Patents

Literature

61 results about "Titanium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium(III) fluoride (TiF3) is a inorganic compound with the formula TiF3. It is a violet solid. It adopts a perovskite-like structure such that each Ti center has octahedral coordination geometry and each fluoride ligand is doubly bridging.

Method for preparing chemical conversion film on aluminum alloy surface on basis of molybdate

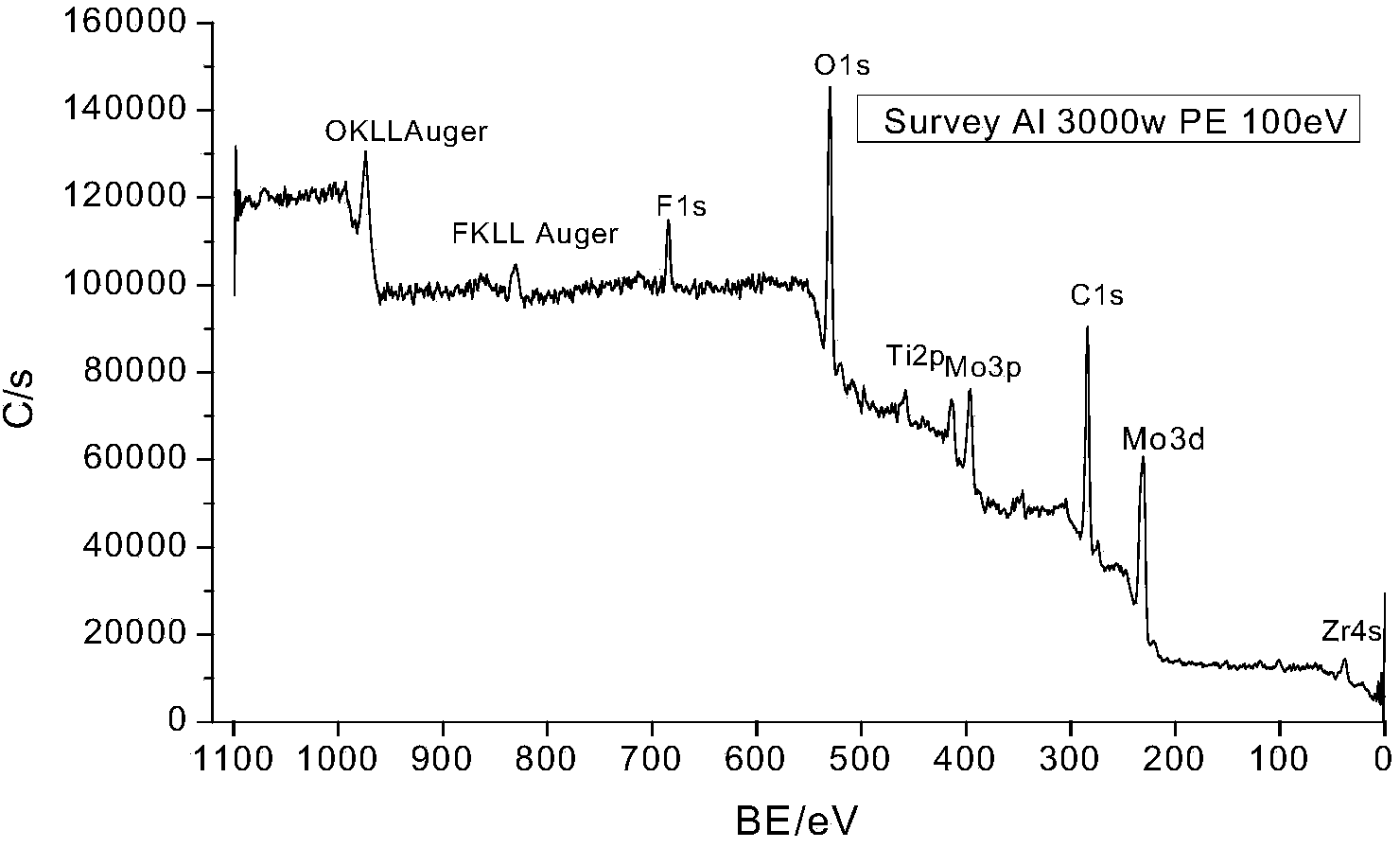

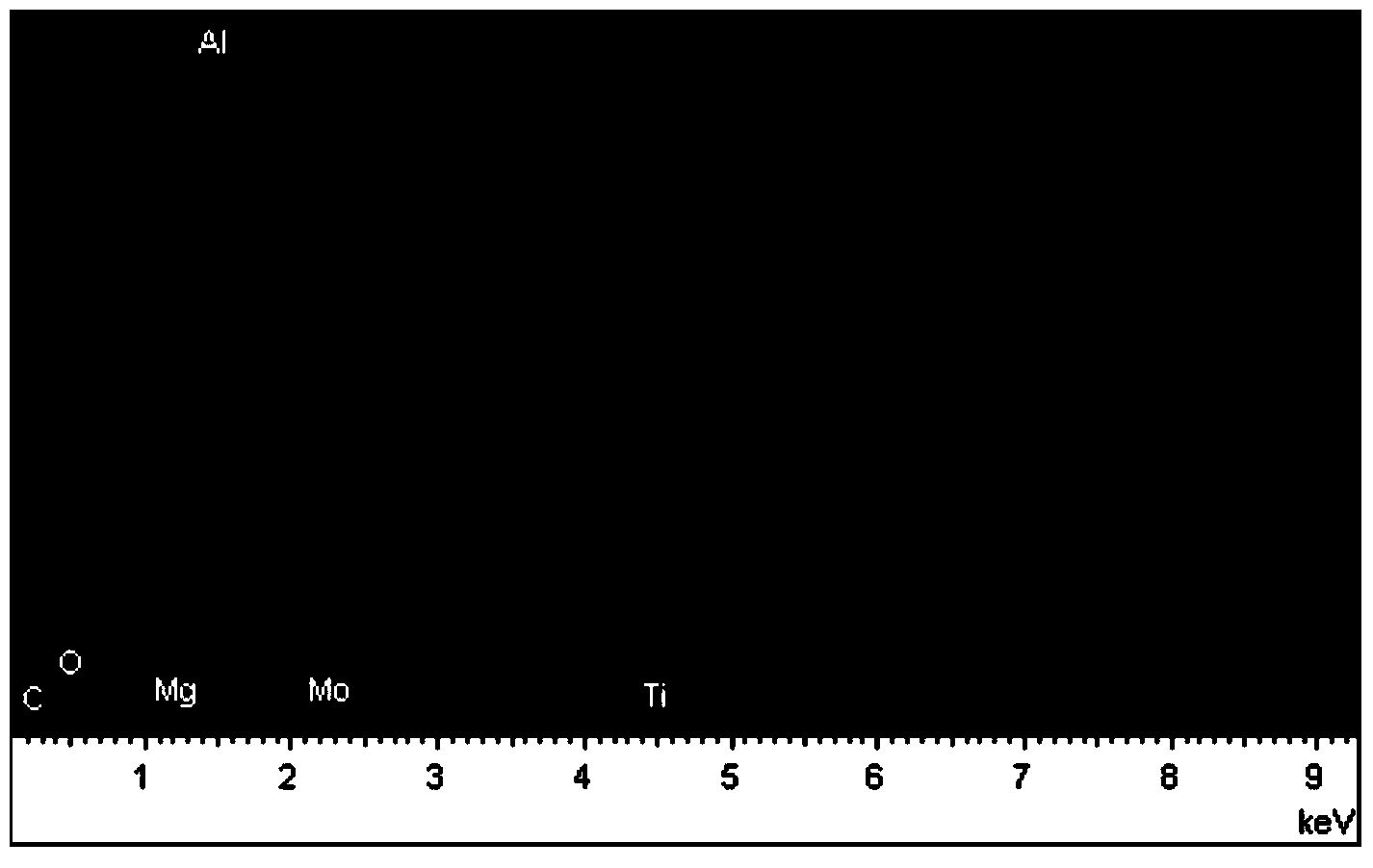

ActiveCN103866311AImprove corrosion resistanceImprove bindingMetallic material coating processesTitanium fluorideBinding force

The invention discloses a method for preparing a chemical conversion film on an aluminum alloy surface on the basis of molybdate and belongs to the technical field of aluminum alloy surface treatment. According to the method, chemical conversion treating fluid for preparing the chemical conversion film consists of molybdate, titanium fluoride, zirconium fluoride and a complexing agent component; according to the formula, the molybdate, the titanium fluoride, the zirconium fluoride and the complexing agent component are added into distilled water in sequence to prepare uniform mixed solution; pH of the solution is regulated to a determined value by dilute nitric acid, thus obtaining the chemical conversion treating fluid; in the chemical conversion treatment, the aluminum alloy is treated for 4-6 minutes at 25 DEG C-30 DEG C, washed with water, and blown to dry to form an uniform golden yellow conversion film on the aluminum alloy surface. According to the method, the chemical conversion treating fluid is low in cost, simple in treatment process, does not contain chromium and does not need after-treatment; and the formed conversion film has good corrosion resistance and binding force, can replace the conventional hexavalent chromium treatment technique for the aluminum alloy surface and can be used for surface treatment of the aluminum alloy.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Titanium oxide-containing material and process for preparing the same

InactiveUS6376023B1Liquid surface applicatorsTitanium dioxideTitanium tetrafluorideTitanium fluoride

A titanium oxide-containing material having a surface plated with titanium oxide. It is prepared by dissolving titanium fluoride (such as titanium tetrafluoride) in an amount of 2.0% owf in water, immersing a raw material in the obtained aqueous solution to treat the material with the aqueous solution at room temperature for 30 min, and adding a 0.5:1:1 (on a weight basis) mixture of boric acid, citric add, and DL-malic add in an amount of 0.5% owf to the aqueous solution to treat the material with the aqueous solution at 50° C. for 30 min, followed by washing with water. The raw materials usable herein include synthetic fibers, metals, glass, and woods, and may be in the form of sheet, plate, fiber, rod, or the like. Introduction of a noble metal, such as gold or silver, in addition to titanium oxide, onto the surface of the material enables the acceleration of the photocatalytic action of titanium oxide.

Owner:KYORASHA +1

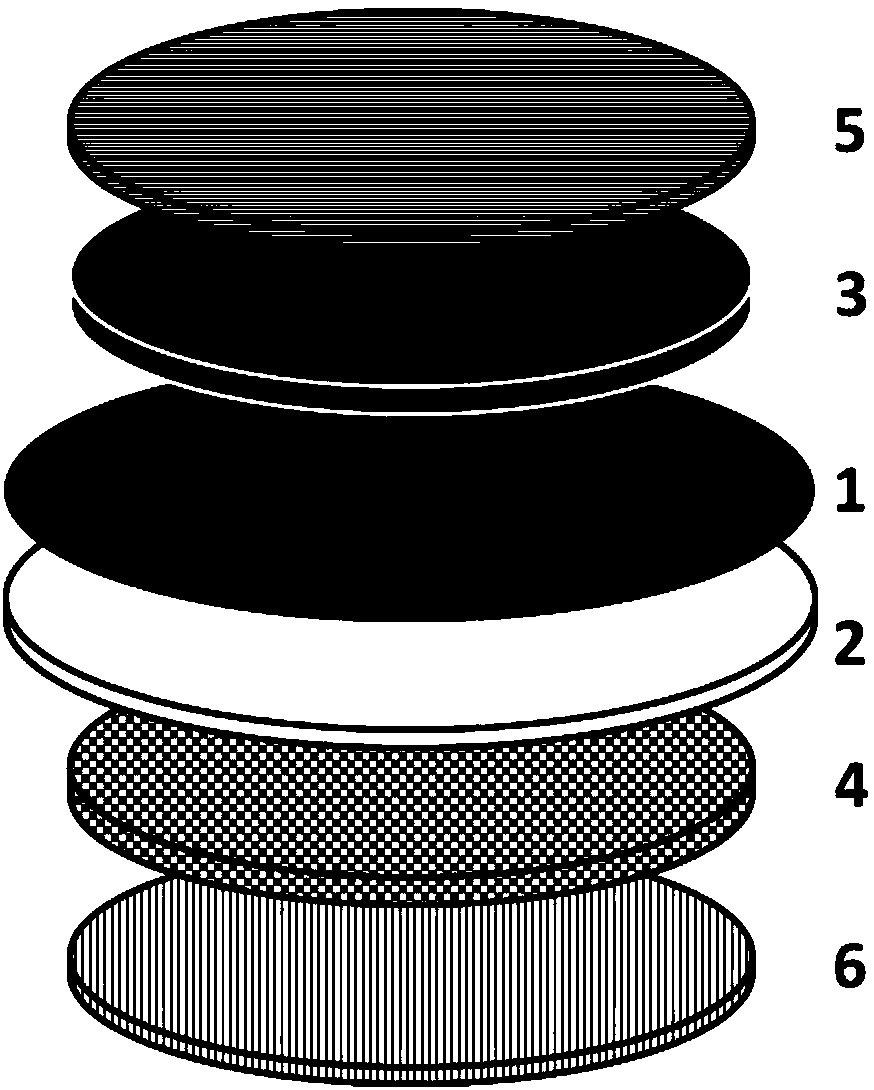

Interface protection structure, preparation method and battery comprising structure

InactiveCN109728249AEffective protectionNo side effectsCell electrodesLi-accumulatorsCyclic processTitanium fluoride

The invention provides an interface protection structure and a preparation method thereof and a battery comprising the interface protection structure. The interface protection structure comprises a metal fluoride and a binder. The metal fluoride is one or more of nickel fluoride, manganese fluoride, iron fluoride, titanium fluoride, copper fluoride, tin fluoride, and the like. The structure can form a protective layer containing lithium fluoride during the cycle process of lithium metal batteries to protect lithium metal electrodes. The interface protection structure is prepared by the following method: (1) providing a mixed slurry comprising a metal fluoride, a binder, a solvent and / or a carbon material; (2) coating one side of a diaphragm with the mixed slurry to obtain a diaphragm containing a first coating; and (3) baking the diaphragm containing the first coating to obtain the interface protection structure.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

