Method for preparing PrTiO3 powder

A technology of powder and praseodymium nitrate, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of high cost, complicated preparation process, and long time consumption, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

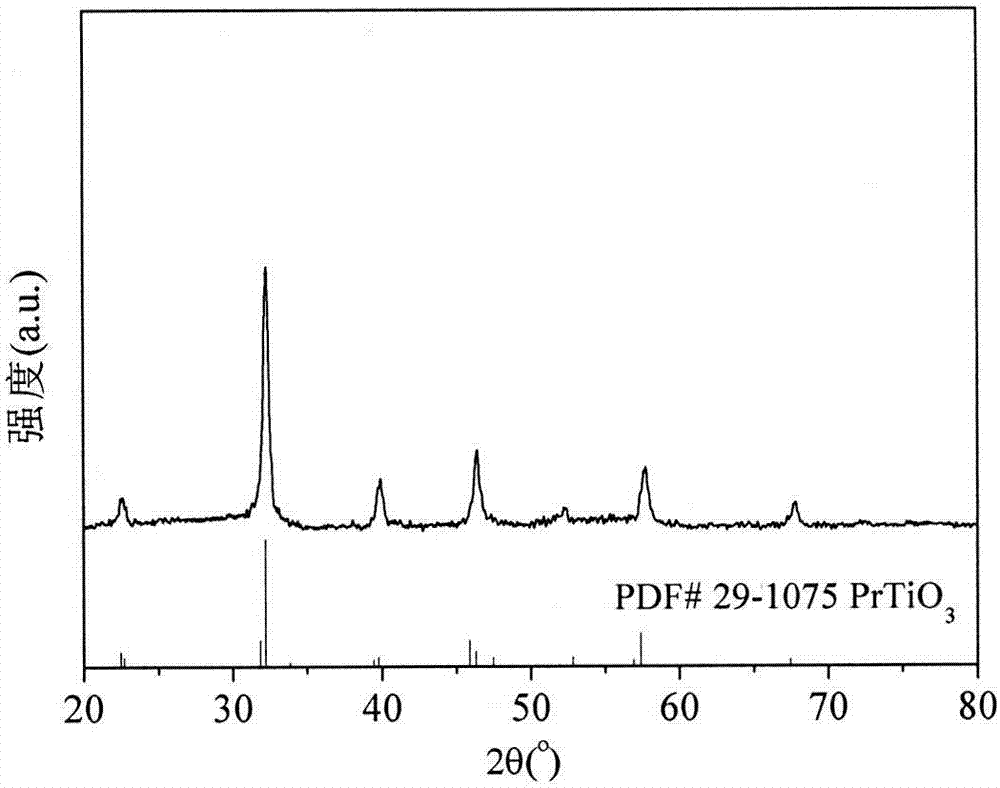

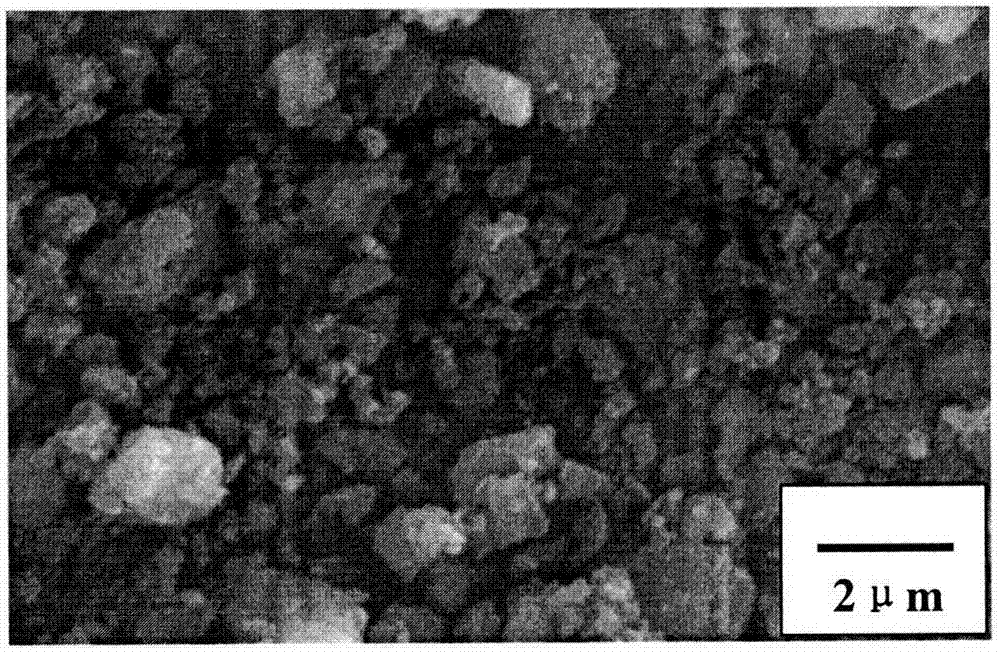

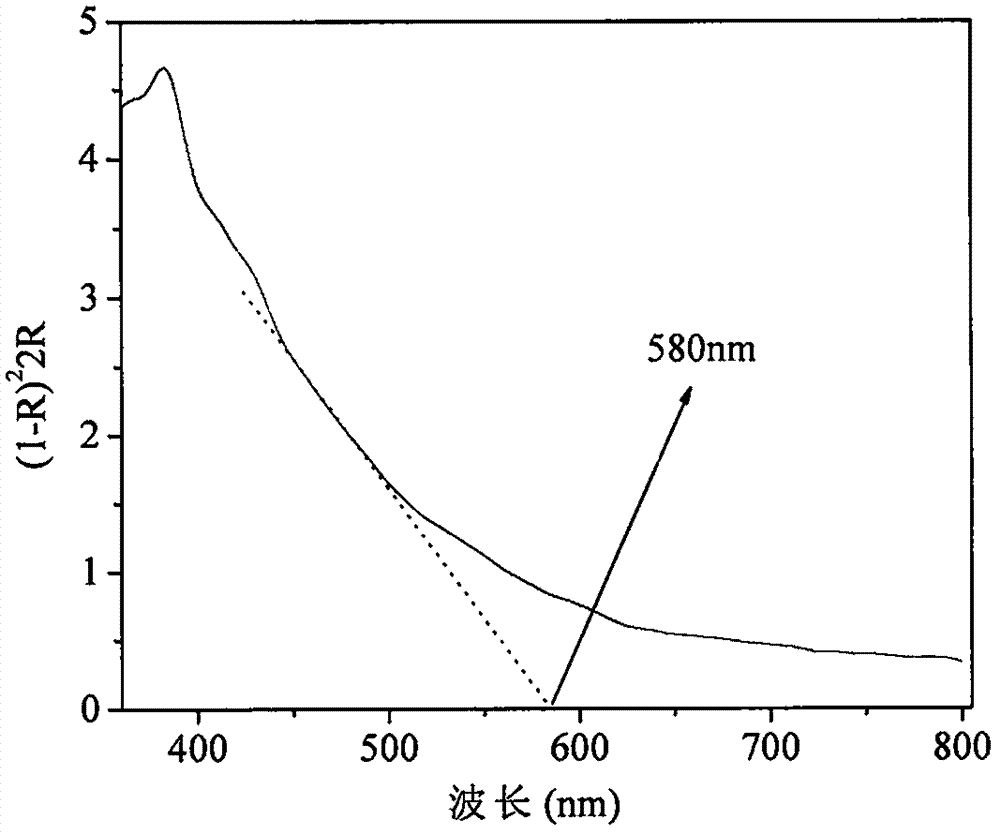

[0017] At room temperature, dissolve 0.0035 mol of praseodymium nitrate in 100 mL of deionized water to obtain a praseodymium nitrate solution, adjust the pH value of the praseodymium nitrate solution to 1 with 0.5 mol / L dilute nitric acid; 0.042 mol of triammonium citrate was added to the praseodymium nitrate solution, and after the triammonium citrate was dissolved, 0.0035 mol of ethyl titanate was added dropwise to obtain a mixed solution, and the mixed solution was stirred and reacted for 10 minutes to obtain a reaction solution. Put 100mL of the reaction liquid into a microwave oven, react for 25 minutes under the condition of maintaining microwave power of 850W until complete combustion to obtain the primary product, cool to room temperature and take out the primary product, put the primary product in a muffle furnace for calcination at 820°C for 2 hours, cool to room temperature and take out Grind finely to get PrTiO 3 Powder products. Carry out X-ray diffraction (XRD)...

Embodiment 2

[0023] At room temperature, 0.0035mol of praseodymium nitrate was dissolved in 100mL of deionized water to obtain a praseodymium nitrate solution, and the pH value of the praseodymium nitrate solution was adjusted to 1 with dilute nitric acid of 0.5mol / L; 0.042 mol of triammonium citrate was added to the praseodymium nitrate solution of 1, and after the