Printed type graphene-based NO2 gas-sensitive element and preparation method thereof

A graphene-based, gas sensor technology, applied in the direction of material resistance, etc., can solve the problems of rough preparation method, uncontrollable graphene sensitive layer thickness, poor performance of graphene-based gas sensor, etc., to achieve good gas sensing characteristics and sensitivity , low cost, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step is to ultrasonically clean the PET substrate in deionized water, dry it, and etch the substrate with oxygen plasma, with an air flow of 100 sccm, a power of 100 W, and an etching time of 20 seconds;

[0031] The second step is to use gravure printing technology to print silver interdigitated electrodes on the PI substrate, and dry them in an oven at 120°C for 30 minutes;

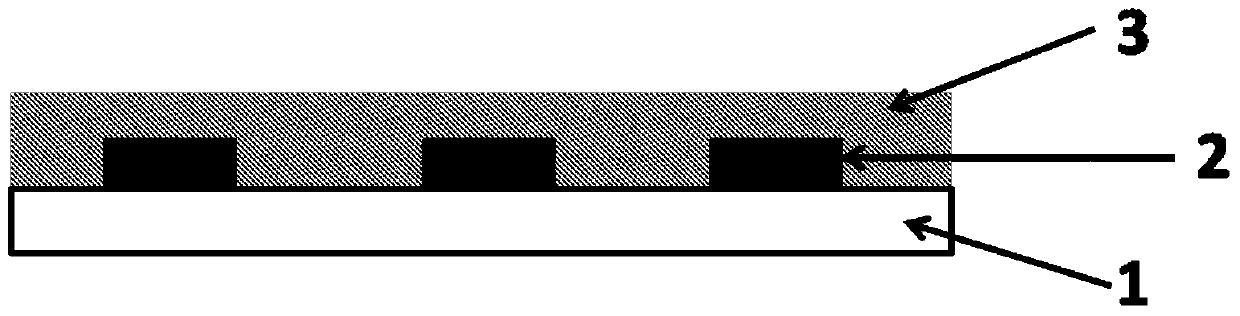

[0032] The third step is to use gravure printing technology to print the graphene-based sensitive ink on the PI substrate with silver interdigitated electrodes, and mark the position of the substrate so that the graphene sensitive film completely covers the surface of the silver interdigitated electrodes. , put it in an oven and dry it at 80°C for 10 minutes to obtain a printed graphene-based NO 2 gas sensor.

