Patents

Literature

294results about How to "Can be produced industrially" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously generating fine gutta-percha through digestion-reextraction

InactiveCN101906176AHigh extraction rateReduce consumptionNatural resin coatingsClimate change adaptationSolventDigestion

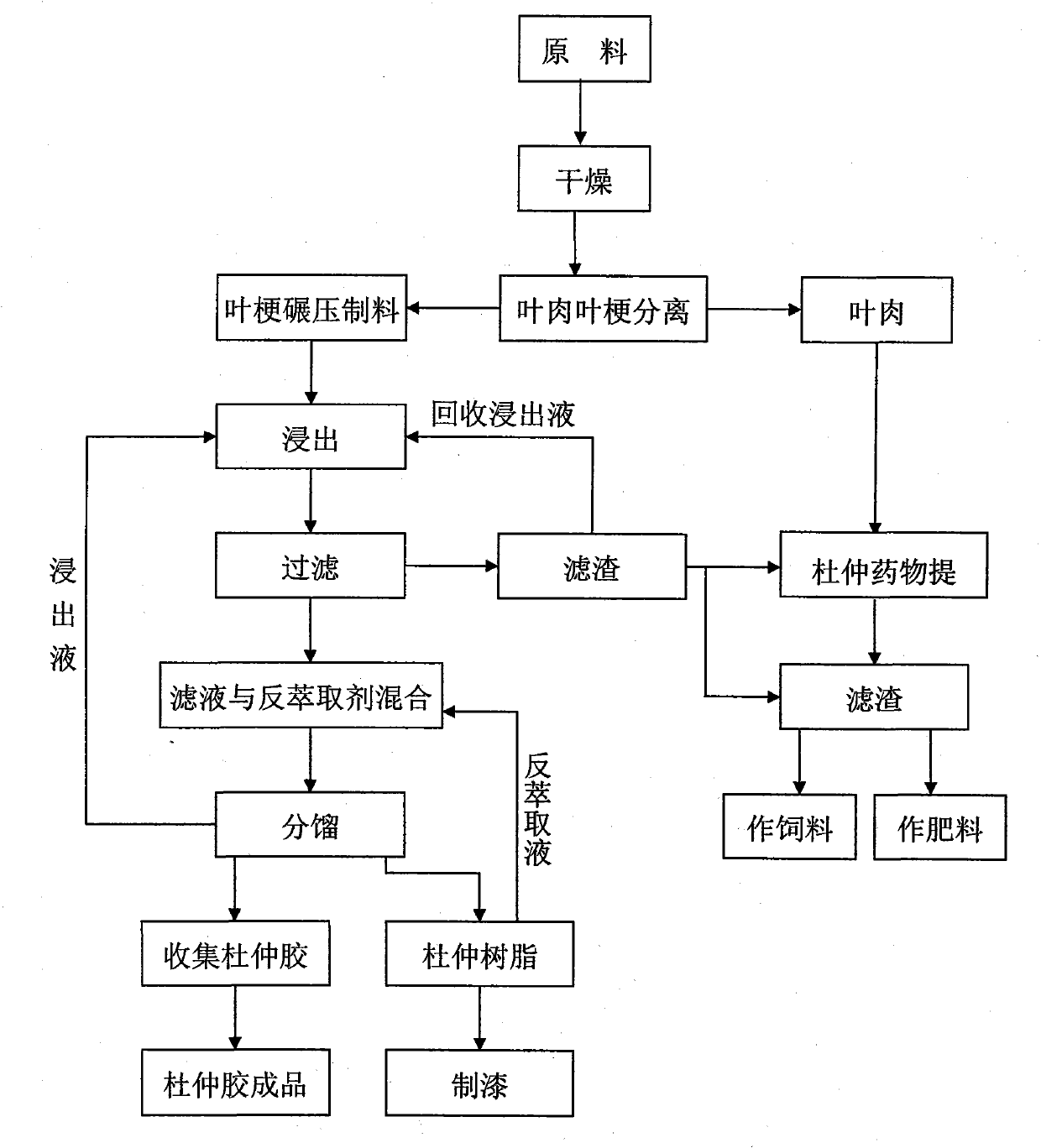

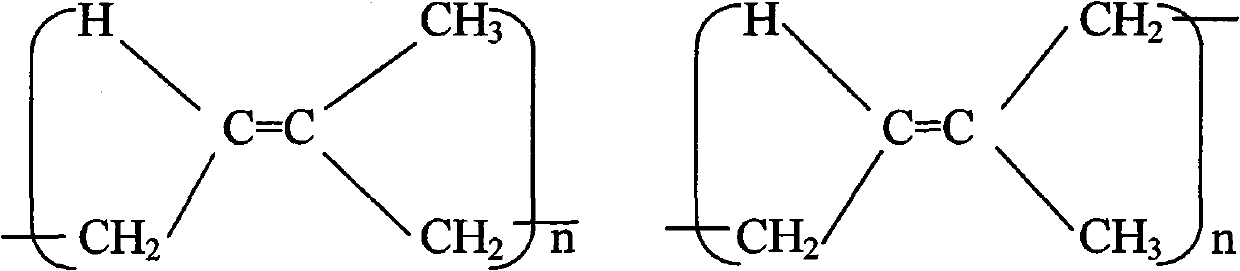

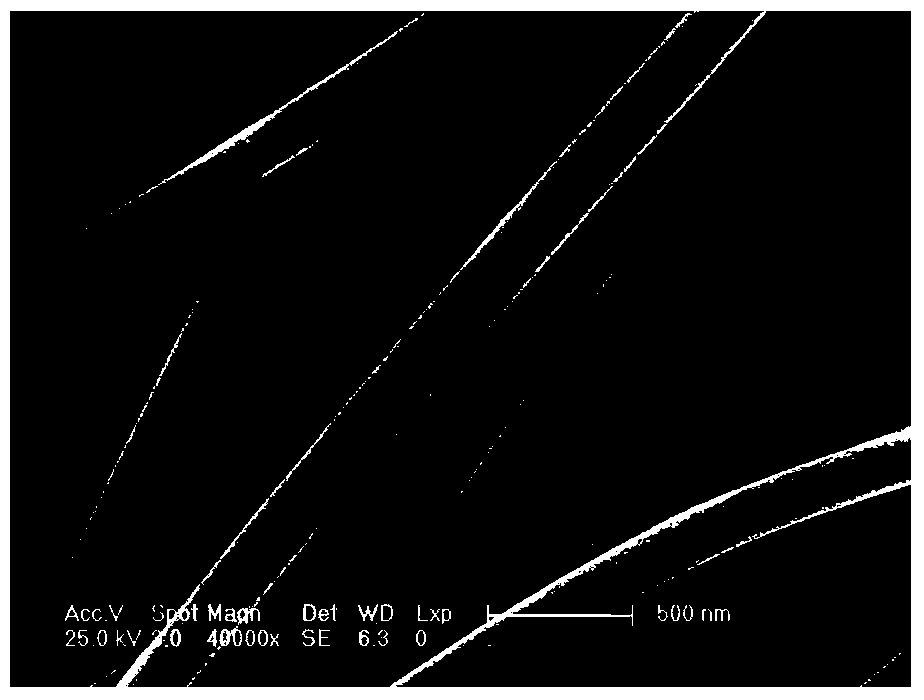

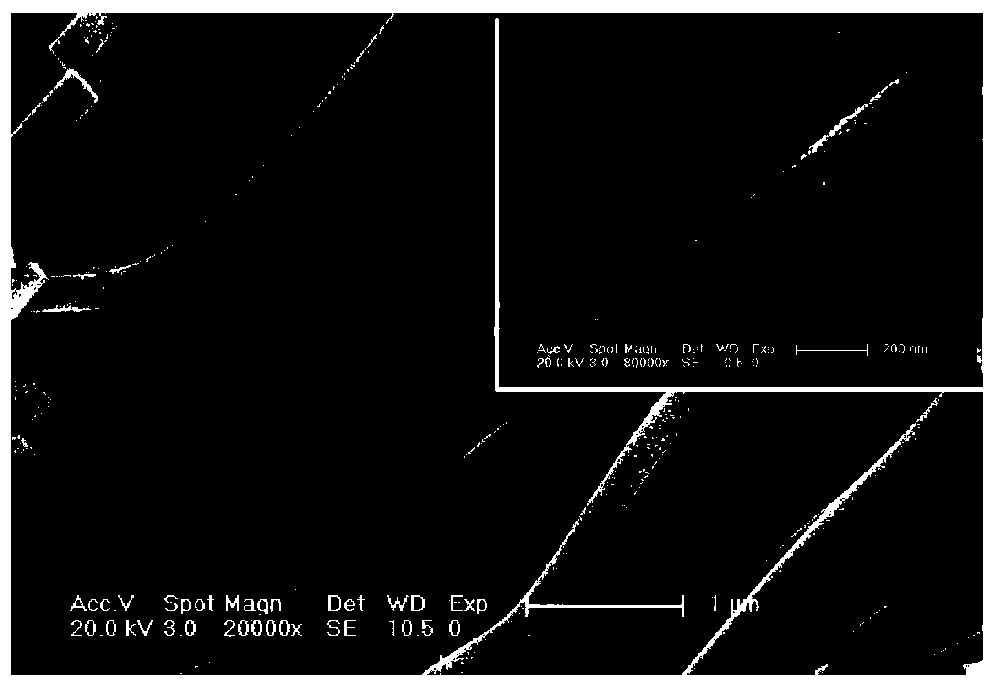

The invention relates to a method for continuously generating fine gutta-percha through digestion-reextraction. The method comprises the steps of: firstly, pre-treating folium cortex eucommiae including drying, crashing and cutting; secondly, digesting gutta-percha from folium cortex eucommiae through leach liquor; thirdly, separating gutta-percha from folium cortex resin through reextraction solution and dissolving the gutta-percha; and fourthly, post-treating materials, principally to dry the dissolved gutta-percha so as to obtain the fine gutta-percha. The method of the invention has the advantages that the leach liquor is nonflammable non-toxic agent, the gutta-percha extraction efficiency is high, the environment is prevented from being polluted, the folium cortex eucommiae is complexly used, no waste generates, the solvent is recycled, the consumption is low, the product quality is high, industrial continuous production is realized, the economic, environment-friendly and social benefits are all better than the traditional production method, and the promotional value is high.

Owner:刘志成

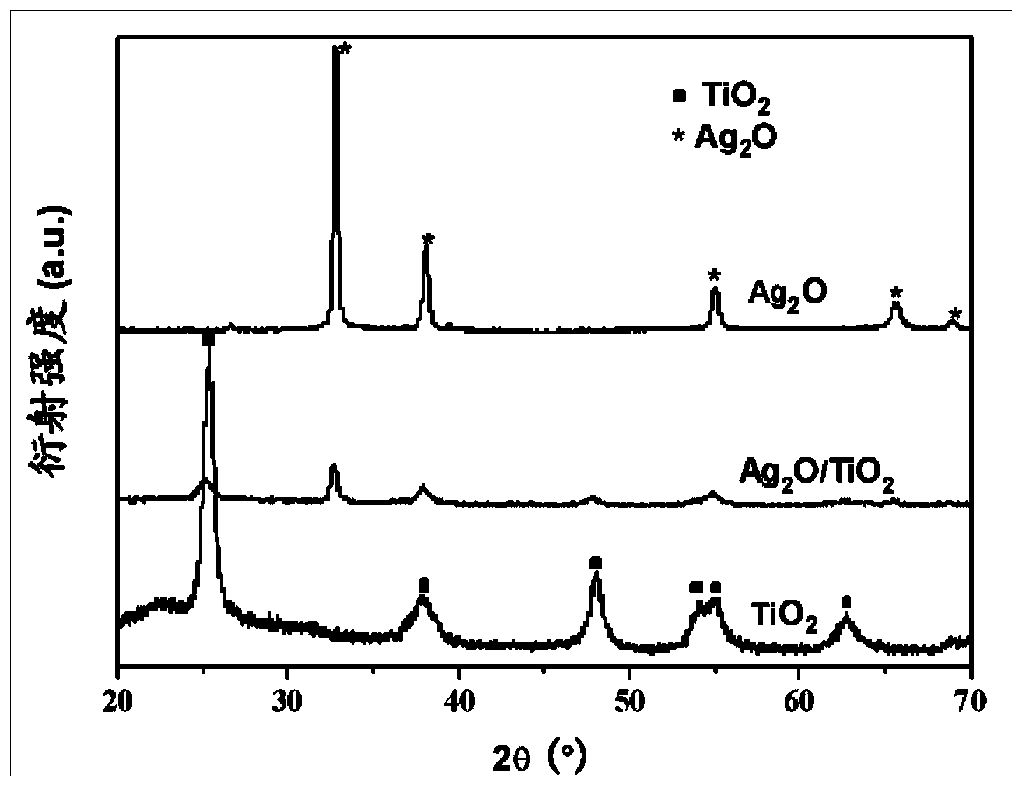

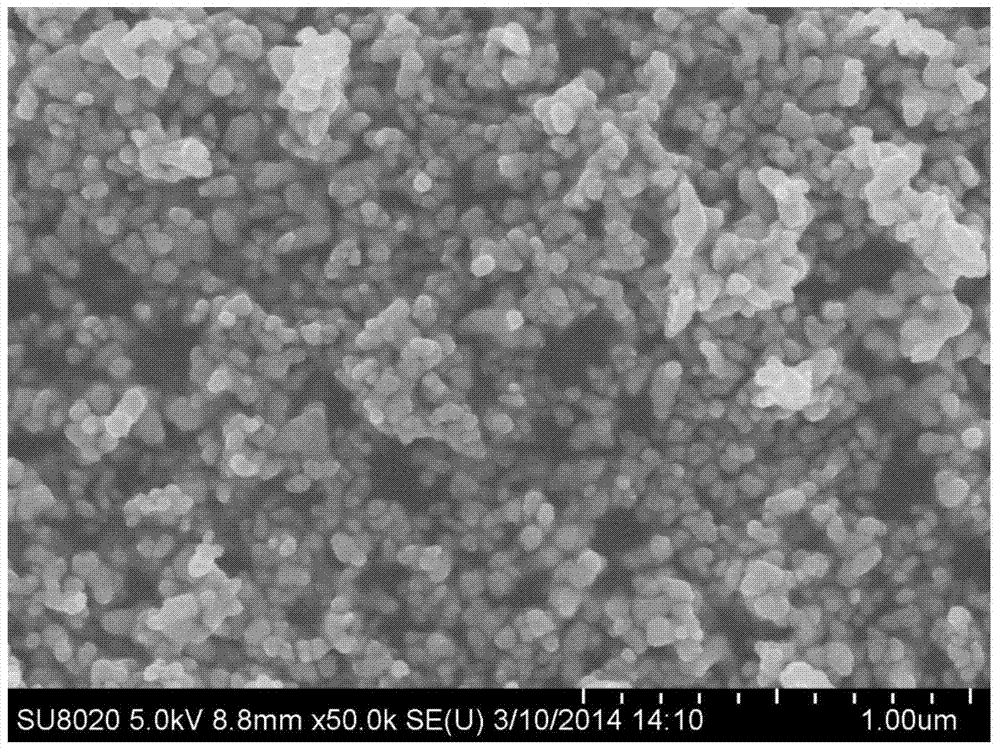

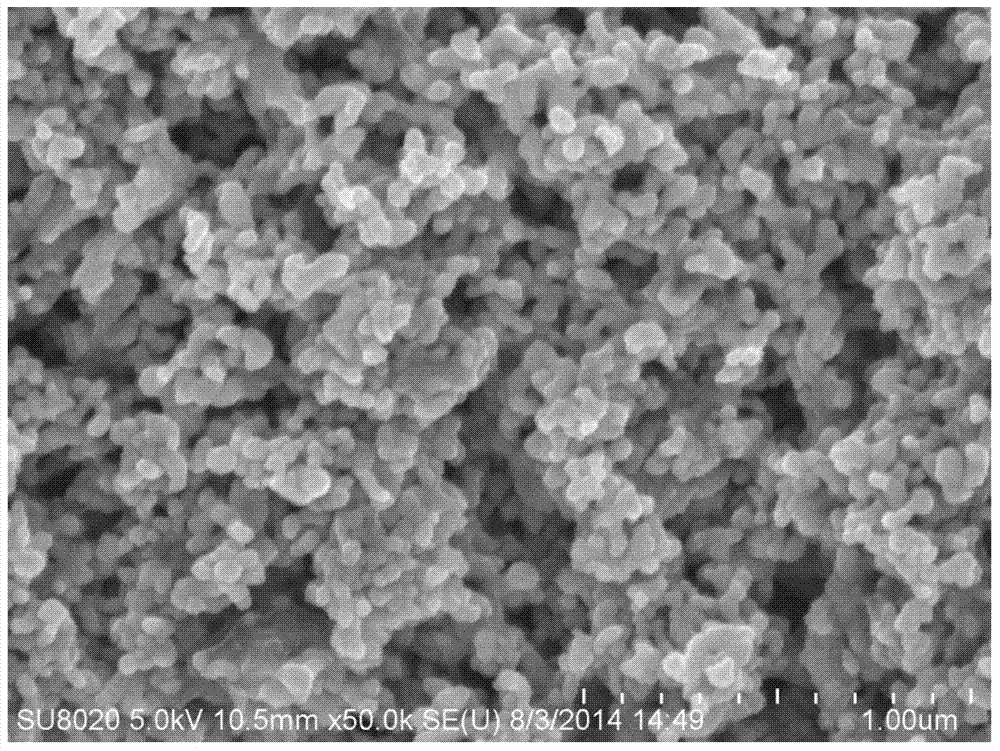

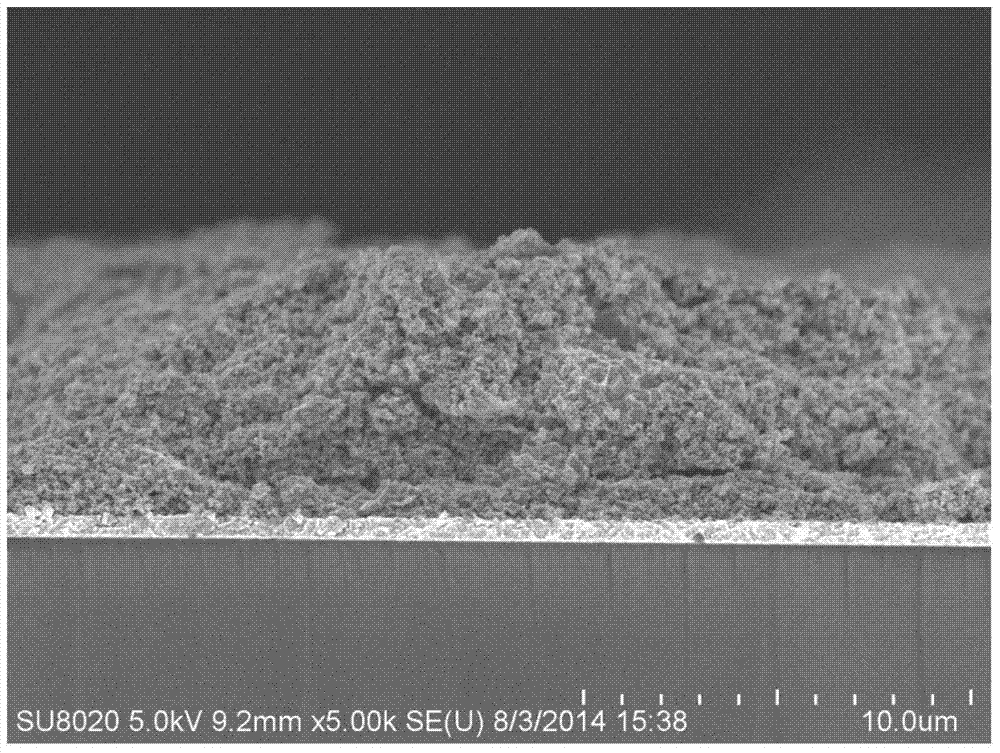

Preparation method and application of silver oxide/titanium dioxide composite nanofiber photocatalyst

