Patents

Literature

35 results about "Titanium ethoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium ethoxide is a chemical compound with the formula Ti₄(OCH₂CH₃)₁₆. It is a colorless liquid that is soluble in organic solvents but hydrolyzes readily. It is sold commercially as a colorless solution. Alkoxides of titanium(IV) and zirconium(IV) are used in organic synthesis and materials science. They adopt more complex structures than suggested by their empirical formulas.

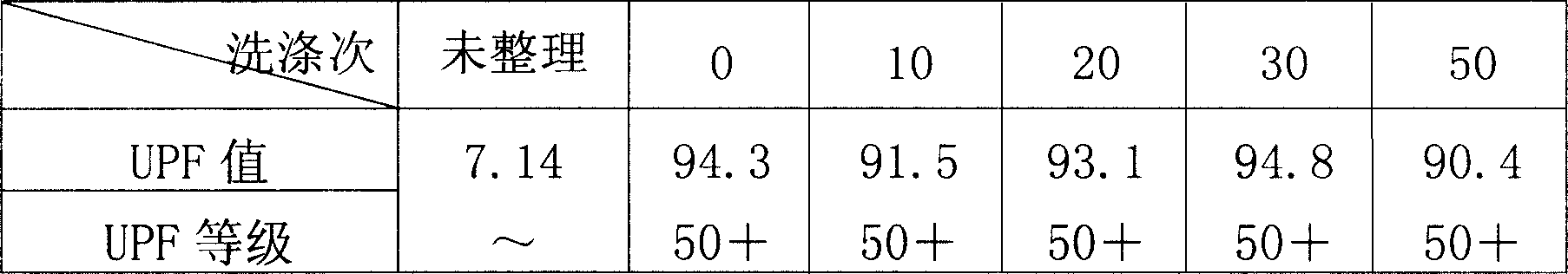

UV light screen agent, uviorosistant fibric finishing agent and its finished fibric

The invention relates to ultraviolet screening agent, ultraviolet resistant fabric finishing liquid, and the finished fabric. The screening agent making method includes the following steps: preparing A solution that aqueous solution contains 0.3-0.5% acid which can be one of hydrochloric acid, sulfuric acid, nitric acid, glacial acetic acid, or phosphoric acid; preparing titanium source alcoholic solution as 100-0.5:1 volume ratio, stirring to form B solution; the titanium source can be one of titanic acid ethyl ester, titanic acid propyl ester, titanic acid butyl ester, or titanium tetrachloride; the alcohol can be one of ethanol, isopropyl alcohol, or butanediol; adding the B solution into the A solution as 5-9:1 volume ratio by stirring from room temperature to 100 degree centigrade; reacting for 24h; aging for 2-6h. The fabric finishing liquid contains 5-80% ultraviolet screening agent and water. The ultraviolet resistant fabric finishing adopts the produced finishing liquid to finish. The function is obvious. And the wash fastness is good.

Owner:TIANJIN POLYTECHNIC UNIV

Environment-friendly hole sealing liquid for anodic aluminum oxide profiles and hole sealing method thereof

ActiveCN103255462AAvoid pollutionEnvironmentally friendlySurface reaction electrolytic coatingTitanium ethoxidePhytic acid

The invention relates to an environment-friendly hole sealing liquid for anodic aluminum oxide profiles and a hole sealing method thereof. The environment-friendly hole sealing liquid for anodic aluminum oxide profiles is characterized by comprising the following components based on the total volume: 10-50 g / L of silicate or titanium ethoxide or ethyl silicate, 2-20 g / L of phytic acid or phytate, 0.5-5 g / L of corrosion inhibitor and 0.005-0.2 g / L of anionic surfactant. The hole sealing method of the environment-friendly hole sealing liquid for anodic aluminum oxide profiles is characterized by comprising the step of immersing aluminum oxide profiles which are subject to anodic oxidation into the environment-friendly hole sealing liquid for hole sealing treatment at the treatment temperature of 60-80 DEG C for 10-40 minutes. Sealing holes by using the environment-friendly hole sealing liquid and the hole sealing method thereof is simple, convenient and environment-friendly, and the production energy consumption of aluminum oxide profile industry is reduced.

Owner:GUANGDONG XINGFA ALUMINUM

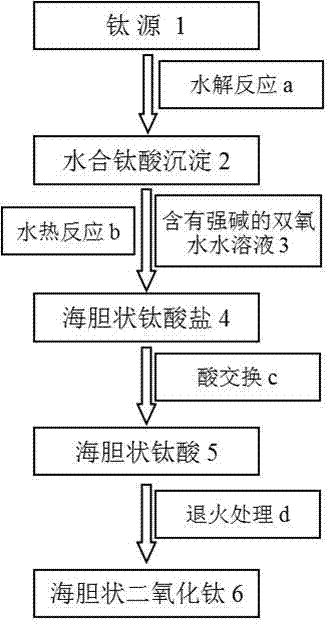

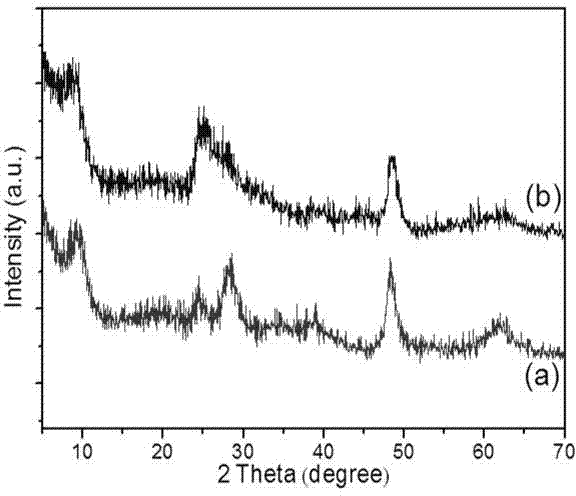

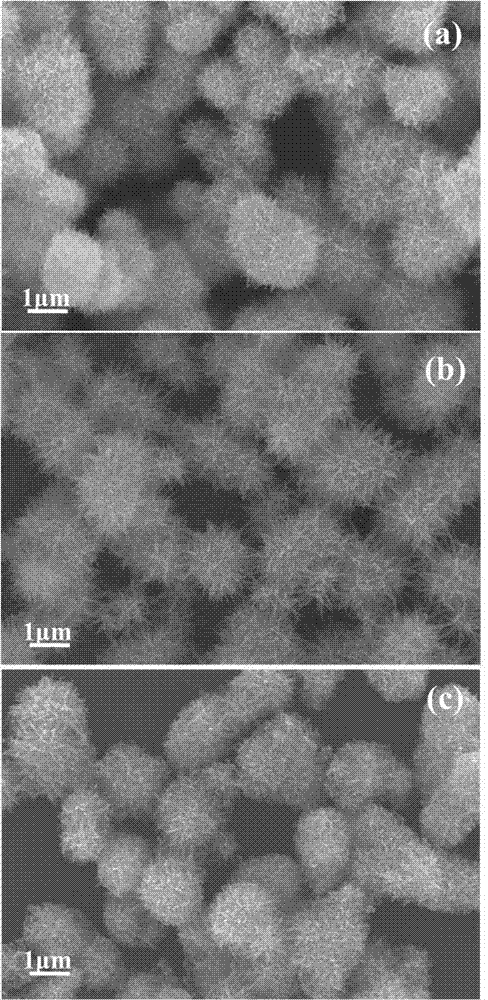

Method for preparing titanate, titanic acid and titanium dioxide

ActiveCN104261465AImprove cycle performanceIncrease capacityMaterial nanotechnologyAlkali titanatesTitanium tetrafluorideMicro nano