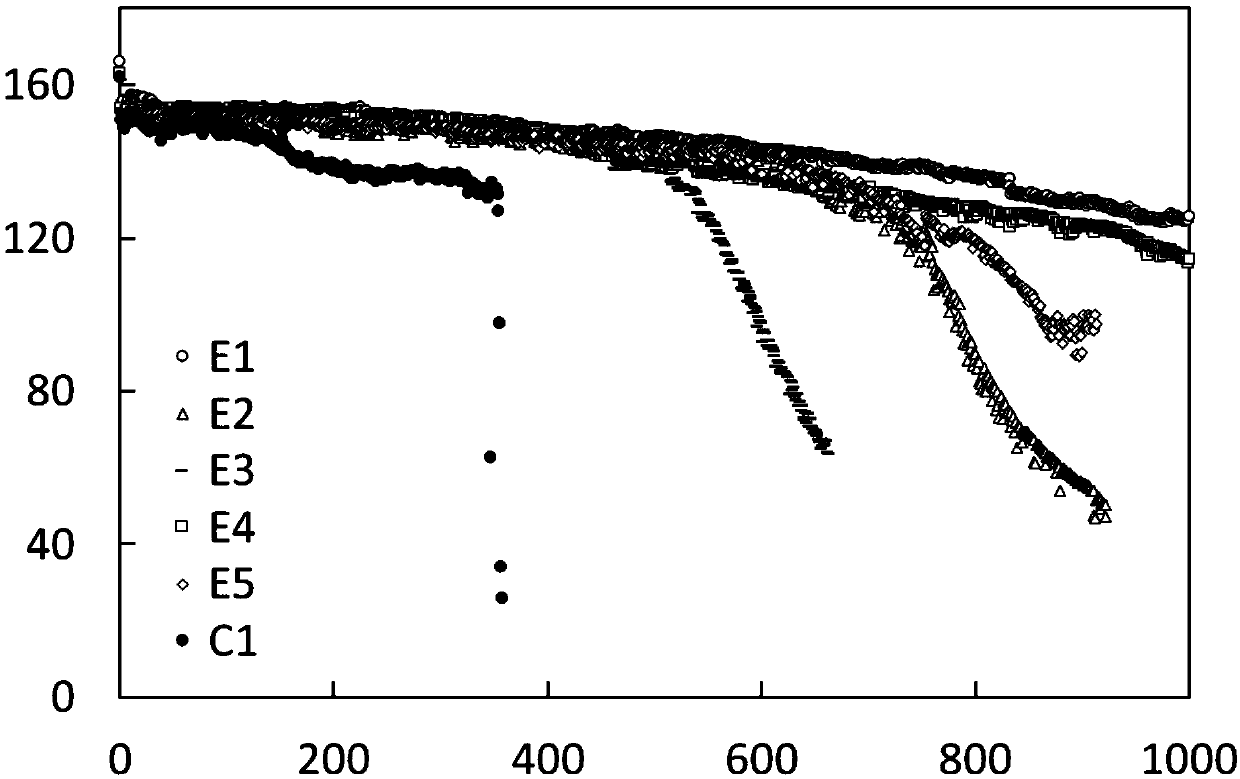

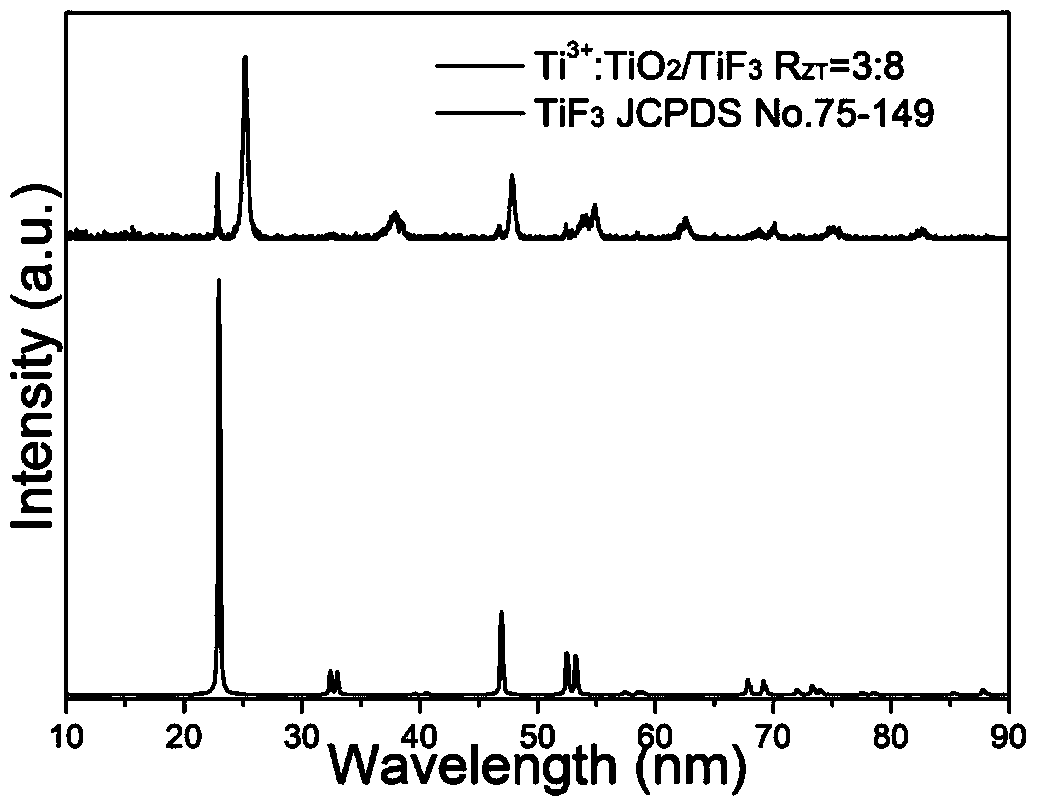

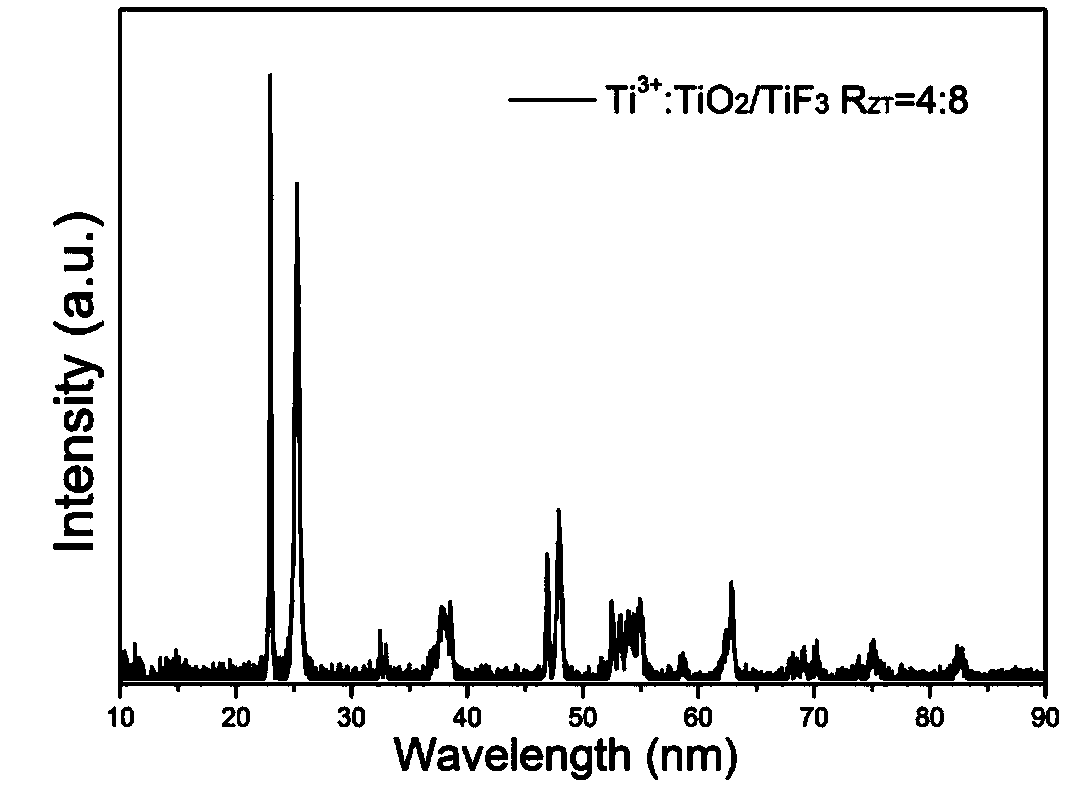

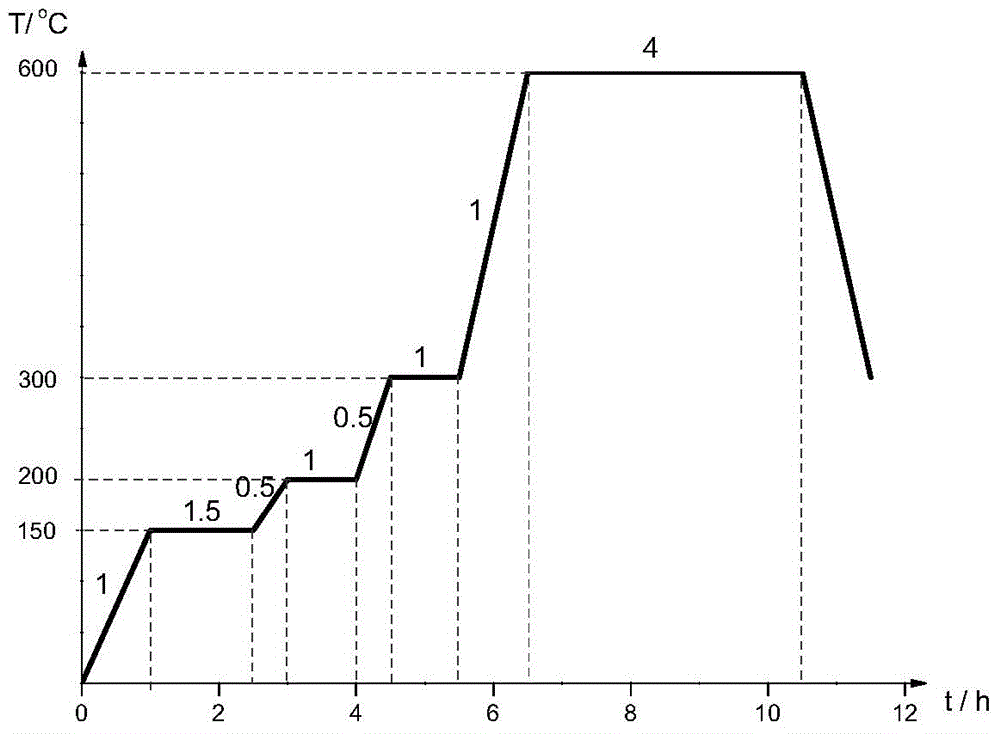

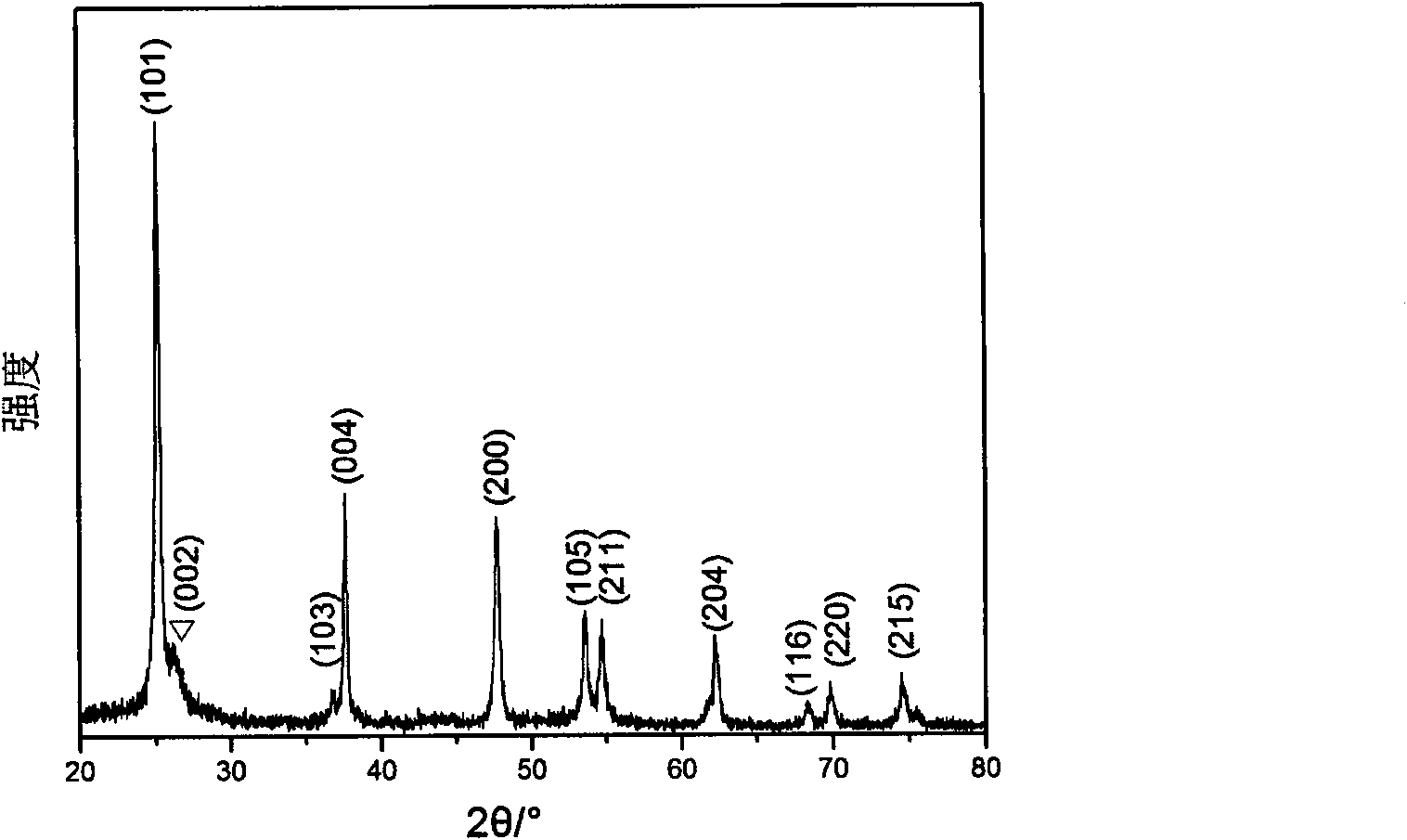

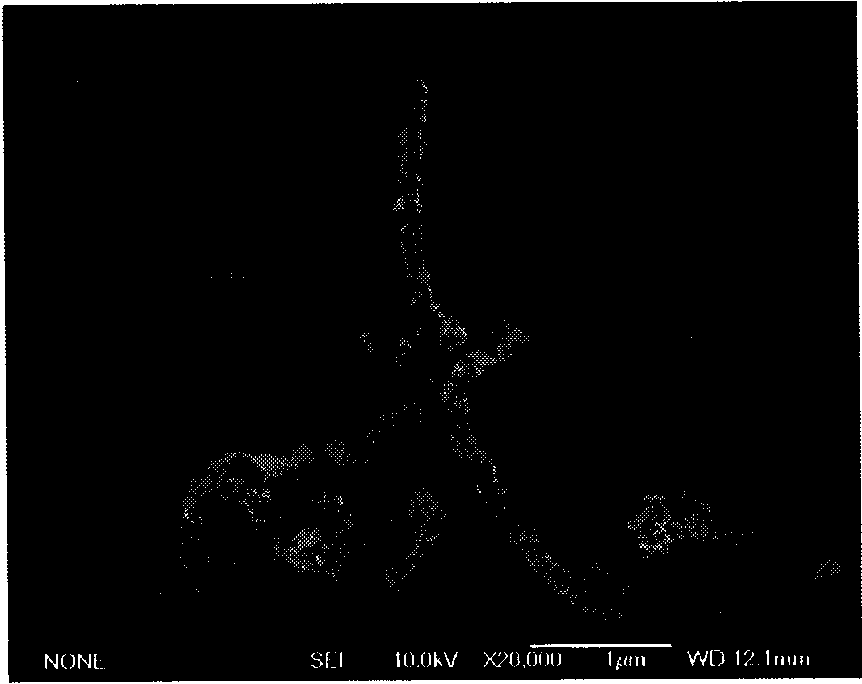

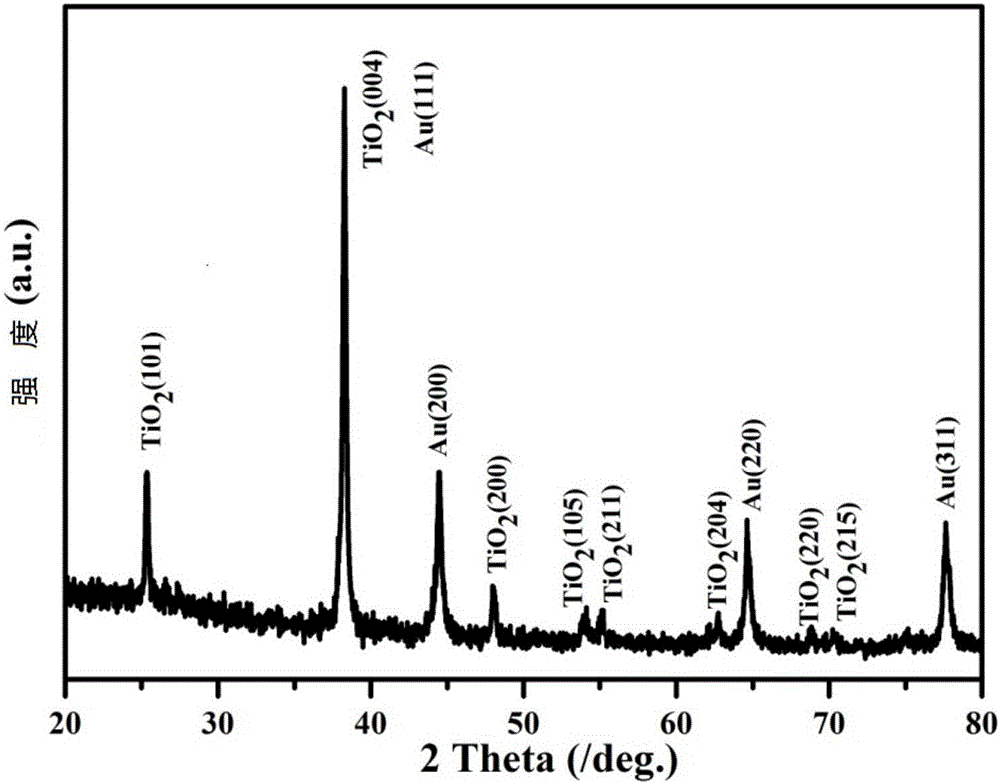

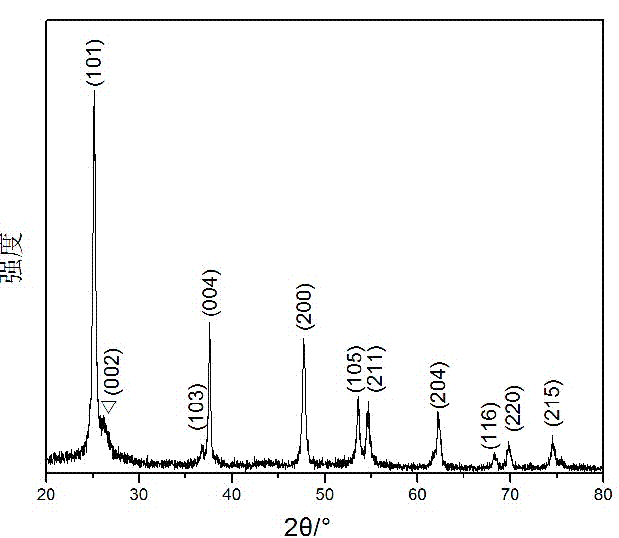

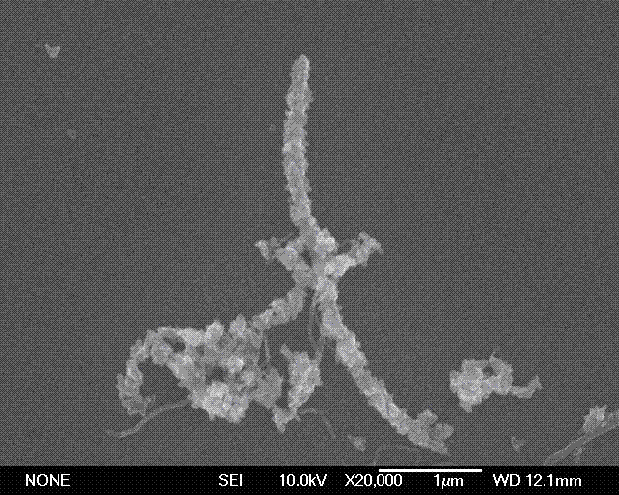

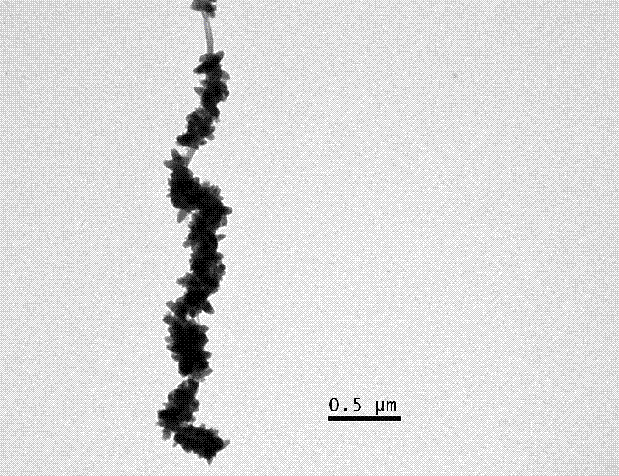

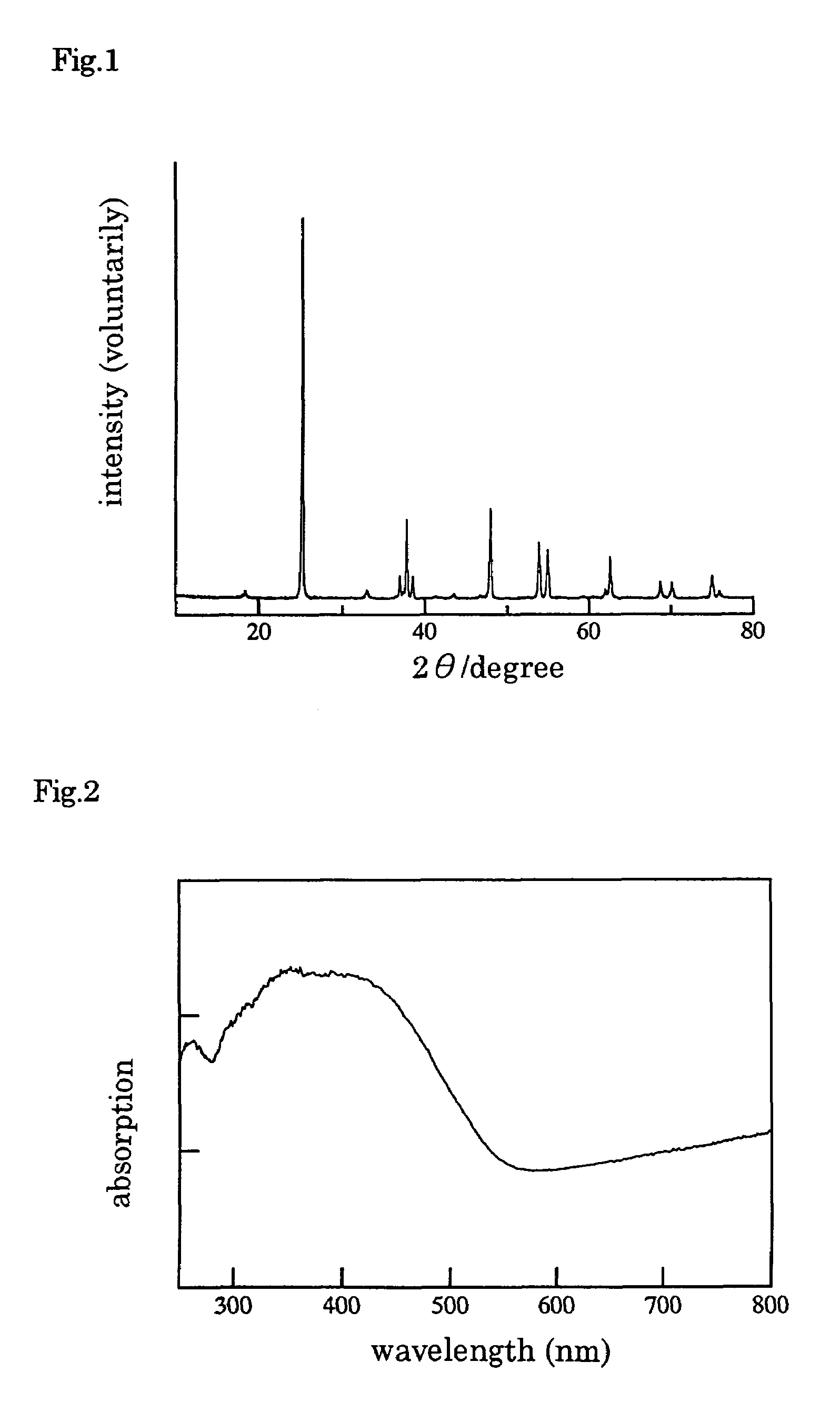

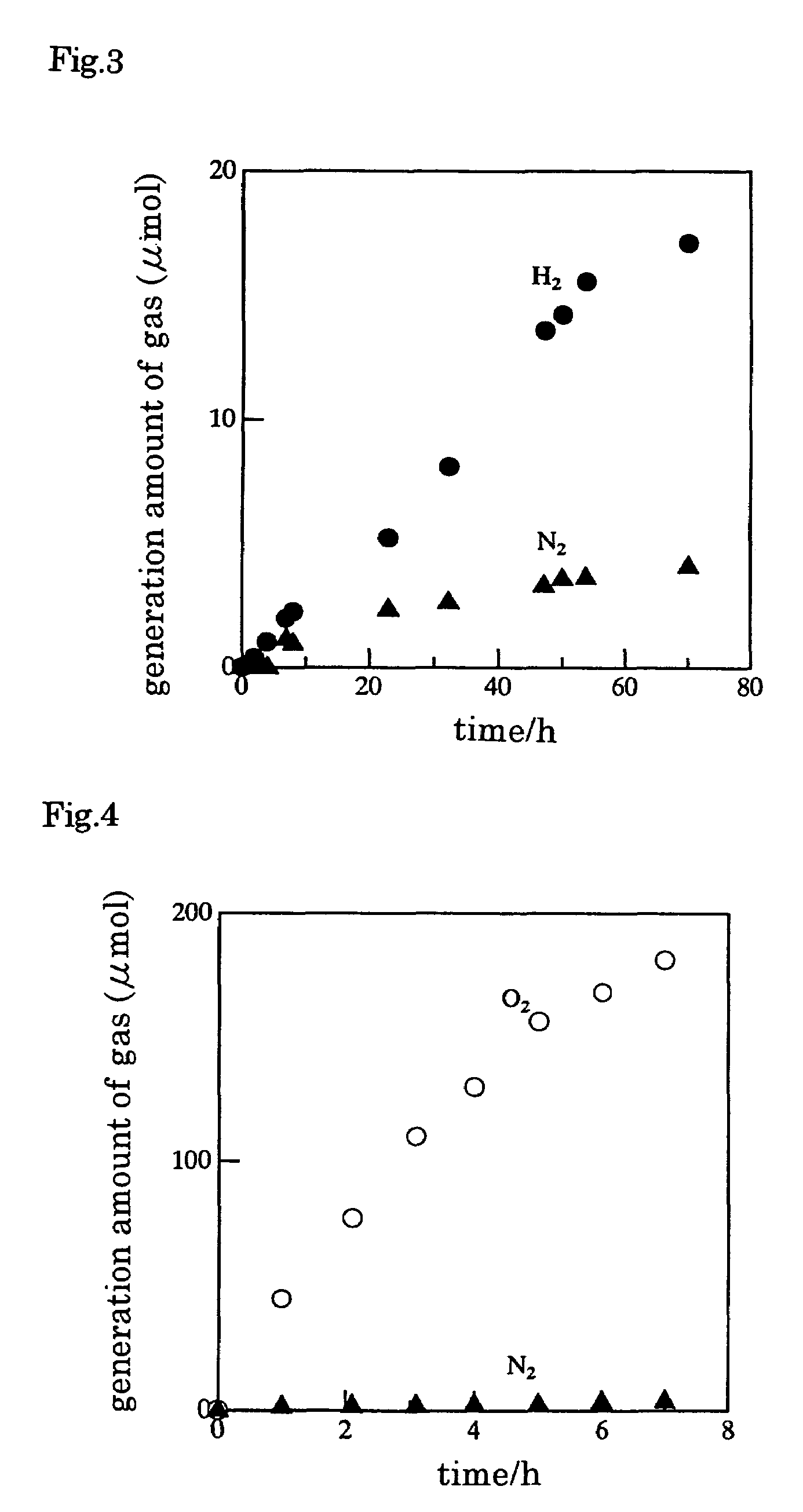

Ti<3+>:TiO2/TiF3 composite semiconductor photocatalyst and preparation method thereof

InactiveCN103920513ATuning Catalytic PerformanceEasy to preparePhysical/chemical process catalystsHeterojunctionTitanium tetrafluoride

The invention discloses a Ti<3+>:TiO2 / TiF3 composite semiconductor photocatalyst. According to the photocatalyst, the diameter of titanium dioxide is 10-20nm, the diameter of titanium fluoride is 100-150nm, a type II heterojunction is formed by titanium dioxide and titanium trifluoride, and the photocatalyst has low carrier recombination efficiency, contains lots of trivalent titanium, has high visible light absorption capacity and can be used for degrading organic pollutants. The invention also discloses a method for preparing the composite semiconductor photocatalyst. Elemental zinc serves as a reducing agent, titanium tetrachloride and titanium tetrafluoride serve as raw materials, and Ti<3+>:TiO2 / TiF3 with different ratios of titanium dioxide to titanium trifluoride can be prepared by changing the amount of elemental zinc in different reactions by utilizing alcohol-thermal method synthesis. The preparation method has the advantages of simplicity in operation, low cost and mild synthesis conditions and has high commercial application prospects.

Owner:SHANDONG UNIV

Metal surface treatment agent as well as preparation method thereof

ActiveCN103540917AImprove corrosion resistanceImprove coating adhesionMetallic material coating processesTitanium fluorideSilanes

The invention relates to a metal surface treatment agent as well as a preparation method thereof. The metal surface treatment agent consists of titanium fluoride, zirconium nitrate, zirconium fluoride, amino silane, 1,2-di(triethoxy silyl) ethane and di(triethoxy silyl) hexane. The titanium fluoride, the zirconium nitrate and the zirconium fluoride account for 110ppm-140ppm or 550ppm-650ppm of