Sheet metal of multi-layer structure

A multi-layer structure, metal sheet technology, applied in sheet material, multi-layer structure metal sheet, pure nickel strip, foil field, can solve the problems of corroded substrate, easy peeling of nickel layer, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

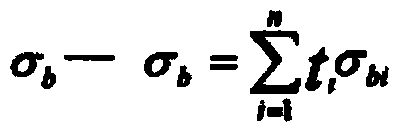

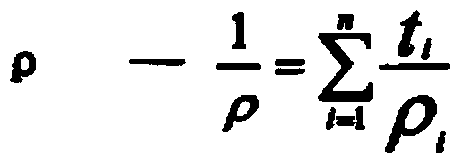

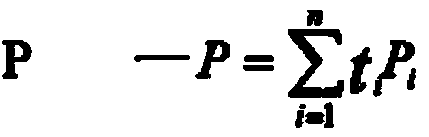

[0026] The material composition of the nickel-substituting composite metal is a four-layer structure of nickel / copper / stainless steel / copper / nickel, and the two outermost layers of pure nickel 1 (the weight percentage of Ni+Co is more than 99.0%) account for about 11.5% of the total thickness. The pure copper layer (copper containing more than 99.50% by weight) accounts for 11% of the total thickness, and the stainless steel layer (1Cr18Ni9 austenitic stainless steel) accounts for 55% of the total thickness, that is, the total thickness (weight) ratio of each component For: outer nickel: copper: stainless steel = 23:22:55. The material designed in this way has been proved by testing after manufacture that the average resistivity of the overall material (annealed state) is 7.1 μΩ.cm, the average tensile strength is 420 MPa, and the elongation is ≥ 30%. All indicators are completely close to and partially better than pure nickel. However, a well-known domestic battery manufactu...

Embodiment 2

[0029]The material group of nickel-substituting composite metal is nickel / stainless steel / copper / nickel four-layer structure, the two outermost layers of pure nickel 1 (the weight percentage of Ni+Co is more than 99.0%) account for about 11.5% of the total thickness, and the stainless steel ( 1Cr18Ni9 austenitic stainless steel) accounts for 27.5% of the total thickness, and pure copper (copper containing more than 99.50% by weight) accounts for 22% of the total thickness. Compared with Example 1, the material designed in this way does not change the total thickness ratio of each component material (outer layer nickel: stainless steel: copper=23: 55: 22), but the second outer layer and the middle layer component material It has been exchanged, but its overall material (annealed state) is completely consistent with most of the performances of Example 1, and it is also completely close to the pure nickel material performance, and its finished product can replace pure nickel strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Average resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com