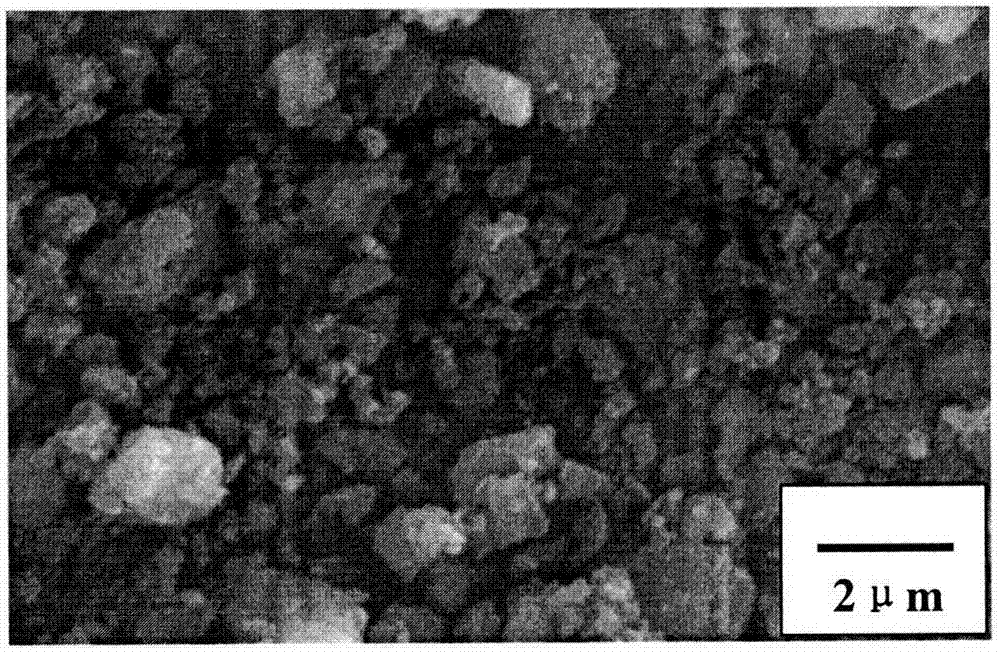

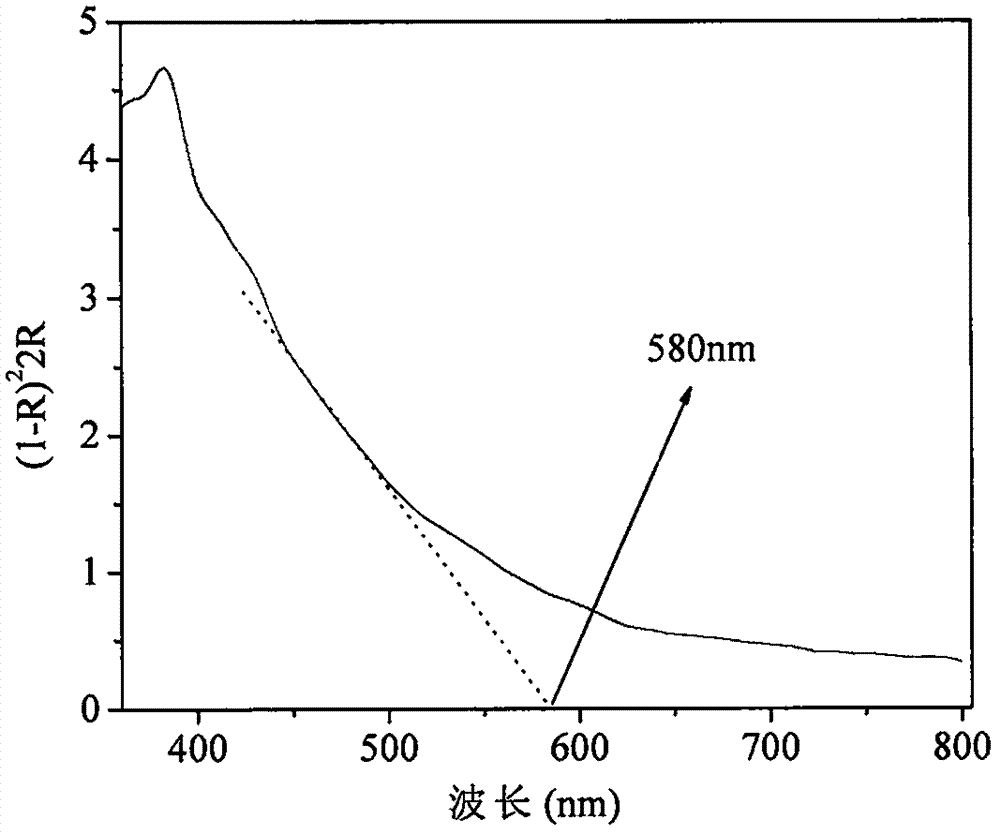

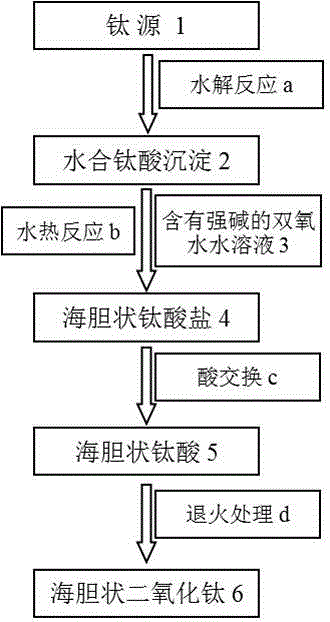

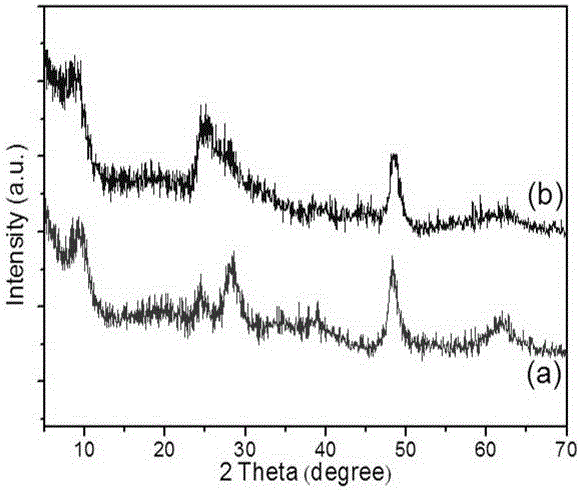

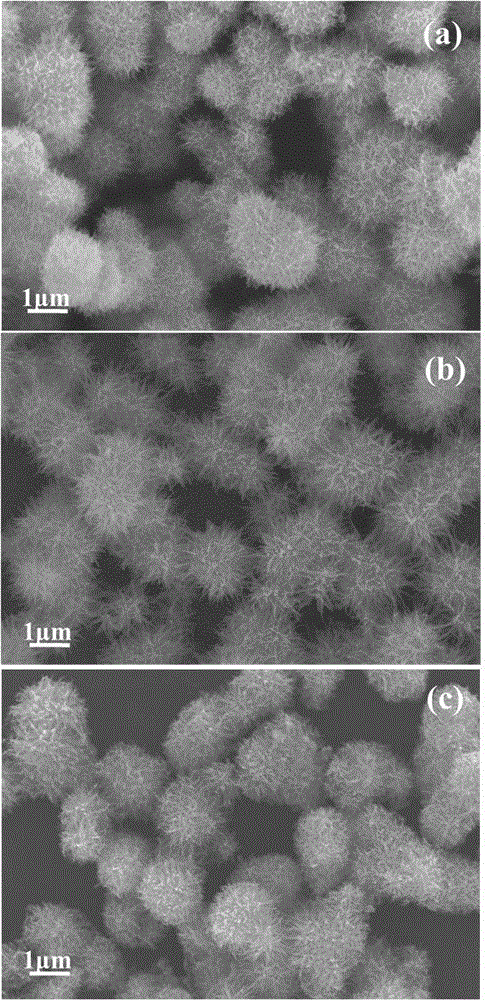

The invention discloses a method for preparing titanate, titanic acid and titanium dioxide. The method for preparing titanate comprises the following steps: carrying out hydrolysis reaction on a titanium source to obtain hydrated titanium acid precipitates, wherein the titanium source is selected from one or a composition of more of titanium sulfate, titanyl sulfate, titanium tetrachloride, titanium tetrafluoride, titanium ethoxide, titanium propoxide, tetrabutyl titanate, ethylene glycol titanium, glycerol titanium and ammonium fluorotitanate; dispersing the hydrated titanium acid precipitates in an aqueous hydrogen peroxide solution containing strong base for hydrothermal reaction, and thus obtaining sea urchin titanate with a micro-nano hierarchical structure. The method can overcome some defects of titanate, titanic acid and titanium dioxide prepared into nanowire or nanotube structures.

Owner:NINGBO NANOJP NEW MATERIAL TECH CO LTD

Preparation method for graphene-loaded multielement-doped magnesium diboride superconducting bulk material

ActiveCN106205861AImprove performanceEvenly distributedSuperconductors/hyperconductorsSuperconductor devicesDopantTitanium ethoxide

The invention discloses a preparation method for a graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method comprises the steps of 1, dropwise adding ethyl silicate and titanium ethoxide into a graphene oxide solution, and stirring uniformly to obtain a mixture material; 2, performing a hydrothermal reaction, filtering and washing and then carrying out vacuum drying to obtain graphene-loaded multielement mixture powder; 3, performing heat treatment to obtain graphene-loaded multielement-doped powder; 4, mixing boron powder and magnesium powder and grinding, then adding the mixture powder to the graphene-loaded multielement-doped powder, uniformly grinding and pressing and shaping to obtain a bulk material; and 5, performing sintering on the bulk material under protection of an inert atmosphere, and performing furnace cooling to the room temperature to obtain the graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method is simple; the prepared multielement dopant is uniform in dispersion, free of agglomeration, high in activity and can rapidly enter magnesium diboride lattices, thereby reducing the phase-forming temperature of the doped magnesium diboride; and in addition, the prepared magnesium diboride bulk material has excellent performance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

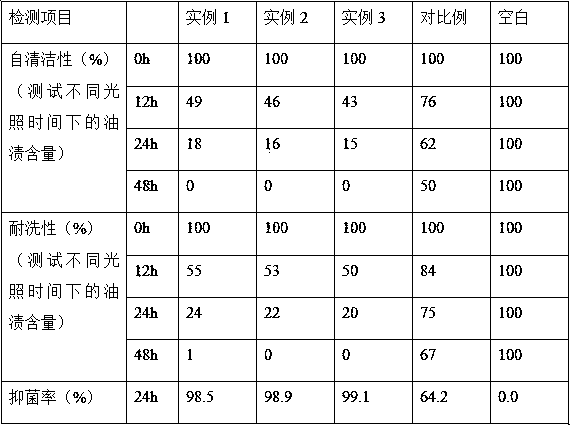

Preparation method of antibacterial self-cleaning fabric

InactiveCN108411615AHigh densityImprove conductivityStain/soil resistant fibresBiochemical fibre treatmentSilicon dioxideMonomer

The invention relates to the technical field of preparation of polymer materials, and in particular relates to a preparation method of an antibacterial self-cleaning fabric. A silver crystal seed solution is prepared from a silver nitrate solution, a trisodium citrate aqueous solution and a sodium borohydride solution, polyvinylpyrrolidone, L-ascorbic acid and the like are added into the silver crystal seed solution, an activated reducing solution is prepared by diluting, a pure cotton fabric is cut and treated as a base fabric to obtain a modified cotton fabric, ethyl orthosilicate and absolute ethanol are mixed, diluted hydrochloric acid is added to obtain a silica sol, absolute ethanol, 5,5-dimethylhydantoin and methacryloyl chloride are mixed and ultrasonically dispersed to obtain an antibacterial monomer suspension, the antibacterial monomer suspension is added to ethyl titanate to obtain a mixed solution, and acetic acid and the silica sol are added dropwise to the mixed solution, ichloromethane is used to dilute to obtain an antibacterial spraying agent, and the antibacterial spraying agent is sprayed by an atomizer to the surface of the modified cotton fabric to obtain theantibacterial self-cleaning fabric, and the application prospect is broad.

Owner:吴刚

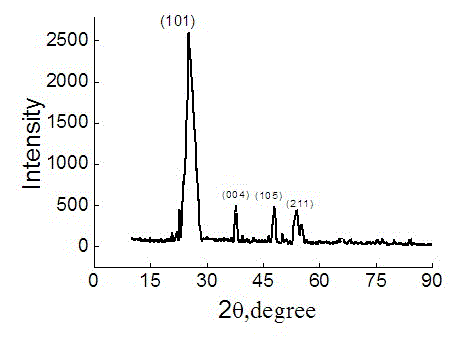

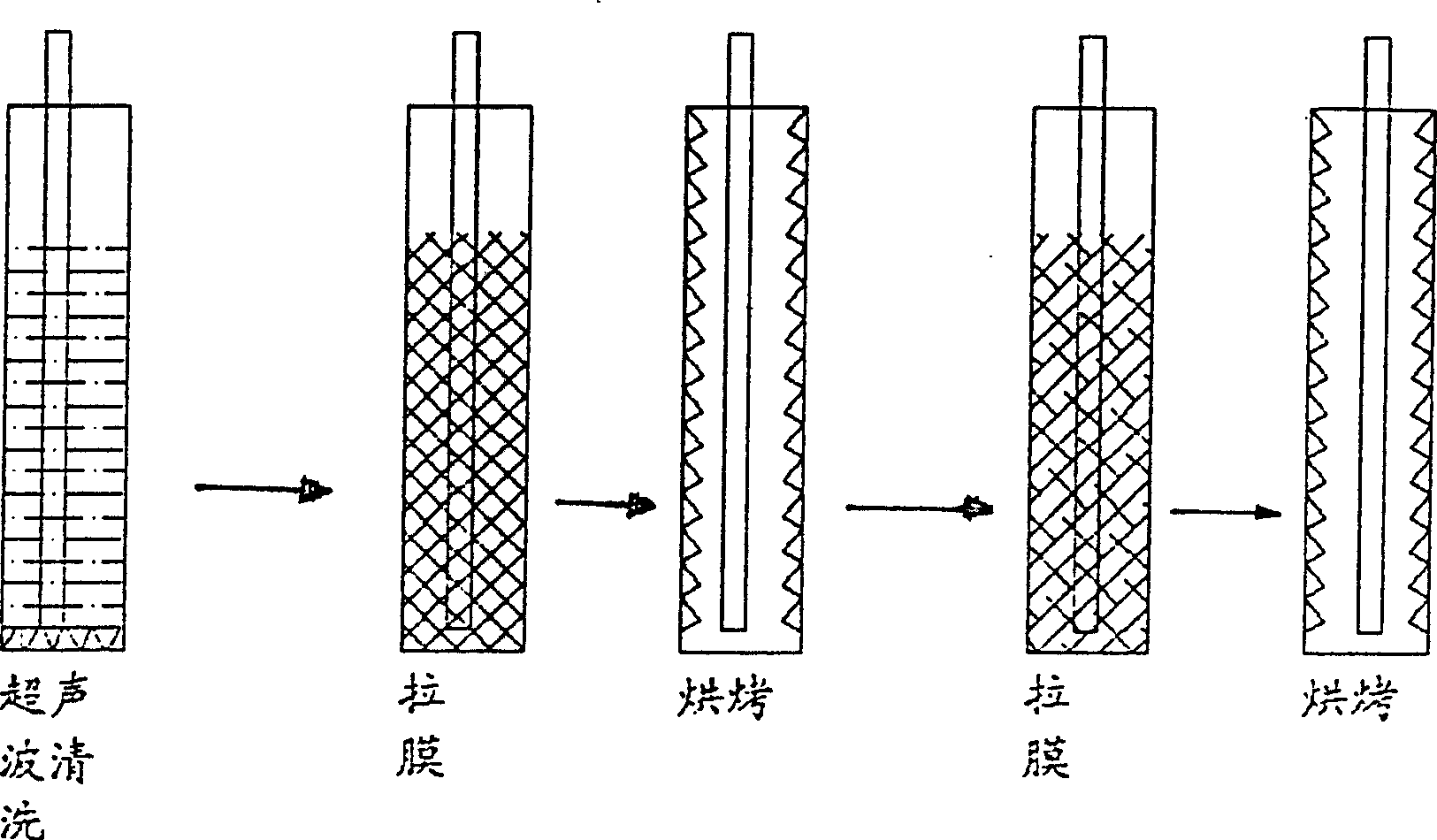

Preparation method of nanometer titanium dioxide film

The invention relates to a preparation method of a nanometer titanium dioxide film. The method is convenient to use. The method comprises the following steps: placing a cleaned glass ware and a quartz glass substrate in a constant temperature vacuum drying box to be dried, uniformly mixing analytically pure absolute ethyl alcohol and acetylacetone in a reaction kettle, and then, adding tetraethyl titanate to obtain a uniform and transparent solution, stirring the solution at room temperature, continuing to drip a small dosage of mixed solution of deionized water and the absolute ethyl alcohol after the solution is uniformly mixed, stirring through a magnetic force to obtain stable, uniform, clear and transparent yellow gel, standing, pulling the gel into a film on the clean quartz glass substrate through a pulling machine, pre-heating the film in a muffle furnace, calcining and annealing the film at a preset temperature to obtain the nanometer titanium dioxide film, and cooling the nanometer titanium dioxide film to the room temperature in an air cooling manner. The preparation method provided by the invention has the advantages of controlling the hydrolysis speed by controlling the dosage of the dripped deionized water and the absolute ethyl alcohol, thereby being convenient and practical; and an anatase type nanometer titanium dioxide film with excellent quality is obtained.

Owner:SHENYANG JIANZHU UNIVERSITY

Modified titanium dioxide/bamboo charcoal composite environment-friendly aerogel and preparation method thereof

ActiveCN104707588ALarge specific surface areaHigh porosityPhysical/chemical process catalystsDispersed particle separationPorosityCatalytic effect

The invention discloses modified titanium dioxide / bamboo charcoal composite environment-friendly aerogel and a preparation method thereof. The modified titanium dioxide / bamboo charcoal composite environment-friendly aerogel comprises the following raw materials: 10mL of titanium ethoxide, 0.001g to 0.006g of a surface active agent, 1mL to 3mL of a 0.001mol / L to 0.006mol / L silver nitrate solution, glacial acetic acid and bamboo charcoal powder, the volume size of the silver nitrate solution to the glacial acetic acid is 1 to (0.01 to 0.04), and the mass of the bamboo charcoal powder is 0.01 to 0.20 percent of the mass of the titanium ethoxide. The preparation method comprises the steps: dissolving the titanium ethoxide into anhydrous ethanol, placing the surface active agent, and uniformly stirring to obtain a solution A; dissolving the silver nitrate solution in a mixed solution of the glacial acetic acid and water, and uniformly stirring to obtain a solution B; and gradually dropwise adding the solution B into the solution A, adding the bamboo charcoal powder, uniformly stirring, standing, aging, carrying out the washing, thermally treating a prepared product in a microwave oven, and then cooling the product to the room temperature to obtain the modified titanium dioxide / bamboo charcoal composite environment-friendly aerogel. The aerogel has advantages of no toxicity, large specific surface area, high porosity and highlight catalytic effect.

