Patents

Literature

65 results about "Titanium tetrafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium(IV) fluoride is the inorganic compound with the formula TiF₄. It is a white hygroscopic solid. In contrast to the other tetrahalides of titanium, it adopts a polymeric structure. In common with the other tetrahalides, TiF₄ is a strong Lewis acid.

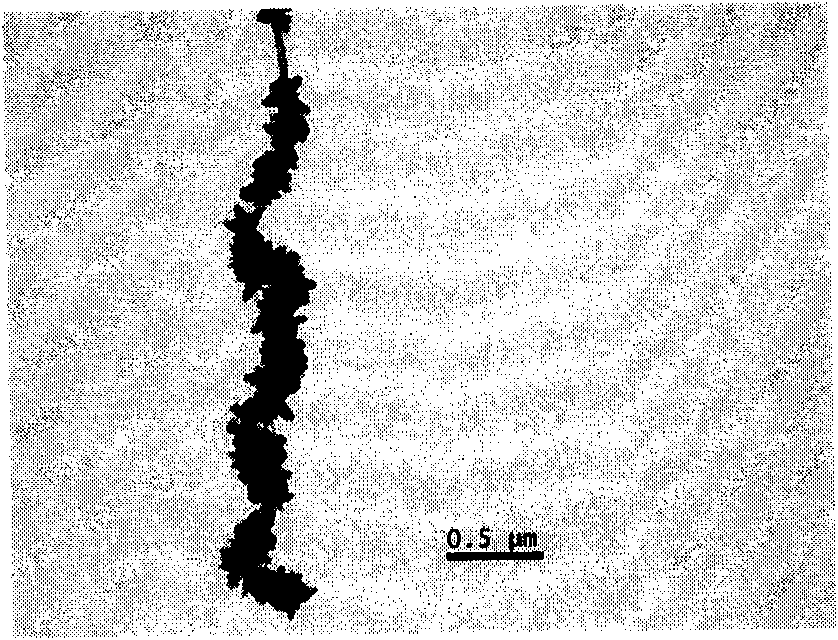

Method for preparing graphene-based titanium dioxide composite photocatalyst by radiation of electron beams

ActiveCN101658786AWrappedPromote growthWater/sewage treatment by irradiationWater contaminantsTitanium tetrafluorideRadiation chemistry

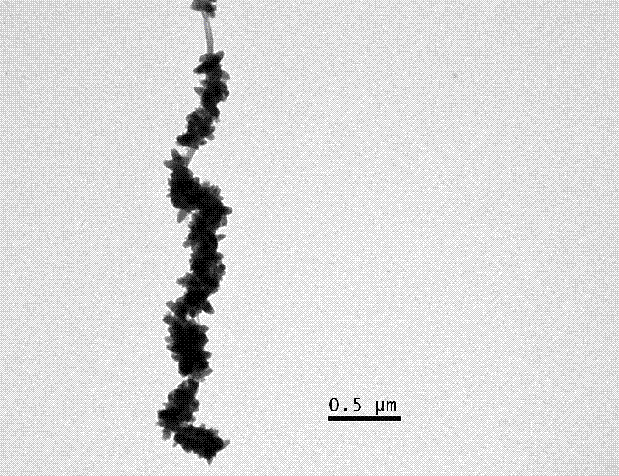

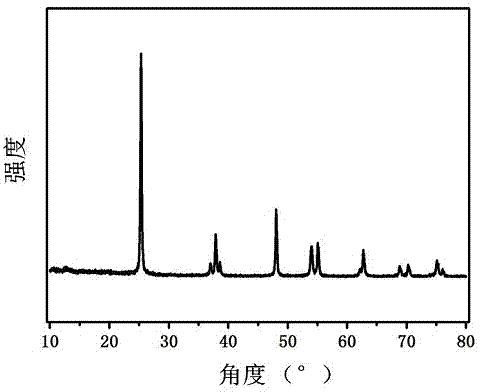

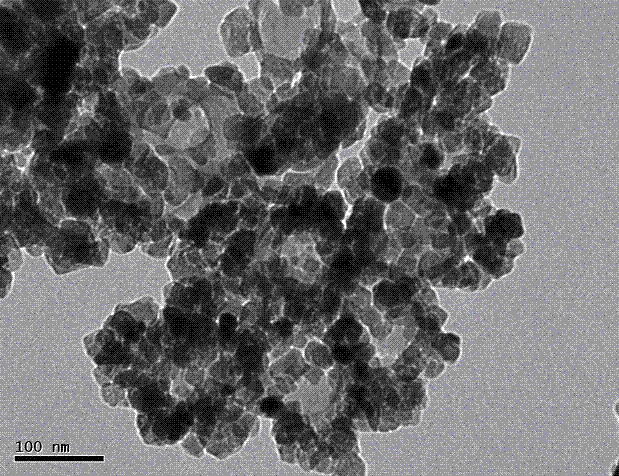

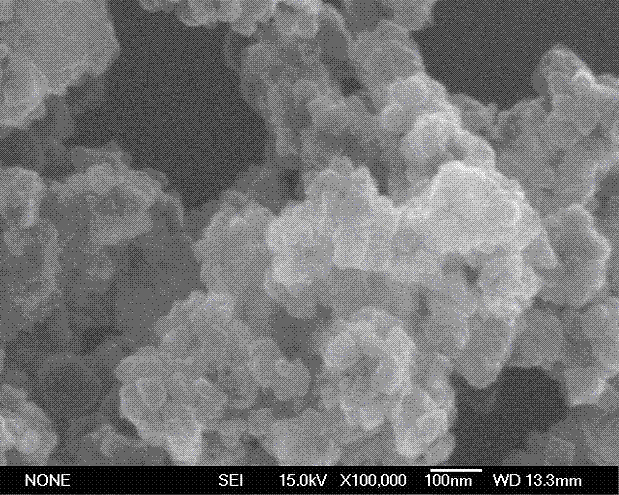

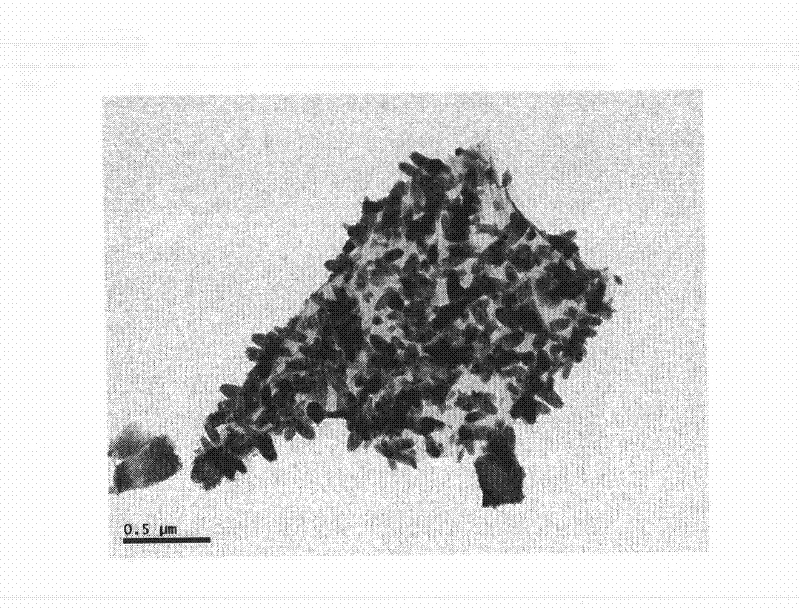

The invention relates to a method for preparing a graphene-based titanium dioxide composite photocatalyst by radiation of electron beams, belonging to the technical fields of radiation chemistry and photocatalyst preparation. The method comprises the following steps: firstly, preparing graphene by the prior art, then adding the graphene powder into a titanium tetrafluoride solution, and dispersingthe graphene powder with ultrasonic waves to obtain a suspension; then putting the suspension in an electron beam generating device to be radiated by a certain dose of electron beams, the irradiationdose of which is 70-280KGy; after sealing, putting the suspension in an oven of 60 DEG C for reaction for 20 hours; and finally, obtaining the graphene-based titanium dioxide composite photocatalystby washing and drying. The inspection proves that the graphene-based titanium dioxide composite photocatalyst prepared by the method of the invention has higher photocatalytic activity. In addition, by inspecting with a transmission electron microscope (TEM), titanium dioxide crystals which are densely and evenly loaded on the graphene matrix can be seen.

Owner:安徽省通源环境节能股份有限公司

Preparation method of barium titanate powder body

InactiveCN1400168ANarrow particle distributionGood dispersionCalcium/strontium/barium carbonatesTitanium compoundsTitanium tetrafluorideBarium titanate

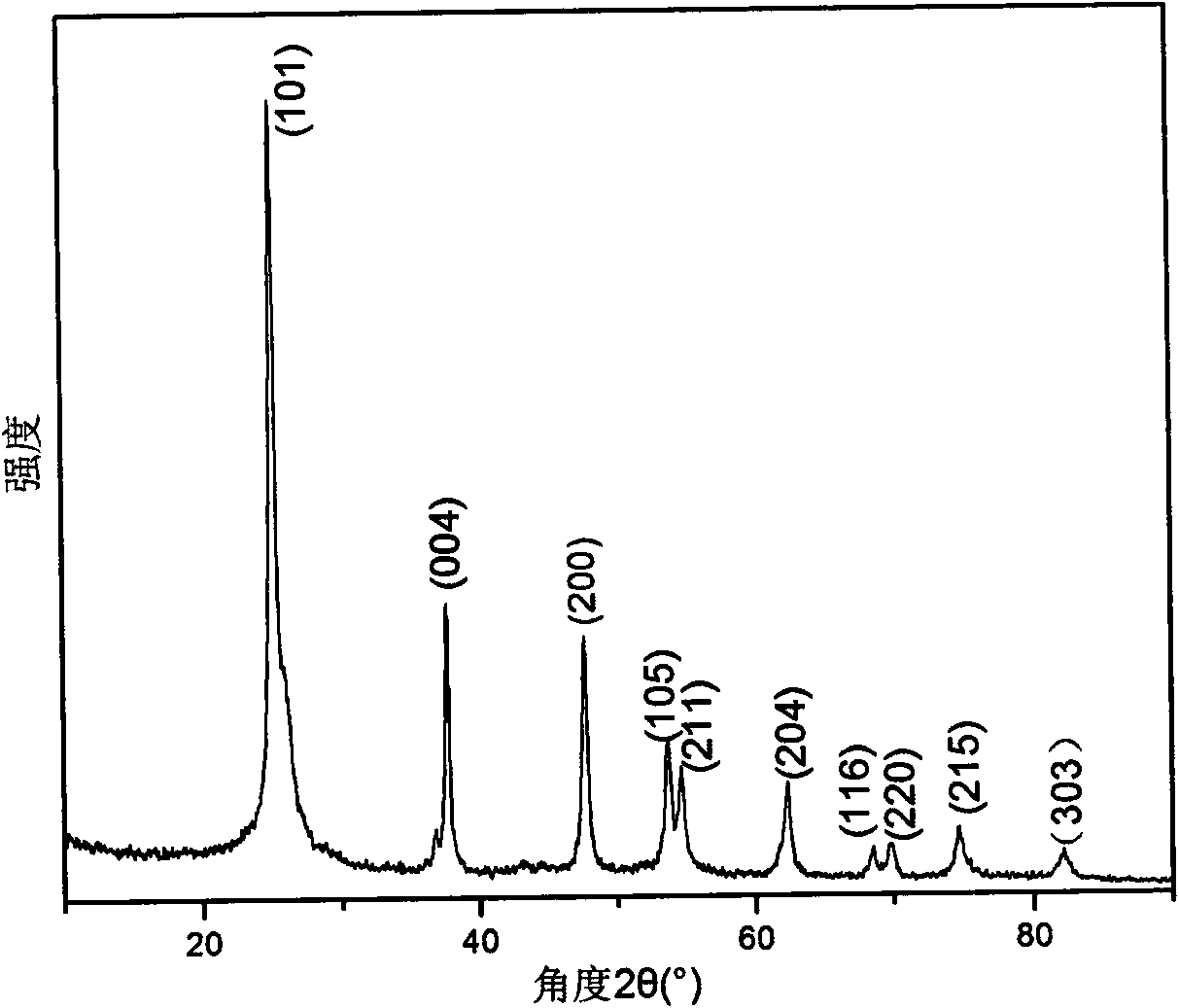

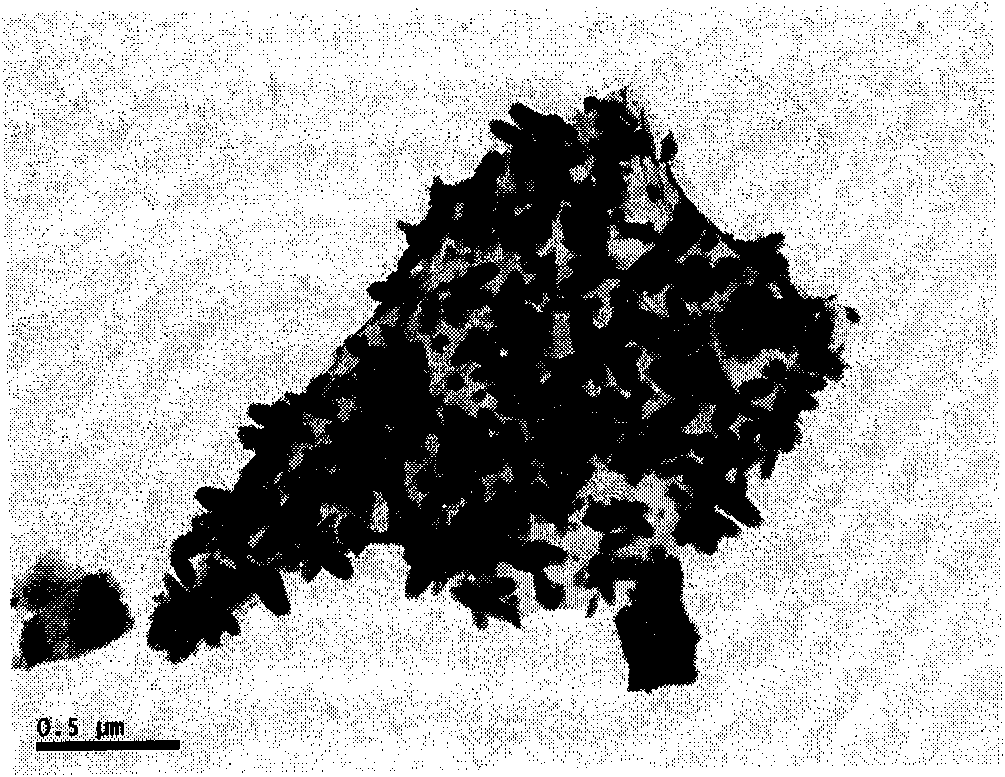

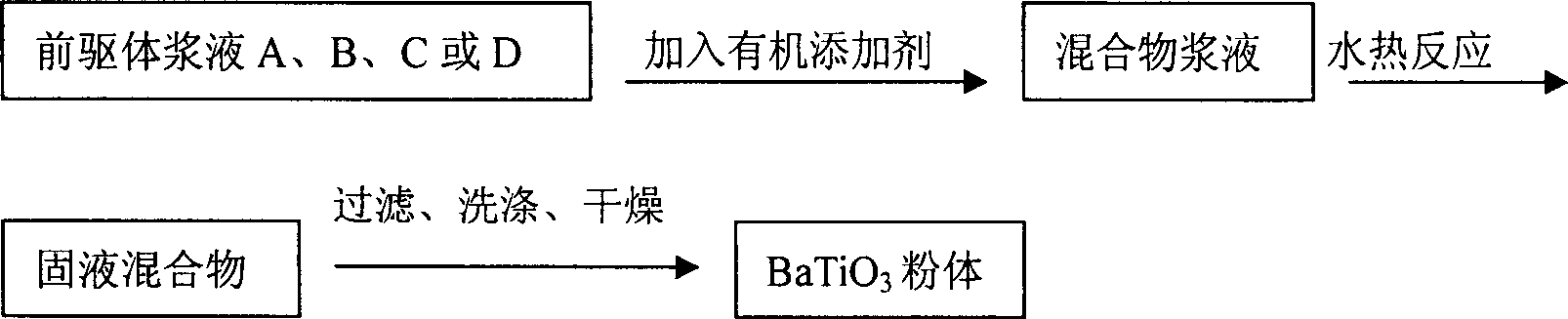

The preparation method of barium titanate (BaTiO3) includes the following steps: using titanium tetrafluoride and barium chloride or barium hydroxide as main raw material to prepare precursor body slurry liquor, then adding organic additive according to a certain ratio, placing them into reaction still to make hydrothermal reaction so as to obtain the invented product BaTiO3 powder body whose grain size is 20-200 nm. Said invented advantage lies in that it utilizes the regulation of class of organic additive and reaction condition to can regulate grain size distribution of product and make its product possess good grain uniformity, high sintering activity, high material property and chemical activity, and said method is easy to implement large-scale industrial production.

