A kind of low temperature preparation method of tiof2 photocatalytic film and its application

A photocatalytic film and low-temperature technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of inconvenient production and use, difficult to form a stable film on the surface of the substrate, etc., to achieve The effect of strong interaction, good stability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

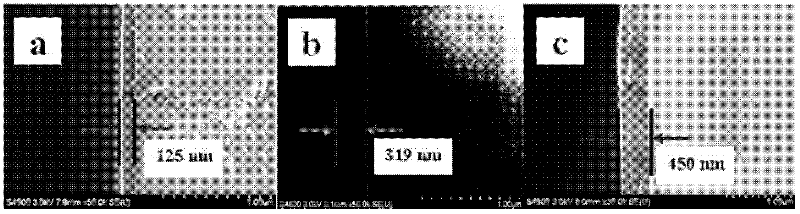

[0018] Add 0.37 g of titanium tetrafluoride to 30 mL of absolute ethanol, and stir at 283 K for 2 h to obtain solution A. Immerse the glass substrate in solution A, then lift it up slowly, remove the excess bottom solution and transfer it to a 373K oven for aging for 8 hours to prepare the photocatalytic film Ti-0.1-100. The obtained photocatalytic film was directly applied to the photocatalytic degradation reaction of Rhodamine B.

Embodiment 2

[0020] Add 1.5 g of titanium tetrafluoride to 60 mL of anhydrous butanol, and stir at 298 K for 5 h to obtain solution A. Immerse the glass substrate in solution A, then lift it up slowly, remove the excess bottom solution and transfer it to a 373K oven for aging for 8 hours to prepare the photocatalytic film Ti-0.2-100. The obtained photocatalytic film was directly applied to the photocatalytic degradation reaction of Rhodamine B.

Embodiment 3

[0022] Add 1.12 g of titanium tetrafluoride to 30 mL of absolute ethanol, and stir at 323 K for 1 h to obtain solution A. Immerse the glass substrate in solution A, then lift it up slowly, remove the excess bottom solution and transfer it to a 373K oven for aging for 8 hours to prepare the photocatalytic film Ti-0.3-100. The obtained photocatalytic film was directly applied to the photocatalytic degradation reaction of Rhodamine B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com