A kind of marine cement mixed with modified metakaolin

A technology of metakaolin and marine cement, which is applied in cement production, etc., to achieve the effects of improving durability, solving the problem of anti-erosion ability, and improving the performance of anti-chloride ion penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

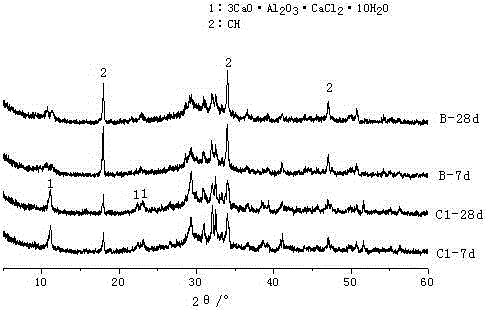

Embodiment 1

[0030] Embodiment 1, a kind of marine cement mixed with modified metakaolin, according to the weight ratio of raw materials is 42.5 grade Portland cement 100, S105 slag powder 50, fly ash 35, silica fume 10, white carbon black 6 and modified Weigh the raw materials of metakaolin 50, put them in a mixer and mix them mechanically to get the desired product, which is recorded as C1. Wherein: the preparation method of modified metakaolin is as follows:

[0031] 1) Mix kaolin and kiln dust evenly at a weight ratio of 9:1, and then put them into the muffle furnace;

[0032] 2) Set the heating rate of the muffle furnace so that the sample can be heated from room temperature to 800°C ± 20°C within 15 minutes, and kept in this temperature range for 20 minutes;

[0033] 3) After the calcination, the sample is taken out and quenched in the air, and the sample is ground to make the fineness meet 80 μm and the sieve residue is less than 1.0%, that is, the required modified metakaolin is o...

Embodiment 2

[0035] Embodiment 2, a kind of marine cement mixed with modified metakaolin, according to the weight ratio of raw materials is 52.5 grade Portland cement 100, S95 slag powder 75, fly ash 25, silica fume 15, white carbon black 5 and modified Weigh the raw materials of metakaolin 35, place them in a mixer and mix them mechanically to obtain the desired product, which is recorded as C2. The preparation method of modified metakaolin is the same as that in Example 1. According to the electric flux method specified in GB / T50082-2009 "Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete" to reflect the anti-chloride ion penetration performance of concrete, the results show that the marine concrete sample ratio prepared by C2 is 52.5 The total electric flux of concrete samples formulated with grade Portland cement was reduced by 73.2%.

Embodiment 3

[0036]Embodiment 3, a kind of marine cement mixed with modified metakaolin, according to the weight ratio of raw materials is 52.5 grade Portland cement 100, S105 slag powder 75, fly ash 25, silica fume 20, white carbon black 5 and modified The raw materials were weighed for metakaolin 30, placed in a mixer and mechanically mixed evenly to obtain the desired product, which was recorded as C3. The preparation method of modified metakaolin is the same as that in Example 1. According to the electric flux method specified in GB / T50082-2009 "Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete" to reflect the anti-chloride ion penetration performance of concrete, the results show that the marine concrete sample ratio prepared by C3 is 52.5 The total electric flux of concrete samples formulated with grade Portland cement was reduced by 75.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com