Owner:秦皇岛杰康视电子科技有限公司

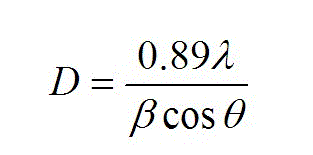

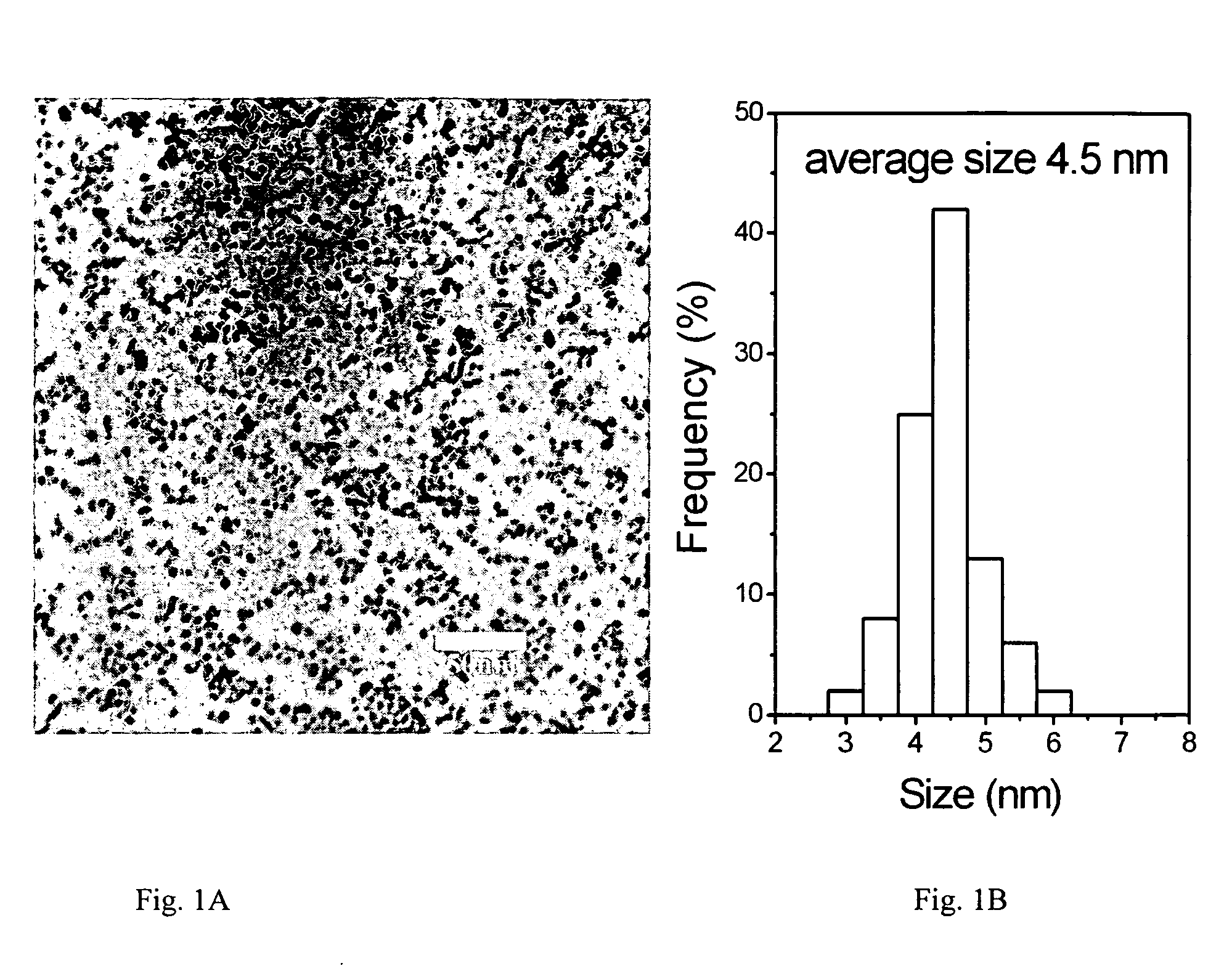

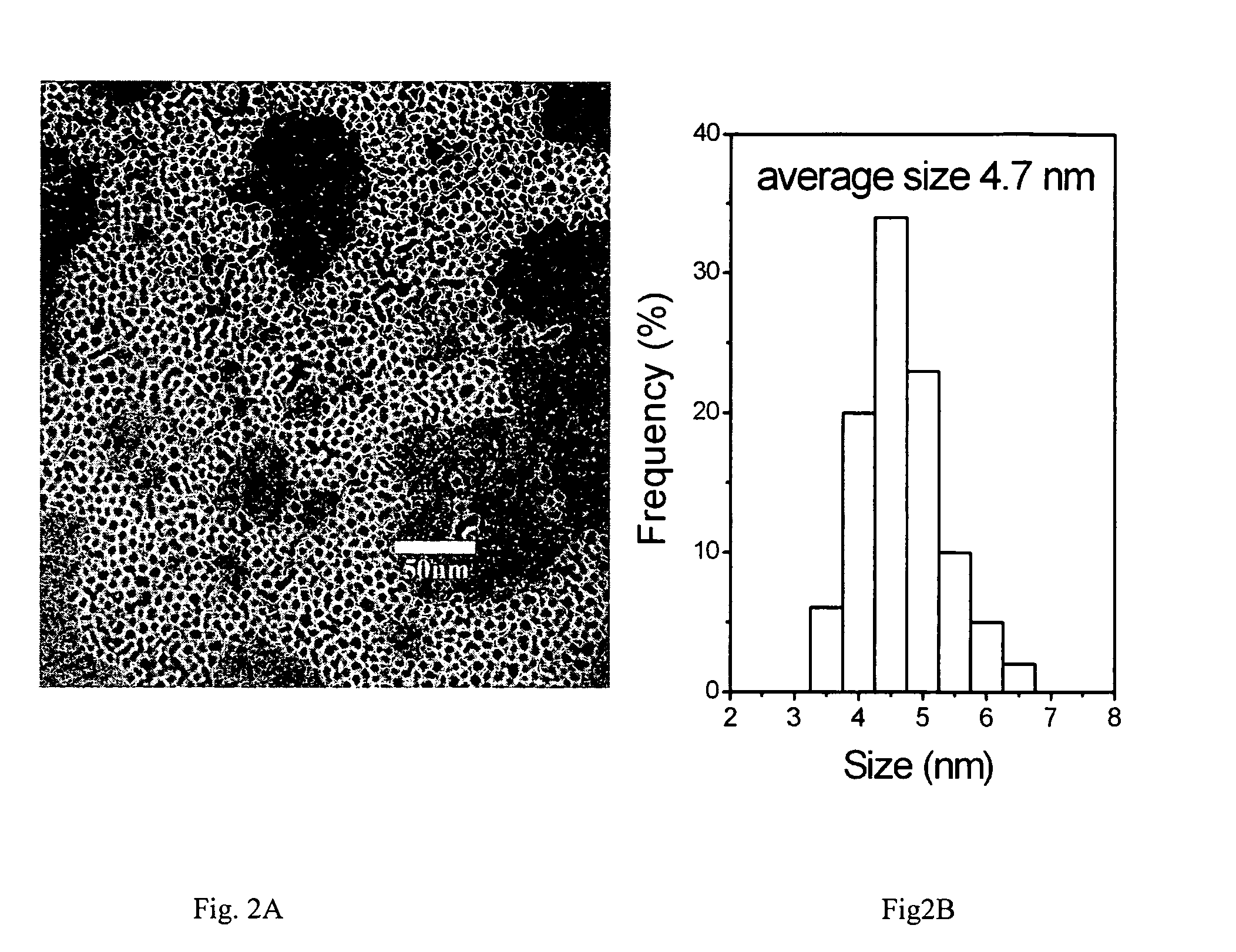

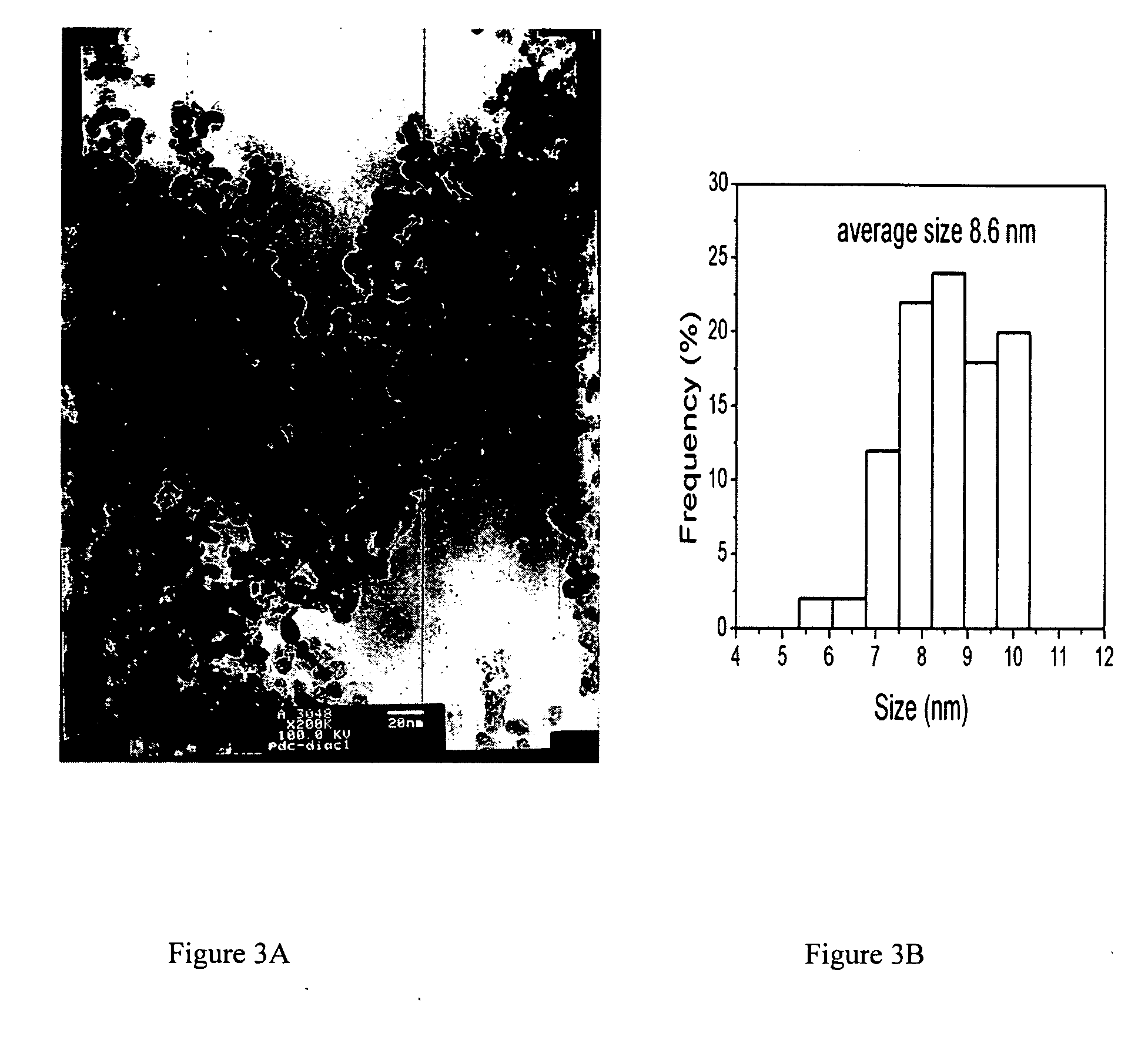

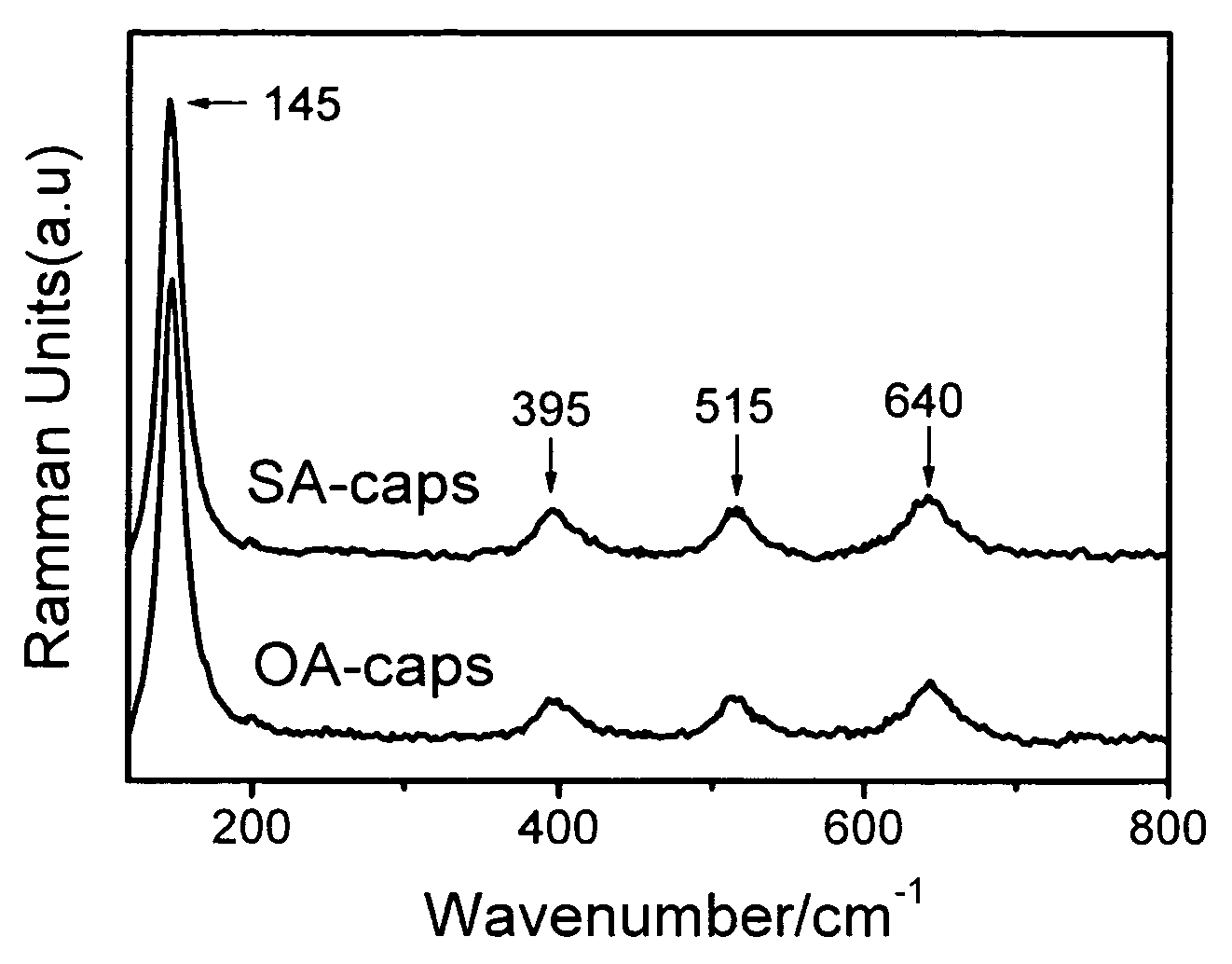

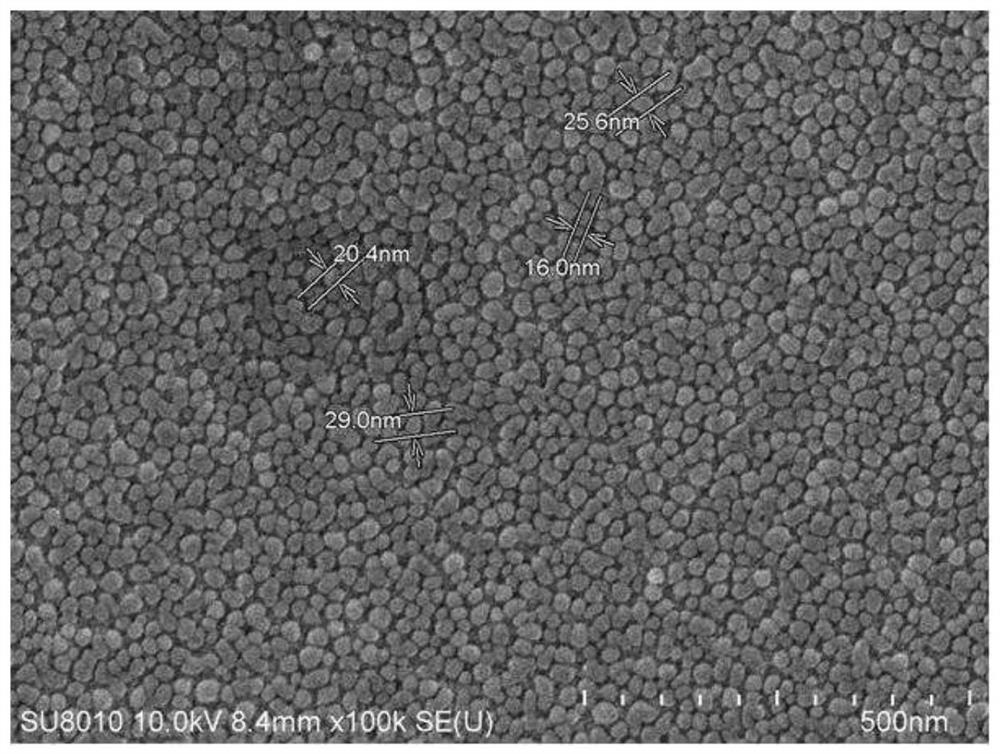

Method for preparing organic ligand-capped titanium dioxide nanocrystals

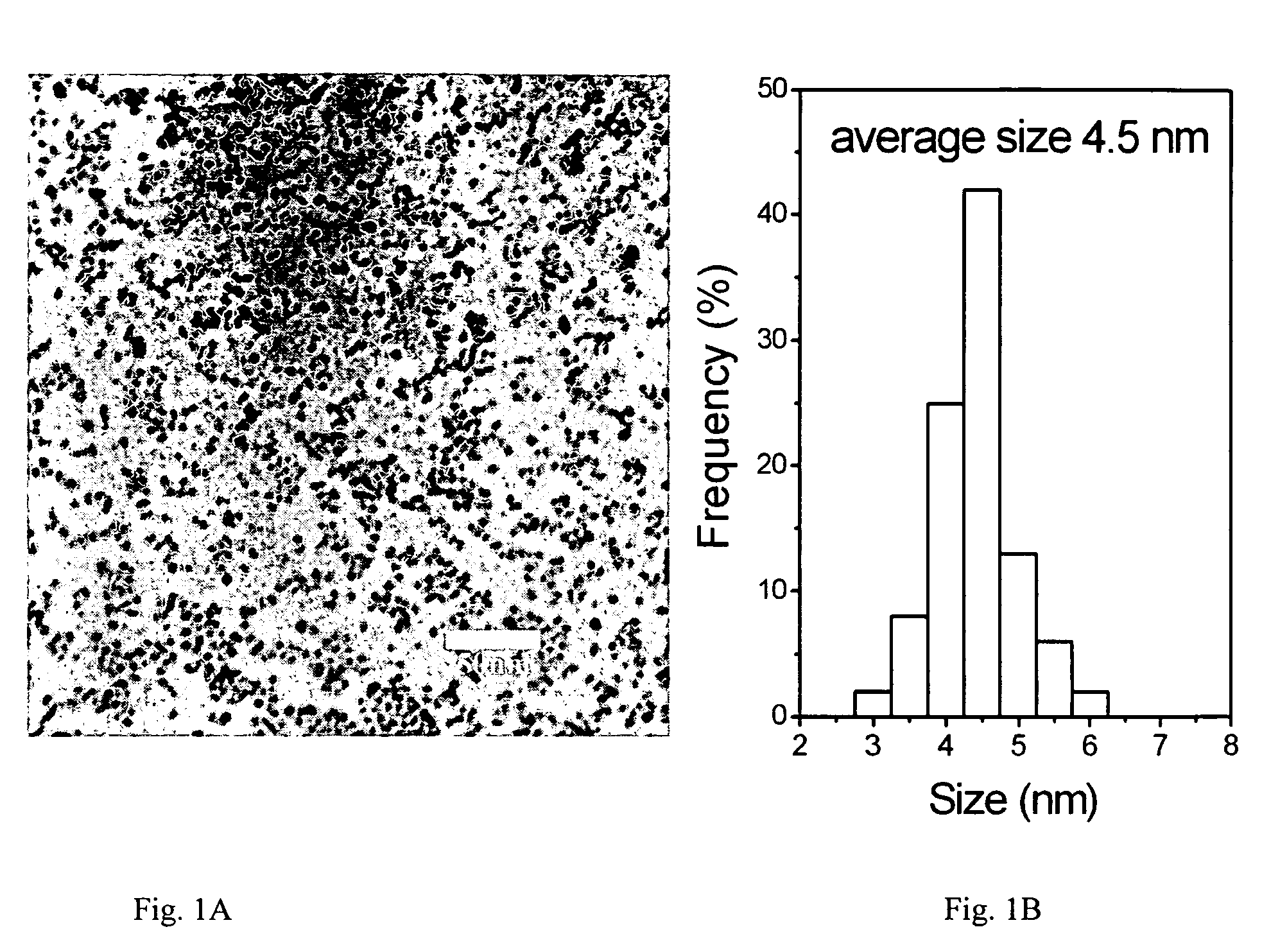

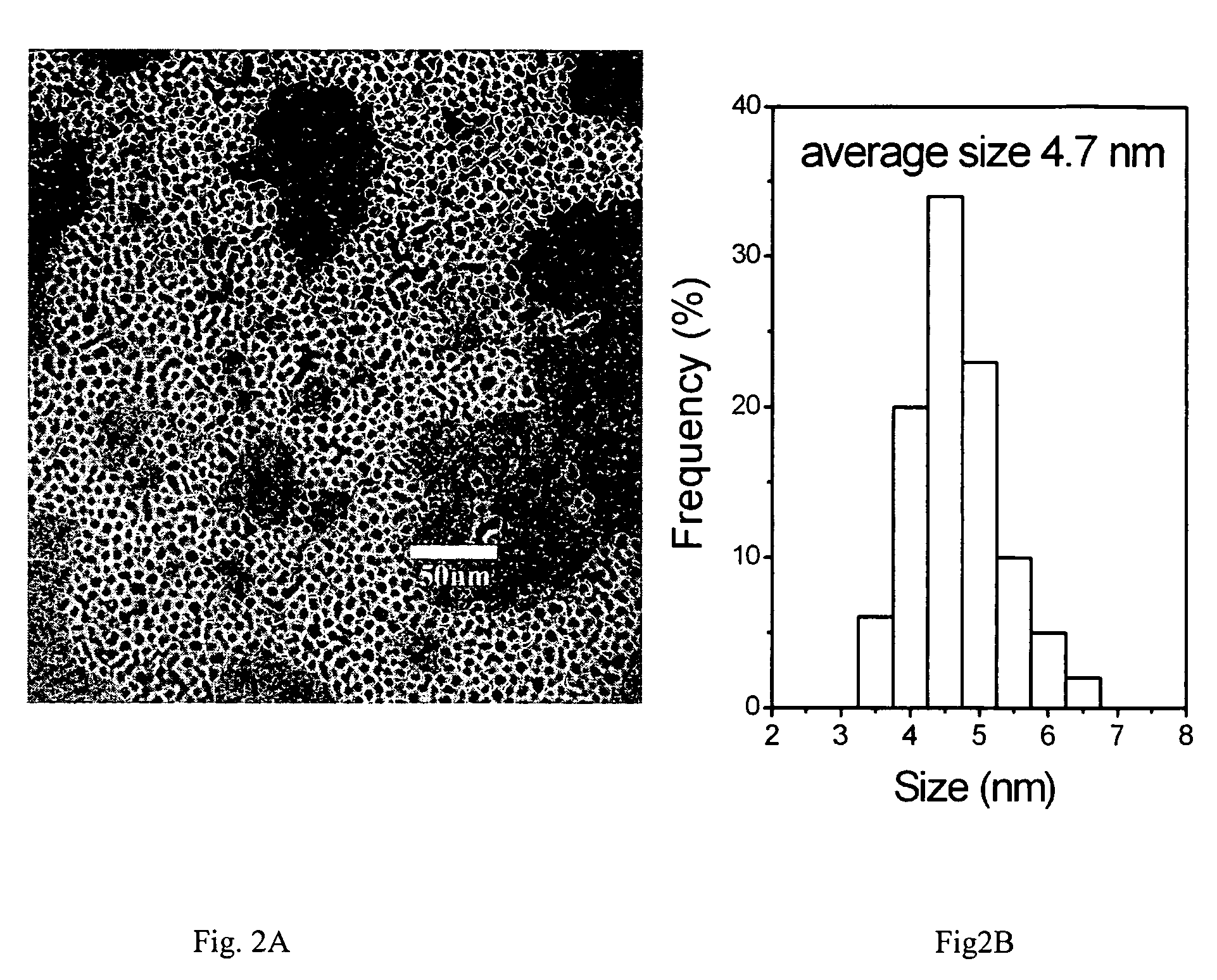

InactiveUS20060188431A1Small sizeNarrow size distributionMaterial nanotechnologyPolycrystalline material growthTitanium ethoxideSolvent

The present invention belongs to a method for preparing organic ligand-capped titanium dioxide nanocrystals, wherein the method comprises steps of using methyl titanate, ethyl titanate, n-propyl titanate, iso-propyl titanate, butyl titanate or titanium tetrachloride as a titanium source, and with capping by oleic acid or an organic capping agent, reacting the titanium source in an organic non-polar solvent with an aqueous alkaline substance solution in the interface at a temperature of 25 to 280° C. for 0.5 to 240 hrs, thus a transparent sol containing titanium dioxide nanocrystals is obtained, said the titanium dioxide nanocrystals have particle diameters of 1-20 nm. The preparing process has the features of mild reaction conditions and is a simpler and easier method with a shorter preparation period, thereby facilitating the industrialization.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Waterproof coating material

InactiveCN106047034AImprove waterproof performanceAccelerated corrosionAnti-corrosive paintsBoron nitrideAntimony trioxide

The invention discloses a waterproof coating material which is composed of the following raw materials in parts by weight: 30-45 parts of phenolic resin, 26-38 parts of amino resin, 18-30 parts of polycarbonate, 10-18 parts of polypropylene 12-26 parts of aramid fiber, 10-15 parts of nitrile-butadiene rubber, 8-15 parts of alumina ceramic particle, 1-4 parts of graphite, 2-8 parts of titanium ethoxide, 1-5 parts of kaolin, 5-12 