Owner:SHANDONG UNIV

Titanium oxide-containing material and process for preparing the same

InactiveUS6376023B1Liquid surface applicatorsTitanium dioxideTitanium tetrafluorideTitanium fluoride

A titanium oxide-containing material having a surface plated with titanium oxide. It is prepared by dissolving titanium fluoride (such as titanium tetrafluoride) in an amount of 2.0% owf in water, immersing a raw material in the obtained aqueous solution to treat the material with the aqueous solution at room temperature for 30 min, and adding a 0.5:1:1 (on a weight basis) mixture of boric acid, citric add, and DL-malic add in an amount of 0.5% owf to the aqueous solution to treat the material with the aqueous solution at 50° C. for 30 min, followed by washing with water. The raw materials usable herein include synthetic fibers, metals, glass, and woods, and may be in the form of sheet, plate, fiber, rod, or the like. Introduction of a noble metal, such as gold or silver, in addition to titanium oxide, onto the surface of the material enables the acceleration of the photocatalytic action of titanium oxide.

Owner:KYORASHA +1

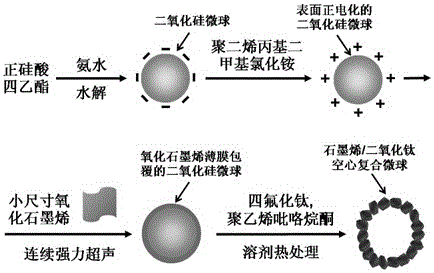

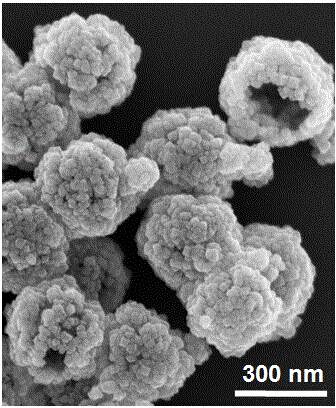

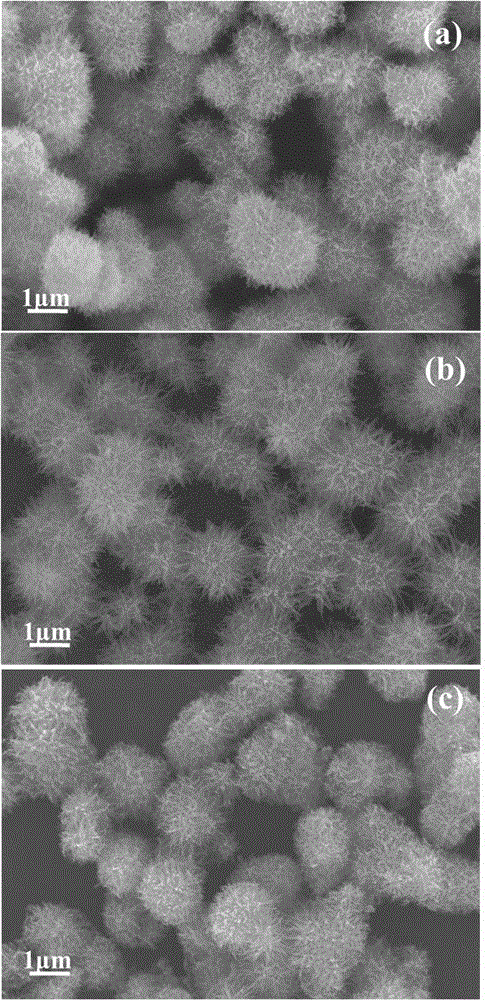

Graphene/titanium dioxide composite adopting hollow microspherical structure and preparation method of composite

ActiveCN105056929AUnique hollow microsphere structureLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationTitanium tetrafluorideMicro nano

The invention relates to graphene / titanium dioxide composite adopting a unique hollow microspherical structure and a simple preparation method convenient to implement and belongs to the technical field of synthesis and preparation of graphene-based micro-nano composite. Firstly, an improved Stober method is adopted for preparing silicon dioxide microspheres, then each silicon dioxide microsphere is coated with an oxidized graphene layer with an ultrasonic assisted self-assembly method, titanium tetrafluoride is taken as a precursor, titanium dioxide is precipitated and crystallized on surfaces of silicon dioxide / oxidized graphene composite microspheres with a solvothermal method, silicon dioxide inner cores are dissolved and removed, the oxidized graphene component coating the spheres is further reduced, and accordingly, the graphene / titanium dioxide composite hollow microspheres are prepared. The composite hollow microspheres show good water dispersibility, has efficient catalytic activity for light degradation of organic dye and have wide application prospects.

Owner:哈尔滨悟山青环保科技有限公司

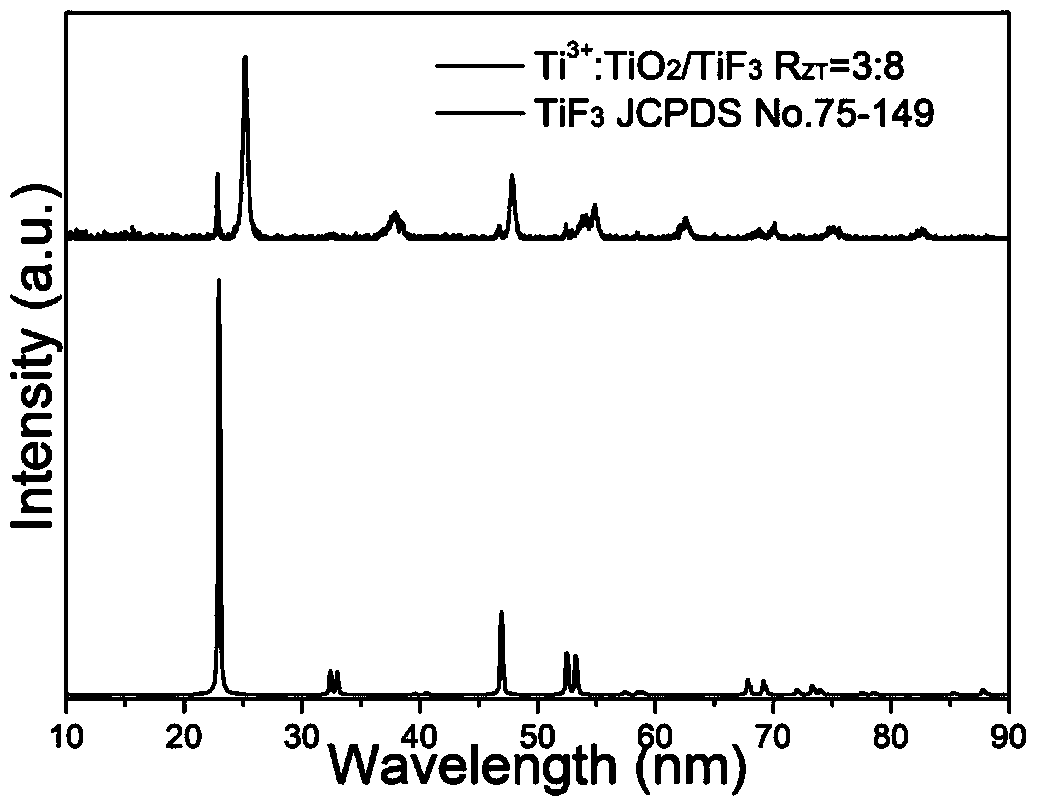

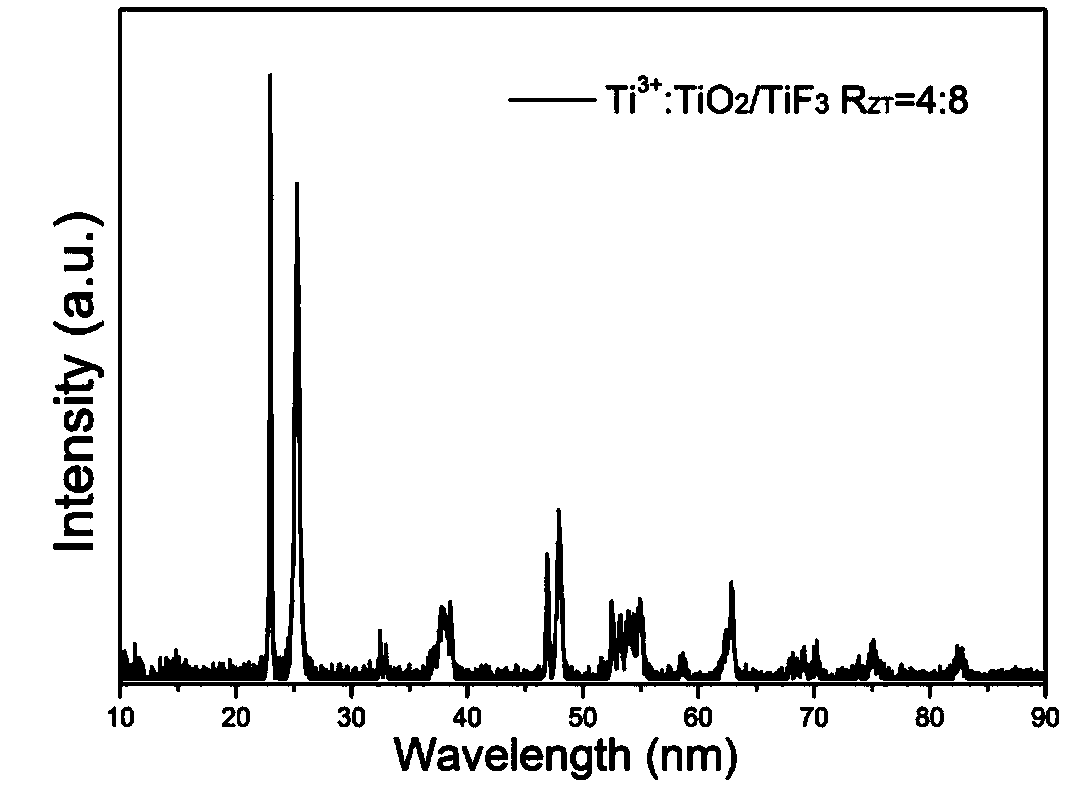

Ti<3+>:TiO2/TiF3 composite semiconductor photocatalyst and preparation method thereof

InactiveCN103920513ATuning Catalytic PerformanceEasy to preparePhysical/chemical process catalystsHeterojunctionTitanium tetrafluoride

