Organic luminous material and preparation method thereof

A luminescent material and organic technology, applied in the field of blue light emitting materials and their preparation, can solve problems such as reducing emission intensity, and achieve the effects of good light transmittance, low energy, broad research and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Put 50g of polydimethylsiloxane in a closed 300ml reaction kettle, quickly heat up to 300°C under the protection of argon, vacuumize and keep it for 2 hours, then fill it with argon at 101KPa, and then heat up at a rate of 1°C / min The temperature was raised to 390°C for 3 hours. After the reaction was completed, after the temperature in the reactor naturally dropped to room temperature, n-hexane was added to dissolve the product, filtered, and the n-hexane was removed in a vacuum.

[0038] 2) The product in step 1) was ground and soaked in absolute ethanol, stirred for 12 hours, and the filtered product was rinsed with absolute ethanol three times and then dried in a vacuum atmosphere at 60° C. to obtain a light yellow powder.

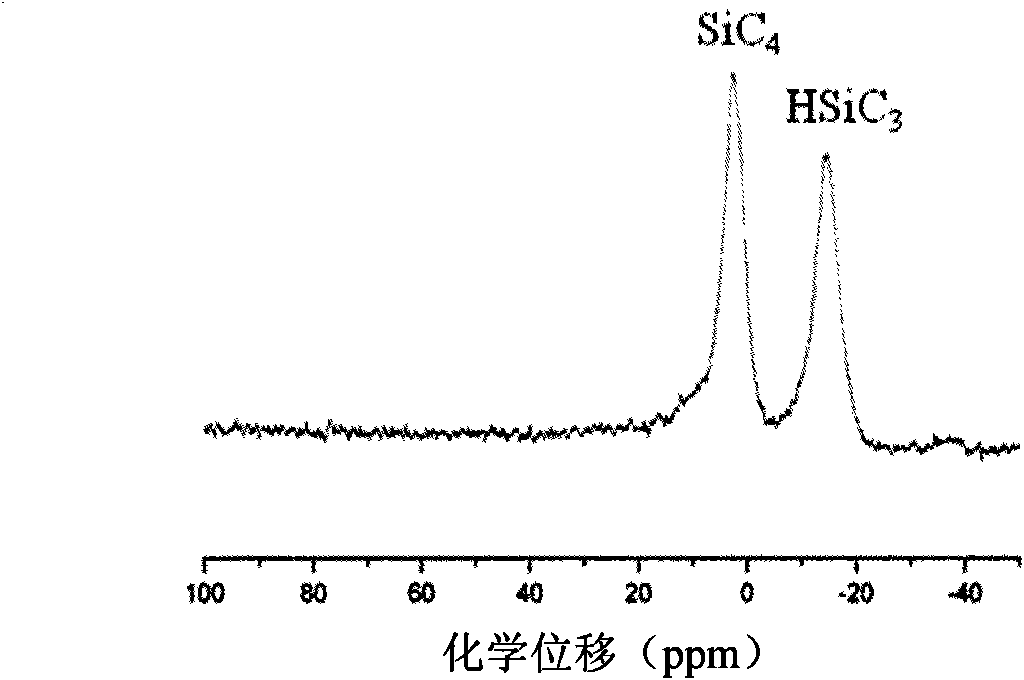

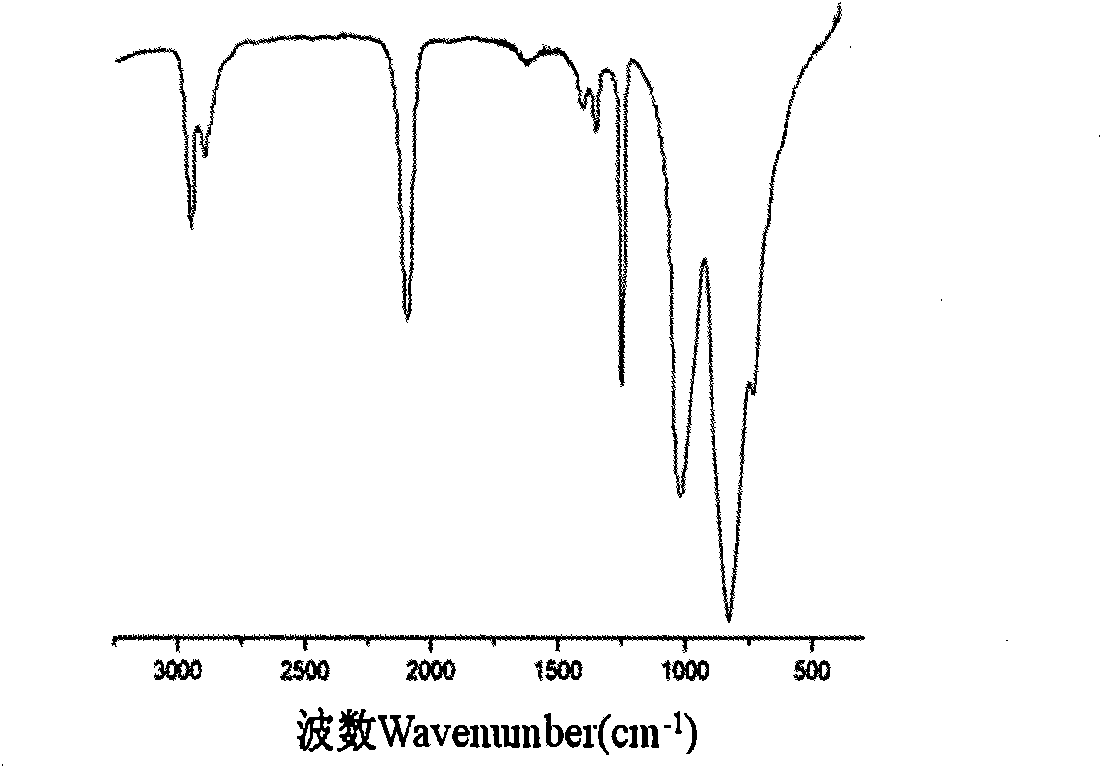

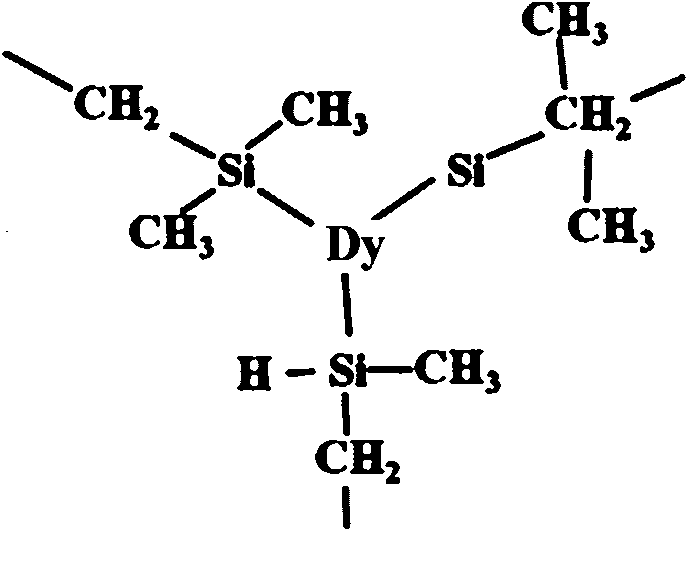

[0039] 3) Take 10g of the product in step 2), grind it into powder and mix it with 1g of dysprosium acetylacetonate Dy(AcAc) 3 The powder was mixed evenly and placed at the bottom of a 100ml three-neck bottle. After the whole system was evac...

Embodiment 2

[0042] 1) Put 50g of polydimethylsiloxane in a closed 300ml reaction kettle, raise the temperature to 300°C under the protection of argon, vacuumize and keep it for 2h, then fill it with argon at 103KPa, and then increase the temperature at a rate of 2°C / min Raise the temperature to 390°C for 3h. After the reaction was completed, after the temperature in the reactor naturally dropped to room temperature, n-hexane was added to dissolve the product, filtered, and the n-hexane was removed in a vacuum.

[0043] 2) The product in step 1) was ground and soaked in absolute ethanol, stirred for 12 hours, and the filtered product was rinsed with absolute ethanol three times and then dried in a vacuum atmosphere at 60° C. to obtain a light yellow powder.

[0044] 3) Take 10 g of the product in step 2), grind it into powder and mix it with 0.5 g of aluminum acetylacetonate Al(AcAc) 3 Mix the powder evenly and place it at the bottom of a 100ml three-neck bottle. After the whole system is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com