InactiveCN103611531AEasy to prepareEasy to operateMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationNanostructure

The invention relates to a preparation method and application of a silver oxide / titanium dioxide composite nanofiber photocatalyst, belonging to the technical field of environment pollution control. The catalyst takes a silver oxide nanostructure as a catalytic active component material and titanium dioxide nanofiber as a carrier material. Through modifying the surface of titanium dioxide by the silver oxide, not only is the separation efficiency of a titanium dioxide photoproduction electron-hole pair increased, but also the light absorption range of the titanium dioxide is expanded to a visible light region, thus the photocatalytic degradation efficiency of the titanium dioxide to organic pollutants is increased. Silver oxide nanoparticles on the surface of the catalyst prepared by the invention are uniform in distribution, relatively small in particle size and controllable in component content; moreover, the composite catalyst is high in catalytic activity and stability, easy to separate, recover and recycle, relatively high in practical value and relatively wide in application prospect.

Owner:CHANGCHUN UNIV OF TECH

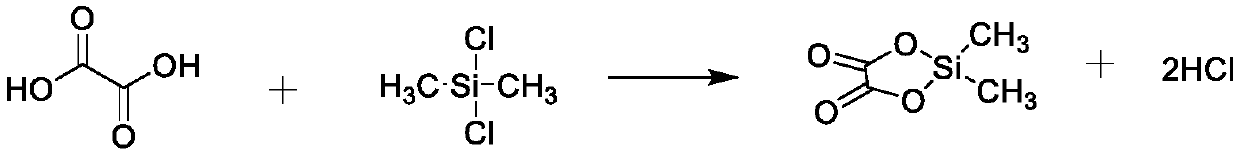

Preparation method of lithium difluorobisoxalate phosphate solution

The invention provides a preparation method of a lithium difluorobisoxalate phosphate solution. The preparation method of the lithium difluorobisoxalate phosphate solution comprises the following steps that (1) dichlorodimethylsilane and oxalic acid are reacted in the presence of a non-aqueous solvent to generate dimethyl silicon-based oxalate; and (2) lithium hexafluorophosphate is added into thereaction solution in the step (1), and reacting is carried out to obtain the lithium difluorobisoxalate phosphate solution. The preparation method is simple and practical, and industrial production can be achieved; the prepared lithium difluorobisoxalate phosphate solution can be directly used as an additive of a non-aqueous electrolyte battery; and the prepared lithium difluorobisoxalate phosphate solution has few chlorine compounds and free acids, wherein the chlorine compounds in terms of chlorine concentration are less than 5 mass ppm, and the free acids in terms of acid concentration converted from hydrofluoric acid are less than 200 mass ppm.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

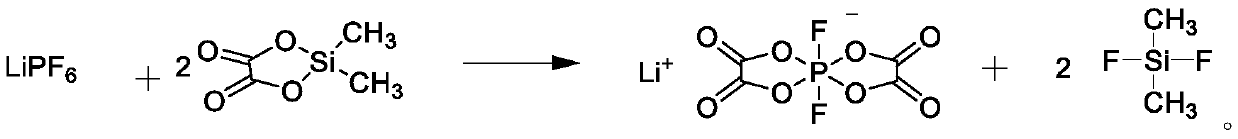

Graphene-enhanced Al-based composite solder auxiliary soldering method

InactiveCN105382440AHigh thermal conductivityLow densityWelding/cutting media/materialsSoldering mediaReduction treatmentGas phase

The invention relates to a solder auxiliary soldering method, in particular to a graphene-enhanced Al-based composite solder auxiliary soldering method. The method solves the problems that existing graphene is poor in aluminum base enhancing effect and poor in dispersibility. The method comprises the steps that an oxidized graphene suspension and an aluminum solder suspension are mixed, dried and then placed into a plasma enhanced chemical vapor deposition vacuum device for reduction treatment, then, the mixture is pressed into foils, the graphene / aluminum-based solder foils are placed between to-be-soldered faces of metal to be soldered for vacuum soldering, and the graphene-enhanced Al-based composite solder auxiliary soldering method is completed. The method is used for graphene-enhanced Al-based composite solder auxiliary soldering.

Owner:HARBIN INST OF TECH

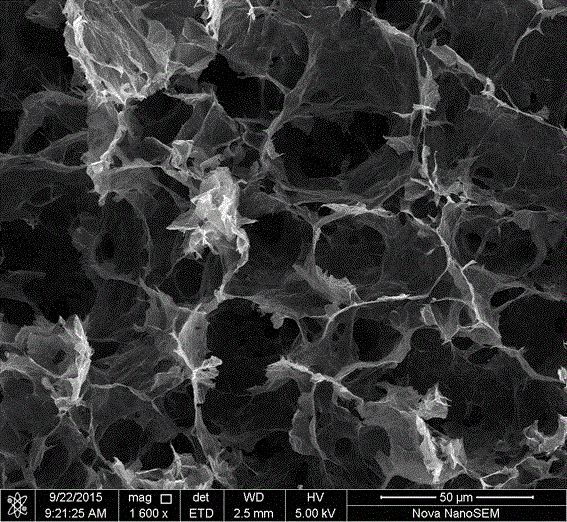

Preparation method of silane functionalized graphene aerogel material

ActiveCN105731432AThe preparation method is simple and safeNo pollution in the processGlass transportation apparatusSilanesOil water

The invention relates to the technical field of aerogels. In order to solve the problem that no simple preparation technique for controlling the pore size and surface properties of the three-dimensional graphene can implement effective control on the structural dimension, lamellar action mode, interface properties and the like of the three-dimensional graphene, the invention provides a preparation method of a silane functionalized graphene aerogel material. The method comprises the following steps: preparing a functionalized graphene hydrogel, and preparing the functionalized graphene aerogel. The preparation process is nontoxic and pollution-free. The prepared graphene aerogel can be used in the fields of oil-water separation, pressure-sensitive / gas-sensitive, polymer nano composite materials and the like.

Owner:HANGZHOU NORMAL UNIVERSITY

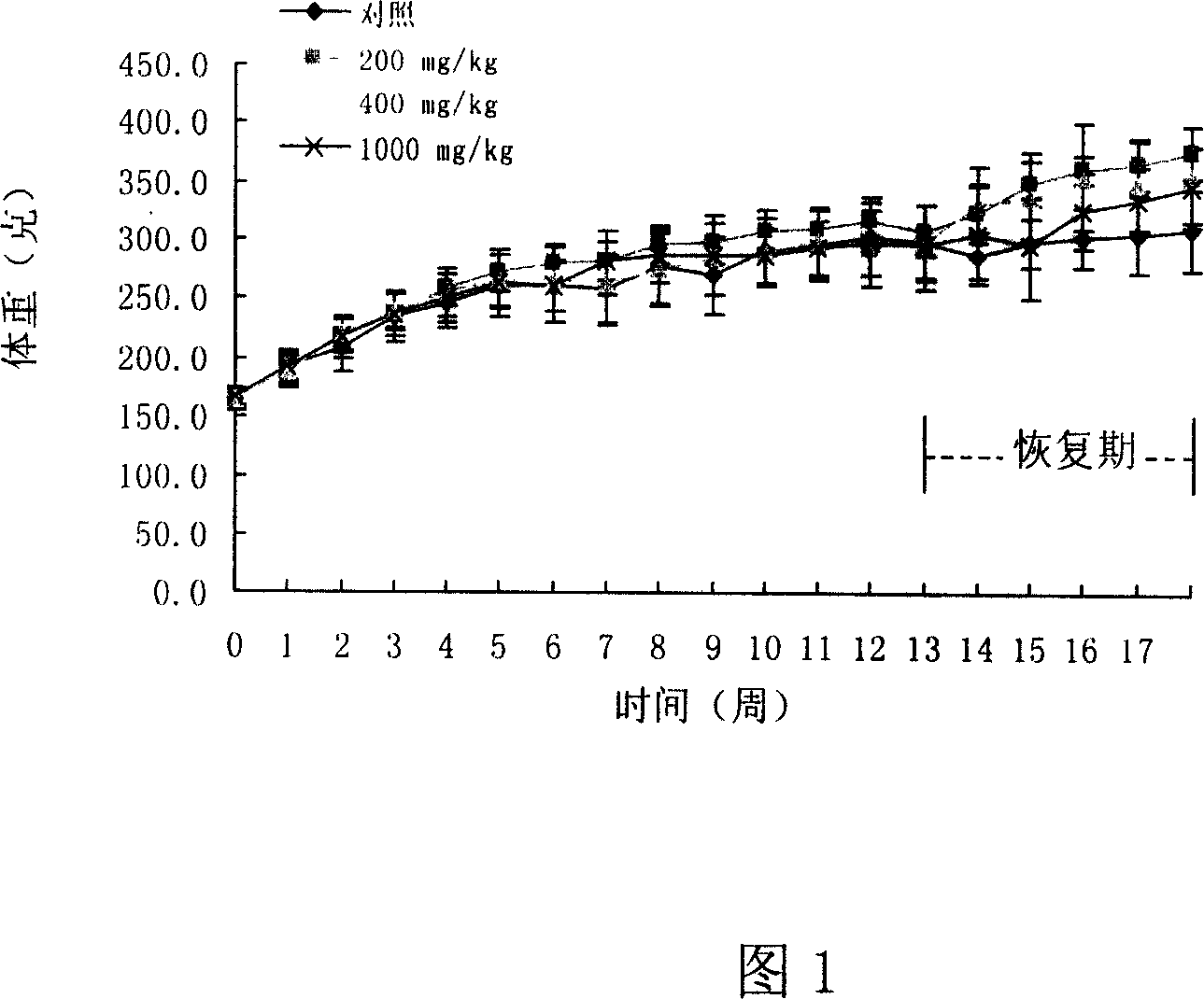

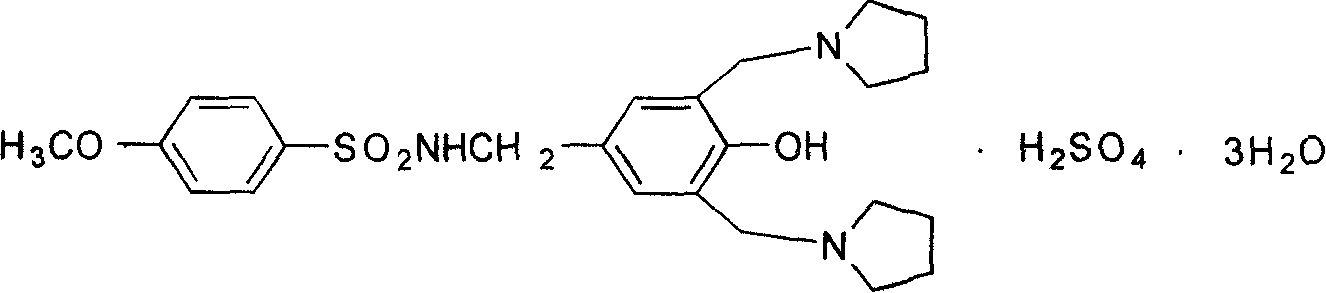

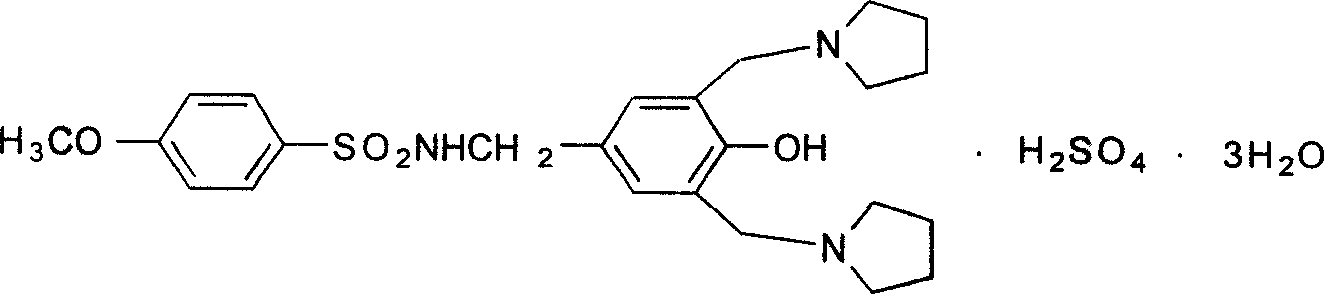

Schuqindin sulfate solid and target preparation and their making method

InactiveCN1939298AThe preparation process is matureImprove product qualityOrganic active ingredientsCapsule deliveryTreatment effectMedicine

A series of Shuxinding sulfate medicines for preventing and treating arrhythmia includes the solid medicine in the form of tablet, capsule, pill or particle with high stability and biologic utilization rate, and the target medicine in the form of microball, millimicro ball, liposome, or microemulsion with high target performance and low toxic by-effect.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Comprehensive extraction technology of rosmarinic acid, ursolic acid, oleanolic acid and carnosic acid

InactiveCN104447334ASimple processEasy to operateOrganic compound preparationSteroidsAlcoholUrsolic acid

The invention discloses a comprehensive extraction technology of rosmarinic acid, ursolic acid, oleanolic acid and carnosic acid. The comprehensive extraction technology comprises the steps of (1) preprocessing raw materials; (2) performing reflux alcohol-extraction; (3) carrying out primary separation; (4) separating out rosmarinic acid; (5) separating out ursolic acid; (6) separating out oleanolic acid. According to the comprehensive extraction technology, the process is simple, the operation is convenient, industrial production can be easily carried out, and meanwhile, the purpose of synchronously extracting rosmarinic acid of rosemary, ursolic acid, oleanolic acid and carnosic acid is achieved, and the active ingredients of rosemary can be extracted to the maximum; the rosmarinic acid, ursolic acid, oleanolic acid and carnosic acid respectively have the purity exceeding 30%, 25%, 20% and 25%.

Owner:付大亮

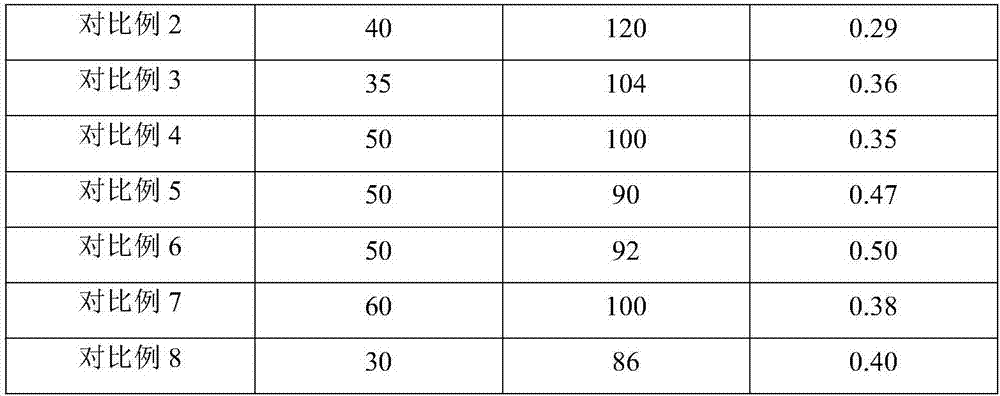

Preparation method of friction type silicon dioxide

ActiveCN106276929AReduce wearEasy to cleanCosmetic preparationsToilet preparationsFiltrationSODIUM SILICATE SOLN

The invention discloses a preparation method of friction type silicon dioxide. The preparation method comprises the following steps of: preparation of a first tank of materials: adding sodium sulfate solution into a reaction tank, heating, and then adding hexadecyl trimethyl ammonium bromide, then adding sodium silicate solution and sulfuric acid, controlling PH value, and after addition of the sodium silicate solution, adding the sulfuric acid till the final PH value is 4.4-5.0; preparation of a second tank of materials: adding sodium sulfate solution into another reaction tank, heating, and then adding hexadecyl trimethyl ammonium bromide, then adding sodium silicate solution and sulfuric acid, controlling PH value, and after addition of the sodium silicate solution, adding the sulfuric acid till the final PH value is 4.4-5.0; while stirring, adding a half of the material of the first tank into the material of the second tank, stirring, carrying out pressing filtration, washing and crushing on the formed silicon dioxide to prepare the friction type silicon dioxide. In the silicon dioxide, the RDA (Relative Dentine Attrition) value is 120-140, the PCR (Pellicular Cleaning Ratio) value is 100-130, and the PCR / RDA is equal to 0.80-1. The friction type silicon dioxide has the advantages of low wear, high cleanness and good thickening property.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

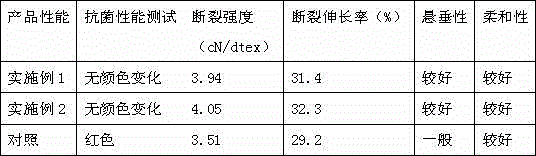

Radiation-proof yarn and production method thereof

The invention belongs to the technical field of textile material production, and discloses a radiation-proof yarn. The radiation-proof yarn is formed by blending of metal wires, polyacrylonitrile fibers and viscose according to a weight ratio of 1: 5: 4. The invention further discloses a production method of the radiation-preventive yarn. The radiation-proof yarn is good in radiation proofing performance and flexibility, not easy to fracture and good in antibacterial effect and market prospect.