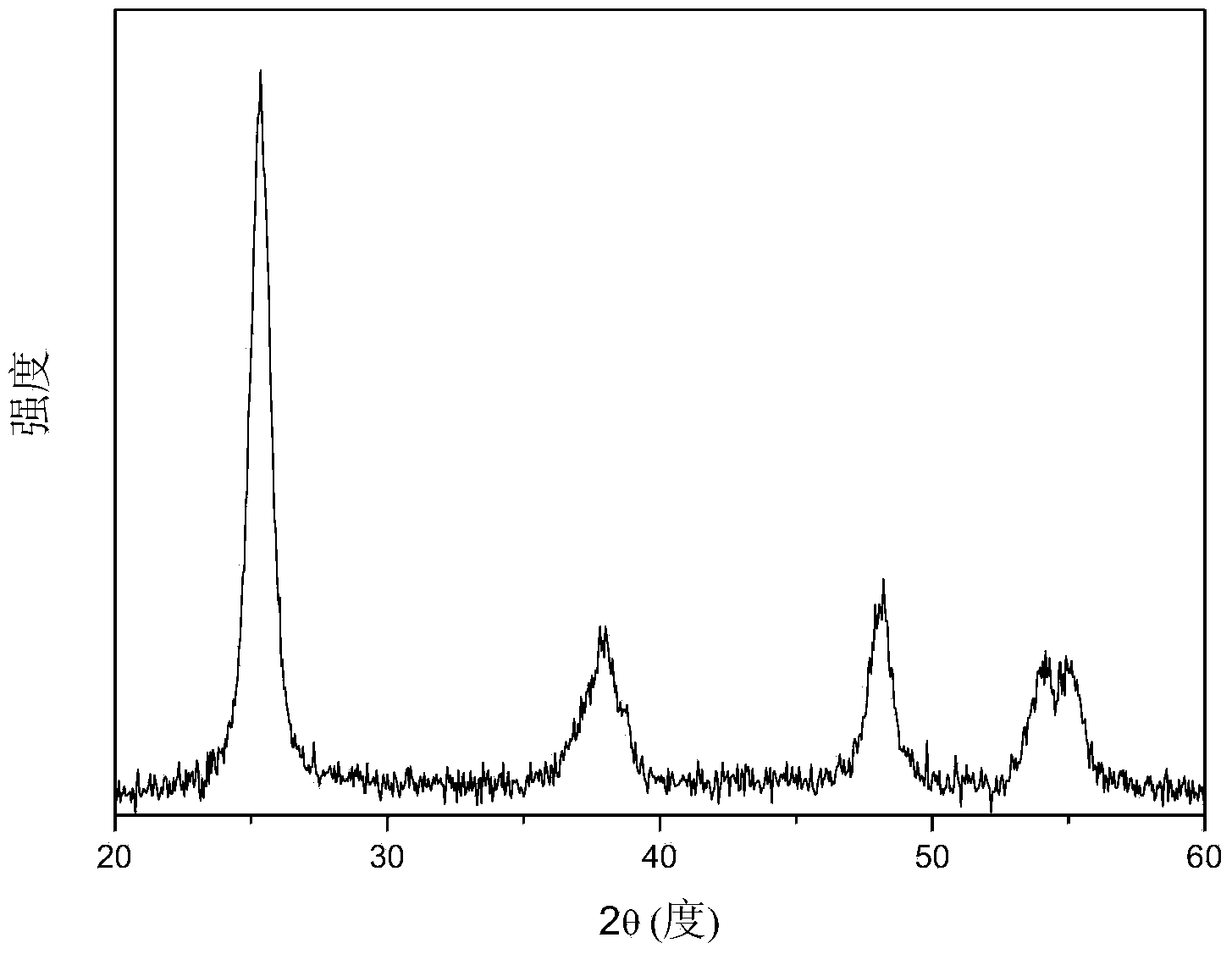

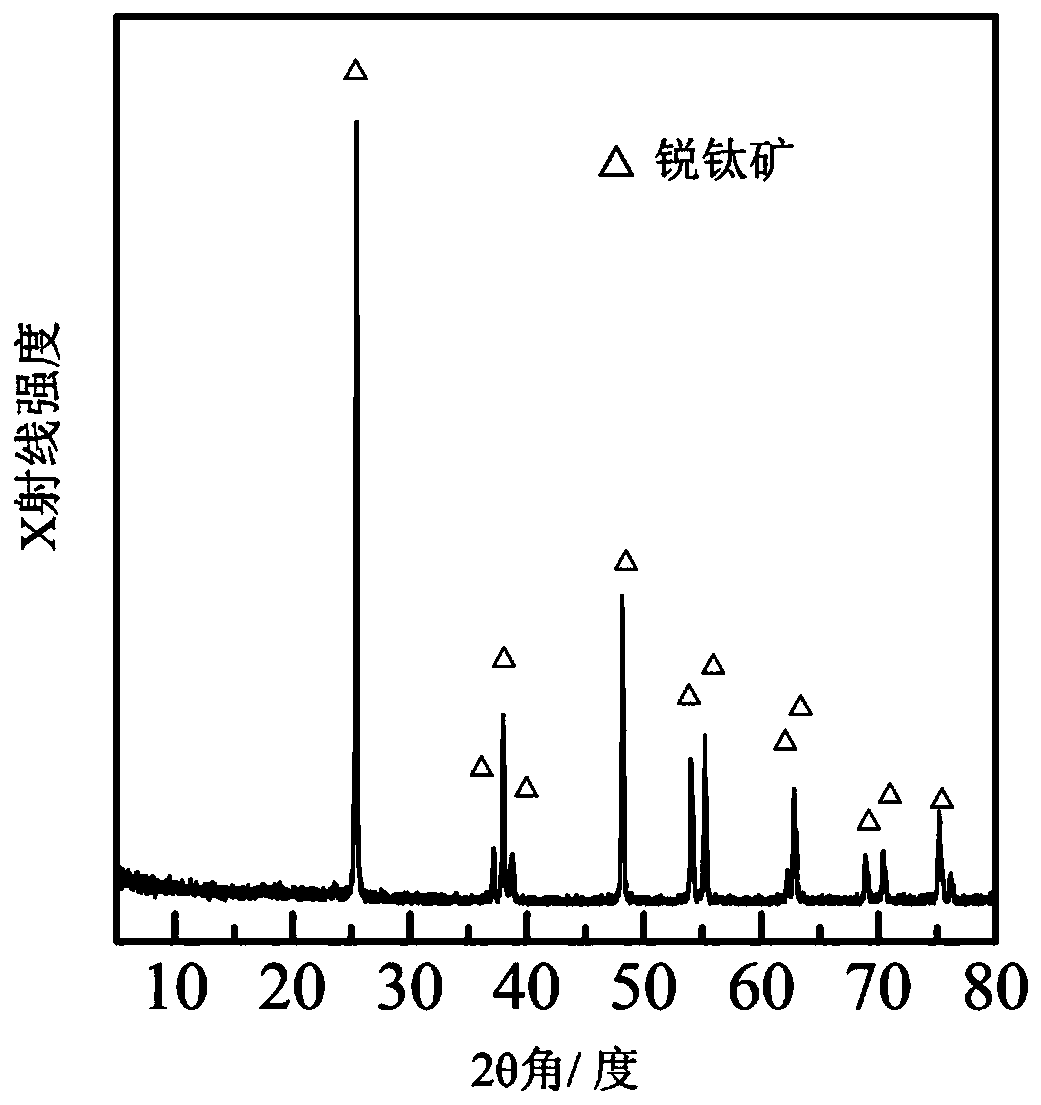

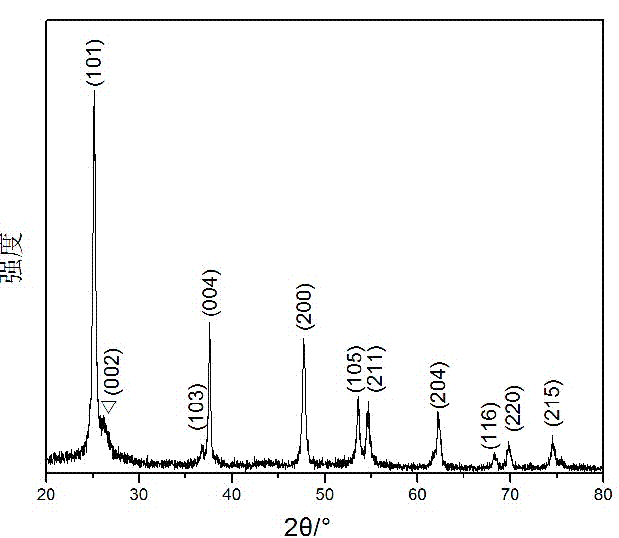

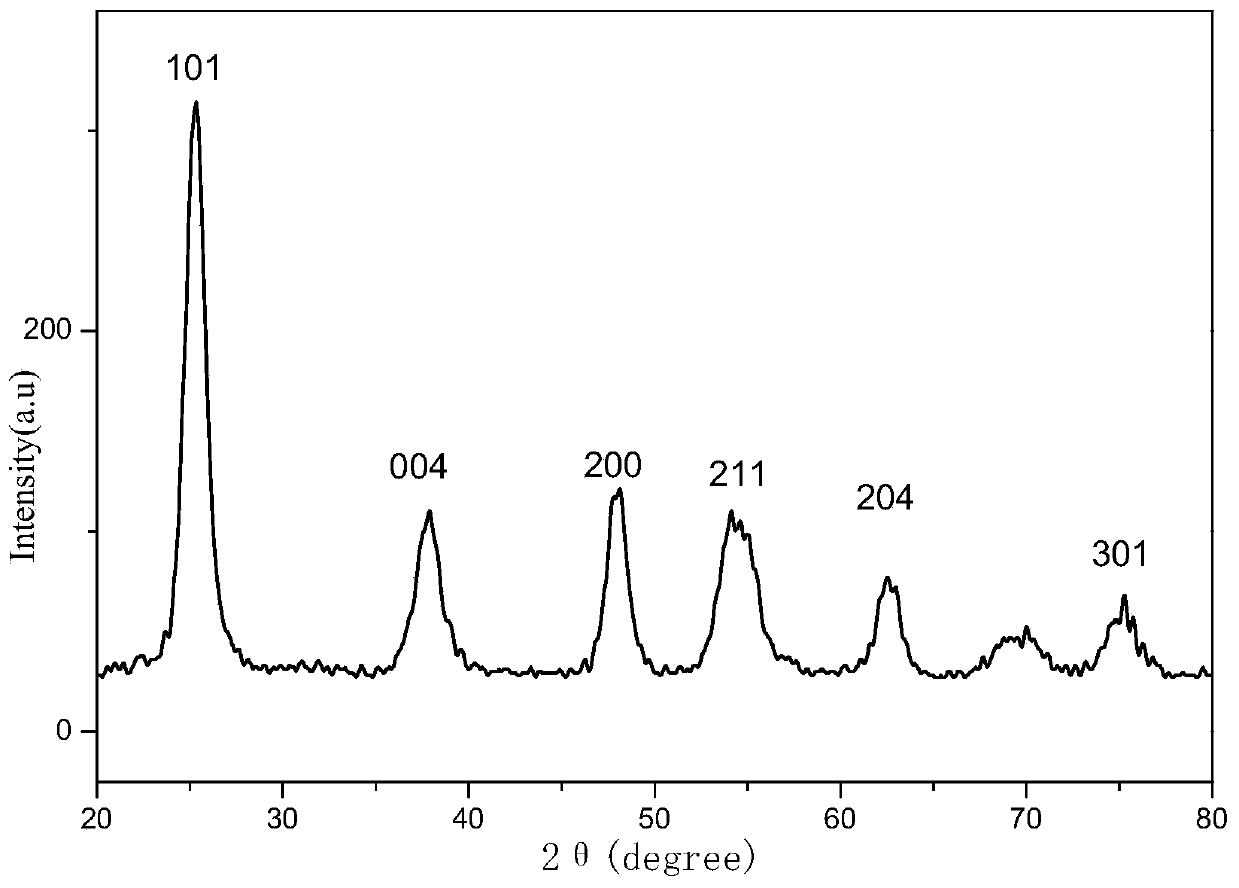

The invention discloses a Ti<3+>:TiO2 / TiF3 composite semiconductor photocatalyst. According to the photocatalyst, the diameter of titanium dioxide is 10-20nm, the diameter of titanium fluoride is 100-150nm, a type II heterojunction is formed by titanium dioxide and titanium trifluoride, and the photocatalyst has low carrier recombination efficiency, contains lots of trivalent titanium, has high visible light absorption capacity and can be used for degrading organic pollutants. The invention also discloses a method for preparing the composite semiconductor photocatalyst. Elemental zinc serves as a reducing agent, titanium tetrachloride and titanium tetrafluoride serve as raw materials, and Ti<3+>:TiO2 / TiF3 with different ratios of titanium dioxide to titanium trifluoride can be prepared by changing the amount of elemental zinc in different reactions by utilizing alcohol-thermal method synthesis. The preparation method has the advantages of simplicity in operation, low cost and mild synthesis conditions and has high commercial application prospects.

Owner:SHANDONG UNIV

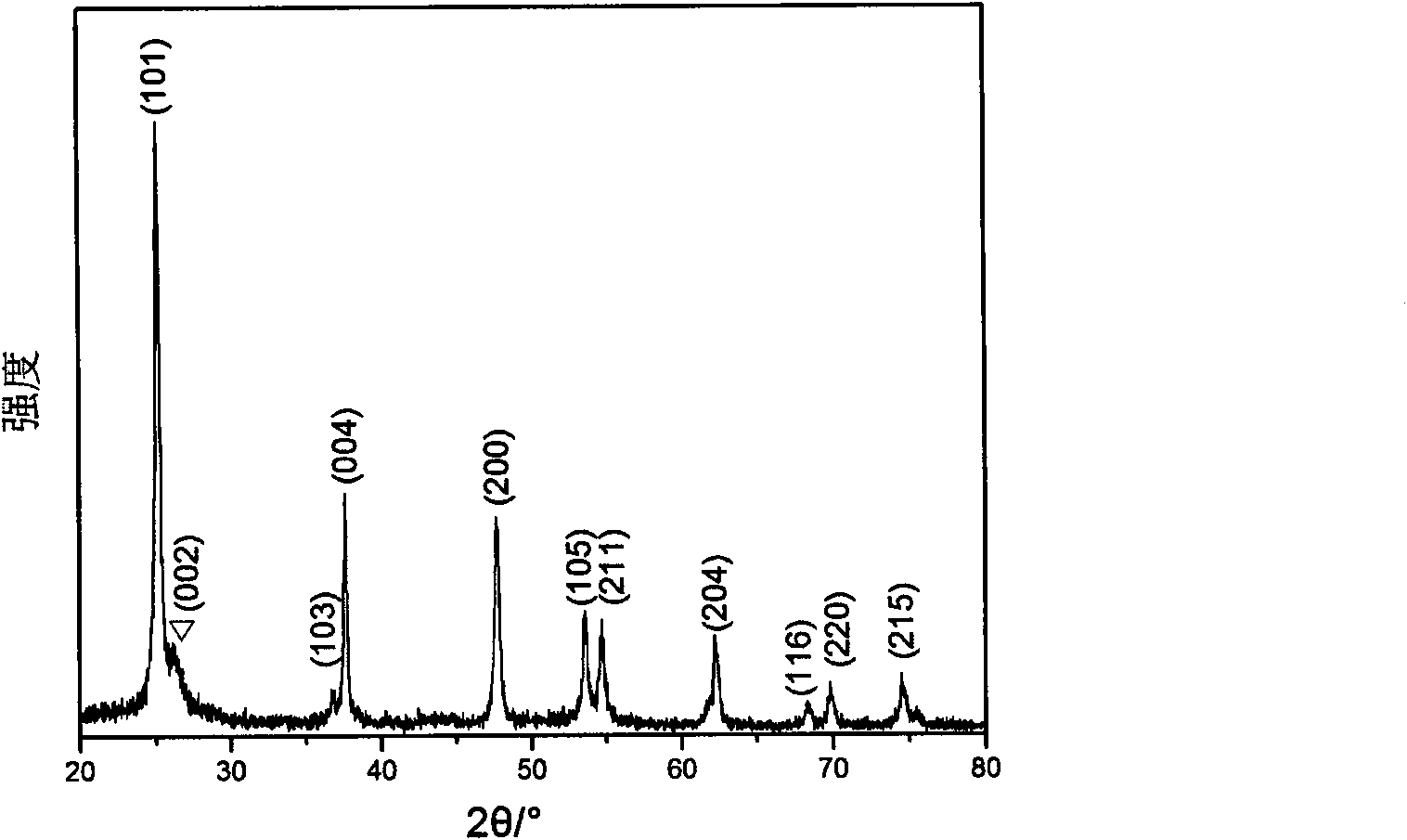

Titanium dioxide mesoporous microsphere photocatalytic material co-doped with nitrogen and fluorine and preparation method of material

InactiveCN103894218AImprove photocatalytic activityHigh catalytic efficiencyPhysical/chemical process catalystsTitanium tetrafluorideMicrosphere

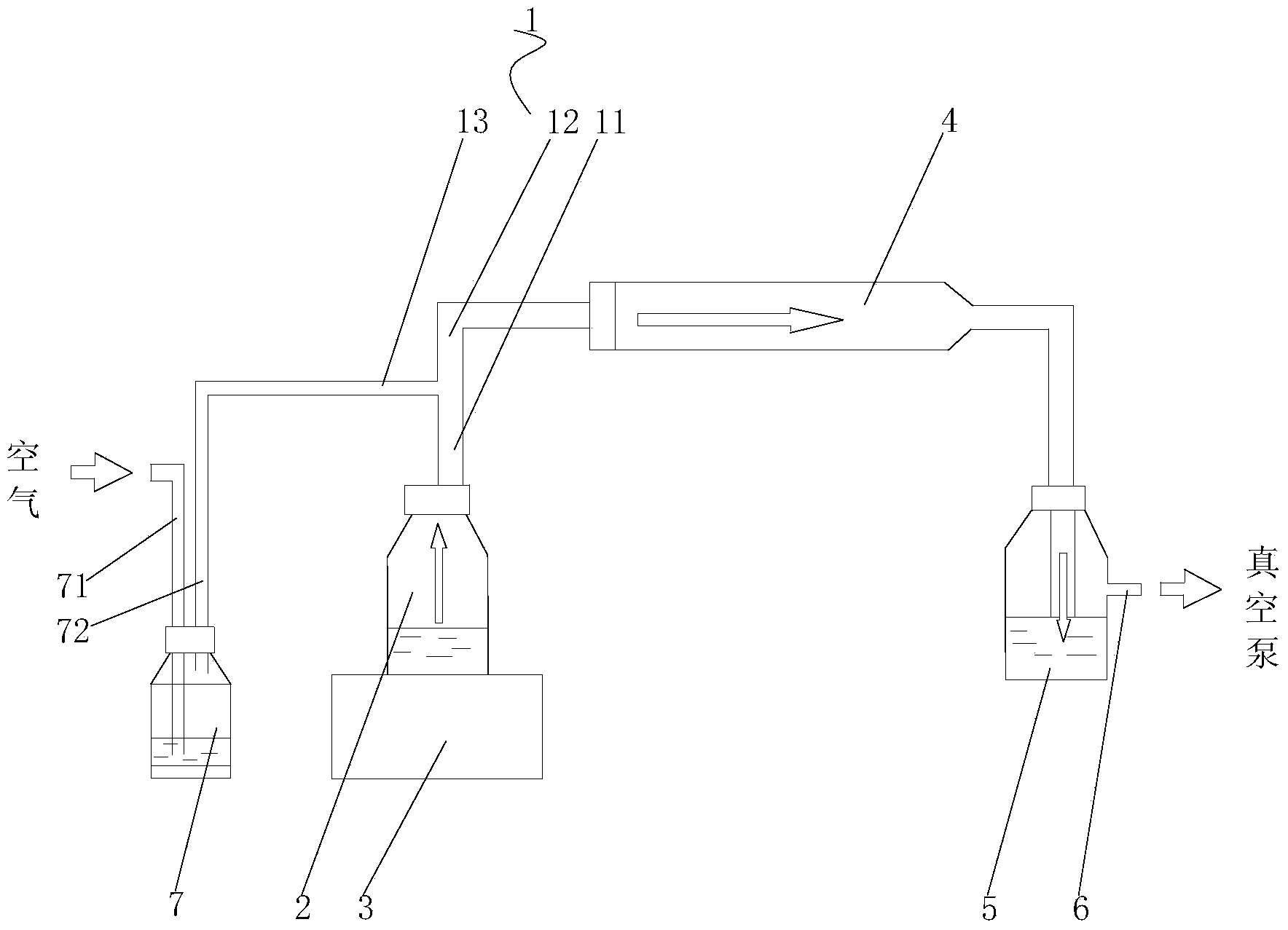

The invention discloses a titanium dioxide mesoporous microsphere photocatalytic material co-doped with nitrogen and fluorine in response to visible light and a preparation method of the material. The preparation method of the material comprises the following steps: firstly dissolving titanium tetrafluoride in hydrochloric acid to obtain a reaction precursor solution, atomizing the precursor solution in an ultrasonic atomizer to generate aerosol rich in tiny droplets, introducing the aerosol into a high-temperature tubular furnace in the presence of ammonia gas to react and generate solid powder, collecting the solid powder by using distilled water, washing, centrifuging and then drying at the temperature of 75-85 DEG C to obtain the solid powder, sequentially roasting for 1.5-2.5 hours in a muffle furnace at the temperature of 450-550 DEG C to prepare the titanium dioxide mesoporous microsphere photocatalytic material co-doped with nitrogen and fluorine. A crystalline phase of the material is an anatase phase; the material comprises the following components by weight percent: 1.5-3.0% of fluorine, 0.8-5.2% of nitrogen and the balance being titanium dioxide; the titanium dioxide co-doped with nitrogen and fluorine has a mesoporous microsphere particle shape; an ultraviolet-visible light spectrum begins to absorb when being below 600nm. The preparation method of the material is simple, practicable and capable of continuously producing, and facilitating the large-scale production and application in industrialization.