parts of antimony trioxide, 6-15 parts of sodium fluosilicate, 2-6 parts of boron nitride and 4-10 parts of stabilizer. The waterproof coating material has the advantages of favorable waterproofness, favorable corrosion resistance, scratch resistance, stable structure, favorable mechanical properties and long service life.

Owner:ANHUI MINGGUANG ZHONGXING SUNLIGHT NEW ENERGY TECH CO LTD

Nickel catalyst for grease hydrogenation and preparation method thereof

InactiveCN104368353ALarge specific surface areaHigh activityFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltReaction temperature

The invention discloses a nickel catalyst for grease hydrogenation and a preparation method thereof. Titania-silica composite oxide acts as a carrier of the catalyst, and nickel and molybdenum act as active components, wherein the nickel content is 10-20wt%, the molybdenum content is 0.5-3.0wt%; the specific surface area is 200-400m<2> / g, and the pore volume is 0.5-0.8ml / g. The preparation method comprises the following steps: adding a tetraethyl titanate solution dropwise into a tetraethoxysilane solution, heating up and removing alcohol, then adding a sulfuric acid solution, putting the mixture into a reaction kettle, carrying out hydro-thermal treatment at 150-220 DEG C, aging, and crystallizing so as to obtain white precipitate, then filtering, washing, drying, roasting, grinding and sieving so as to obtain the carrier; adding a soluble nickel salt solution and an alkaline precipitating agent in a parallel flow mode into a turbid liquid of the carrier and a soluble molybdenum salt solution, controlling the pH value to be 7-9 and the reaction temperature to be 70-80 DEG C, and further stirring for 0.5-1 hour after feeding is completed; filtering, washing until no acid radical ion exists; stoving and dry crushing; and introducing hydrogen for reduction so as to obtain the nickel catalyst. The catalyst is high in activity, and the initial iodine value of palm oil is reduced from 42.8 to below 1.0 after palm oil is hydrogenated.