Owner:SHANDONG WENDAO TRADING

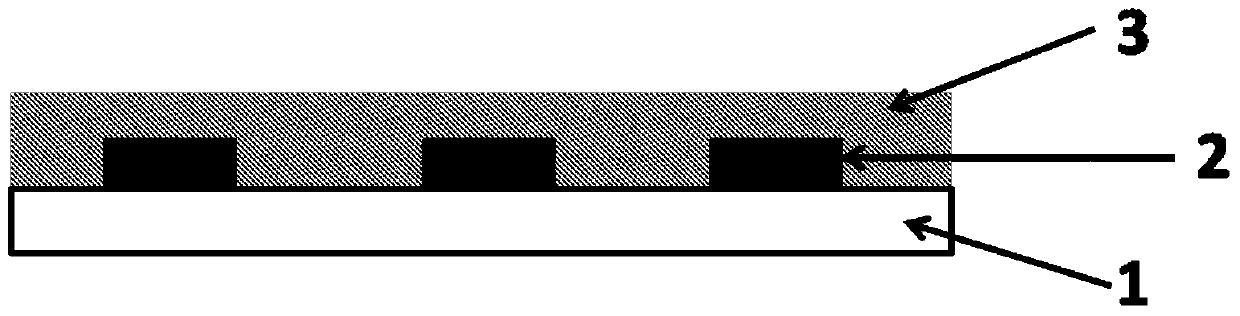

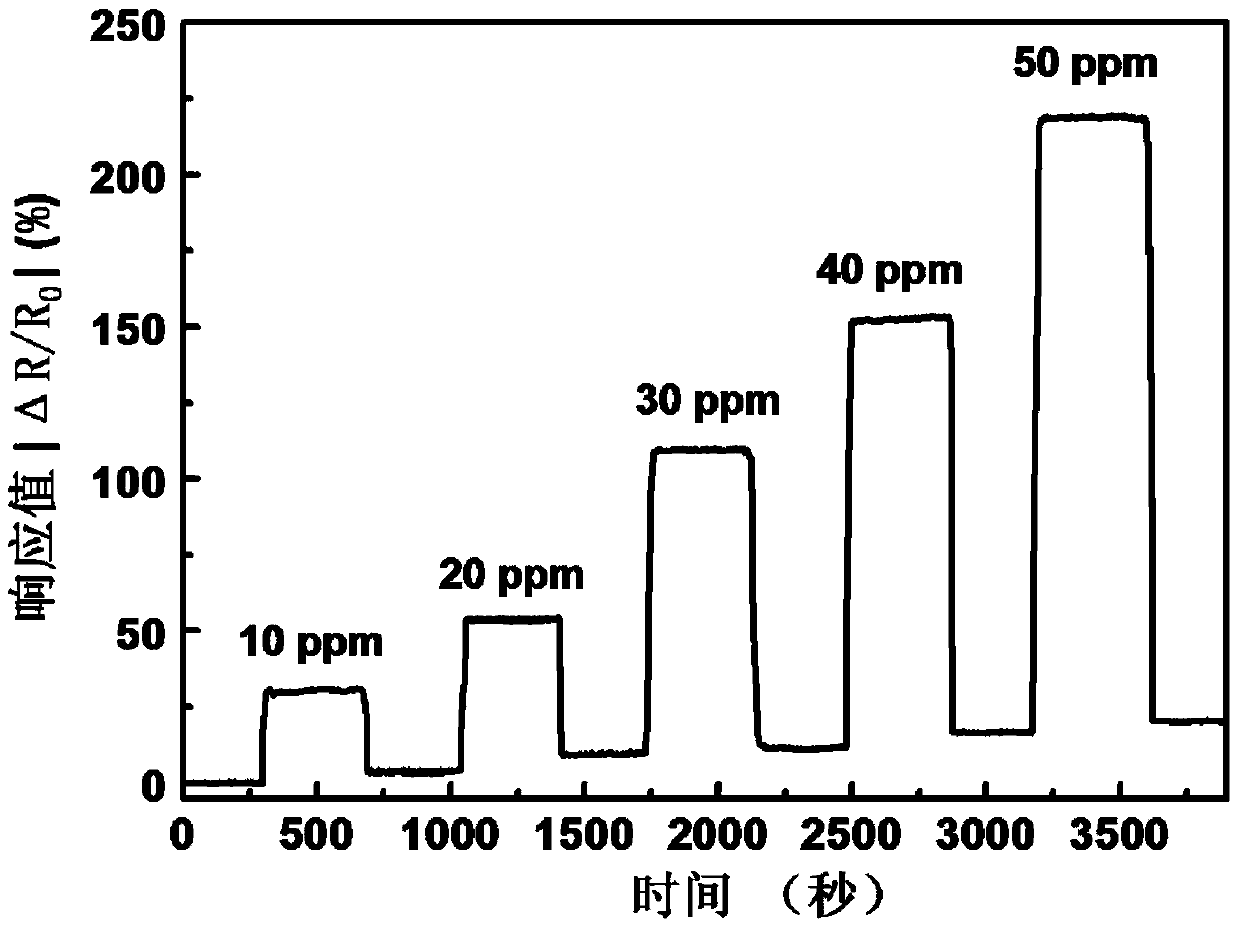

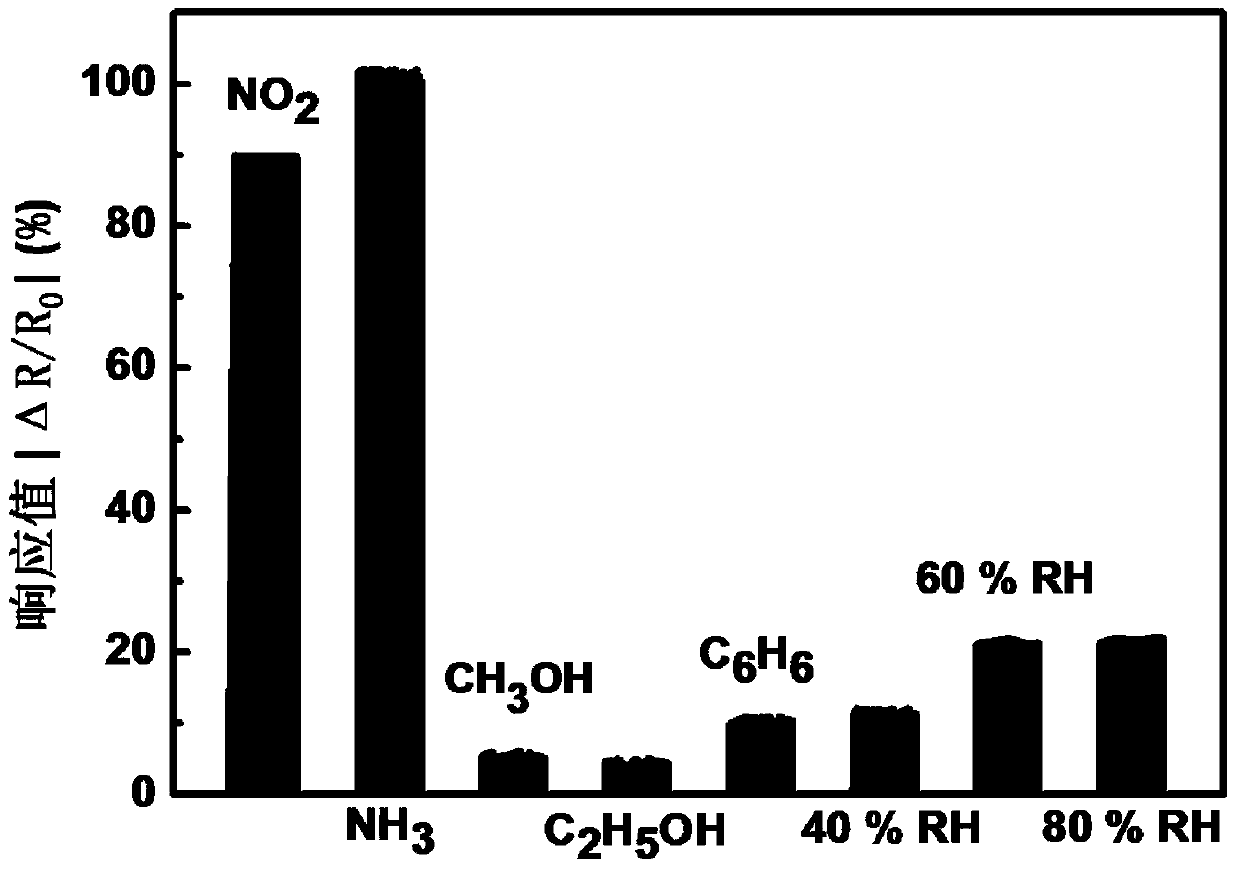

Printed type graphene-based NO2 gas-sensitive element and preparation method thereof

The invention discloses a printed type graphene-based NO2 gas-sensitive element and a preparation method thereof. The preparation method comprises the following step: by fully combining the advantages of intaglio printing technology and graphene, sequentially printing a comb-type interdigital electrode and a graphene sensitive layer on a substrate, thus finally obtaining the printed type graphene-based NO2 gas-sensitive element. The printed type graphene-based NO2 gas-sensitive element has the following advantages that (1) the NO2 gas-sensitive element based on the comb-type interdigital electrode and the graphene sensitive layer has excellent gas-sensitive characteristic and sensitivity on NO2 under the room-temperature condition; (2) the printed type graphene-based NO2 gas-sensitive element is scientific in design, and stable in performance running, and can meet the demands of accurately and continuously monitoring the concentration of NO2 in a life environment in real time; (3) the graphene-based NO2 gas-sensitive element prepared by adopting a printing manner is simple in technology, convenient to operate, low in cost, and suitable for industrial mass production, and technology parameters are easy to control.