the total amount of the treatment agent in terms of metal elements, wherein a ratio of metal element atoms of the titanium fluoride to metal element atoms of the zirconium nitrate and the zirconium fluoride is 1:1-1:3; a ratio of metal element atoms of the zirconium nitrate to the metal element atoms of the zirconium fluoride is 2:5; a molar ratio of the amino silane to the 1,2-di(triethoxy silyl) ethane and the di(triethoxy silyl) hexane is 17:3-9:1; a molar ratio of the 1,2-di(triethoxy silyl) ethane to the di(triethoxy silyl) hexane is 1:1.

Owner:宁波英科特精工机械股份有限公司

Titanium fluoride modified load type chrome alum double-active center catalyst and preparation method thereof

InactiveCN105199021AIncrease contentHigh hydrogen sensitivityBulk chemical productionTitanium fluorideHydrogen

The invention belongs to polyethylene catalysts, and particularly relates to a titanium fluoride modified load type chrome alum double-active center catalyst. The titanium fluoride modified load type chrome alum double-active center catalyst comprises an inorganic carrier and loaded active components and modified components. The active components comprise chromium oxides and vanadium oxides, and the modified components comprise fluorine and titanium. According to the catalyst, the content and distribution of comonomers are improved, the number of the comonomers inserted into a low molecular weight end is reduced, the number of the comonomers inserted into a high molecular weight end is increased, and therefore more chalaza molecules can be formed easily, and polyethylene products with better performance are prepared. Meanwhile, the catalyst has the advantages of being high in activity, sensitive in hydrogen regulation response performance and the like. The invention further provides a preparation method of the catalyst. The inorganic carrier is firstly loaded with one of the modified components, and then loaded with the rest of the components, the process is reasonable, and industrial production is easy.

Owner:CHINA PETROLEUM & CHEM CORP

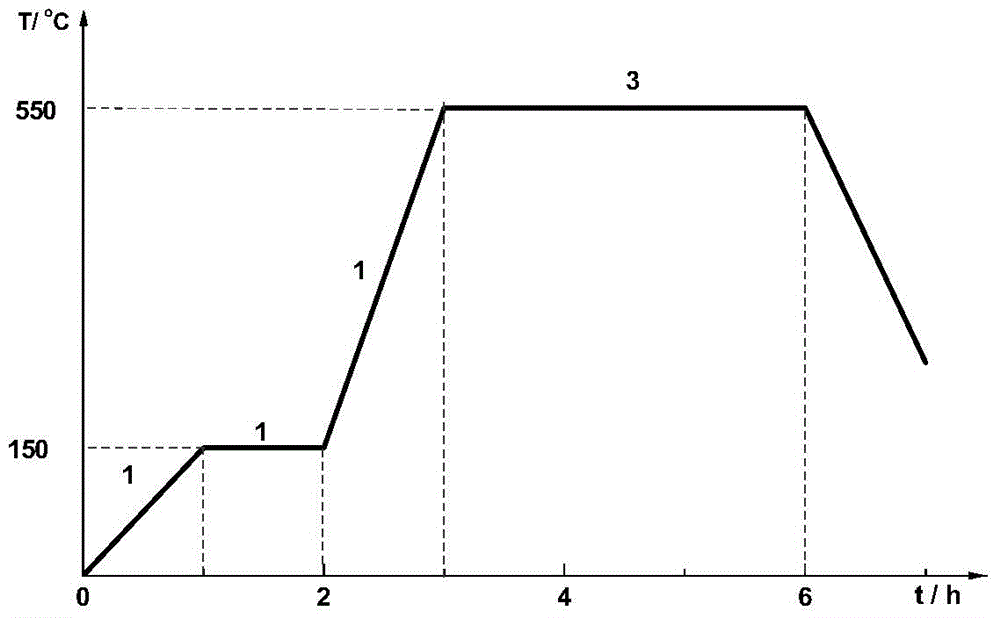

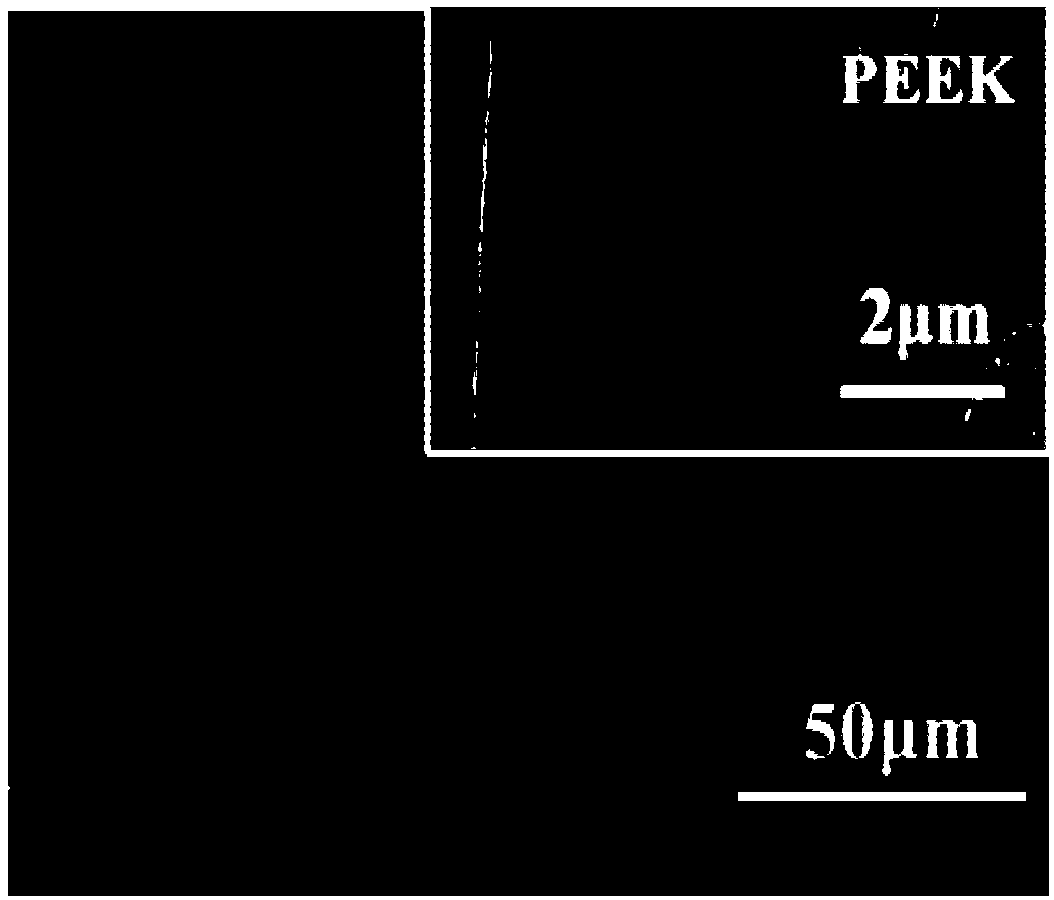

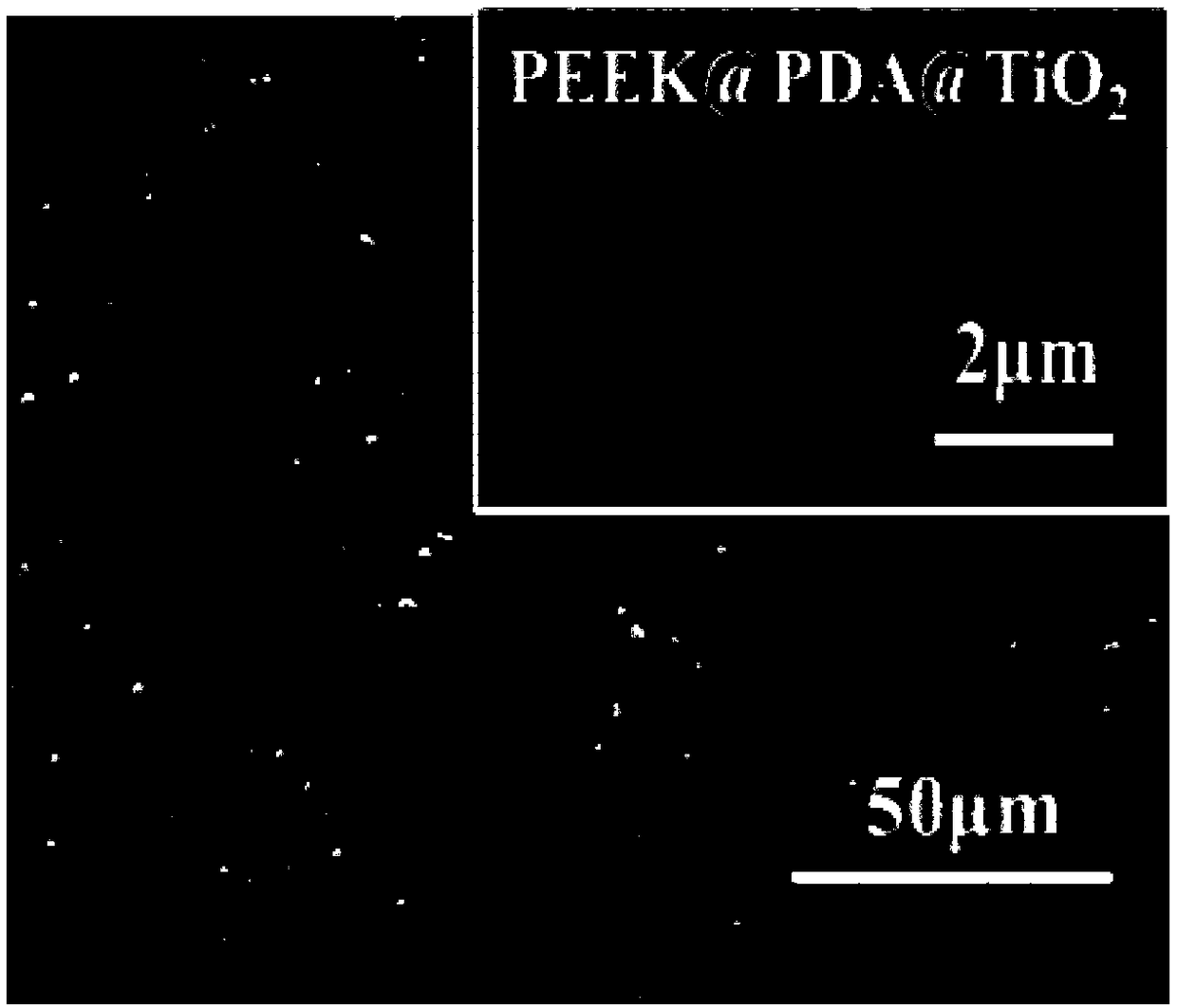

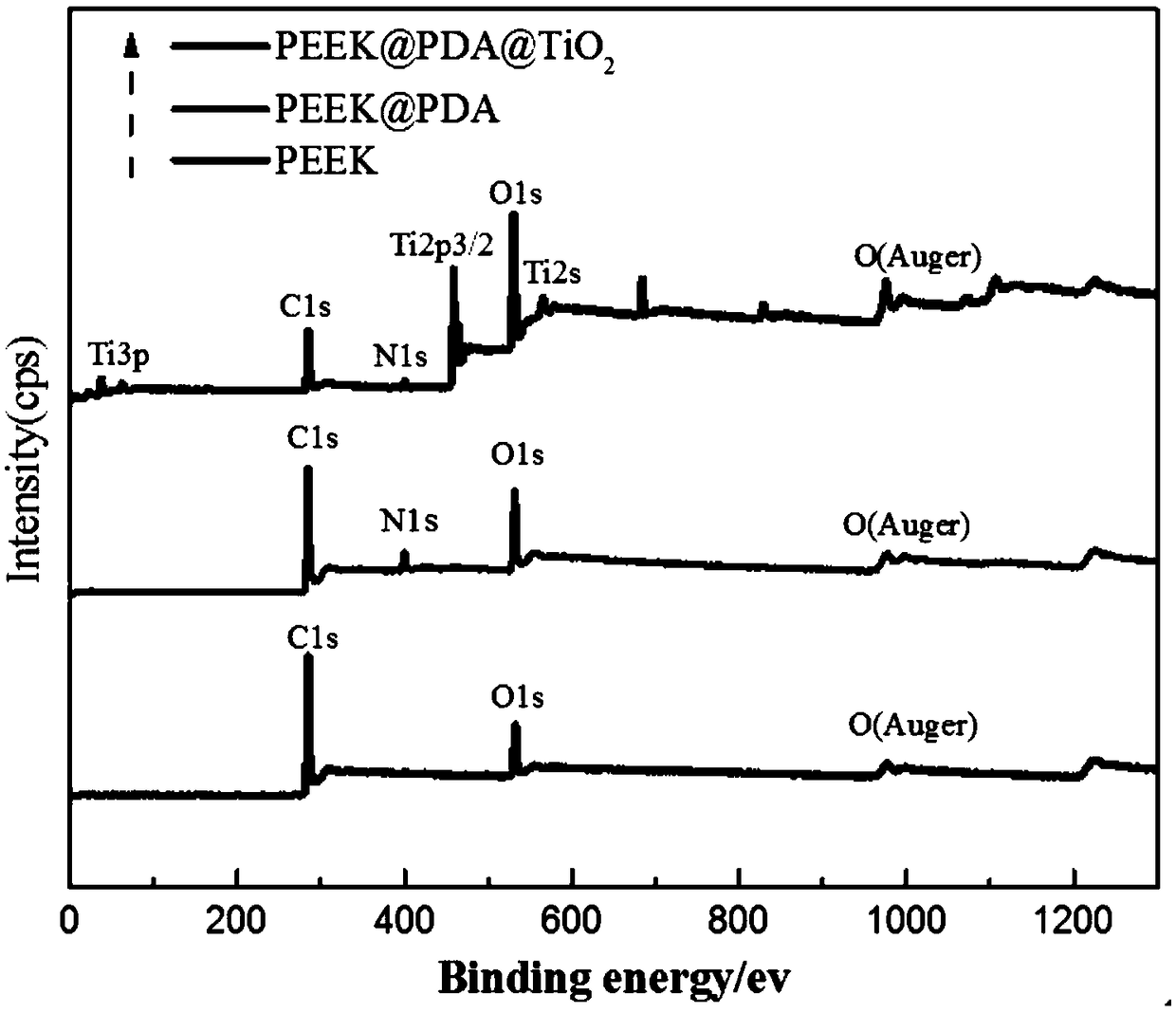

Method for preparing PEEK biological coating and PEEK biomaterial

InactiveCN108939149AImprove antibacterial propertiesHas antibacterial propertiesCoatingsProsthesisFiberTitanium fluoride