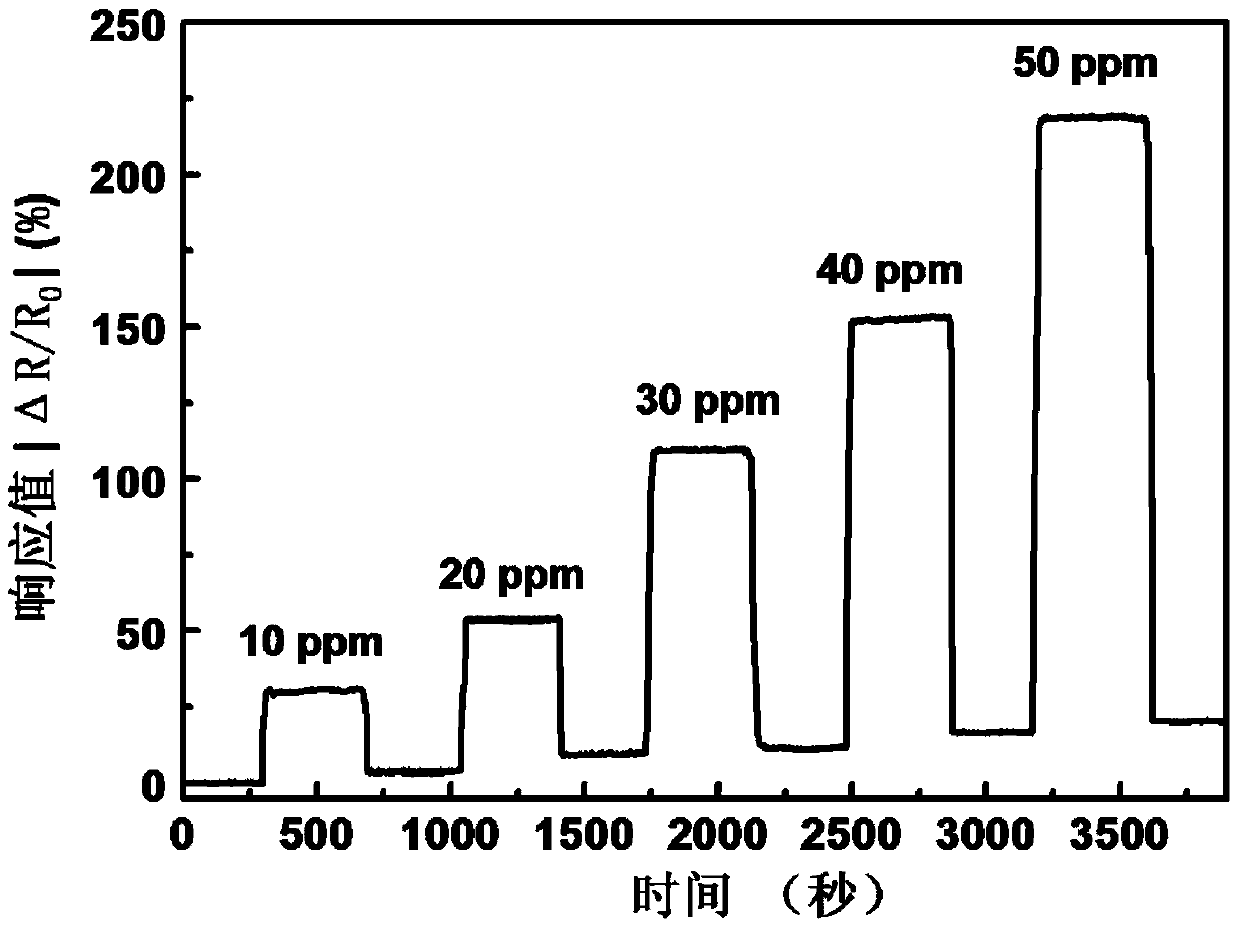

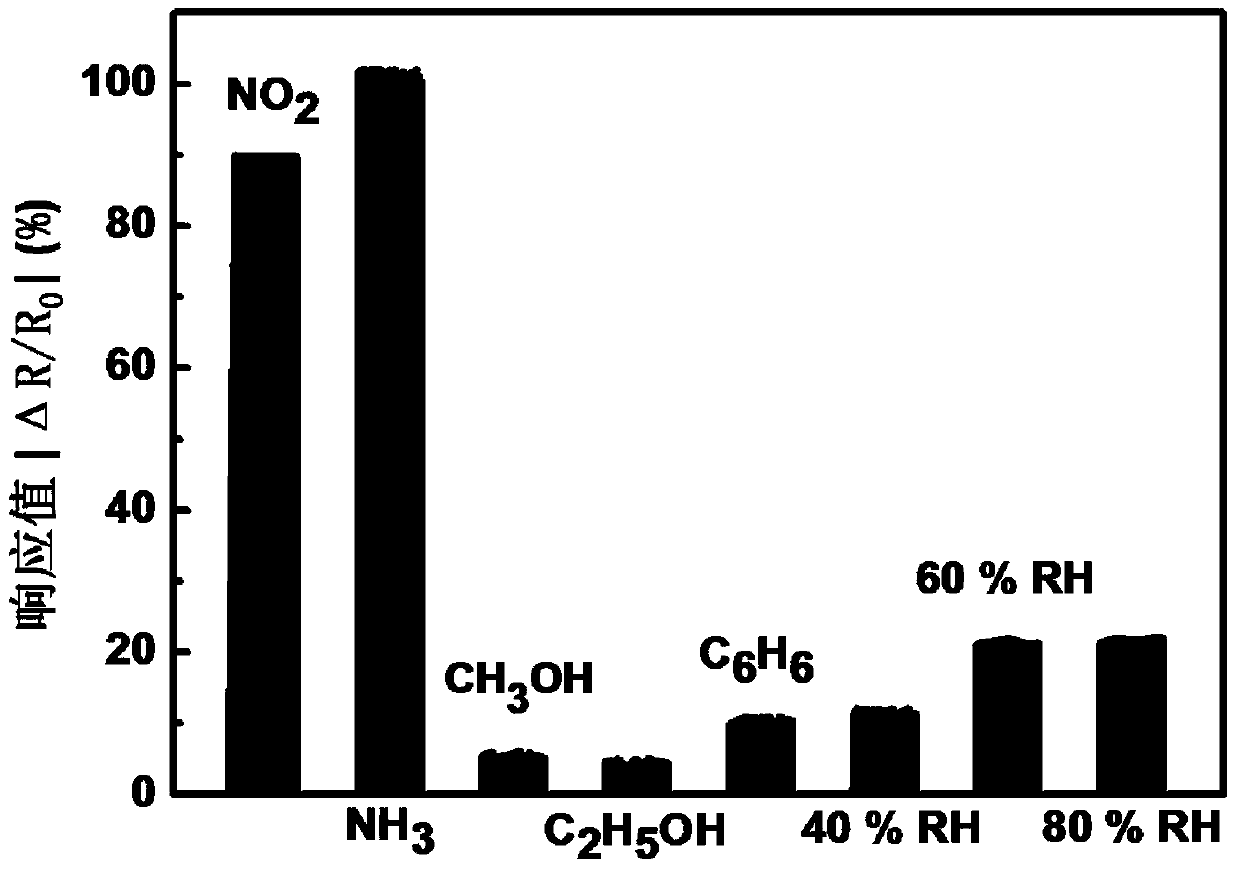

[0033] figure 2 It is the printed graphene-based NO prepared in this embodiment 2 Gas sensor for 10,20,30,40,50ppm NO 2 The gas-sensing characteristics, the working conditio...

Embodiment 2

[0036] The first step is to ultrasonically clean the PI substrate in deionized water, dry it, and etch the substrate with oxygen plasma, with an air flow of 100sccm, a power of 100W, and an etching time of 20 seconds;

[0037] The second step is to use gravure printing technology to print silver interdigitated electrodes on the PI substrate, and dry them in an oven at 120°C for 30 minutes;

[0038] The third step is to use gravure printing technology to print the graphene-based sensitive ink on the PI substrate with silver interdigitated electrodes, and mark the position of the substrate so that the graphene sensitive film completely covers the surface of the silver interdigitated electrodes. , put it in an oven to dry at 80°C for 10 minutes, repeat the above operation according to the position of the substrate mark, and obtain a graphene-based NO layer with a multi-layer graphene sensitive layer. 2 gas sensor.

Embodiment 3

[0040] The first step is to ultrasonically clean the PI substrate in deionized water and dry it;

[0041] The second step is to use gravure printing technology to directly print the graphene-based sensitive ink on the PI substrate, and dry it in an oven at 80°C for 10 minutes to obtain a printed graphene-based NO ink. 2 gas sensor.

[0042] Among them, the graphene-based sensitive ink is prepared according to the following steps: uniformly disperse graphene in deionized water, control the concentration to 15-80 mg / mL, stir with low-speed magnetic force for 5-10 minutes, and then ultrasonically vibrate for 5-10 minutes; repeat the process Step 3-5 times are completely uniformly dispersed to obtain graphene-based sensitive ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com