Owner:SHANGHAI NORMAL UNIVERSITY

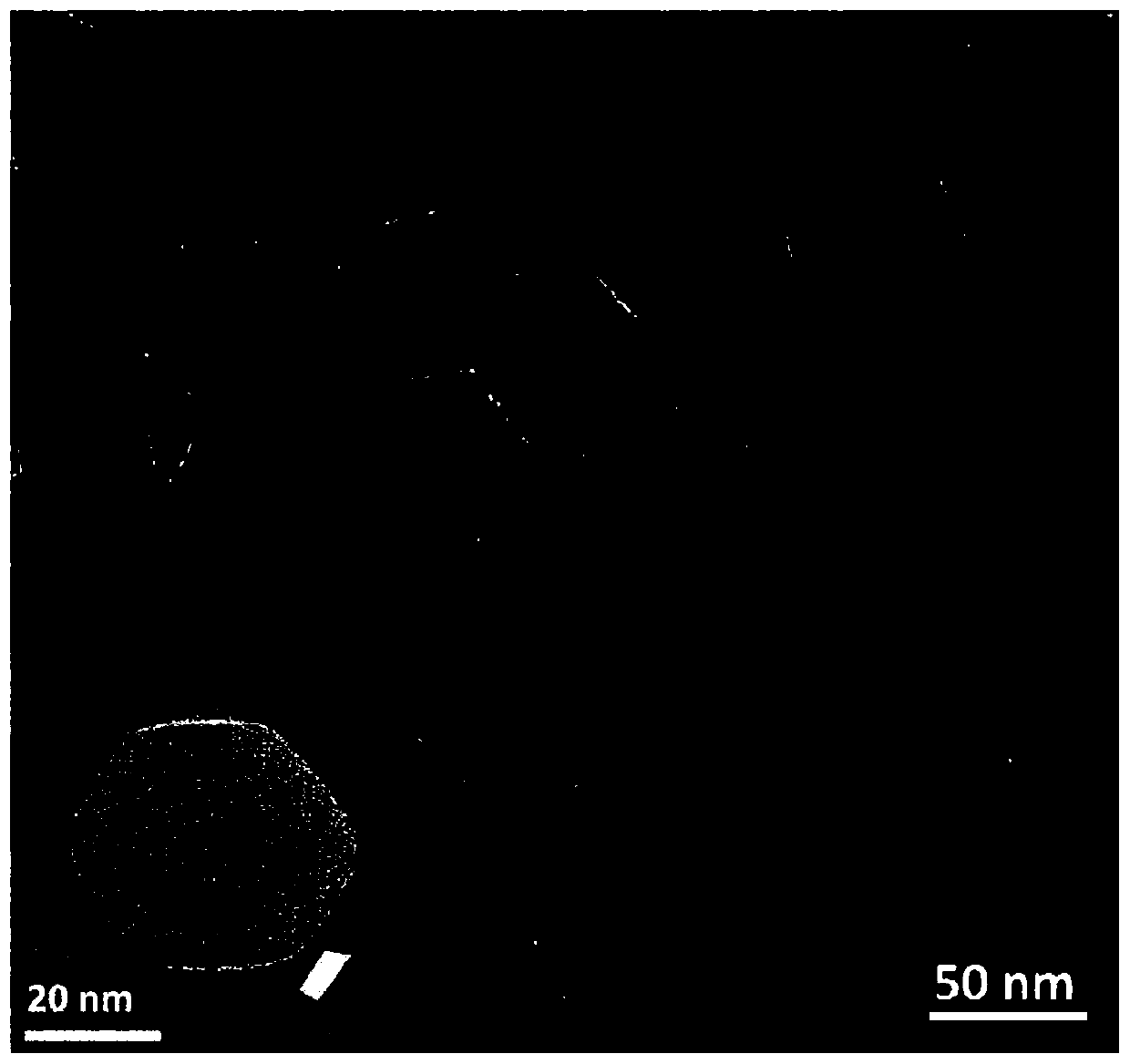

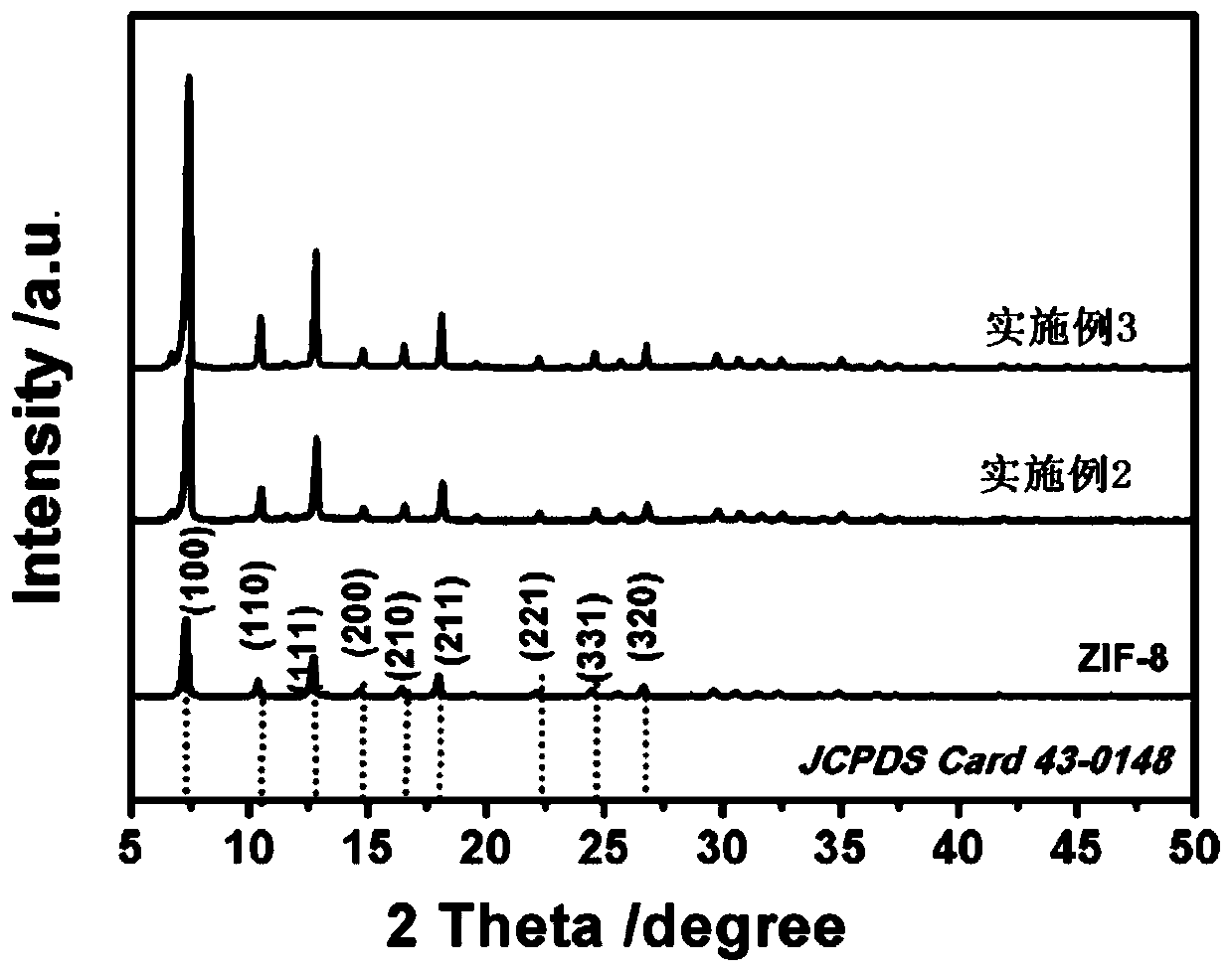

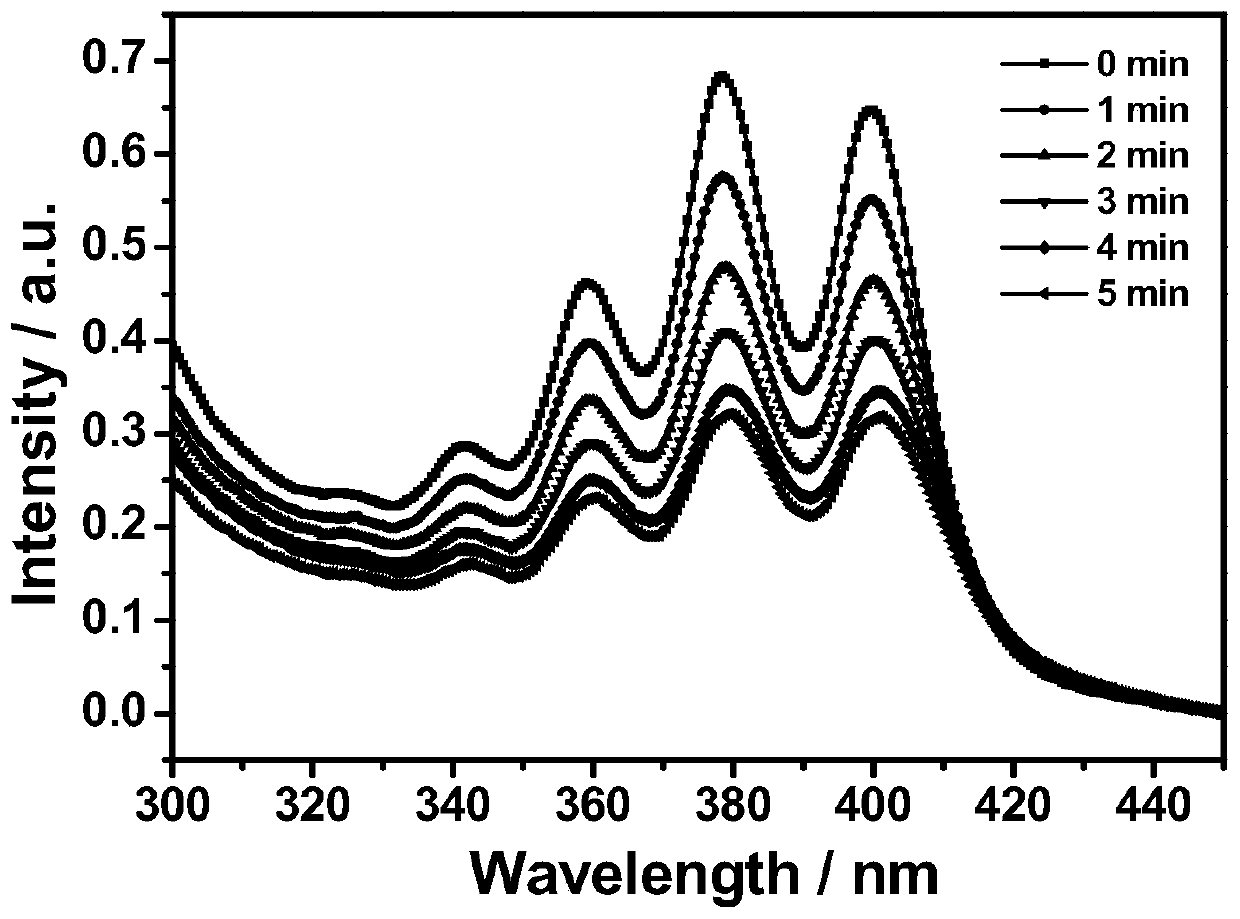

Method for preparing mixed-valent-state iron doped zeolite imidazate skeleton nano-material

InactiveCN110724272AUniform and controllable particle sizeHigh ROS Generation EfficiencyIron saltsMeth-

The invention relates to a method for preparing a mixed-valent-state iron doped zeolite imidazate skeleton nano-material. The method comprises the steps of simultaneously dispersing bivalent and trivalent iron salts and zinc nitrate into a methanol solvent to form an iron-zinc precursor solution, mixing a 2-methylimidazole methanol solution with the precursor solution, placing the mixture in an oil bath with the temperature of 40 DEG C to 100 DEG C, carrying out a sustained magnetic stirring reaction, and then, subjecting a product to centrifugation, washing and drying treatment, thereby obtaining the mixed-valent-state iron doped zeolite imidazate skeleton nano-material. The mixed-valent-state iron doped zeolite imidazate skeleton nano-material with relatively high yield and uniform and controllable particle size is obtained. According to the method disclosed by the invention, the total iron doped amount can reach 50% to the maximum through adjusting a ratio of bivalent iron salts totrivalent iron salts, and conversion ratios of zinc ions and iron ions can separately reach up to 78% and 60%. The method is simple and economical, and reacted mother liquor can be reused. The obtained nano-material has a relatively high active oxygen generating efficiency under ultrasonic induction, has a tremendous application value in degradation of environmental pollutants and sonodynamic therapy of tumors and can be applied to preparation of high-concentration monoatomic iron-carbon based catalysts.

Owner:BEIJING UNIV OF CHEM TECH

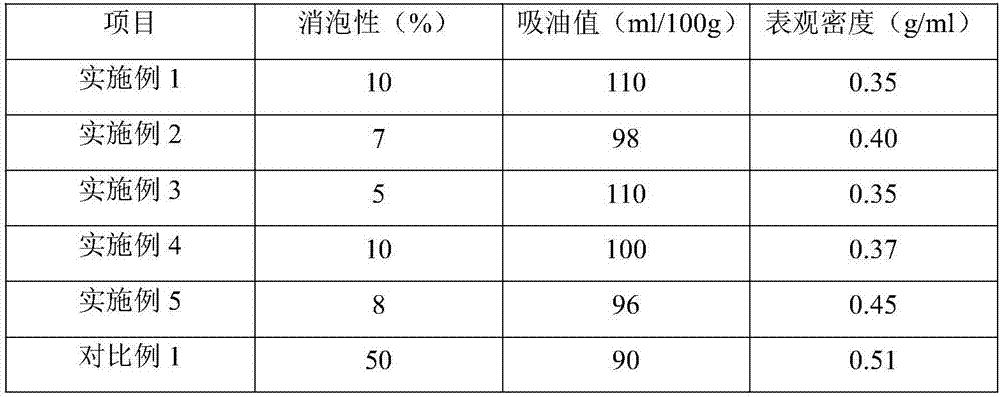

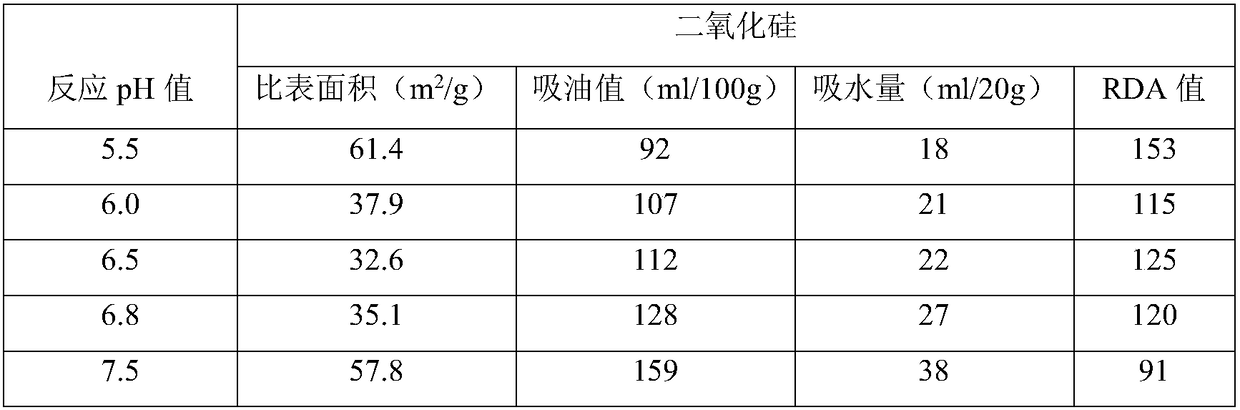

Preparation method of low defoaming silica

ActiveCN106986349AReduced defoamingReduce adsorptionCosmetic preparationsToilet preparationsFoaming agentToothpaste

The invention belongs to the technical field of silica and relates to a preparation method of low defoaming silica. The preparation method comprises S1, adding a sodium sulfate solution into a reactor, stirring the solution, adding a complex surfactant into the solution, and uniformly stirring and heating the solution, S2, adding a sodium silicate solution into the solution, after 0.5min, adding a sulfuric acid solution into the mixed solution, adjusting a sulfuric acid addition rate to control pH to 9.0-9.5 in the reaction process, and then adding a sulfuric acid solution into the mixed solution until terminal pH of 4.0-5.0, S3, continuously stirring the solution at the temperature, carrying out filter pressing on the formed silica, and carrying out washing, drying and crushing to obtain the low defoaming silica. The preparation method has the advantages of simple process, stable process, low production cost and less pollution. The low defoaming silica has low defoaming ability, has good compatibility with a toothpaste foaming agent and effectively enhances washing foam feeling of the toothpaste.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Process for extracting folium mori flavone

InactiveCN1683360ANo pollution in the processLow priceSugar derivativesMetabolism disorderAlcoholSolvent

The mulberry leaf flavone extracting process adopts mulberry leaf powder material, alcohol and water as extracting solvent and eluant and macroporous resin as separating material. The extract has mulberry leaf flavone content over 50 %. The present invention has the advantages of non-toxic cheap recoverable solvent, no environmental pollution, great extracted amount, capacity of industrial production and high extracting efficiency.

Owner:SHANXI UNIV

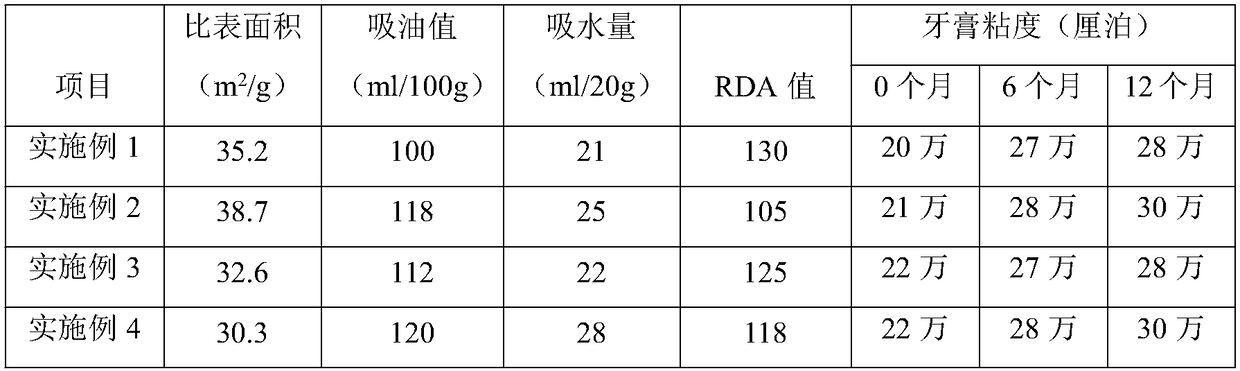

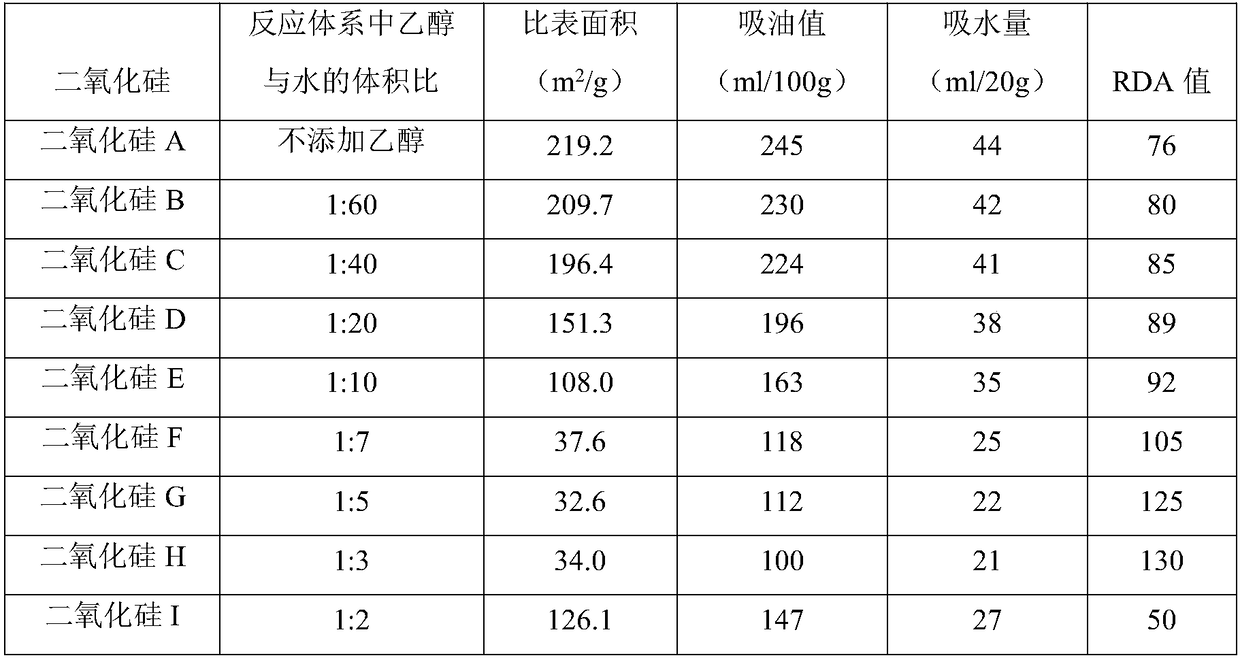

Preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide

InactiveCN108190900ASmall specific surface areaSimple methodSilicon compoundsChemistryAqueous solution

The invention belongs to the technical field of silicon dioxide, and particularly relates to a preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide.The preparation method comprises the steps that S1, 8-12 m<3> of ethanol aqueous solution is injected and heated to 60-70 DEG C, and stirring starts; S2, water glass and sulfuric acid are added dropwise to carry out a parallel flow reaction, the pH value in the reaction process is controlled to be 6.0-6.8, meanwhile, absolute ethyl alcohol is added every 5-10 minutes in the reaction process to keep the volume ratio of ethyl alcohol to water in a reaction system to be 1:(3-7), after the water glass is dropwise added, dropwise addition of sulfuric acid is stopped, and stirring continues; S3, stirring and heating are stopped, aging is conducted for one hour, and pressure filtration, washing, drying and crushing are conducted on the on formed silicon dioxide to prepare silicon dioxide. The silicon dioxide has the advantages of a low in specific surface area, a high oil absorption value, a high water absorption amount, the friction property and the like; toothpaste has good friction and cleaning performance after the silicon dioxide is used, and meanwhile, the problem of expansion of the viscosity of the toothpaste is well solved.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