The invention relates to the field of biomaterials, and particularly relates to a method for preparing PEEK (Polyetheretherketone) biological coatings and a PEEK biomaterial. The PEEK, of which the surface is adhered with polydopamine, is put in a titanium fluoride solution; heat insulation is carried out for 10 hours to 15 hours at 45 DEG C to 55 DEG C and titanium fluoride is deposited; after the surface of the PEEK is adhered with the polydopamine, a titanium fluoride compounded coating is deposited; by using phenolic hydroxyl in the polydopamine as an anchoring point of titanium dioxide, the hybrid compounded coating is prepared through liquid phase deposition. Compared with the prior art, the compounded coating prepared by adopting the method disclosed by the invention has the advantages that the polydopamine and TiO2 are bonded through powerful chemical bonds, so that the bonding effect is very good. The titanium dioxide has an antibacterial effect, so that the finally prepared compounded coating has excellent antibacterial performance. Due to the polydopamine, adhesive growth of the fibroblasts can be promoted, and adhesion, growth and differentiation of the fibroblasts canbe effectively promoted; and finally, the sealing ability of soft tissues is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Metal surface anti-corrosion treatment agent

InactiveCN103540920AImprove corrosion resistanceImprove coating adhesionMetallic material coating processesTitanium fluorideSilanes

The invention relates to a metal surface anti-corrosion treatment agent. The metal surface anti-corrosion treatment agent consists of titanium fluoride, zirconium nitrate, zirconium fluoride, peroxy-vanadic acid, amino silane, 1,2-di(triethoxy silyl) ethane and di(triethoxy silyl) hexane. The titanium fluoride, the zirconium nitrate and the zirconium fluoride account for 110ppm-140ppm or 550ppm-650ppm of the total amount of the treatment agent in terms of metal elements, wherein a ratio of metal element atoms of the titanium fluoride to metal element atoms of the zirconium nitrate and the zirconium fluoride is 1:1-1:3; a ratio of metal element atoms of the zirconium nitrate to the metal element atoms of the zirconium fluoride is 2:5; a molar ratio of the amino silane to the 1,2-di(triethoxy silyl) ethane and the di(triethoxy silyl) hexane is 17:3-9:1; a molar ratio of the 1,2-di(triethoxy silyl) ethane to the di(triethoxy silyl) hexane is 1:1.

Owner:宁波英科特精工机械股份有限公司

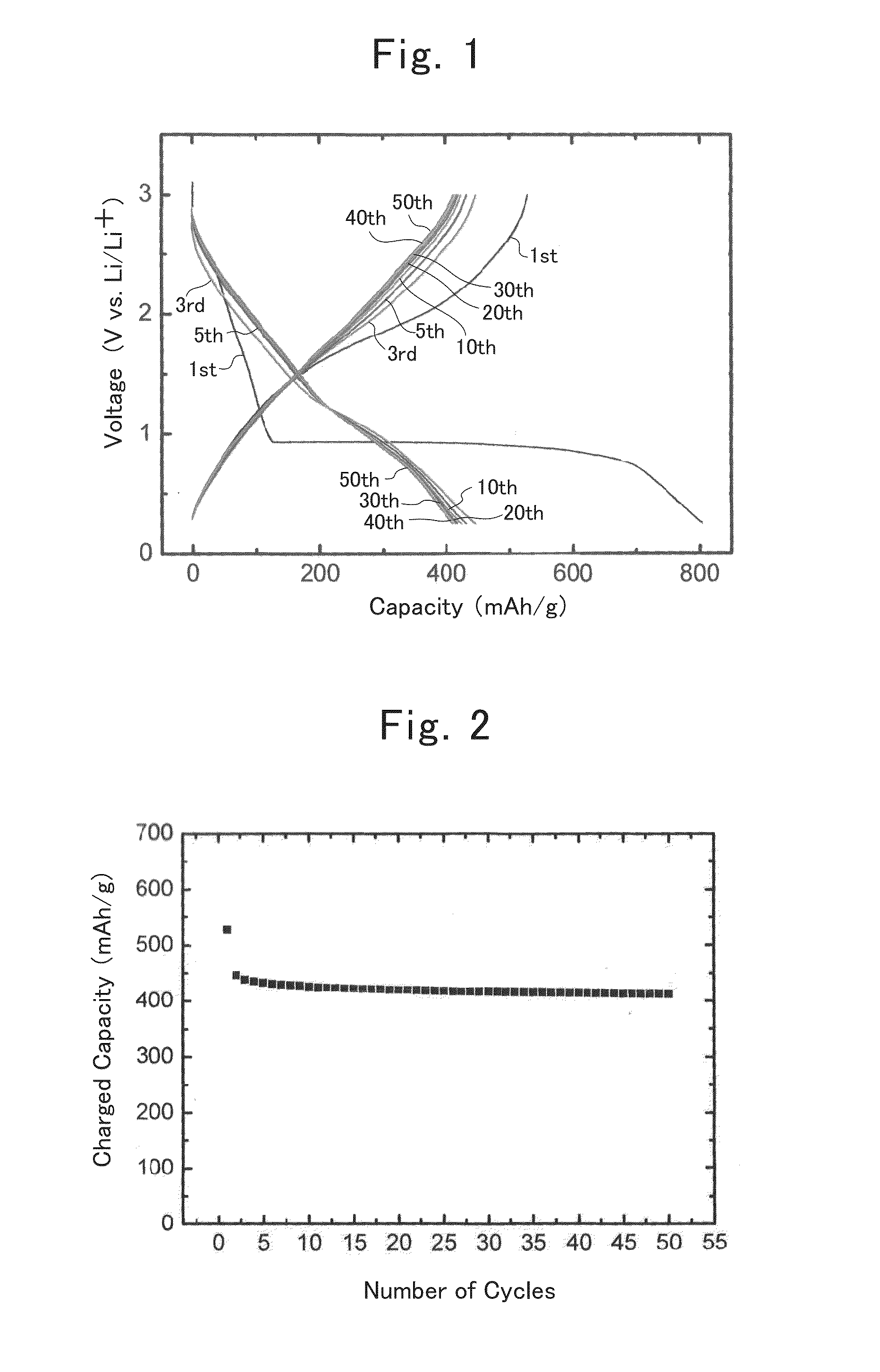

Negative-electrode active material for lithium-ion secondary battery and process for producing the same as well as lithium-ion secondary battery and process for manufacturing the same

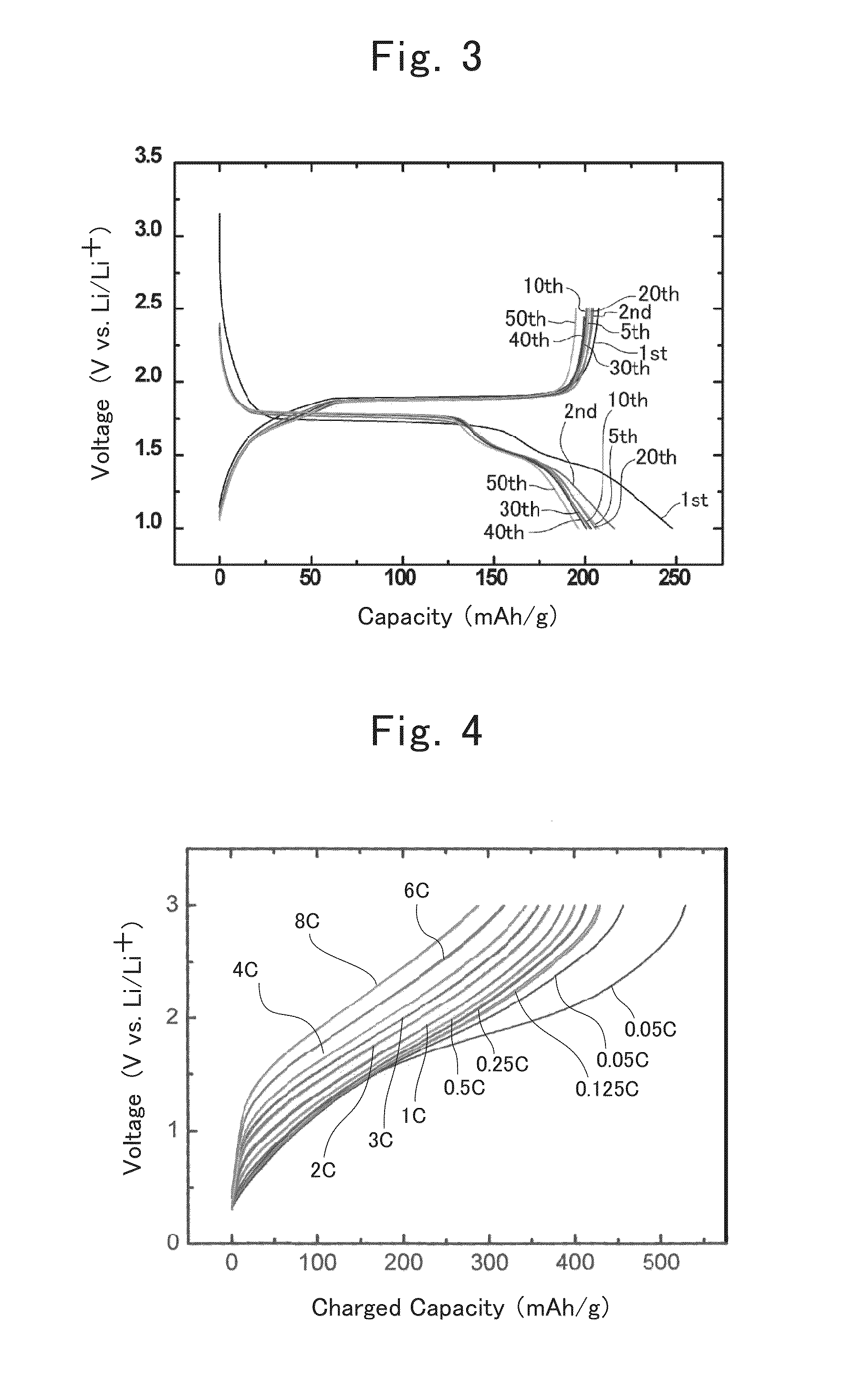

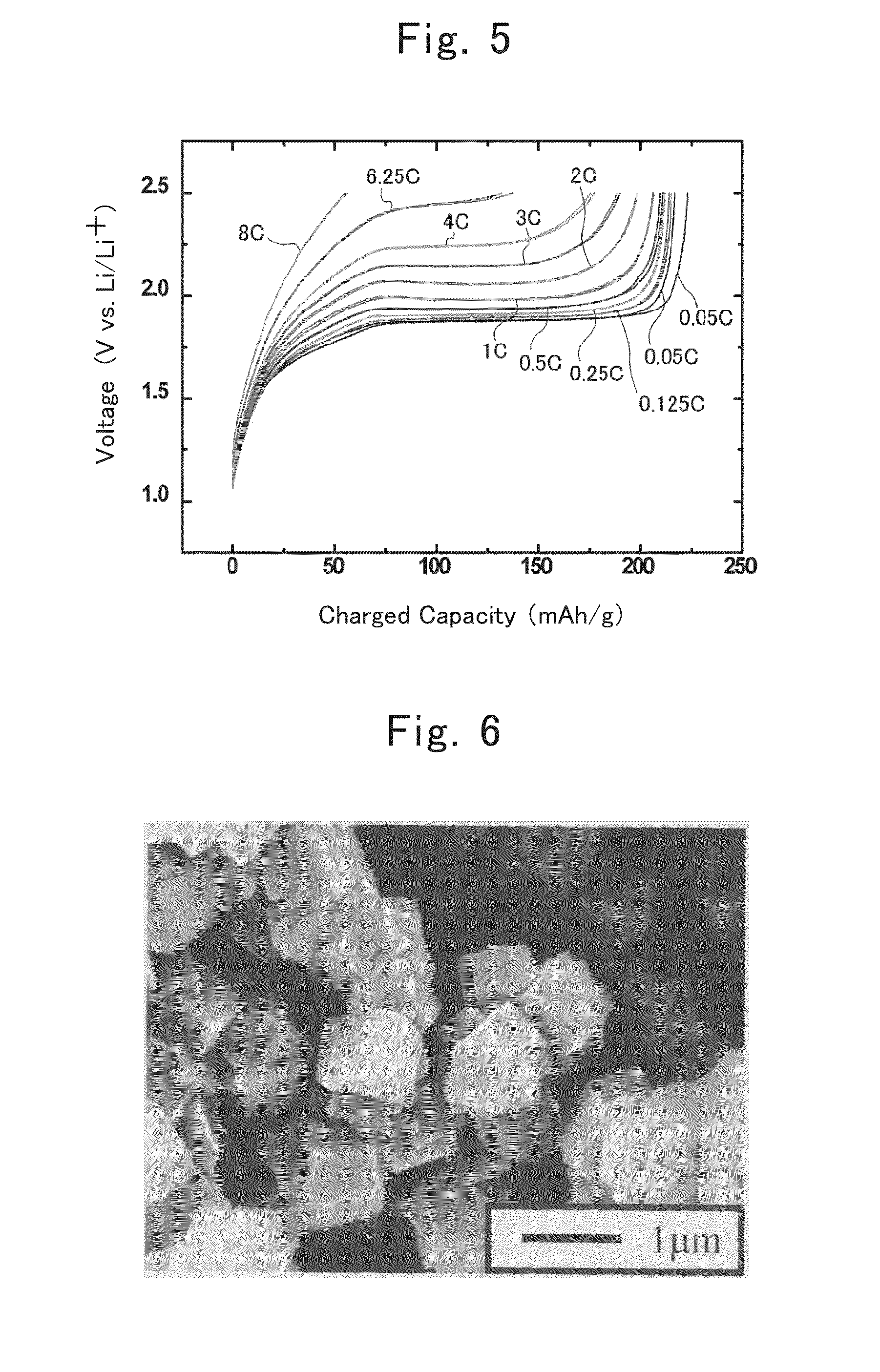

InactiveUS20140093779A1Large capacityHigh speedSecondary cellsNon-aqueous electrolyte accumulator electrodesHydrofluoric acidHydrogen fluoride

An object of the present invention is to provide a negative-electrode active material for lithium-ion secondary battery, negative-electrode active material which makes it possible for lithium-ion secondary batteries to exhibit higher capacities, and which makes it feasible to charge and discharge lithium-ion secondary batteries at a faster speed. In a production process according to the present invention, oxidized titanium fluoride is obtained by heating a mixed raw material, which includes a mixture of anatase-type TiO2 and hydrofluoric acid, at 70° C. or more (i.e., a heating step). This mixed raw material includes hydrogen fluoride in an amount exceeding 2 mol per the anatase-type TiO2 making 1 mol. When the oxidized titanium fluoride, which is obtained by this production process, is used as a negative-electrode active material of lithium-ion secondary battery, high-capacity and rapidly-chargeable / dischargeable lithium-ion secondary batteries are obtainable.

Owner:TOYOTA IND CORP +1

Cast iron surface anti-corrosion treatment agent

InactiveCN103540918AImprove corrosion resistanceImprove coating adhesionMetallic material coating processesTitanium fluorideSilanes

The invention relates to a cast iron surface anti-corrosion treatment agent which comprises titanium fluoride, zirconium nitrate, zirconium fluoride, amino silane, 1, 2-bi (triethoxy silicyl) ethane and di (triethoxy silicyl) hexane. The treatment agent also comprises 10-50ppm of free fluorine ions, and the performance factor (PF) value of the treatment agent is 3.2-4.5.

Owner:NINGBO JINHENG MACHINERY MFG

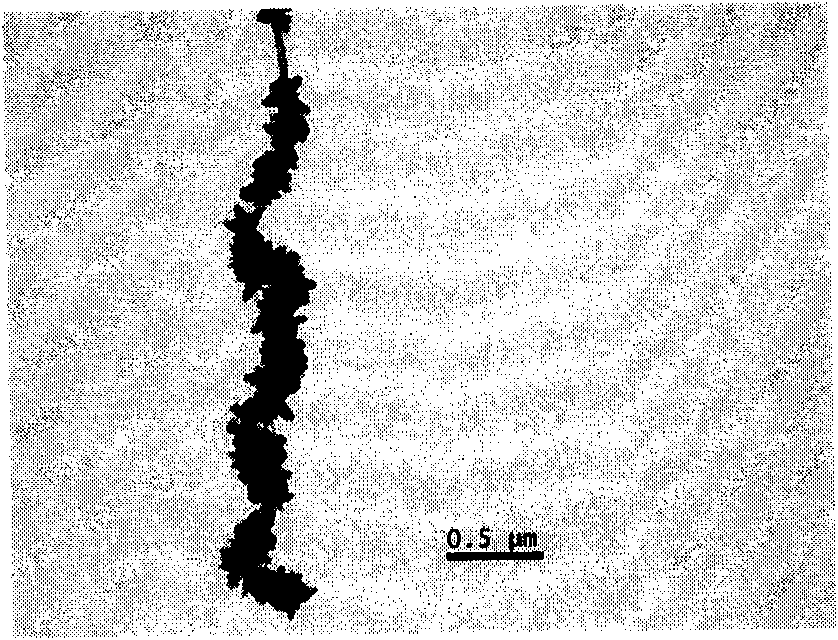

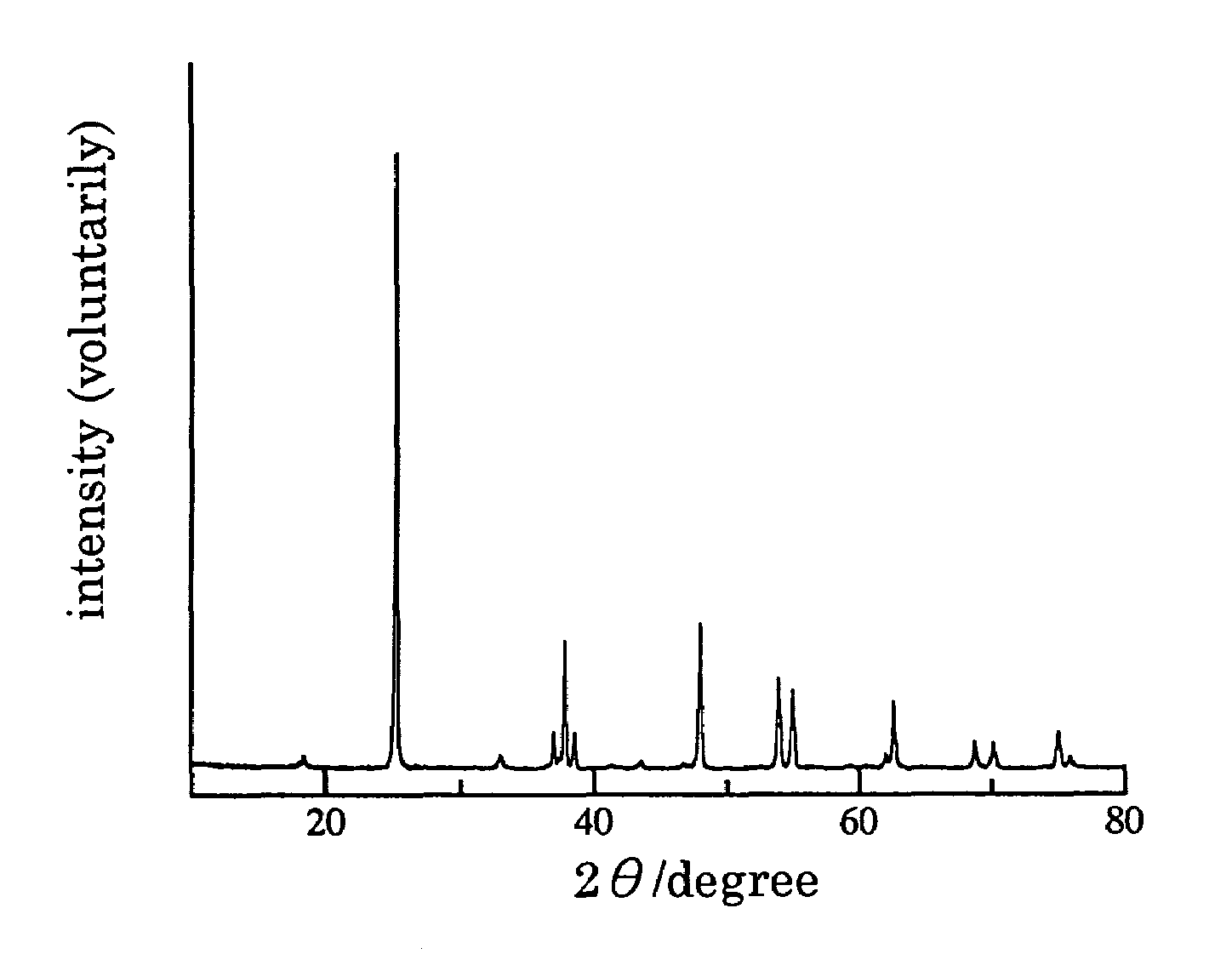

Method for preparing composite photocatalyst of titanium oxide/multi-wall carbon nano pipe by electron-beam irradiation

