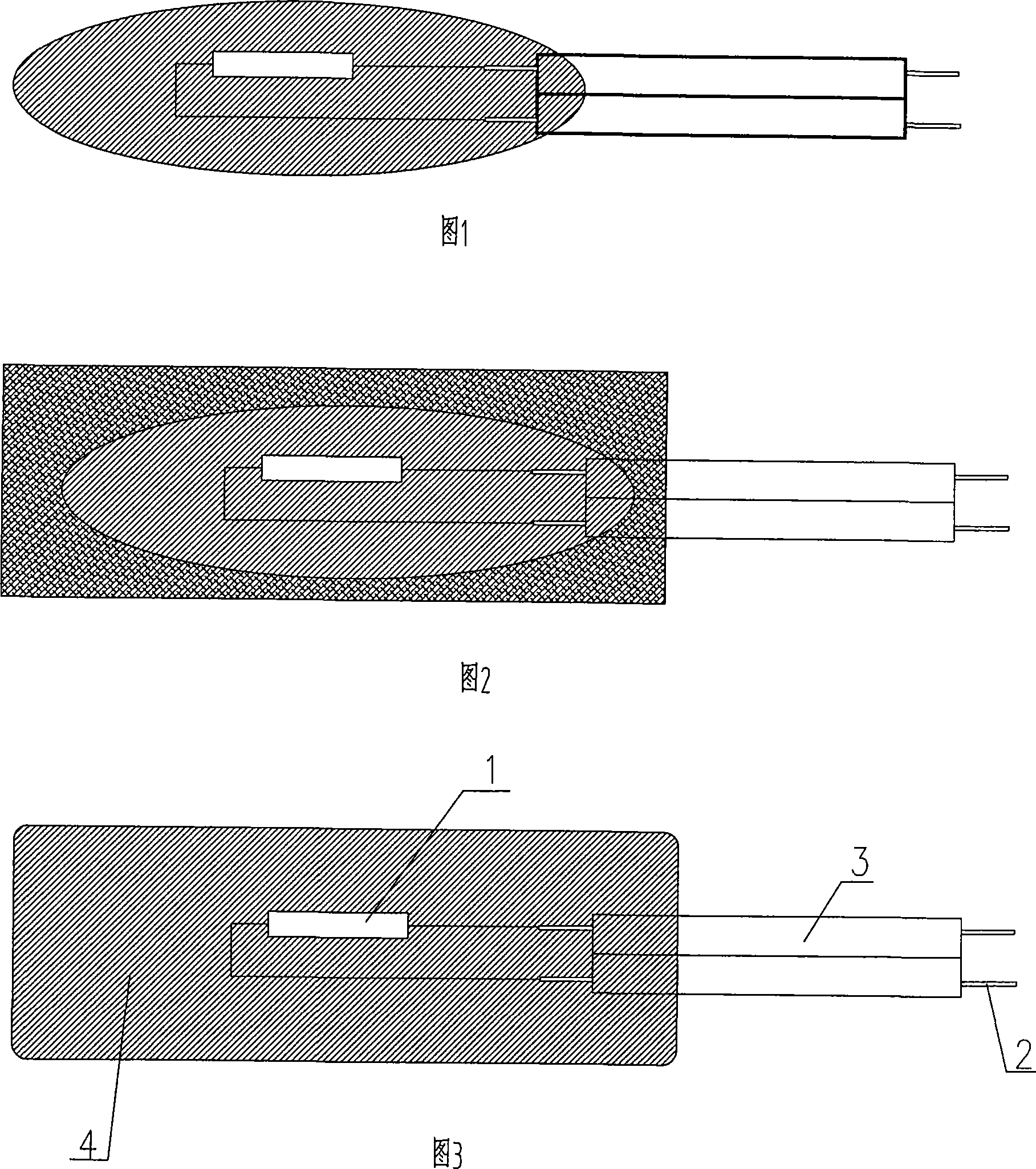

[0014] A method for manufacturing a temperature sensor. After the thermistor 1 is connected to the wire 2 by welding or welding, the same material as the wire insulation layer 3 is used as the coating layer 4 of the thermistor 1. The material can be PVC, PE, TPE or Teflon, heated and pressurized, the heating temperature is within the range of ±20°C of the melting point of the material, and the pressure range is 2-5MP, and the coating layer 4 and the wire insulation layer 3 are mutually fused into one structure. Ensure that the thickness of the cladding layer is ≥0.2mm, and at the same time make the thickness ≥0.5mm as much as possible, so as to ensure that the cladding layer can effectively protect the thermistor inside the cladding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com