Steel ladle brick cup joint filler and preparation method thereof

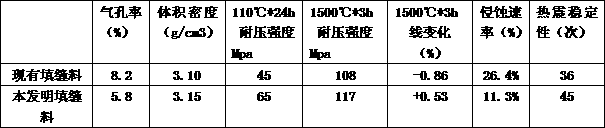

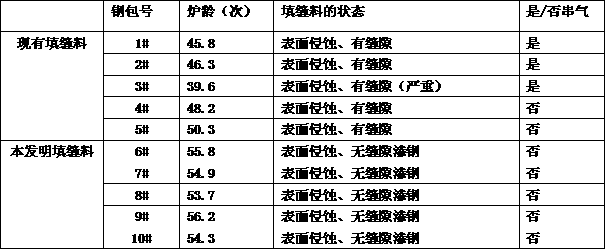

A joint filler and ladle seat technology, which is applied in the field of ladle seat brick joint sealant and its preparation, can solve problems such as easy penetration of molten steel, ladle off-line, gas leakage, etc., reduce labor intensity, improve production efficiency, and solve intolerance erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A ladle seat brick joint filler, raw materials: corundum, Al 2 O 3 Powder, fused magnesia, cement, composite additives in parts by weight, the Al 2 O 3 Powder by a-Al 2 O 3 Powder and ρ-Al 2 O 3 Powder composition.

[0023] Preferably, the a-Al 2 O 3 Powder is 500 mesh a-Al 2 O 3 Powder and 1 um a-Al 2 O 3 Mixture of powder.

[0024] The composite additive is composed of silicon micropowder, high-efficiency composite water reducer and explosion-proof fiber.

Embodiment 2

[0026] As a design of embodiment 1, the weight ratio of the raw materials: corundum 75-80%, Al 2 O 3 Powder 10-14%, cement 3-7%, fused magnesia 3-7%, compound additive 0.1-1%.

[0027] Preferably, the composite additive is composed of 55-70% silicon micropowder, 15-30% high-efficiency composite water reducer, and 10-20% explosion-proof fiber.

[0028] Preferably, the corundum is composed of corundum aggregate and corundum powder, wherein the corundum aggregate: corundum powder=4-5:1, and the corundum powder is 300-350 mesh.

Embodiment 3

[0030] A ladle seat brick joint filler is weighed according to the proportion, and then produced according to the following production process.

[0031] 1) Preparation of raw materials: corundum aggregate (5-3, 3-1, 0-1) 62.25%, corundum powder 325 mesh 15%, alumina powder 12% (a-Al 2 O 3 Powder and ρ-Al 2 O 3 Powder, a-Al 2 O 3 Powder is 500 mesh a-Al 2 O 3 Powder and 1 um a-Al 2 O 3 Mixture of powder), 70 cement 5%, 200 mesh fused magnesia 5%, composite additives (silicon powder 0.5%, high-efficiency composite water reducing agent 0.15%, explosion-proof fiber 0.1%);

[0032] 2) Preparation of pre-mixed powder: evenly mix the powder and compound additives for later use;

[0033] 3) Mixing: Add the aggregate in step 1) and the pre-mixed powder in step 2) to the mixer and stir for 1-2 minutes, then add 4.5% water, and stir for 3-5 minutes to release the material;

[0034] 4) Put the mixed material into a standard 40mm*40mm*160mm abrasive tool for sample preparation;

[0035] 5) Demouldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com