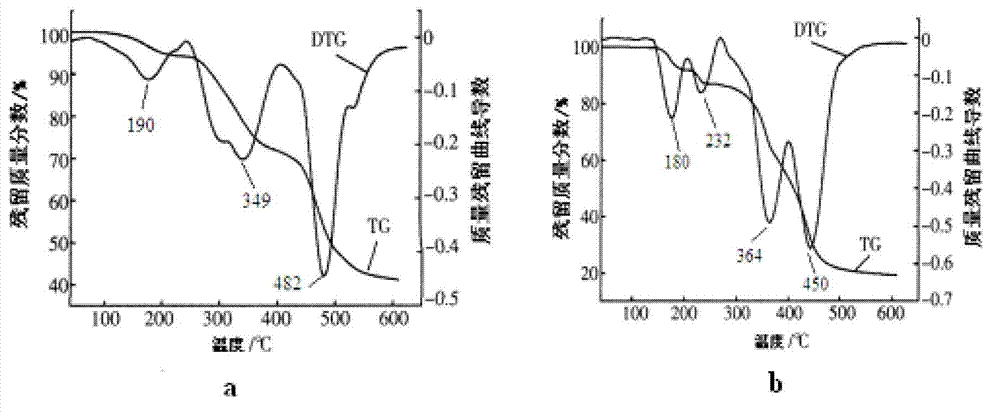

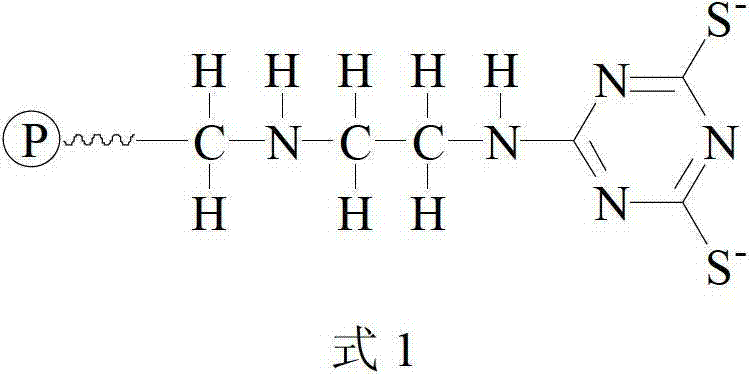

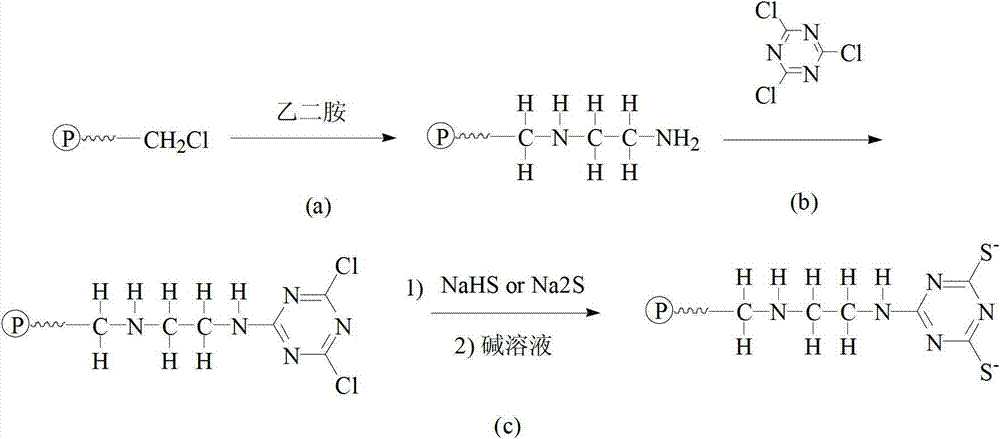

Functional resin containing 4,6-dimercapto-1,3,5-triazine alkali metal salt and preparation method thereof

InactiveCN103087245AImprove adsorption capacityExpand the scope of activitiesOther chemical processesWater/sewage treatment by sorptionSolventEthyl Chloride

The invention discloses functional resin containing 4,6-dimercapto-1,3,5-triazine alkali metal salt and a preparation method thereof. The method comprises the steps of dripping ethanediamine into chloromethylated bead mixture swelled by a solvent to carry out nucleophilic substitution to obtain the resin containing active amino; carrying out substituted grafting reaction on the obtained resin containing the active amino and cyanuric chloride to obtain the resin grafted with the cyanuric chloride; carrying out sulfhydrylation reaction on the prepared resin grafted with the cyanuric chloride in water solution of Na2S and / or NaSH, and then alkalifying with aqueous alkali after the sulfhydrylation reaction is finished. The method is simple in processing equipment, and convenient and simple to operate; and the sulfydryl resin prepared by the method is high in sulfydryl content, large in adsorbing capacity on heavy metal ions, strong in adsorption capacity, strong in regeneration capacity, good in repeated use effect, free of pollution, and low in cost, can remove and gather metal ions of heavy metals such as copper, lead, nickel, chromium, mercury and the like in waste water at the same time, and especially has good absorption efficiency when the concentration of the heavy metals in the waste water is low.

Owner:JIENTE NEW MATERIAL TECH CO LTD

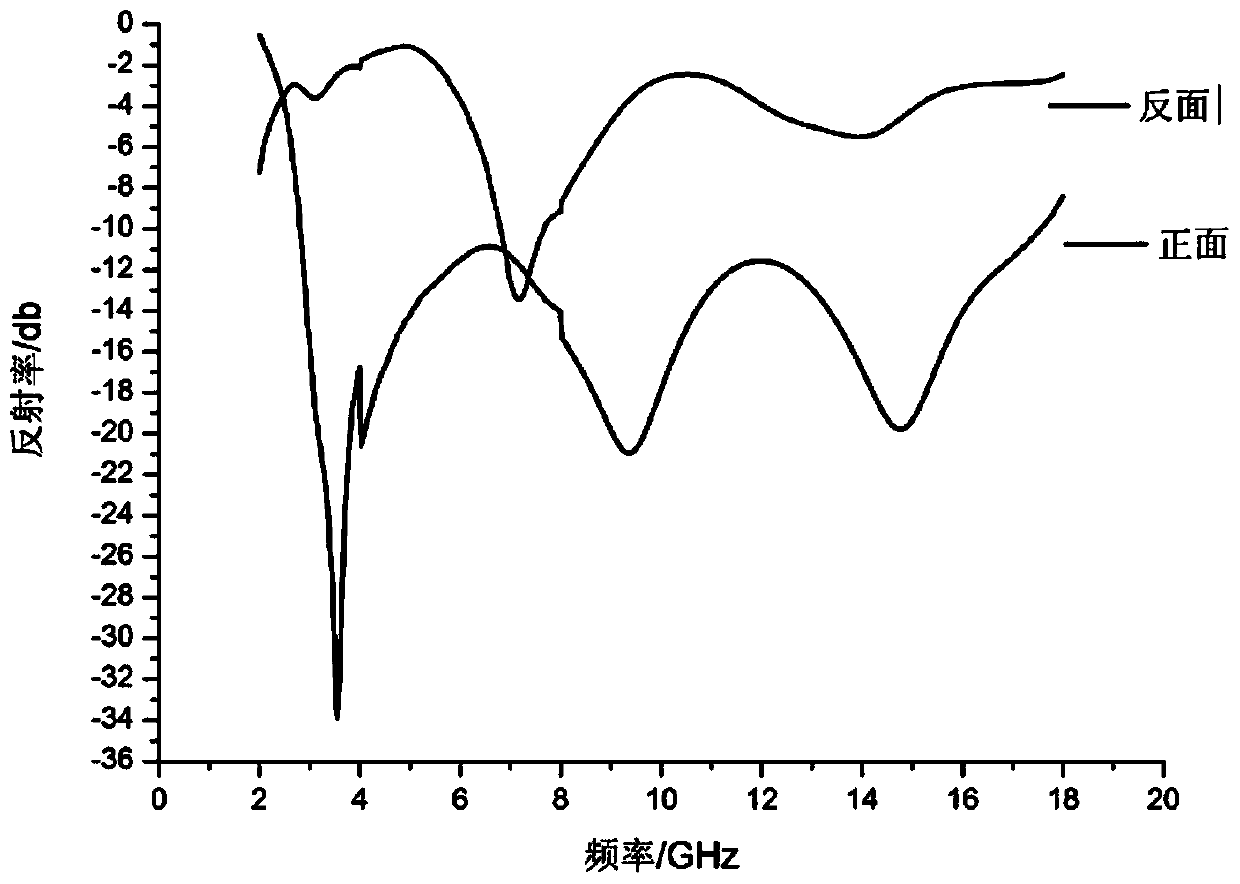

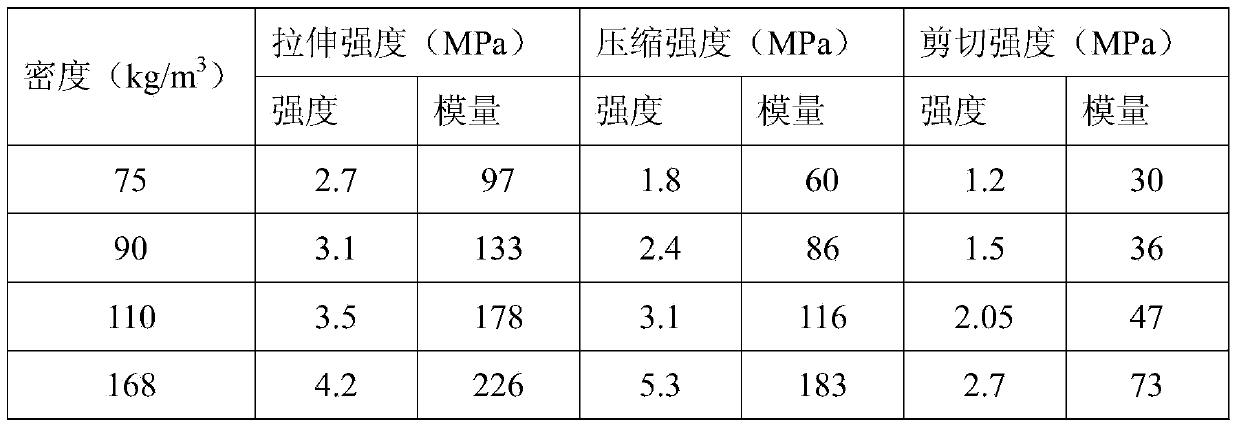

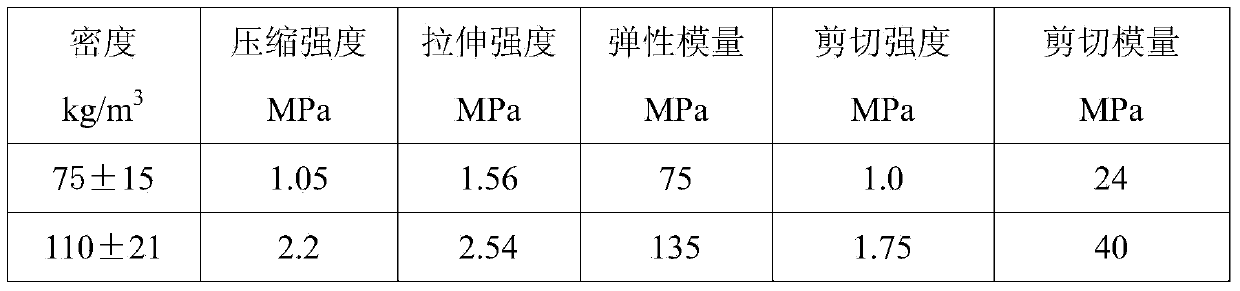

Wave-absorbing type polymethacrylimide foam/chopped fiber composite material and preparation method thereof

ActiveCN104177745AImprove mechanical propertiesImprove thermal stabilityFibrous compositesMechanical property

The invention discloses a wave-absorbing type polymethacrylimide foam / chopped fiber composite material and a preparation method thereof. The composite material is formed by uniformly dispersing a chopped fiber wave-absorbing agent in a methacrylic acid / methacrylonitrile copolymer substrate. The composite material is simple in preparation method and low in cost, and the comprehensive mechanical property of the composite material is obviously improved in comparison with that of a polymethacrylimide foam material in the prior art. In addition, the composite material has a certain wave-absorbing effect. Thus, an application range of the polymethacrylimide foam material is enlarged.

Owner:CENT SOUTH UNIV

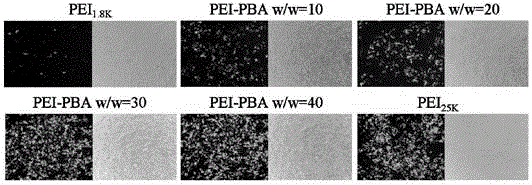

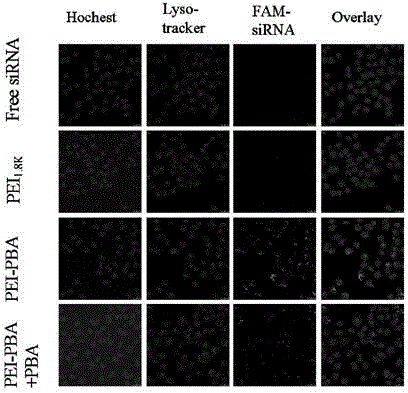

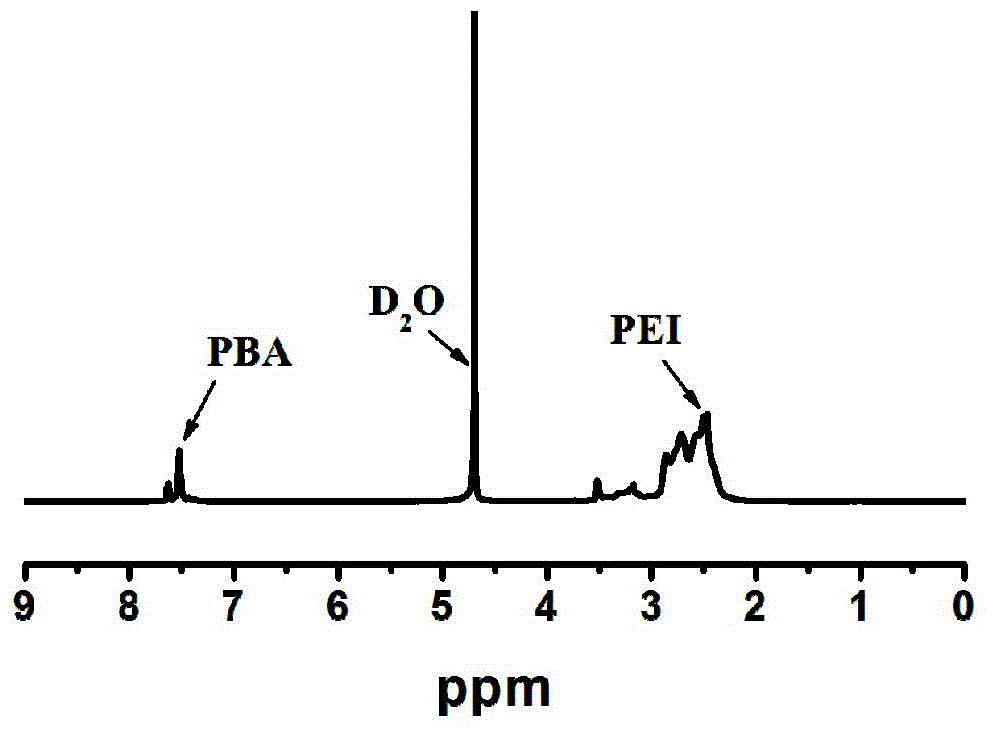

Modified polyethyleneimine, a gene vector composition, and a preparing method and applications of the gene vector composition

InactiveCN105732981AImprove bindingEasy to identifyGenetic material ingredientsOther foreign material introduction processesPhenylboronic acidCell membrane

The invention provides modified polyethyleneimine, and a preparing method and applications of the modified polyethyleneimine. The modified polyethyleneimine is prepared through modifying polyethyleneimine with different molecular weights with phenylboronic acid compounds. The modified polyethyleneimine has an active targeting property for tumor cell membranes, and can carry genes to form a gene vector composition used for gene therapy. The gene vector composition is uniform in particle size, proper in charge, stable in properties, low in cell toxicity, high in cell transfection efficiency, high in target power, and good in biocompatibility and biodegradability. The modified polyethyleneimine and the gene vector composition can be used for the gene therapy. Preparing processes of the modified polyethyleneimine and the gene vector composition are simple, high in reaction degree controllability and capable of industrial production.

Owner:SHENZHEN INST OF ADVANCED TECH

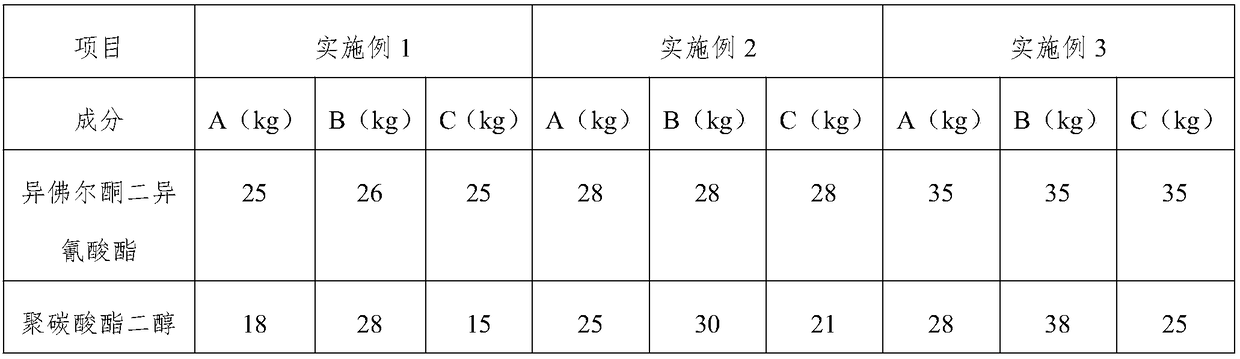

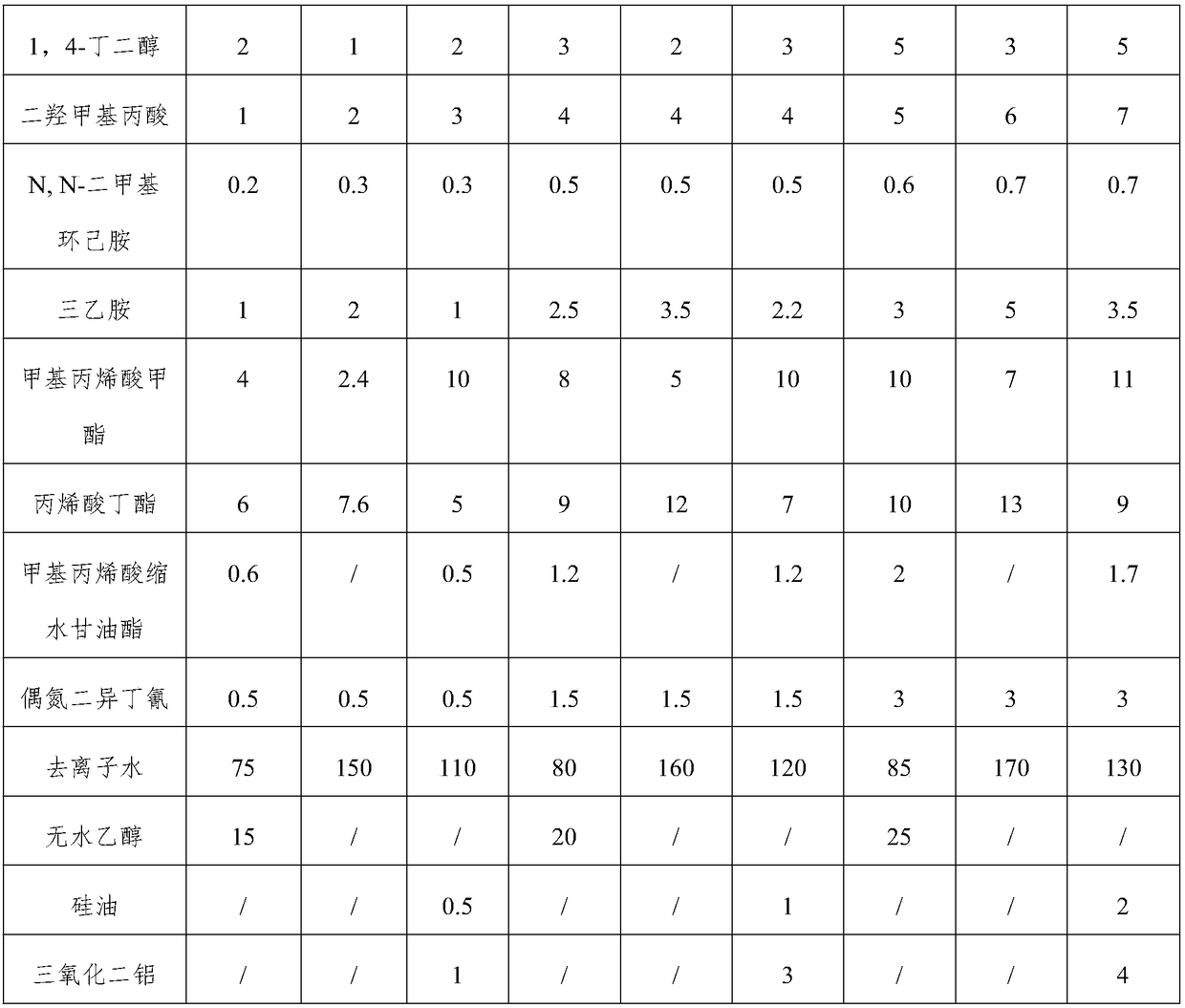

Formaldehyde-free decorative adhesive film paper and preparation method thereof

ActiveCN109457536AInhibition releaseIn line with consumer trendsPaper coatingCoatingsPolymer scienceHardness

