Threaded connection type all-aluminum alloy drill stem

A threaded connection and aluminum alloy technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of complex production of all aluminum alloy drill pipes, high assembly precision, electrochemical corrosion, etc., and achieve low processing accuracy requirements, The effect of improving assembly efficiency and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

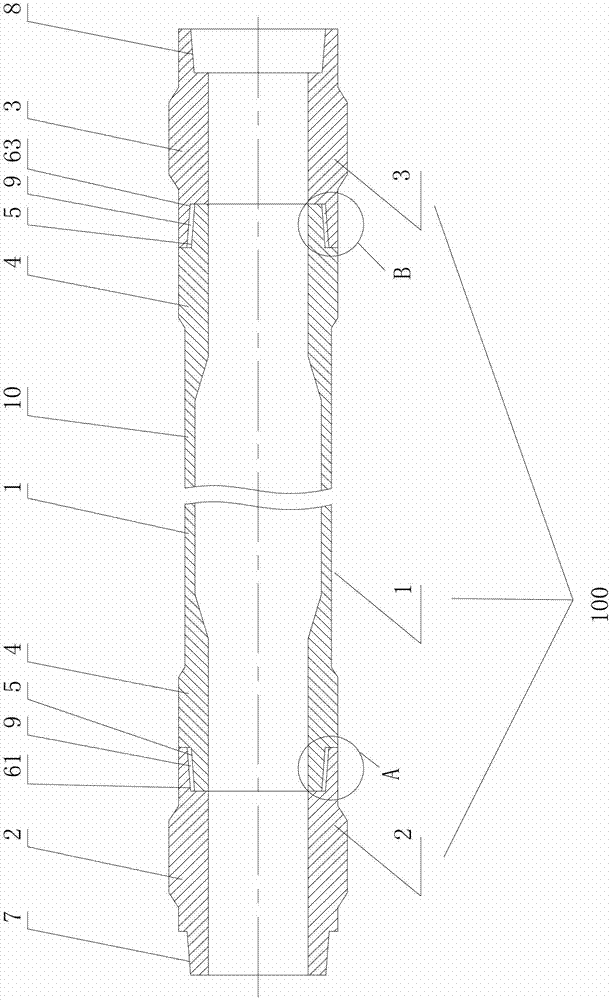

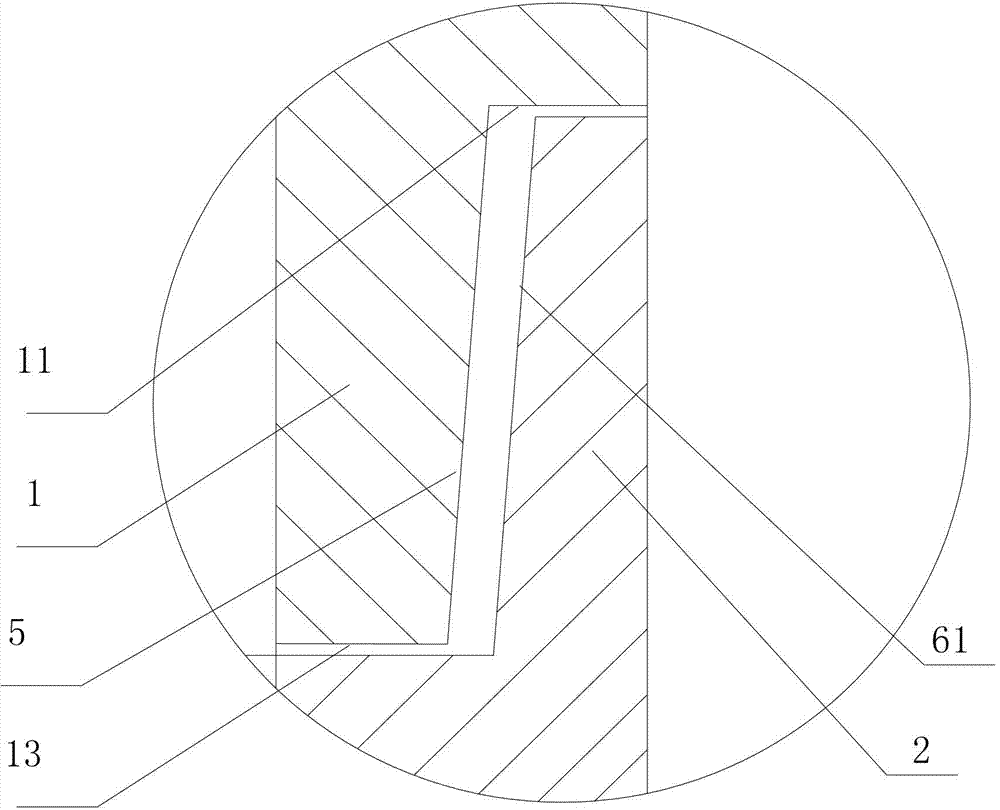

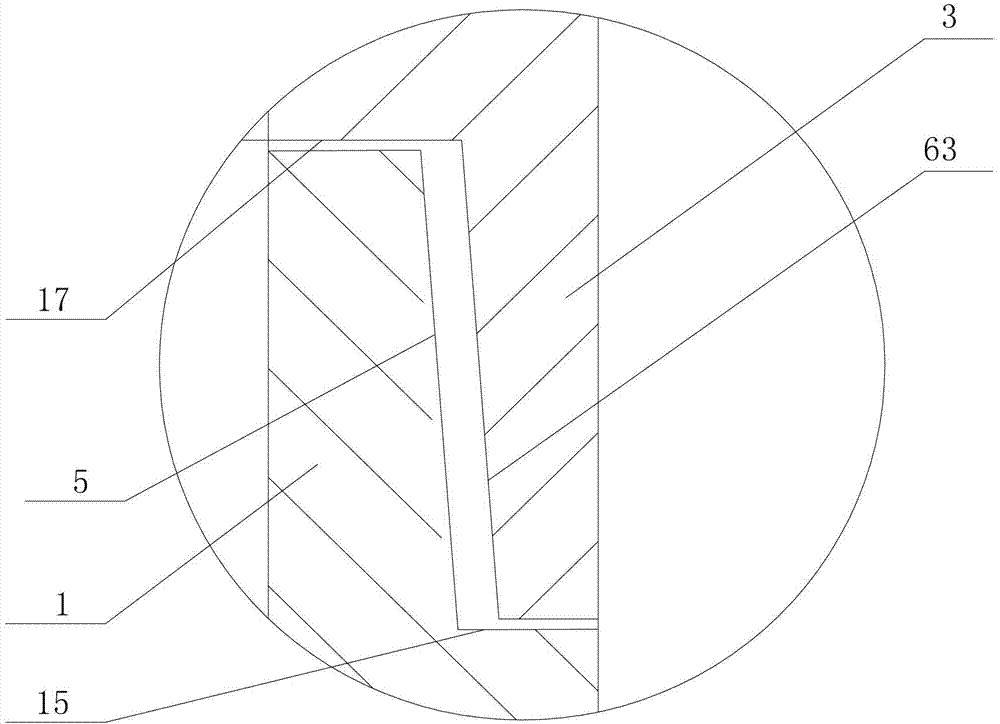

[0028] Such as figure 1 As shown, the threaded all-aluminum alloy drill pipe 100 according to the embodiment of the present invention includes: an aluminum alloy drill pipe body 1 and an aluminum alloy drill pipe joint threaded at the end of the aluminum alloy drill pipe body. Different from the existing aluminum alloy drill pipe with steel joints, the aluminum alloy drill pipe body 1 and the drill pipe joint of the present invention are both made of aluminum alloy, and the assembly of the aluminum alloy drill pipe body 1 and the drill pipe joint It is carried out at room temperature without hot charging process. Different from the existing integral all-aluminum alloy drill pipe, the aluminum alloy drill pipe body 1 and the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com