InactiveCN101670283AImprove photocatalytic performanceEasy to operateCatalyst activation/preparationTitanium tetrafluorideRadiation chemistry

The invention relates to a method for preparing a composite photocatalyst of a titanium oxide / multi-wall carbon nano pipe by electron-beam irradiation, which belongs to the technical fields of radiation chemistry and the preparation technique of the photocatalyst. The method mainly comprises the following preparation processes: adding a multi-wall carbon nano pipe (MWCNTs) into a titanium fluoride(TiF4) solution, dispersing by ultrasonic and mixing fully and evenly, wherein the mass ratio of the multi-wall carbon nano pipe (MWCNTs) and the titanium fluoride (TiF4), i.e. the MWCNTs:the TiF4 isequal to 0.05-0.15; then, putting the solution in an irradiation area under an electron accelerator and carrying out irradiation processing, wherein the irradiation dose is 280-560KYy; afterwards, moving to the other container, putting into a baking oven after sealing a sealed opening, and reacting for 20 hours at the temperature of 60 DEG C; and afterwards, washing a product, drying and finallypreparing the composite photocatalyst of the titanium oxide / multi-wall carbon nano pipe. The composite photocatalyst obtained by the method has favorable photocatalysis property and better photocatalysis effect.

Owner:SHANGHAI UNIV

Foam concrete for civil engineering

InactiveCN109776054AStrong mechanical resistanceHigh strengthCeramicwareFoam concreteTitanium fluoride

The invention discloses foam concrete for civil engineering. The foam concrete is prepared from, 50-70 parts of ordinary Portland cement, 20-30 parts of aggregate, 0.8-1.6 parts of a foaming agent, 0.5-1 part of a fiber expanding agent, 1.3-5 parts of high-activity titanium fluoride, 8-15 parts of fly ash, 3-8 parts of graphene oxide, 3-7.2 parts of an acrylate emulsion, 0.1-0.32 part of diethylenetriamine sodium penta-carboxylic ester, 1.5-2.5 parts of calcium carbonate whiskers, 1.5-2.3 parts of cast stone powder, 4-5.8 parts of an ethylene-acrylic emulsion, 0.01-0.03 part of hydroxypropyl methyl cellulose, 0.3-1.3 parts of sulphoaluminate clinker, 0.3-0.5 part of triethanolamine, 0.5-0.7 part of polyether imine, 0.7-1.3 parts of a water reducing agent and 20-30 parts of water. The obtained foam concrete has excellent compression resistance and crack resistance.

Owner:EASTERN GANSU UNIVERSITY

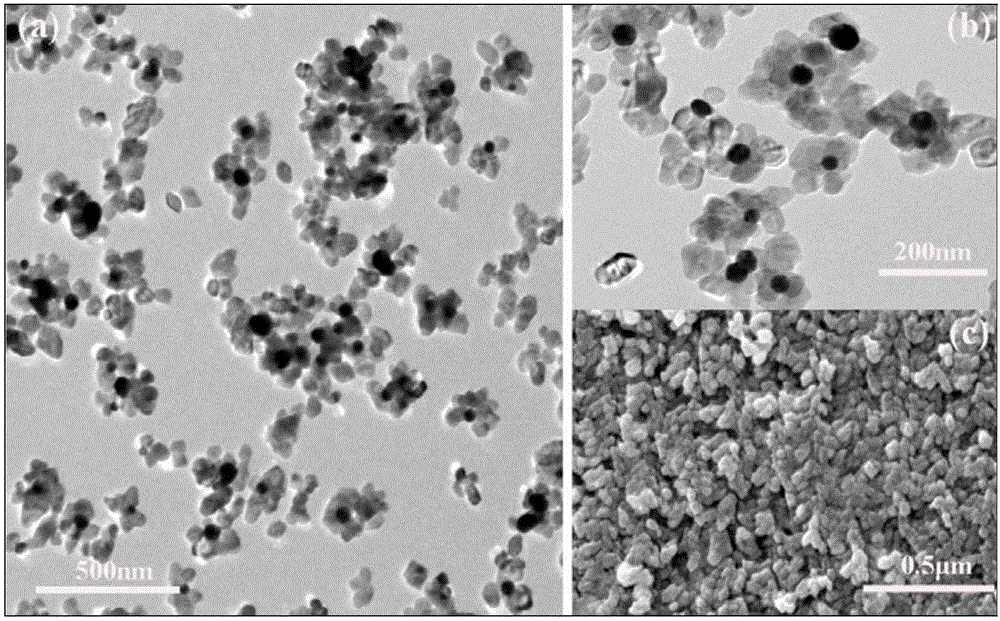

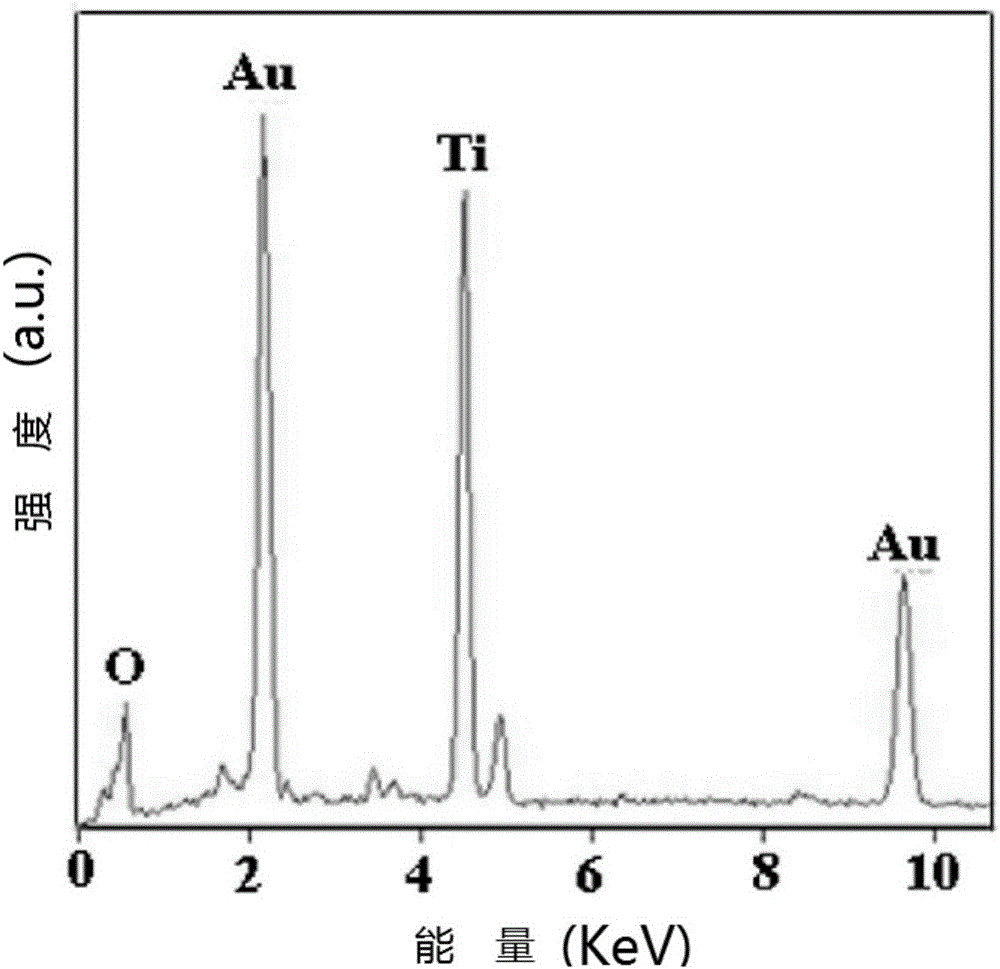

Gold-doped titanium dioxide flower-like nanostructured material and preparation method and application thereof

InactiveCN106216656AThe preparation method is simple and controllableThe preparation method is simple and environmentally friendlyMaterial nanotechnologyTransportation and packagingTitanium tetrafluorideMaterials science

The invention discloses a gold-doped titanium dioxide flower-like nanostructured material and a preparation method and an application thereof. In the nanostructured material, the average size of gold nanometer particle as a nucleus (pistil) is 20-50nm, and the average size of titanium dioxide nanoparticle as a casing (petal) is 50-100 nm. The preparation method comprises the steps of (1) mixing an auric chloride acid solution and a trisodium citrate solution, stirring, then adding a ascorbic acid solution and stirring, then adding a titanium tetrafluoride solution and stirring uniformly to obtain a mixed solution; (2) conducting high temperature hydrothermal reaction to the mixed solution obtained from step (1) for a period of time, and washing and drying a sediment obtained from the reaction to obtain a gold-doped titanium dioxide flower-like nanostructured material. The obtained material has the advantages that the size of the nanometer particles are uniform, and the disperse performance is good. The material is applied for preparing gas-sensitive elements, and has a high sensitivity and selectivity and short response recovery time to carbon monoxide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

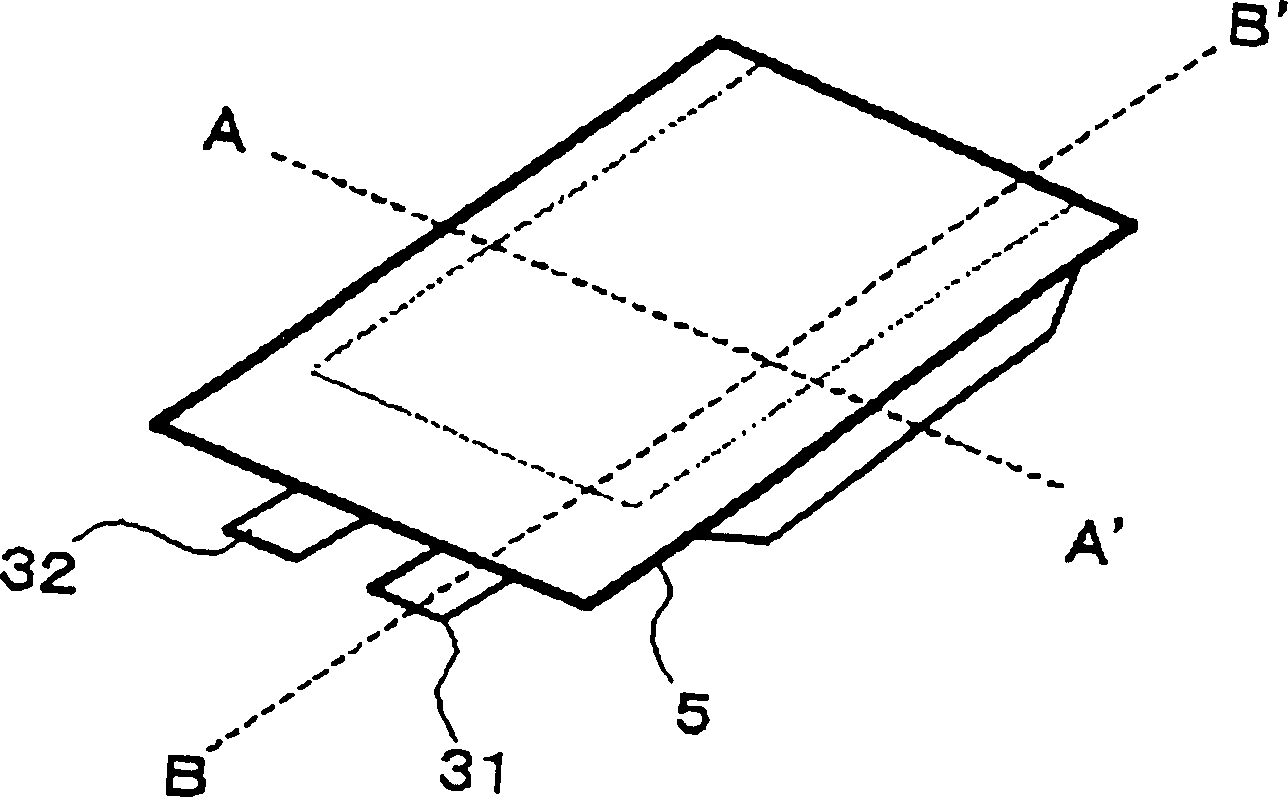

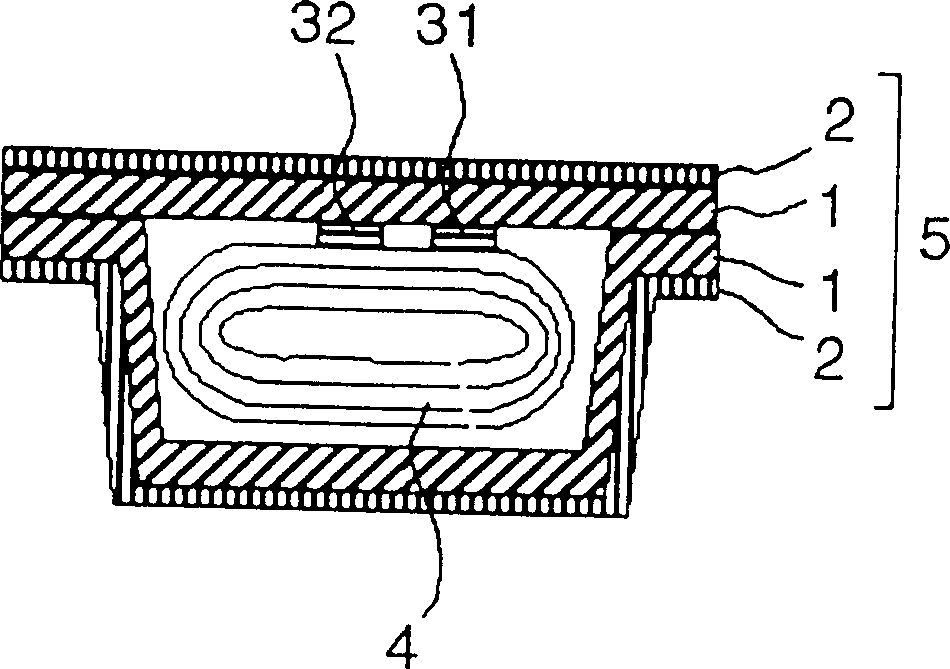

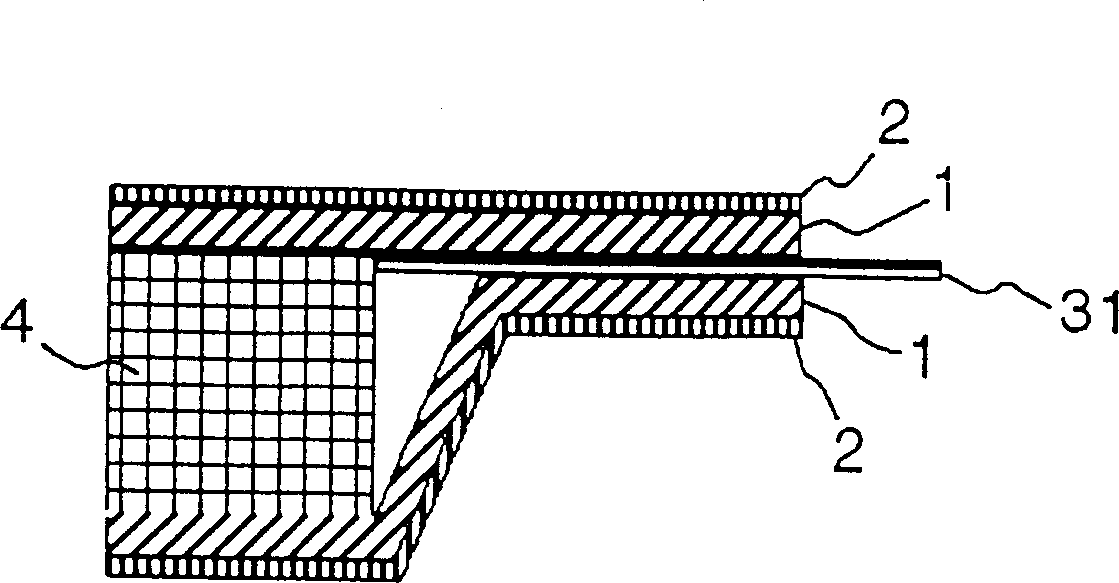

Film packed nonaqueous electrolyte battery with improved surface treated lead terminal

A membrane-sealed non-aqueous electrolyte battery includes: a battery element including a non-aqueous electrolyte; a membrane casing having at least one sealant polymer resin film for sealing the battery element; at least one membrane extending from the battery element and being The lead terminal protruding from the film case, and the lead terminal having one surface has a contact area that directly contacts the encapsulant polymer resin film, and at least the contact area of the surface of the lead terminal is coated There is an anti-corrosion coating film, wherein the anti-corrosion coating film includes: (A) a polymer having a phenolic compound structural unit, and at least a part of the structural unit includes a substituent containing an amino group or a substituted amino group; (B) a phosphate compound; and (C) titanium fluoride compounds.

