Method for increasing charging capacity of single crystal furnace

A technology of single crystal furnace and feeding amount, which is applied in the direction of single crystal growth, chemical instruments and methods, crystal growth, etc., to achieve the effect of increasing output and production efficiency without affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1. A method for increasing the feeding amount of a single crystal furnace, wherein:

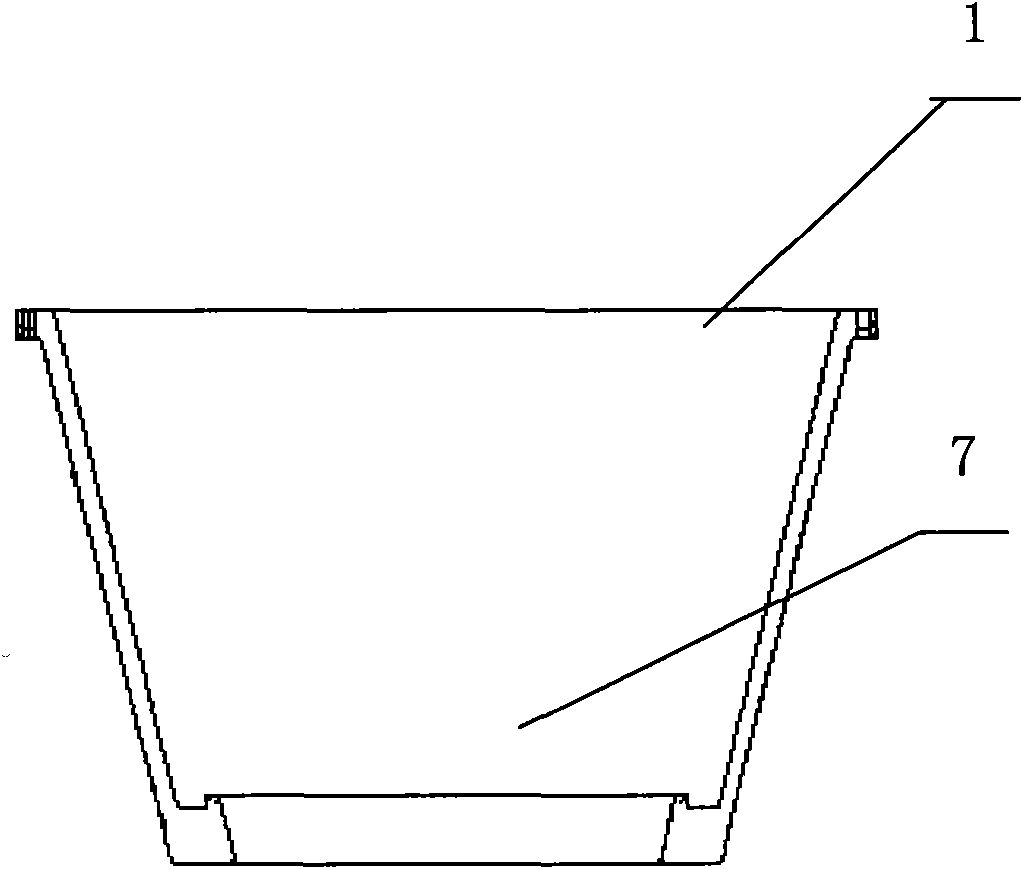

