Rice hull ash modified rubber concrete and preparation method thereof

A technology of modifying rubber and rice husk ash, which is applied in the field of rubber concrete, can solve the problem of high cost, achieve the effects of improving impermeability, improving mechanical properties, and improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

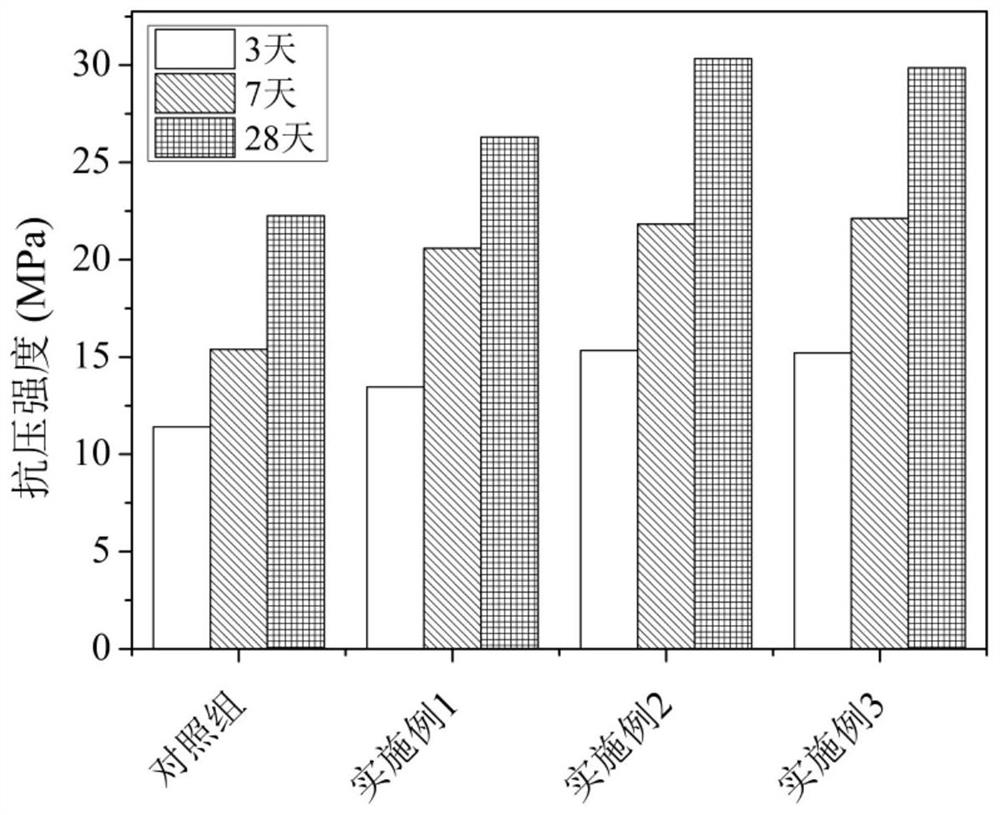

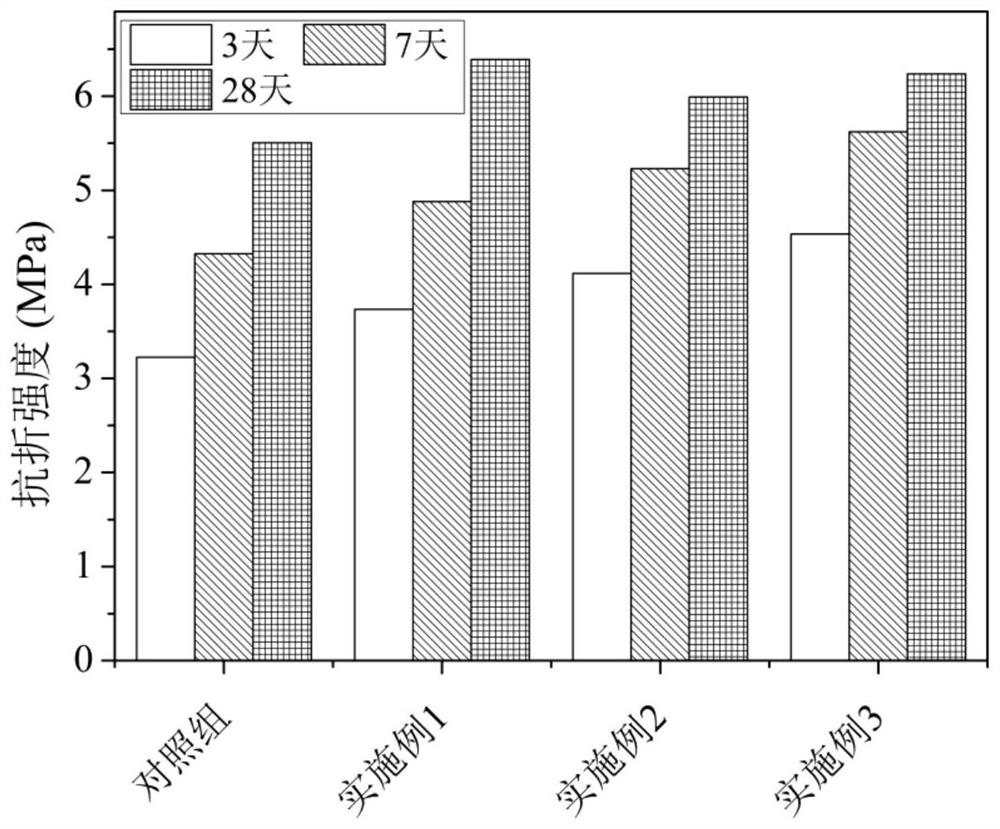

Embodiment 1

[0031] A rice husk ash modified rubber concrete and a preparation method thereof, which are prepared by the following method:

[0032] S1. Wash the 40-80 mesh rubber particles with water, and dry them in an oven at 80°C to obtain rubber particles;

[0033] S2, weighed by weight: 182 parts of cement, 520 parts of coarse aggregate, 173 parts of fine aggregate, 96 parts of water, 75 parts of rubber particles, 9.6 parts of rice husk ash;

[0034] S3, put the weighed cement, coarse aggregate, fine aggregate, and rubber particles into the mixing pot, start the mixer and stir for 1 minute, then add rice husk ash and continue stirring for 1 minute until uniformly mixed;

[0035] S4. After adding water into the mixing pot and continuing to stir for 3 minutes, pour it into a mold and form it. After curing for 28 days, rice husk ash modified rubber concrete is obtained.

Embodiment 2

[0037] A rice husk ash modified rubber concrete and a preparation method thereof, which are prepared by the following method:

[0038] S1. Wash the 40-80 mesh rubber particles with water, and dry them in an oven at 80°C to obtain rubber particles;