Owner:NEC CORP +1

Metal surface treating process and metal surface treating agent

ActiveCN108165968AAccelerated corrosionImprove wear resistanceMetallic material coating processesTitanium fluorideSodium hydroxide

The invention relates to a metal surface treating process and a metal surface treating agent. The metal surface treating process comprises the steps that a metal workpiece is degreased, subjected to wax removing and cleaned and then dried; sodium hydroxide aqueous solution steam of 0.8Mpa is pumped into a sealed erosion chamber, the metal workpiece is arranged in the erosion chamber and then placed in a salpeter solution for neutralizing treatment, and the surface of the metal workpiece is completely washed and then dried; and the surface of the metal workpiece is coated with the metal surfacetreating agent and subjected to heat treatment; and the metal surface treating agent is composed of an organic condensation compound, zirconium nitrate, titanium fluoride, hydrofluoric acid, modifiedborax and modified ferromanganese sulfate. According to the technical scheme, by using sodium hydroxide aqueous solution steam with pressure, sodium hydroxide does not form liquid flow on the metal surface, the surface of the metal workpiece eroded by the process is uniform, thus, the adhesiveness of the surface treating agent on the metal surface is balanced, and the corrosion resistance and abrasion resistance of the metal surface are improved.

Owner:NINGBO CITY XINGUANG SHELF

Preparation of TiB2-TiB/Ti gradient composite porous material used for aluminum electrolysis

InactiveCN105088277AExtended service lifeStable cathode reaction interfaceTitanium fluorideElectrolysis

The invention discloses preparation of a TiB2-TiB / Ti gradient composite porous material used for aluminum electrolysis. The composite material reacts with a mixture of borofluoride and titanium fluoride to generate titanium boride and cryolite, and a cathode material with a TiB crystal whisker layer existing between a TiB2 plated layer and matrix titanium is obtained through solid infiltration processing. The bonding strength of a TiB2 deposition layer and a matrix of the cathode material is high. Under the use condition, the TiB2 layer is not prone to falling off from the matrix, and therefore the service life of the cathode material is effectively prolonged, and complete wetting of molten aluminum is achieved through the porous structure of the cathode material. The preparation is simple in method and process, easy to control and low in production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

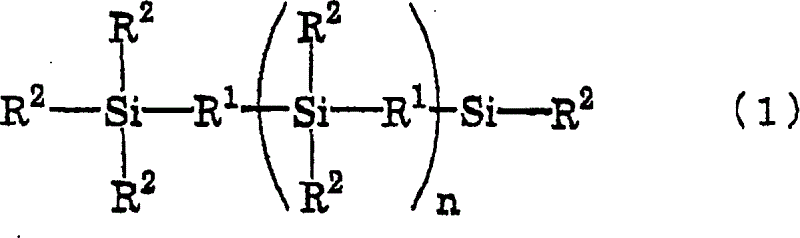

Method for treating adhesive before coating and aluminium alloy part

InactiveCN1775882AHigh bonding strengthGood adhesionAdhesive processes with surface pretreatmentChemical treatmentPretreatment method

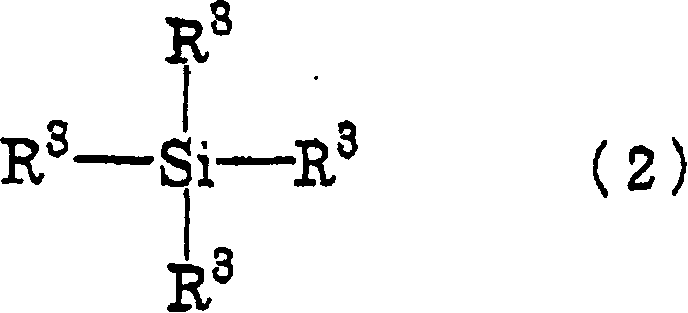

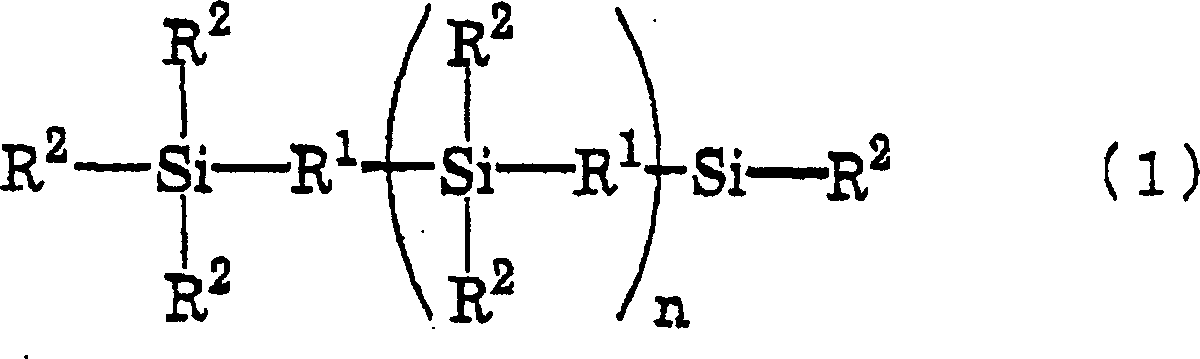

The invention provides a pretreatment method for adhesive coating, which does not use harmful heavy metals such as chromium, can improve the adhesiveness of the subsequent coated adhesive and metal, and can improve the adhesion between the metal and other parts to be bonded strength and bond durability. The present invention relates to a pretreatment method for adhesive coating of metal parts, the method comprising the following steps (I) and (II), in the step (I), using at least one zirconium fluoro complex and / or Or the chemical treatment solution of titanium fluoride complex to treat the object to be treated; in the process (II), the surface treatment solution containing the hydrolyzed polycondensate of (A) and (B) is coated, and the (A) is based on At least one crosslinking silane coupling agent represented by formula (1) or its hydrolyzed polycondensate; (B) is at least one adhesion-promoting silane coupling agent represented by formula (2) on the right or its hydrolyzed condensation polymer.

Owner:JAPAN BRAKE IND CO LTD

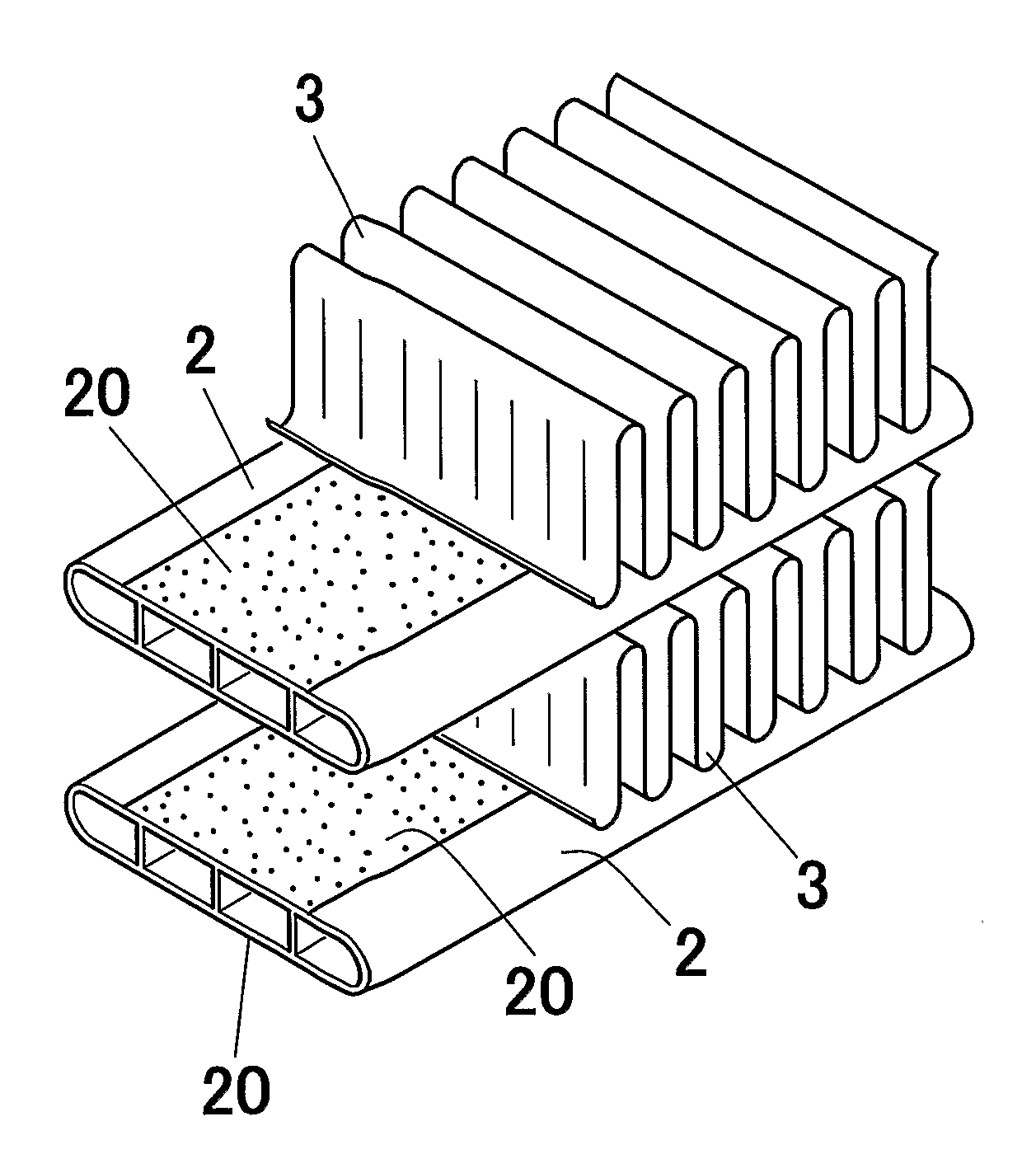

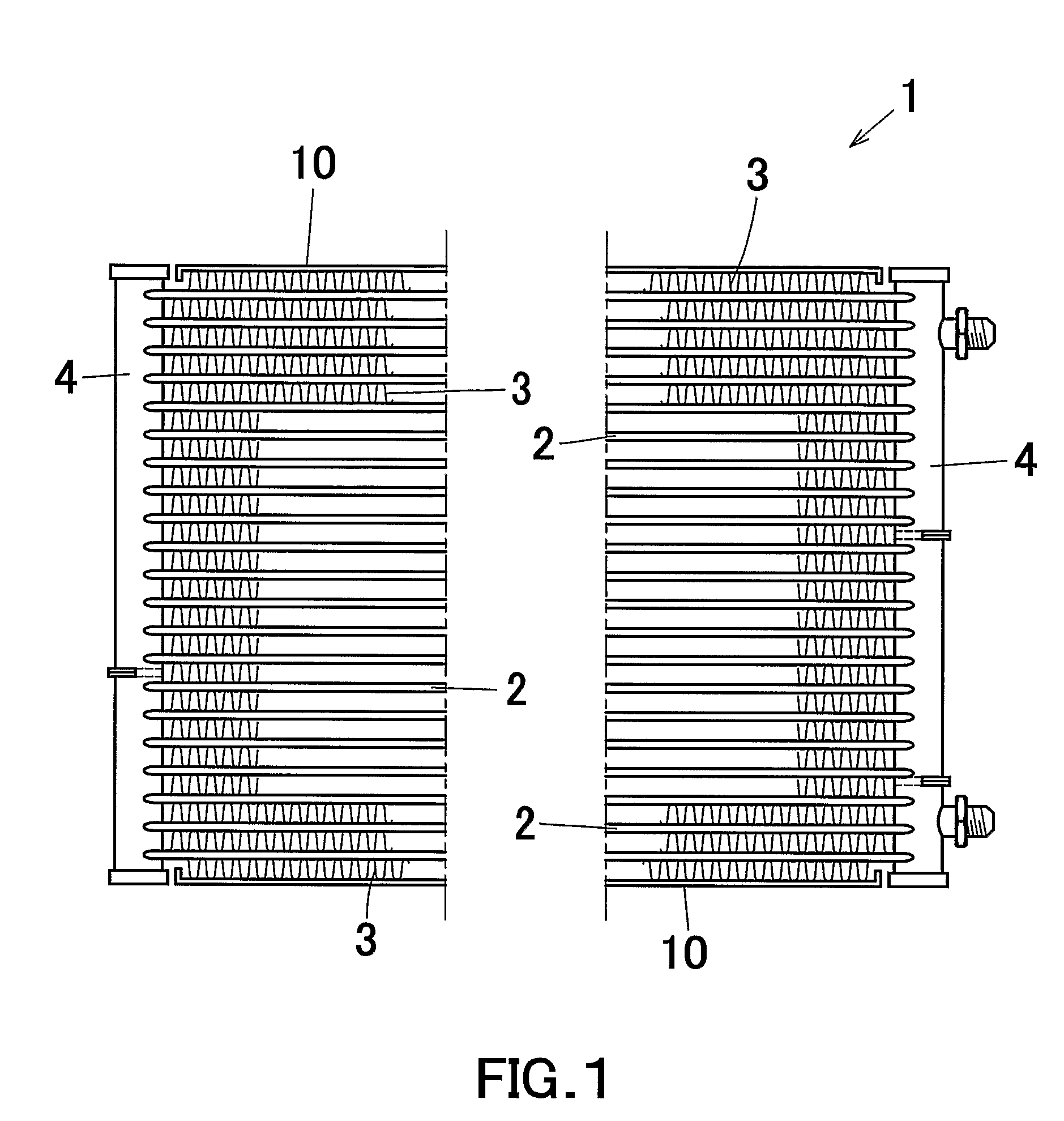

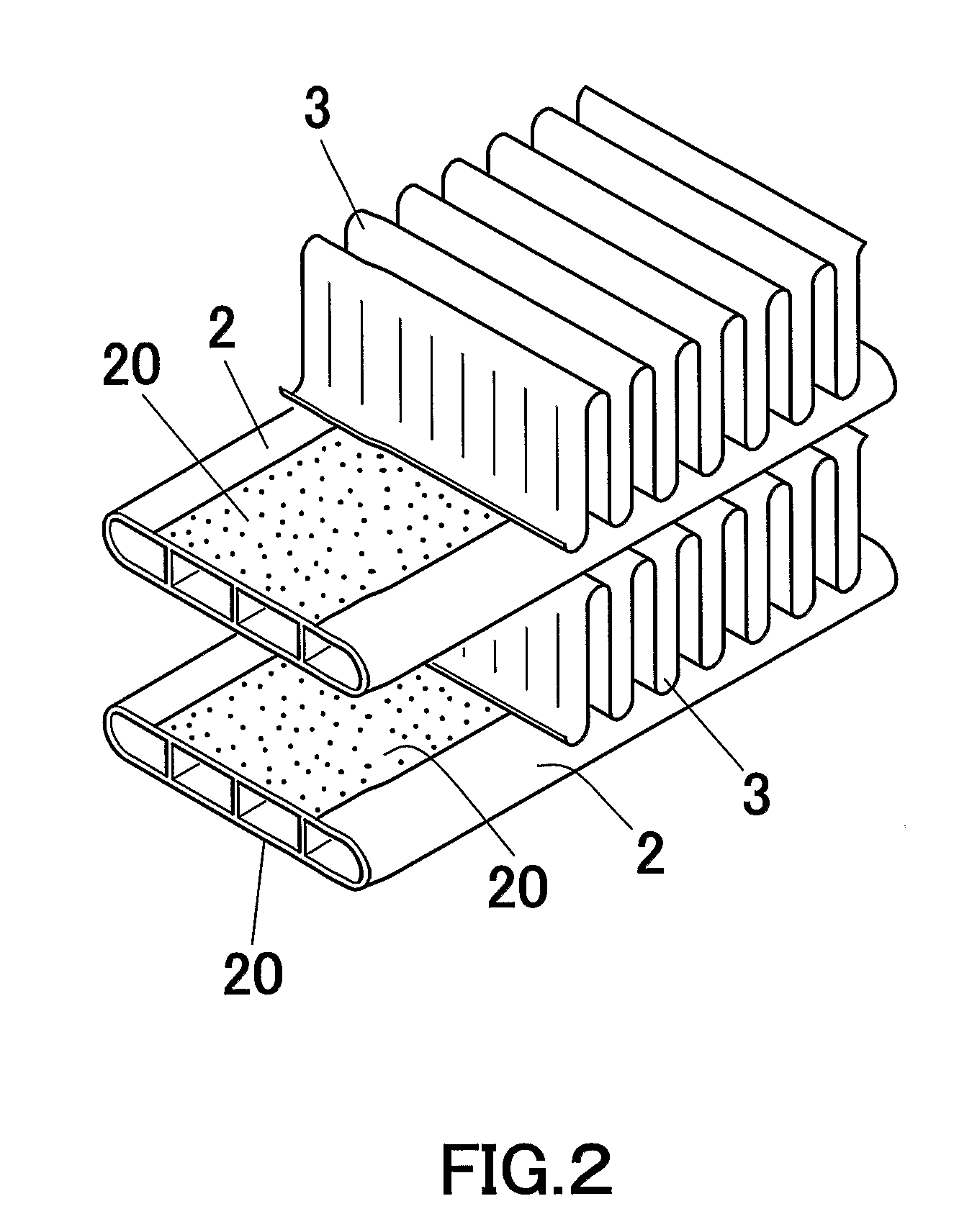

Heat exchanger and method for manufacturing the same

InactiveUS20070163761A1Improve corrosion resistanceAvoid it happening againEvaporators/condensersCorrosion preventionO-Phosphoric AcidEngineering

A method for manufacturing an aluminum heat exchanger includes the steps of: obtaining a heat exchanger tube 2 by forming a Zn thermally sprayed layer on a surface of an aluminum flat tube core so as to adjust Zn adhesion amount to 1 to 10 g / m2; obtaining a heat exchanger core by alternatively arranging the heat exchanger tube 2 and an aluminum fin 3 and brazing the heat exchanger tube and the fin with end portions of the heat exchanger tube connected to aluminum headers in fluid communication; and forming a chemical conversion treatment coat (corrosion resistance coat) on a surface of the heat exchanger core by subjecting the surface of the heat exchanger core to chemical conversion treatment using at least one chemical conversion treatment agent selected from the group consisting of phosphoric acid chromate, chromic acid chromate, phosphoric acid zirconium series, phosphoric acid titanium series, fluoridation zirconium series, and fluoridation titanium series. The obtained heat exchanger has a long last good corrosion resistance and can prevent occurrence of fin detachment and pit corrosion.

Owner:SHOWA DENKO KK

Metal surface anti-corrosion treating agent and preparation method thereof

ActiveCN103526195AImprove corrosion resistanceImprove coating adhesionMetallic material coating processesTitanium fluorideMetal

The invention relates to a metal surface anti-corrosion treating agent and a preparation method thereof. The metal surface anti-corrosion treating agent comprises titanium fluoride, zirconium nitrate, zirconium fluoride, peroxy-vanadic acid, aminosilane, 1,2-bis(triethoxysilyl)ethane and bis(triethoxysilyl)hexane, wherein the titanium fluoride, the zirconium nitrate and the zirconium fluoride account for 110-1400ppm or 550-650ppm of the total amount of the treating agent if converted into metallic elements, the ratio of metallic element atoms of the titanium fluoride, the zirconium nitrate and the zirconium fluoride is 1:1-1:3, the ratio of metallic element atoms of the zirconium nitrate and the zirconium fluoride is 2:5, the molar ratio of the aminosilane to the 1,2-bis(triethoxysilyl)ethane and the bis(triethoxysilyl)hexane is 17:3-9:1, and the molar ratio of the 1,2-bis(triethoxysilyl)ethane to the bis(triethoxysilyl)hexane is 1:1.