Owner:PUTIAN UNIV

All-solid-state lithium battery and preparation method thereof

ActiveCN108511786ASolve the problem of interdiffusionFinal product manufactureElectrolyte accumulators manufactureInterfacial reactionSolid state electrolyte

The invention relates to an all-solid-state lithium battery and a preparation method thereof. The all-solid-state lithium battery comprises a positive plate, a negative plate and a solid electrolyte layer, wherein the positive plate comprises a positive active substance, and the positive active substance comprises positive material particles and a fluorine-containing lithium titanate layer coatingthe surfaces of the positive material particles. According to the method for preparing the positive active substance with a positive material coated by the fluorine-containing lithium titanate layerfrom the positive material, titanium tetrafluoride and a lithium salt through mixing and sintering, the surface of the positive material can be uniformly modified so as to obtain the positive materialwith controllable fluorine content and fluorine-containing lithium titanate layer thickness on its surface. When the positive material is used in the all-solid lithium battery, the structure of a coating can be stabilized, interfacial reaction or element diffusion between the positive material and the solid electrolyte can be avoided, and interface impedance is reduced.

Owner:BYD CO LTD

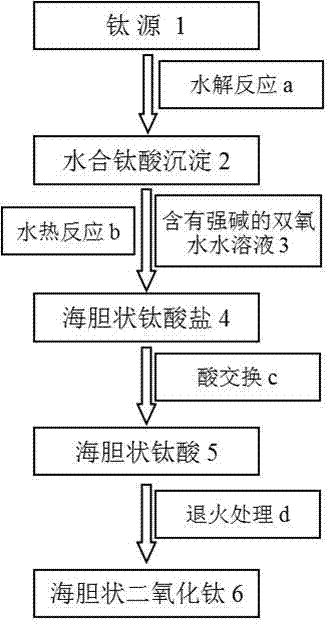

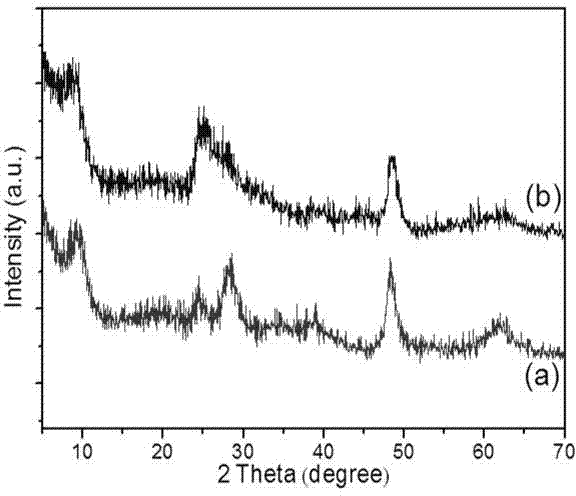

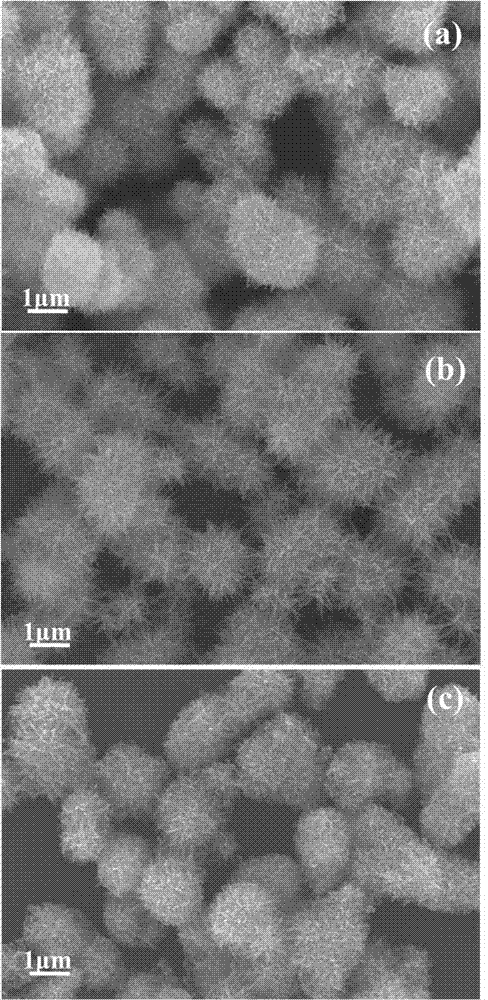

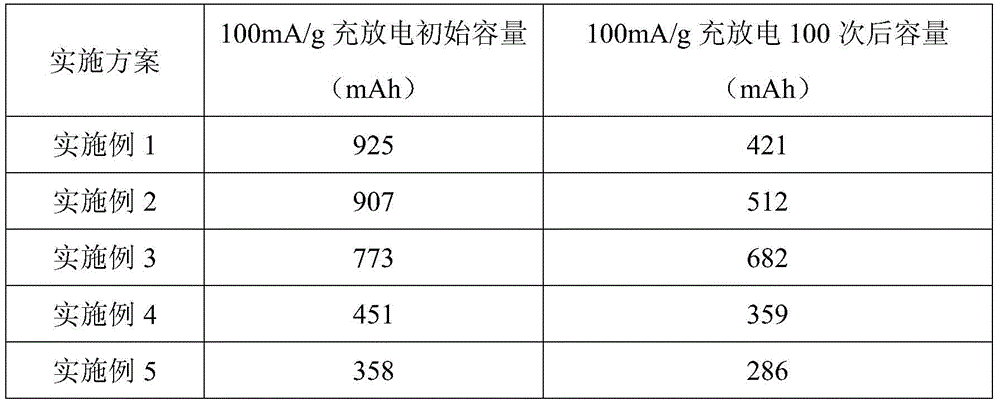

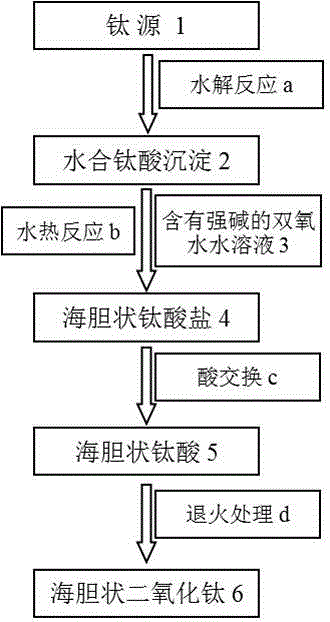

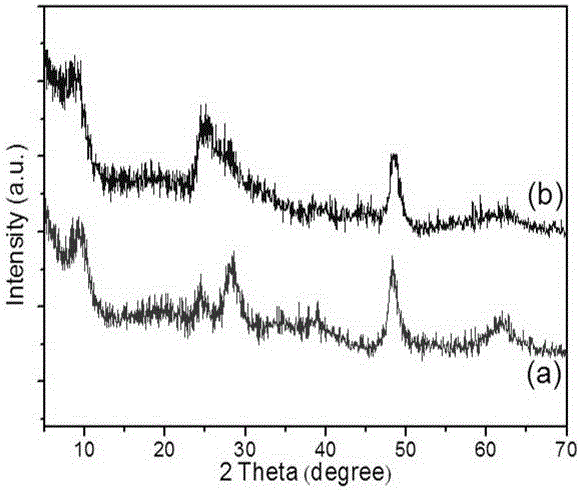

Method for preparing titanate, titanic acid and titanium dioxide

ActiveCN104261465AImprove cycle performanceIncrease capacityMaterial nanotechnologyAlkali titanatesTitanium tetrafluorideMicro nano

The invention discloses a method for preparing titanate, titanic acid and titanium dioxide. The method for preparing titanate comprises the following steps: carrying out hydrolysis reaction on a titanium source to obtain hydrated titanium acid precipitates, wherein the titanium source is selected from one or a composition of more of titanium sulfate, titanyl sulfate, titanium tetrachloride, titanium tetrafluoride, titanium ethoxide, titanium propoxide, tetrabutyl titanate, ethylene glycol titanium, glycerol titanium and ammonium fluorotitanate; dispersing the hydrated titanium acid precipitates in an aqueous hydrogen peroxide solution containing strong base for hydrothermal reaction, and thus obtaining sea urchin titanate with a micro-nano hierarchical structure. The method can overcome some defects of titanate, titanic acid and titanium dioxide prepared into nanowire or nanotube structures.

Owner:NINGBO NANOJP NEW MATERIAL TECH CO LTD

Anticorrosive paint containing dimethyl sulfoxide

InactiveCN103173094AGood flexibilityHigh impact strengthAnti-corrosive paintsEpoxy resin coatingsTitanium tetrafluoridePolyacrylamide

The invention discloses an anticorrosive paint containing dimethyl sulfoxide. The anticorrosive paint is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 84-90 parts of epoxy resin E44, 10-15 parts of high chlorinated polyethylene resin, 10-15 parts of precipitated barium sulfate, 1-2 parts of titanium tetrafluoride, 2-4 parts of sodium monofluorophosphate, 2-4 parts of dimethyl sulfoxide, 2-3 parts of ethylene glycol monobutyl ether, 2-4 parts of ethyl acrylate, 3-5 parts of urea, 2-3 parts of polyacrylamide, 2-3 parts of diethylamine, 2-3 parts of diphenylmethane diisocyanate, 3-5 parts of diisooctyl phthalate, 1-2 parts of ethylene diamine tetra methylene phosphonic acid sodium, 5-7 parts of hydrotalcite, 1-2 parts of dimethylethanolamine, 15-20 parts of compound modifier, 25-30 parts of dimethylbenzene, 10-15 parts of n-butyl acetate, 0.8-1 parts of dilauryl thiodipropionate, 0.8-1 parts of vinyltriethoxysilane and 0.5-1 part of methyl silicone oil. A paint film prepared by the invention has the advantages of good adhesive force to metal, small structure pores, compact structure, good adhesive force, good flexibility, high impact strength and strong corrosion resistance, and plays an efficient protection effect on base metal.

Owner:ANHUI MINGZHU PIGMENT TECH

Preparation method of layered stacked TiO2/MoS2 core-shell structural composite material as lithium ion battery cathode

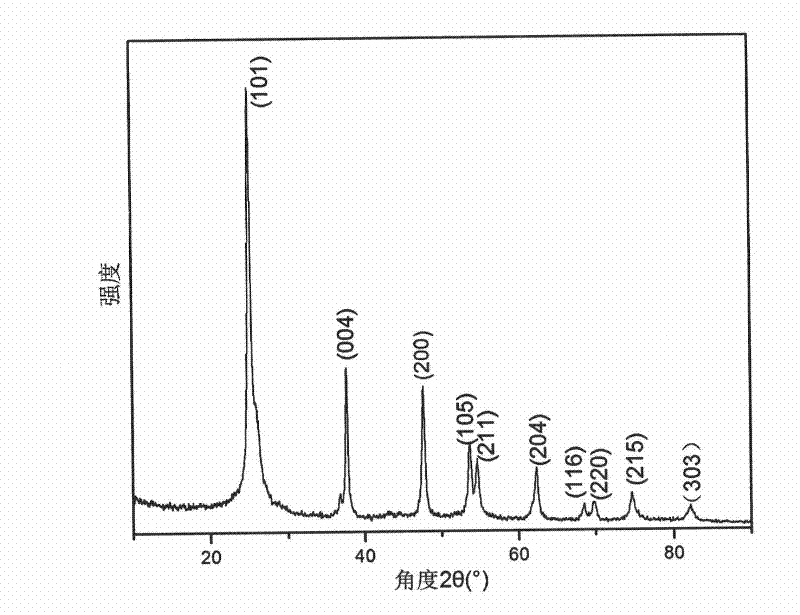

InactiveCN105655553AIncrease energy densityHigh purityCell electrodesSecondary cellsTitanium tetrafluorideCrystallinity

The invention discloses a preparation method of a layered stacked TiO2 / MoS2 core-shell structure composite material as a lithium ion battery cathode. The preparation method comprises the following steps: firstly, dissolving titanium tetrafluoride into phenylcarbinol to prepare a solution of 2.5g / L; secondly, pouring the solution obtained in the step S1 into a hydrothermal kettle, heating to 180 DEG C, and preserving the heat for 12 hours; centrifuging and washing a product obtained in the step S2, drying the product at 60 DEG C to obtain TiO2, and annealing TiO2 for two hours at 500 DEG C; performing the hydrothermal reaction on TiO2 and oxalic acid, thioacetamide and sodium molybdate for 20 hours at 500 DEG C; and finally washing the product obtained in the step S4 by utilizing water and ethanol, and drying in the air at the temperature of 60 DEG C to obtain the TiO2 / MoS2 core-shell structure composite material. The prepared TiO2 / MoS2 core-shell structure composite material is high in energy density, high in purity and high in degree of crystallinity.

Owner:XINYANG NORMAL UNIVERSITY

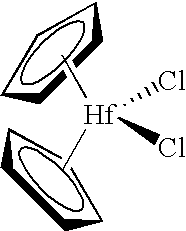

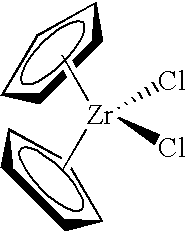

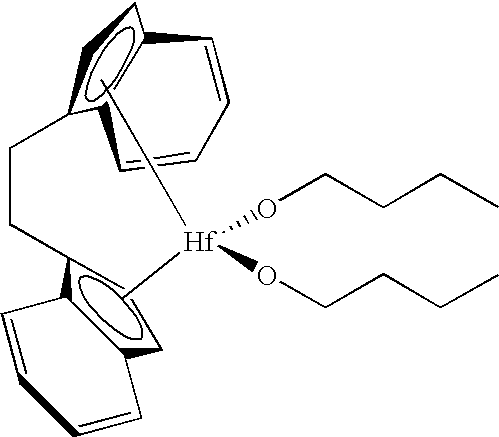

Organometal catalyst composition

InactiveUS6838533B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTitanium tetrafluorideOrganometallic catalysis

This invention provides catalyst compositions that are useful for polymerizing at least one monomer to produce a polymer. This invention also provides catalyst compositions that are useful for polymerizing at least one monomer to produce a polymer, wherein said catalyst composition comprises contacting an organometal compound, an organoaluminum compound, and a solid, wherein said solid is selected from the group consisting of titanium tetrafluoride, zirconium tetrafluoride, and a treated solid oxide compound.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

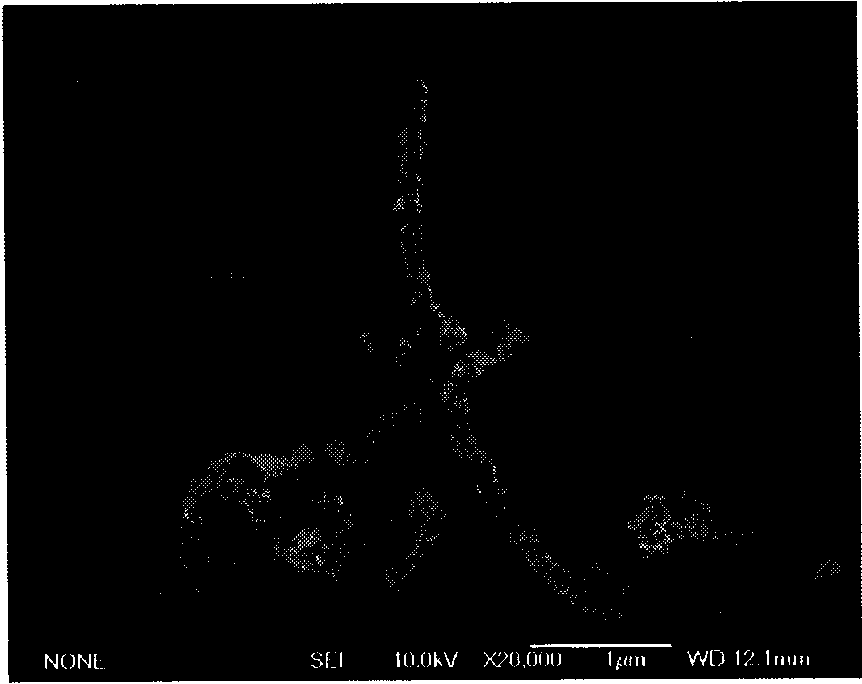

Method for preparing composite photocatalyst of titanium oxide/multi-wall carbon nano pipe by electron-beam irradiation

