Manufacturing method of aluminum alloy petroleum drill rod

An oil drill pipe and aluminum alloy technology, which is applied to the preparation field of aluminum alloy oil drill pipe, can solve the problems of great difference in performance, poor corrosion resistance, high cost, low requirements for thread size machining accuracy, simple assembly process, and high cost. The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

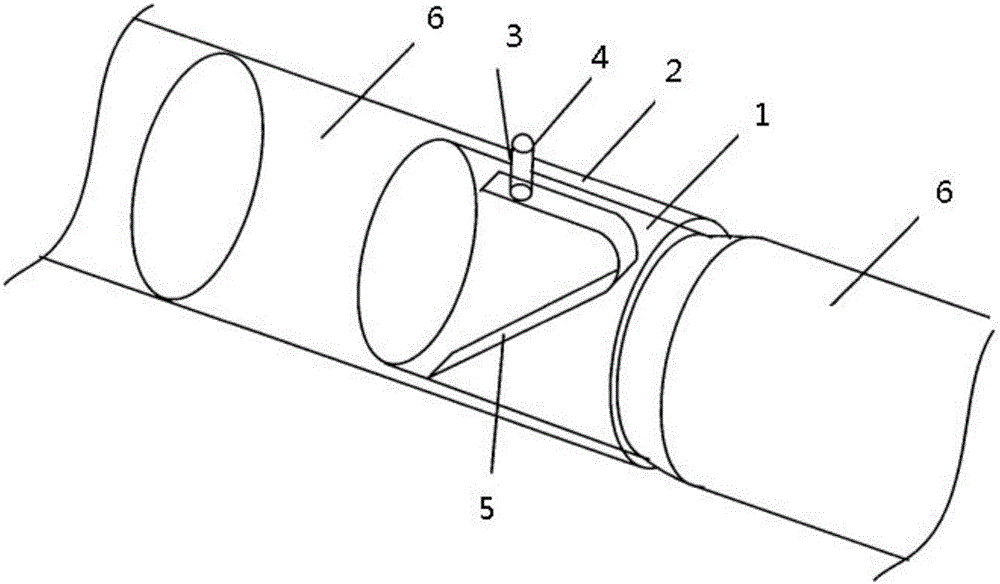

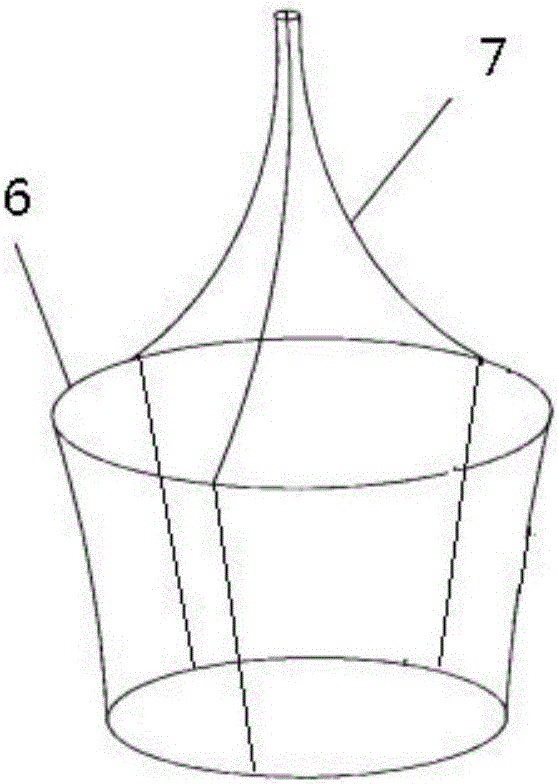

[0032] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described in conjunction with specific embodiments and accompanying drawings.

[0033] As attached to the manual figure 1 and figure 2 Shown: the preparation method of aluminum alloy oil drill pipe, the aluminum alloy oil drill pipe is a hollow tube, it is characterized in that it is carried out according to the following steps:

[0034] 1) Melting and casting: casting the molten aluminum alloy into a solid aluminum rod in the mold cavity;

[0035] 2) Extrusion: Extrude the aluminum rod into a hollow tube in the extrusion die;

[0036] 3) Stretching: The round tube is pulled out in a stretching machine with stretching inner and outer molds, and there are several strips on the outer surface of the stretching inner mold, which are at an angle of more than 0 degrees and 45 degrees with the axial direction. The fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com