Owner:宁波英科特精工机械股份有限公司

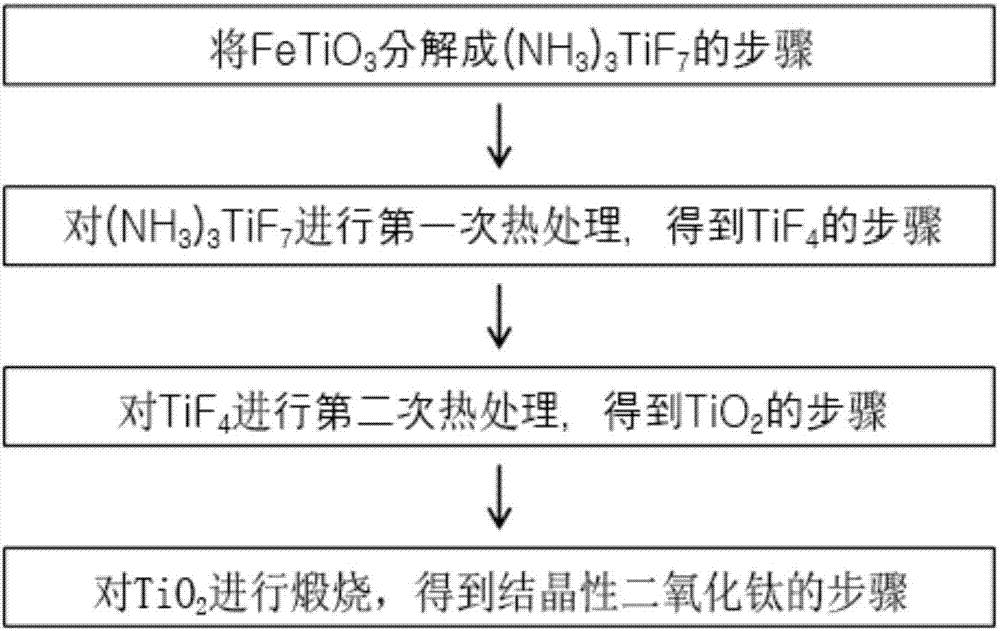

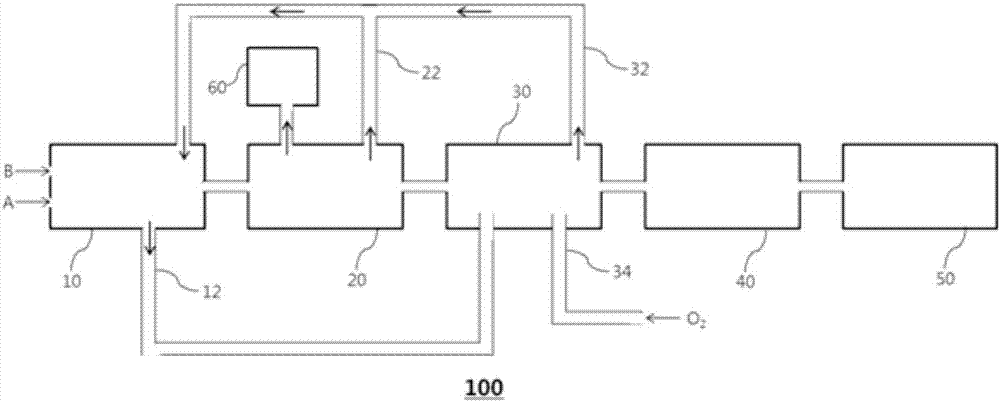

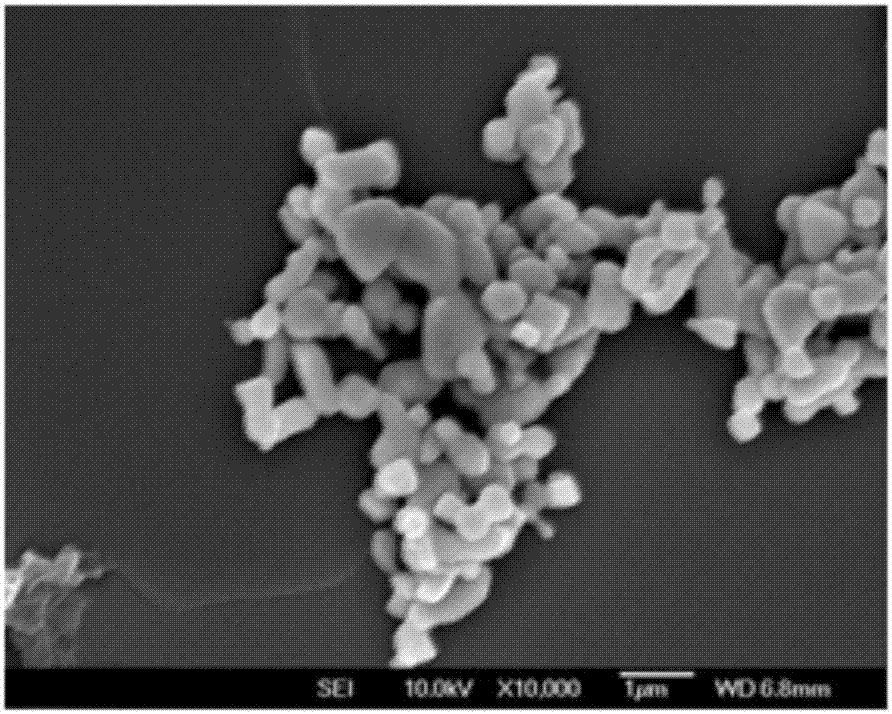

Method and apparatus for manufacturing titania

InactiveCN107226482AEasy dischargeHigh reactivityMaterial nanotechnologyTitanium dioxideHydrogen fluorideTitanium fluoride

The present invention relates to a method and an apparatus for producing titania. The method comprises the steps of: i) reacting ilmenite (FeTiO_3) with ammonia gas (NH_3) and hydrogen fluoride gas (HF) in an inert atmosphere to cause it to decompose into a titanium compound ((NH_3)_3TiF_7) and an iron compound ((NH_3)_3FeF_6); ii) subjecting the titanium compound to a first thermal treatment to produce a titanium fluoride (TiF_4); iii) subjecting the titanium fluoride to a second thermal treatment with ammonia water (NH_4OH) in an oxidizing atmosphere to produce titania (TiO_2); and iv) sintering the titania to prepare anatase-type titania or rutile-type titania, wherein the NH_3 and HF gases generated in the steps ii) and iii) are collected and recirculated to the step i).

Owner:莫诺利特株式会社

Titanium oxide-containing material and process for preparing the same

InactiveCN1257461AAntibacterialPromote photocatalytic functionTitanium dioxideCoatingsTitanium tetrafluorideTitanium fluoride

A titanium oxide-containing material having a surface plated with titanium oxide. It is prepared by dissolving titanium fluoride (such as titanium tetrafluoride) in an amount of 2.0 % owf in water, immersing a raw material in the obtained aqueous solution to treat the material with the aqueous solution at room temperature for 30 min, and adding a 0.5 : 1 : 1 (on a weight basis) mixture of boric acid, citric acid, and DL-malic acid in an amount of 0.5 % owf to the aqueous solution to treat the material with the aqueous solution at 50 DEG C for 30 min, followed by washing with water. The raw materials usable herein include synthetic fibers, metals, glass, and woods, and may be in the form of sheet, plate, fiber, rod, or the like. Introduction of a noble metal, such as gold or silver, in addition to titanium oxide, into the surface of the material enables the acceleration of the photocatalytic action of titanium oxide.

Owner:森敏股份有限公司

Synthetic method for high-performance liquid-phase chromatography column packing materials

The invention relates to a synthetic method for high-performance liquid-phase chromatography column packing materials. The synthetic method includes 1, buying market-sold multi-walled carbon nanotubes (MWCNTs) and taking 0.1g of the MWCNTs, adding 15ml thick HNO3 (Nitric acid) and 45ml thick H2SO4 (sulfuric acid) sequentially, performing ultrasonic processing for a period of time respectively, washing the mixture repeatedly with deionized water to be neutral, drying the mixture at the temperature of 100 DEG C for 12 hours, weighting proper processed MWCNTs and adding the MWCNTs into a titanium fluoride (TiF4) solution with certain concentration, and performing the ultrasonic processing on the mixed solution for 30 minutes to mix the mixed solution evenly; 2, pouring the prepared solution into a self-sealed bag, and placing the solution under a 2.5MeV (million electron volt) and 40mA (milliampere) electronic accelerator to be irradiated; 3, transferring the solution into a 200ml beaker, sealing the beaker with a sealing film, and putting the beaker in a baking oven at the temperature of 60 DEG C for 20 hours; and 4, washing the reacted products with water and ethanol sequentially, putting the washed products into a vacuum drying oven at the temperature of 60 DEG C for 6 hours, and then obtaining TiO2 (titanium dioxide) / MWCNTs. TiO2 / MWCNTs high-performance liquid-phase chromatography column packing materials prepared by the synthetic method have good separating efficiency, and separating detection effects of organic pollutants can be effectively improved.

Owner:SHANGHAI UNIV

Surface coating method of aluminum alloy wheel

PendingCN111763944AImprove bindingImprove stress residueVacuum evaporation coatingPretreated surfacesTitanium fluorideOxygen ions

The invention discloses a surface coating method for an aluminum alloy wheel. The surface coating method comprises the following steps of S1, grinding and polishing the aluminum alloy wheel; S2, cleaning the aluminum alloy wheel; S3, immersing the aluminum alloy wheel in a titanium fluoride / zirconium fluoride solution, thereby forming an Al2O3.ZrO2.TiO2 conversion film on the surface of the aluminum alloy wheel; S4, ionizing oxygen with the concentration of 99.999% through radio frequency, and forming oxygen ions to treat the surface of the aluminum alloy wheel; S5, adding acetylene gas whilecarrying out magnetron sputtering coating; and S6, spraying a transparent protective layer, baking and curing. The coating film is better in corrosion resistance, low in cost and low in energy consumption, toxic metal such as hexavalent chromium is not contained, and the technological process is green and environmentally friendly.

Owner:CITIC DICASTAL

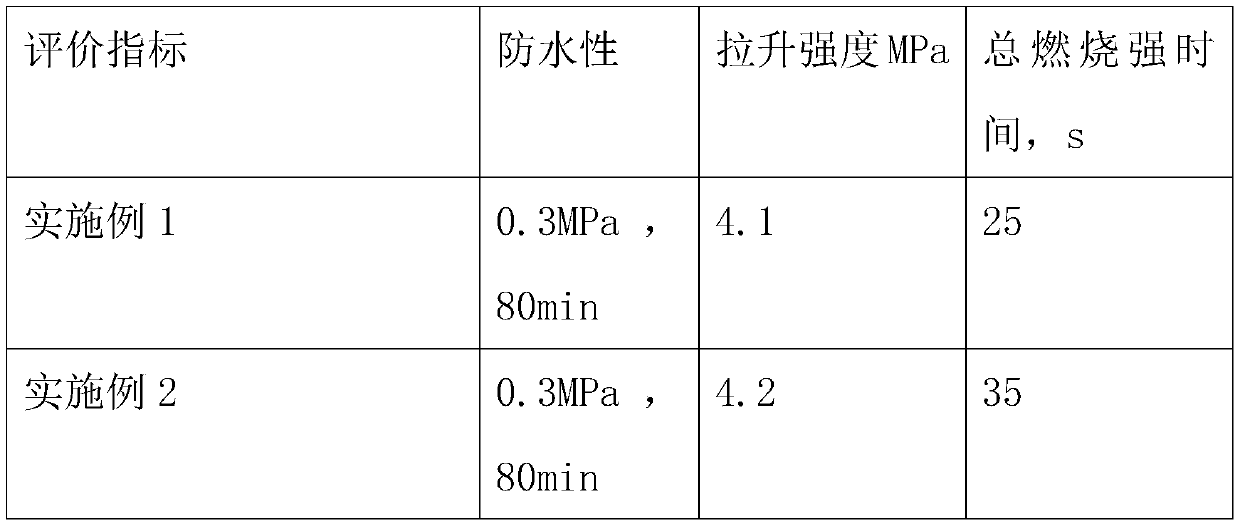

Photocatalyst comprising titanium fluoride nitride for water decomposition with visible light irradiation

InactiveUS7015171B2Catalyst activation/preparationHydrogen productionTitanium fluorideAlkaline earth metal

A photo-catalyst containing titanium fluoride nitride comprising, Ti(IV)OaNbFc or a compound represented by MeTi(IV)OaNbFc prepared by doping at least one metal Me selected from the group consisting of alkali or alkaline earth metals on Ti(IV)OaNbFc. (wherein, b is 0.1 to 1, c is 0.1 to 1 and a is a value to maintain Ti(IV) and is decided in relation to b and c.). The photo-catalyst containing titanium fluoride nitride is especially characterized by loading at least one promoter selected from the group consisting of Pt, Ni and Pd.

Owner:JAPAN SCI & TECH CORP

Polyurethane waterproof coating and preparation method thereof

InactiveCN110982408AImprove adhesionImprove waterproof performanceAntifouling/underwater paintsPaints with biocidesCyclohexanonePolymer science

Polyurethane waterproof coating is disclosed, including following raw materials by weight: 40-45 parts of high-strength hydrophobic polyurethane, 3-8 parts of epoxy resin, 20-25 parts of short-oil alkyd resin, 12-15 parts of petroleum asphalt, 1-2 parts of carbon black, 2-3 parts of polyethylene oxide, 0.2-0.6 part of calcium lignosulfonate, 1-2 parts of highly active titanium fluoride, 2-5 partsof nano silica, 15-20 parts of a hot-melt adhesive, 3-5 parts of high-density polyethylene, 3-6 parts of nanometer graphene, 4-8 parts of nano tin antimony oxide, 2-3 parts of polypropylene fibers, 1-3 parts of nano alumina, 2-3 parts of parathion-methyl, 3-8 parts of bentonite, 3-6 parts of a mixture of polyvinyl chloride wax and castor oil, 2-5 parts of a coupling agent, 1-3 parts of cyclohexanone, 5-15 parts of a highly effective antibacterial component, 4-8 parts of an antifungal agent, 0.1-0.4 part of a defoaming agent, 1-2 parts of an ultraviolet absorber and 1-3 parts of a flame retardant. The coating has the advantages of high antibacterial property, strong adhesion and good waterproof property.

Owner:广东向诚新材料有限公司

Cast iron surface treatment agent and treatment method

InactiveCN103526250AImprove corrosion resistanceImprove coating adhesionSurface reaction electrolytic coatingTitanium fluorideSilanes

The invention relates to a cast iron surface treatment agent and a treatment method. The cast iron surface treatment agent comprises titanium fluoride, zirconium nitrate, zirconium fluoride, amino silane, 1, 2-bis(triethoxysilyl) ethane and bis(triethoxysilyl) hexane, further comprises 10-50ppm free fluoride ions and has the PF value of 3.2-4.5. The treatment method comprises the following steps of arranging a cast iron material at a cathode of an electroplating device and electrolyzing the cast iron material in an anticorrosive agent.

Owner:NINGBO JINHENG MACHINERY MFG

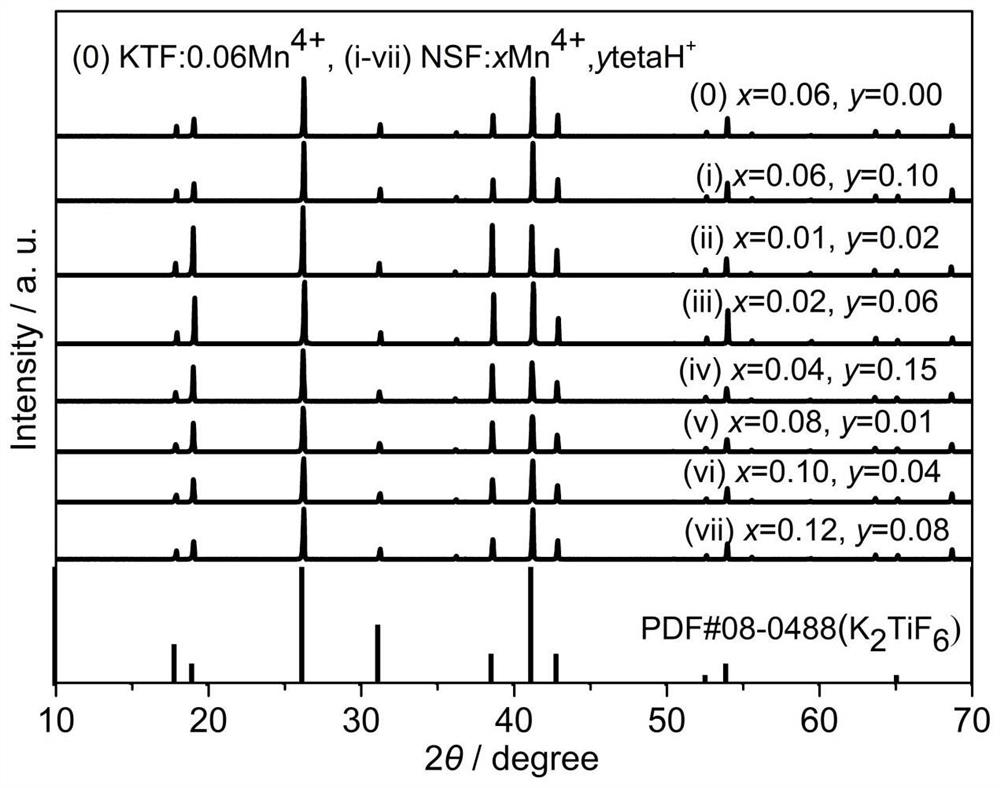

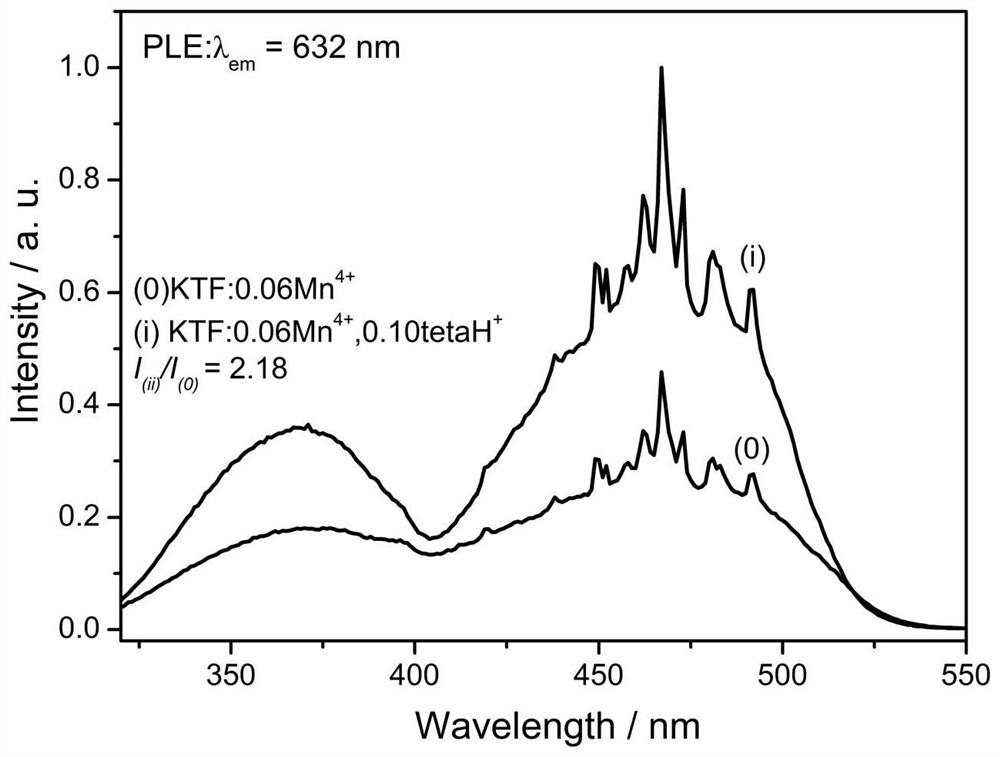

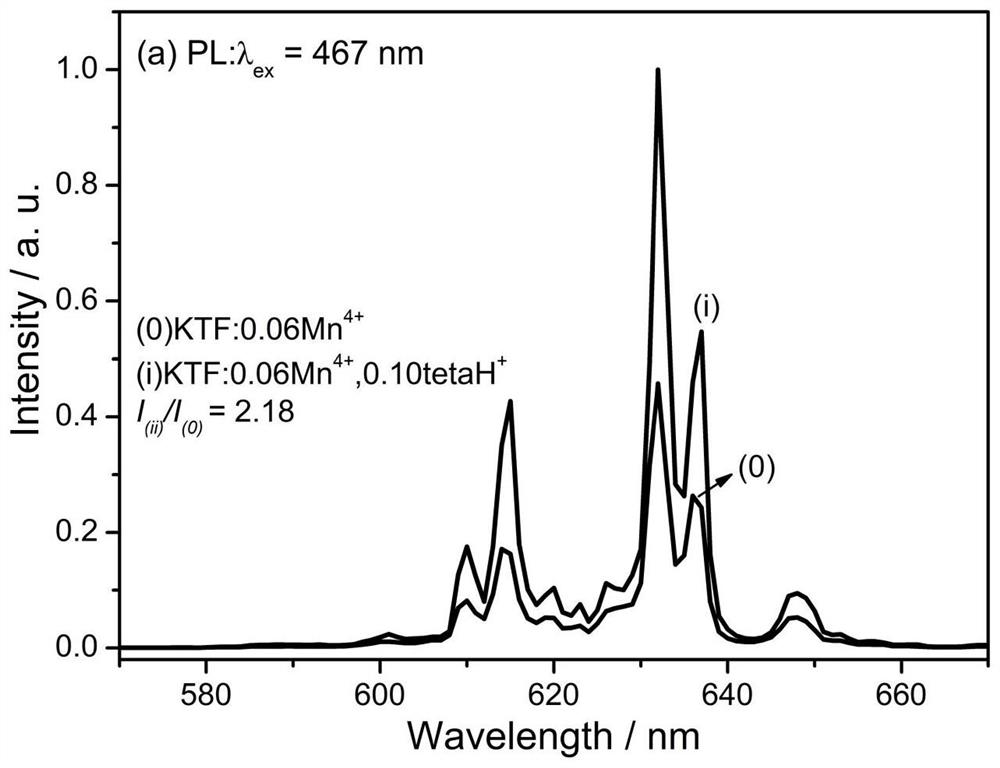

Organic-inorganic hybrid fluorine titanium potassium red-light fluorescent powder and preparation method thereof

