Method and device for producing plasma surface metallurgical metal wire

A technology of metal wire and production method, applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve problems such as production that cannot be segmented, unsuitable for plasma surface metallurgical treatment, etc., to improve production efficiency and Yield, guarantee requirements, and the effect of improving the uniformity of the seepage layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1 Single-chamber metal wire rod plasma surface metallurgy production device

[0074] The plasma surface metallurgy production device provided in this embodiment includes a plasma surface metallurgy chamber, which can be called a single-chamber metal wire plasma surface metallurgy production device.

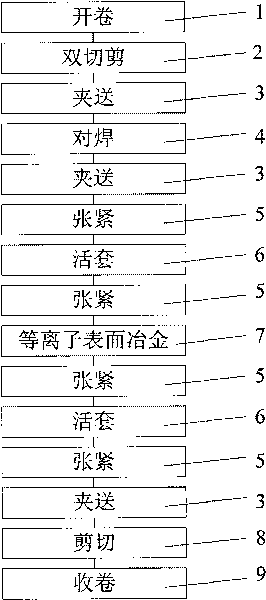

[0075] figure 1 The production flow chart of the plasma surface metallurgy metal wire provided by the present invention includes the following production process:

[0076] Uncoiling 1-double shearing 2-pinching 3-butt welding 4-pinching 3-tensioning 5-looper 6-tensioning 5-plasma surface metallurgy 7-tensioning 5-looper 6-tensioning 5-clip Sending 3-cutting 8-winding 9.

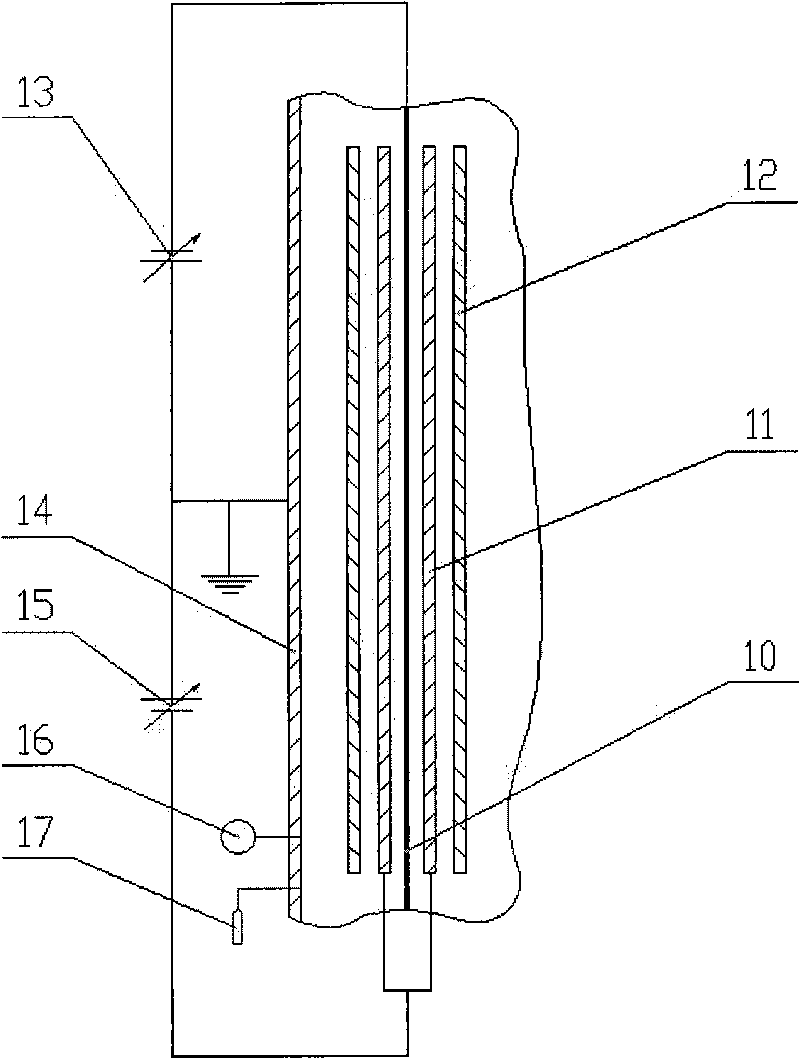

[0077] figure 2 It is a schematic diagram of the principle of the plasma surface metallurgy working section. Such as figure 2 As shown, the plasma surface metallurgy chamber (vacuum chamber, filled with inert gas during working state) is provided with a source electrode 11 made of alloyin...

