Aluminum alloy electroless nickel plating mixed metal activation method

A mixed metal and electroless nickel plating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as environmental pollution, nickel layer peeling, nickel plating solution pollution, etc., to reduce production costs, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

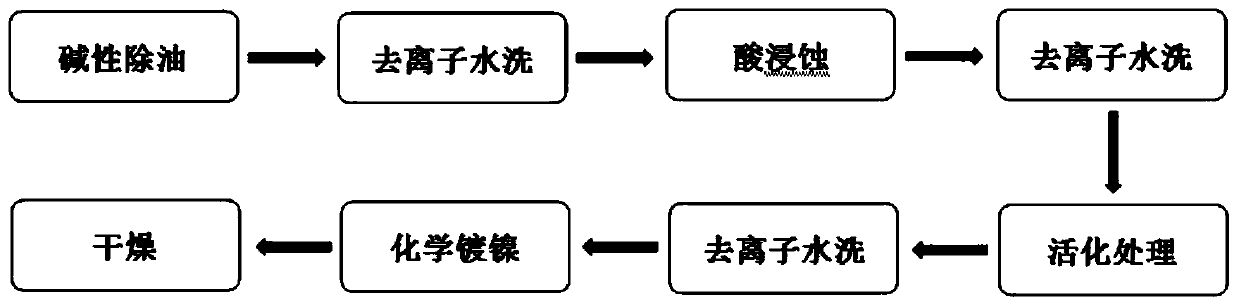

Method used

Image

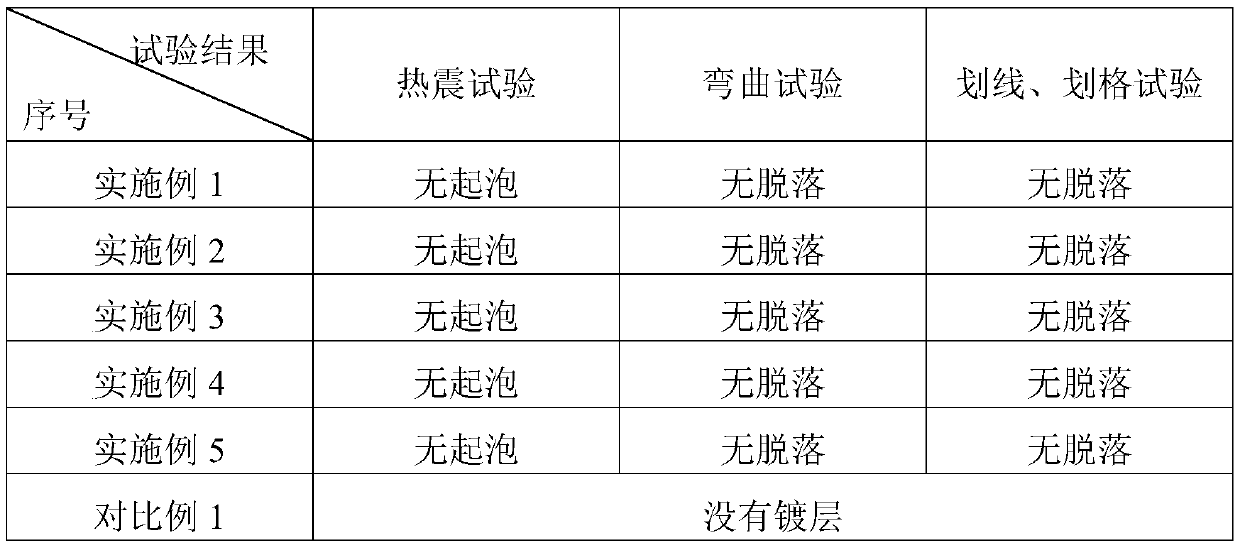

Examples

Embodiment 1

[0030] 1. Alkaline degreasing liquid components: 10g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, 10g / L sodium phosphate;

[0031] 2. Preparation of acid etching solution: Measure 10ml of hydrochloric acid, add it to 90ml of deionized water, and stir evenly to obtain acid etching solution;

[0032] 3. The components of the acidic mixed metal activation solution: 0.02g / L palladium chloride, 1ml / L concentrated hydrochloric acid, 0.02g / L ammonium chloride, 10g / L nickel chloride.

[0033] A method for activation of aluminum alloy electroless nickel plating mixed metals, said method comprising the steps of:

[0034] (1) The cutting area is 2×2cm 2 Put the aluminum substrate into the alkaline degreasing solution for alkaline degreasing for 5 minutes at a temperature of 70°C, and then fully wash with deionized water;

[0035] (2) Put the degreased substrate into the acid etching solution for 60s, the temperature is 25°C, and then fully wash it with deionized wa...

Embodiment 2

[0038] 1. Alkaline degreasing liquid components: 20g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, 20g / L sodium phosphate;

[0039] 2. Preparation of acid etching solution: Measure 30ml of hydrochloric acid, add it to 70ml of deionized water, and stir evenly to obtain acid etching solution;

[0040] 3. The components of the acidic mixed metal activation solution: 0.02g / L palladium chloride, 1ml / L concentrated hydrochloric acid, 0.03g / L ammonium chloride, 30g / L copper chloride.

[0041] A method for activation of aluminum alloy electroless nickel plating mixed metals, said method comprising the steps of:

[0042] (1) The cutting area is 2×2cm 2 Put the aluminum substrate into the alkaline degreasing solution for alkaline degreasing for 3 minutes at a temperature of 60°C, and then fully wash with deionized water;

[0043] (2) Put the degreased substrate into the acid etching solution for 15s, the temperature is 25°C, and then fully wash it with deionized wate...

Embodiment 3

[0046] 1. Alkaline degreasing liquid components: 10g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, 10g / L sodium phosphate;

[0047] 2. Preparation of acid etching solution: Measure 10ml of hydrochloric acid, add it to 90ml of deionized water, and stir evenly to obtain acid etching solution;

[0048] 3. Components of alkaline mixed metal activation solution: 0.05g / L silver sulfate, 0.03g / L ammonia water, 5g / L EDTA, 5g / L copper sulfate.

[0049] A method for activation of aluminum alloy electroless nickel plating mixed metals, said method comprising the steps of:

[0050] (1) The cutting area is 2×2cm 2 Put the aluminum base material into the alkaline degreasing solution for alkaline degreasing for 5 minutes at a temperature of 60°C, and then fully wash it with deionized water;

[0051] (2) Put the degreased substrate into the acid etching solution for 5s, the temperature is 25°C, and then fully wash it with deionized water;

[0052] (3) Put the acid-etche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com