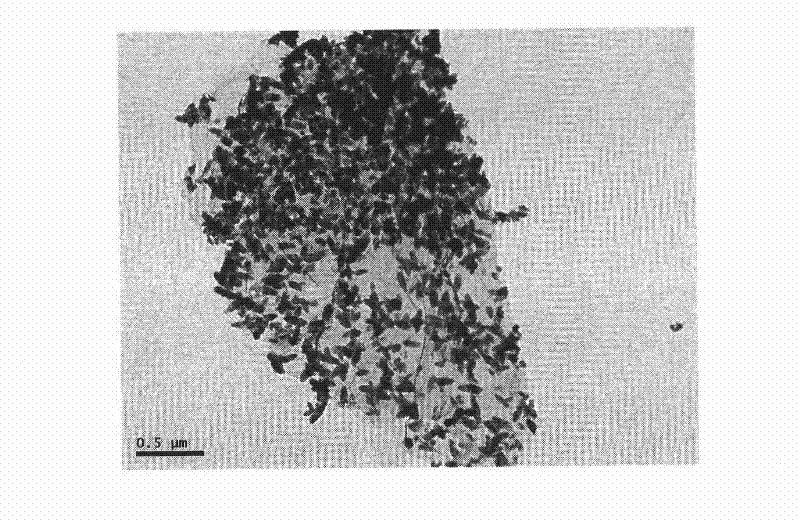

InactiveCN101670283AImprove photocatalytic performanceEasy to operateCatalyst activation/preparationTitanium tetrafluorideRadiation chemistry

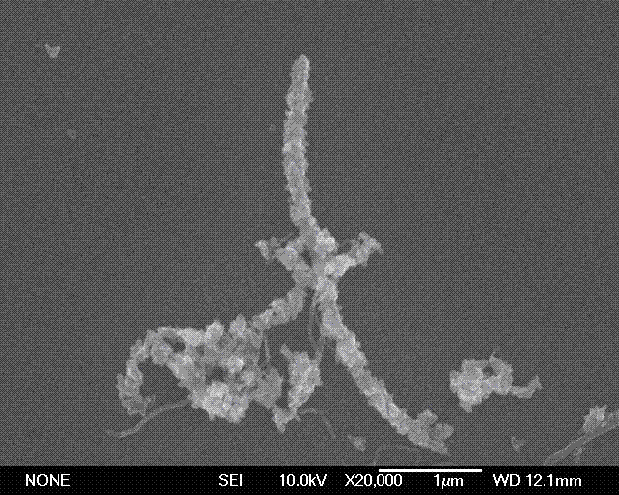

The invention relates to a method for preparing a composite photocatalyst of a titanium oxide / multi-wall carbon nano pipe by electron-beam irradiation, which belongs to the technical fields of radiation chemistry and the preparation technique of the photocatalyst. The method mainly comprises the following preparation processes: adding a multi-wall carbon nano pipe (MWCNTs) into a titanium fluoride(TiF4) solution, dispersing by ultrasonic and mixing fully and evenly, wherein the mass ratio of the multi-wall carbon nano pipe (MWCNTs) and the titanium fluoride (TiF4), i.e. the MWCNTs:the TiF4 isequal to 0.05-0.15; then, putting the solution in an irradiation area under an electron accelerator and carrying out irradiation processing, wherein the irradiation dose is 280-560KYy; afterwards, moving to the other container, putting into a baking oven after sealing a sealed opening, and reacting for 20 hours at the temperature of 60 DEG C; and afterwards, washing a product, drying and finallypreparing the composite photocatalyst of the titanium oxide / multi-wall carbon nano pipe. The composite photocatalyst obtained by the method has favorable photocatalysis property and better photocatalysis effect.

Owner:SHANGHAI UNIV

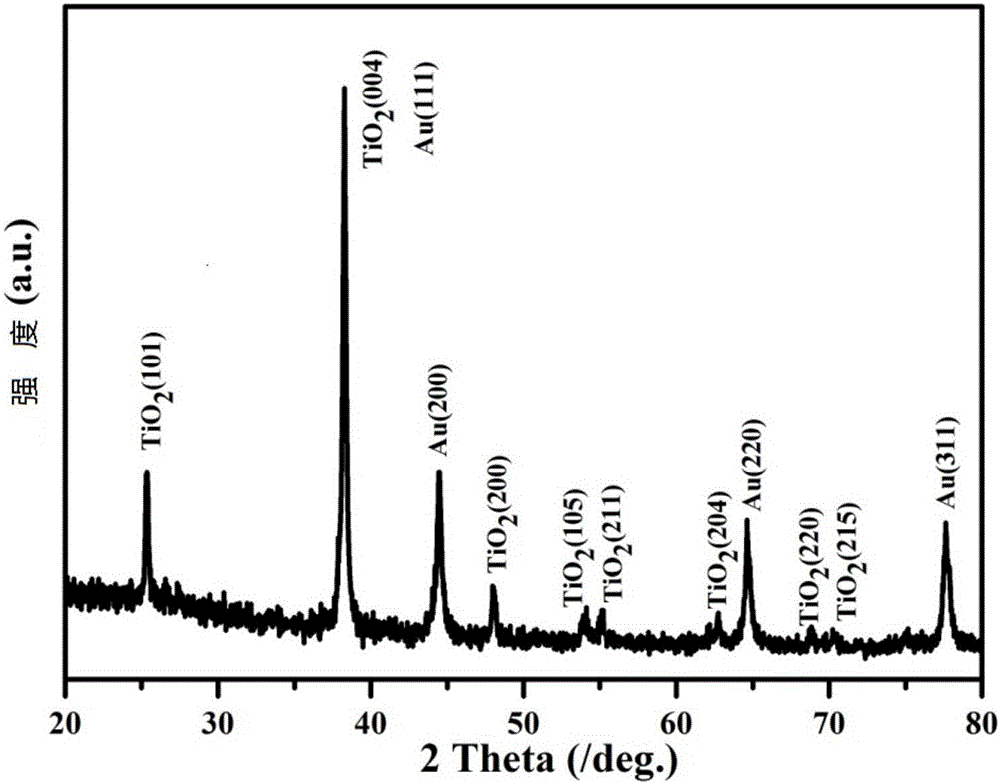

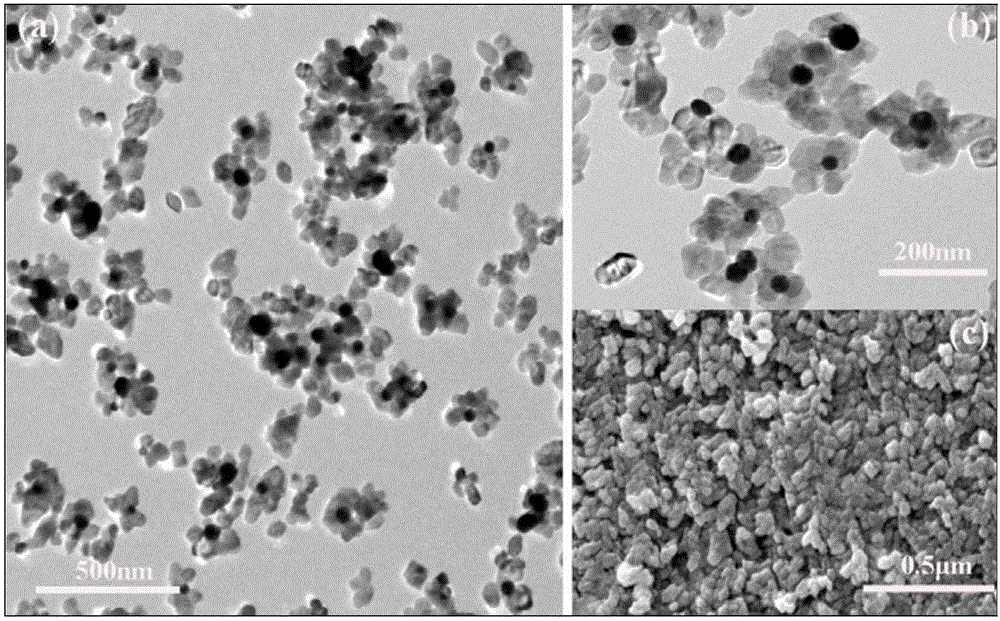

Gold-doped titanium dioxide flower-like nanostructured material and preparation method and application thereof

InactiveCN106216656AThe preparation method is simple and controllableThe preparation method is simple and environmentally friendlyMaterial nanotechnologyTransportation and packagingTitanium tetrafluorideMaterials science

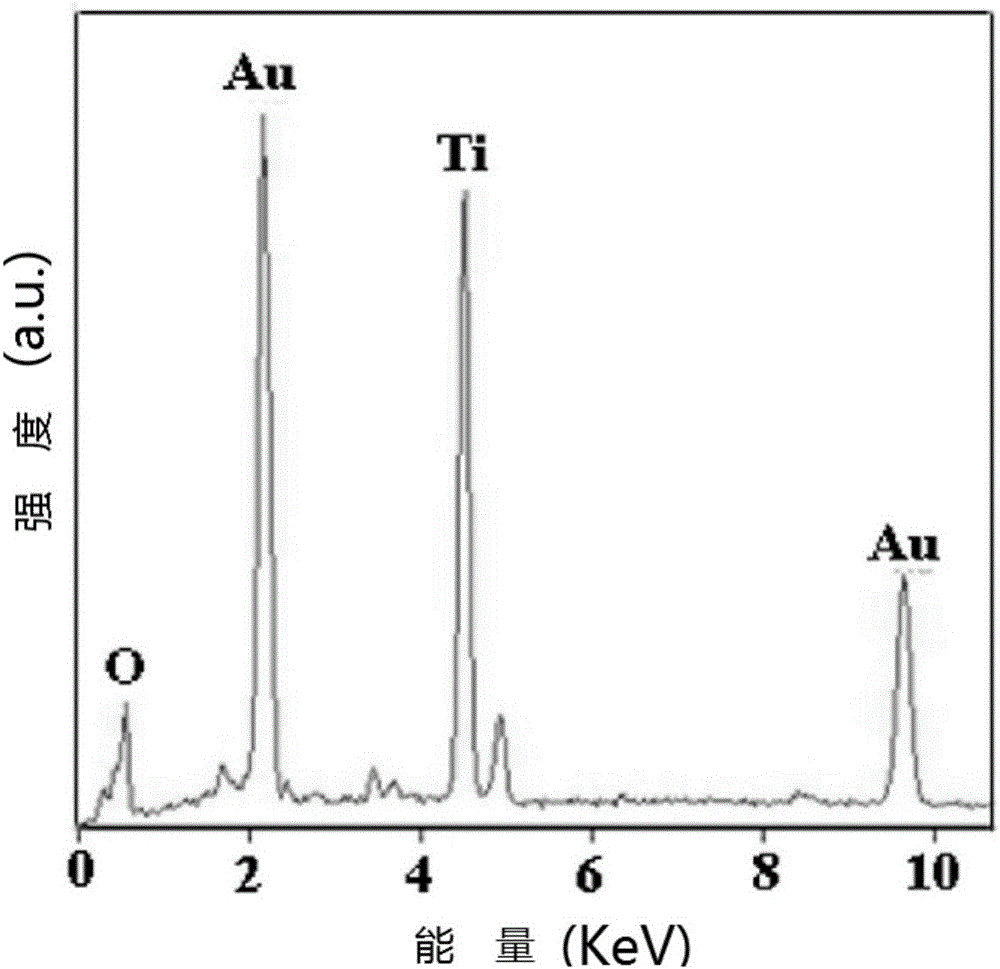

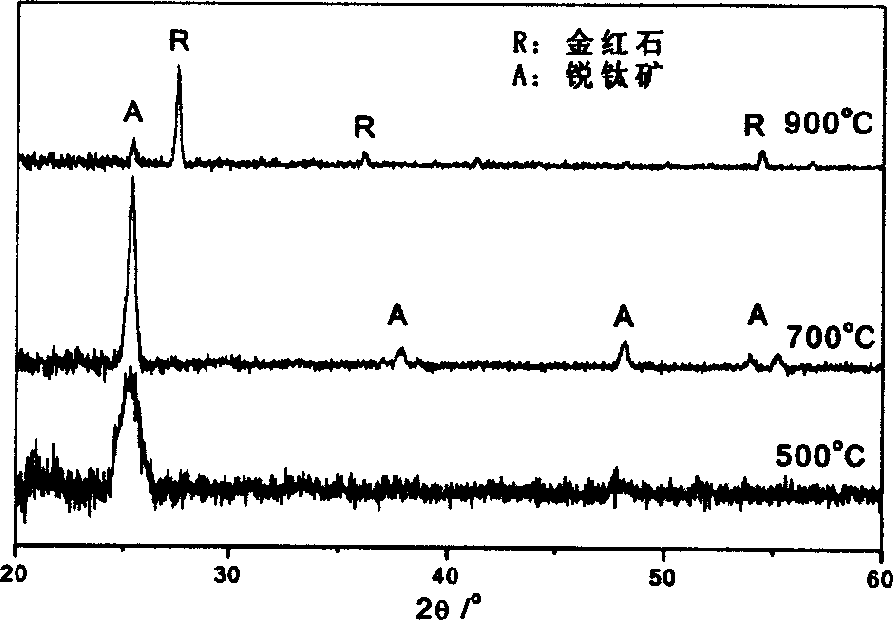

The invention discloses a gold-doped titanium dioxide flower-like nanostructured material and a preparation method and an application thereof. In the nanostructured material, the average size of gold nanometer particle as a nucleus (pistil) is 20-50nm, and the average size of titanium dioxide nanoparticle as a casing (petal) is 50-100 nm. The preparation method comprises the steps of (1) mixing an auric chloride acid solution and a trisodium citrate solution, stirring, then adding a ascorbic acid solution and stirring, then adding a titanium tetrafluoride solution and stirring uniformly to obtain a mixed solution; (2) conducting high temperature hydrothermal reaction to the mixed solution obtained from step (1) for a period of time, and washing and drying a sediment obtained from the reaction to obtain a gold-doped titanium dioxide flower-like nanostructured material. The obtained material has the advantages that the size of the nanometer particles are uniform, and the disperse performance is good. The material is applied for preparing gas-sensitive elements, and has a high sensitivity and selectivity and short response recovery time to carbon monoxide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

In-situ preparing method for composite TiO2 and SiO2 thin film as photo-catalyst

InactiveCN1586712AEffective thickness controlConcentration effective controlCatalyst activation/preparationTitanium tetrafluorideBoric acid

The in-situ preparation process of composite TiO2 and SiO2 film as photocatalyst is one liquid phase deposition-heat treatment process. The process includes compounding supersaturated water solution with the material including ammonium fluorotitanate and / or titanium tetrafluoride and boric acid and / or aluminum powder; soaking glass suibstrate into the supersaturated water solution for some time; flushing the soaked glass suibstrate, stoving and high temperature heat treatment at 400-1100 deg.c to obtain the composite TiO2 and SiO2 film as photocatalyst. The process is simple.

