Double-layer epoxy resin coating reinforcing steel bar

A technology of epoxy resin coating and steel bars, which is applied to structural elements, building components, building insulation materials, etc., can solve the problems of affecting service life and project quality, poor wear resistance of steel bars, and easy corrosion, etc., to achieve simple structure, The effect of prolonging the service life and ensuring the quality of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

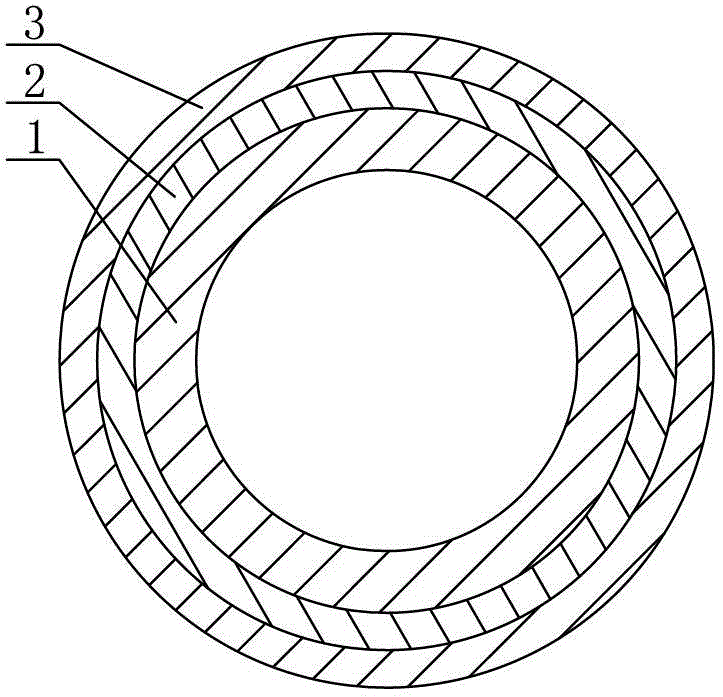

[0013] Such as figure 1 As shown, the double-layer epoxy resin-coated steel bar includes a steel bar body 1, and the outer periphery of the steel bar body 1 is sprayed with a corrosion-resistant layer 2 and a wear-resistant layer 3 in sequence. In this embodiment, the corrosion-resistant layer 2 is a seawater-resistant fusion-bonded epoxy-modified powder coating layer; the wear-resistant layer 3 is a wear-resistant fusion-bonded epoxy-modified powder coating layer.

[0014] The corrosion-resistant layer 2 can prevent the steel bars from being corroded, thereby prolonging the service life of the steel bars and improving the quality of the project. The outermost wear-resistant layer 3 can prevent the steel bars from being damaged during transportation or construction and ensure the quality of the steel bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com