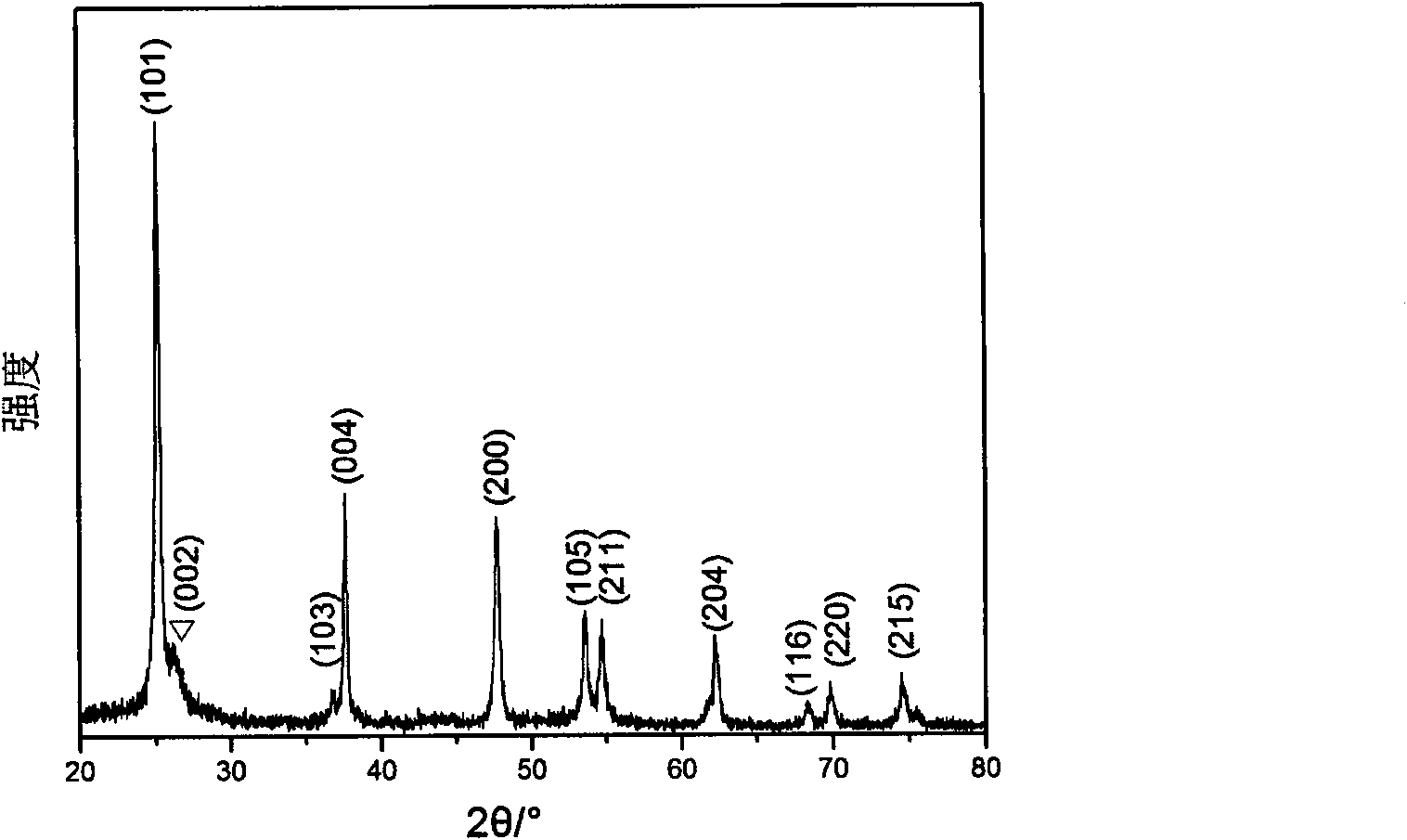

Method for preparing composite photocatalyst of titanium oxide/multi-wall carbon nano pipe by electron-beam irradiation

A technology of multi-walled carbon nanotubes and electron beam irradiation, which can be used in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc. problem, to achieve the effect of convenient operation, low cost and good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