triammonium citrate was dissolved, 0.0035 mol of ethyl titanate was added dropwise to obtain a mixed solution, and the mixed solution was stirred and reacted for 10 minutes to obtain a reaction solution. Put 100mL of the reaction liquid into a microwave oven, react for 25 minutes under the condition of maintaining the microwave power of 950W until the initial product is completely burned, cool to room temperature and take out the initial product, put the initial product in a muffle furnace for calcination at 880°C for 2 hours, cool to room temperature and take out Grind finely to get PrTiO 3 Powder products. According to the s...

Embodiment 3

[0025] At room temperature, 0.0035mol of praseodymium nitrate was dissolved in 100mL of deionized water to obtain a praseodymium nitrate solution, and the pH value of the praseodymium nitrate solution was adjusted to 1 with dilute nitric acid of 0.5mol / L; 0.042 mol of triammonium citrate was added to the praseodymium nitrate solution of 1, and after the triammonium citrate was dissolved, 0.0035 mol of ethyl titanate was added dropwise to obtain a mixed solution, and the mixed solution was stirred and reacted for 10 minutes to obtain a reaction solution. Put 100mL of the reaction liquid into a microwave oven, react for 25 minutes under the condition of maintaining microwave power of 900W until complete combustion to obtain the primary product, cool to room temperature and take out the primary product, put the primary product in a muffle furnace for calcination at 850°C for 2 hours, cool to room temperature and take out Grind finely to get PrTiO 3 Powder products. According to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Band gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com