Owner:CHINA NAT OFFSHORE OIL CORP +2

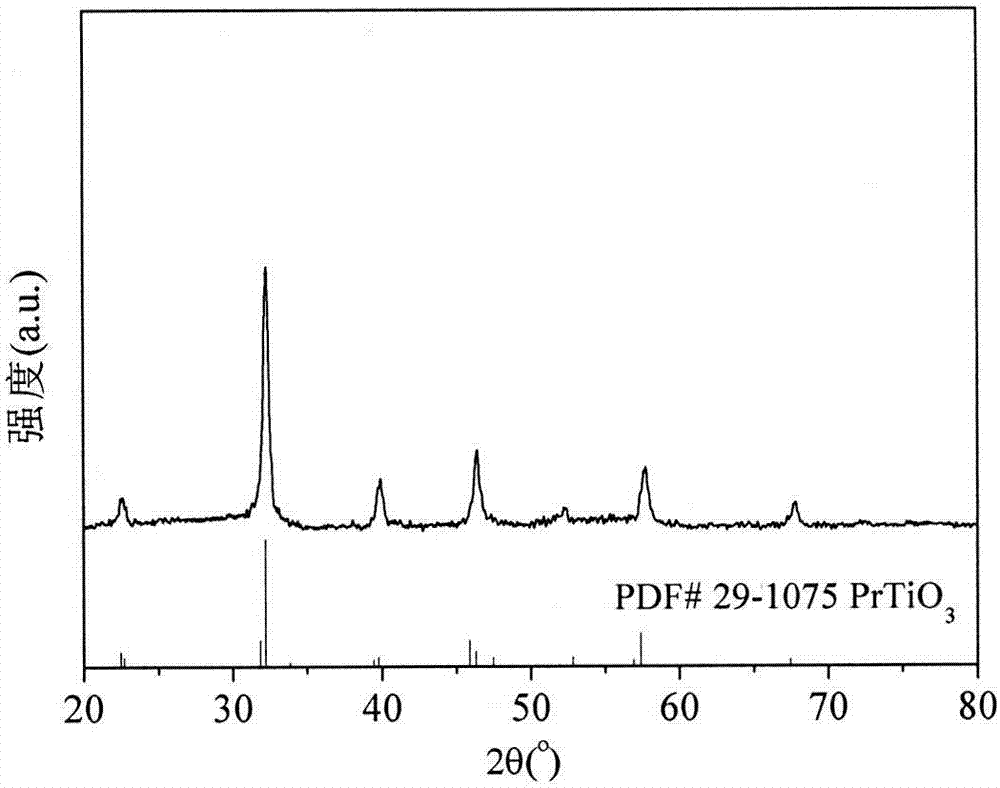

Method for preparing PrTiO3 powder

The invention discloses a method for preparing PrTiO3 powder and relates to a method for preparing an ABO3 type rare-earth perovskite-type compound oxide PrTiO3 material. A microwave assisted method is adopted, praseodymium nitrate, titanium ethoxide and ammonium citrate are taken as raw materials, and the PrTiO3 powder with average particle size of around 0.5umm and good in visible-light catalytic activity is prepared. The method includes two steps of preparation of a reaction solution and preparation of a powder product. A new industry is developed for preparation of the PrTiO3 powder product, and purposes of simpleness in operation, rapidness and high efficiency, relatively low cost, and industrial production of the PrTiO3 powder are achieved.

Owner:佛山市顺德区均安镇永基实业有限公司

Waterborne epoxy resin paint

InactiveCN105949957AImprove bending strengthHigh tensile strengthAntifouling/underwater paintsPaints with biocidesEpoxySodium stearate

Owner:枞阳县新天地高新材料有限公司

Preparation method of composite titanium dioxide nanoparticles

InactiveCN104998690AStable structureUniform sizeMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsComposite nanoparticlesUltrasonic oscillation

The invention discloses a preparation method of composite titanium dioxide nanoparticles. The preparation method comprises the following steps: dispersing titanium ethoxide in an organic solvent through ultrasonic oscillation equipment, adding amine salt, uniformly stirring at room temperature, placing a reaction solution into a reaction vessel and reacting for 2-3.5h, naturally cooling to room temperature, separating out a solid phase, placing the solid phase into a mixing agitator, successively adding a flame retardant synergist, a brominated flame retardant and a heat stabilizer, uniformly mixing, pouring the mixture into a twin-screw extruder, and injecting supercritical carbon dioxide to obtain mixed powders; dispersing the mixed powders into a mixed solution containing isopropanol, deionized water and ammoniacal liquor through the ultrasonic oscillation equipment so as to form a dispersion; and adding the dispersion into an aqueous solution of chloroauric acid, stirring in a dark place, conducting an ultrasonic reaction and drying so as to obtain the composite nanoparticles. The preparation method has a simple process, is easy to operate and has good repeatability. The prepared composite nanoparticles have advantages of stable granule structure, uniform size, flame retardance, heat resistance and corrosion resistance.

Owner:BOHAI UNIV

A kind of preparation method of titanate, titanic acid and titanium dioxide

ActiveCN104261465BPreserve Microstructural FunctionMaterial nanotechnologyAlkali titanatesMicro nanoTitanium tetrafluoride

This application discloses a method for preparing titanate, titanic acid and titanium dioxide. The preparation method of titanate includes: obtaining a hydrated titanic acid precipitation through a hydrolysis reaction of a titanium source. The titanium source is selected from the group consisting of titanium sulfate and oxygen sulfate. One or a combination of titanium, titanium tetrachloride, titanium tetrafluoride, titanium ethoxide, titanium propoxide, tetrabutyl titanate, titanium ethylene glycol, titanium glycerol, and ammonium fluorotitanate; The hydrated titanic acid precipitate is dispersed in a hydrogen peroxide aqueous solution containing a strong base and undergoes a hydrothermal reaction to obtain a sea urchin-like titanate with a nano-micro hierarchical structure. The preparation method of titanate, titanic acid and titanium dioxide provided in this application can make up for some shortcomings of preparing titanate, titanic acid and titanium dioxide materials into nanowire or nanotube structures.

Owner:NINGBO NANOJP NEW MATERIAL TECH CO LTD

Environment-friendly sealing liquid for anodized aluminum profiles and method for applying it to sealing holes

ActiveCN103255462BAvoid pollutionEnvironmentally friendlySurface reaction electrolytic coatingTitanium ethoxidePhytic acid

Owner:GUANGDONG XINGFA ALUMINUM

Wood pallet insecticide liquid and preparation process thereof

InactiveCN112006033AQuality assuranceWell mixedBiocideShaking/oscillating/vibrating mixersCelluloseN-Butyl Alcohol

The invention belongs to the technical field of insecticidal treatment of wood products, and particularly relates to a wood pallet insecticide liquid and a preparation process thereof. The wood palletinsecticide liquid is prepared from, by mass, 10-18 parts of ethyl titanate, 30-40 parts of n-butyl alcohol, 0.03-1 part of glacial acetic acid and 0.1-1 part of diethanolamine. When the wood palletis soaked by the insecticide liquid in the scheme; ethyl titanate can enter the wood pallet to react with water in the wood pallet, a reaction product and cellulose of the wood pallet are subjected toa condensation polymerization reaction, so that titanium and fibers of the wood pallet are stably combined and finally cured in the cellulose, titanium ions of the dried wood pallet are irradiated inthe using process to form titanium dioxide, and the titanium dioxide has very good antibacterial performance and can effectively achieve the sterilization effect. The diethanolamine can improve the wettability of the wood pallet, so that the insecticide liquid can permeate better, and the insecticidal and sterilizing effects are further improved.

Owner:重庆龙浩木业有限责任公司

Method for preparing organic ligand-capped titanium dioxide nanocrystals

InactiveUS7709540B2Small sizeNarrow size distributionMaterial nanotechnologyPolycrystalline material growthSolventTitanium tetrachloride

The present invention belongs to a method for preparing organic ligand-capped titanium dioxide nanocrystals, wherein the method comprises steps of using methyl titanate, ethyl titanate, n-propyl titanate, iso-propyl titanate, butyl titanate or titanium tetrachloride as a titanium source, and with capping by oleic acid or an organic capping agent, reacting the titanium source in an organic non-polar solvent with an aqueous alkaline substance solution in the interface at a temperature of 25 to 280° C. for 0.5 to 240 hrs, thus a transparent sol containing titanium dioxide nanocrystals is obtained, said the titanium dioxide nanocrystals have particle diameters of 1-20 nm. The preparing process has the features of mild reaction conditions and is a simpler and easier method with a shorter preparation period, thereby facilitating the industrialization.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

