Preparation method and application of silver oxide/titanium dioxide composite nanofiber photocatalyst

A technology of composite nanofibers and titanium dioxide, applied in the field of environmental pollution control, can solve the problems of difficult to meet long-term catalytic requirements, difficult to settle, difficult to separate and recycle, etc., to improve the separable and reusable performance, the preparation method is simple, and the operation is simple. Ease of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

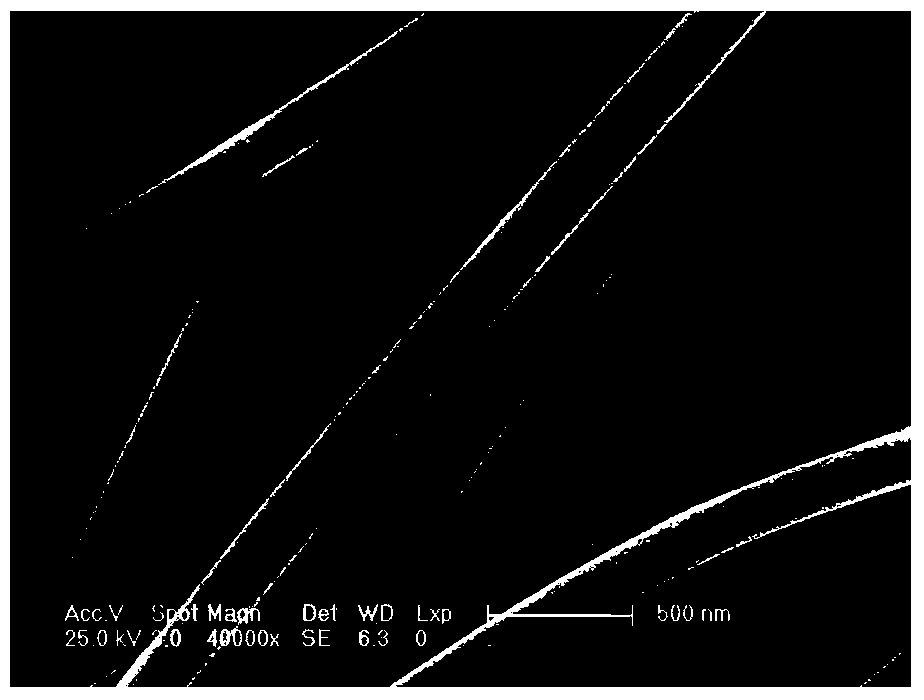

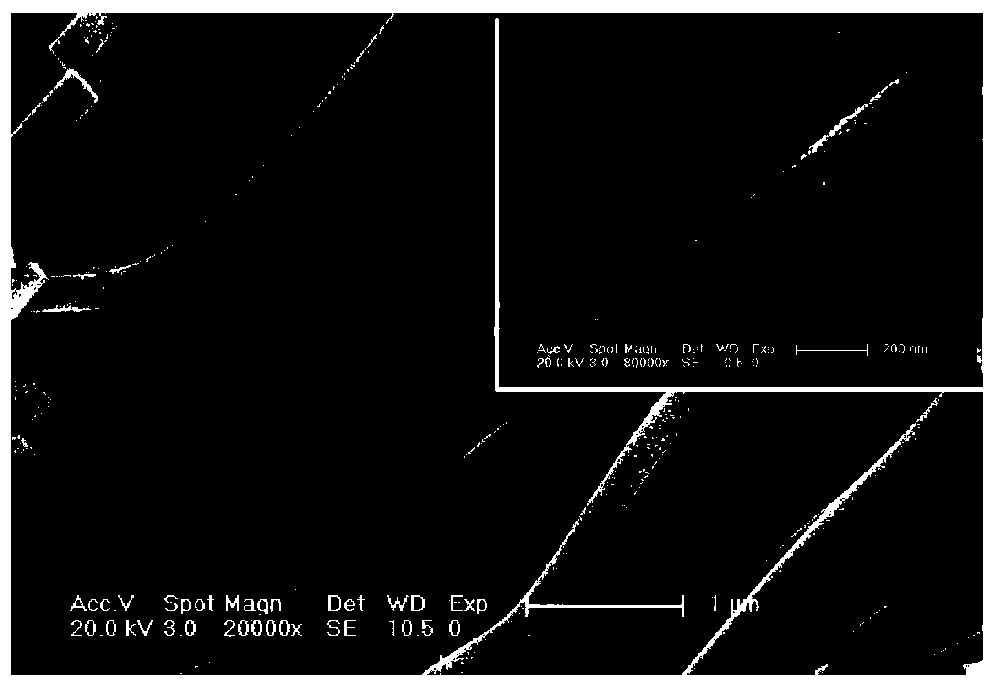

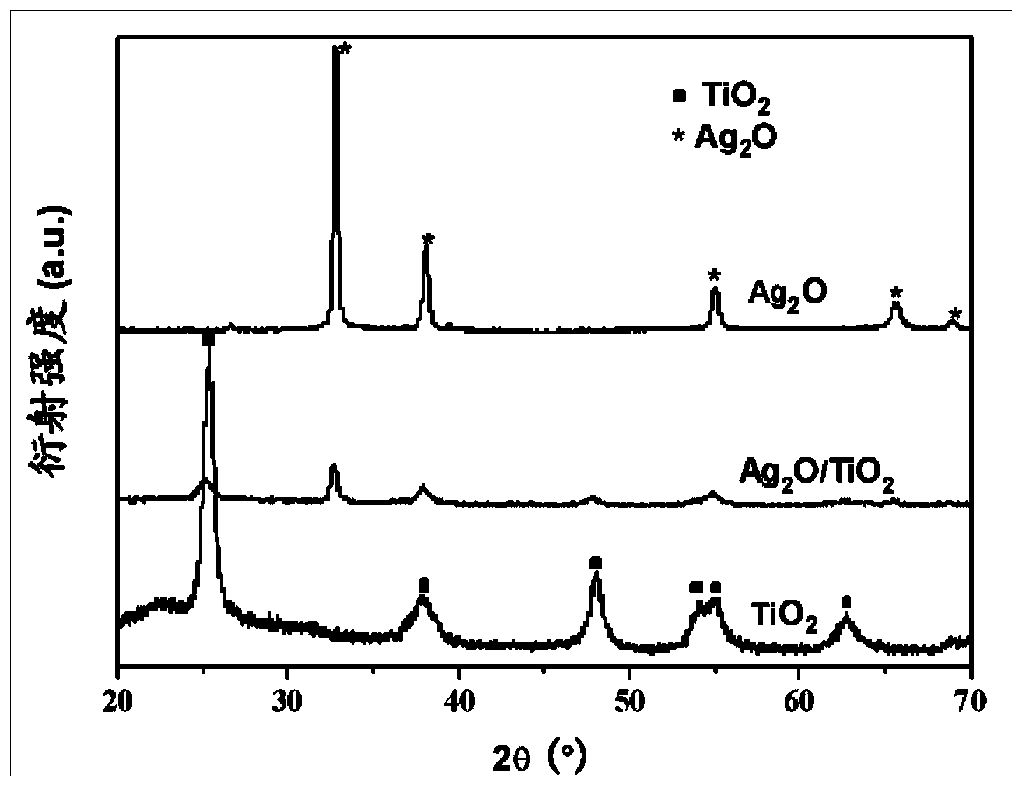

[0039] Dissolve polyvinylpyrrolidone (PVP, Mn=1300000) in 7ml of absolute ethanol; then dissolve 1.5ml of glacial acetic acid and 1ml of butyl titanate in 3ml of absolute ethanol; then mix the above two solutions to prepare titanium The n-butyl titanate-PVP solution is used to prepare the n-butyl titanate-PVP composite nanofibers by electrospinning; then the composite nanofibers are calcined at a high temperature at 530°C to obtain titanium dioxide nanofibers. The scanning electron microscope (SEM) photos of the prepared titanium dioxide nanofibers are as follows figure 1 Shown. It can be clearly seen from the figure that the average diameter of titanium dioxide nanofibers is 100-200 nm, and the fiber length is tens of microns, which has a large aspect ratio. The titanium dioxide nanofibers prepared above were immersed in 25 mL of 0.04 mol / L ammonia solution for 30 minutes, and then 25 mL of 0.02 mol / L silver nitrate solution was added dropwise, and magnetically stirred for 10 ...

Embodiment 2

[0041] According to the preparation method of the present invention in Example 1, except that the ammonia solution, silver salt solution and alkali solution are respectively replaced with 0.2mol / L ammonia, 0.1mol / L silver acetate and 0.2mol / L sodium hydroxide, Silver oxide / titanium dioxide composite nanofiber photocatalyst.

Embodiment 3

[0043] According to the preparation method of the present invention in Example 1, except that the ammonia solution, the silver salt solution and the alkali solution are respectively replaced with 0.4mol / L ammonia, 0.2mol / L silver acetate and 0.4mol / L sodium hydroxide, Silver oxide / titanium dioxide composite nanofiber photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com