Embodiment 2

[0088] Embodiment 2 Multi-chamber metal wire rod plasma surface metallurgy production device

[0089] In order to improve the uniformity of the production capacity and the infiltration layer of the metal wire rod on the circumferential surface, two or more plasma surface metallurgy chambers can be adopted on the basis of embodiment 1 to obtain a multi-chamber metal wire rod plasma surface metallurgy production device. The two plasma surface metallurgy chambers 58 are connected by a tension diverter 59, Figure 9 The specific connection method (top view) of the two metallurgical chambers is shown. The adjacent plasma surface metallurgy chambers are mutually rotated by 90°, and are connected by a tension diverter 59 (its specific structure is shown in Embodiment 3). steering function.

[0090] In order to complete the continuation of the previous process and the subsequent process of the production process and realize continuous production, multiple plasma surface metallurgy c...

Embodiment 3

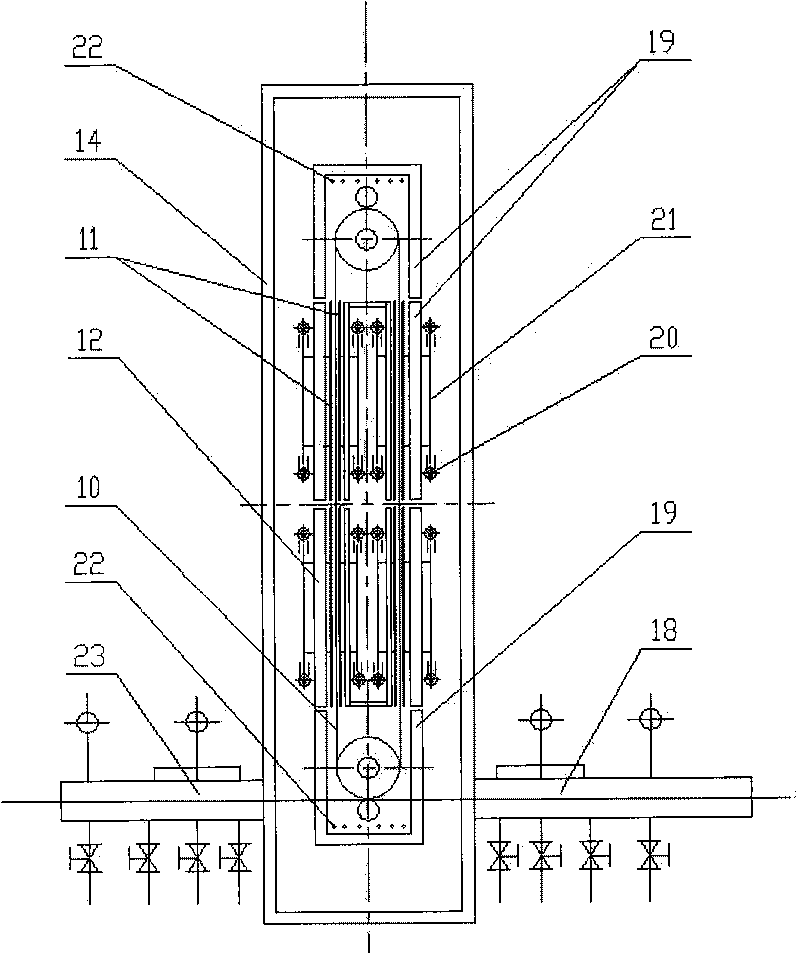

[0092] Embodiment 3 Tension steering gear

[0093] Such as Figure 7 and Figure 8 As shown, the tensioning diverter 59 includes a housing, which may be a sealed water-cooled housing 43, and a steering roller, a double-roller S tensioning device, and a guide device located in the cavity formed by the housing, and the tensioning diverter 59 It is respectively connected with the plasma surface metallurgy chambers on both sides through the inlet connecting pipe and the outlet connecting pipe, wherein:

[0094] The inlet connecting pipe and the outlet connecting pipe are connected with the housing 43 of the tensioning diverter 59, respectively forming the inlet and the outlet of the tensioning diverter 59, and forming the metal wire 10 to enter and exit at the corresponding position in the cavity formed by the housing 43. The entrance and exit of the cavity, the direction of the entrance and exit of the metal wire rod form an angle of 90° and are located on the same horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com