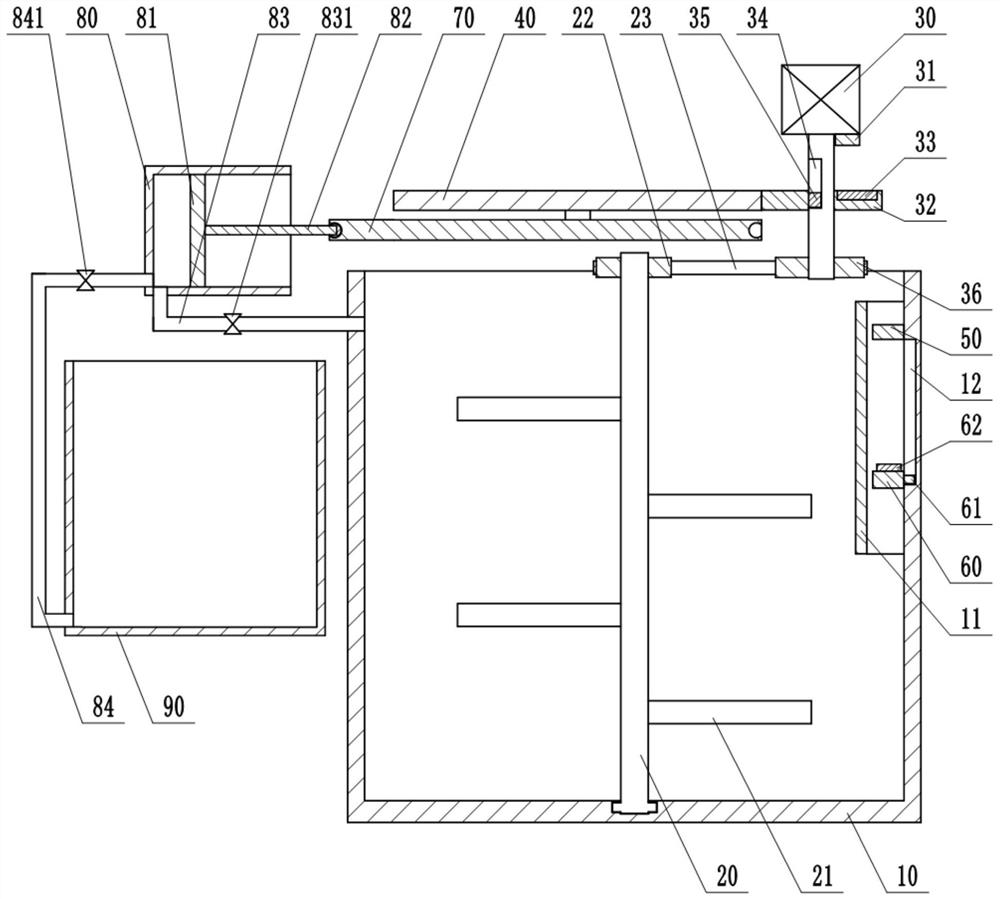

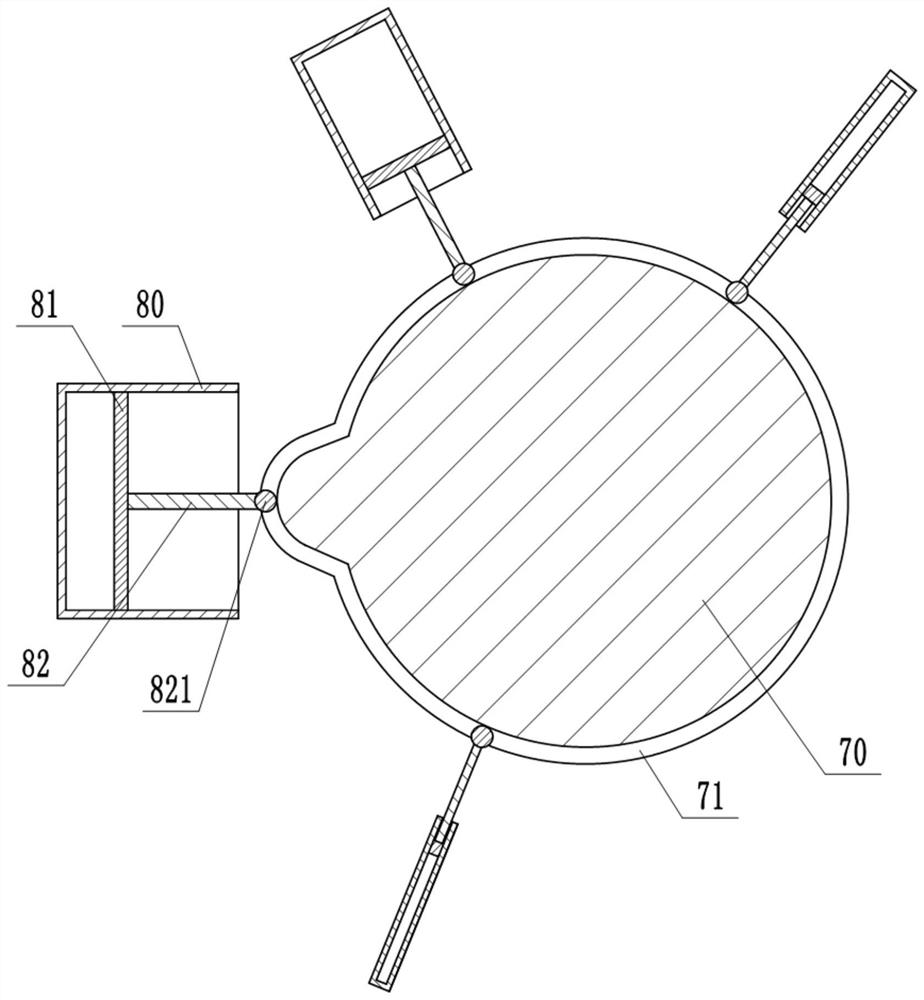

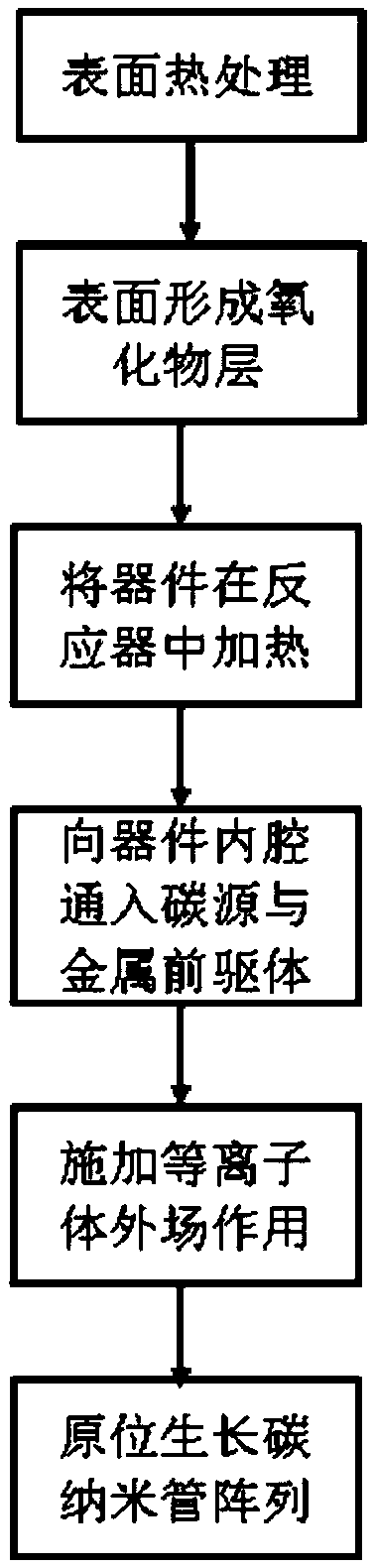

Uniformity control method for growing carbon nano tubes in titanium alloy shading cover

ActiveCN105543804AIncrease contact areaNot easy to fall offChemical vapor deposition coatingWater vaporCarbon nanotube

The invention relates to a uniformity control method for growing carbon nano tubes in a titanium alloy shading cover. The uniformity control method includes the steps that (1) the titanium alloy shading cover is subject to heat treatment under the condition that high temperature and process gas exist, regular protrusions containing carbon-titanium compounds are formed on the surface of the titanium alloy shading cover, and then oxidation is carried out; (2) the titanium alloy shading cover is soaked into pure tetraethoxysilane or titanium ethoxide liquid for reacting, then water or water vapor is led into an inner cavity to be heated, and a silicon oxide or titanium oxide layer is formed on the surface of the inner cavity of the titanium alloy shading cover; (3) the titanium alloy shading cover is placed into a cavity reactor with a feeding pipe, and then the cavity reactor is heated; (4) a carbon source and a metal precursor are led into the cavity reactor through a feeding pipe at the same time, and carbon nano tube arrays are decomposed and precipitated at different positions of the inner cavity of the titanium alloy shading cover; and (5) a plasma field is applied to the outer side of the reactor simultaneously, leading of the carbon source is stopped after reacting, a temperature rise system is stopped, inert gas is led in, and final products are taken out after the temperature falls to the room temperature.

Owner:BEIJING INST OF CONTROL ENG

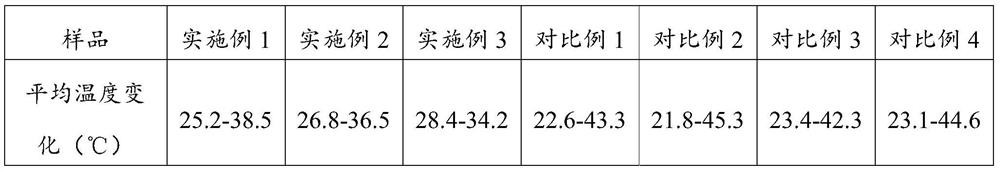

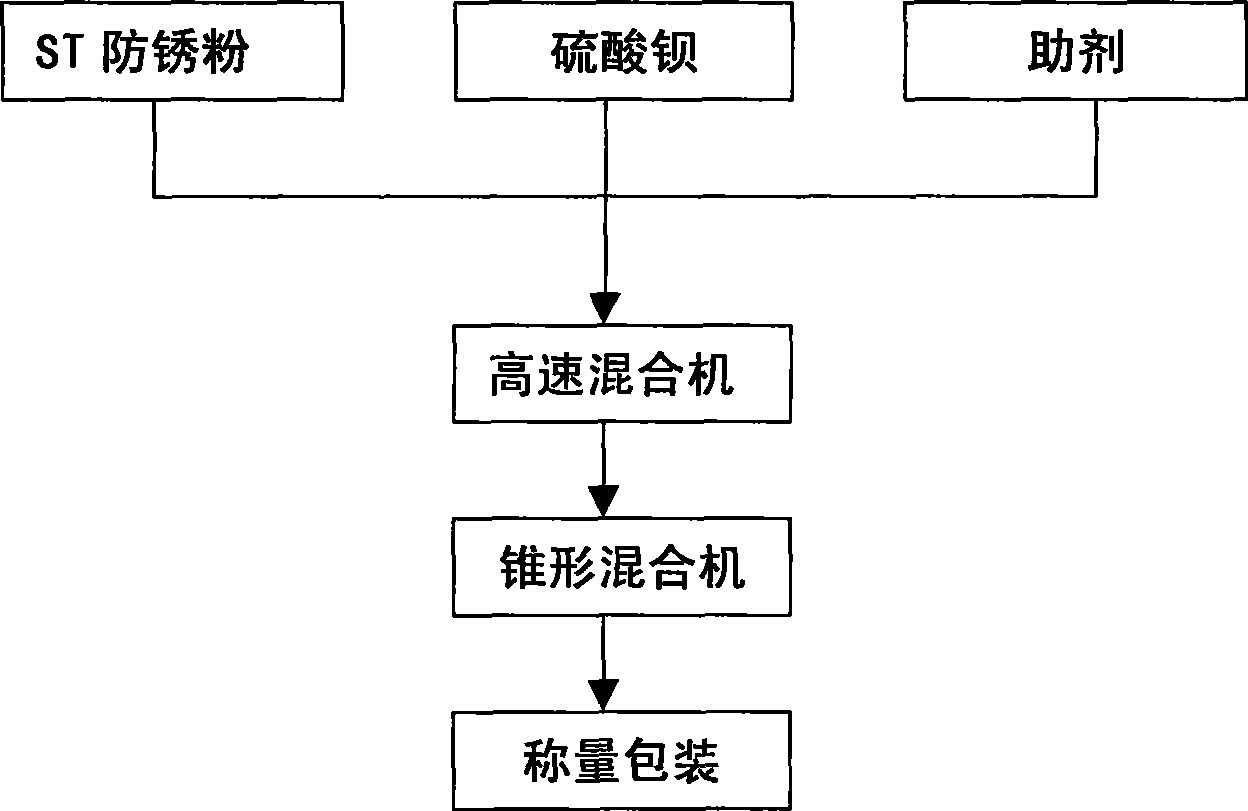

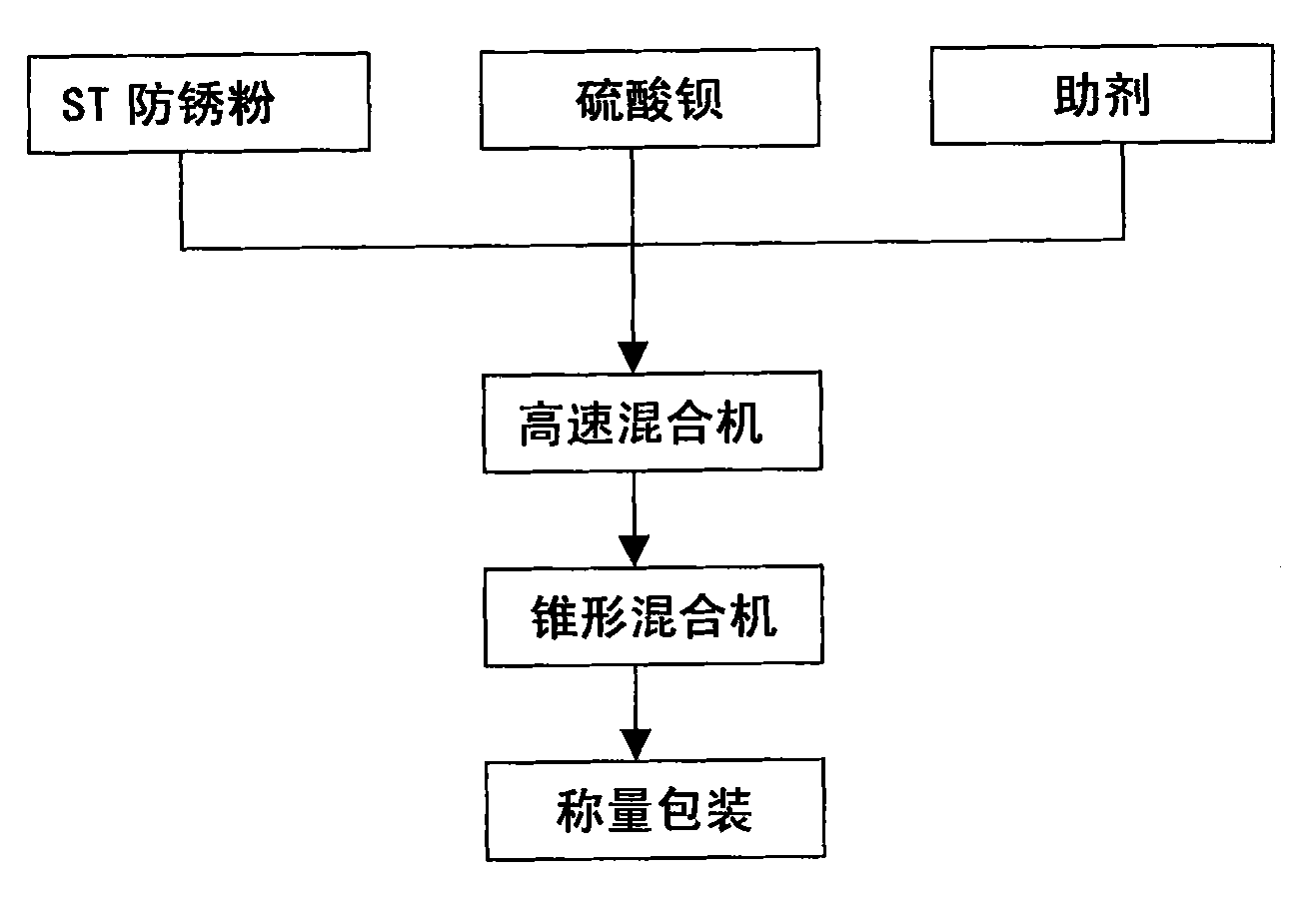

Composite iron-titanium powder and its production process

InactiveCN101100566AReduce heavy metal contentReduce pollutionAnti-corrosive paintsAluminateFerric oxide yellow

A composite ferro-titanium powder and its production are disclosed. The components consist of ST antirust powder 1-8 proportion, barium sulfate 1-8 proportion, iron oxide red 0.1-2.5 proportion, iron oxide yellow or sun proof yellow 0.1-2.5 proportion and accessories 0.1-0.5 proportion. The accessories are selected from one kind or above of silicane coupling agent, titanic butyrin, titanic carbethoxy and aluminate ester. The process is carried out by adding ST anti-rust powder and barium sulfate into high-speed mixer, adding into iron oxide red, iron oxide yellow or sun proof yellow successively, adding into accessories into high-speed mixer, low-speed agitating for 3-10 mins and high-speed agitating for 10-20 mins. It costs low and has better stability, deposit and rust resistances.

Owner:张均彦

Efficient air purifying material and preparation method thereof

InactiveCN107042096AImprove adsorption capacityGood for healthGas treatmentOther chemical processesEpoxyFiber

The invention discloses an efficient air purifying material and a preparation method thereof. The efficient air purifying material is prepared from the following raw materials in parts by weight: 80-250 parts of activated carbon, 10-50 parts of chitin nano-fiber, 5-35 parts of titanium dioxide, 10-60 parts of nano-zirconia, 0.5-4 parts of nano-lithospermum, 1-15 parts of nano-zinc oxide, 0.5-15 parts of nano-mint, 5-25 parts of epoxy resin, 40-100 parts of titanium ethoxide, 5-30 parts of citric acid, 1-15 parts of polyethylene glycol, 5-30 parts of sodium tripolyphosphate and 150-600 parts of absolute ethyl alcohol. The preparation method comprises the steps of uniformly stirring and mixing the raw materials, and carrying out evaporation drying, heating and compression molding, so as to obtain the efficient air purifying material. The efficient air purifying material prepared by virtue of the preparation method has the beneficial effects that the internal and external specific surface areas of activated carbon are increased, the adsorption capacity of the material to molecules of formaldehyde, ammonia gas and other volatile organic pollutants is improved, and the goals of purifying indoor air, preventing decoration defects and increasing the health level of residents are achieved; and the raw materials are easily available, a preparation process is simple, easy in operation and low in cost, and the efficient air purifying material is convenient to replace and applicable to industrial production and large-scale use.