The invention belongs to the technical field of decorative paper, and particularly relates to formaldehyde-free decorative adhesive film paper and a preparation method thereof. The formaldehyde-free decorative adhesive film paper sequentially comprises a back-coated resin layer, a first resin-impregnated layer, base material paper, a second resin-impregnated layer and a surface-coated resin layerfrom inside to outside. According to the formaldehyde-free decorative adhesive film paper, formaldehyde-free waterborne polyurethane resin serves as a preparation raw material and replaces traditionalurea resin and melamine resin, the prepared decorative adhesive film paper is green, environmentally friendly, free from formaldehyde, high in drying speed, excellent in performance and simple and convenient to construct, has hardness and toughness and can be popularized and applied.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD +1

Preparation method and application of cross-linked resin modified by imidazole

InactiveCN105859962AImprove adsorption capacityEnhanced dense pore structureOther chemical processesCross-linkLewis acid catalysis

The invention discloses a preparation method and application of cross-linked resin modified by imidazole. The preparation method of cross-linked modified by imidazole comprises the steps that a vinyl-containing imidazole monomer, a divinylbenzene cross-linking agent, an initiator, an o-xylene and / or benzyl alcohol pore-forming agent and a dispersing agent are subjected to suspension polymerization to obtain precursor resin; the precursor resin is subjected to a Friedel-Crafts reaction under the Lewis acid catalytic action, and the cross-linked resin modified by imidazole with the high specific surface area, large pore volume and the proper pore structure and polarity is obtained. The resin is particularly applicable to adsorbing small polar molecular aromatic organic compounds in water. In addition, the preparation method of the cross-linked resin modified by imidazole is simple, low in cost and capable of achieving industrial production.

Owner:CENT SOUTH UNIV +1

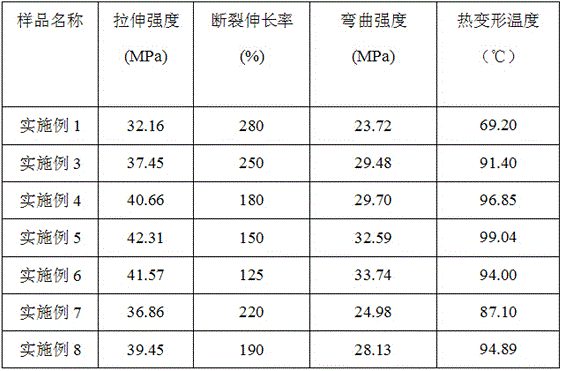

Heat-resistant poly(butylenes succinate) and preparation method thereof

InactiveCN106279646AHigh molecular weightHigh heat distortion temperatureHeat deflection temperaturePoly(butylene succinate)

The invention relates to a heat-resistant poly(butylenes succinate) and a preparation method thereof. According to the invention, the poly(butylenes succinate) having high molecular weight, biodegradablity and high heat deformation temperature is prepared by combining a mico-crosslinking process and a nucleating agent addition process through a melt polycondensation one-step method. The method is simple in process and simple to operate, and can realize continuous production.

Owner:HANGZHOU XINFU TECH CO LTD

Bacterial cellulose-based antibacterial dry film for acute trauma and preparation method and application thereof

InactiveCN102091346ALight and soft textureGood biocompatibilityAbsorbent padsBandagesBiocompatibility TestingAntibacterial agent

Owner:DONGHUA UNIV

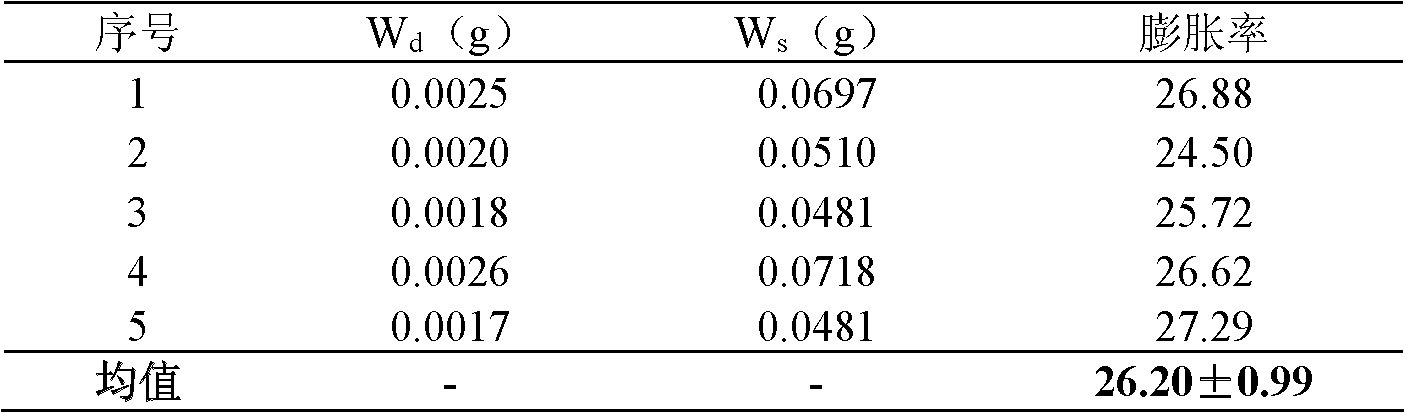

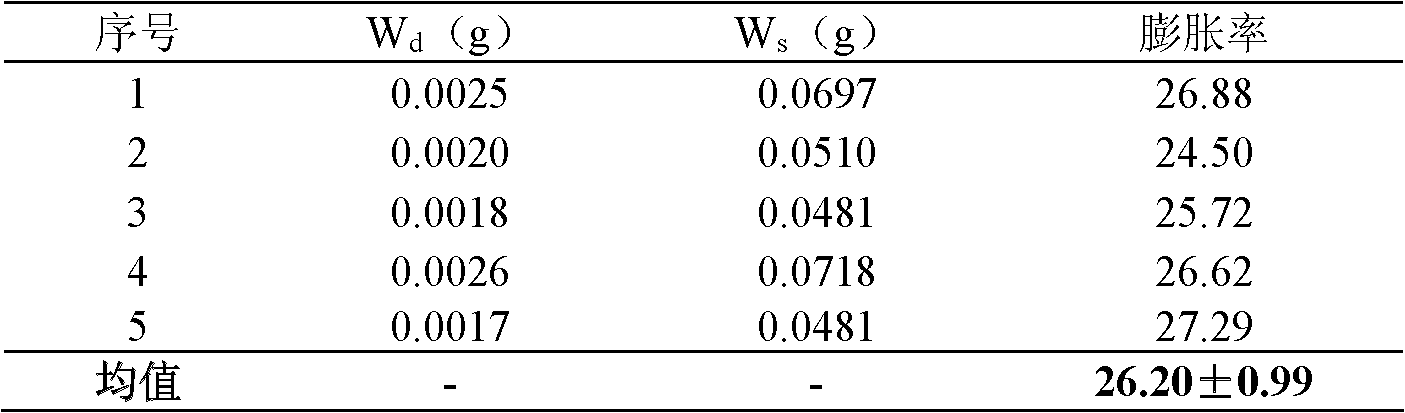

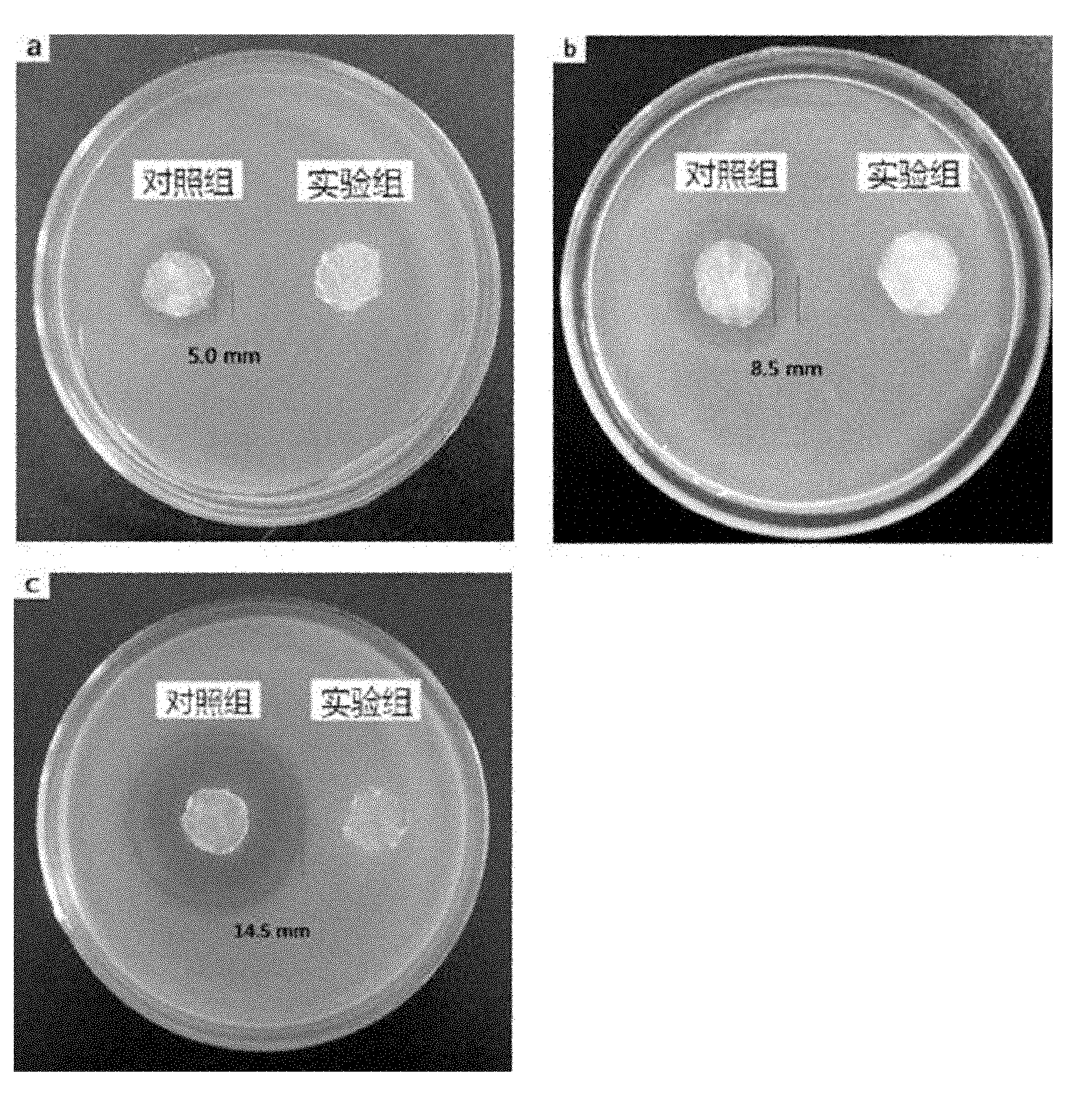

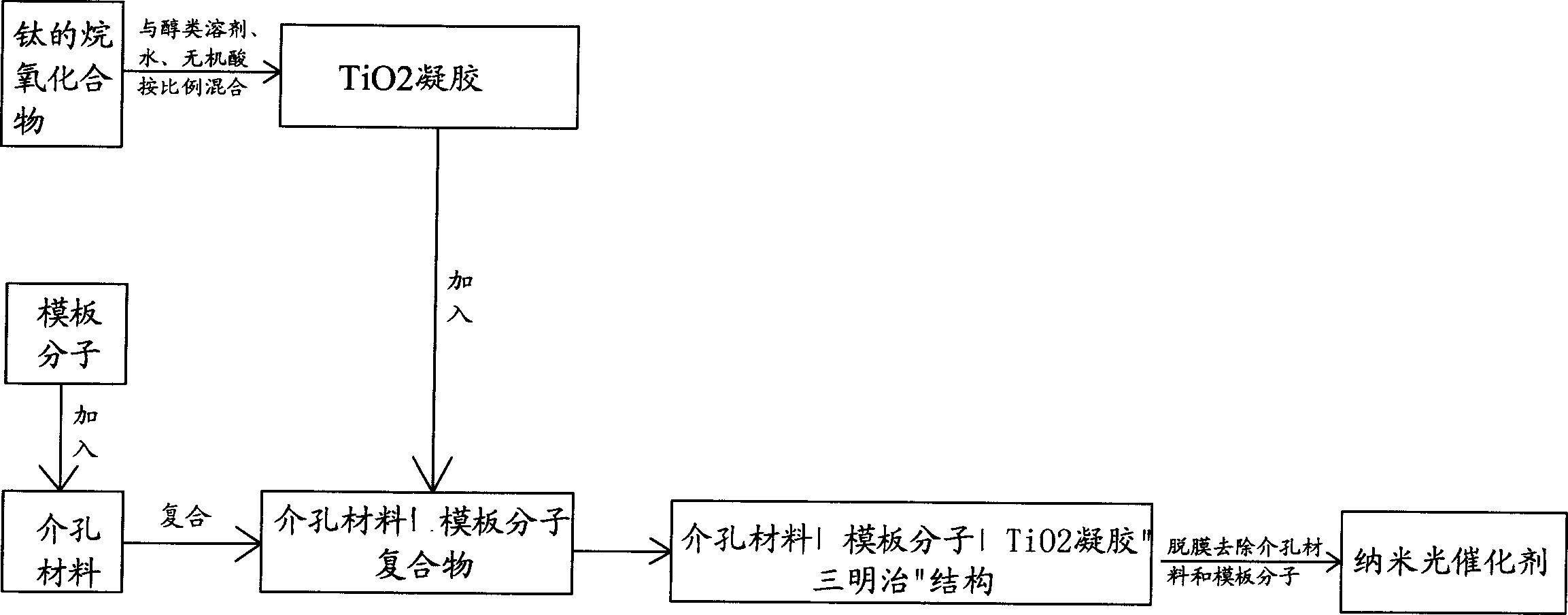

Nano photocatalyst of possessing function of molecular engram, preparation method and usage

InactiveCN1915487AImprove adsorptionReduce the concentration of gaseous pollutantsCatalyst carriersDispersed particle separationStereochemistryIndoor air quality

A nano-photocatalyst with molecular engram function has a 3D pore structure matched fully with the space structure of the compounds in formaldehyde or benzene system and combined specifically with them. It can be used to improve indoor air by adsorbing and degradating said compounds. Its preparing process is also disclosed.

