Liquid powder forming machine

A forming machine and liquid technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problem that the production volume cannot meet the needs of social development, and achieve the effect of improving production efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

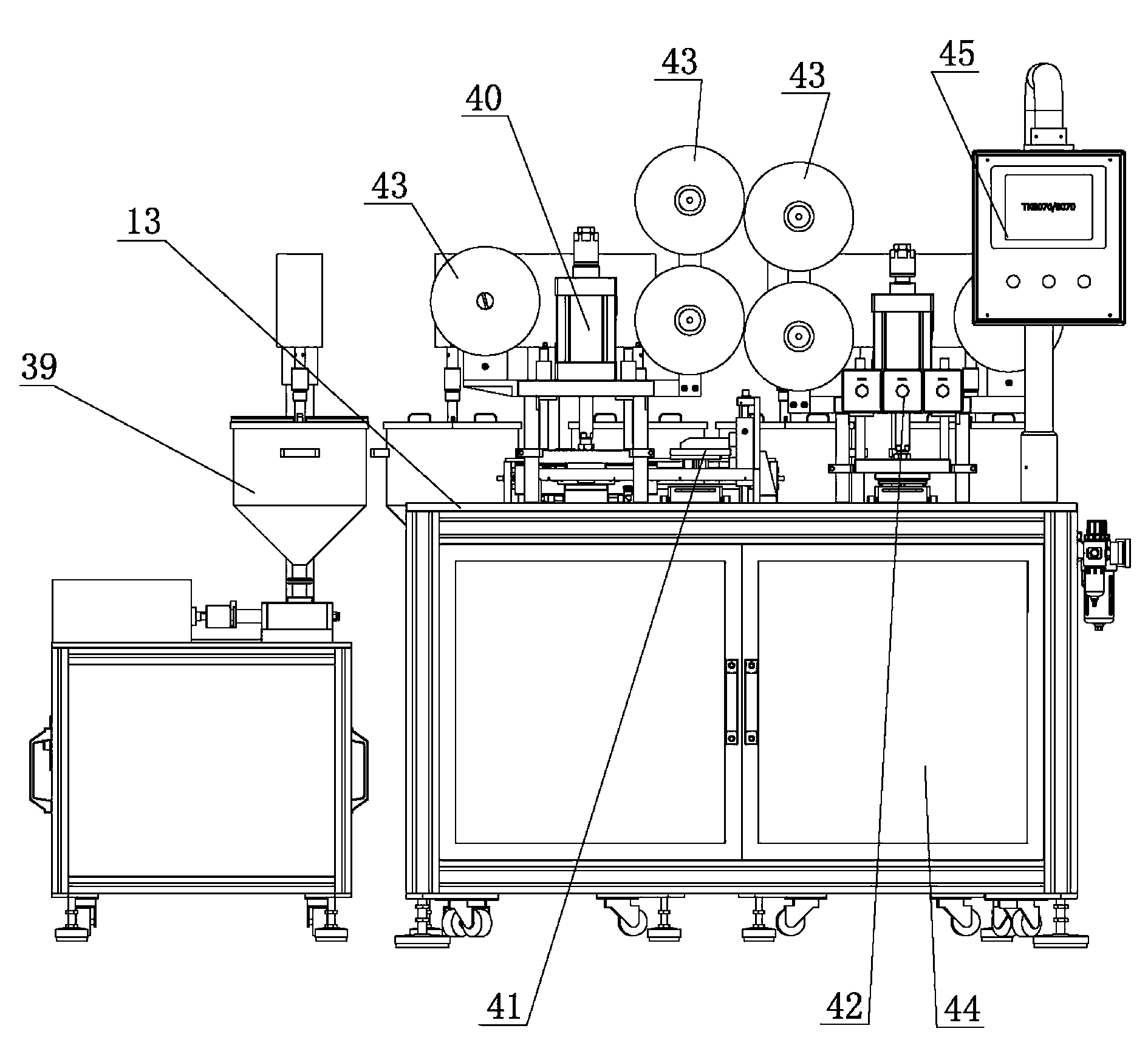

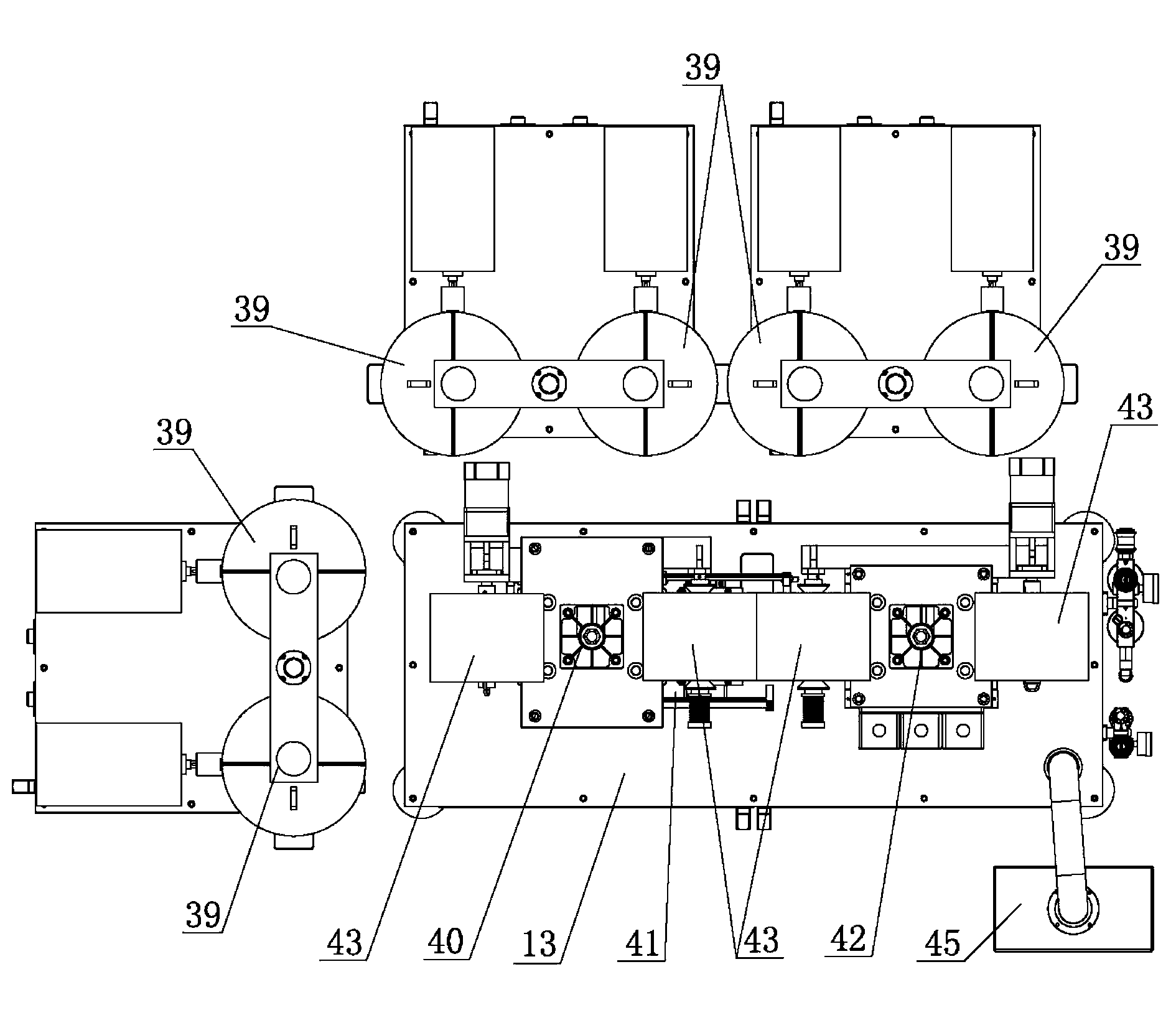

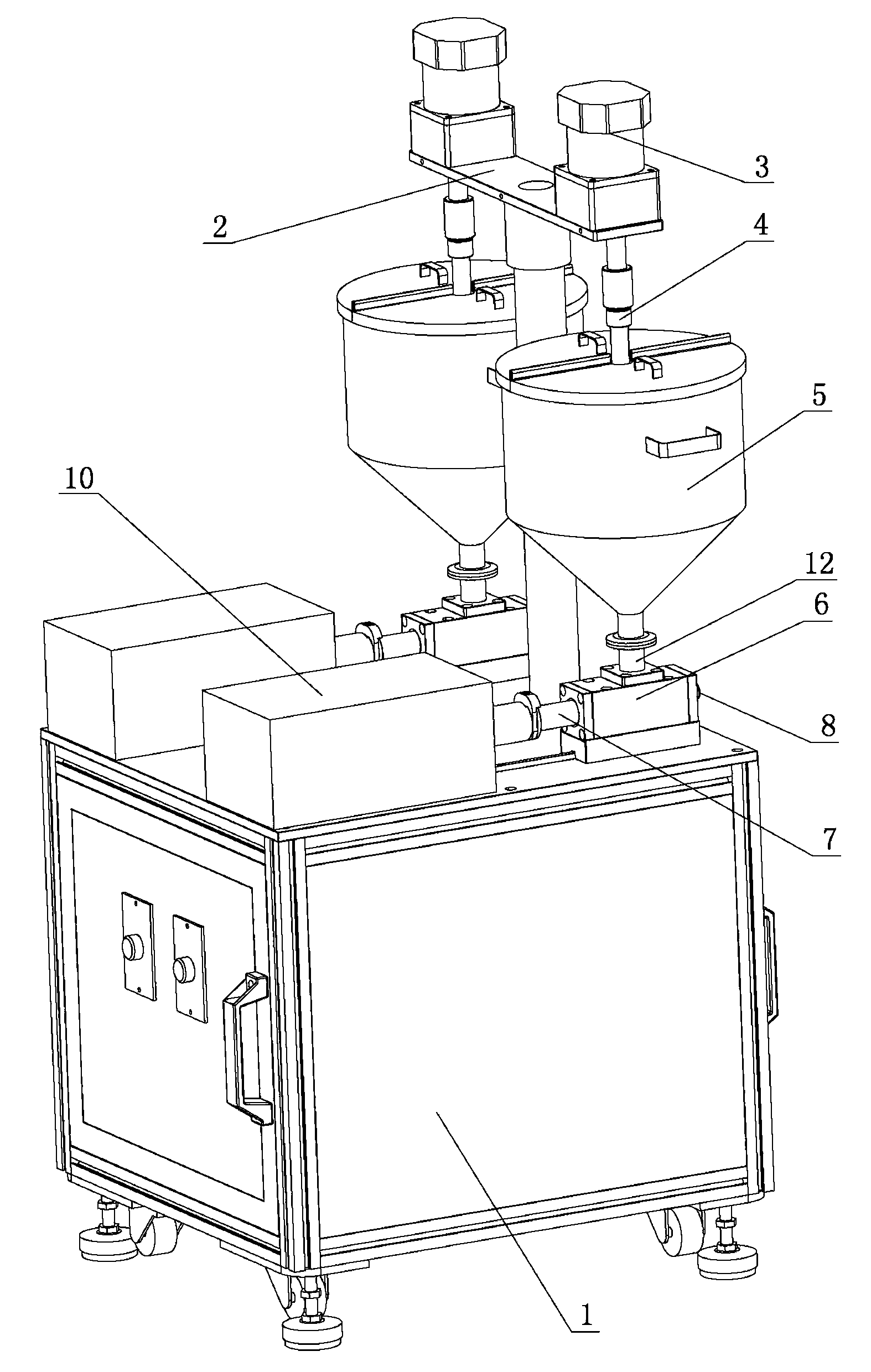

[0042] Such as figure 1 and figure 2 As shown, the liquid powder molding machine described in this embodiment includes a semi-finished product preliminary forming device 40, a semi-finished product pushing device 41, a product shaping device 42, a machine base 44, a numerical control computer 45, a plurality of cloth rolls 43 and multiple sets of pushing devices 39. In this embodiment, there are six sets of pushing devices 39 and six cloth rolls 43. In other embodiments of the present invention, the number of pushing devices 39 and cloth rolls 43 is not limited by the above numbers; semi-finished products The preliminary forming device 40, the semi-finished product pushing device 41 and the product shaping device 42 are respectively arranged on the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com