[0039] S2, weighed by weight: 173 parts of cement, 520 parts of coarse aggregate, 173 parts of fine aggregate, 96 parts of water, 75 parts of rubber particles, 19.2 parts of rice husk ash;

[0040] S3, put the weighed cement, coarse aggregate, fine aggregate, and rubber particles into the mixing pot, start the mixer and stir for 1 minute, then add rice husk ash and continue stirring for 1 minute until uniformly mixed;

[0041] S4. After adding water into the mixing pot and continuing to stir for 3 minutes, pour it into a mold and form it. After curing for 28 days, rice husk ash modified rubber concrete is obtained.

Embodiment 3

[0043] A rice husk ash modified rubber concrete and a preparation method thereof, which are prepared by the following method:

[0044] S1. After washing the 40-80 mesh rubber particles with water, dry them in an oven at 80°C to obtain rubber particles;

[0045] S2, weighed by weight: 163 parts of cement, 520 parts of coarse aggregate, 173 parts of fine aggregate, 96 parts of water, 75 parts of rubber particles, 28.8 parts of rice husk ash;

[0046] S3, put the weighed cement, coarse aggregate, fine aggregate, and rubber particles into the mixing pot, start the mixer and stir for 1 minute, then add rice husk ash and continue stirring for 1 minute until uniformly mixed;

[0047] S4. After adding water into the mixing pot and continuing to stir for 3 minutes, pour it into a mold and form it. After curing for 28 days, rice husk ash modified rubber concrete is obtained.

[0048] Control group:

[0049] A rice husk ash modified rubber concrete and a preparation method thereof, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com