Owner:ZHEJIANG UNIV

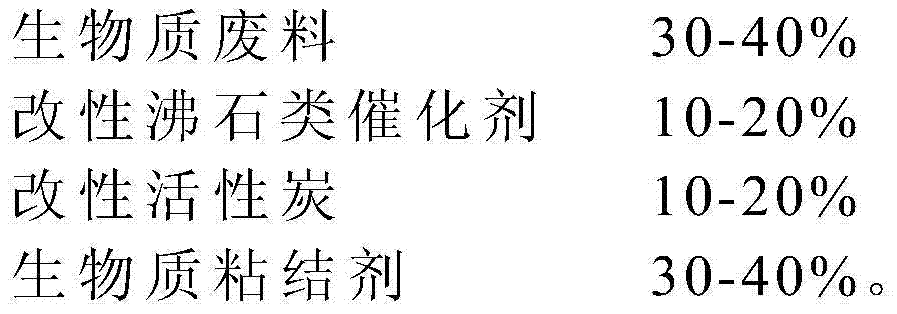

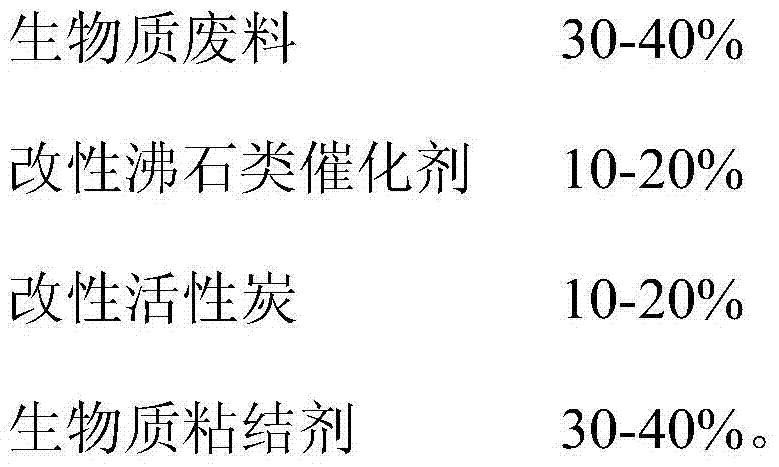

Desulphurization and denitration agent based on waste biomass and preparation method thereof

ActiveCN103495434AHas sulfur fixationEmission reductionMolecular sieve catalystsDispersed particle separationMixed materialsPollution

The invention discloses a desulphurization and denitration agent based on waste biomass and a preparation method thereof. The desulphurization and denitration agent contains zeolite catalysts loaded with metal oxides, modified active carbon, waste biomass and a biomass binder. The preparation method of the desulphurization and denitration agent based on the waste biomass comprises the following main steps: firstly, crushing the solid-state biomass waste, the zeolite catalysts and the active carbon to obtain powder; then, uniformly mixing the crushed materials in the biomass binder; and finally, drying and forming the mixed materials to obtain the desulphurization and denitration agent disclosed by the invention. The desulphurization and denitration agent disclosed by the invention not only can be directly used for purifying a high-temperature flue gas of over 600 DEG C, but also can be used for effectively realizing treatment of wastes with processes of wastes against one another, i.e., the biomass waste including crop straws, crop processing waste, timber processing waste or municipal domestic waste, and the like are effectively used to govern flue gas pollution.

Owner:北京绿洁美科技有限公司

Preparation method of porous nanocrystalline Cu2S counter electrode of quantum-dot-sensitized solar cell

InactiveCN104332315ALarge specific surface areaIncrease contact surfaceLight-sensitive devicesCuprous sulfideSolar cell

The invention belongs to the technical field of solar cells and energies, and particularly relates to a preparation method of a porous nanocrystalline Cu2S counter electrode of a quantum-dot-sensitized solar cell. The preparation method comprises the steps of: regarding copper acetate and thioacetamide as precursors; obtaining 20-100 nm cuprous sulfide (Cu2S) nanometer particles through solvothermal reaction; preparing the cuprous sulfide (Cu2S) nanometer particles and ethanol into a thick liquid; forming 5-10 microns Cu2S nanocrystalline porous film on a conductive base body by utilizing a knife coating method, a silk screen print method or a spin-coating method; sintering at 300-500 DEG C in an inert atmosphere or vacuum for 10-60 min to obtain a battery electrode. The prepared Cu2S nanometer porous counter electrode extremely increases contact area of the counter electrode and electrolyte, further increases catalytic reaction site of the Cu2S and the electrolyte, and improves performance of the solar cell. In addition, the preparation method of the porous nanocrystalline Cu2S counter electrode of the quantum-dot-sensitized solar cell is simple in preparation technology, relatively low in cost and has wide application foreground and wide research values.

Owner:UNIV OF SCI & TECH BEIJING

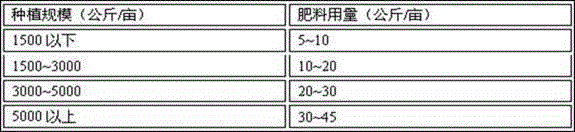

Special water-soluble fertilizer for pineapple and preparation method of special water-soluble fertilizer

InactiveCN104591876AIncrease travel distancePromote absorptionUrea compound fertilisersPotassium fertilisersSoil scienceNutrition

The invention belongs to the field of crop fertilizers, and particularly relates to a special water-soluble fertilizer for pineapple and a preparation method of the special water-soluble fertilizer. A high-content nitrogen-phosphoric fertilizer phosphorus oxanamide is adopted as a nitrogen source and a phosphorus source; a potassium resource, medium trace elements, a growth promoter and organosilicone are added according to the growth requirements of the pineapple. The preparation method comprises the following steps: sequentially adding the components, and carrying out mixing reaction to generate a special water-soluble fertilizer for the pineapple. The special water-soluble fertilizer for the pineapple can be mixed and dissolved into water, and is applied to spraying or drip irrigation on the pineapple together with water; the special water-soluble fertilizer is uniform in content, high in utilization rate and low in fertilizer amount; balanced nutrients can be provided for the pineapple; synthesis of an organic acid and a vitamin in the pineapple is promoted; and the yield and the quality of the pineapple are improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

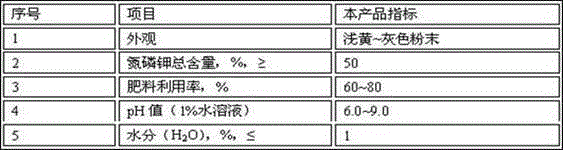

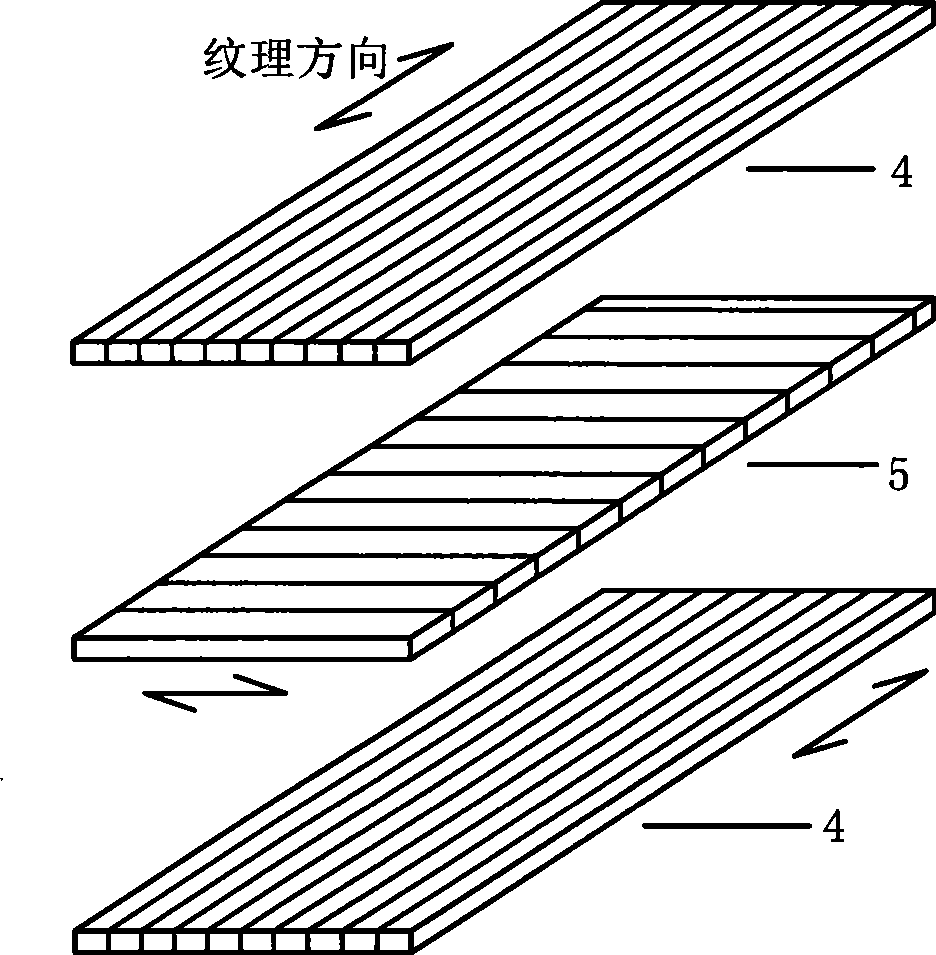

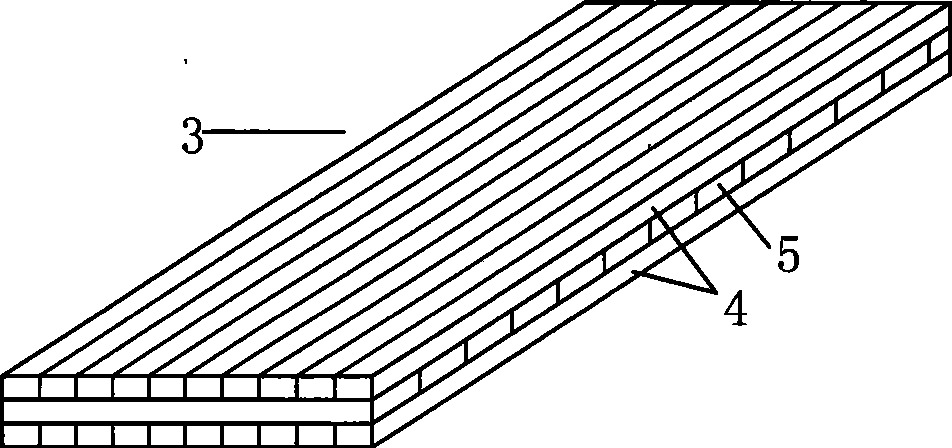

High-strength plywood for building shutter panel

InactiveCN101498171AEasy to assemble and disassembleHigh turnoverSynthetic resin layered productsWood layered productsHigh turnoverWeather resistance

The invention provides a veneer which is used for fair-faced concrete building template and has the advantages of lightness, high strength, convenient disassembly and assembly, easy cutting, high cost performance, weather resistance, corrosion prevention, strong durability, easy demoulding, high turnover frequency and being suitable for industrial production. The veneer consists of a covering film, a panel and a core plate; the covering film is prepared from a resin pressed film; the panel is prepared by gluing a gum dipping fiber reinforced composite material; and the core plate is a three-layer structural plate. The invention is mainly used for panels in building template systems, particularly for panels of fair-faced concrete templates.

Owner:NANJING UNIV OF TECH

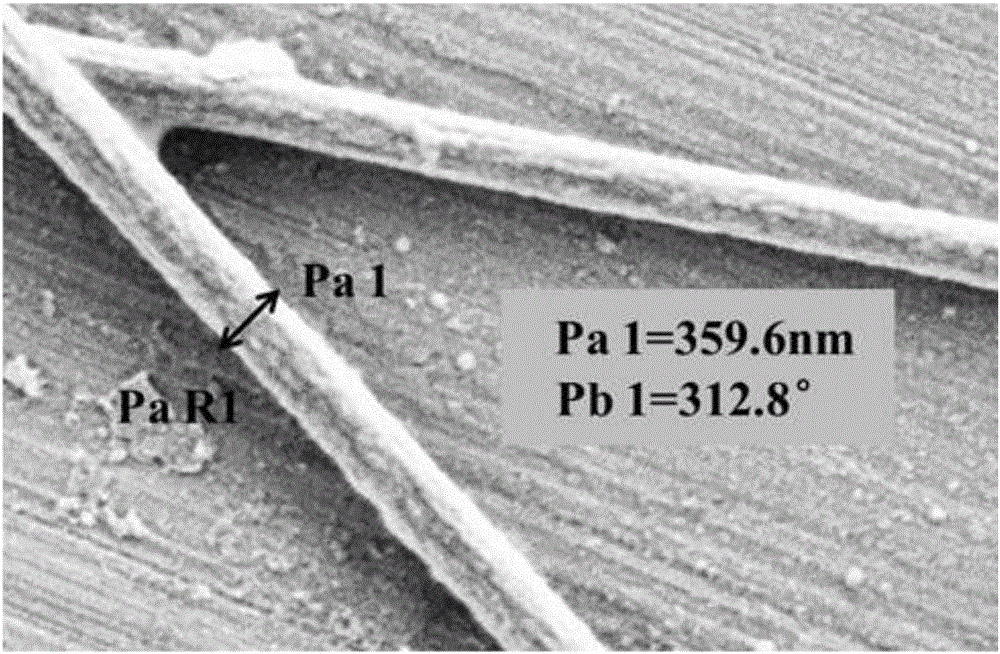

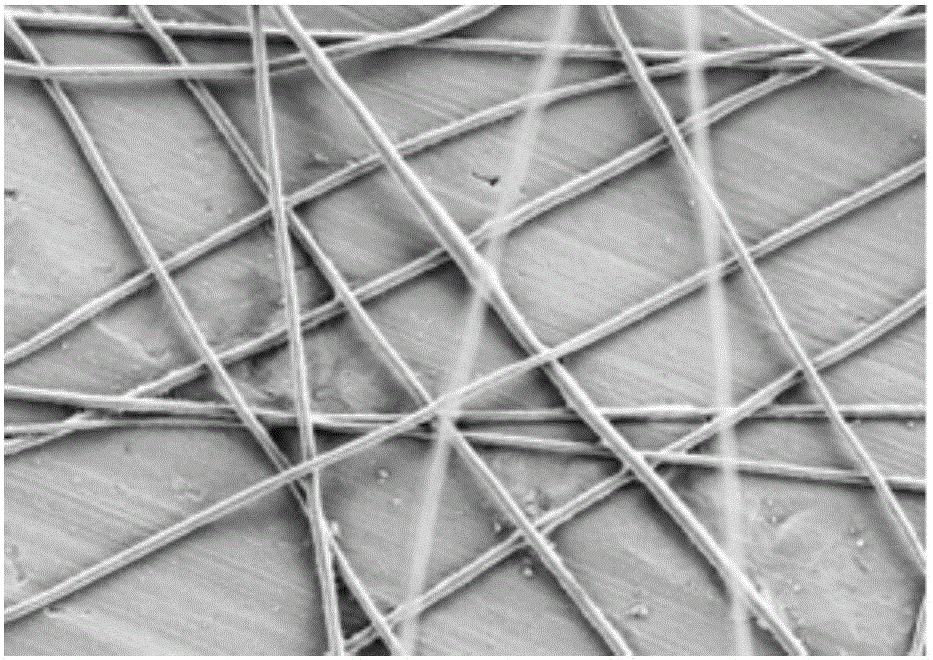

Electrostatic spinning directional nanofiber membrane and preparation method and application thereof

InactiveCN105970483AHigh porosityUniform pore sizeHeating/cooling textile fabricsElectro-spinningFiberNanofiber

The invention discloses an orienting fiber membrane through electrospinning, a preparation method and application thereof. The preparation method of the present invention mainly includes the following steps: the preparation of polyamic acid electrospinning solution; accepting the fiber membrane through a self-made electrospinning receiving device, and the nanofiber has a certain orientation; Amination to prepare polyimide nanofiber membrane. The invention adopts a relatively simple process, and realizes good orientation of the nanofiber through a simple receiving device.