ActiveCN114181700AStrong red light emissionHigh luminous thermal stabilityEnergy efficient lightingLuminescent compositionsTitanium fluorideTetramine

The invention belongs to the technical field of preparation of fluorescent powder, and particularly relates to organic-inorganic hybrid fluorine titanium potassium red-light fluorescent powder, the general formula of which is K2TiF6: xMn < 4 + >, ytetaH < + >, tetaH < + > represents that triethylene tetramine is subjected to organic-inorganic hybridization, and triethylene tetramine exists in a protonation form after hybridization; x is the mole fraction of Mn < 4 + > doping, y is the mole fraction of triethylene tetramine doping, x is larger than or equal to 0.01 and smaller than or equal to 0.12, and y is larger than or equal to 0.0 and smaller than or equal to 0.15. The invention also provides a preparation method of the organic-inorganic hybrid potassium titanium fluoride red-light fluorescent powder, which comprises the following steps: (1) reacting triethylene tetramine with an H2TiF6 solution and a K2CO3 solution, and drying to obtain K2TiF6: ytetaH < + >; and (2) reacting KF. 2H2O with an HF solution, a K2MnF6 solution and K2TiF6: ytetaH < + >, sealing, standing, carrying out suction filtration, washing and drying to obtain the K2TiF6: xMn < 4 + >, ytetaH < + >. The obtained red-light fluorescent powder has the advantages of high luminescence, high intensity, water resistance, thermal stability and the like.

Owner:广西经正涂料有限公司 +1

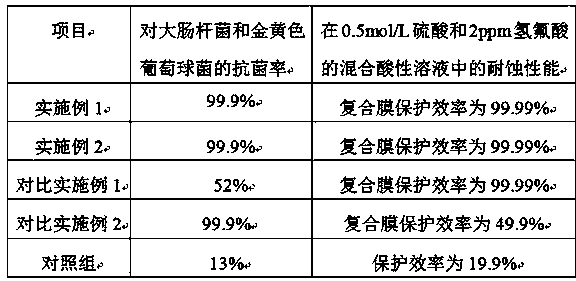

Antibacterial functionalizing-corrosion-resistant modification method for aluminum alloy surface

InactiveCN109852960AImprove corrosion resistanceAchieve compositeMetallic material coating processesTitanium fluorideSilanes

The invention discloses an antibacterial functionalizing-corrosion-resistant modification method for the aluminum alloy surface. The aluminum alloy after the hot water processing and surface activating is soaked in the quaternary ammonium salt solution and then taken out, the dehydration coupling reaction is conducted in a heat insulation box, the obtained product is taken out, carried out still standing, soaked and rinsed in the ethanol solution and the deionized water, and the obtained product is taken out, and dried to obtain the surface graft antibacterial aluminum alloy; and the obtainedsurface graft antibacterial aluminum alloy is immersed in the titanium fluoride modified silane conversion solution, the obtained product is taken out after deposition, the surface residue liquid is absorbed with the water absorbing paper, the obtained product is dried to obtain the aluminum alloy through the surface composite transformation, the aluminum alloy through the surface composite transformation is placed in the polyethylene imine solution, still standing in the water, washing, and natural drying are conducted, then the obtained product is soaked in the graphene oxide solution, washed with a large amount of deionized water, dried with the cold air, then soaked in the chitosan-acetic acid water solution, washed with a large amount of deionized water, and dried with the cold wind,and self-assembling circulating is conducted in the graphene oxide solution and the chitosan-acetic acid water solution alternately and circularly.

Owner:姜水英

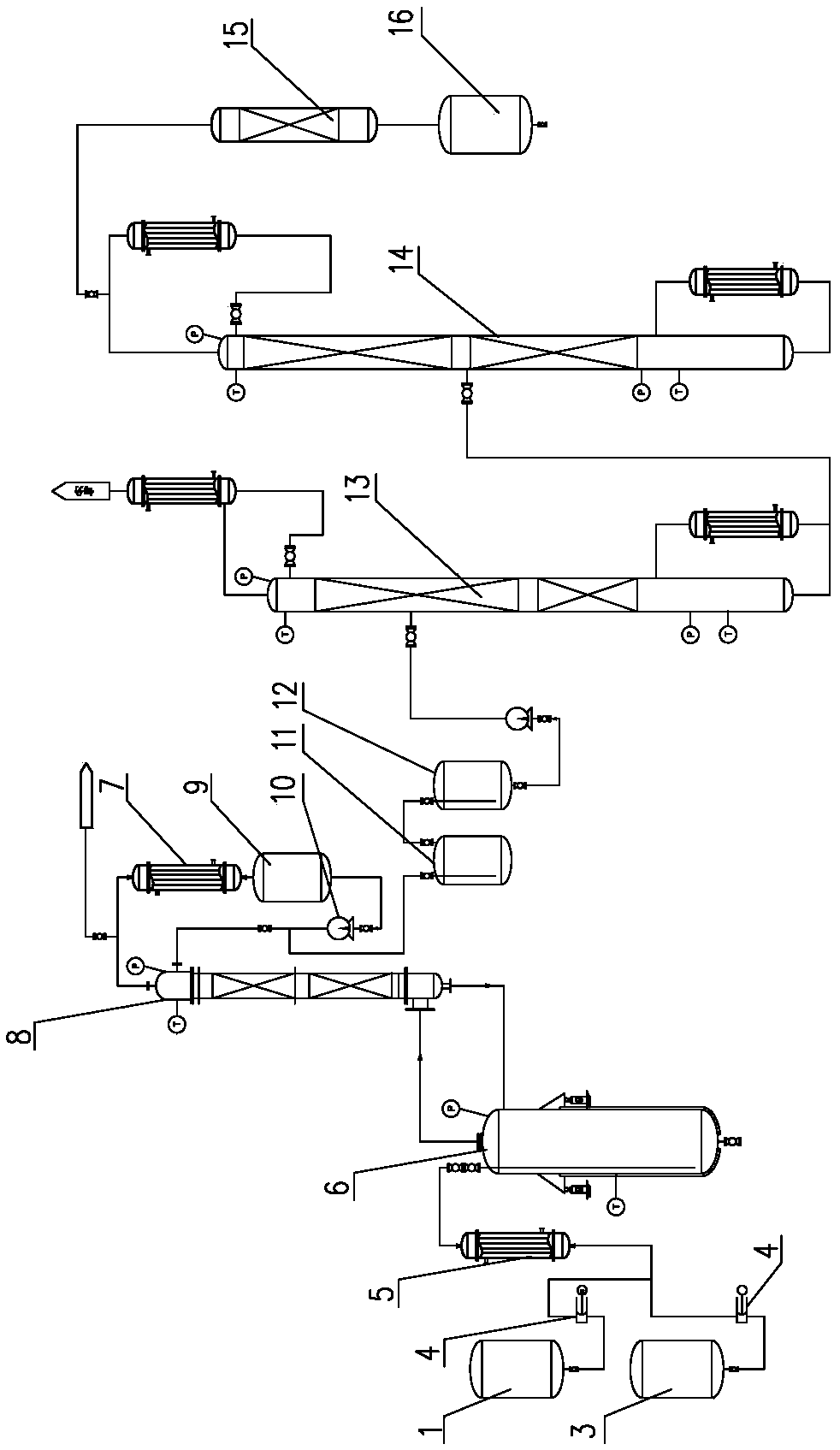

Preparation device and preparation method for 2,3,3,3-tetrafluoropropene

ActiveCN109384640ASimple structureEasy to operatePreparation by hydrogen halide split-offPreparation by halogen replacementAluminium chlorideTitanium fluoride

The invention relates to a preparation device and a preparation method for 2,3,3,3-tetrafluoropropene and belongs to the technical field of fluorochemical industry. The preparation device for 2,3,3,3-tetrafluoropropene is simple in structure, easy to operate, low in energy consumption and suitable for industrial production. According to the preparation method for 2,3,3,3-tetrafluoropropene, 1,1,1,2,3-pentachloropropane or 1,1,2,3-tetrachloropropene and hydrogen fluoride are taken as raw materials, any one or a combination of tin tetrachloride, stannous fluoride, antimony chloride, titanium tetrachloride, titanium fluoride, aluminium chloride and aluminum fluoride is taken as a catalyst, and 2,3,3,3-tetrafluoropropene is synthesized with a one-step liquid phase method with high catalyst contact rate. The process is simple, and the technological flow is simplified greatly; equipment investment is reduced remarkably due to less equipment, and 99.9% 2,3,3,3-tetrafluoropropene can be obtained. The product selectivity is high, reaction is completed by one step, the flow is short, the conversion rate is high, few byproducts are produced, and energy consumption is low.

Owner:SHANDONG HUAAN NEW MATERIAL

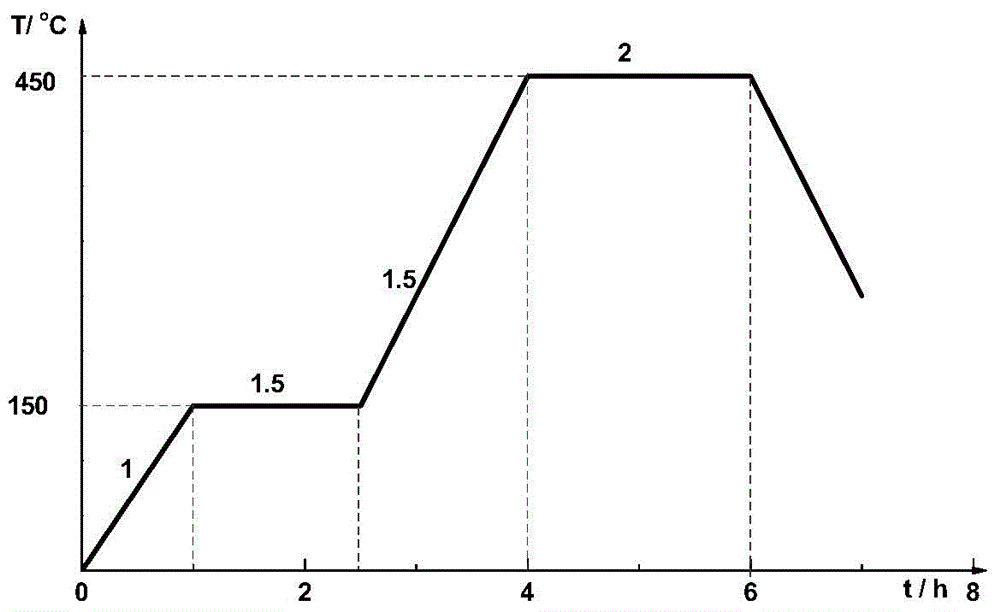

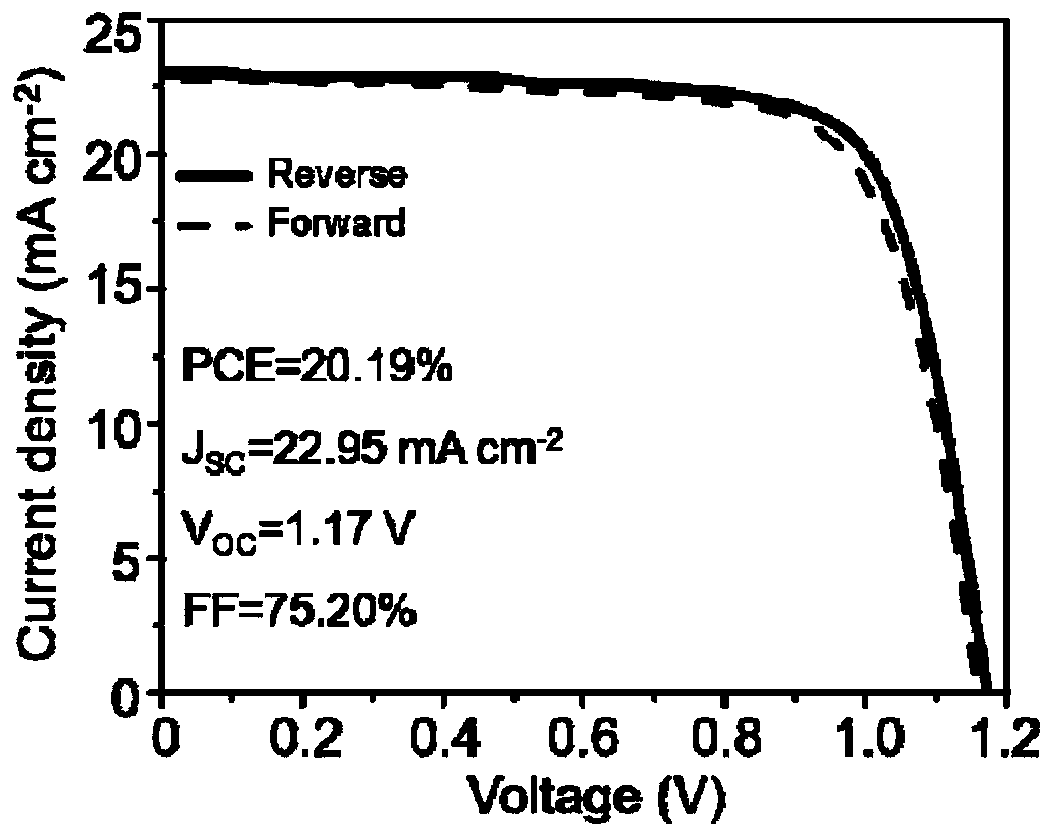

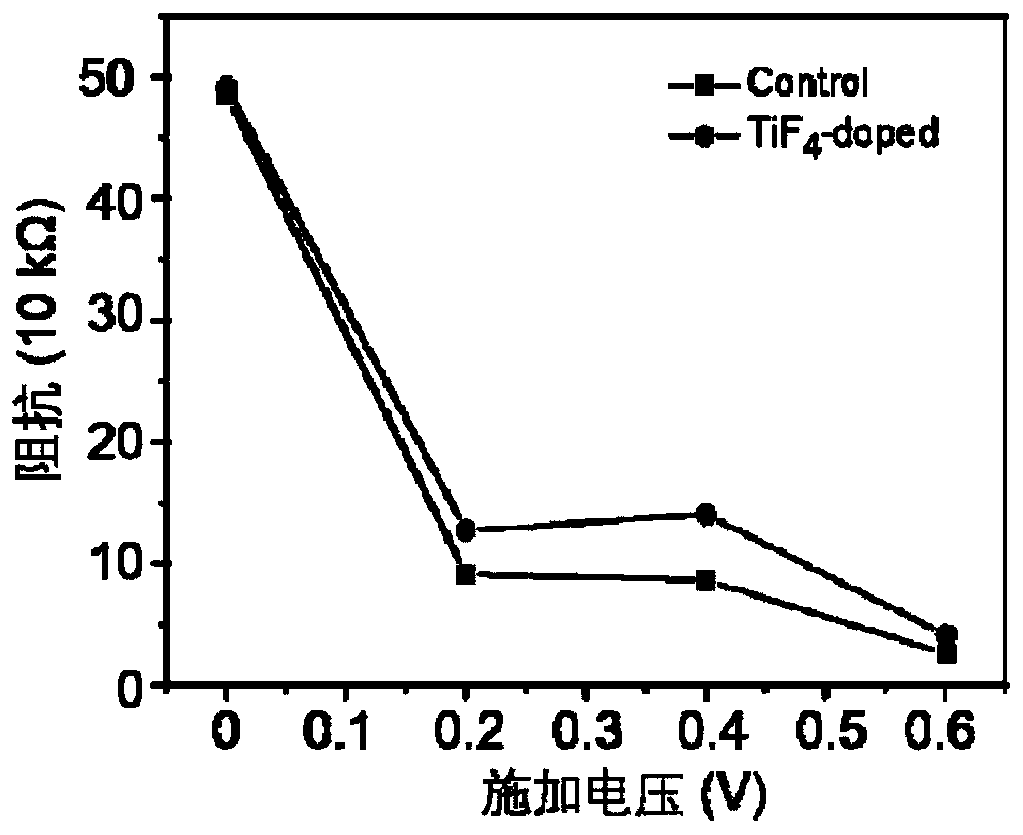

Preparation method and application of titanium tetrafluoride passivated perovskite battery interface

ActiveCN110854276ASimple and fast operationGood repeatabilitySolid-state devicesSemiconductor/solid-state device manufacturingTitanium tetrafluorideTitanium fluoride

The invention relates to a preparation method and an application of a titanium tetrafluoride passivated perovskite battery interface. The preparation method comprises the following steps: dissolving 2-8mg of titanium tetrafluoride powder into 1mL of N, N-dimethylformamide solution; taking and diluting 2-20[mu]L of titanium tetrafluoride-N, N-dimethylformamide solution, adding less than 20[mu]L ofthe diluted N, N-dimethylformamide solution into 100[mu]L of an FACs-based perovskite precursor solution with a concentration of 0.8-1.2 mol / mL; and shaking the solution to a uniform state, spin-coating conductive glass FTO covered by titanium dioxide with the solution to form a film, carrying out annealing and cooling, applying a hole layer by spin-coating, vapor-depositing conductive electrode silver, and assembling a complete perovskite solar cell. Fluorine and titanium ions of titanium tetrafluoride in the perovskite solution are spontaneously dispersed on the upper interface and the lowerinterface of the perovskite absorption layer film, so that corresponding defects at the interface of the battery film can be passivated, the performance of an original battery is improved by about 12.6%, and the stability is obviously improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com