Composite iron-titanium powder and its production process

An anti-rust pigment and production process technology, applied in the field of anti-rust pigments, can solve the problems of no fundamental breakthrough in technology, increased protection expenses, and decreased anti-rust performance, achieving significant cost performance, reduced cost per ton, and improved dispersion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

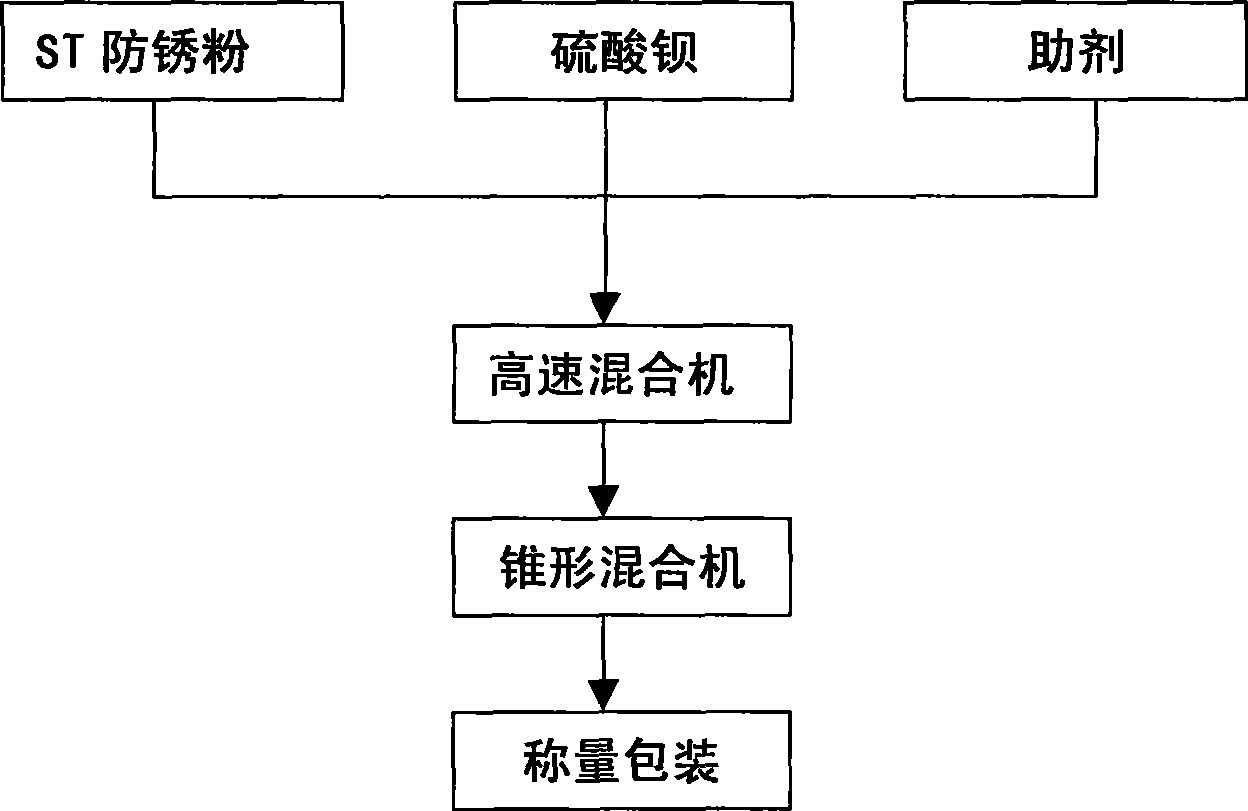

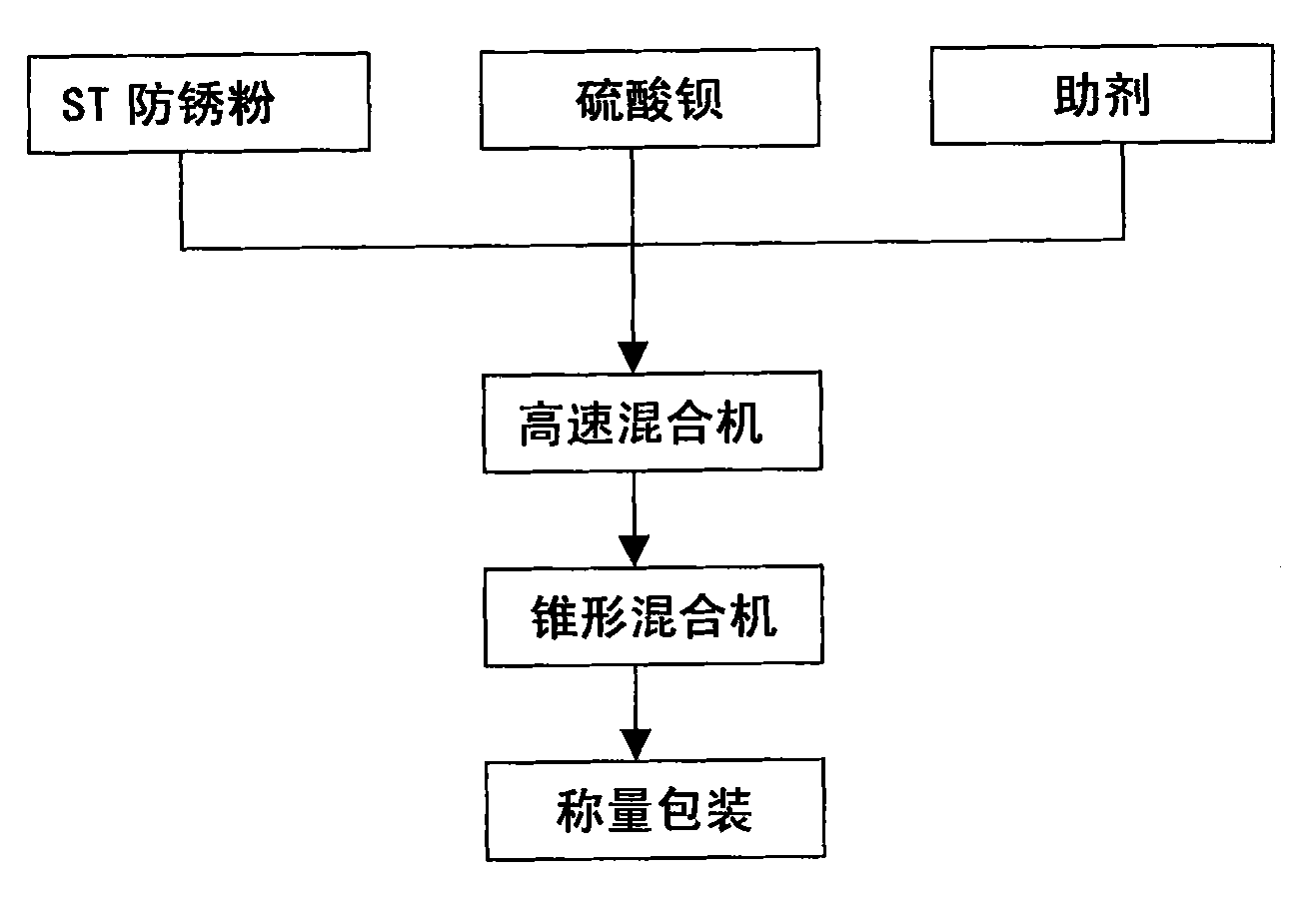

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of antirust pigment, its component and content by weight are:

[0031] ST antirust powder with a particle size of 400 mesh 2

[0032] Barium sulfate with a particle size of 600 mesh 1

[0033] Silane coupling agent 0.2.

Embodiment 2

[0034] Embodiment 2 A kind of antirust pigment, its component and content by weight are:

[0035] ST antirust powder with a particle size of 600 mesh 7.5

[0036] Barium sulfate with a particle size of 500 mesh 7.2

[0037] Ethyl titanate 0.3

Embodiment 3

[0038] Embodiment 3 A kind of antirust pigment, its component and content by weight are:

[0039] ST antirust powder with a particle size of 500 mesh 5

[0040] Barium sulfate with a particle size of 400 mesh 5

[0041] Silane coupling agent 0.15

[0042] Ethyl titanate 0.15

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com