Owner:苏州纳赛博丝新材料科技有限公司

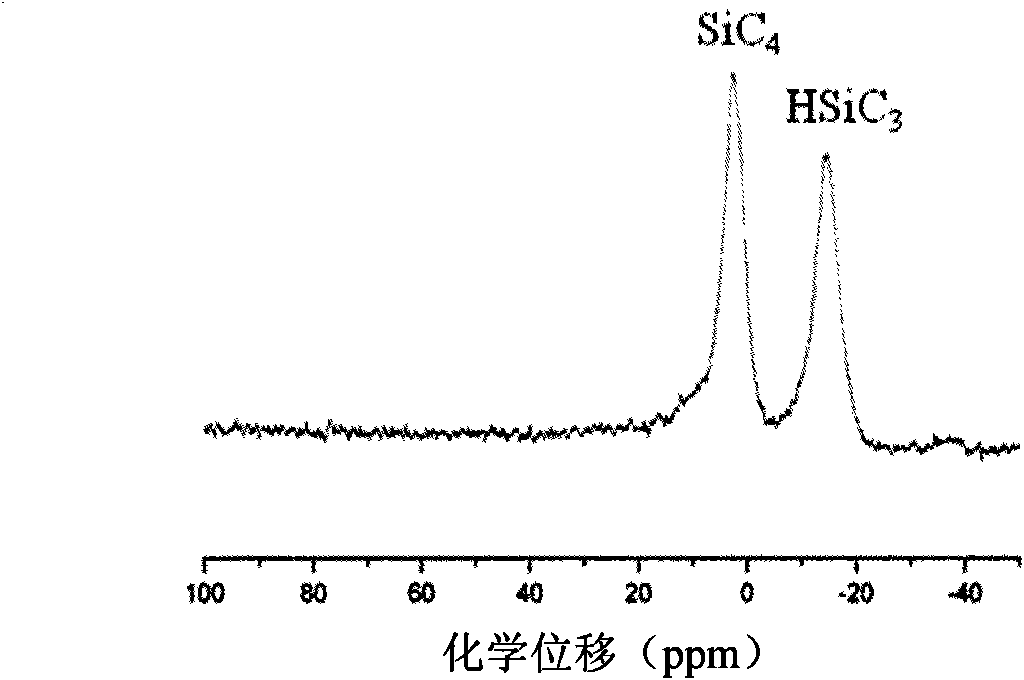

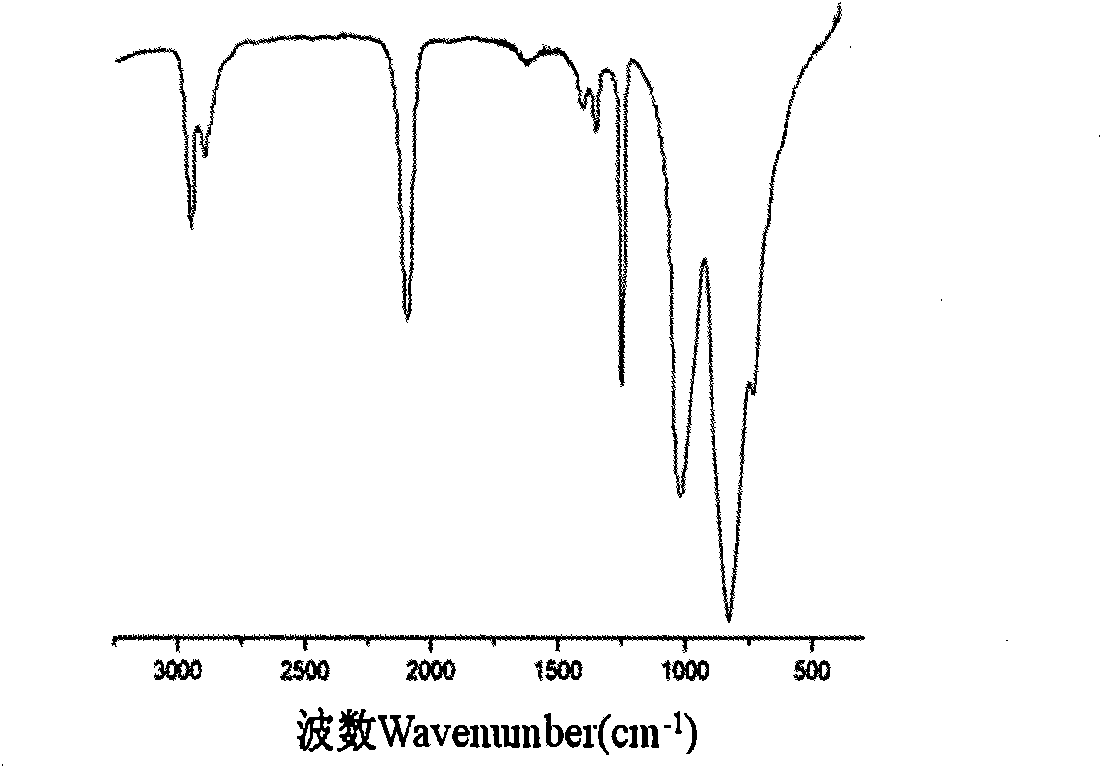

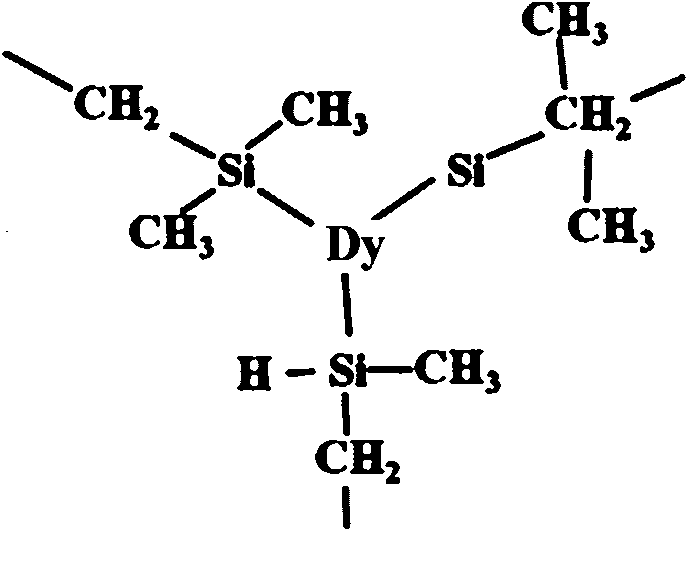

Organic luminous material and preparation method thereof

InactiveCN101962534ASimple manufacturing processCan be produced industriallyLuminescent compositionsBottleDimethyl siloxane

The invention provides an organic luminous material and a preparation method thereof, and relates to an organic silicon polymer. Raw materials of the organic luminous material comprise metallic organic substance and polycarbosilane. The preparation method comprises the following steps of: putting polydimethylsiloxane into a reaction kettle, heating the polydimethylsiloxane under the protection ofargon, inflating the argon to the reaction kettle, adding n-hexane into the reaction kettle to dissolve the product after the temperature in the reaction kettle is naturally cooled to room temperature, filtering the product, removing the n-hexane in vacuum to obtain the polycarbosilane, soaking the ground polycarbosilane into ethanol, flushing the insoluble substances by using the ethanol and then drying the insoluble substances in vacuum; and pouring the polycarbosilane powder and the metallic organic substance powder into a three-necked bottle, heating the mixed powder to between 150 and 160 DEG C under the protective atmosphere of argon, preserving the heat for 1 to 1.5 hours, heating the mixed powder to between 260 and 270 DEG C, preserving the heat for 1 to 1.5 hours, dissolving the product by using the dry n-hexane after the reaction is finished and the product is cooled, filtering the product to remove the insoluble substances, and finally distilling the product with reduced pressure to obtain the powdery solid organic luminous material.

Owner:XIAMEN UNIV

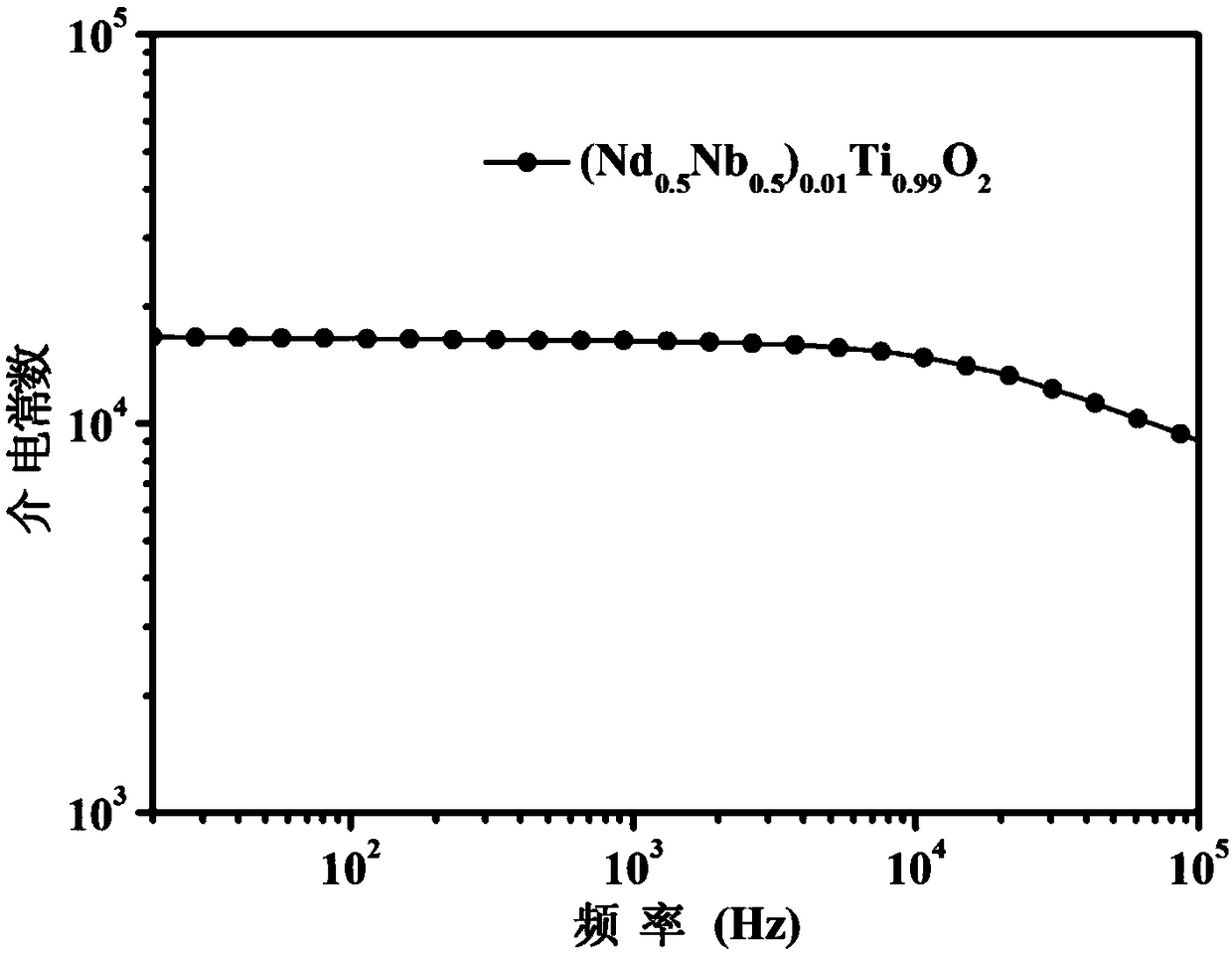

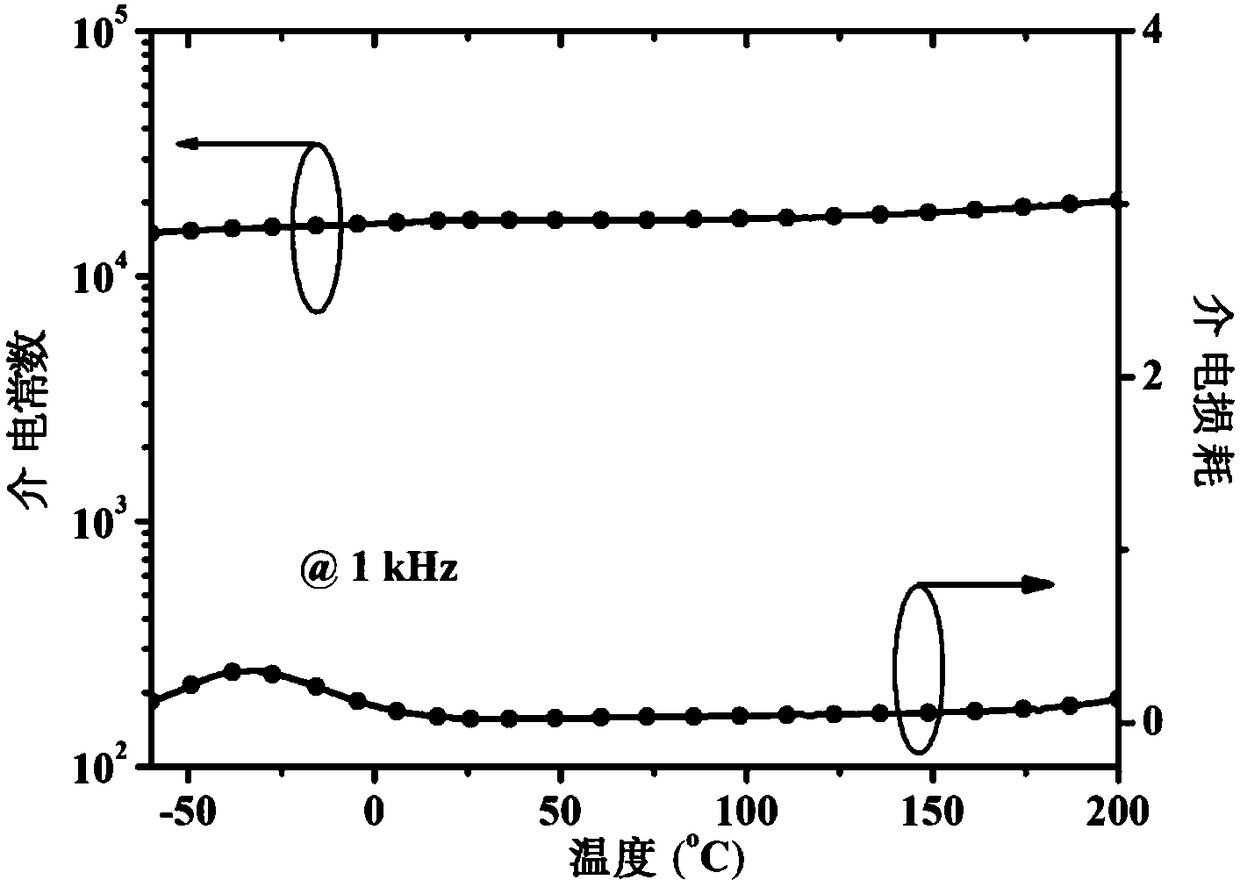

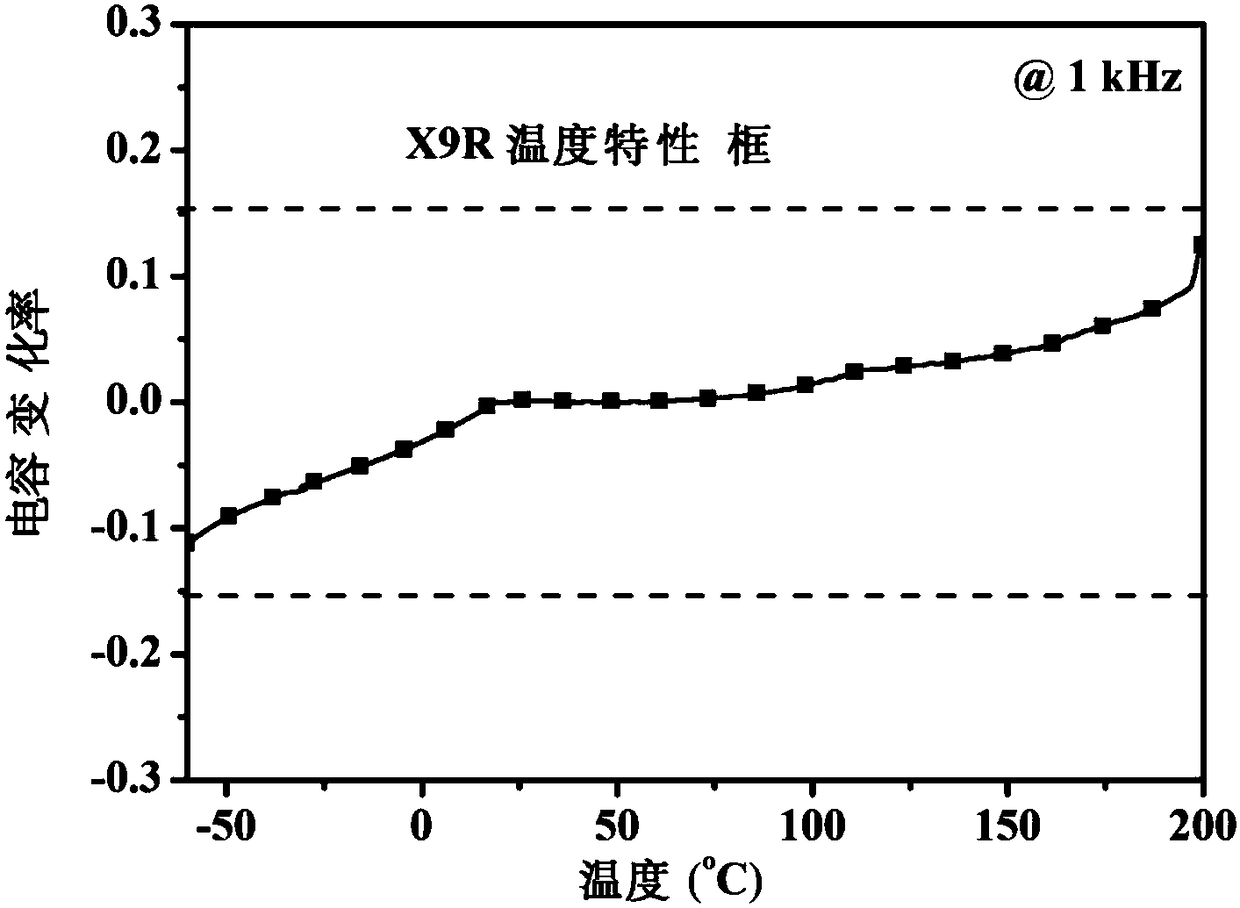

Low-loss and high-dielectric constant X9R ceramic capacitor dielectric material and preparation method thereof

InactiveCN108178626AImprove temperature stabilityExcellent dielectric propertiesFixed capacitor dielectricDielectric lossCeramic capacitor

The invention provides a low-loss and high-dielectric constant X9R ceramic capacitor dielectric material and a preparation method thereof. The chemical formula of the material is (Nd0.5Nb0.5)xTi1-xO2,and the value of x ranges from 0.005 to 0.11. The preparation method comprises the following steps: taking and proportioning Nd2O3, Nb2O5 and TiO2 according to the standard stoichiometry of (Nd0.5Nb0.5)xTi1-xO2, mixing and ball-milling the taken materials, and sequentially performing drying, sieving, pre-sintering, secondary wet ball-milling, cold isostatic pressing molding and sintering ceramicformation to produce the low-loss and high-dielectric constant X9R ceramic capacitor dielectric material. The high dielectric constant (being more than 10<4>), the low dielectric loss (being less than2.5%), the good frequency (20 to 10<4> Hz), the good temperature stability (-55 to 200 DEG C) and the temperature change rate (being less than + / - 15%) of the material meet EIAX9R standards. The preparation method is simple, has no pollution to the environment, and is suitable for industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Polyvinyl-phosphorylcholine elaioplast preparation and its making method

InactiveCN1895224ANo vascular irritationEasy to useDigestive systemPhosphorous compound active ingredientsVitamin CCholesterol

A polyene phosphatidylcholine liposome with high curative effect is prepared through dissolving polyene phosphatifylcholine, phosphatide and cholesterol in organic solvent, constant-temp drying for removing solvent, filming, adding vitamin, stabilizer and mannitol or glucose solution, dissolving, ultrasonic vibration or homogenizing, filtering by membrane for removing bacteria, loading in containers, filling N2 or H2 and sealing.

Owner:裴泽军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com