Owner:张红卫

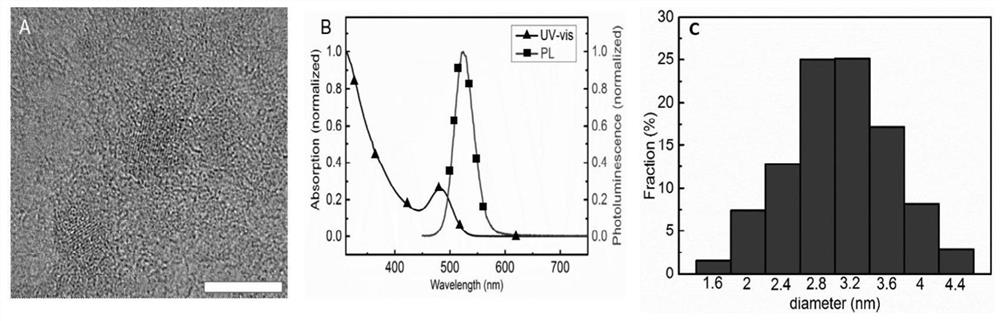

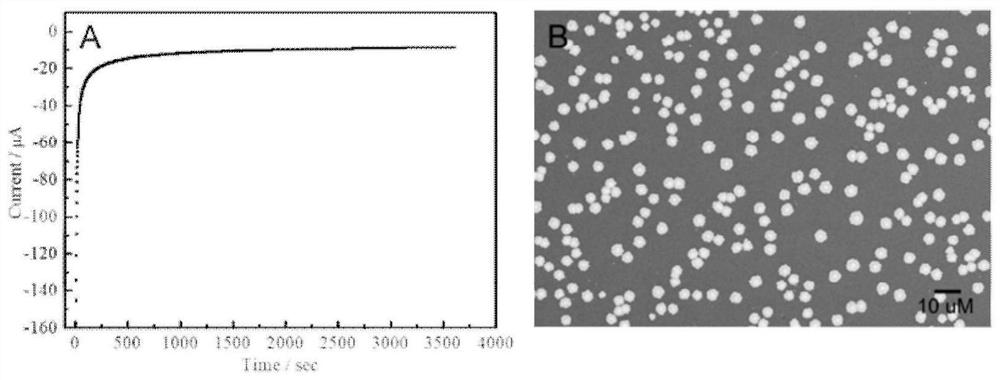

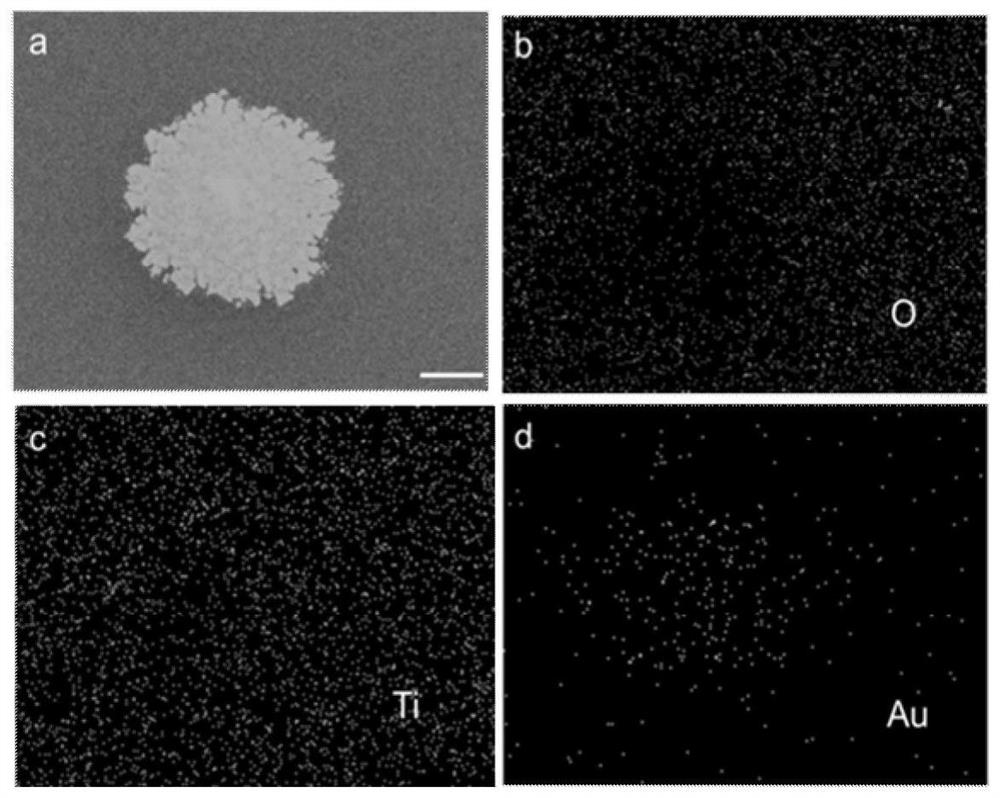

Photoelectrochemical sensor preparation method based on efficient and stable in-situ growth of titanium dioxide/nanogold photo-anode

PendingCN111796012AHigh reproducibility of preparationGood storage stabilityMicrobiological testing/measurementMaterial analysis by electric/magnetic meansIndiumPhotochemistry

The invention discloses a photoelectrochemical sensor preparation method based on efficient and stable in-situ growth of a titanium dioxide / nanogold photo-anode. The preparation method comprises the following steps: cleaning ITO (indium tin oxide) slices of an indium tin oxide electrode; sequentially putting the ITO slices into acetone, ethanol and an ultrapure water solution for ultrasonic treatment; wiping with an ethanol cotton ball, washing with ultrapure water, annealing in a culture dish with one side of ITO upward, taking out the ITO slices, and carrying out plasma and ozone treatment;spin-coating a tetraisopropyl titanate, butyl titanate or ethyl titanate precursor on the treated ITO slices, and then annealing a spin-coated ITO substrate to obtain an ITO / TiO2 electrode; and cooling the ITO / TiO2 electrode to room temperature, and carrying out in-situ gold nanoparticle loading to obtain an ITO / TiO2 / Au NPs photo-anode. The photoelectrochemical sensor has the advantages of being efficient, uniform, stable, high in preparation repeatability, simple in structure, good in storage stability, good in detection repeatability, sensitive to miRNA-21, specific to miRNA-21 and the like,and is used for detecting miRNA.

Owner:NANJING UNIV OF POSTS & TELECOMM

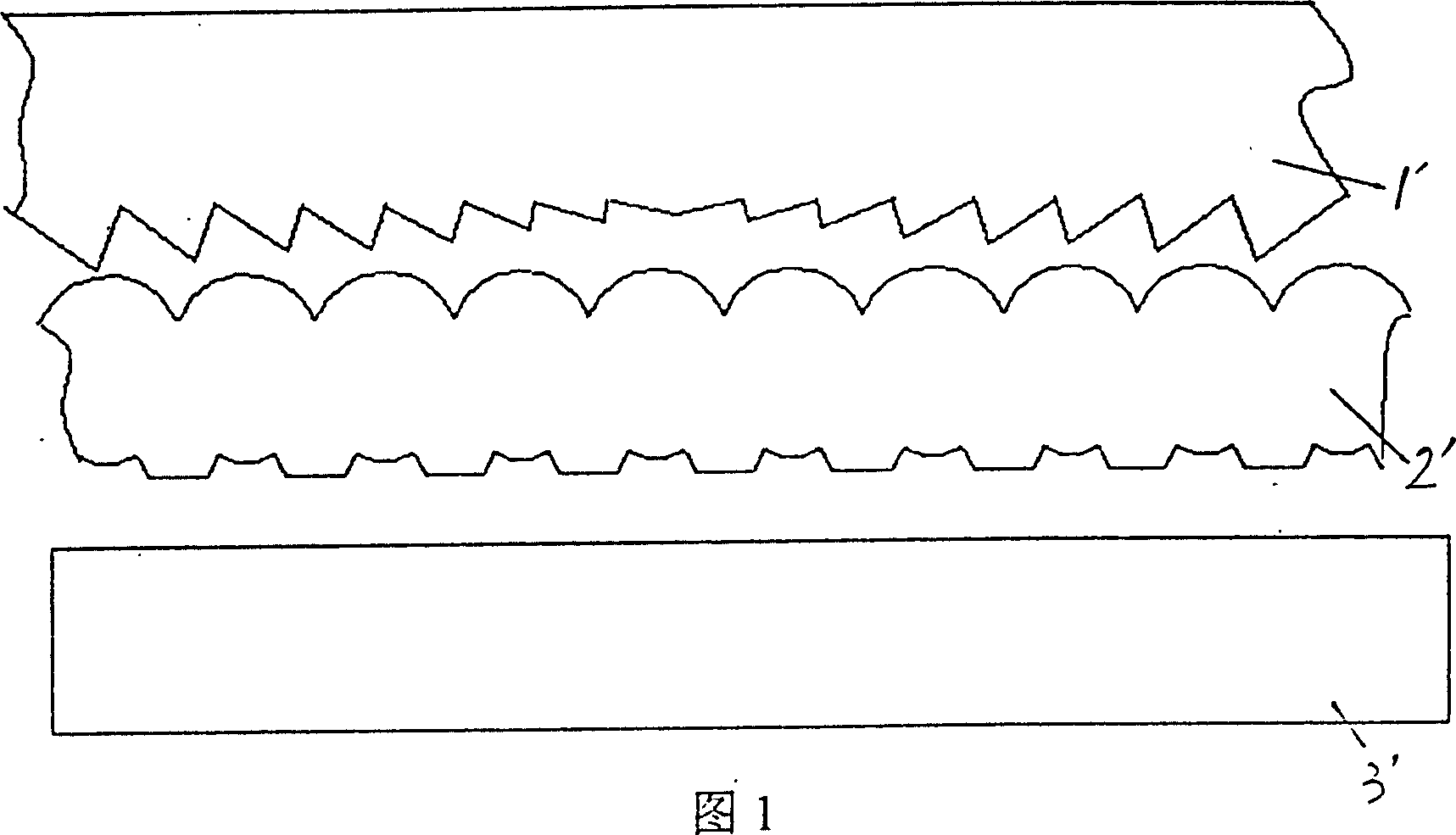

Making process of antireflecting protection component for projecting screen

InactiveCN1170202CThickness is easy to controlUniform thicknessProjectorsTitanium ethoxideSilicic acid

The making process of protective antireflecting constituent includes the step of: cleaning glass; coating titanate solution films onto the two sides of the glass through soaking the glass inside ethyl titanate solution, stoving to eliminate water andethanol of the titanate solution films and form homogeneous titania films; coating silicic acid sol films by soaking the glass with titania films in ethyl silicate solution, stoving to eliminate water and ethanol to form homogeneous silica films.

Owner:张益民

A preparation method of graphene-supported multi-component doped magnesium diboride superconducting bulk material

ActiveCN106205861BImprove performanceEvenly distributedSuperconductors/hyperconductorsSuperconductor devicesVacuum dryingGraphite oxide

The invention discloses a preparation method for a graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method comprises the steps of 1, dropwise adding ethyl silicate and titanium ethoxide into a graphene oxide solution, and stirring uniformly to obtain a mixture material; 2, performing a hydrothermal reaction, filtering and washing and then carrying out vacuum drying to obtain graphene-loaded multielement mixture powder; 3, performing heat treatment to obtain graphene-loaded multielement-doped powder; 4, mixing boron powder and magnesium powder and grinding, then adding the mixture powder to the graphene-loaded multielement-doped powder, uniformly grinding and pressing and shaping to obtain a bulk material; and 5, performing sintering on the bulk material under protection of an inert atmosphere, and performing furnace cooling to the room temperature to obtain the graphene-loaded multielement-doped magnesium diboride superconducting bulk material. The preparation method is simple; the prepared multielement dopant is uniform in dispersion, free of agglomeration, high in activity and can rapidly enter magnesium diboride lattices, thereby reducing the phase-forming temperature of the doped magnesium diboride; and in addition, the prepared magnesium diboride bulk material has excellent performance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Composite ceramic material with phase-change temperature regulation function and preparation method and application thereof

PendingCN114231254AGuaranteed StrengthApplicable to the needs of productionHeat-exchange elementsInsulation layerComposite ceramic

The invention belongs to the technical field of phase-change lightweight ceramic materials, and particularly discloses a composite ceramic material with a phase-change temperature adjustment function, a preparation method of the composite ceramic material and a lightweight ceramic tile. The composite ceramic material has a double-layer wrapped core-shell structure, an organic phase change material is contained in a core of the core-shell structure, and a shell layer of the core-shell structure comprises a heat insulation layer and a protection layer from inside to outside; the heat insulation layer contains zinc oxide, and the protection layer contains titanium dioxide. The preparation method comprises the following steps: adding paraffin into water and an anionic surfactant, mixing, dropwise adding zinc acetate dihydrate, adjusting the pH value to be alkaline, aging, washing and drying to obtain a single-layer wrapping material; adding the single-layer wrapping material into an ethanol solution and an ethyl orthotitanate solution, carrying out hydrothermal reaction, washing and drying to obtain the composite ceramic material. After the composite ceramic material is calcined at high temperature, the energy storage effect of the phase-change material can still be reserved, and the composite ceramic material is applied to a lightweight ceramic product, so that the lightweight ceramic product with phase-change temperature regulation is obtained.

Owner:FOSHAN OCEANO CERAMICS

Insect prevention liquid for Chinese fir boards

InactiveCN108544616AImprove permeabilityImprove the firmness of the bondWood treatment detailsWood impregnation detailsTitanium ethoxideCarbon nanotube

The invention discloses insect prevention liquid for Chinese fir boards. The insect prevention liquid comprises the following components including, by weight, 3.3-3.8 parts of titanium ethoxide, 3-3.3parts of sodium silicate, 2.5-2.8 parts of sodium hypochlorite, 2-2.5 parts of natrium aceticum, 4.5-5 parts of polyethylene glycol, 2.2-2.8 parts of nanometer copper oxide fine grains, 4-6 parts ofcarbendazim, 2-3 parts of imidacloprid, 0.8-1.2 parts of nano-silica, 0.5-0.7 part of carbon nano tubes and 20-23 parts of deionized water. The insect prevention liquid has the beneficial effect thatthe insect prevention effect for the Chinese fir boards can be improved.