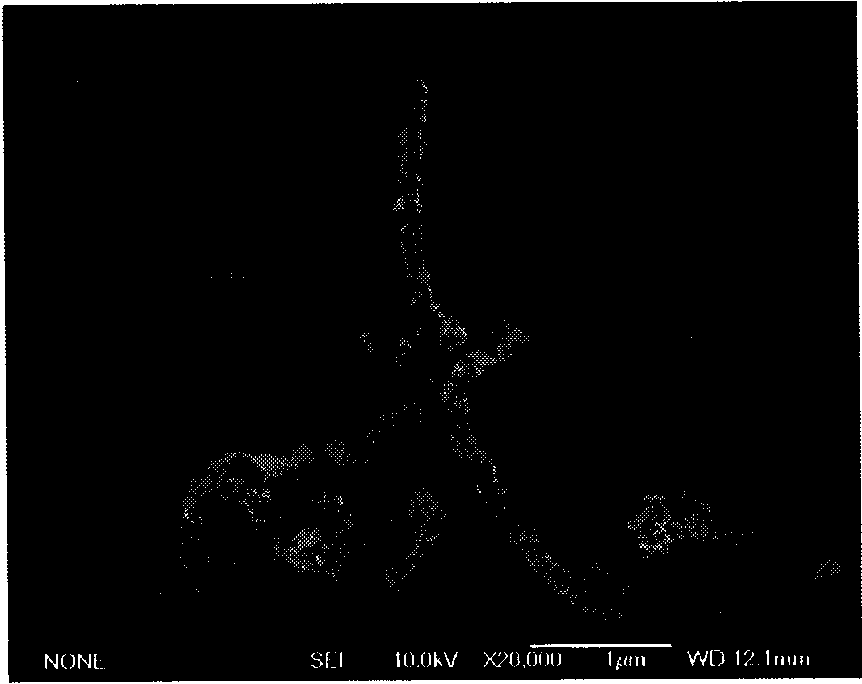

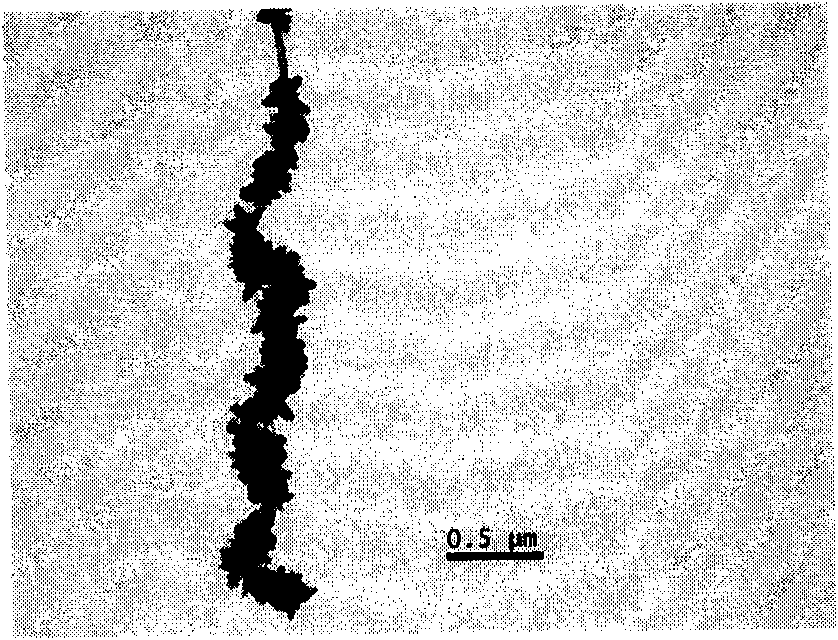

Embodiment 1

[0021] The preparation process and steps of this embodiment are as follows:

[0022] a. Weigh 0.025g of multi-walled carbon nanotubes (MWCNTs) with an electronic balance and add to 40mL of 0.08mol / L TiF 4 In the aqueous solution, and ultrasonic for 30min to make it evenly mixed;

[0023] b. Transfer the above solution to a self-made sealed bag, and place it in the irradiation area under the electron accelerator for irradiation, the irradiation dose is 280kGy;

[0024] c. Transfer the irradiated solution into a 200mL beaker, seal it with a parafilm and put it in an oven at 60°C for 20 hours;

[0025] d. Wash the reaction product with water and ethanol successively;

[0026] e. Put the washed product in a vacuum drying oven at 60℃ for 6 hours to dry, and finally get TiO 2 / MWCNTs composite photocatalyst.

Embodiment 2

[0028] The steps in this embodiment are exactly the same as the first embodiment described above. The difference is: weigh 0.050g MWCNTs and add it to TiF 4 In the aqueous solution, the composite photocatalyst is finally prepared.

Embodiment 3

[0030] The steps in this embodiment are exactly the same as the first embodiment described above. The difference is: weigh 0.075g MWCNTs and add to TiF 4 In the aqueous solution, the composite photocatalyst is finally prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com