Owner:WUHAN UNIV OF TECH

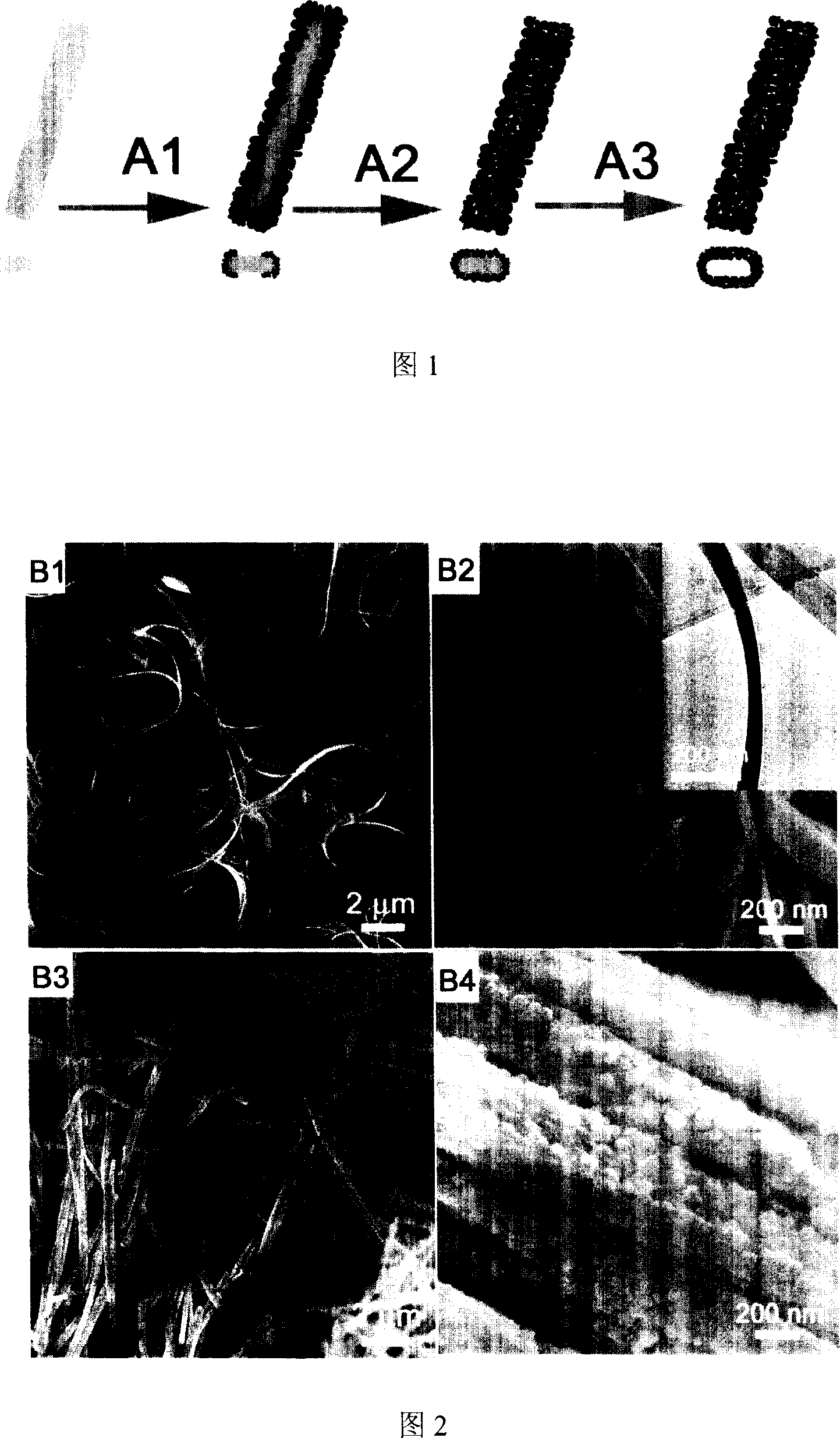

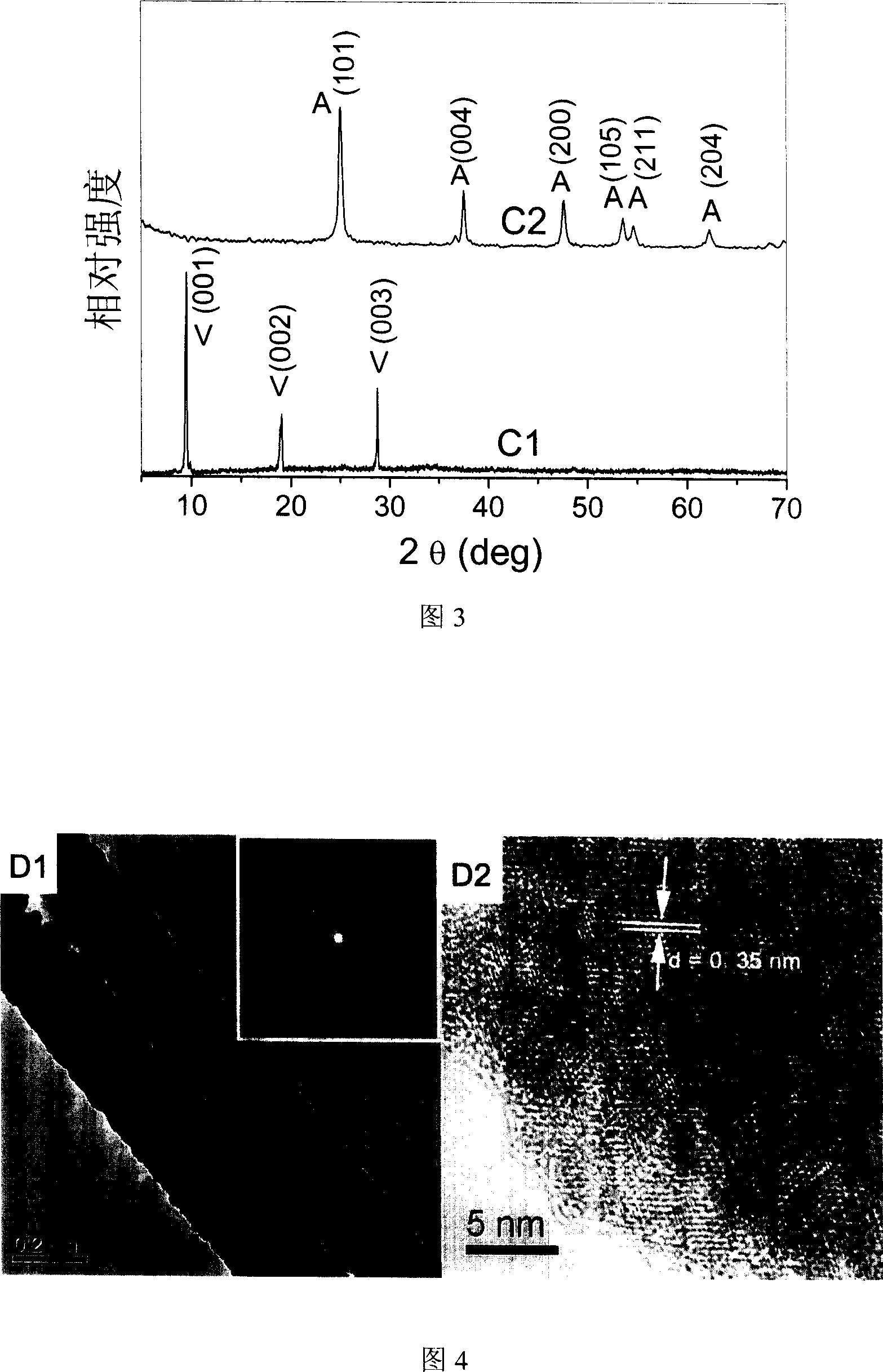

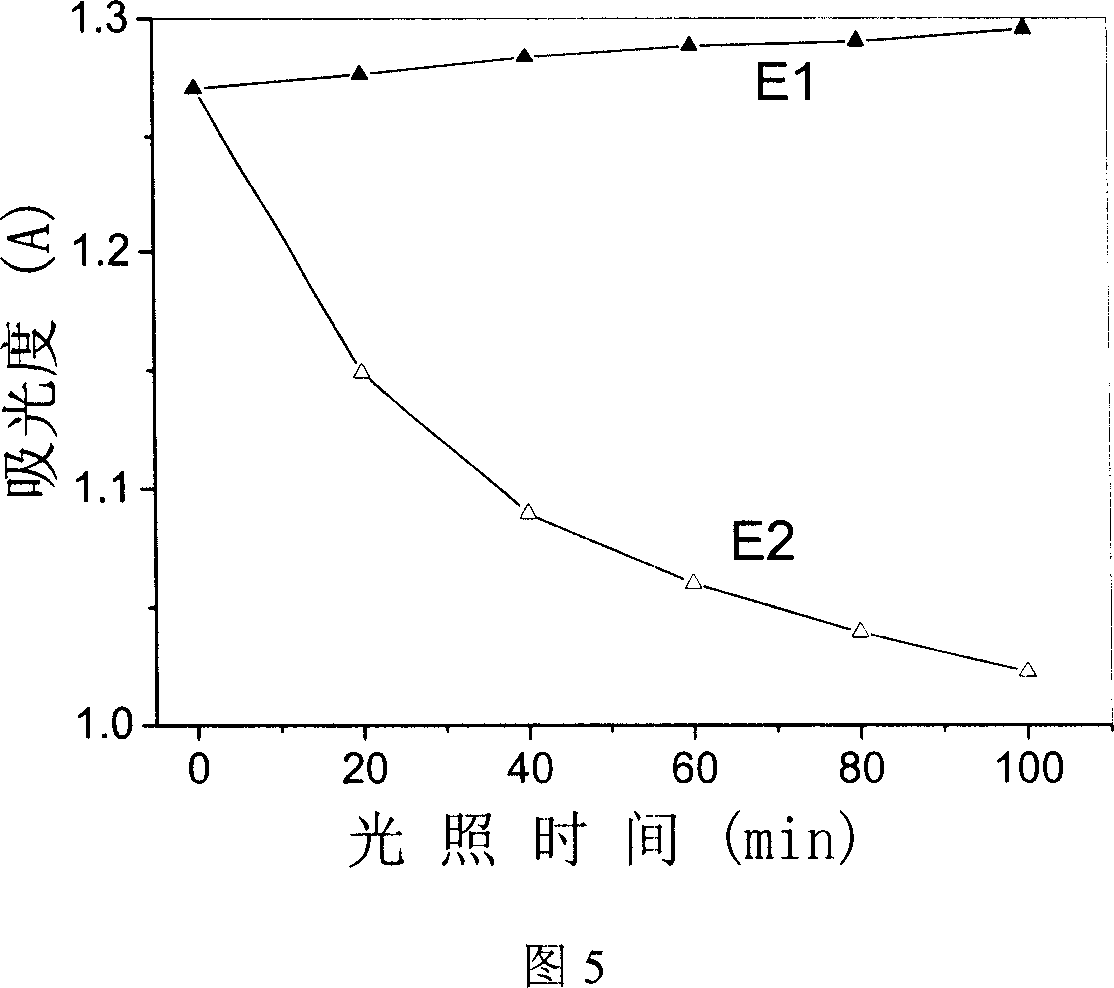

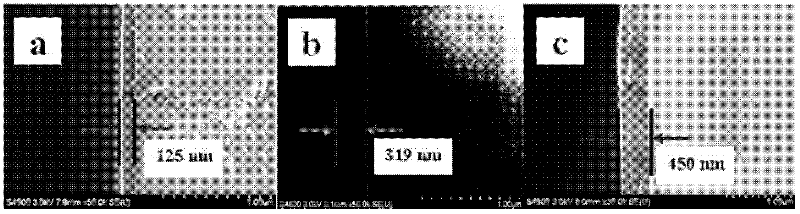

Method for preparing unidimensional TiO2 hollow structured photocatalyst using vanadium oxide nanobelt as template

The invention relates to a method for using vanadia nanometer band as template to produce one-dimension TiO2 hollow optical catalyst, wherein said method comprises that: dissolving titanium tetrafluoride into deionized water; immerges the vanadia nanometer band into said solution to be treated at low temperature to obtain the final catalyst. The invention uses vanadia nanometer band template to induce the deposition of TiO2 nanometer particle to form corn-frame structure and the vanadia nanometer band template is dissolved by HF to form hollow structure. The inventive method can simplify the TiO2 surface deposition (or growth) and template removing process, to overcome the group and hard separate problems of powder optical catalyst.