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

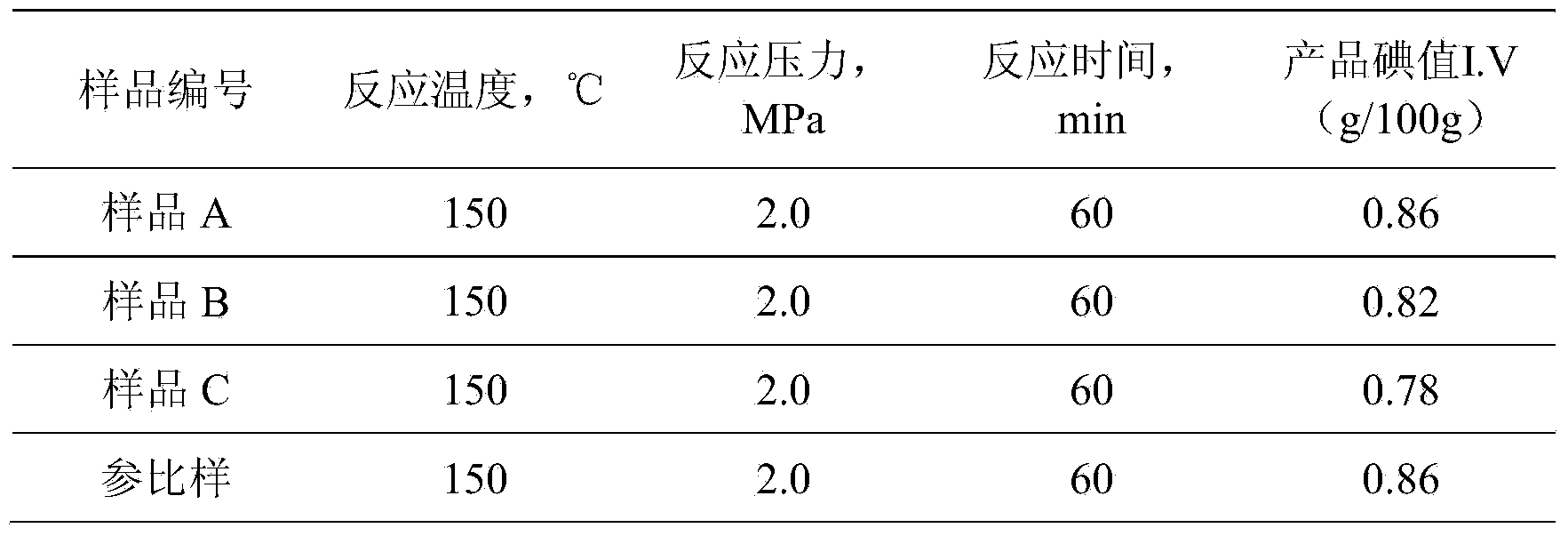

Preparation method of polytrimethylene terephthalate

ActiveCN103642013AReduce dosageHigh intrinsic viscosityMonocomponent polyesters artificial filamentOXALIC ACID DIHYDRATEPolytrimethylene terephthalate

The invention belongs to technical field of polyester fiber preparation, and specifically relates to a preparation method of polytrimethylene terephthalate. According to the preparation method, terephthalic acid and 1, 3-propanediol are taken as raw materials. The preparation method comprises following steps: (1) titanium ethoxide, terephthalic acid and 1, 3-propanediol are delivered into an esterification reaction tank, oxalic acid is added dropwise so as to obtain a mixture, and the mixture is subjected to normal pressure esterification for 30 to 60min at a temperature of 220 to 240 DEG C; and (2) titanium ethoxide is added for stirring, and at the same time oxalic acid is added dropwise for condensation polymerization for 3 to 5h, at a temperature of 220 to 240 DEG C, under a reaction pressure of 0.01 to 0.05 MPa so as to obtain polytrimethylene terephthalate. Technology of the preparation method is simple, and effect is excellent.

Owner:临沂星火知识产权服务有限公司

Composite iron-titanium powder and its production process

InactiveCN101100565BBarrier erosionBright appearanceAnti-corrosive paintsTitanium ethoxidePhysical chemistry

Owner:张均彦

A kind of preparation method of composite titanium dioxide nanoparticles

InactiveCN104998690BStable structureUniform sizeMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsComposite nanoparticlesSupercritical carbon dioxide

The invention discloses a preparation method of composite titanium dioxide nanoparticles, which comprises the following steps: dispersing ethyl titanate in an organic solvent through an ultrasonic oscillation device, adding an amine salt, stirring evenly at room temperature, and placing the reaction solution in a reaction kettle , after reacting for 2‑3.5h, cool naturally to room temperature, separate the solid phase, put it in a mixing mixer, add flame retardant synergist, brominated flame retardant, heat stabilizer in sequence, mix well, and put it in the twin-screw In the extruder, supercritical carbon dioxide is injected to obtain a mixed powder; the obtained mixed powder is dispersed in a mixed solution containing isopropanol, deionized water and ammonia water through an ultrasonic oscillation device to form a dispersion; the dispersion is placed in In the aqueous solution of chloroauric acid, stir in the dark, and after ultrasonic reaction, dry to obtain composite nanoparticles. The preparation method of the invention has the advantages of simple process, easy operation, good repeatability, stable particle structure, uniform size, flame retardancy, heat resistance and corrosion resistance.

Owner:BOHAI UNIV

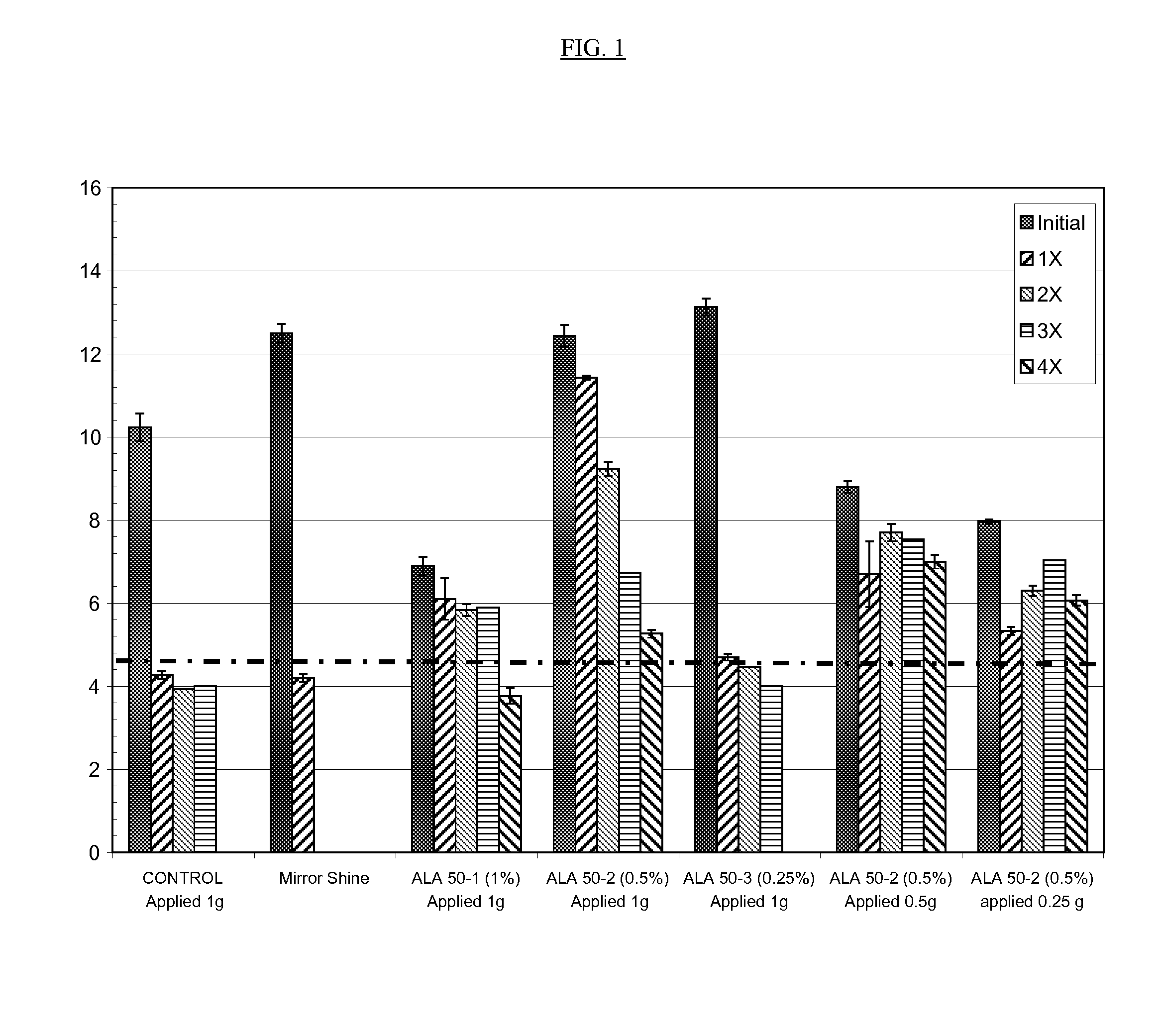

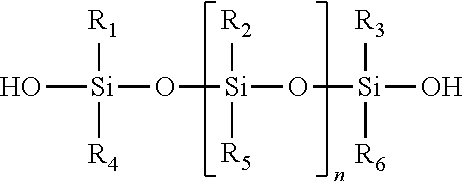

Long-wearing transfer resistant film-forming ingredient

InactiveUS20150175751A1Easy to wearImprove comfortCosmetic preparationsHair cosmeticsPolymer scienceTitanium ethoxide

Cosmetic compositions having improved transfer resistance are provided. The compositions the reaction product of a transition metal, such a titanium ethoxide or tantalum ethoxide, and a hydroxyl-functionalized silicone polymer or resin.

Owner:AVON PROD INC

Mineral particle preparation method

PendingCN112275269ANo health concernsSimplify production stepsBiocideCatalyst activation/preparationTitanium tetraisopropoxideTitanium ethoxide

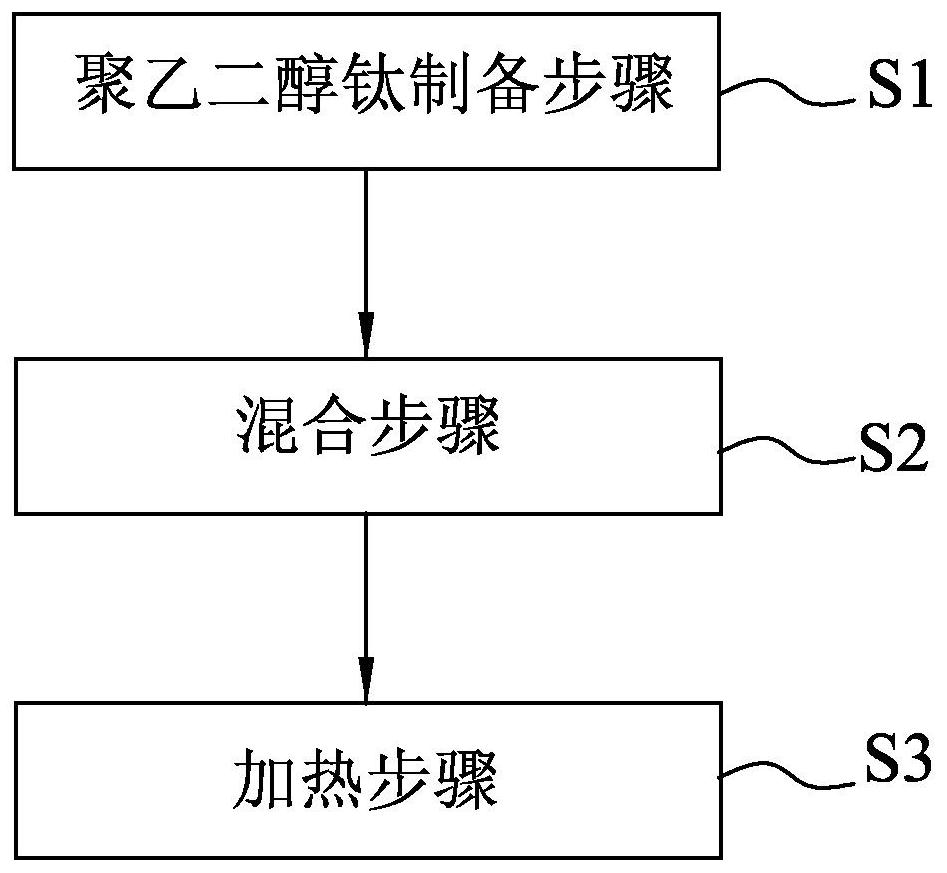

The invention relates to a mineral particle preparation method, which comprises the steps of: A, taking 1 part by weight of a titanium material, and performing mixing with 10-25 parts by weight of diol to obtain a polyglycol titanium solution, wherein the titanium material is selected from at least one of titanium isopropylate, titanium ethoxide, n-propyl titanium oxide, titanium isopropoxide, third butyl titanium oxide, n-butyl titanium oxide and a group composed of the above materials; B, mixing the polyglycol titanium solution, weak carboxylic acid and water to obtain an intermediate solution with a pH value of x, wherein x is larger than or equal to 6 and smaller than 8; and C, maintaining the temperature of the intermediate solution at more than 70DEG C but less than 100DEG C for at least 8 hours. The materials used in the preparation method do not contain chlorine, so that the finished product does not contain chlorine and does not need to be washed with water, the whole preparation process is simpler, and the cost is lower. In addition, the finished product does not have the health problem of residual chlorine derivation.

Owner:丽钛科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com