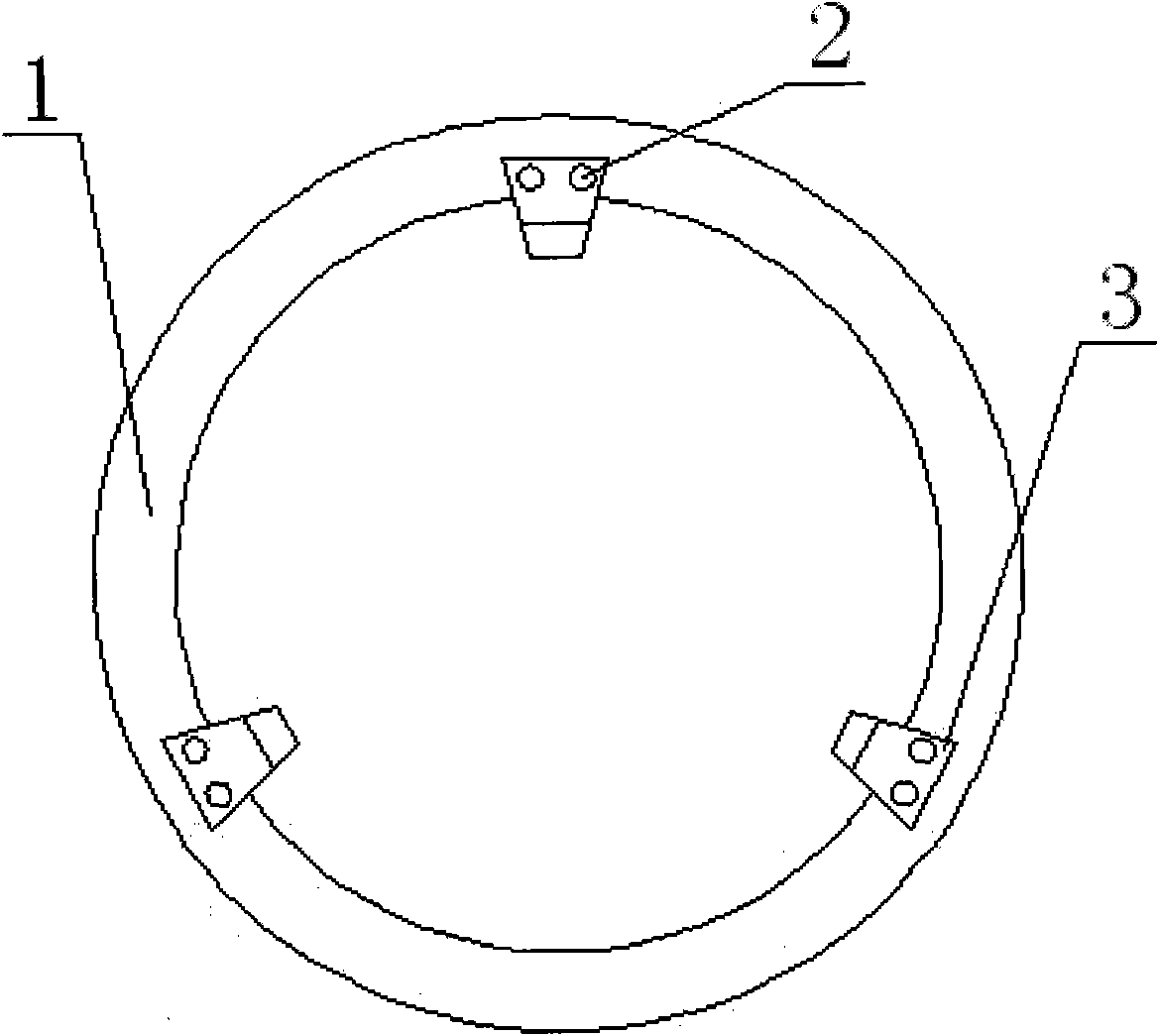

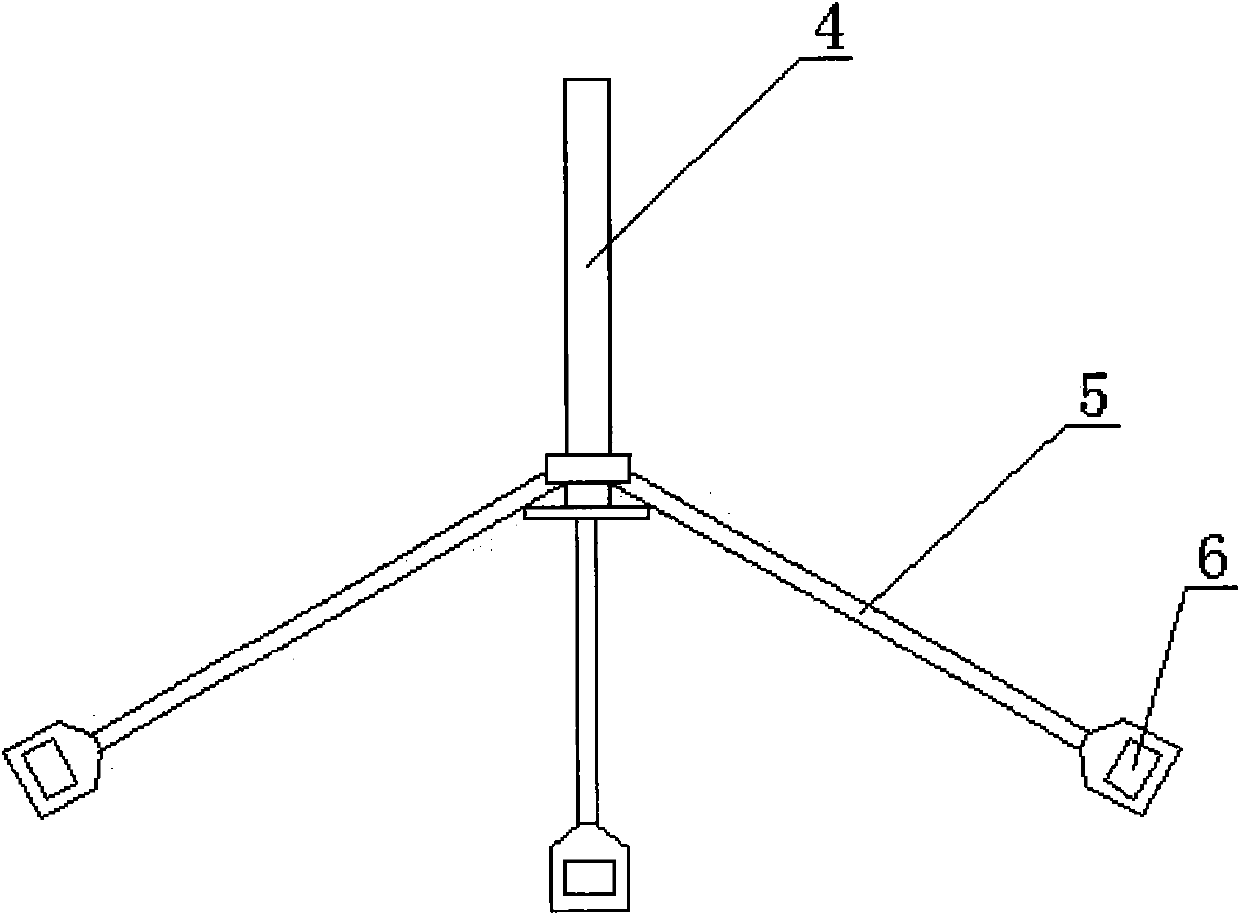

[0021] The supporting device of the method for increasing the feeding amount of a single crystal furnace includes a deflector mouth flange 1 and a guide cylinder 7; the outer ring of the guide cylinder 7 is provided with a guide cylinder flange 1; The flanging 1 is flexibly connected by connecting components; the clamping device is composed of a long handle 4, claws 5 and hooks 6; the connecting component is composed of a hook 3, a round hole 2, and a wire; wherein: the flange 1 at the mouth of the guide tube is provided with multiple Set a round hole 2, one end of the hook 3 is provided with a through hole, and the through hole and the round hole 2 are fixed by a wire; the hook 6 is fixed at the end of the claw 5, and the other end of the hook 3 passes through the hole on the hook 6 and the hole of the claw 5 One end is movably buckled, and the other end of the claw 5 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com