Owner:WUHAN UNIV OF TECH

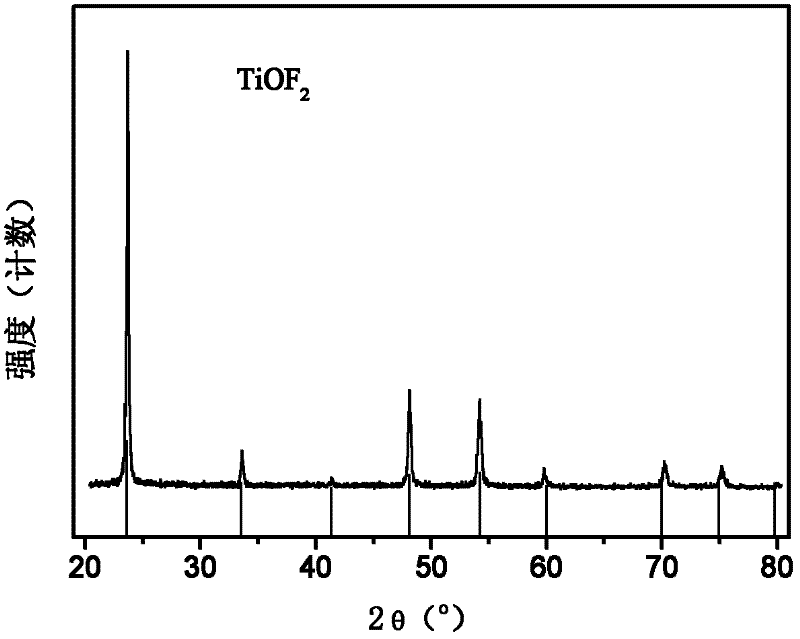

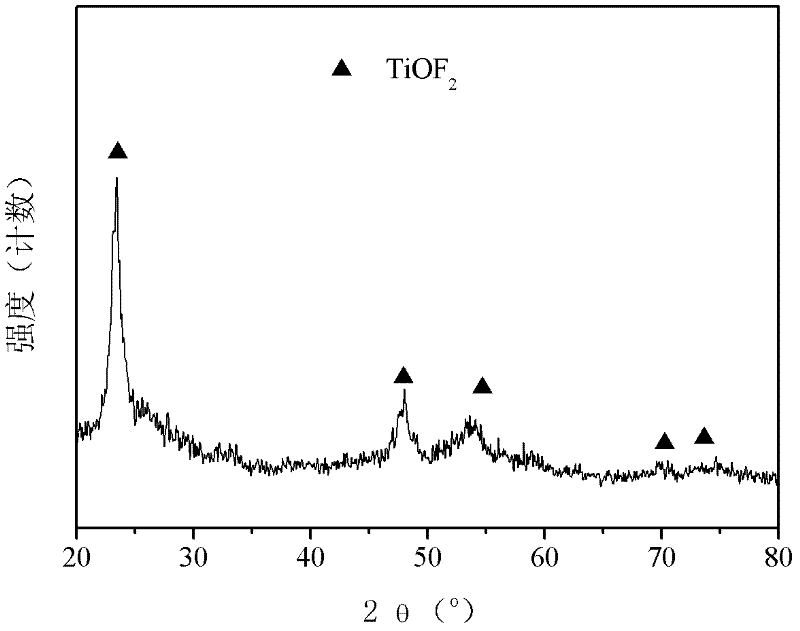

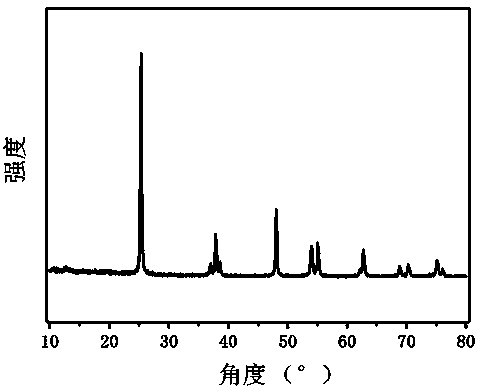

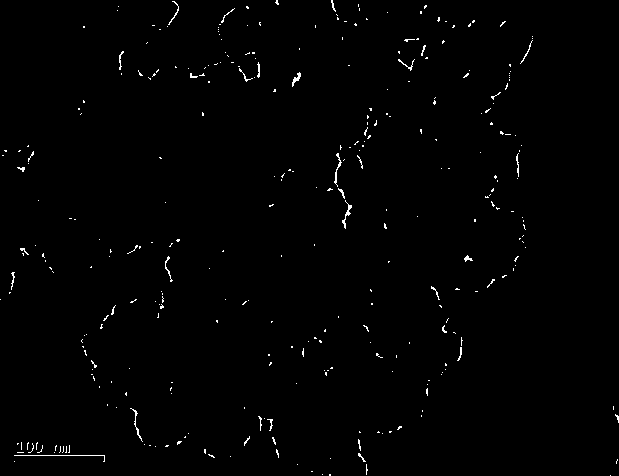

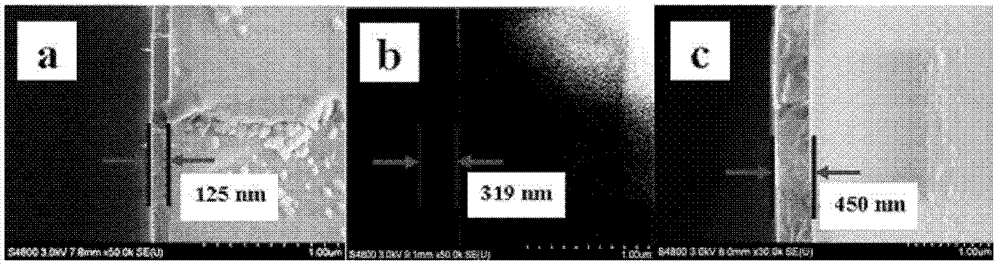

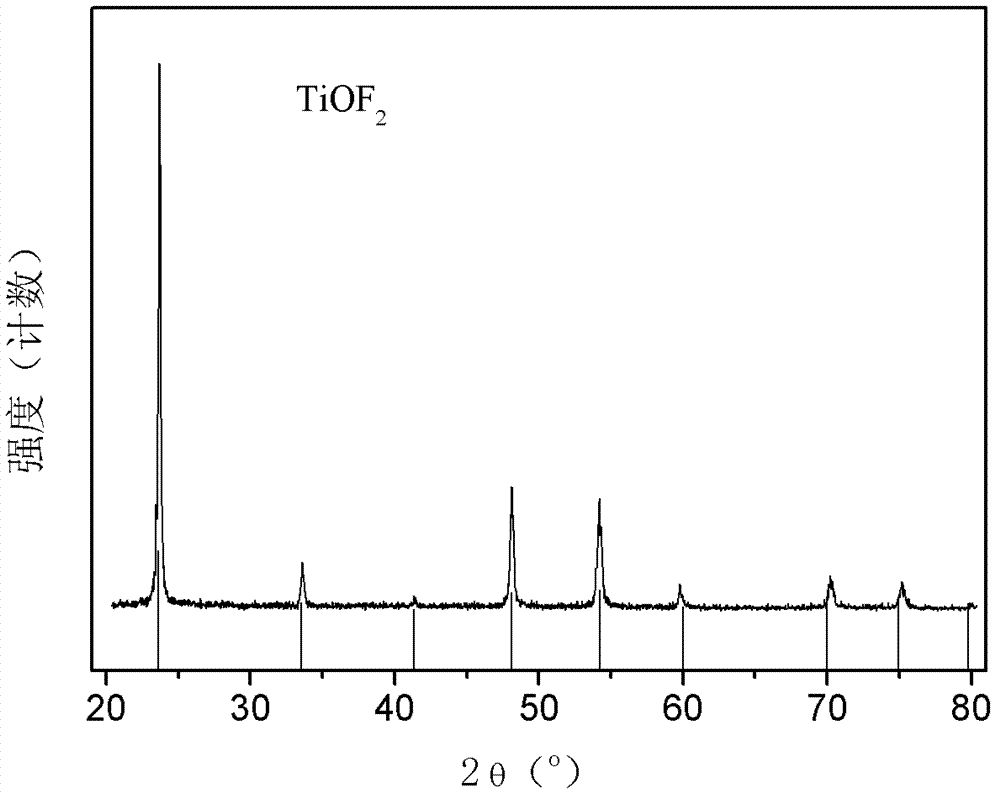

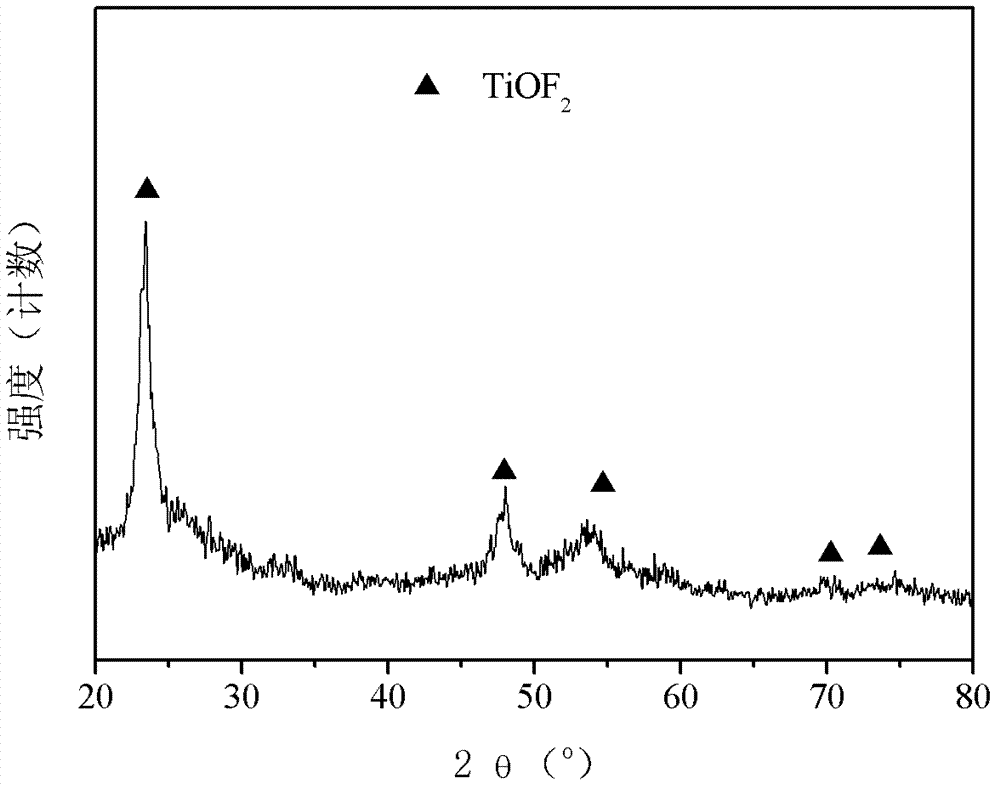

A kind of low temperature preparation method of tiof2 photocatalytic film and its application

ActiveCN102294253AStrong interactionImprove stabilityPhysical/chemical process catalystsTitanium tetrafluorideOrganic solvent

The invention discloses a low temperature preparation method for a TiOF2 photocatalyst film. The method comprises the following steps: 1) adding proper amount of titanium tetrafluoride to an organic solvent to prepare a solution A; strongly stirring the solution A for 1-5 hours at a temperature of 283-323 K temperature to obtain a clear precursor solution; 2) dipping and coating the precursor solution on a substrate of glass or ceramic, such that the precursor solution reacts with the substrate; baking for 8-24 hours at the temperature of 313-433 K to obtain the TiOF2 photocatalyst film product. With the present invention, the TiOF2 film is uniformly generated on the surface of the glass or the ceramic through the chemical reactions; the interaction between the film and the substrate is strong, the formed film has good stability, such that the disadvantages of difficulty in forming the stable film on the substrate of the glass or the ceramic at the temperature of 373 K or the requirement of the follow-up baking in the traditional sol-gel method are overcome; the prepared film through the method has wide application prospects in degradation of rhodamine B solution through liquid-phase photocatalysis and air purification.

Owner:上海万铭环保科技股份有限公司

Preparation method for hollow carbon/titanium dioxide composite nano material

InactiveCN103588245AInhibition of hydrolysis rateUniform shapeMaterial nanotechnologyCarbon preparation/purificationTitanium tetrafluorideEtching

The invention relates to a preparation method for a hollow carbon / titanium dioxide composite nano material. TiO2 (titanium dioxide) is generated on the surface of a carbon shell by taking TiF4 (titanium tetrafluoride) as a titanium source, an ethanol / water mixed solution as a solvent and silicon dioxide wrapped by carbon as a hard template through hydrolysis of the titanium source by an in-situ etching method, and the silicon dioxide template can be effectively removed through byproducts HF produced in a reaction process, so that the carbon / titanium dioxide composite nano material which has a hollow characteristic and a uniform appearance can be prepared. The method disclosed by the invention can be used for preparing the hollow carbon / titanium dioxide composite nano material with a good crystallization effect and high performance; furthermore, the byproducts HF can be fully used; therefore, the cost is saved, the efficiency is improved, and the environment pollution is effectively prevented.

Owner:SHANGHAI UNIV

Method for selectively depositing homogeneous nanoparticles on the surface of titanium dioxide microcrystals to enhance photocatalytic activity

ActiveCN109967061AImprove adsorption capacityIncrease roughnessPhysical/chemical process catalystsTitanium tetrafluorideHigh energy

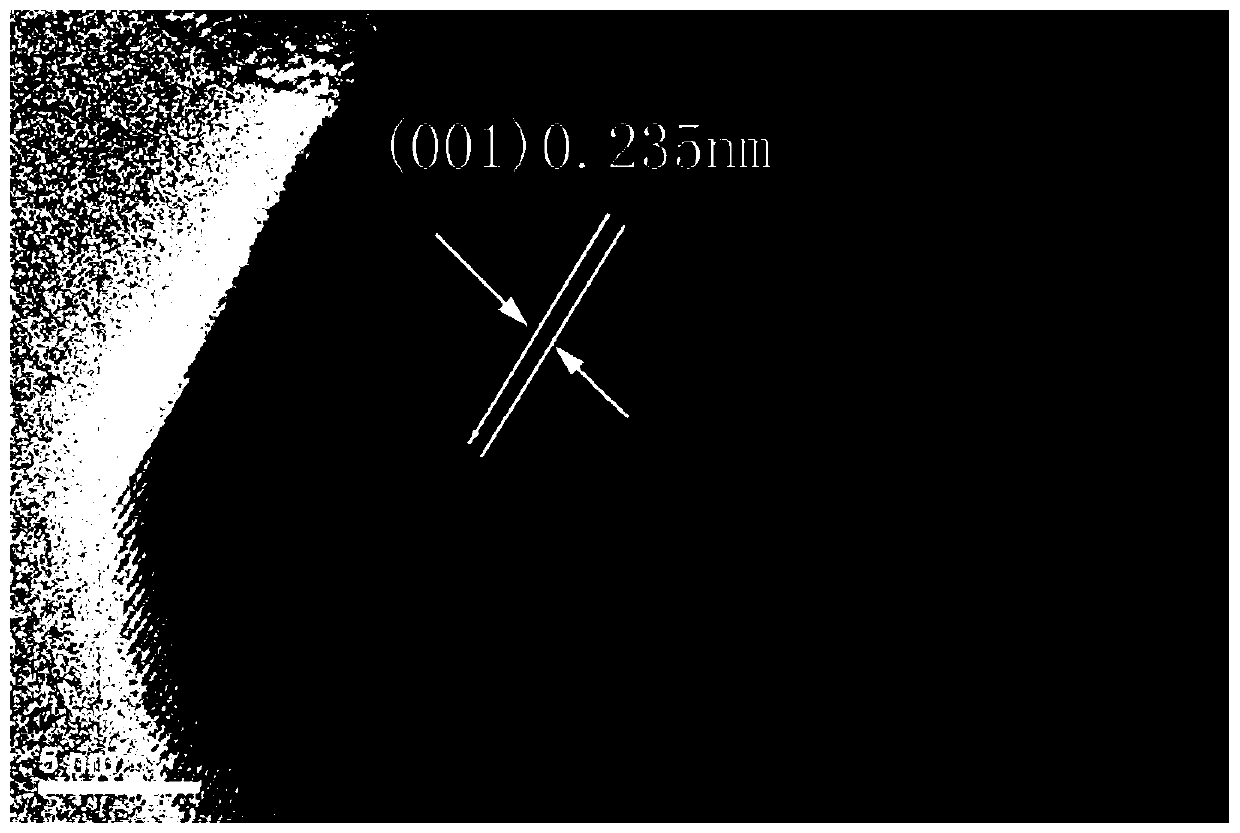

The invention discloses a method for selectively depositing homogeneous nanoparticles on the surface of titanium dioxide microcrystals to enhance photocatalytic activity. The method comprises the following steps: dispersing titanium dioxide microcrystals with (001) surface exposure into an aqueous solution of titanium tetrafluoride, and holding the temperature of the solution for a certain time toselectively grow titanium dioxide nanoparticles on the (101) crystal surface of the microcrystals. The invention skillfully utilizes two dynamic processes of selective adsorption of fluorine ions onhigh energy surface and heterogeneous nucleation and growth of titanium dioxide nanoparticles in the reaction system, The nano-morphology of (001) high-energy surface with high photocatalytic activityin titanium dioxide microcrystals is successfully preserved, and the nano-modification of other crystal surfaces is realized, finally the photocatalytic activity of the crystallites is improved obviously.

Owner:ZHEJIANG UNIV

Dehydrofluorination catalyst

ActiveCN101637733AHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationTitanium tetrafluorideChromium Compounds

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalsyt and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consistsof 30-80 percent of trivalent chromium compound, 10-35 percent of metal halide and 10-35 percent of fluoride of ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, the metal halide is stannic chloride, titanium tetrachloride, tantalum chloride, antimony pentachloride, tin tetrafluoride, titanium tetrafluoride, tantalic fluoride or antimony pentafluoride, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound, the metal halideand the fluoride of ammonium by mass percent, pressing and shaping the mixture, and then baking and activating by hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivityto the Z-type fluoroolefin and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

Titanium oxide-containing material and process for preparing the same

InactiveCN1257461AAntibacterialPromote photocatalytic functionTitanium dioxideCoatingsTitanium tetrafluorideTitanium fluoride

A titanium oxide-containing material having a surface plated with titanium oxide. It is prepared by dissolving titanium fluoride (such as titanium tetrafluoride) in an amount of 2.0 % owf in water, immersing a raw material in the obtained aqueous solution to treat the material with the aqueous solution at room temperature for 30 min, and adding a 0.5 : 1 : 1 (on a weight basis) mixture of boric acid, citric acid, and DL-malic acid in an amount of 0.5 % owf to the aqueous solution to treat the material with the aqueous solution at 50 DEG C for 30 min, followed by washing with water. The raw materials usable herein include synthetic fibers, metals, glass, and woods, and may be in the form of sheet, plate, fiber, rod, or the like. Introduction of a noble metal, such as gold or silver, in addition to titanium oxide, into the surface of the material enables the acceleration of the photocatalytic action of titanium oxide.

Owner:森敏股份有限公司

Synthetic method for high-performance liquid-phase chromatography column packing materials

The invention relates to a synthetic method for high-performance liquid-phase chromatography column packing materials. The synthetic method includes 1, buying market-sold multi-walled carbon nanotubes (MWCNTs) and taking 0.1g of the MWCNTs, adding 15ml thick HNO3 (Nitric acid) and 45ml thick H2SO4 (sulfuric acid) sequentially, performing ultrasonic processing for a period of time respectively, washing the mixture repeatedly with deionized water to be neutral, drying the mixture at the temperature of 100 DEG C for 12 hours, weighting proper processed MWCNTs and adding the MWCNTs into a titanium fluoride (TiF4) solution with certain concentration, and performing the ultrasonic processing on the mixed solution for 30 minutes to mix the mixed solution evenly; 2, pouring the prepared solution into a self-sealed bag, and placing the solution under a 2.5MeV (million electron volt) and 40mA (milliampere) electronic accelerator to be irradiated; 3, transferring the solution into a 200ml beaker, sealing the beaker with a sealing film, and putting the beaker in a baking oven at the temperature of 60 DEG C for 20 hours; and 4, washing the reacted products with water and ethanol sequentially, putting the washed products into a vacuum drying oven at the temperature of 60 DEG C for 6 hours, and then obtaining TiO2 (titanium dioxide) / MWCNTs. TiO2 / MWCNTs high-performance liquid-phase chromatography column packing materials prepared by the synthetic method have good separating efficiency, and separating detection effects of organic pollutants can be effectively improved.

Owner:SHANGHAI UNIV

Metal surface silicane treating agent containing hexamethylphosphoric triamide and preparing method thereof

ActiveCN103059727AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsTitanium tetrafluorideGlycerol

The invention discloses a metal surface silicane treating agent containing hexamethylphosphoric triamide. The metal surface silicane treating agent containing the hexamethylphosphoric triamide is characterized by being a mixed solution which is prepared from following compositions of, by weight in every liter of the mixed solution, 35-45g of aniline methyl triethoxy silicane, 35-45g of N-(beta- aminoethyl)-gamma-aminopropyl trimethoxy silicane, 100-180g of aqueous nanometer zinc oxide material, 3-4g of glycerol, 2-3g of diethylene glycol, 2-4g of ethylene glycol monobutyl ether, 2-3g of titanium tetrafluoride, 2-3g of hexamethylphosphoric triamide, 2-3g of urea, 1-2g of citric acid, 0.3-0.6g of benzotriazole, and the balance water. The metal surface silicane treating agent containing the hexamethylphosphoric triamide has the advantages that, a silicane coating formed on the surface of metal after the metal is processed by using the surface silicane treating agent has good decay resistance, service life of the metal is prolonged, and a compact and firm coating is formed on the surface of the metal by combining the aniline methyl triethoxy silicane and the N-(beta- aminoethyl)-gamma-aminopropyl trimethoxy silicane for use.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Method for preparing nitrogen doped titanium dioxide with high-energy crystal surface on surface

InactiveCN109746020AEasy to prepareShorten the production cyclePhysical/chemical process catalystsTitanium tetrafluorideAlcohol

The invention relates to a method for preparing nitrogen doped titanium dioxide with a high-energy crystal surface on a surface. The method comprises the following steps: 1) dissolving urea into an alcohol solvent, dispersing titanium tetrachloride and titanium tetrafluoride into the alcohol solvent, and carrying out a hydrothermal reaction on a turbid liquid at 140-220 DEG C so as to obtain a solid product; and (2) calcining the solid product at 180-300 DEG C, thereby obtaining the nitrogen doped titanium dioxide with the high-energy crystal surface on the surface. The nitrogen doped titaniumdioxide with the high-energy crystal surface on the surface, which is prepared by using the method, has excellent visible catalysis properties.

Owner:ZHEJIANG SCI-TECH UNIV

Low temperature preparation method for TiOF2 photocatalyst film, and application thereof

ActiveCN102294253BStrong interactionImprove stabilityPhysical/chemical process catalystsTitanium tetrafluorideOrganic solvent

Owner:上海万铭环保科技股份有限公司

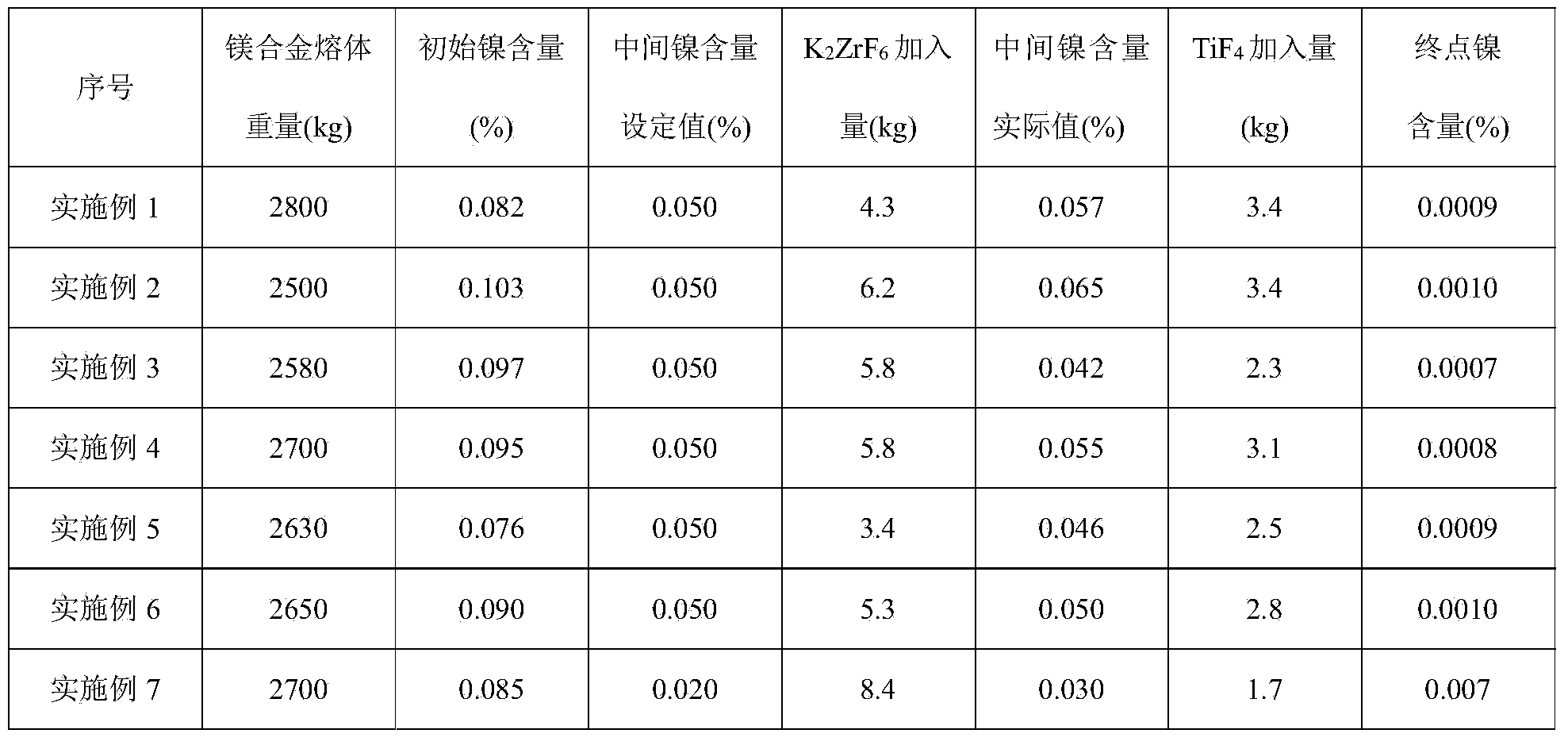

Nickel removing method for magnesium alloy

The invention provides a nickel removing method for magnesium alloy. The nickel removing method comprises the following steps: quantitative potassium fluozirconate is adopted to react with the magnesium alloy for the first nickel removing reaction; the quantitative titanium tetrafluoride is adopted to react with the magnesium alloy for the second nickel removing reaction, wherein the mass ratio of nickel in the potassium fluozirconate to the magnesium alloy is 3-4 to 1; the mass ratio of nickel in the titanium tetrafluoride and the magnesium alloy is 2-3 to 1. Compared with the prior art, the nickel removing method for the magnesium alloy provided by the invention has the advantages that the operation is simple, the reaction time is short, the cost is lower, no special requirement for equipment is needed and the method is suitable for industrial production; the nickel content in the magnesium alloy treated by the method is not greater than 0.001%; compared with nickel removing methods in the prior art, remarkable improvement is achieved in the invention; the technical problem that the nickel content exceeds the standard in the magnesium alloy production or magnesium alloy waste recycling process is solved and the range of the magnesium alloy production or magnesium alloy waste recycling is further expanded.

Owner:HUNAN S R M SCI & TECH

Preparation method for hollow carbon/titanium dioxide composite nano material

InactiveCN103588245BInhibition of hydrolysis rateUniform shapeMaterial nanotechnologyCarbon preparation/purificationTitanium tetrafluorideEtching

Owner:SHANGHAI UNIV

Method for preparing graphene-based titanium dioxide composite photocatalyst by radiation of electron beams

ActiveCN101658786BPromote crystallizationImprove photocatalytic performanceWater/sewage treatment by irradiationWater contaminantsTitanium tetrafluorideRadiation chemistry

The invention relates to a method for preparing a graphene-based titanium dioxide composite photocatalyst by radiation of electron beams, belonging to the technical fields of radiation chemistry and photocatalyst preparation. The method comprises the following steps: firstly, preparing graphene by the prior art, then adding the graphene powder into a titanium tetrafluoride solution, and dispersing the graphene powder with ultrasonic waves to obtain a suspension; then putting the suspension in an electron beam generating device to be radiated by a certain dose of electron beams, the irradiation dose of which is 70-280KGy; after sealing, putting the suspension in an oven of 60 DEG C for reaction for 20 hours; and finally, obtaining the graphene-based titanium dioxide composite photocatalystby washing and drying. The inspection proves that the graphene-based titanium dioxide composite photocatalyst prepared by the method of the invention has higher photocatalytic activity. In addition, by inspecting with a transmission electron microscope (TEM), titanium dioxide crystals which are densely and evenly loaded on the graphene matrix can be seen.

Owner:安徽省通源环境节能股份有限公司

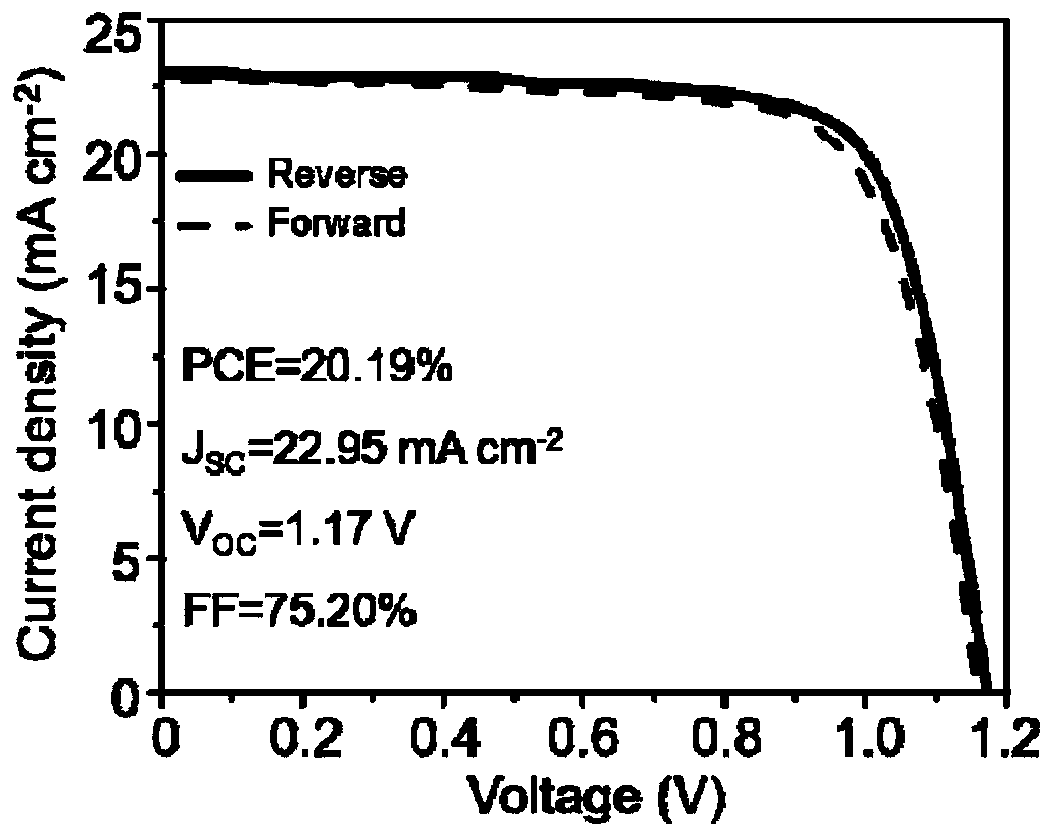

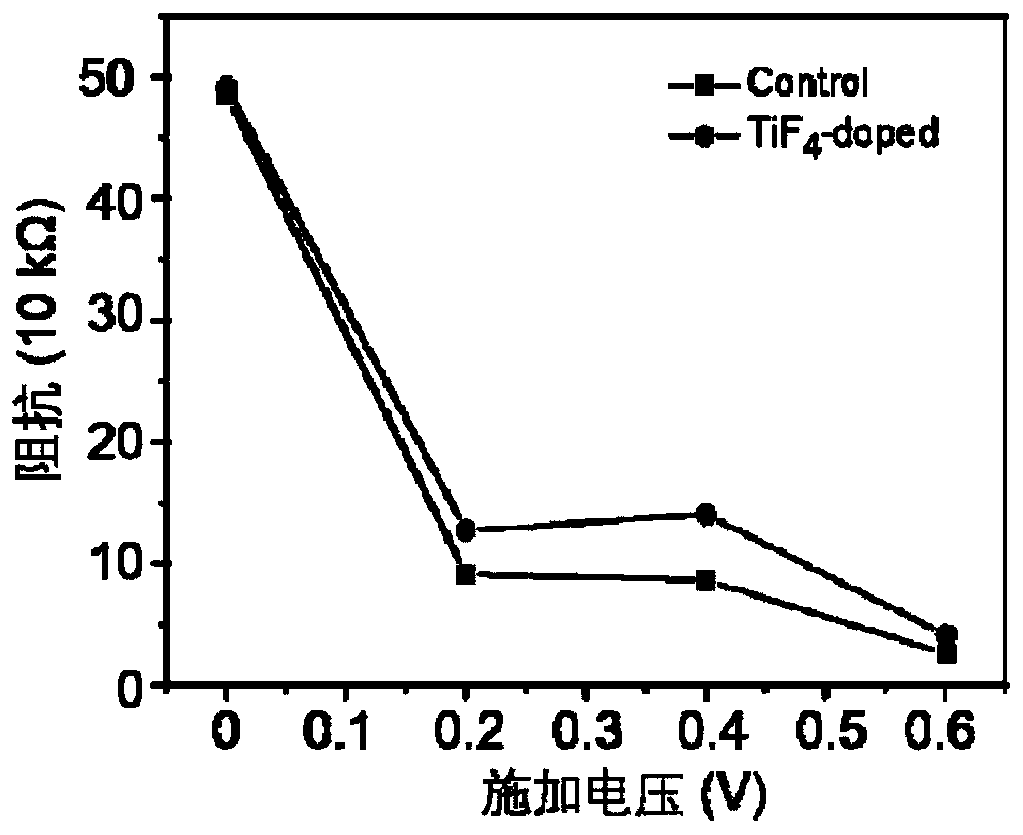

Preparation method and application of titanium tetrafluoride passivated perovskite battery interface

ActiveCN110854276ASimple and fast operationGood repeatabilitySolid-state devicesSemiconductor/solid-state device manufacturingTitanium tetrafluorideTitanium fluoride

The invention relates to a preparation method and an application of a titanium tetrafluoride passivated perovskite battery interface. The preparation method comprises the following steps: dissolving 2-8mg of titanium tetrafluoride powder into 1mL of N, N-dimethylformamide solution; taking and diluting 2-20[mu]L of titanium tetrafluoride-N, N-dimethylformamide solution, adding less than 20[mu]L ofthe diluted N, N-dimethylformamide solution into 100[mu]L of an FACs-based perovskite precursor solution with a concentration of 0.8-1.2 mol / mL; and shaking the solution to a uniform state, spin-coating conductive glass FTO covered by titanium dioxide with the solution to form a film, carrying out annealing and cooling, applying a hole layer by spin-coating, vapor-depositing conductive electrode silver, and assembling a complete perovskite solar cell. Fluorine and titanium ions of titanium tetrafluoride in the perovskite solution are spontaneously dispersed on the upper interface and the lowerinterface of the perovskite absorption layer film, so that corresponding defects at the interface of the battery film can be passivated, the performance of an original battery is improved by about 12.6%, and the stability is obviously improved.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of preparation method of titanate, titanic acid and titanium dioxide

ActiveCN104261465BPreserve Microstructural FunctionMaterial nanotechnologyAlkali titanatesMicro nanoTitanium tetrafluoride

This application discloses a method for preparing titanate, titanic acid and titanium dioxide. The preparation method of titanate includes: obtaining a hydrated titanic acid precipitation through a hydrolysis reaction of a titanium source. The titanium source is selected from the group consisting of titanium sulfate and oxygen sulfate. One or a combination of titanium, titanium tetrachloride, titanium tetrafluoride, titanium ethoxide, titanium propoxide, tetrabutyl titanate, titanium ethylene glycol, titanium glycerol, and ammonium fluorotitanate; The hydrated titanic acid precipitate is dispersed in a hydrogen peroxide aqueous solution containing a strong base and undergoes a hydrothermal reaction to obtain a sea urchin-like titanate with a nano-micro hierarchical structure. The preparation method of titanate, titanic acid and titanium dioxide provided in this application can make up for some shortcomings of preparing titanate, titanic acid and titanium dioxide materials into nanowire or nanotube structures.

Owner:NINGBO NANOJP NEW MATERIAL TECH CO LTD

Preparation method of titanium dioxide particle electrode loaded with high {001} crystal face

ActiveCN114162912APromote degradationStable growthWater contaminantsWater/sewage treatment by oxidationTitanium tetrafluorideElectrolysis

The invention relates to a preparation method of a titanium dioxide particle electrode loaded with a high {001} crystal face, and the particle electrode is composed of granular active carbon and titanium dioxide loaded on the granular active carbon and having the high {001} crystal face. Comprising the following steps: pretreatment of activated carbon, hydrothermal reaction of a mixture of powdered activated carbon and titanium tetrafluoride, high-temperature heat treatment, extrusion forming of granular activated carbon and the like, titanium tetrafluoride is adopted as a titanium source, and titanium dioxide can stably grow a {001} crystal face with high surface energy in a fluorine environment by utilizing relatively high binding energy between fluorine and titanium, so that the surface of the titanium dioxide is uniform, and the surface of the titanium dioxide is uniform. When the prepared particle electrode is applied to a three-dimensional electrolysis system, the electrocatalytic oxidation activity can be remarkably improved, degradation of biorefractory organic pollutants is promoted, the treatment time can be shortened, and the service life can be prolonged; a fixed bed of an up-flow type three-dimensional electrode reactor is filled with the mixed solution for an electrolytic oxidation experiment of electrolyzing the acid orange 7, and the removal rate of the acid orange 7 can reach 91.2% after the acid orange 7 is electrolyzed for 5 min.

Owner:QUANZHOU INST FOR ENVIRONMENTAL PROTECTION IND NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com